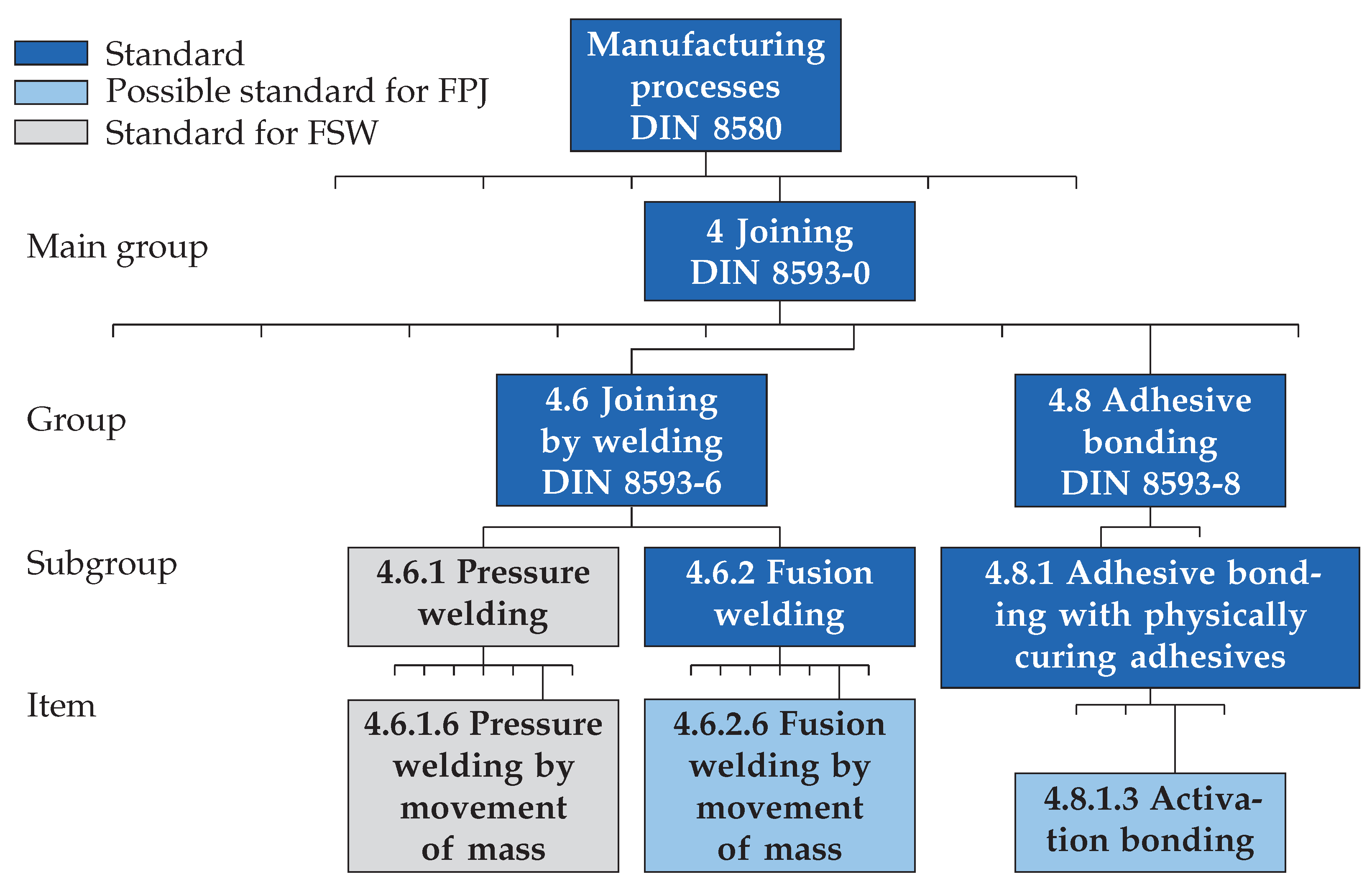

6. Classification of the FPJ Process

Finally, after discussing the technological and economical aspects, this paragraph deals with the classification and categorization of the FPJ process into the DIN 8580 [

47] standard. In the following section, a proposal is discussed to classify the process based on the current knowledge in the literature (see

Figure 11).

The objective of the classification is to promote the advancement of the joining process based on the current data available rather than constraining it within a specific manufacturing processing. It is possible that the category of the process needs to be redefined or new sub-categories need to be proposed to more accurately describe the process.

Friction press joining is a manufacturing process for joining thermoplastic materials and metal sheets. Thus, it belongs to the fourth main group

Joining, defined in DIN 8593-0 [

47,

48]. The related process

friction stir welding (FSW), from which FPJ was derived, is standardized in DIN EN ISO 25239-1 [

49] and assigned to

Pressure welding (1st subgroup) under DIN 8593-6 [

50] (Joining by welding). Pressure welding is subdivided further according to DIN 1910-100 [

51], where the FSW process is classified in item 4.6.1.6

Pressure welding by movement of mass [

50]. However, since one joining partner (the thermoplastic material) has to be melted during friction press joining, it is not classifiable as a pressure welding process, according to DIN 8593-6 [

50].

In the second subgroup, 4.6.2

Fusion welding (DIN 8593-6 [

50]), item 4.6.2.6

Fusion welding by movement of mass would be a possible alternative. Thus far, no processes are listed under this item. An essential criterion for the classification in this item is the type of the bond. According to Wirth et al. [

9], FPJ is based on micro-form-closure, and according to Meyer et al. [

8] on micro-form-closure and Van der Waals forces. As these two phenomena are based on cohesive forces, a classification in this category is conceivable. In addition, Liu et al. [

10,

52] showed that Al-0-C bonds were formed at the aluminum/polyamide interface. Here, the carbonyl group at the PA66 surface was essential for the formation of this a bond mechanism. This type of formation proved to be a key factor to achieve a high joint strength. It provided also an explanation why aluminum alloys can be directly welded to PA66 plates with a high joint strength.

Based on the bonding mechanisms, a second possibility is a classification according to DIN 8593-8 (Adhesive bonding) [

53]. For FPJ, the plastic serves as a joining partner, as well as an adhesive. During the process, the heat input is conducted externally through friction into the metallic joining partner and through conduction into the joining zone, causing the adhesive (plastic) to be melted. Therefore, this process can be seen as a hot-melt process, which belongs to 4.8.1.3

Activation bonding.

In summary, an indexing to Fusion welding by movement of mass (item 4.6.2.6) and an assignment to Activation bonding (item 4.8.1.3) is conceivable. Since FPJ can be seen as a hot-melt process, the authors recommend classifying FPJ as Activation bonding. For this reason, we use the term joining or bonding, instead of welding.

Author Contributions

Conceptualization, S.P.M.; methodology, S.P.M.; validation, S.P.M. and M.T.H.; formal analysis, S.P.M. and M.T.H.; investigation, S.P.M. and M.T.H.; resources, S.P.M. and J.B.H.; data curation, S.P.M. and M.T.H.; writing—original draft preparation, S.P.M. and J.B.H.; writing—review and editing, J.B.H. and M.F.Z.; visualization, S.P.M.; supervision, S.P.M.; project administration, S.P.M.; and funding acquisition, S.P.M., J.B.H. and M.F.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This work was funded by the Deutsche Forschungsgemeinschaft (DFG, German Research Foundation) (418104776).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Marsh, G. Airbus A350 XWB update. Reinf. Plast. 2010, 54, 20–24. [Google Scholar] [CrossRef]

- Higgins, A. Adhesive bonding of aircraft structures. Int. J. Adhes. Adhes. 2000, 20, 367–376. [Google Scholar] [CrossRef]

- Hertle, S.; Kleffel, T.; Wörz, A.; Drummer, D. Production of polymer-metal hybrids using extrusion-based additive manufacturing and electrochemically treated aluminum. Addit. Manuf. 2020, 33, 101135. [Google Scholar] [CrossRef]

- Lucchetta, G.; Marinello, F.; Bariani, P.F. Aluminum sheet surface roughness correlation with adhesion in polymer metal hybrid overmolding. CIRP Ann. 2011, 60, 559–562. [Google Scholar] [CrossRef]

- Arai, S.; Sugawara, R.; Shimizu, M.; Inoue, J.; Horita, M.; Nagaoka, T.; Itabashi, M. Excellent bonding strength between steel and thermoplastic resin using roughened electrodeposited Ni/CNT composite layer without adhesives. Mater. Lett. 2020, 263, 127241. [Google Scholar] [CrossRef]

- Balle, F.; Wagner, G.; Eifler, D. Ultrasonic Metal Welding of Aluminium Sheets to Carbon Fibre Reinforced Thermoplastic Composites. Adv. Eng. Mater. 2009, 11, 35–39. [Google Scholar] [CrossRef]

- Emrich, N.; Meyer, S.P.; Daub, R. Ageing behavior of thermally joined hybrids of laser pre-treated metal and thermoplastic polymers. In Proceedings of the 35th International Conference of the Polymer Processing Society (Pps-35), Çeşme-Izmir, Turkey, 26–30 May 2019; AIP Publishing: New York, NY, USA, 2020; p. 020001. [Google Scholar] [CrossRef]

- Meyer, S.P.; Wunderling, C.; Zaeh, M.F. Influence of the laser-based surface modification on the bond strength for friction press joining of aluminum and polyethylene. Prod. Eng. 2019, 13, 721–730. [Google Scholar] [CrossRef]

- Wirth, F.X.; Zaeh, M.F.; Krutzlinger, M.; Silvanus, J. Analysis of the Bonding Behavior and Joining Mechanism during Friction Press Joining of Aluminum Alloys with Thermoplastics. Procedia CIRP 2014, 18, 215–220. [Google Scholar] [CrossRef]

- Liu, F.C.; Liao, J.; Nakata, K. Joining of metal to plastic using friction lap welding. Mater. Des. 2014, 54, 236–244. [Google Scholar] [CrossRef]

- Meyer, S.P.; Bernauer, C.J.; Grabmann, S.; Zaeh, M.F. Design, evaluation, and implementation of a model-predictive control approach for a force control in friction stir welding processes. Prod. Eng. 2020, 54, 20. [Google Scholar] [CrossRef]

- Nagatsuka, K.; Yoshida, S.; Tsuchiya, A.; Nakata, K. Direct joining of carbon-fiber–reinforced plastic to an aluminum alloy using friction lap joining. Compos. Part B Eng. 2015, 73, 82–88. [Google Scholar] [CrossRef]

- Wu, L.H.; Nagatsuka, K.; Nakata, K. Direct joining of oxygen-free copper and carbon-fiber-reinforced plastic by friction lap joining. J. Mater. Sci. Technol. 2018, 34, 192–197. [Google Scholar] [CrossRef]

- Custódio, J.; Broughton, J.; Cruz, H. A review of factors influencing the durability of structural bonded timber joints. Int. J. Adhes. Adhes. 2009, 29, 173–185. [Google Scholar] [CrossRef]

- Arenas, J.M.; Alía, C.; Narbón, J.J.; Oca na, R.; González, C. Considerations for the industrial application of structural adhesive joints in the aluminium-composite material bonding. Compos. Part B Eng. 2013, 44, 417–423. [Google Scholar] [CrossRef]

- Zimmermann, S.; Specht, U.; Spieß, L.; Romanus, H.; Krischok, S.; Himmerlich, M.; Ihde, J. Improved adhesion at titanium surfaces via laser-induced surface oxidation and roughening. Mater. Sci. Eng. A 2012, 558, 755–760. [Google Scholar] [CrossRef]

- Mankins, J.C. Technology Readiness Levels; A White Paper; Office of Space Access and Technology, NASA: Greenbelt, MD, USA, 1995.

- Cetindamar, D.; Phaal, R.; Probert, D. Understanding technology management as a dynamic capability: A framework for technology management activities. Technovation 2009, 29, 237–246. [Google Scholar] [CrossRef]

- Brousseau, E.; Barton, R.; Dimov, S.; Bigot, S. A Methodology for Evaluating the Technological Maturity of Micro and Nano Fabrication Processes. In Precision Assembly Technologies and Systems; Ratchev, S., Ed.; Springer: Berlin/Heidelberg, Germany, 2010; pp. 329–336. [Google Scholar]

- Reinhart, G.; Schindler, S. A Strategic Evaluation Approach for Defining the Maturity of Manufacturing Technologies. Int. J. Ind. Manuf. Eng. 2010, 4, 1291–1296. [Google Scholar]

- Ford, D.; Ryan, C. Taking technology to market. Harv. Bus. Rev. 1981, 59, 117–126. [Google Scholar]

- Hofer, A.; Schnell, J.; Beck, B.; Reinhart, G. Potential-based Technology Planning for Production Companies. Procedia CIRP 2019, 81, 1400–1405. [Google Scholar] [CrossRef]

- Amancio-Filho, S.T.; dos Santos, J.F. Joining of polymers and polymer-metal hybrid structures: Recent developments and trends. Polym. Eng. Sci. 2009, 49, 1461–1476. [Google Scholar] [CrossRef]

- S-POLYTEC GmbH. Technical Data Sheet: PE-HD; S-POLYTEC GmbH: Goch, Germany, 2019. [Google Scholar]

- Schäfer, C.; Meyer, S.P.; Osswald, T.A. A novel extrusion process for the production of polymer micropellets. Polym. Eng. Sci. 2018, 44, 1391. [Google Scholar] [CrossRef]

- Kurth, M.; Eyerer, P.; Ascherl, R.; Dittel, K.; Holz, U. An evaluation of retrieved UHMWPE hip joint cups. J. Biomater. Appl. 1988, 3, 33–51. [Google Scholar] [CrossRef] [PubMed]

- Ensinger Ltd. TECAMID 6 GF30 Black—Stock Shapes; Ensinger Ltd.: Nufringen, Germany, 2019. [Google Scholar]

- Wolf, M.; Kleffel, T.; Leisen, C.; Drummer, D. Joining of Incompatible Polymer Combinations by Form Fit Using the Vibration Welding Process. Int. J. Polym. Sci. 2017, 2017, 6809469. [Google Scholar] [CrossRef]

- Mathijsen, D. Leading the way in thermoplastic composites. Reinf. Plast. 2016, 60, 405–407. [Google Scholar] [CrossRef]

- André, N.M.; Goushegir, S.M.; dos Santos, J.F.; Canto, L.B.; Amancio-Filho, S.T. Friction Spot Joining of aluminum alloy 2024-T3 and carbon-fiber-reinforced poly(phenylene sulfide) laminate with additional PPS film interlayer: Microstructure, mechanical strength and failure mechanisms. Compos. Part B Eng. 2016, 94, 197–208. [Google Scholar] [CrossRef]

- TenCate Advanced Composites BV. Data Sheet: Cetex TC1100 PPS; TenCate Advanced Composites BV: Morgan Hill, CA, USA, 2019; Available online: https://www.toraytac.com/media/221a4fcf-6a4d-49f3-837f-9d85c3c34f74/smphpw/TAC/Documents/Data_sheets/Thermoplastic/UD%20tapes,%20prepregs%20and%20laminates/Toray-Cetex-TC1100_PPS_PDS.pdf (accessed on 14 March 2021).

- Gemmel Metalle & Co. GmbH. Technical Data Sheet: AlMgSi1 F30; Gemmel Metalle & Co. GmbH: Berlin, Germany, 2019. [Google Scholar]

- Meyer, S.P.; Wunderling, C.; Zaeh, M.F. Friction press joining of dissimilar materials: A novel concept to improve the joint strength. In Proceedings of the 22nd International ESAFORM Conference on Material Forming: ESAFORM 2019, Vitoria-Gasteiz, Spain, 8–10 May 2019; AIP Publishing: New York, NY, USA, 2019; p. 050031. [Google Scholar] [CrossRef]

- Batz + Burgel GmbH & Co. KG. Data Sheet: EN AW-2024; Batz + Burgel GmbH & Co. KG: Friedberg, Germany, 2019. [Google Scholar]

- Kumar, B.; Widener, C.; Jahn, A.; Tweedy, B.; Cope, D.; Lee, R. Review of the Applicability of FSW Processing to Aircraft Applications. In Proceedings of the 46th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference, Austin, TX, USA, 18–21 April 2005; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2005; p. 423. [Google Scholar] [CrossRef]

- Lambiase, F.; Paoletti, A.; Grossi, V.; Di Ilio, A. Friction assisted joining of aluminum and PVC sheets. J. Manuf. Process. 2017, 29, 221–231. [Google Scholar] [CrossRef]

- 3M. Technical Data Sheet: Scotch-Weld Structural Plastic Adhesive: DP-8005. 2020. Available online: https://www.bindingsource.com/images/Customer-files/8005dsd.pdf (accessed on 14 March 2021).

- Oguma, H.; Naito, K. Effect of stress ratio on the fatigue fracture mechanism of adhesive single-lap joints: In case of GF/PP plates and an acrylic-based structural adhesive. Procedia Struct. Integr. 2019, 19, 224–230. [Google Scholar] [CrossRef]

- DELO. Data Sheet: DELO 02 Rapid. 2020. Available online: https://www.delo.de/fileadmin/datasheet/DELO-DUOPOX_02%20rapid_%28TIDB-de%29.pdf (accessed on 14 March 2021).

- DELO. Data Sheet: DELO-PUR AD948. 2020. Available online: https://substratec.com/de/download/1c1b1a18-66af-4eba-a4e6-fb9c5869f0de/DELO-PUR_AD948_%28TIDB-D%29.pdf (accessed on 14 March 2021).

- Henkel, A.G. Data Sheet: LOCTITE EA9466. 2020. Available online: http://tds.henkel.com/tds5/Studio/ShowPDF/EA%209466-EN?pid=EA%209466&format=MTR&subformat=REAC&language=EN&plant=WERCS (accessed on 14 March 2021).

- Spaggiari, A.; Dragoni, E. Effect of Mechanical Surface Treatment on the Static Strength of Adhesive Lap Joints. J. Adhes. 2013, 89, 677–696. [Google Scholar] [CrossRef]

- Soykok, I.F. Degradation of single lap adhesively bonded composite joints due to hot water ageing. J. Adhes. 2017, 93, 357–374. [Google Scholar] [CrossRef]

- Don, R.C.; Gillespie, J., Jr.; McKnight, S. Bonding Techniques for High Performance Thermoplastic Compositions. U.S. Patent 5643390A, 1 July 1997. [Google Scholar]

- Soni, N.; Chandrashekhar, S.; Kumar, A.; Chary, V. Defects Formation during Friction Stir Welding: A Review. Int. J. Eng. Manag. Res. 2017, 7, 121–125. [Google Scholar]

- Ruhstorfer, M. Friction Stir Welding of Tubes. Ph.D. Thesis, Technical University of Munich (TUM), Munich, Germany, 2012. [Google Scholar]

- DIN 8580:2003-09, Manufacturing Processes—Terms and Definitions, Division; Beuth Verlag GmbH: Berlin, Cermany, 2003. [CrossRef]

- DIN 8593-0:2003-09, Manufacturing Processes Joining—Part 0: General: Classification, Subdivision, Terms and Definitions; Beuth Verlag GmbH: Berlin, Cermany, 2003. [CrossRef]

- DIN EN ISO 25239-1:2019-06, Friction Stir Welding—Aluminium—Part 1: Vocabulary; Beuth Verlag GmbH: Berlin, Cermany, 2019. [CrossRef]

- DIN 8593-6:2003-09, Manufacturing Processes Joining—Part 6: Joining by Welding; Beuth Verlag GmbH: Berlin, Cermany, 2003. [CrossRef]

- DIN 1910-100:2008-02, Welding and Allied Processes—Vocabulary—Part 100: Metal Welding Processes with Additions to DIN EN 14610:2005; Beuth Verlag GmbH: Berlin, Cermany, 2008. [CrossRef]

- Liu, F.C.; Dong, P.; Lu, W.; Sun, K. On formation of Al O C bonds at aluminum/polyamide joint interface. Appl. Surf. Sci. 2019, 466, 202–209. [Google Scholar] [CrossRef]

- DIN 8593-8:2003-09, Manufacturing Processes Joining—Part 8: Joining by Means of Adhesives; Beuth Verlag GmbH: Berlin, Cermany, 2003. [CrossRef]

- Otto Fuchs KG. Technical Information: Material Data Sheet Aluminium; Otto Fuchs KG: Meinerzhagen, Germany, 2019; Available online: https://www.otto-fuchs.com/en/service/material-information.html (accessed on 14 March 2021).

| Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).