Experimental Analysis and Optimization of EDM Parameters on HcHcr Steel in Context with Different Electrodes and Dielectric Fluids Using Hybrid Taguchi-Based PCA-Utility and CRITIC-Utility Approaches

Abstract

1. Introduction

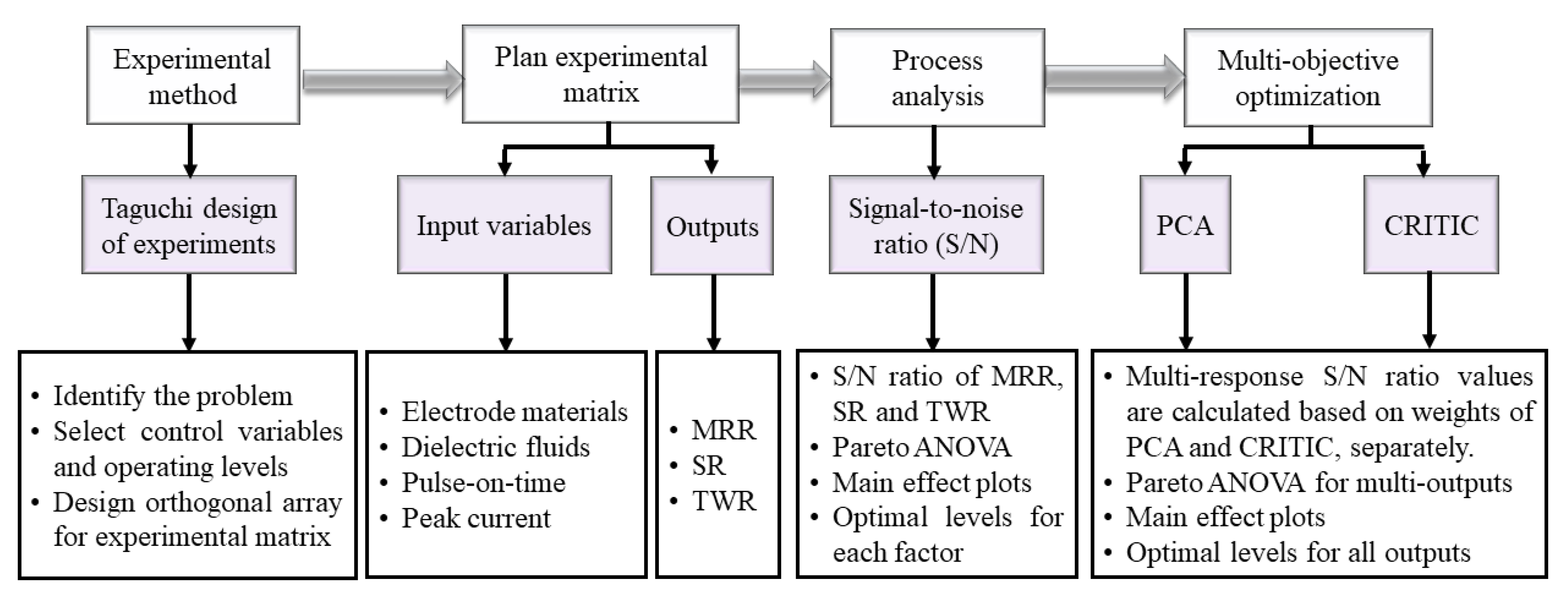

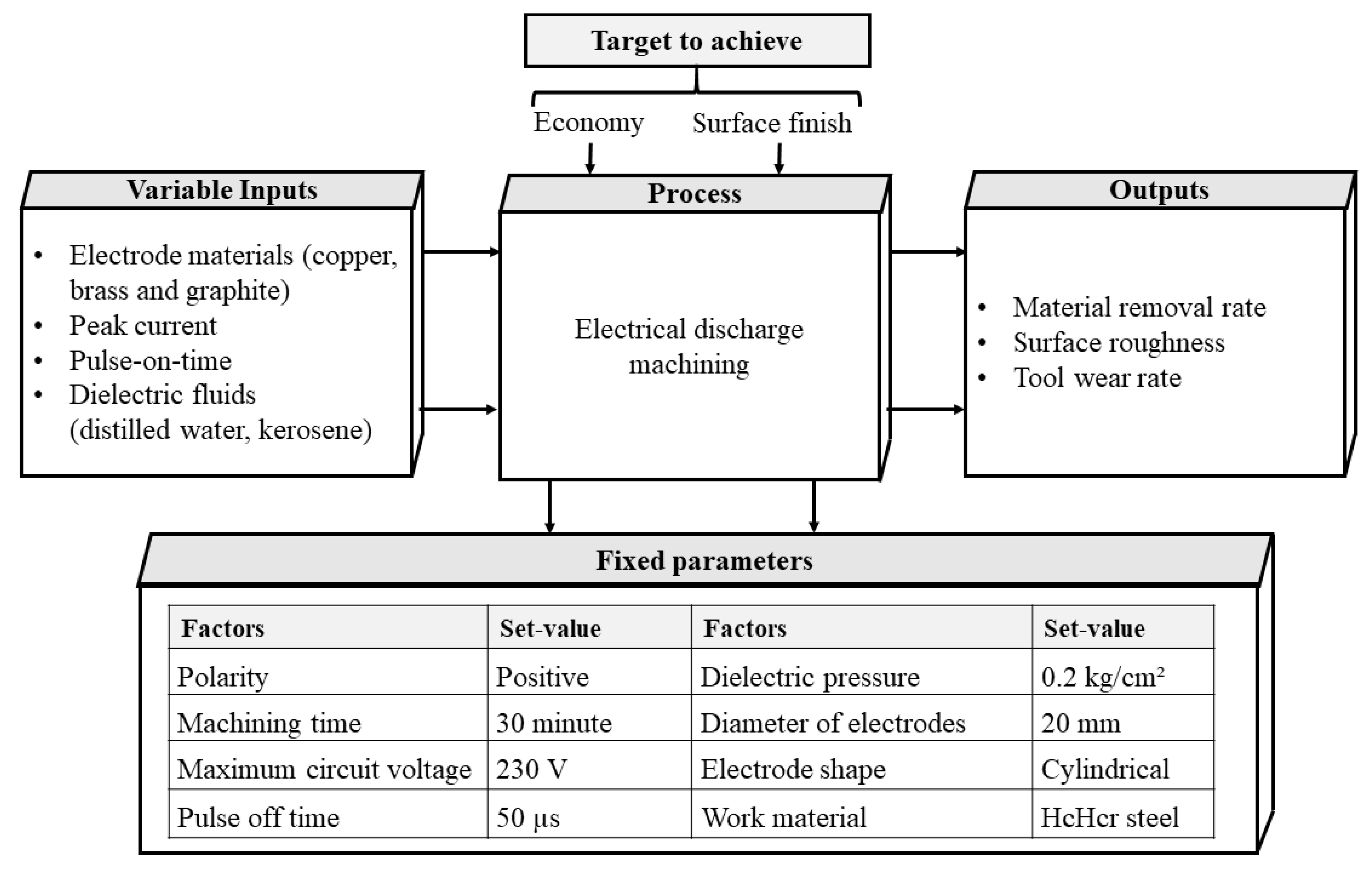

2. Materials and Methods

2.1. Work Materials

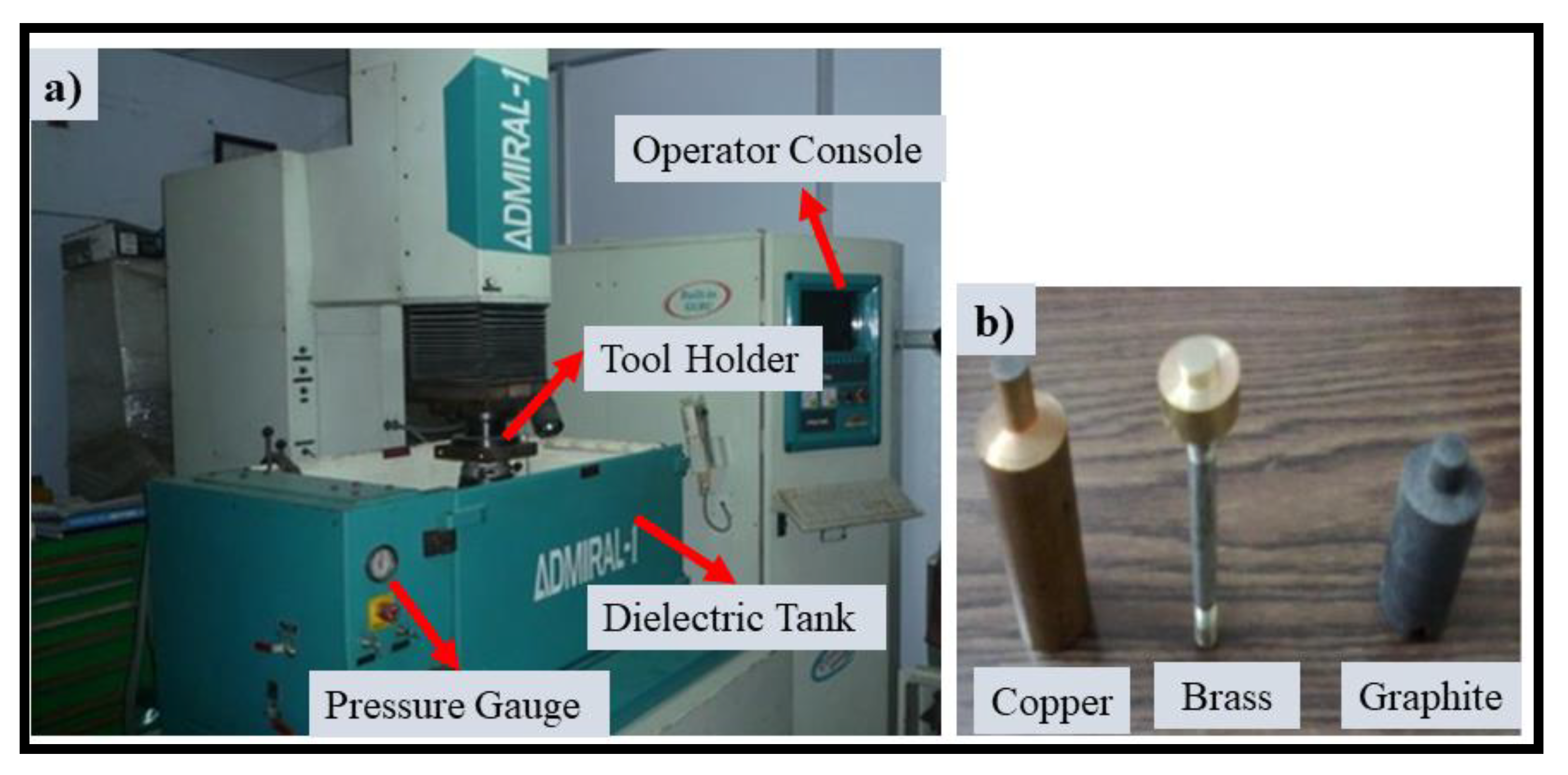

2.2. Dielectric Fluids and Electrodes Material

2.3. Experimental Details

Response Measurements

2.4. Taguchi Method

2.5. Utility Concept

2.6. Principal Component Analysis (PCA)

2.7. Criteria Importance through Criteria Inter-Correlation (CRITIC)

3. Results and Discussions

3.1. Taguchi Method and Analysis

3.2. Analysis of EDM Process Variables on Different Responses

3.2.1. Response: MRR

3.2.2. Response: Surface Roughness

3.2.3. Response: Tool Wear Rate

3.3. Weight Determination for Each Response: PCA and CRITIC

3.3.1. Principal Component Analysis:

3.3.2. Criteria Importance through Criteria Inter-Correlation (CRITIC)

3.3.3. Utility Approach

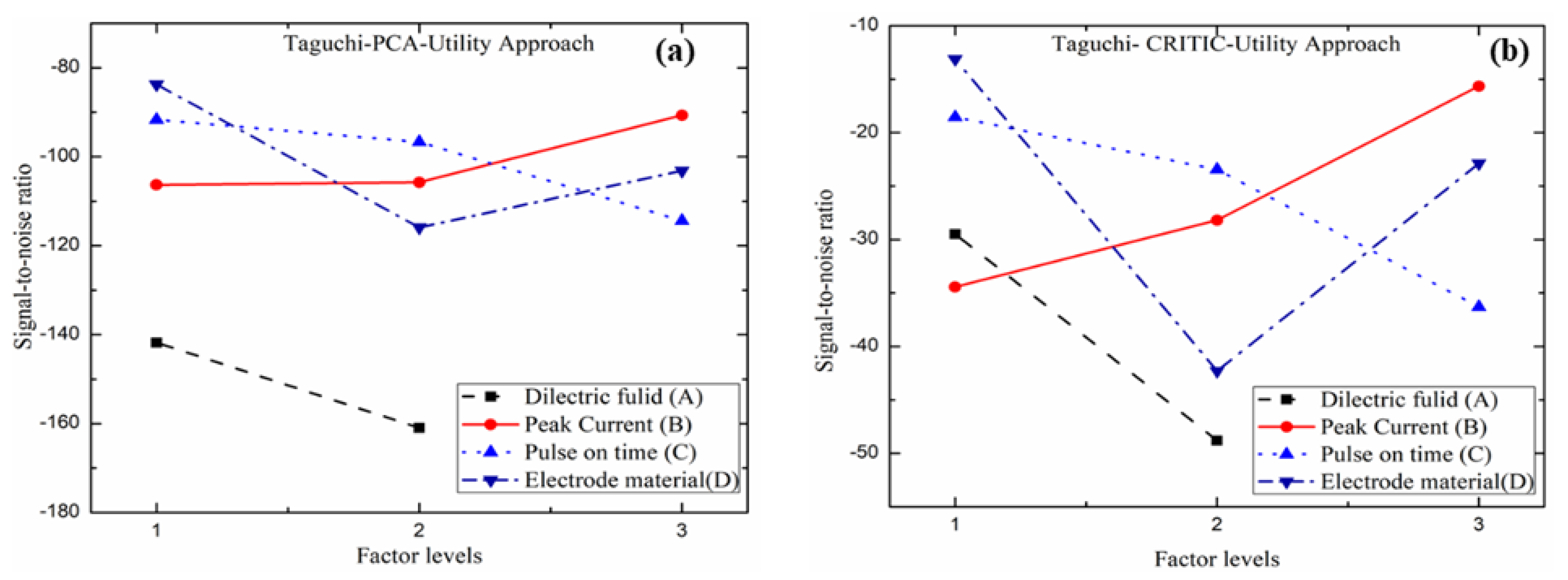

3.3.4. Multi-Objective Optimization Taguchi-PCA-Utility and Taguchi-CRITIC-Utility Approach

3.4. Confirmation Experiments

4. Conclusion

- The electrode material is found the most dominating factor for higher MRR, lower SR and TWR compare to the other parameters.

- Higher MRR, lower SR and TWR are attained by graphite electrode in presence of distilled water as dielectric fluid compared to brass and copper.

- The optimal setting obtained by both hybrid methods is the same at A1B3C1D1, (i.e., A1: DW; B3: 9 A, C1: 50 µs; D1: graphite). This signifies that both the hybrid methods are equally capable to provide better results in responses (i.e., high MRR of 0.0632 gm/min, low values of SR of 1.68 µm and TWR of 0.012 gm/min).

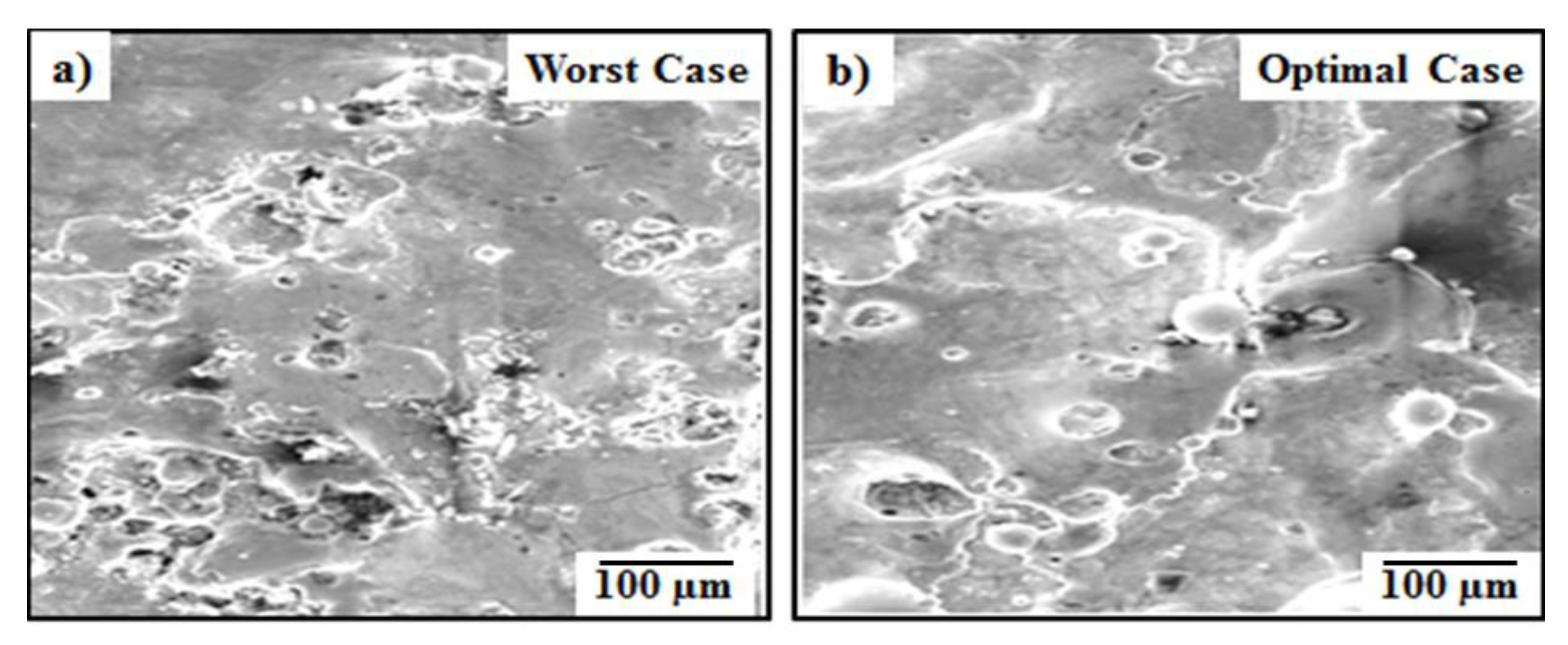

- Micrographic analysis of the optimal conditions shows better surface and uniform distribution of surface compared to the worst conditions.

- Interesting observation related to the weight calculation by PCA method. PCA possesses major drawbacks such as eigenvalues correspond to two PC are greater than 1 for PC1 and close to unity for PC2, and the explained variation of the first PC is less than 50%. Note that there is no universal rule defined yet to determine the weights for the said drawbacks of PCA. However, the CRITIC method determined the weights of each response are found equal to 0.3470 for MRR, 0.3067 for SR, and 0.3463 for TWR. Hence, the Taguchi-CRITIC-Utility approach is treated as the best model to optimize the multi-responses.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Tripathy, S.; Tripathy, D.K. Surface Characterization and Multi-response optimization of EDM process parameters using powder mixed dielectric. Mater. Today Proc. 2017, 4, 2058–2067. [Google Scholar] [CrossRef]

- Konig, W.; Rummenholler, S. Technological and industrial safety aspects in milling FRP. ASME Mach. Adv. Comp. 1993, 45, 1–14. [Google Scholar]

- Sivapirakasam, S.P.; Mathew, J.; Suryanarayana, M. Multiattribute decision making for green electrical discharge machining. Expert Syst. Appl. 2011, 38, 8370–8374. [Google Scholar] [CrossRef]

- Weller, E.J. Non-Traditional Machining Process; Society of Manufacturing Engineers: Dearbom, MI, USA, 1984; pp. 15–71. [Google Scholar]

- Dubey, A.K.; Yadava, V. Laser beam machining—A review. Int. J. Mach. Tool Manu. 2008, 48, 609–628. [Google Scholar] [CrossRef]

- Gupta, V.; Pandey, P.M.; Garg, M.P.; Khanna, R.; Batra, N.K. Minimization of kerf taper angle and kerf width using Taguchi’s method in abrasive water jet machining of marble. Proc. Mat. Sci. 2014, 6, 140–149. [Google Scholar] [CrossRef]

- Bhowmik, S.; Gupta, K.J. Modeling and optimization of abrasive water jet machining process. In Modeling and Optimization of Advanced Manufacturing Processes; Springer Briefs in Applied Sciences and Technology; Springer: Hoboken, NJ, USA, 2019. [Google Scholar]

- Gupta, K.J. Introduction to abrasive water jet machining. In Abrasive Water Jet Machining of Engineering Materials; Springer Briefs in Applied Sciences and Technology; Springer: Hoboken, NJ, USA, 2020. [Google Scholar]

- Singh, R.; Khamba, J.S. Mathematical modeling of tool wear rate in ultrasonic machining of titanium. Int. J. Adv. Manuf. Tech. 2009, 43, 573–580. [Google Scholar] [CrossRef]

- Wang, G.Q.; Li, H.S.; Qu, N.S.; Zhu, D. Investigation of the hole-formation process during double-sided through-mask electrochemical machining. J. Mater. Process. Tech. 2016, 234, 95–101. [Google Scholar] [CrossRef]

- Sabyrov, N.; Jahan, M.P.; Bilal, A.; Perveen, A. Ultrasonic vibration assisted electro-discharge machining (edm)—An overview. Materials 2019, 12, 522. [Google Scholar] [CrossRef]

- Pramanik, A.; Islam, M.N.; Basak, A.K.; Dong, Y.; Littlefair, G.; Prakash, C. Optimizing dimensional accuracy of titanium alloy features produced by wire electrical discharge machining. Mater. Manuf. Process. 2019, 34, 1083–1090. [Google Scholar] [CrossRef]

- Tan, T.H.; Yan, J. Atomic-scale characterization of subsurface damage and structural changes of single-crystal silicon carbide subjected to electrical discharge machining. Acta Mater. 2017, 123, 362–372. [Google Scholar] [CrossRef]

- Priyadarshini, M.; Pal, K. Grey-Taguchi based optimization of EDM process for titanium alloy. Mater. Today Proc. 2015, 2, 2472–2481. [Google Scholar] [CrossRef]

- Bhattacharya, A.; Batish, A.; Kumar, N. Surface characterization and material migration during surface modification of die steels with silicon, graphite and tungsten powder in EDM process. J. Mater. Sci. Technol. 2013, 27, 133–140. [Google Scholar] [CrossRef]

- Abbas, N.M.; Solomon, D.G.; Bahari, M.F. A review on current research trends in electrical discharge machining. Int. J. Mach. Tool Manu. 2007, 47, 1214–1228. [Google Scholar] [CrossRef]

- Beri, N.; Mahajan, A. Performance evaluation of powder metallurgy electrode in electrical discharge machining of AISI D2 steel using Taguchi method. Int. J. Mech. Mechatron. Eng. 2008, 2, 167–171. [Google Scholar]

- Lajis, M.A.; Radzi, H.C.D.M.; Amin, A.K.M.N. The implementation of Taguchi method on EDM process of tungsten carbide. Eur. J. Sci. Res. 2009, 26, 609–617. [Google Scholar]

- Kumar, V.; Beri, N.; Kumar, A.; Singh, P. Some studies on Electric discharge machining of Hastalloy using powder metallurgy electrode. Int. J. Adv. Eng. Tech. 2010, 1, 16–27. [Google Scholar]

- Beri, N.; Kumar, A.; Maheshwari, S.; Sharma, C. Optimisation of electrical discharge machining process with CuW powder metallurgy electrode using grey relation theory. Int. J. Mach. Mach. Mater. 2011, 9, 103–115. [Google Scholar] [CrossRef]

- Patel, V.D.; Patel, C.P.; Patel, U.J. Analysis of different tool material on MRR and Surface roughness of mild steel in EDM. Int. J. Eng. Res. Appl. 2011, 1, 394–397. [Google Scholar]

- Ghewade, D.V.; Nipanikar, S.R. Experimental study of Electro discharge machining for Inconel Material. Int. J. Adv. Eng. Tech. 2011, 2, 107–112. [Google Scholar]

- Leão, F.N.; Pashby, I.R. A review on the use of environmentally friendly dielectric fluids in electrical discharge machining. J. Mater. Process. Tech. 2004, 149, 341–346. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, Y.; Ji, R.; Cai, B. Study of the recast layer of a surface machined by sinking electrical discharge machining using water-in-oil emulsion as dielectric. Appl. Surf. Sci. 2011, 257, 5989–5997. [Google Scholar] [CrossRef]

- Chakraborty, S.; Dey, V.; Ghosh, S. A reviews on the use of dielectric fluids and their effects in electrical discharge machining characteristics. Precis. Eng. 2015, 40, 1–6. [Google Scholar] [CrossRef]

- Liew, P.J.; Yan, J.; Masaki, T. Effect of different dielectric fluids on micro EDM of low conductivity ceramic material RB-SiC. Adv. Mater. Res. 2012, 565, 529–534. [Google Scholar] [CrossRef]

- Wang, X.; Liu, Z.; Xue, R.; Tian, Z.; Huang, Y. Research on the influence of dielectric characteristics on the EDM of titanium alloy. Int. J. Adv. Manuf. Tech. 2014, 72, 979–987. [Google Scholar] [CrossRef]

- Chen, S.; Yan, B.; Huang, F. Influence of kerosene and distilled water as dielectrics on the electric discharge machining characteristics of Ti-6A1-4V. J. Mater. Process. Tech. 1999, 87, 107–111. [Google Scholar] [CrossRef]

- Bai, C.Y.; Koo, C.H. Effects of kerosene or distilled water as dielectric on electrical discharge alloying of super alloy Haynes 230 with Al-Mo composite electrode. Surf. Coat. Tech. 2006, 200, 4127–4135. [Google Scholar] [CrossRef]

- Tao, J.; Shih, A.J.; Ni, J. Experimental study of the dry and near-dry electrical discharge milling processes. J. Manuf. Sci. Eng. 2008, 130, 011002. [Google Scholar] [CrossRef]

- Jeanvoine, N.; Holzapfel, C.; Soldera, F.; Muecklich, F. Microstructure characterisation of electrical discharge craters using FIB/SEM dual beam techniques. Adv. Eng. Mater. 2008, 10, 973–977. [Google Scholar] [CrossRef]

- Prakash, C.; Singh, S.; Pruncu, C.I.; Mishra, V.; Królczyk, G.; Pimenov, D.Y.; Pramanik, A. Surface modification of Ti-6Al-4V alloy by electrical discharge coating process using partially sintered Ti-Nb electrode. Materials 2019, 12, 1006. [Google Scholar] [CrossRef]

- Rathi, P.; Ghiya, R.; Shah, H.; Srivastava, P.; Patel, S.; Chaudhari, R.; Vora, J. Multi-response optimization of Ni55. 8Ti shape memory alloy using Taguchi-Grey relational analysis approach. In Lecture Notes in Intelligent Transportation and Infrastructure; Recent Advances in Mechanical Infrastructure; Parwani, A., Ramkumar, P., Eds.; Springer: Singapore, 2020; pp. 13–23. [Google Scholar]

- Sahu, A.K.; Mahapatra, S.S. Optimization of surface roughness parameters by different multi-response optimization techniques during electro-discharge machining of titanium alloy. In Non-Conventional Machining in Modern Manufacturing Systems; Kumar, K., Kumari, N., Davim, J., Eds.; IGI Global: Hershey, PA, USA, 2019; pp. 82–108. [Google Scholar]

- Babu, K.N.; Karthikeyan, R.; Punitha, A. An integrated ANN–PSO approach to optimize the material removal rate and surface roughness of wire cut EDM on INCONEL 750. Mater. Today Proc. 2019, 19, 501–505. [Google Scholar] [CrossRef]

- Das, D.; Pratihar, D.K.; Roy, G.G.; Pal, A.R. Phenomenological model-based study on electron beam welding process, and input-output modeling using neural networks trained by back-propagation algorithm, genetic algorithms, particle swarm optimization algorithm and bat algorithm. Appl. Intell. 2018, 48, 2698–2718. [Google Scholar] [CrossRef]

- Liao, H.C.; Chen, Y.K. Optimizing multi-response problem in the Taguchi method by DEA based ranking method. Int. J. Qual. Reliab. Manag. 2002, 19, 825–837. [Google Scholar] [CrossRef]

- Kumar, S.; Grover, S.; Walia, R.S. Effect of hybrid wire EDM conditions on generation of residual stresses in machining of HCHCr D2 tool steel under ultrasonic vibration. Int. J. Interact. Des. Manuf. 2018, 12, 1119–1137. [Google Scholar] [CrossRef]

- Jeswani, M.L. Electrical discharge machining in distilled water. Wear 1981, 72, 81–88. [Google Scholar] [CrossRef]

- Kumari, S.; Datta, S.; Masanta, M. Electro-Discharge Machining of Inconel 825 Super alloy: Effects of Tool Material and Dielectric Flushing. Silicon 2018, 10, 2079–2099. [Google Scholar] [CrossRef]

- Valaki, J.B.; Rathod, P.P. Assessment of operational feasibility of waste vegetable oil based bio-dielectric fluid for sustainable electric discharge machining (EDM). Int. J. Adv. Manuf. Tech. 2016, 87, 1509–1518. [Google Scholar] [CrossRef]

- Shabgard, M.R.; Najafabadi, A.F. The influence of dielectric media on nano-structured tungsten carbide (WC) powder synthesized by electro-discharge process. Adv. Powder Technol. 2014, 25, 937–945. [Google Scholar] [CrossRef]

- Khan, A.A. Electrode wear and material removal rate during EDM of aluminum and mild steel using copper and brass electrodes. Int. J. Adv. Manuf. Tech. 2008, 39, 482–487. [Google Scholar] [CrossRef]

- Khan, M.A.R.; Rahman, M.M.; Kadirgama, K. An experimental investigation on surface finish in die-sinking EDM of Ti-5Al-2.5Sn. Int. J. Adv. Manuf. Tech. 2015, 77, 1727–1740. [Google Scholar] [CrossRef]

- Choudhary, R.; Kumar, H.; Garg, R.K. Analysis and evaluation of heat affected zones in electric discharge machining of EN-31 die steel. Indian J. Eng. Mater. Sci. 2010, 17, 91–98. [Google Scholar]

- George, J.; Chandan, R.; Manu, R. Experimental Investigation of Silicon Powder Mixed EDM Using Graphene and CNT Nano Particle Coated Electrodes. Silicon 2020, 1–17. [Google Scholar] [CrossRef]

- Phan, N.H.; Muthuramalingam, T. Multi Criteria Decision Making of Vibration Assisted EDM Process Parameters on Machining Silicon Steel Using Taguchi-DEAR Methodology. Silicon 2020, 1–7. [Google Scholar] [CrossRef]

- Yuan, J.; Wang, K.; Yu, T.; Fang, M. Integrating relevance vector machines and genetic algorithms for optimization of seed-separating process. Eng. Appl. Artif. Intel. 2007, 20, 970–979. [Google Scholar] [CrossRef]

- Kumar, P.; Barua, P.B.; Gaindhar, J.L. Quality optimization (multi-characteristics) through Taguchi’s technique and utility concept. Qual. Reliab. Eng. Int. 2000, 16, 475–485. [Google Scholar] [CrossRef]

- Gaitonde, V.N.; Karnik, S.R.; Davim, J.P. Taguchi multiple-performance characteristics optimization in drilling of medium density fibreboard (MDF) to minimize delamination using utility concept. J. Mater. Process. Tech. 2008, 196, 73–78. [Google Scholar] [CrossRef]

- Gaitonde, V.N.; Karnik, S.R.; Davim, J.P. Multiperformance optimization in turning of free-machining steel using Taguchi method and utility concept. J. Mater. Eng. Perform. 2009, 18, 231–236. [Google Scholar] [CrossRef]

- Gaikwad, V.S.; Jatti, V.S.; Pawar, P.J.; Nandurkar, K.N. Multi-objective Optimization of Electrical Discharge Machining Process During Machining of NiTi Alloy Using Taguchi and Utility Concept. In Techno-Societal; Pawar, P., Ronge, B., Balasubramaniam, R., Vibhute, A., Apte, S., Eds.; Springer: Berlin/Heidelberg, Germany, 2020; pp. 479–489. [Google Scholar]

- Pearson, K. On lines and planes of closest fit to systems of points in space. Lond. Edinb. Dublin Philos. Mag. J. Sci. 1901, 62, 559–572. [Google Scholar] [CrossRef]

- Hotelling, H. Analysis of a complex of statistical variables into principal components. J. Educ. Psychol. 1993, 24, 417–441. [Google Scholar] [CrossRef]

- Chate, G.R.; Patel, G.C.M.; Kulkarni, R.M.; Vernekar, P.; Deshpande, A.S.; Parappagoudar, M.B. Study of the effect of nano-silica particles on resin-bonded moulding sand properties and quality of casting. Silicon 2018, 10, 1921–1936. [Google Scholar] [CrossRef]

- Nayak, C.V.; Patel, G.C.M.; Ramesh, M.R.; Desai, V.; Samanta, S.K. Analysis and optimization of metal injection moulding process. In Materials Forming, Machining and Post Processing. Materials Forming, Machining and Tribology; Gupta, K., Ed.; Springer: Berlin/Heidelberg, Germany, 2020; pp. 41–74. [Google Scholar]

- Patel, G.C.M.; Kumar, R.S.J.; Naidu, N.S. Optimization of abrasive water jet machining for green composites using multi-variant hybrid techniques. In Optimization of Manufacturing Processes. Springer Series in Advanced Manufacturing; Gupta, K., Gupta, M., Eds.; Springer: Berlin/Heidelberg, Germany, 2020; pp. 129–162. [Google Scholar]

- Kumari, M.; Kulkarni, M.S. Single-measure and multi-measure approach of predictive manufacturing control: A comparative study. Comput. Ind. Eng. 2019, 127, 182–195. [Google Scholar] [CrossRef]

- Adalı, E.A.; Işık, A.T. CRITIC and MAUT methods for the contract manufacturer selection problem. Europ. J. Multidiscip. Stud. 2017, 2, 93–101. [Google Scholar] [CrossRef]

- Diakoulaki, D.; Mavrotas, G.; Papayannakis, L. Determining objective weights in multiple criteria problems: The critic method. Comput. Oper. Res. 1995, 22, 763–770. [Google Scholar] [CrossRef]

- Slebi-Acevedo, C.J.; Pascual-Muñoz, P.; Lastra-González, P.; Castro-Fresno, D. Multi-Response Optimization of porous asphalt mixtures reinforced with aramid and polyolefin fibers employing the CRITIC-TOPSIS based on Taguchi methodology. Materials 2019, 12, 3789. [Google Scholar] [CrossRef]

- Slebi-Acevedo, C.J.; Silva-Rojas, I.M.; Lastra-González, P.; Pascual-Muñoz, P.; Castro-Fresno, D. Multiple-response optimization of open graded friction course reinforced with fibers through CRITIC-WASPAS based on Taguchi methodology. Constr. Build. Mater. 2020, 233, 117274. [Google Scholar] [CrossRef]

- Ali, M.M.; Laily, S.; Manshoor, B.; Syahrian, N.; Izamshah, R.; Hadzley, M.; Muhamad, M. Performance of copper, copper tungsten, graphite and brass electrode on MRR, EWR and SR of aluminium LM6 in EDM die sinking. J. Adv. Res. Appl. Mech. 2015, 6, 30–36. [Google Scholar]

- Ranganath, B.J. Electric Discharge Machining. In Thermal Metal Cutting Processes; International Publishing House Pvt. Ltd.: New Delhi, India, 2008; pp. 7–18. [Google Scholar]

- Khanra, A.K.; Pathak, L.C.; Godkhindi, M.M. Microanalysis of debris formed during electrical discharge machining (EDM). J. Mat. Sci. 2007, 42, 872–877. [Google Scholar] [CrossRef]

- Su, C.T.; Tong, L.I. Multi-response robust design by principal component analysis. Total Qual. Manag. 1997, 8, 409–416. [Google Scholar] [CrossRef]

- Kao, C. Weight determination for consistently ranking alternatives in multiple criteria decision analysis. Appl. Math. Model. 2010, 34, 1779–1787. [Google Scholar] [CrossRef]

- Jagadish, R.A. Optimization of process parameters of green electrical discharge machining using principal component analysis (PCA). Int. J. Adv. Manuf. Technol. 2016, 87, 1299–1311. [Google Scholar] [CrossRef]

- Venkata, R.R.; Kalyankar, V.D. Parameter optimization of machining processes using a new optimization algorithm. Mater. Manuf. Process. 2012, 27, 978–985. [Google Scholar] [CrossRef]

- Sanjeev, K.; Rupinder, S.; Singh, T.P.; Sethi, B.L. Surface modification by electrical discharge machining: A review. J. Mater. Process. Technol. 2009, 209, 3675–3687. [Google Scholar]

| Elements | % C | % Si | % Mn | % Cr | % Ni | % Mo | % Fe |

|---|---|---|---|---|---|---|---|

| Weight (%) | 1.83 | 0.25 | 0.61 | 12.45 | 0.12 | 0.78 | Bal |

| Properties | Value |

|---|---|

| Density (kg/m3) | 7700 |

| Melting point (°C) | 1421 |

| Hardness (HRC) | 62 |

| Poisson ratio | 0.27–0.3 |

| Elastic Modulus (GPa) | 190–210 |

| Thermal Expansion (/°C) | 10.4 × 10−6 |

| Thermal Conductivity (W/m-K) | 20 |

| Properties | Kerosene | Distilled Water |

|---|---|---|

| Flash point, °C | 81.0 | 100 |

| Dielectric strength, MV/cm | 160 | 229 |

| Density (g/cm3) | 0.80 | 1.00 |

| Kinematic viscosity at 40 °C, cSt | 2.71 | 8.01 × 106 |

| Properties | Graphite | Copper | Brass |

|---|---|---|---|

| Density (g/cm3) | 1.77 | 8.904 | 8.55 |

| Melting point (°C) | 3350 | 1083 | 990 |

| Electrical Resistivity (Ω. m) | 60 × 10−5 | 1.96 × 10−8 | 4.7 × 10−8 |

| Thermal conductivity (W/m.k) | 160–230 | 388 | 159 |

| Specific heat capacity (J/g°C) | 7.10 | 0.385 | 0.380 |

| Input Parameters | Symbol | Units | Levels (1, 2, and 3) |

|---|---|---|---|

| Dielectric fluids | A | - | Distilled water and kerosene |

| Peak current (ampere) | B | A | 3, 6, and 9 |

| Pulse-on time (seconds) | C | µs | 50, 75, and 100 |

| Electrode materials | D | - | Graphite, copper, and brass |

| Exp. No | Input variables | Outputs | |||||

|---|---|---|---|---|---|---|---|

| Dielectric Fluids | Peak Current, A | Pulse on Time, µs | Electrode Materials | MRR g/min | SR µm | TWR g/min | |

| 1 | Distilled water | 3 | 50 | Graphite | 0.0452 | 6.89 | 0.030 |

| 2 | Distilled water | 3 | 75 | Copper | 0.0154 | 3.60 | 0.050 |

| 3 | Distilled water | 3 | 100 | Brass | 0.0077 | 5.96 | 0.012 |

| 4 | Distilled water | 6 | 50 | Graphite | 0.0365 | 4.76 | 0.025 |

| 5 | Distilled water | 6 | 75 | Copper | 0.0040 | 5.20 | 0.012 |

| 6 | Distilled water | 6 | 100 | Brass | 0.0153 | 4.59 | 0.010 |

| 7 | Distilled water | 9 | 50 | Copper | 0.0614 | 1.65 | 0.015 |

| 8 | Distilled water | 9 | 75 | Brass | 0.0170 | 4.48 | 0.010 |

| 9 | Distilled water | 9 | 100 | Graphite | 0.0450 | 2.90 | 0.014 |

| 10 | Kerosene | 3 | 50 | Brass | 0.0045 | 1.34 | 0.010 |

| 11 | Kerosene | 3 | 75 | Graphite | 0.0294 | 2.89 | 0.022 |

| 12 | Kerosene | 3 | 100 | Copper | 0.0026 | 3.87 | 0.045 |

| 13 | Kerosene | 6 | 50 | Copper | 0.0049 | 2.95 | 0.017 |

| 14 | Kerosene | 6 | 75 | Brass | 0.0146 | 2.98 | 0.019 |

| 15 | Kerosene | 6 | 100 | Graphite | 0.0153 | 4.59 | 0.016 |

| 16 | Kerosene | 9 | 50 | Brass | 0.0152 | 6.06 | 0.014 |

| 17 | Kerosene | 9 | 75 | Graphite | 0.0410 | 3.16 | 0.018 |

| 18 | Kerosene | 9 | 100 | Copper | 0.0015 | 3.89 | 0.021 |

| Exp. No. | S/N Ratio Value | ||

|---|---|---|---|

| MRR (dB) | SR (dB) | TWR (dB) | |

| 1 | −26.90 | −16.76 | 30.46 |

| 2 | −36.25 | −11.13 | 26.02 |

| 3 | −42.27 | −15.50 | 38.42 |

| 4 | −28.75 | −13.55 | 32.04 |

| 5 | −47.96 | −14.32 | 38.42 |

| 6 | −36.31 | −13.24 | 40.00 |

| 7 | −24.24 | −4.35 | 36.48 |

| 8 | −35.39 | −13.03 | 40.00 |

| 9 | −26.94 | −9.25 | 37.08 |

| 10 | −46.94 | −2.54 | 40.00 |

| 11 | −30.63 | −9.22 | 33.15 |

| 12 | −51.70 | −11.75 | 26.94 |

| 13 | −46.20 | −9.40 | 35.39 |

| 14 | −36.71 | −9.48 | 34.42 |

| 15 | −36.31 | −13.24 | 35.92 |

| 16 | −36.36 | −15.65 | 37.08 |

| 17 | −27.74 | −9.99 | 34.89 |

| 18 | −56.48 | −11.80 | 33.56 |

| Factors | Levels | A | B | C | D | Total |

|---|---|---|---|---|---|---|

| Sum at factor levels (SFL) | 1 | −305.00 | −234.69 | −209.38 | −177.27 | −674.07 |

| 2 | −369.07 | −232.23 | −214.69 | −262.82 | ||

| 3 | −207.15 | −250.00 | −233.98 | |||

| Sum of squares of differences (SSD) | 4105.05 | 1393.59 | 2924.26 | 11,366.29 | 19,789.19 | |

| Percent contribution (PC) | 20.74 | 7.04 | 14.78 | 57.44 | 100.00 | |

| Optimal levels (OL) | A1B3C1D1 (Not the combination of L18 experiments) | |||||

| Figure | Levels | A | B | C | D | Total |

|---|---|---|---|---|---|---|

| SFL | 1 | −111.13 | −66.91 | −62.25 | −72.01 | −204.20 |

| 2 | −93.07 | −73.23 | −67.17 | −62.75 | ||

| 3 | −64.07 | −74.78 | −69.44 | |||

| SSD | 325.93 | 131.89 | 238.93 | 137.33 | 834.08 | |

| PC | 39.08 | 15.81 | 28.65 | 16.47 | 100.00 | |

| OL | A2B3C1D2 (Not the combination of L18 experiments) | |||||

| Factors | Levels | A | B | C | D | Total |

|---|---|---|---|---|---|---|

| SFL | 1 | 318.91 | 194.98 | 211.45 | 203.54 | 630.26 |

| 2 | 311.35 | 216.19 | 206.91 | 196.80 | ||

| 3 | 219.08 | 211.90 | 229.92 | |||

| SSD | 57.14 | 1039.07 | 45.75 | 1838.32 | 2980.28 | |

| PC | 1.92 | 34.86 | 1.53 | 61.68 | 100.00 | |

| OL | A1B3C3D3 (Not the combination of L18 experiments) | |||||

| Eigen Value | 1.1500 | 0.9840 | 0.8659 |

|---|---|---|---|

| Principal components | First principal component (PC1) | Second principal component (PC2) | Third principal component (PC3) |

| Explained variation (%) | 38.30 | 32.80 | 28.90 |

| Cumulative proportion (%) | 38.30 | 71.10 | 100.0 |

| Eigenvectors (MRR, SR, TWR) | −0.646, 0.682, 0.341 | 0.360, −0.121, −0.925 | 0.673, 0.721, −0.168 |

| Exp. No. | Outputs | ||

|---|---|---|---|

| MRR, gm/min | SR, µm | TWR, gm/min | |

| 1 | 0.730 | 0.000 | 0.500 |

| 2 | 0.232 | 0.593 | 0.000 |

| 3 | 0.104 | 0.168 | 0.950 |

| 4 | 0.584 | 0.384 | 0.625 |

| 5 | 0.042 | 0.305 | 0.950 |

| 6 | 0.230 | 0.414 | 1.000 |

| 7 | 1.000 | 0.944 | 0.875 |

| 8 | 0.259 | 0.434 | 1.000 |

| 9 | 0.726 | 0.719 | 0.900 |

| 10 | 0.050 | 1.000 | 1.000 |

| 11 | 0.466 | 0.721 | 0.700 |

| 12 | 0.018 | 0.544 | 0.125 |

| 13 | 0.057 | 0.710 | 0.825 |

| 14 | 0.219 | 0.705 | 0.775 |

| 15 | 0.230 | 0.414 | 0.850 |

| 16 | 0.229 | 0.150 | 0.900 |

| 17 | 0.659 | 0.672 | 0.800 |

| 18 | 0.000 | 0.541 | 0.725 |

| SD | 0.2978 | 0.2675 | 0.2851 |

| Correlation Coefficient of Different Responses | Summation of Different Responses | Weights of Different Responses | |||||||

|---|---|---|---|---|---|---|---|---|---|

| MRR | SR | TWR | MRR | SR | TWR | Summation | Cj | Wj | |

| MRR | 1 | 0.1305 | 0.0233 | 0 | 0.8695 | 0.9767 | 1.8462 | 0.5498 | 0.3470 |

| SR | 0.1305 | 1 | 0.0529 | 0.8695 | 0 | 0.9471 | 1.8166 | 0.4859 | 0.3067 |

| TWR | 0.0233 | 0.0529 | 1 | 0.9767 | 0.9471 | 0 | 1.9238 | 0.5485 | 0.3463 |

| Criteria | PCA | CRITIC |

|---|---|---|

| MRR, W1 | 0.4173 | 0.3470 |

| SR, W2 | 0.4651 | 0.3067 |

| TWR, W3 | 0.1163 | 0.3463 |

| Exp. No. | Multi-Response S/N Ratio (Taguchi-PCA-Utility Approach) | Multi-Response S/N Ratio (Taguchi-CRITIC-Utility Approach) |

|---|---|---|

| 1 | −15.47 | −3.93 |

| 2 | −17.27 | −6.98 |

| 3 | −20.37 | −6.12 |

| 4 | −14.56 | −3.04 |

| 5 | −22.19 | −7.73 |

| 6 | −16.65 | −2.81 |

| 7 | −7.88 | 2.89 |

| 8 | −16.16 | −2.42 |

| 9 | −11.22 | 0.66 |

| 10 | −16.11 | −3.22 |

| 11 | −13.20 | −1.98 |

| 12 | −23.90 | −12.21 |

| 13 | −19.52 | −6.66 |

| 14 | −15.71 | −3.73 |

| 15 | −17.12 | −4.22 |

| 16 | −18.13 | −4.58 |

| 17 | −12.15 | −0.61 |

| 18 | −25.14 | −11.60 |

| Factors | Levels | A | B | C | D | Total |

|---|---|---|---|---|---|---|

| SFL | 1 | −141.77 | −106.32 | −91.67 | −83.72 | −302.75 |

| 2 | −160.98 | −105.75 | −96.68 | −115.90 | ||

| 3 | −90.68 | −114.40 | −103.13 | |||

| SSD | 369.02 | 472.04 | 855.75 | 1575.37 | 3272.19 | |

| PC | 11.28 | 14.43 | 26.15 | 48.14 | 100.00 | |

| OL | A1B3C1D1 (Not the combination of L18) | |||||

| Factors | Levels | A | B | C | D | Total |

|---|---|---|---|---|---|---|

| SFL | 1 | −29.48 | −34.44 | −18.54 | −13.12 | −78.29 |

| 2 | −48.81 | −28.19 | −23.45 | −42.29 | ||

| 3 | −15.66 | −36.30 | −22.88 | |||

| SSD | 373.65 | 548.75 | 504.65 | 1322.89 | 2749.94 | |

| PC | 13.59 | 19.96 | 18.35 | 48.11 | 100.00 | |

| OL | A1B3C1D1 (Not the combination of L18) | |||||

| Models and Weights for Output | Optimal Conditions | Multi-Response S/N Ratio (dB) | ||

|---|---|---|---|---|

| Levels | Input Variables | Output Variables and S/N Ratio | ||

| Taguchi-PCA-Utility MRR, W1 = 0.4173 SR, W2 = 0.4651 TWR, W3 = 0.1163 | A1B3C1D1 | A: DW B: 9 A C: 50 µs D: Graphite | MRR: 0.0632 gm/min SR: 1.68 µm TWR: 0.012 gm/min | −7.63 |

| Taguchi-CRITIC-Utility MRR, W1 = 0.3470 SR, W2 = 0.3067 TWR, W3 = 0.3463 | A1B3C1D1 | MRR: −23.986 dB SR: −4.506 dB TWR: 38.42 dB | 3.60 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Patel Gowdru Chandrashekarappa, M.; Kumar, S.; Jagadish; Pimenov, D.Y.; Giasin, K. Experimental Analysis and Optimization of EDM Parameters on HcHcr Steel in Context with Different Electrodes and Dielectric Fluids Using Hybrid Taguchi-Based PCA-Utility and CRITIC-Utility Approaches. Metals 2021, 11, 419. https://doi.org/10.3390/met11030419

Patel Gowdru Chandrashekarappa M, Kumar S, Jagadish, Pimenov DY, Giasin K. Experimental Analysis and Optimization of EDM Parameters on HcHcr Steel in Context with Different Electrodes and Dielectric Fluids Using Hybrid Taguchi-Based PCA-Utility and CRITIC-Utility Approaches. Metals. 2021; 11(3):419. https://doi.org/10.3390/met11030419

Chicago/Turabian StylePatel Gowdru Chandrashekarappa, Manjunath, Sandeep Kumar, Jagadish, Danil Yurievich Pimenov, and Khaled Giasin. 2021. "Experimental Analysis and Optimization of EDM Parameters on HcHcr Steel in Context with Different Electrodes and Dielectric Fluids Using Hybrid Taguchi-Based PCA-Utility and CRITIC-Utility Approaches" Metals 11, no. 3: 419. https://doi.org/10.3390/met11030419

APA StylePatel Gowdru Chandrashekarappa, M., Kumar, S., Jagadish, Pimenov, D. Y., & Giasin, K. (2021). Experimental Analysis and Optimization of EDM Parameters on HcHcr Steel in Context with Different Electrodes and Dielectric Fluids Using Hybrid Taguchi-Based PCA-Utility and CRITIC-Utility Approaches. Metals, 11(3), 419. https://doi.org/10.3390/met11030419