Fabrication and Characterization of the Modified EV31-Based Metal Matrix Nanocomposites

Abstract

1. Introduction

2. Materials and Methods

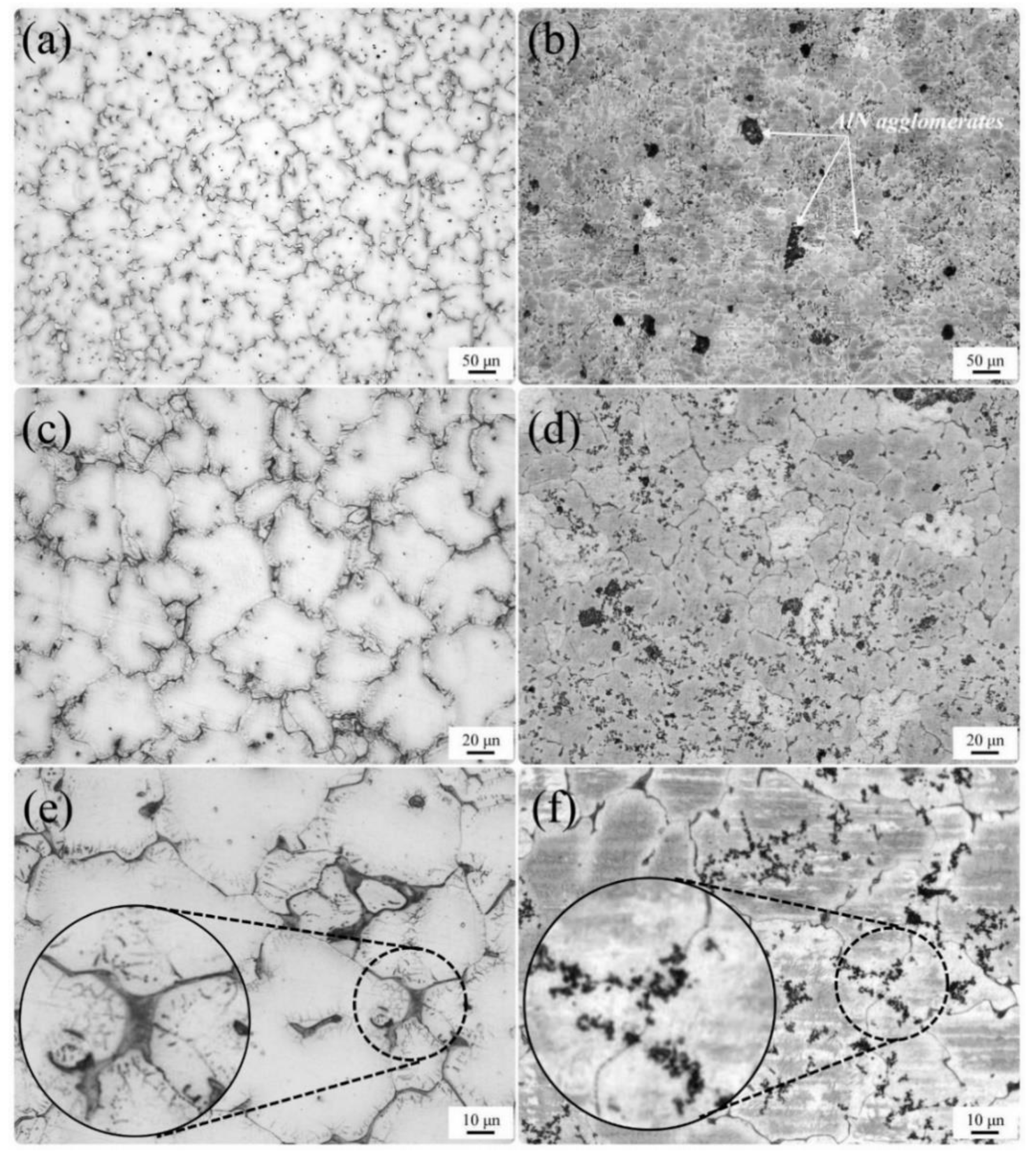

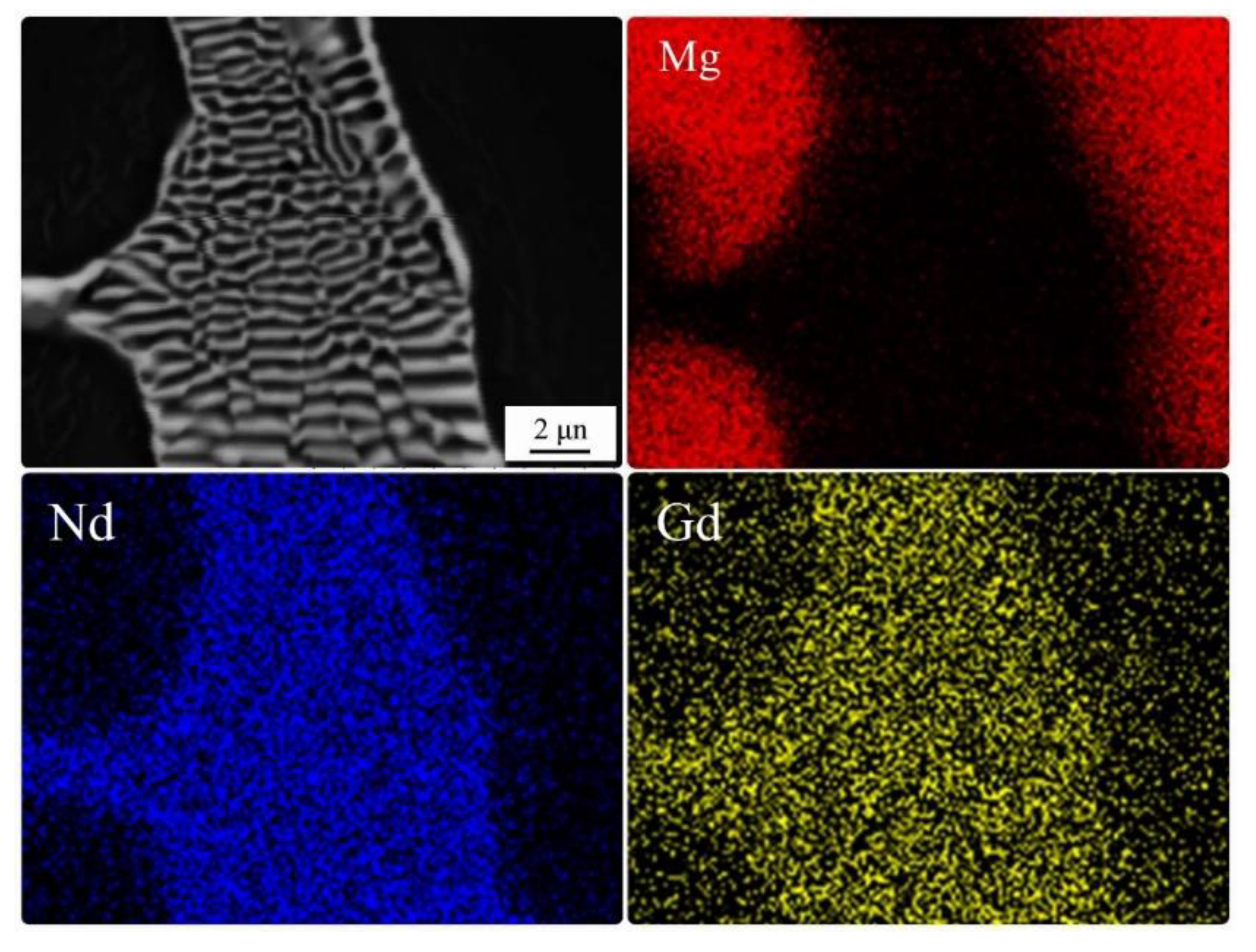

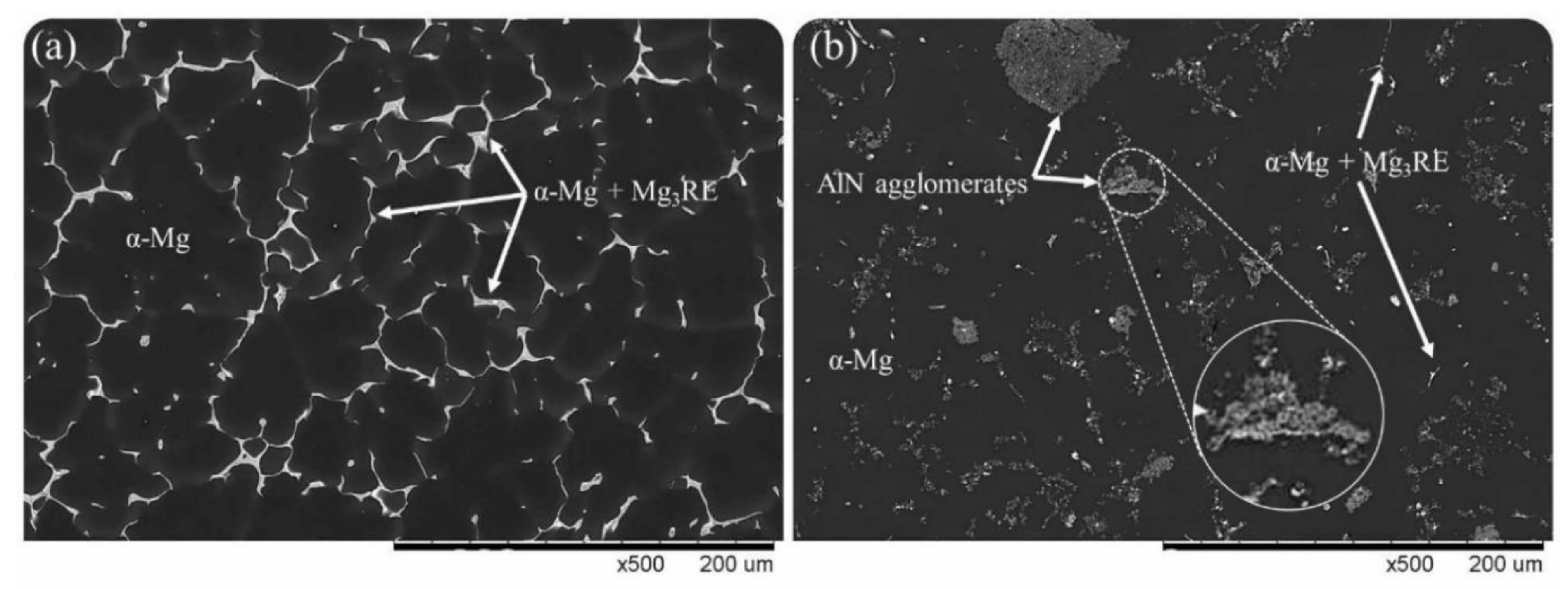

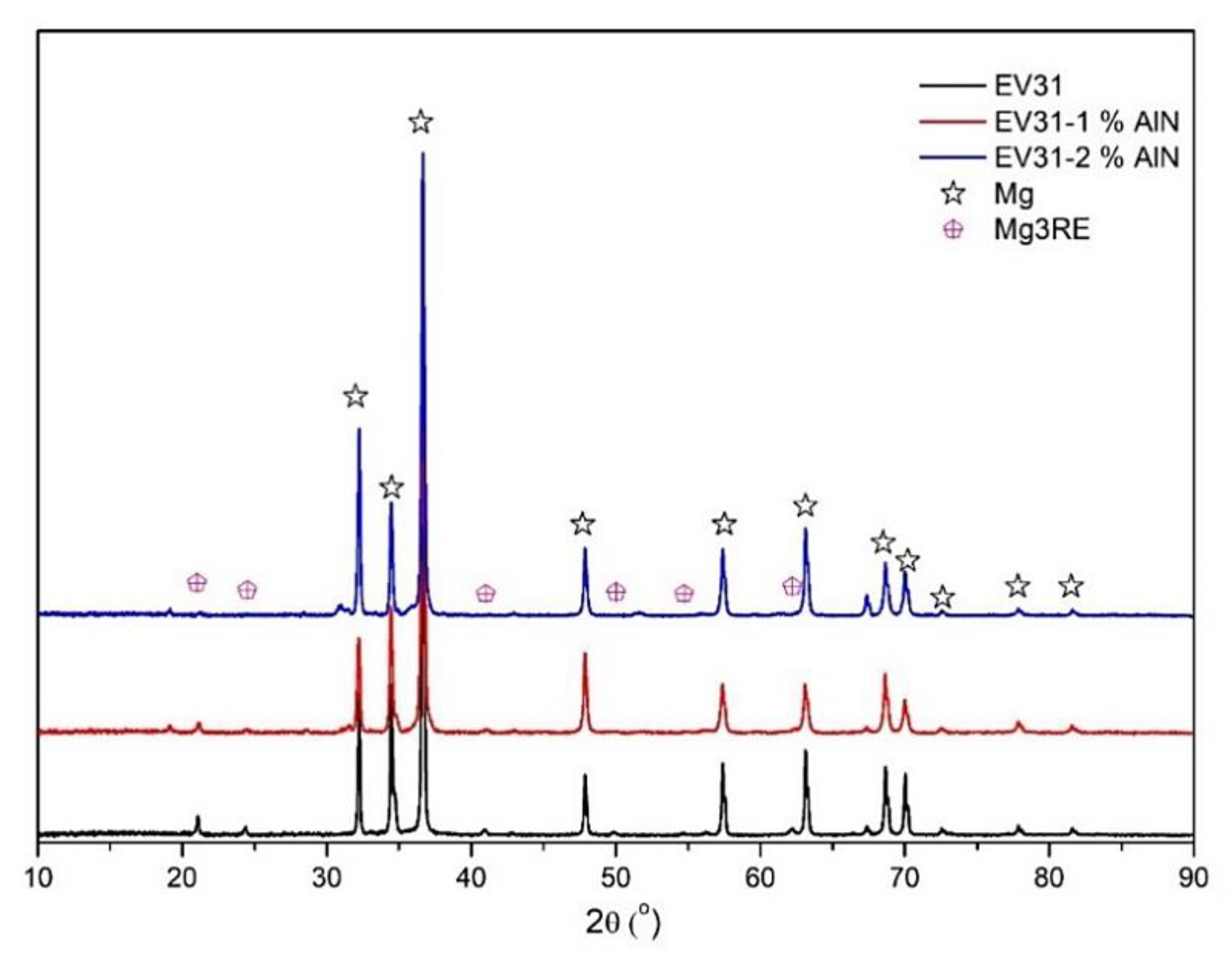

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Saboori, A.; Moheimani, S.K.; Pavese, M.; Badini, C.; Fino, P. New Nanocomposite Materials with Improved Mechanical Strength and Tailored Coefficient of Thermal Expansion for Electro-Packaging Applications. Metals 2017, 7, 536. [Google Scholar] [CrossRef]

- Mosallanejad, M.H.; Shafyei, A.; Akhavan, S. Simultaneous co-deposition of SiC and CNT into the Ni coating. Can. Metall. Q. 2016, 55, 147–155. [Google Scholar] [CrossRef]

- Daavari, M.; Atapour, M.; Mohedano, M.; Arrabal, R.; Matykina, E.; Taherizadeh, A. Biotribology and biocorrosion of MWCNTs-reinforced PEO coating on AZ31B Mg alloy. Surf. Interfaces 2020, 22, 100850. [Google Scholar] [CrossRef]

- He, X.; Song, S.; Luo, X.; Liu, J.; An, L.; Bai, Y. Predicting ductility of Mg/SiCp nanocomposite under multiaxial loading conditions based on unit cell modeling. Int. J. Mech. Sci. 2020, 184, 105831. [Google Scholar] [CrossRef]

- Chen, L.; Xu, J.; Choi, H.; Pozuelo, M.; Ma, X.; Bhowmick, S.; Yang, J.; Mathaudhu, S.; Li, X. Processing and properties of magnesium containing a dense uniform dispersion of nanoparticles. Nature 2015, 528, 539–543. [Google Scholar] [CrossRef] [PubMed]

- Jinwang, Z.; Shebin, W.; Junyuan, Z.; Jinling, Z.; Bingshe, X. Effects of Nd on Microstructures and Mechanical Properties of AM60 Magnesium Alloy in Vacuum Melting. Rare Met. Mater. Eng. 2009, 38, 1141–1145. [Google Scholar] [CrossRef]

- Sillekens, W.H.; Jarvis, D.J.; Vorozhtsov, A.; Bojarevics, V.; Badini, C.F.; Pavese, M.; Terzi, S.; Salvo, L.; Katsarou, L.; Dieringa, H. The ExoMet Project: EU/ESA Research on High-Performance Light-Metal Alloys and Nanocomposites. Met. Mater. Trans. A 2014, 45, 3349–3361. [Google Scholar] [CrossRef]

- Saboori, A.; Pavese, M.; Badini, C.; Fino, P. Microstructure and Thermal Conductivity of Al--Graphene Composites Fabricated by Powder Metallurgy and Hot Rolling Techniques. Acta Metall. Sin. Engl. Lett. 2017, 30, 675–687. [Google Scholar] [CrossRef]

- Saboori, A.; Pavese, M.; Badini, C.; Fino, P. Development of Al- and Cu-based nanocomposites reinforced by graphene nanoplatelets: Fabrication and characterization. Front. Mater. Sci. 2017, 11, 171–181. [Google Scholar] [CrossRef]

- Saboori, A.; Pavese, M.; Badini, C.; Fino, P. A Novel Cu–GNPs Nanocomposite with Improved Thermal and Mechanical Properties. Acta Metall. Sin. Engl. Lett. 2018, 31, 148–152. [Google Scholar] [CrossRef]

- Hu, H.; Yu, A.; Li, N.; Allison, J.E. Potential Magnesium Alloys for High Temperature Die Cast Automotive Applications: A Review. Mater. Manuf. Proc. 2003, 18, 687–717. [Google Scholar] [CrossRef]

- Kulekci, M.K. Magnesium and its alloys applications in automotive industry. Int. J. Adv. Manuf. Technol. 2008, 39, 851–865. [Google Scholar] [CrossRef]

- Musfirah, A.; Jaharah, A. Magnesium and Aluminum Alloys in Automotive Industry. J. Appl. Sci. Res. 2012, 8, 4865–4875. [Google Scholar]

- Polmear, I.J. Magnesium alloys and applications. Mater. Sci. Technol. 1994, 10, 1–16. [Google Scholar] [CrossRef]

- Barati, F.; Latifi, M.; Moayerifar, E.; Mosallanejad, M.H.; Saboori, A. Novel AM60-SiO2 Nanocomposite Produced via Ultrasound-Assisted Casting; Production and Characterization. Materials 2019, 12, 3946. [Google Scholar] [CrossRef]

- Saboori, A.; Padovano, E.; Pavese, M.; Badini, C. Novel Magnesium Elektron21-AlN Nanocomposites Produced by Ultrasound-Assisted Casting; Microstructure, Thermal and Electrical Conductivity. Materials 2018, 11, 27. [Google Scholar] [CrossRef]

- Dieringa, H. Properties of magnesium alloys reinforced with nanoparticles and carbon nanotubes: A review. J. Mater. Sci. 2011, 46, 289–306. [Google Scholar] [CrossRef]

- Lyon, P.; Syed, I.; Heaney, S. Elektron 21-An aerospace magnesium alloy for sand cast and investment cast applications. Adv. Eng. Mater. 2007, 9, 793–798. [Google Scholar] [CrossRef]

- Saboori, A.; Padovano, E.; Pavese, M.; Dieringa, H.; Badini, C. Effect of Solution Treatment on Precipitation Behaviors, Age Hardening Response and Creep Properties of Elektron21 Alloy Reinforced by AlN Nanoparticles. Materails 2017, 10, 1380. [Google Scholar] [CrossRef]

- Luo, A.A. Magnesium casting technology for structural applications. J. Magnes. Alloy. 2013, 1, 2–22. [Google Scholar] [CrossRef]

- Moreno, I.P.; Nandy, T.K.; Jones, J.W.; Allison, J.E.; Pollock, T.M. Microstructural stability and creep of rare-earth containing magnesium alloys. Scr. Mater. 2003, 48, 1029–1034. [Google Scholar] [CrossRef]

- He, S.M.; Zeng, X.Q.; Peng, L.M.; Gao, X.; Nie, J.F.; Ding, W.J. Precipitation in a Mg–10Gd–3Y–0.4Zr (wt.%) alloy during isothermal ageing at 250 °C. J. Alloy. Compd. 2006, 421, 309–313. [Google Scholar] [CrossRef]

- Kiełbus, A. Microstructure and Properties of Elektron 21 Magnesium Alloy. In Magnesium Alloys-Design, Processing and Properties; InTech: London, UK, 2011; Volume 4, pp. 281–296. ISBN 9789533075204. [Google Scholar]

- Kiełbus, A.; Rzychoń, T.; Moskal, G. The Influence of Heat Treatment Parameters on the Thermal Diffusivity of WE54 and Elektron 21 Magnesium Alloys. In Diffusion in Solids and Liquids VI. Defect and Diffusion Forum; Trans Tech Publications Ltd.: Stafa-Zurich, Switzerland, 2011; Volume 312, pp. 489–494. [Google Scholar]

- Pohlmann, C.; Röntzsch, L.; Kalinichenka, S.; Hutsch, T.; Kieback, B. Magnesium alloy-graphite composites with tailored heat conduction properties for hydrogen storage applications. Int. J. Hydrogen Energy 2010, 35, 12829–12836. [Google Scholar] [CrossRef]

- Tani, J.; Kido, H. Fabrication and thermoelectric properties of Mg2Si-based composites using reduction reaction with additives. Intermetallics 2013, 32, 72–80. [Google Scholar] [CrossRef]

- Xu, G.; Zhang, L.; Liu, L.; Du, Y.; Zhang, F.; Xu, K.; Liu, S.; Tan, M.; Jin, Z. Thermodynamic database of multi-component Mg alloys and its application to solidification and heat treatment. J. Magnes. Alloy. 2016, 4, 249–264. [Google Scholar] [CrossRef]

- Liu, D.; Song, J.; Jiang, B.; Zeng, Y.; Wang, Q.; Jiang, Z.; Liu, B.; Huang, G.; Pan, F. Effect of Al content on microstructure and mechanical properties of as-cast Mg-5Nd alloys. J. Alloys Compd. 2018, 737, 263–270. [Google Scholar] [CrossRef]

- Yang, H.; Zander, D.; Huang, Y.; Kainer, K.U.; Dieringa, H. Individual/synergistic effects of Al and AlN on the microstructural evolution and creep resistance of Elektron21 alloy. Mater. Sci. Eng. A 2020, 777, 139072. [Google Scholar] [CrossRef]

- Tokarev, O.A.; Demchyshyn, A.V.; Avtonomov, G.A. The structure and mechanical properties of multilayer nanocrystalline TiN/ZrN coatings obtained by vacuum-arc deposition. Proc. Appl. Ceramics 2007, 1, 43–47. [Google Scholar] [CrossRef]

- Cheng, Y.-T.; Cheng, C.-M. Relationships between hardness, elastic modulus, and the work of indentation. Appl. Phys. Lett. 1998, 73, 614–616. [Google Scholar] [CrossRef]

- Xiuqing, Z.; Haowei, W.; Lihua, L.; Xinying, T.; Naiheng, M. The mechanical properties of magnesium matrix composites reinforced with (TiB2+TiC) ceramic particulates. Mater. Lett. 2005, 59, 2105–2109. [Google Scholar] [CrossRef]

- Zhao, S.; Zheng, Z.; Huang, Z.; Dong, S.; Luo, P.; Zhang, Z.; Wang, Y. Cu matrix composites reinforced with aligned carbon nanotubes: Mechanical, electrical and thermal properties. Mater. Sci. Eng. A 2016, 675, 82–91. [Google Scholar] [CrossRef]

- Koltsov, A. Wetting and interfacial reactivity in Ag–Zr/sintered AlN system. Scr. Mater. 2003, 48, 351–357. [Google Scholar] [CrossRef]

- López-Pérez, W.; González-Hernández, R.; Rodríguez, M.J.A. Zirconium adsorption and incorporation on a reconstructed Al-T4 AlN(0001) surface. J. Phys. Chem. Solids 2013, 74, 1387–1391. [Google Scholar] [CrossRef]

- Chen, J.; Bao, C.-G.; Liu, Z.-W.; Sun, B.-S.; Shu, Y.-C.; Li, Q.-K. Thermal Properties of Mg–Al/AlN Composites Fabricated by Powder Metallurgy. Acta Metall. Sin. Engl. Lett. 2018, 31, 641–649. [Google Scholar] [CrossRef]

- Vaidya, R.U.; Chawla, K. Thermal expansion of metal-matrix composites. Compos. Sci. Technol. 1994, 50, 13–22. [Google Scholar] [CrossRef]

- Hort, N.; Huang, Y.; Kainer, K.U. Intermetallics in Magnesium Alloys. Adv. Eng. Mater. 2006, 8, 235–240. [Google Scholar] [CrossRef]

| Chemical Composition | Nd | Gd | Zn | Zr | Al | Mg |

|---|---|---|---|---|---|---|

| Standard (Wt.%) | 2.6–3.1 | 1.0–1.7 | 0.2–0.5 | Saturated | - | Bal. |

| Nominal (wt.%) | 2.9 | 1.3 | 0.4 | 0.4 | 0.1 | Bal. |

| Material | EV31 | EV31-0.1Al | EV31-0.1Al-AlN | EV31-0.1Al-2AlN |

|---|---|---|---|---|

| Electrical Resistivity (Ω·m) | 7.46 × 10−8 | 7.02 × 10−8 | 5.38 × 10−8 | 4.85 × 10−8 |

| Thermal conductivity (W/m·k) | 114.8 | 119.7 | 130.8 | 149.5 |

| Coefficient of Thermal Expansion (1/K) | 25.8 × 10−6 | 25.1 × 10−6 | 24.2 × 10−6 | 23.4 × 10−6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moheimani, S.K.; Dadkhah, M.; Mosallanejad, M.H.; Saboori, A. Fabrication and Characterization of the Modified EV31-Based Metal Matrix Nanocomposites. Metals 2021, 11, 125. https://doi.org/10.3390/met11010125

Moheimani SK, Dadkhah M, Mosallanejad MH, Saboori A. Fabrication and Characterization of the Modified EV31-Based Metal Matrix Nanocomposites. Metals. 2021; 11(1):125. https://doi.org/10.3390/met11010125

Chicago/Turabian StyleMoheimani, Seyed Kiomars, Mehran Dadkhah, Mohammad Hossein Mosallanejad, and Abdollah Saboori. 2021. "Fabrication and Characterization of the Modified EV31-Based Metal Matrix Nanocomposites" Metals 11, no. 1: 125. https://doi.org/10.3390/met11010125

APA StyleMoheimani, S. K., Dadkhah, M., Mosallanejad, M. H., & Saboori, A. (2021). Fabrication and Characterization of the Modified EV31-Based Metal Matrix Nanocomposites. Metals, 11(1), 125. https://doi.org/10.3390/met11010125