Intrinsic Fatigue Crack Growth in Al-Cu-Li-Mg-Zr Alloys: The Effect of the Iron Constituent Particles

Abstract

1. Introduction

2. Materials and Methods

3. Results

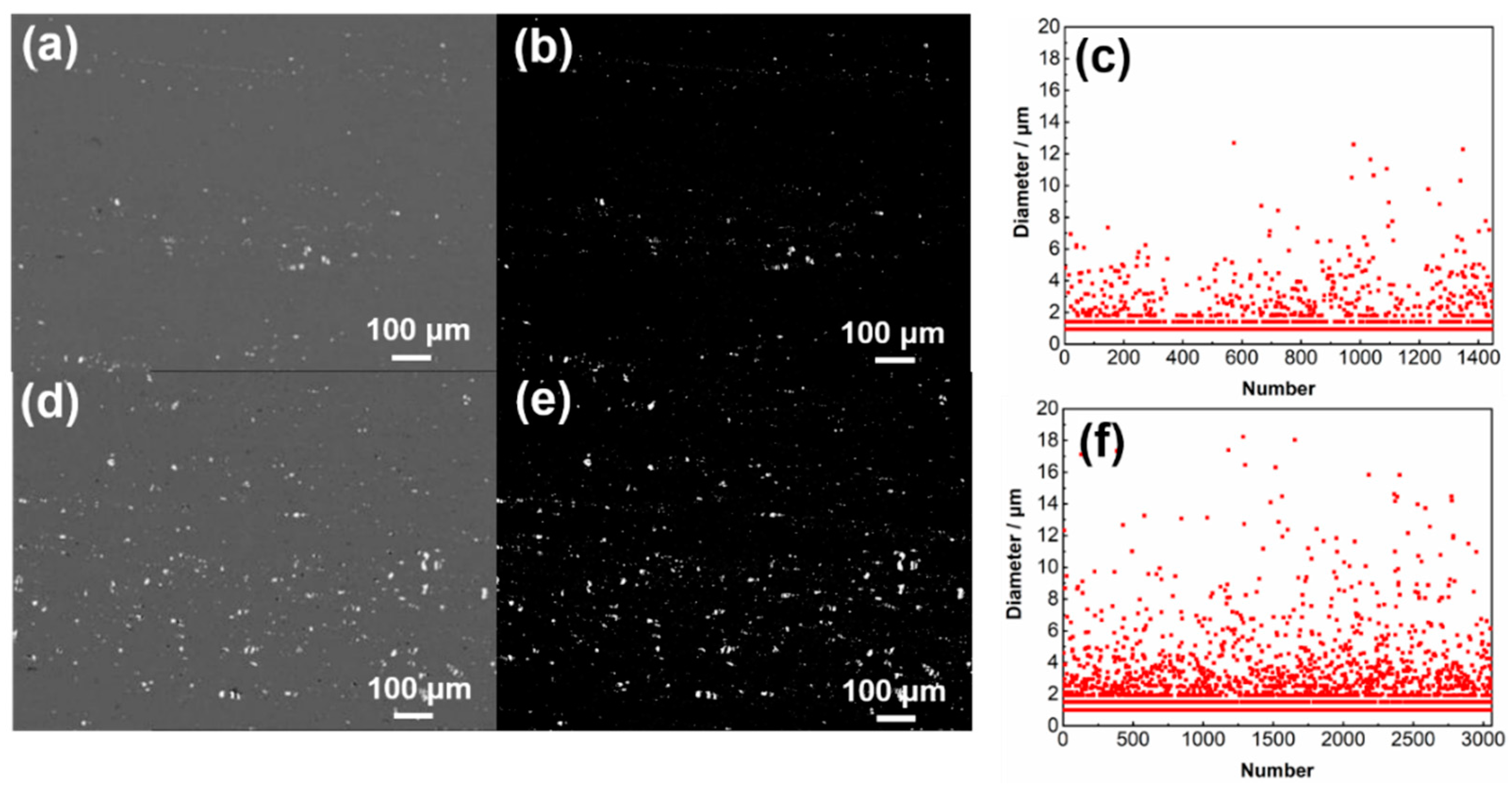

3.1. The Starting Microstructure

3.2. Mechanical Properties

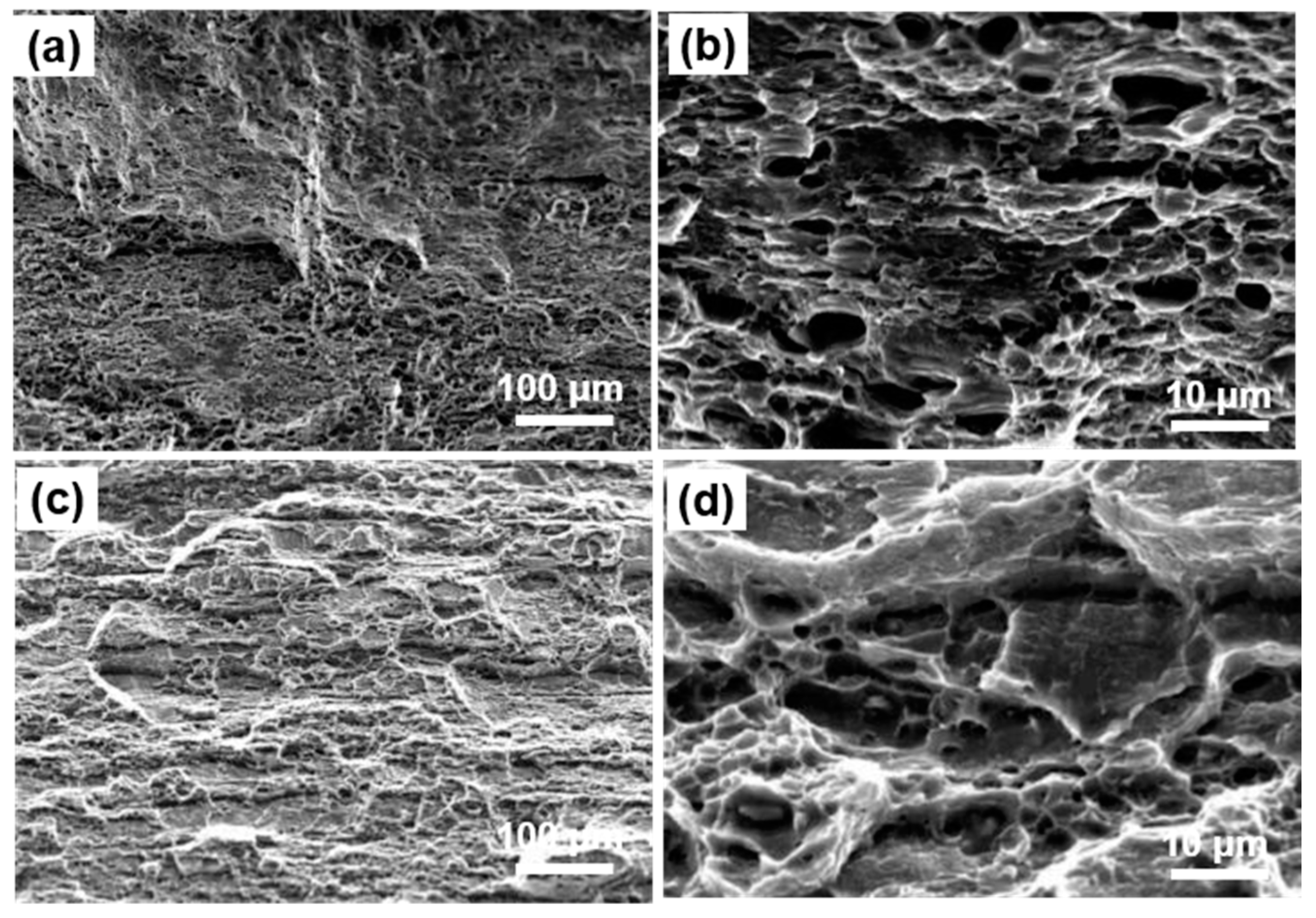

3.3. FCG Tests Fractography

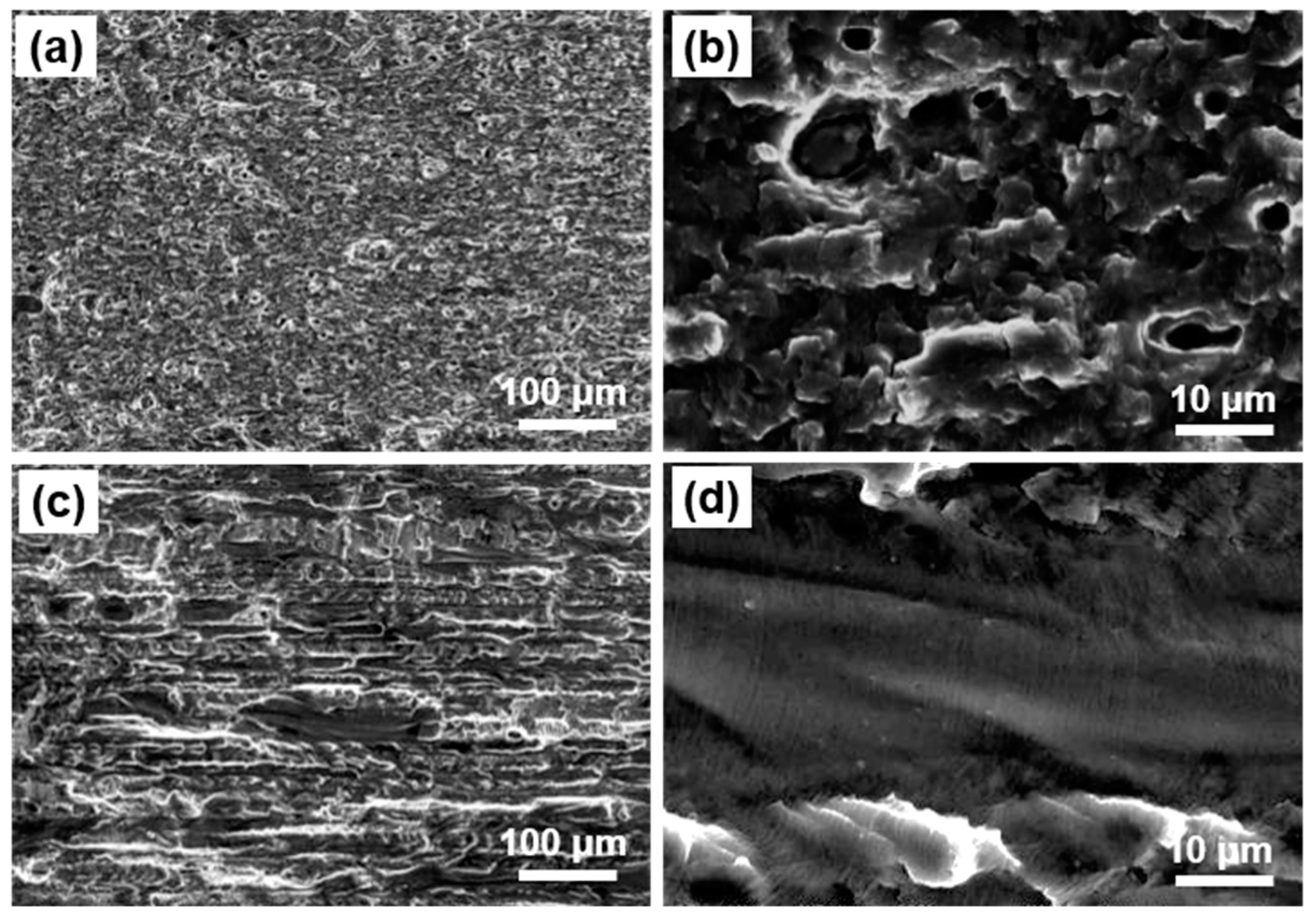

3.3.1. The Near-Threshold Regime (Stage I)

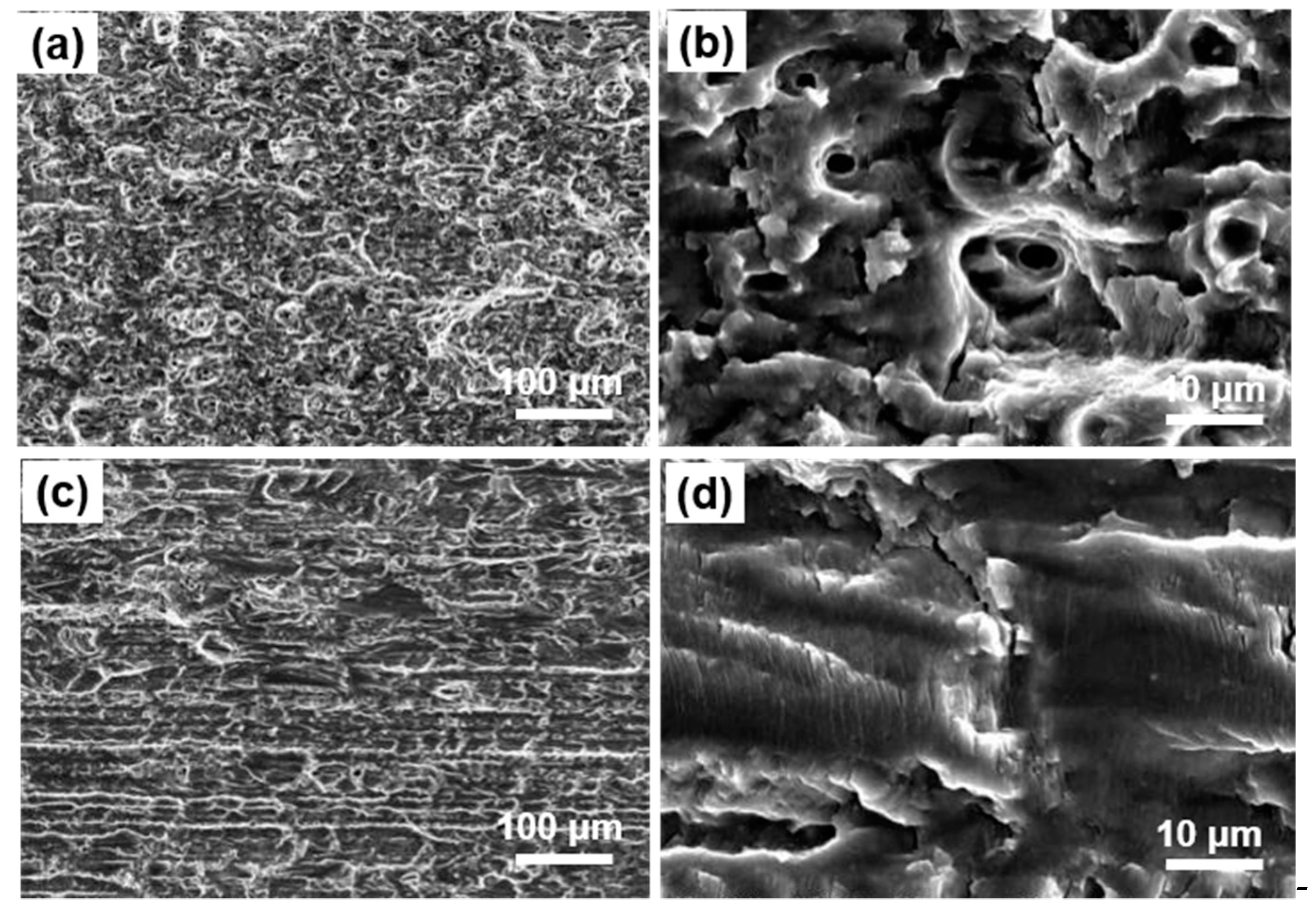

3.3.2. The Intermediate-∆K Region (Stage II)

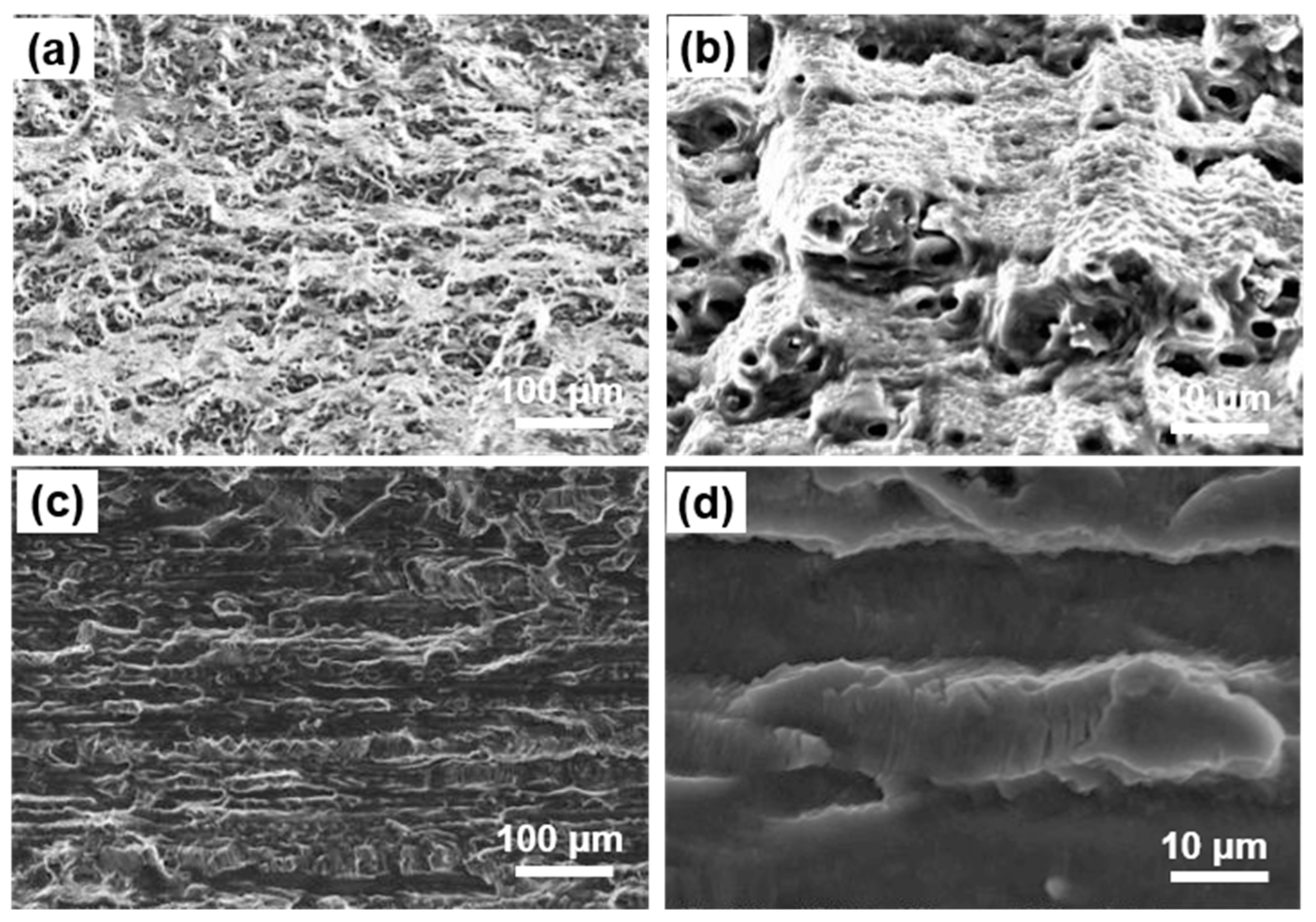

3.3.3. The High-∆K Region (Stage III)

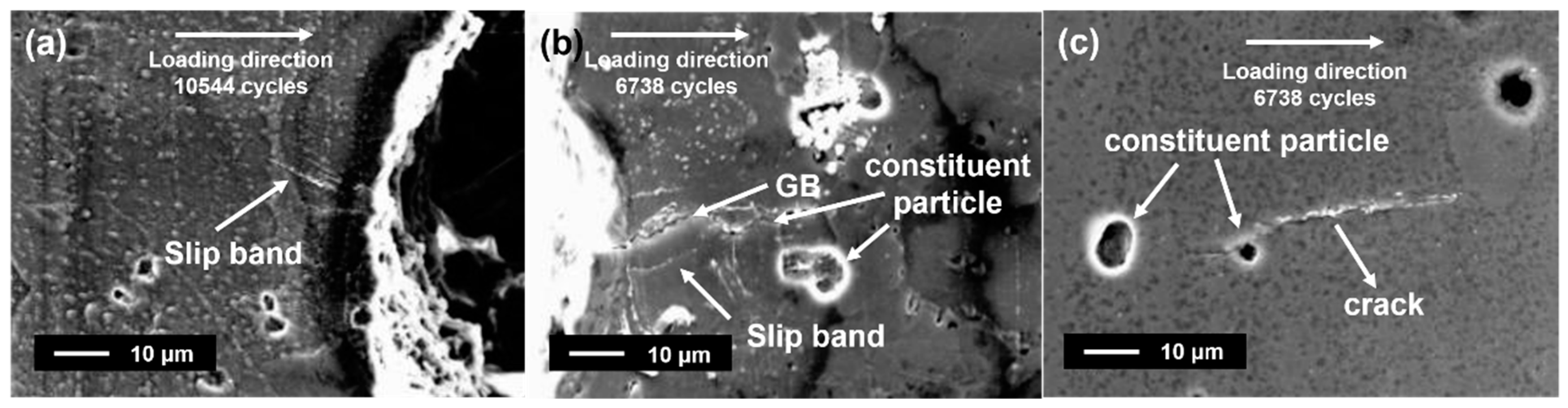

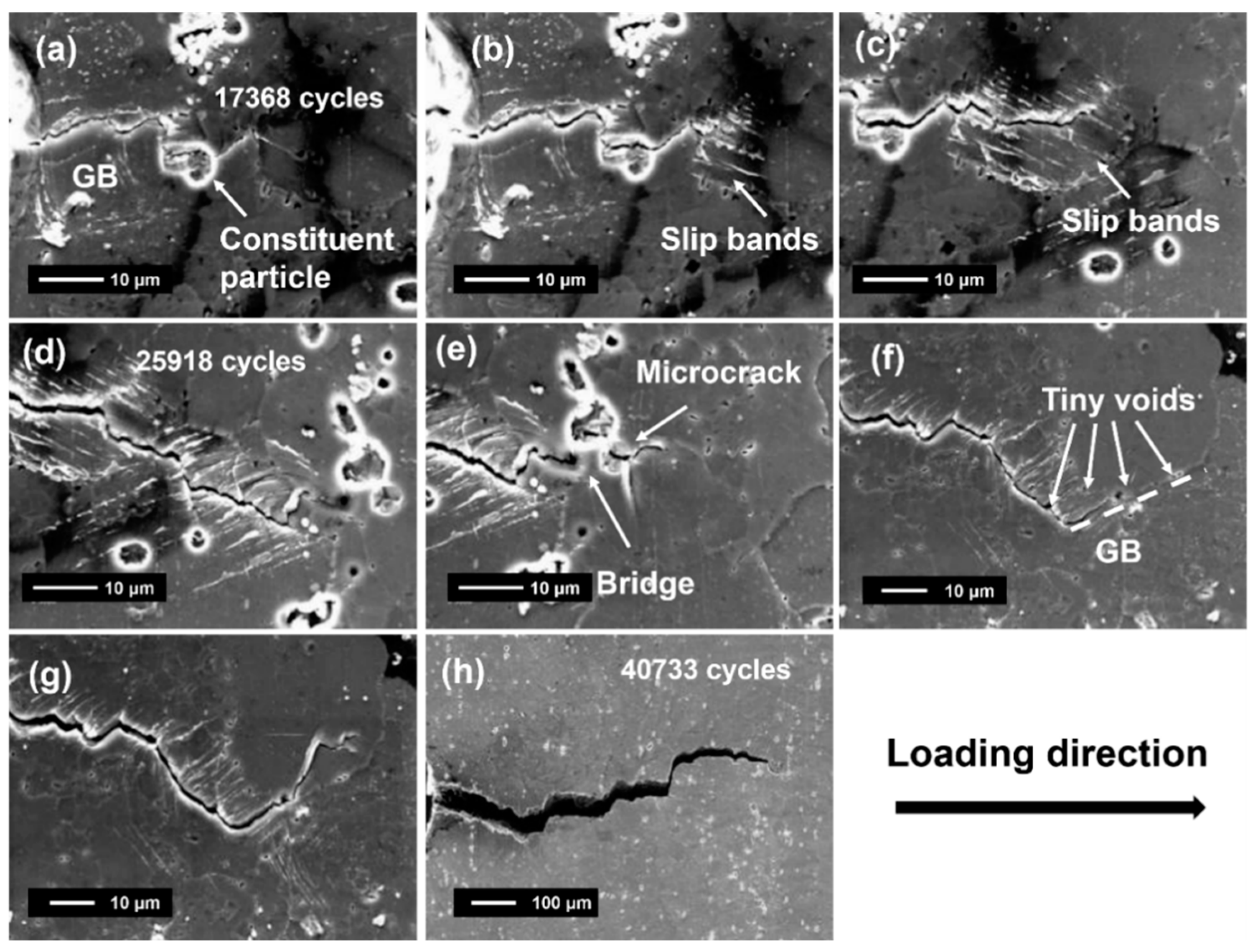

3.4. In-Situ SEM Fatigue

4. Discussion

5. Conclusions

- Compared to the alloy with a high Fe content level, the alloy with a low Fe content level exhibits a higher ultimate tensile strength, tensile yield strength, and elongation. Especially when ∆K is 33 MPa⋅m1/2, the FCG rate decreases by 20%. Moreover, the alloy with a low Fe content level (2A97-T3) exhibited a lower density, accompanying equivalent tensile strength and FCG rate compared to damage-tolerant 2524-T3 alloy.

- The coarse Fe constituent particles accelerate the initiation and propagation of fatigue crack of the Al-3.8 Cu-1.5 Li-0.4 Mg-0.11 Zr alloys. The fatigue crack growth of both alloys is dominated by transgranular expansion, accompanied by intergranular expansion. The alloy with a high level of Fe content alloy presents more characteristics of intergranular expansion.

- It is postulated here that the micro-cracks formed around the coarse Fe-containing particles are merged with the primary crack to produce a bridging effect, accelerating the growth of fatigue crack in the alloy with a high level of Fe content.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gayle, F.W.; Heubaum, F.H.; Pickens, J.R. Structure and properties during aging of an ultra-high strength Al-Cu-Li-Ag-Mg alloy. Scr. Metall. Mater. 1990, 24, 79–84. [Google Scholar] [CrossRef]

- Starke, E.A.; Staley, J.T. Application of modern aluminum alloys to aircraft. Prog. Aerosp. Sci. 1996, 32, 131–172. [Google Scholar] [CrossRef]

- Rioja, R.J. Fabrication methods to manufacture isotropic Al-Li alloys and products for space and aerospace applications. Mater. Sci. Eng. A 1998, 257, 100–107. [Google Scholar] [CrossRef]

- Araullo-Peters, V.; Gault, B.; Geuser, F.D.; Deschamps, A.; Cairney, J.M. Microstructural evolution during ageing of Al–Cu–Li–x alloys. Acta Mater. 2014, 66, 199–208. [Google Scholar] [CrossRef]

- Dong, Y.H.; He, X.F.; Sun, X.N.; Li, Y.H. Fatigue crack growth of a corner crack at the edge of a hole. Int. J. Fatigue 2020, 139, 105699. [Google Scholar] [CrossRef]

- Rocha, M.M.; Schuëller, G.I. A probabilistic criterion for evaluating the goodness of fatigue crack growth models. Eng. Fract. Mech. 1996, 53, 707–731. [Google Scholar] [CrossRef]

- Lados, D.A. Chapter 17—Design for fatigue crack growth resistance in aluminum alloys. In Fundamentals of Aluminium Metallurgy, 1st ed.; Lumley, R., Ed.; Woodhead Publishing: Cambridge, UK, 2011; pp. 504–537. [Google Scholar]

- Wanhill, R.J.H.; Bray, G.H. Chapter 12—Fatigue Crack Growth Behavior of Aluminum–Lithium Alloys. In Aluminum-Lithium Alloys Processing, Properties, and Applications, 1st ed.; Prasad, N.E., Gokhale, A., Wanhil, R.J.H., Eds.; Butterworth-Heinemann: Oxford, UK, 2014; pp. 381–413. [Google Scholar]

- Shou, W.B.; Yi, D.Q.; Liu, H.Q.; Tang, C.; Shen, F.H.; Wang, B. Effect of grain size on fatigue-crack growth in 2524 aluminium alloy. Int. J. Fatigue 2016, 84, 9–16. [Google Scholar]

- Rioja, R.J.; Liu, J. The evolution of Al-Li base products for aerospace and space applications. Metall. Mater. Trans. A 2012, 43A, 3325–3337. [Google Scholar] [CrossRef]

- Li, F.D.; Liu, Z.Y.; Wu, W.T.; Xia, P.; Ying, P.Y.; Zhao, Q.; Li, J.L.; Bai, S. On the role of texture in governing fatigue crack propagation behavior of 2524 aluminum alloy. Mater. Sci. Eng. A 2016, 669, 367–378. [Google Scholar] [CrossRef]

- Zhang, Z.F.; Wang, Z.G. Dependence of intergranular fatigue cracking on the interactions of persistent slip bands with grain boundaries. Acta Mater. 2003, 51, 347–364. [Google Scholar] [CrossRef]

- Estrin, Y.; Vinogradov, A. Fatigue behaviour of light alloys with ultrafine grain structure produced by severe plastic deformation: An overview. Int. J. Fatigue 2010, 32, 898–907. [Google Scholar] [CrossRef]

- Cauthen, C.; Anderson, K.V.; Avery, D.Z.; Baker, A.; Williamson, C.J.; Daniewicz, S.R.; Jordon, J.B. Fatigue Crack Nucleation and Microstructurally Small Crack Growth Mechanisms in High Strength Aluminum Alloys. Int. J. Fatigue 2020, 140, 105790. [Google Scholar] [CrossRef]

- Harlow, D.G.; Nardiello, J.; Payne, J. The effect of constituent particles in aluminum alloys on fatigue damage evolution: Statistical observations. Int. J. Fatigue 2010, 21, 505–511. [Google Scholar] [CrossRef]

- Soni, K.K.; Williams, D.B.; Chabala, J.M.; Levi-Setti, R.; Newbury, D.E. Electron and ion microscopy studies of Fe-rich second-phase particles in Al-Li alloys. Acta Metall. Mater. 1992, 40, 663–671. [Google Scholar] [CrossRef]

- Tiryakioglu, M.; Staley, J.T. Physical Metallurgy and Processes. In Handbook of Aluminum; Totten, G.E., Mackenzie, D.S., Eds.; Marcel Dekker: New York, NY, USA, 2003; Volume 1, p. 123. [Google Scholar]

- Lin, F.S. Effect of intermetallic particles on the fracture behavior of aluminum alloy 2020. Metallurgical 1983, 16, 361–373. [Google Scholar] [CrossRef]

- Lynch, S.P.; Wanhill, R.J.H.; Byrnes, R.T.; Bray, G.H. Chapter 13: Fracture Toughness and Fracture Modes of Aerospace Aluminum–Lithium Alloys. In Aluminum-Lithium Alloys Processing, Properties, and Applications, 1st ed.; Prasad, N.E., Gokhale, A., Wanhil, R.J.H., Eds.; Butterworth-Heinemann: Oxford, UK, 2014; pp. 415–455. [Google Scholar]

- Buck, O.; Marcus, H.L. Fatigue crack initiation and early propagation in Al 2219-T851. Metall. Trans. A 1976, 1, 1161–1165. [Google Scholar]

- Morris, W.L. The effect of intermetallics composition and microstructure on fatigue crack initiation in A1 2219-T85l. Metall. Trans. A 1978, 9, 1345–1348. [Google Scholar] [CrossRef]

- Nakai, M.; Eto, T. Effect of Constituents and Dispersoids Morphology on Fracture Toughness and Fatigue Crack Propagation in 2024 Aluminum Alloys. Mater. Sci. Forum 1996, 217–222, 1517–1522. [Google Scholar]

- Staley, J.T. Influence of Microstructure on Fatigue and Fracture of Aluminum Alloys. Int. J. Fatigue 2003, 24, 244–246. [Google Scholar]

- Nakai, M.; Eto, T. New aspect of development of high strength aluminum alloys for aerospace applications. Mater. Sci. Eng. A 2000, 285, 62–68. [Google Scholar] [CrossRef]

- Rojas, J.I.; Crespo, D. Onset Frequency of Fatigue Effects in Pure Aluminum and 7075 (AlZnMg) and 2024 (AlCuMg) Alloys. Metals 2016, 6, 50. [Google Scholar] [CrossRef]

- Yan, L.; Fan, J.K. In-situ SEM study of fatigue crack initiation and propagation behavior in 2524 aluminum alloy. Mater. Des. 2016, 110, 592–601. [Google Scholar] [CrossRef]

- Golden, P.J.; Grandt, A.F.; Bray, G.H. A comparison of fatigue crack formation at holes in 2024-T3 and 2524-T3 aluminum alloy specimens. Int. J. Fatigue 1999, 21 (Suppl. 1), S211–S219. [Google Scholar] [CrossRef]

- Bray, G.H.; Glazov, M.; Rioja, R.J.; Li, D.; Gangloff, R.P. Effect of Artificial Aging on the Fatigue Crack Propagation Resistance of 2000 Series Aluminum Alloys. Int. J. Fatigue 2001, 23, 264–276. [Google Scholar] [CrossRef]

- Liu, Y.B.; Liu, Z.Y.; Li, Y.T.; Xia, Q.K.; Zhou, J. Enhanced Fatigue Crack Propagation Resistance of an Al-Cu-Mg Alloy by Artificial Aging. Mater. Sci. Eng. A 2008, 492, 333–336. [Google Scholar]

- Rozumek, D.; Faszynka, S. Surface cracks growth in aluminum alloy AW-2017A-T4 under combined loadings. Eng. Fract. Mech. 2020, 226, 106896. [Google Scholar] [CrossRef]

- Rozumek, D.; Marciniak, Z. Fatigue crack growth in AlCu4Mg1 under nonproportional bending with torsion loading. Mater. Sci. 2011, 46, 685–694. [Google Scholar] [CrossRef]

- Yuan, Z.S.; Lu, Z.; Xie, Y.H.; Dai, S.L.; Liu, C.S. Effects of RRA Treatments on Microstructures and Properties of a New High-strength Aluminum-Lithium Alloy-2A97. Trans. Nonferrous Met. Soc. China 2007, 20, 87–192. [Google Scholar] [CrossRef]

- Zhang, X.F.; Li, G.A.; Lu, Z.; Yu, J.; Hao, M. Effect of preaged stretch after quenched on the properties and microstructure of a naturallyaged Al-Li alloy. Acta Metall. Sin. 2016, 52, 1497–1502. [Google Scholar]

- Lin, Y.; Zheng, Z.Q.; Zhang, H.F.; Han, Y. Effect of heat treatment process on tensile properties of 2A97 Al-Li alloy: Experiment and B.P. neural network simulation. Trans. Nonferrous Met. Soc. China 2013, 23, 1728–1736. [Google Scholar] [CrossRef]

- Chen, H.Y.; Fu, L.; Liang, P. Microstructure, texture and mechanical properties of friction stir welded butt joints of 2A97 Al-Li alloy ultra-thin sheets. J. Alloys Comp. 2017, 692, 155–169. [Google Scholar] [CrossRef]

- Yu, W.C.; Li, H.Y.; Du, R.; You, W.; Zhao, M.C.; Wang, Z.A. Characteristic constitution model and microstructure of an Al-3.5Cu-1.5Li alloy subjected to thermal deformation. Mater. Charact. 2018, 145, 53–64. [Google Scholar] [CrossRef]

- Zhang, X.X.; Zhou, X.R.; Teruo, H.; Liu, B.; Chen, L.; Sun, Z.H.; Tang, Z.H.; Lu, F.; Ma, Y.L. Corrosion behaviour of 2A97-T6 Al-Cu-Li alloy: The influence of non-uniform precipitation. Corros. Sci. 2018, 132, 1–8. [Google Scholar] [CrossRef]

- Zhong, J.; Zhong, S.; Zheng, Z.Q.; Zhang, H.F.; Luo, X.F. Fatigue crack initiation and early propagation behavior of 2A97 Al–Li alloy. Trans. Nonferrous Met. Soc. China 2014, 24, 303–309. [Google Scholar] [CrossRef]

- ASTM E8. Standard test methods for tension testing of metallic materials. In Annual Book of ASTM Standards; ASTM E8; ASTM: West Conshohocken, PA, USA, 2001. [Google Scholar]

- ASTM. Standard test method for measurement of fatigue crack growth rates. In Annual Book of ASTM Standards; ASTM E647; ASTM: West Conshohocken, PA, USA, 2001. [Google Scholar]

- Chapter 3 Aluminum. In Materials Properties Development and Standardization (MMPDS-11); Battelle Memorial Institute: Columbus, OH, USA, 2016; pp. C3-348–C3-350.

| Alloy | Fe | Si | Cu | Li | Mg | Zr | Al |

|---|---|---|---|---|---|---|---|

| Low Fe alloy | 0.07 | 0.05 | 3.78 | 1.47 | 0.46 | 0.11 | Balance |

| High Fe alloy | 0.20 | 0.04 | 3.78 | 1.47 | 0.39 | 0.11 | Balance |

| Alloy | Low Fe Alloy (2A97-T3) | High Fe Alloy | 2524-T3 [27] |

|---|---|---|---|

| Thickness (mm) | 1.5 | 1.5 | 0.81–1.59 |

| UTS (MPa) | 320 | 310 | 303 |

| TYS (MPa) | 426 | 405 | 420 |

| Elongation (%) | 18.4 | 13.6 | 19.0 |

| da/dN (mm/cycle) ∆K = 33 MPa⋅m1/2 | 1.8 × 10–3 | 1.4 × 10−2 | 2.3 × 10−3 |

| Density (g/cm3) | 2.67 | 2.67 | 2.77 [41] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hao, M.; Wang, L.; Chen, J.-Z.; Wang, R.; Li, G.-A. Intrinsic Fatigue Crack Growth in Al-Cu-Li-Mg-Zr Alloys: The Effect of the Iron Constituent Particles. Metals 2021, 11, 110. https://doi.org/10.3390/met11010110

Hao M, Wang L, Chen J-Z, Wang R, Li G-A. Intrinsic Fatigue Crack Growth in Al-Cu-Li-Mg-Zr Alloys: The Effect of the Iron Constituent Particles. Metals. 2021; 11(1):110. https://doi.org/10.3390/met11010110

Chicago/Turabian StyleHao, Min, Liang Wang, Jun-Zhou Chen, Ren Wang, and Guo-Ai Li. 2021. "Intrinsic Fatigue Crack Growth in Al-Cu-Li-Mg-Zr Alloys: The Effect of the Iron Constituent Particles" Metals 11, no. 1: 110. https://doi.org/10.3390/met11010110

APA StyleHao, M., Wang, L., Chen, J.-Z., Wang, R., & Li, G.-A. (2021). Intrinsic Fatigue Crack Growth in Al-Cu-Li-Mg-Zr Alloys: The Effect of the Iron Constituent Particles. Metals, 11(1), 110. https://doi.org/10.3390/met11010110