Effect of Processing Parameters on Interphase Precipitation and Mechanical Properties in Novel CrVNb Microalloyed Steel

Abstract

1. Introduction

| Steel Composition, wt.% | Processing | σppt, MPa | Method of Calculation | Reference |

|---|---|---|---|---|

| 0.1C-0.1Ti-0.6Cr | Reheat at 1050 °C, cooling at 20 °C/s, holding at 650 °C for 2 min | 160 | Based on the experiment compared to steel without Ti | [17] |

| 0.06C-0.1Ti-0.5Cr | 0.5 strain at 880 °C, cooling at 30 °C/s, holding at 760–640 °C for 5 min | 220–320 | Dislocation looping | [37] |

| 0.06C-0.1Ti-0.2Mo | Heating to 1200 °C, cooling at 15 °C/s, holding at 720–630 °C for 30 min | 230–400 | Dislocation looping | [24] |

| 0.04C-0.09Ti-0.2Mo | Finish rolling at 900 °C, cooling at 10 °C/s, holding at 620 for 60 min | 300 | Subtraction of other strengthening mechanisms from experimental yield strength value | [2] |

| 0.1C-0.2Ti | Heating to 1200 °C, cooling at 10 °C/s, holding at 630 °C for 90 min | 240 | Dislocation looping | [38] |

| 0.1C-0.2Ti-0.5Mo | 260 | |||

| 0.1C-0.2V | 130 | |||

| 0.1C-0.2V-0.5Mo | 240 | |||

| 0.1C-0.2Ti-0.6Cr | Reheat at 1050 °C, cooling at 20° C/s, holding at 650 °C for 8 s | 326 | Dislocation looping | [18] |

| 0.1C-0.2Ti-0.1Al | 300 | |||

| 0.1C-0.04Nb-0.11Ti | Finish rolling at 900 °C, cooling at 10 °C/s, coiling at 650 °C | 112 | Dislocation looping | [16] |

| 0.44C-0.3V | Reheating at 1200 °C, holding at 650 °C for 2 min | 180 | Based on the experiment compared to steel without V | [23] |

| 0.44C-0.5V | 320 | |||

| 0.07C-0.086Nb-0.047Ti | From room temperature reheating to 650 °C, holding for 60 min | 234 | Subtraction of other strengthening mechanisms from experimental yield strength value | [43] |

| 0.023C-0.34Nb | Finish forged at 910 °C, cooled at 0.13 °C/s to room temperature | 210 | Dislocation looping | [13] |

| 0.08C-0.035Nb-0.085Ti-0.11Mo | Finish rolling at 835 °C, cooling at 2 °C/s to 600 °C, no holding | 320 | Dislocation looping | [32] |

| 0.08C-0.047Nb-0.079Ti | 170 | |||

| ~(0.08 ± 0.003)C-1.5Mn-0.3Si-0.2Ni-(0.0131 ± 0.0002)N-0.68 (Cr + Mo + V + Nb) | Total strain 1.35, coiling at 600 °C, 15 min holding | 401 | Dislocation cutting | [7] |

2. Materials and Methods

3. Results

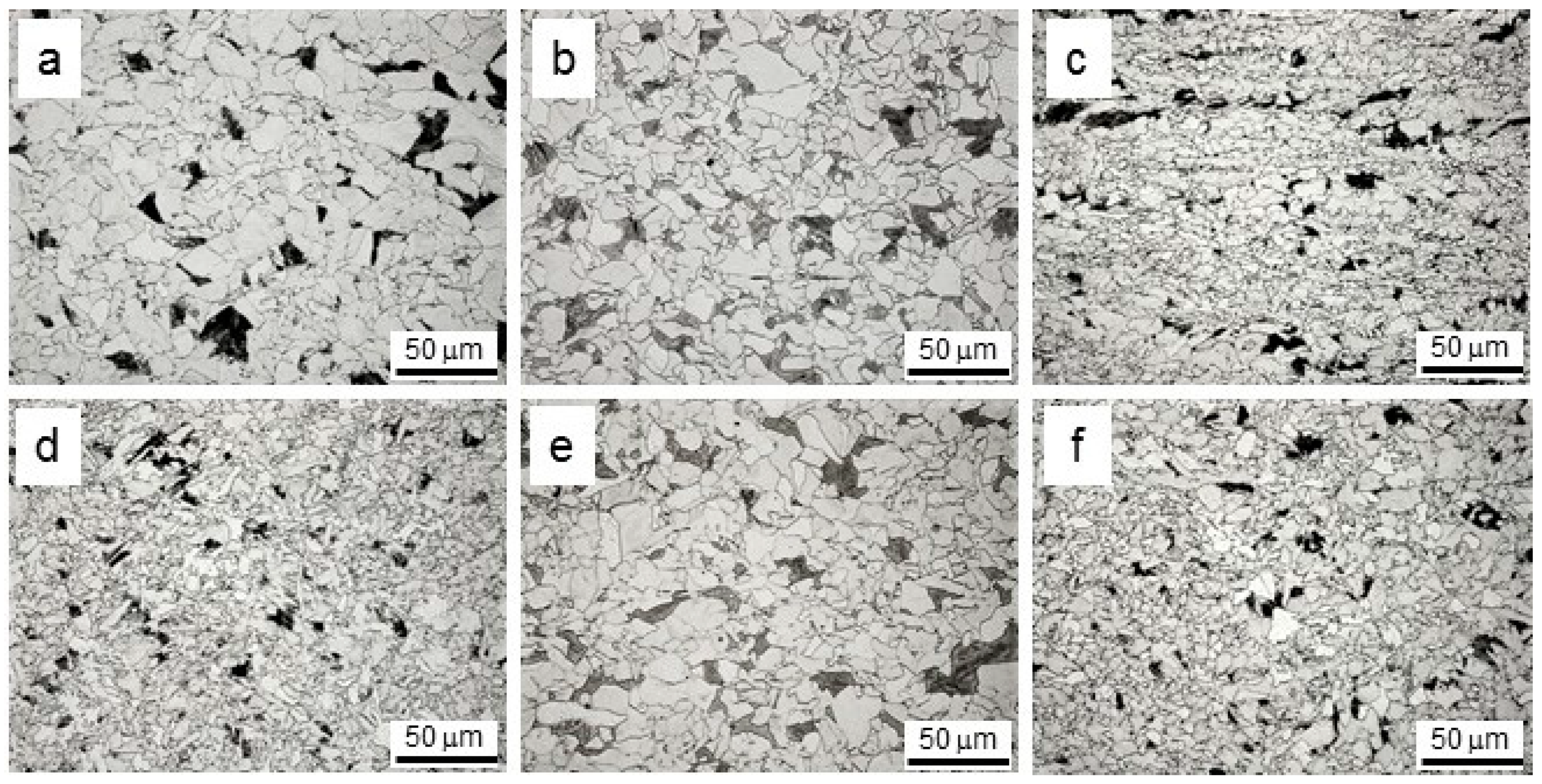

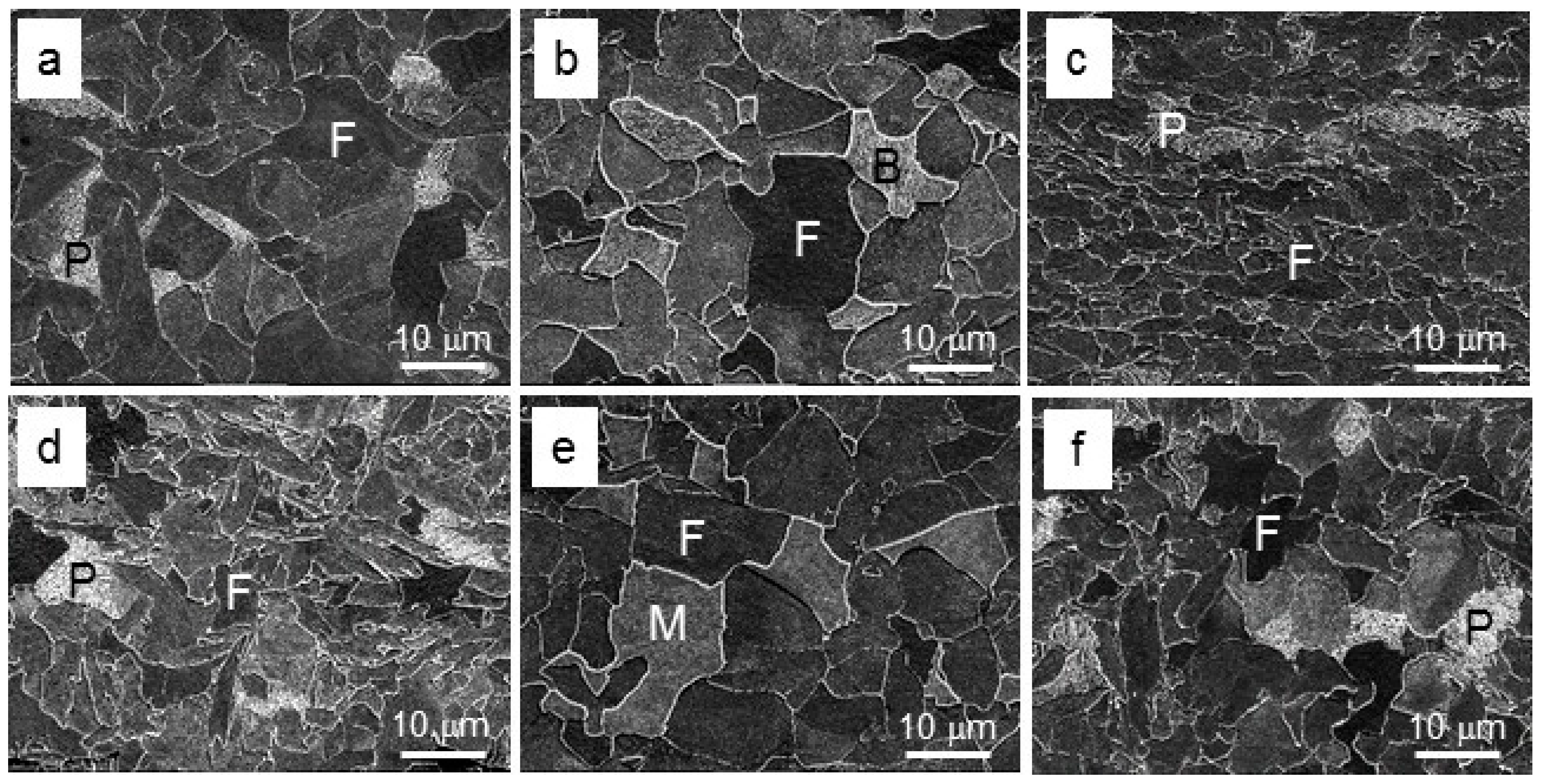

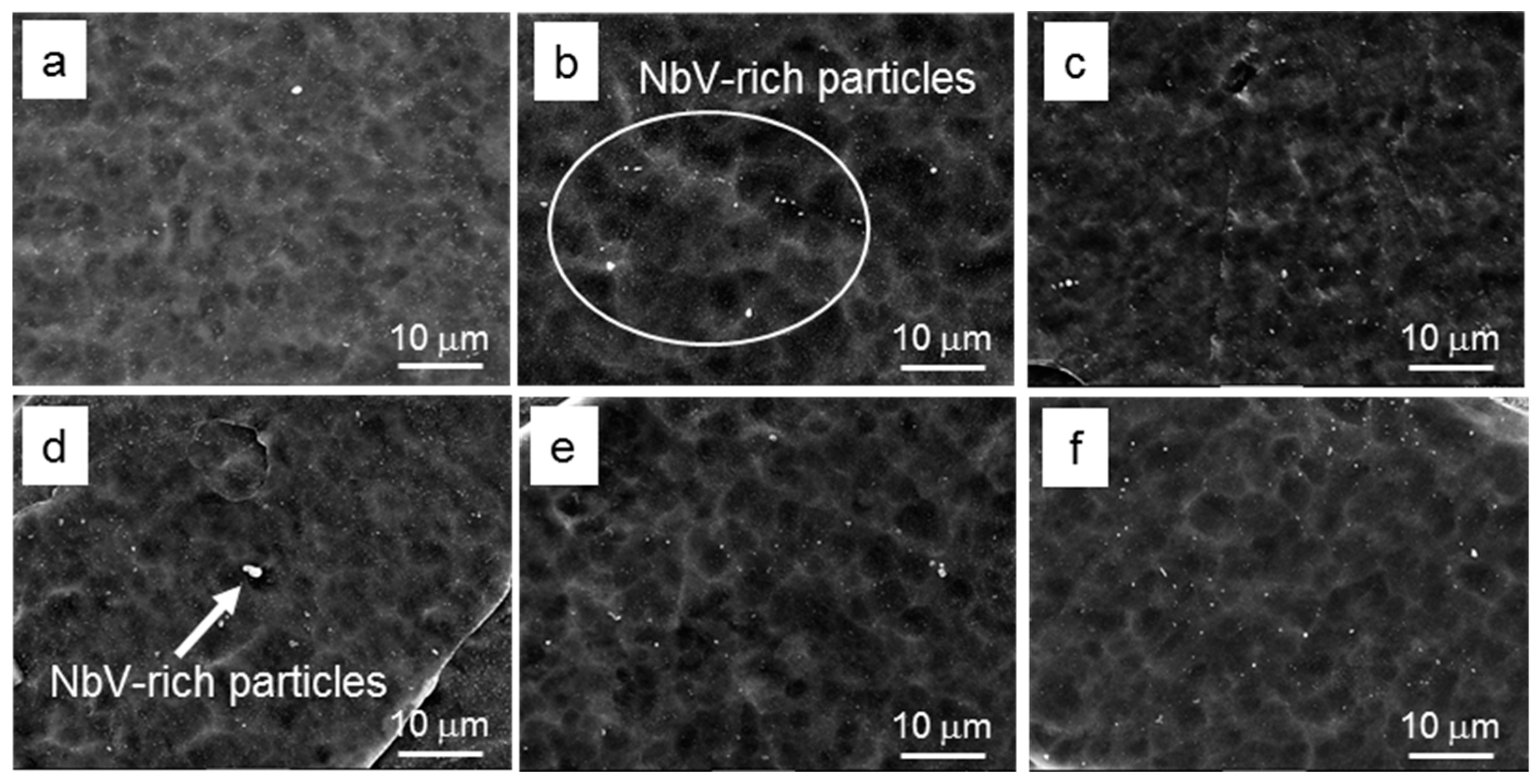

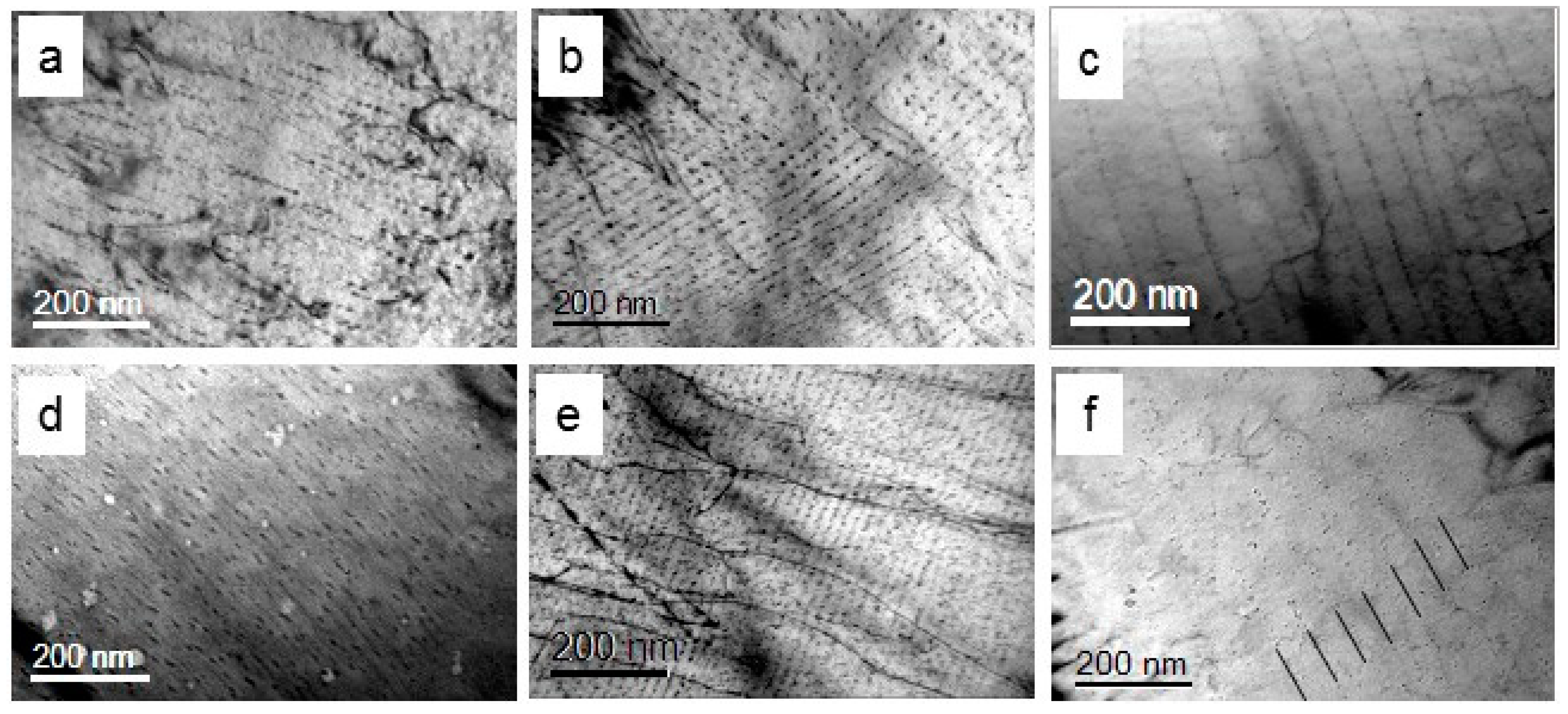

3.1. Effect of Processing on Microstructure

3.2. Effect of Processing on Mechanical Properties

4. Discussion

4.1. Coiling Temperature

4.2. Finish Deformation Temperature

- intersheet spacing after LFT (55 nm) was twice that after HFT (28 nm) for the same coiling temperature of 600 °C;

- particle size was 1.7–2.2 times (depending on coiling time) smaller after LFT;

- growth of these particles during 30 min holding time was slower after LFT (from 3 to 5 nm) than that after HFT (from 5 to 11 nm).

4.3. Holding Time

4.4. Mechanical Properties

5. Conclusions

- Lower finish deformation temperature resulted in finer ferrite microstructure with a higher number density of >20 nm strain-induced precipitates, compared to the higher finish deformation temperature.

- Interphase precipitation occurred under all processing conditions but with various characteristics. For the same coiling temperature, the intersheet spacing decreased when the deformation was finished at a higher temperature. This was associated with more solute present (lower volume fraction of >20 nm particles) in austenite at the start of austenite to ferrite transformation.

- Reduction in simulated coiling temperature led to unexpected increase in intersheet and interparticle spacing, which requires further investigation.

- The increase in volume fraction of interphase precipitates due to their growth during extended holding time to 30 min at simulated coiling temperatures was responsible for the observed strength increment of up to 75 MPa.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Batte, A.D.; Honeycombe, R.W.K. Strengthening of ferrite by vanadium carbide precipitation. Met. Sci. J. 1973, 7, 160–168. [Google Scholar] [CrossRef]

- Funakawa, Y.; Shiozaki, T.; Tomita, K.; Yamamoto, T.; Maeda, E. Development of High Strength Hot-rolled Sheet Steel Consisting of Ferrite and Nanometer-sized Carbides. ISIJ Int. 2004, 44, 1945–1951. [Google Scholar] [CrossRef]

- Baker, T.N. Microalloyed steels. Ironmak. Steelmak. 2016, 43, 264–307. [Google Scholar] [CrossRef]

- Baker, T.N. Processes, microstructure and properties of vanadium microalloyed steels. Mater. Sci. Technol. 2009, 25, 1083–1107. [Google Scholar] [CrossRef]

- Funakawa, Y.; Fujita, T.; Yamada, K. Metallurgical Features of Nanohiten™ and Application to Warm Stamping; JFE: Tokyo, Japan, 2013; pp. 74–79. [Google Scholar]

- Kamikawa, N.; Abe, Y.; Miyamoto, G.; Funakawa, Y.; Furuhara, T. Tensile Behavior of Ti, Mo-added Low Carbon Steels with Interphase Precipitation. ISIJ Int. 2014, 54, 212–221. [Google Scholar] [CrossRef]

- Singh, N.; Casillas, G.; Wexler, D.; Killmore, C.; Pereloma, E. Application of advanced experimental techniques to elucidate the strengthening mechanisms operating in microalloyed ferritic steels with interphase precipitation. Acta Mater. 2020, 201, 386–402. [Google Scholar] [CrossRef]

- Davenport, A.T.; Berry, F.G.; Honeycombe, R.W.K. Interphase Precipitation in Iron Alloys. Met. Sci. J. 1968, 2, 104–106. [Google Scholar] [CrossRef]

- Davenport, A.T.; Honeycombe, R.W.K. Precipitation of Carbides at γ-α Boundaries in Alloy Steels. Proc. R. Soc. A Math. Phys. Eng. Sci. 1971, 322, 191–205. [Google Scholar]

- Barbacki, A.; Honeycombe, R.W.K. Transitions in carbide morphology in molybdenum and vanadium steels. Metallography 1976, 9, 277–291. [Google Scholar] [CrossRef]

- Ricks, R.; Howell, P. The formation of discrete precipitate dispersions on mobile interphase boundaries in iron-base alloys. Acta Metall. 1983, 31, 853–861. [Google Scholar]

- Deardo, A.J. Niobium in modern steels. Int. Mater. Rev. 2003, 48, 371–402. [Google Scholar] [CrossRef]

- Kestenbach, H.J. Dispersion hardening by niobium carbonitride precipitation in ferrite. Mater. Sci. Technol. 1997, 13, 731–739. [Google Scholar] [CrossRef]

- Kestenbach, H.J.; Gallego, J. On dispersion hardening of microalloyed hot strip steels by carbonitride precipitation in austenite. Scr. Mater. 2001, 44, 791–796. [Google Scholar] [CrossRef]

- Morrison, W.B.; Woodhead, J.H. Influence of small niobium additions on mechanical properties of commercial mild steels. J. Iron Steel Inst. 1963, 201, 317–325. [Google Scholar]

- Kestenbach, H.J.; Campos, S.S.; Morales, E.V. Role of interphase precipitation in microalloyed hot strip steels. Mater. Sci. Technol. 2006, 22, 615–626. [Google Scholar] [CrossRef]

- Tsai, S.-P.; Jen, C.-H.; Yen, H.-W.; Chen, C.-Y.; Tsai, M.-C.; Huang, C.-Y.; Wang, Y.-T.; Yang, J.-R. Effects of interphase TiC precipitates on tensile properties and dislocation structures in a dual phase steel. Mater. Charact. 2017, 123, 153–158. [Google Scholar] [CrossRef]

- Tsai, S.-P.; Su, T.-C.; Yang, J.-R.; Chen, C.-Y.; Wang, Y.-T.; Huang, C.-Y. Effect of Cr and Al additions on the development of interphase-precipitated carbides strengthened dual-phase Ti-bearing steels. Mater. Des. 2017, 119, 319–325. [Google Scholar] [CrossRef]

- Balliger, N.K.; Honeycombe, R.W.K. The effect of nitrogen on precipitation and transformation kinetics in vanadium steels. Metall. Trans. A 1980, 11, 421–429. [Google Scholar] [CrossRef]

- Miyamoto, G.; Hori, R.; Poorganji, B.; Furuhara, T. Crystallographic analysis of proeutectoid ferrite/austenite interface and interphase precipitation of vanadium carbide in medium-carbon steel. Metall. Mater. Trans. A 2013, 44, 3436–3443. [Google Scholar] [CrossRef]

- Chen, M.Y.; Gouné, M.; Verdier, M.; Bréchet, Y.; Yang, J.R. Interphase precipitation in vanadium-alloyed steels: Strengthening contribution and morphological variability with austenite to ferrite transformation. Acta Mater. 2014, 64, 78–92. [Google Scholar] [CrossRef]

- Zhang, Y.J.; Miyamoto, G.; Shinbo, K.; Furuhara, T. Quantitative measurements of phase equilibria at migrating α/γ interface and dispersion of VC interphase precipitates: Evaluation of driving force for interphase precipitation. Acta Mater. 2017, 128, 166–175. [Google Scholar] [CrossRef]

- Miyamoto, G.; Hori, R.; Poorganji, B.; Furuhara, T. Interphase precipitation of VC and resultant hardening in V-added medium carbon steels. ISIJ Int. 2011, 51, 1733–1739. [Google Scholar] [CrossRef]

- Yen, H.W.; Chen, P.Y.; Huang, C.Y.; Yang, J.R. Interphase precipitation of nanometer-sized carbides in a titanium–molybdenum-bearing low-carbon steel. Acta Mater. 2011, 59, 6264–6274. [Google Scholar]

- Yen, H.-W.; Huang, C.-Y.; Yang, J.-R. Characterization of interphase-precipitated nanometer-sized carbides in a Ti-Mo-bearing steel. Scr. Mater. 2009, 61, 616–619. [Google Scholar] [CrossRef]

- Mukherjee, S. Nanoscale Precipitation in Advanced High Strength Steels. Ph.D. Thesis, Deakin University, Geelong, Australia, 2012. [Google Scholar]

- Mukherjee, S.; Timokhina, I.B.; Zhu, C.; Ringer, S.P.; Hodgson, P.D. Three-dimensional atom probe microscopy study of interphase precipitation and nanoclusters in thermomechanically treated titanium–molybdenum steels. Acta Mater. 2013, 61, 2521–2530. [Google Scholar]

- Wang, J.; Weyland, M.; Bikmukhametov, I.; Miller, M.K.; Hodgson, P.D.; Timokhina, I. Transformation from cluster to nano-precipitate in microalloyed ferritic steel. Scr. Mater. 2019, 160, 53–57. [Google Scholar] [CrossRef]

- Jang, J.H.; Heo, Y.-U.; Lee, C.-H.; Bhadeshia, H.K.D.H.; Suh, D.-W. Interphase precipitation in Ti-Nb and Ti-Nb-Mo bearing steel. Mater. Sci. Technol. 2013, 29, 309–313. [Google Scholar]

- Jang, J.H.; Lee, C.-H.; Heo, Y.-U.; Suh, D.-W. Stability of (Ti,M)C (M=Nb, V, Mo and W) carbide in steels using first-principles calculations. Acta Mater. 2012, 60, 208–217. [Google Scholar] [CrossRef]

- Dhara, S.; Marceau, R.K.W.; Wood, K.; Dorin, T.; Timokhina, I.B.; Hodgson, P.D. Precipitation and clustering in a Ti-Mo steel investigated using atom probe tomography and small-angle neutron scattering. Mater. Sci. Eng. A 2018, 718, 74–86. [Google Scholar] [CrossRef]

- Bu, F.Z.; Wang, X.M.; Yang, S.W.; Shang, C.J.; Misra, R.D.K. Contribution of interphase precipitation on yield strength in thermomechanically simulated Ti–Nb and Ti–Nb–Mo microalloyed steels. Mater. Sci. Eng. A 2015, 620, 22–29. [Google Scholar] [CrossRef]

- Pereloma, E.; Timokhina, I. Clustering and Precipitation in Ferritic Microalloyed Steels. In Reference Module in Materials Science and Materials Engineering; Elsevier: Amsterdam, The Netherlands, 2020. [Google Scholar] [CrossRef]

- Xiong, Z.; Timokhina, I.; Pereloma, E. Clustering, nano-scale precipitation and strengthening of steels. Prog. Mater. Sci. 2020, 100764, in press. [Google Scholar] [CrossRef]

- Bikmukhametov, I.; Beladi, H.; Wang, J.; Hodgson, P.D.; Timokhina, I. The effect of strain on interphase precipitation characteristics in a Ti-Mo steel. Acta Mater. 2019, 170, 75–86. [Google Scholar] [CrossRef]

- Smith, R.M.; Dunne, D. Structural aspects of alloy carbonitride precipitation in microalloyed steels. Mater. Forum 1988, 11, 166–181. [Google Scholar]

- Li, C.-N.; Li, X.-L.; Yuan, G.; Misra, R.D.K.; Kang, J.; Wang, G.-D. Precipitation behavior and mechanical properties of a hot rolled Ti-bearing dual phase steel. Mater. Sci. Eng. A 2016, 673, 213–221. [Google Scholar] [CrossRef]

- Gong, P.; Liu, X.G.; Rijkenberg, A.; Rainforth, W.M. The effect of molybdenum on interphase precipitation and microstructures in microalloyed steels containing titanium and vanadium. Acta Mater. 2018, 161, 374–387. [Google Scholar] [CrossRef]

- Okamoto, R.; Borgenstam, A.; Ågren, J. Interphase precipitation in niobium-microalloyed steels. Acta Mater. 2010, 58, 4783–4790. [Google Scholar]

- Iza-Mendia, A.; Altuna, M.A.; Pereda, B.; Gutiérrez, I. Precipitation of Nb in Ferrite After Austenite Conditioning. Part I: Microstructural Characterization. Metall. Mater. Trans. A 2012, 43, 4553–4570. [Google Scholar] [CrossRef]

- Chen, C.Y.; Chen, C.C.; Yang, J.R. Microstructure characterization of nanometer carbides heterogeneous precipitation in Ti-Nb and Ti-Nb-Mo steel. Mater. Charact. 2014, 88, 69–79. [Google Scholar]

- Mukherjee, S.; Timokhina, I.; Zhu, C.; Ringer, S.P.; Hodgson, P.D. Clustering and precipitation processes in a ferritic titanium-molybdenum microalloyed steel. J. Alloys Compd. 2017, 690, 621–632. [Google Scholar]

- Charleux, M.; Poole, W.J.; Militzer, M.; Deschamps, A. Precipitation behavior and its effect on strengthening of an HSLA-Nb/Ti steel. Metall. Mater. Trans. A 2001, 32, 1635–1647. [Google Scholar]

- Kostryzhev, A.; Singh, N.; Chen, L.; Killmore, C.; Pereloma, E. Comparative effect of Mo and Cr on microstructure and mechanical properties in NbV-microalloyed bainitic steels. Metals 2018, 8, 134. [Google Scholar] [CrossRef]

- Baker, R.G.; Nutting, J. The tempering of a Cr-Mo-V-W and a Mo-V steel in precipitation processes in steels. Iron Steel Inst. Spec. Rep. 1959, 64, 1–22. [Google Scholar]

- Fors, D.H.R.; Wahnström, G. Theoretical study of interface structure and energetics in semicoherent Fe(001)/MX(001) systems (M=Sc, Ti, V, Cr, Zr, Nb, Hf, Ta; X=C or N). Phys. Rev. B 2010, 82, 195410. [Google Scholar] [CrossRef]

- Morales, E.V.; Gallego, J.; Kestenbach, H.J. On coherent carbonitride precipitation in commercial microalloyed steels. Philos. Mag. Lett. 2003, 83, 79–87. [Google Scholar] [CrossRef]

- Tirumalasetty, G.K.; van Huis, M.A.; Fang, C.M.; Xu, Q.; Tichelaar, F.D.; Hanlon, D.N.; Sietsma, J.; Zandbergen, H.W. Characterization of NbC and (Nb,Ti)N nanoprecipitates in TRIP assisted multiphase steels. Acta Mater. 2011, 59, 7406–7415. [Google Scholar] [CrossRef]

- Pereloma, E.; Cortie, D.; Singh, N.; Casillas, G.; Niessen, F. Uncovering the mechanism of dislocation interaction with nanoscale (<4 nm) interphase precipitates in microalloyed ferritic steels. Mater. Res. Lett. 2020, 8, 341–347. [Google Scholar]

- Zhang, Y.J.; Miyamoto, G.; Shinbo, K.; Furuhara, T.; Ohmura, T.; Suzuki, T.; Tsuzaki, K. Effects of transformation temperature on VC interphase precipitation and resultant hardness in low-carbon steels. Acta Mater. 2015, 84, 375–384. [Google Scholar] [CrossRef]

- Zhang, Y.J.; Miyamoto, G.; Shinbo, K.; Furuhara, T. Weak influence of ferrite growth rate and strong influence of driving force on dispersion of VC interphase precipitation in low carbon steels. Acta Mater. 2020, 186, 533–544. [Google Scholar] [CrossRef]

- Lagneborg, R.; Zajac, S. A model for interphase precipitation in V-microalloyed structural steels. Metall. Mater. Trans. A 2001, 32, 39–50. [Google Scholar] [CrossRef]

- Gleiter, H. Microstructure. In Physical Metallurgy; Cahn, R.W., Haasen, P., Eds.; Elsevier: Amstredam, The Netherlands, 1996; pp. 844–942. [Google Scholar]

- Bikmukhametov, I. Investigation of Clusters and Nano-particles in Thermomechanically Processed Ti-Mo Steel. Ph.D. Thesis, Deakin University, Geelong, Australia, 2019. [Google Scholar]

| Parameters | HFT | LFT | |||||

|---|---|---|---|---|---|---|---|

| 600/15 | 600/30 | 650/15 | 650/30 | 600/15 | 600/30 | ||

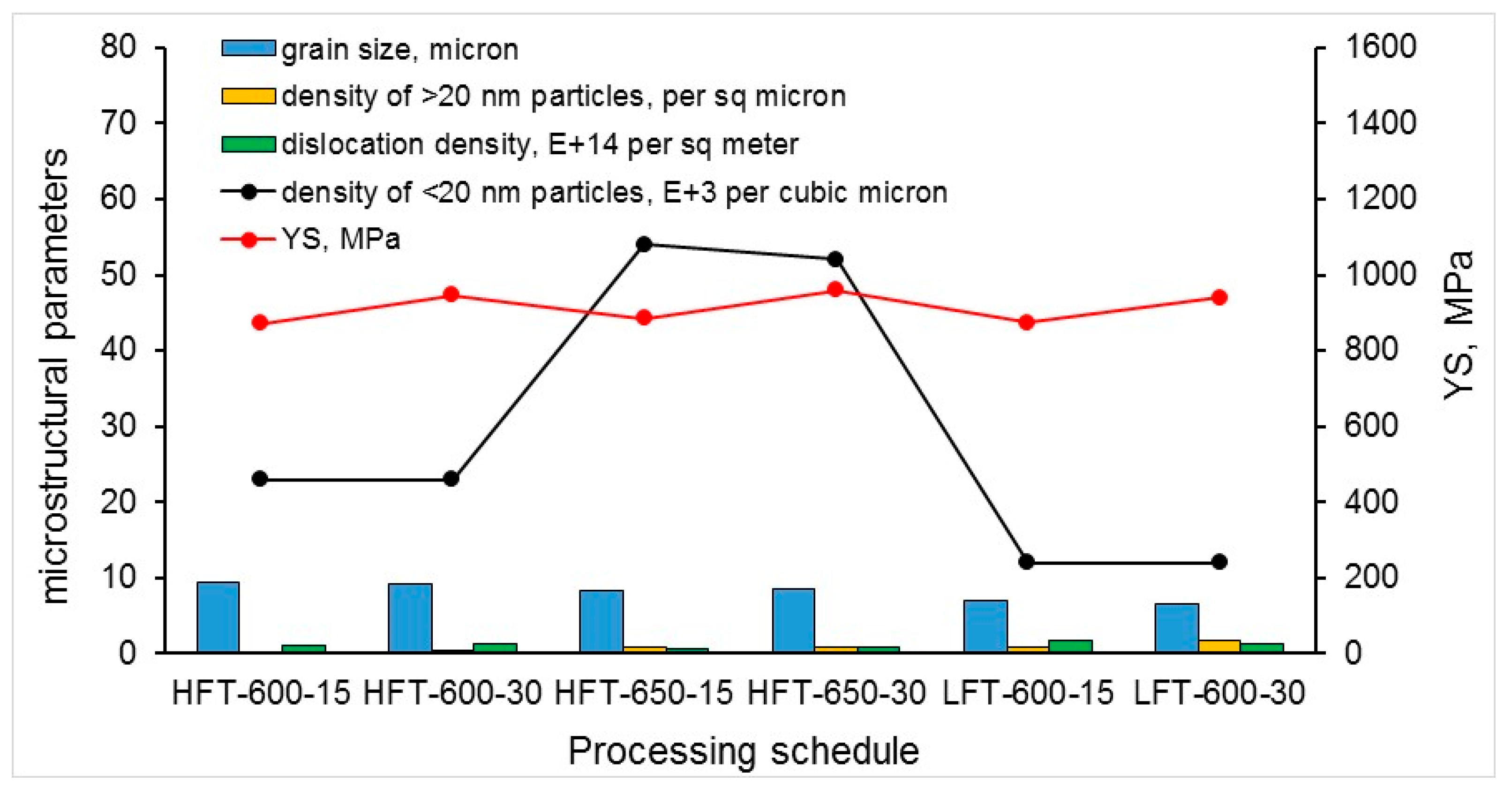

| Average ferrite grain size, μm | 9.5 ± 4.7 | 9.3 ± 4.1 | 8.3 ± 3.9 | 8.5 ± 4.0 | 7.0 ± 3.0 | 6.6 ± 2.9 | |

| Second phase fraction | 0.04 | 0.03 | 0.11 | 0.10 | 0.04 | 0.04 | |

| >20 nm particles (SEM) | Average size, nm | 48 ± 24 | 42 ± 19 | 33 ± 16 | 32 ± 16 | 30 ± 13 | 27 ± 9 |

| Number density, μm−2 | 0.22 | 0.32 | 0.88 | 0.88 | 0.85 | 1.65 | |

| Area fraction | 0.0005 | 0.0005 | 0.0009 | 0.0009 | 0.0007 | 0.0011 | |

| Chemistry | 27% NbV | 50% NbV 20% V | 100% NbV | 50% NbV 50% V | 60% NbV 30% V | 60% NbV 40% V | |

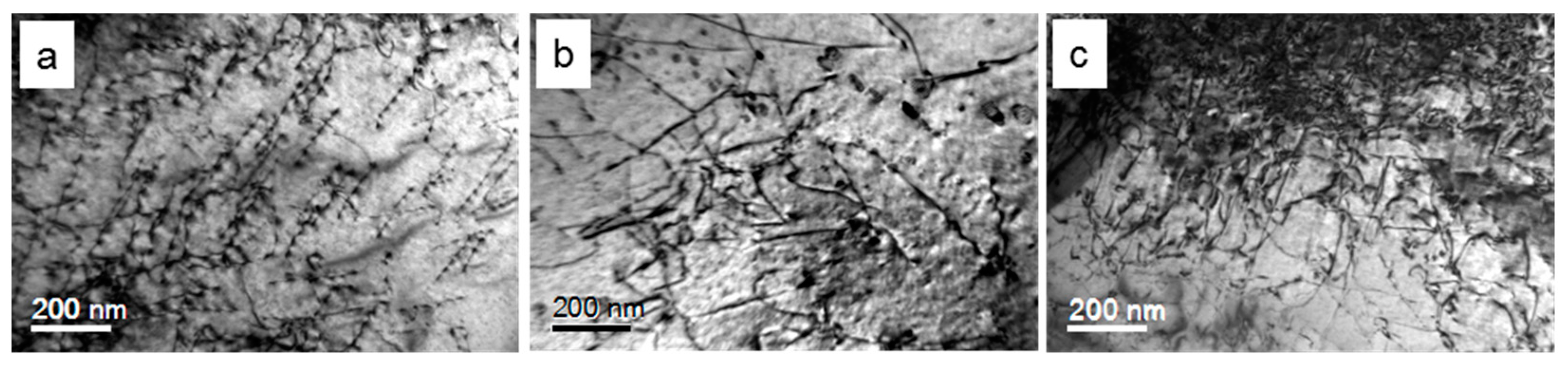

| <20 nm particles (TEM) | Average size, nm | 5 ± 2 | 11 ± 2 | 3 ± 1 | 5 ± 1 | 3 ± 1 | 5 ± 1 |

| Interparticle spacing, nm | 22 ± 5 | 22 ± 7 | 12 ± 2 | 12 ± 4 | 22 ± 4 | 22 ± 5 | |

| Intersheet spacing, nm | 28 ± 9 | 28 ± 7 | 20 ± 5 | 21 ± 2 | 55 ± 11 | 55 ± 15 | |

| Number density, ×103 μm−3 | 23 | 23 | 54 | 52 | 12 | 12 | |

| Volume fraction | 0.0015 | 0.0161 | 0.0008 | 0.0034 | 0.0002 | 0.0008 | |

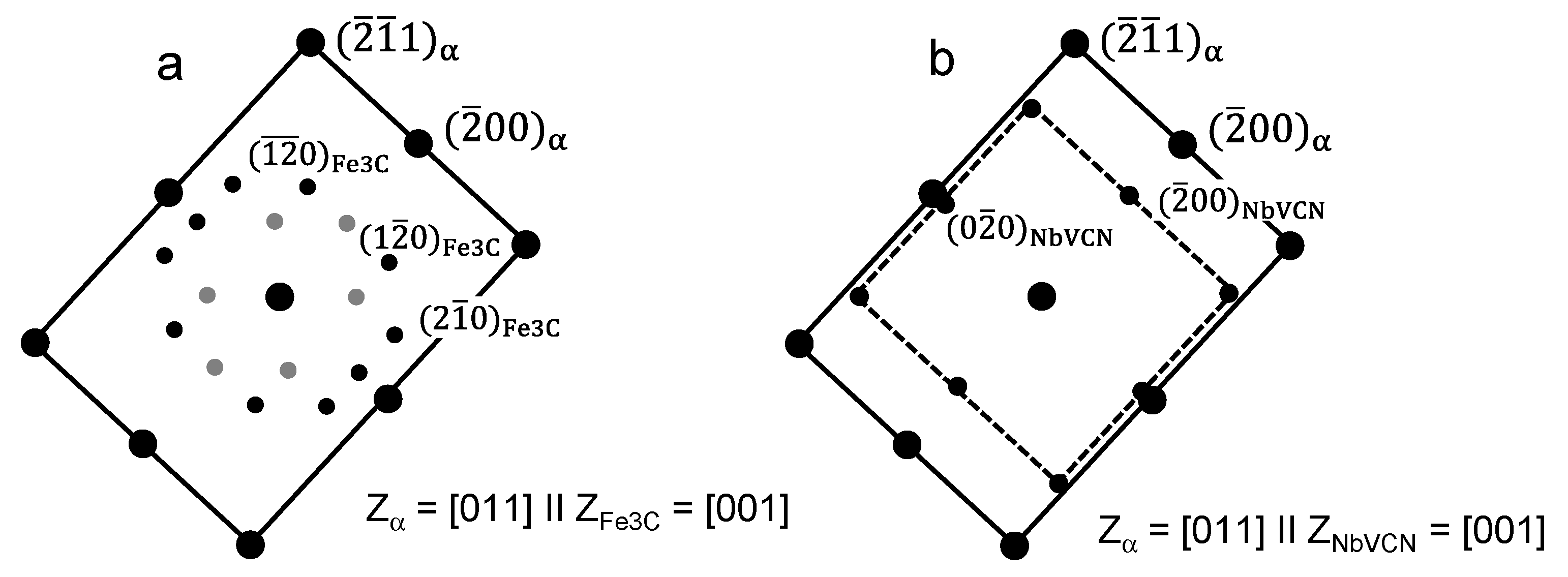

| Chemistry | (VCrNb)C | ||||||

| Dislocation density, ×1014 m−2 | 1.1 ± 0.2 | 1.2 ± 0.1 | 0.7 ± 0.1 | 0.8 ± 0.1 | 1.8 ± 0.2 | 1.2 ± 0.1 | |

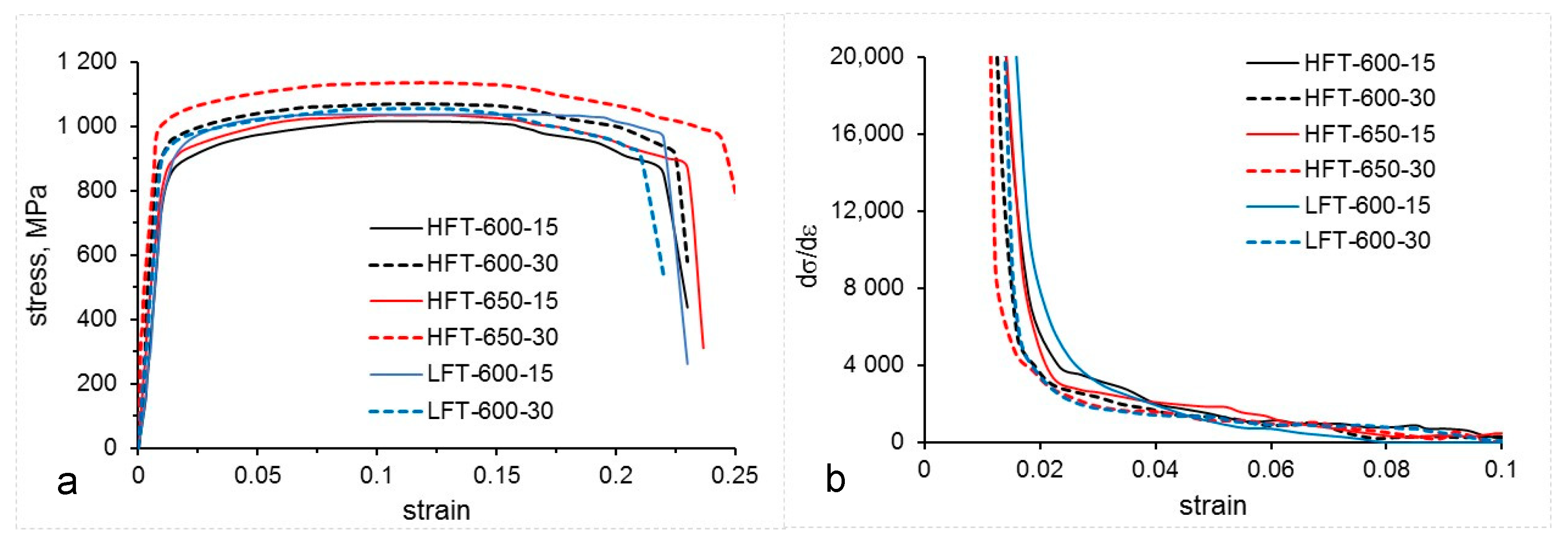

| YS, MPa | 872 ± 50 | 946 ± 15 | 885 ± 35 | 960 ± 20 | 875 ± 45 | 940 ± 20 | |

| UTS, MPa | 1030 ± 30 | 1075 ± 20 | 1030 ± 30 | 1100 ± 20 | 1035 ± 15 | 1055 ± 10 | |

| Elongation, % | 23 ± 2 | 23 ± 2 | 23 ± 3 | 25 ± 2 | 21 ± 3 | 21 ± 2 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kostryzhev, A.; Killmore, C.; Pereloma, E. Effect of Processing Parameters on Interphase Precipitation and Mechanical Properties in Novel CrVNb Microalloyed Steel. Metals 2021, 11, 107. https://doi.org/10.3390/met11010107

Kostryzhev A, Killmore C, Pereloma E. Effect of Processing Parameters on Interphase Precipitation and Mechanical Properties in Novel CrVNb Microalloyed Steel. Metals. 2021; 11(1):107. https://doi.org/10.3390/met11010107

Chicago/Turabian StyleKostryzhev, Andrii, Chris Killmore, and Elena Pereloma. 2021. "Effect of Processing Parameters on Interphase Precipitation and Mechanical Properties in Novel CrVNb Microalloyed Steel" Metals 11, no. 1: 107. https://doi.org/10.3390/met11010107

APA StyleKostryzhev, A., Killmore, C., & Pereloma, E. (2021). Effect of Processing Parameters on Interphase Precipitation and Mechanical Properties in Novel CrVNb Microalloyed Steel. Metals, 11(1), 107. https://doi.org/10.3390/met11010107