3.1. The Results of the Analysis of the Fatigue Behavior of the Transition Fittings

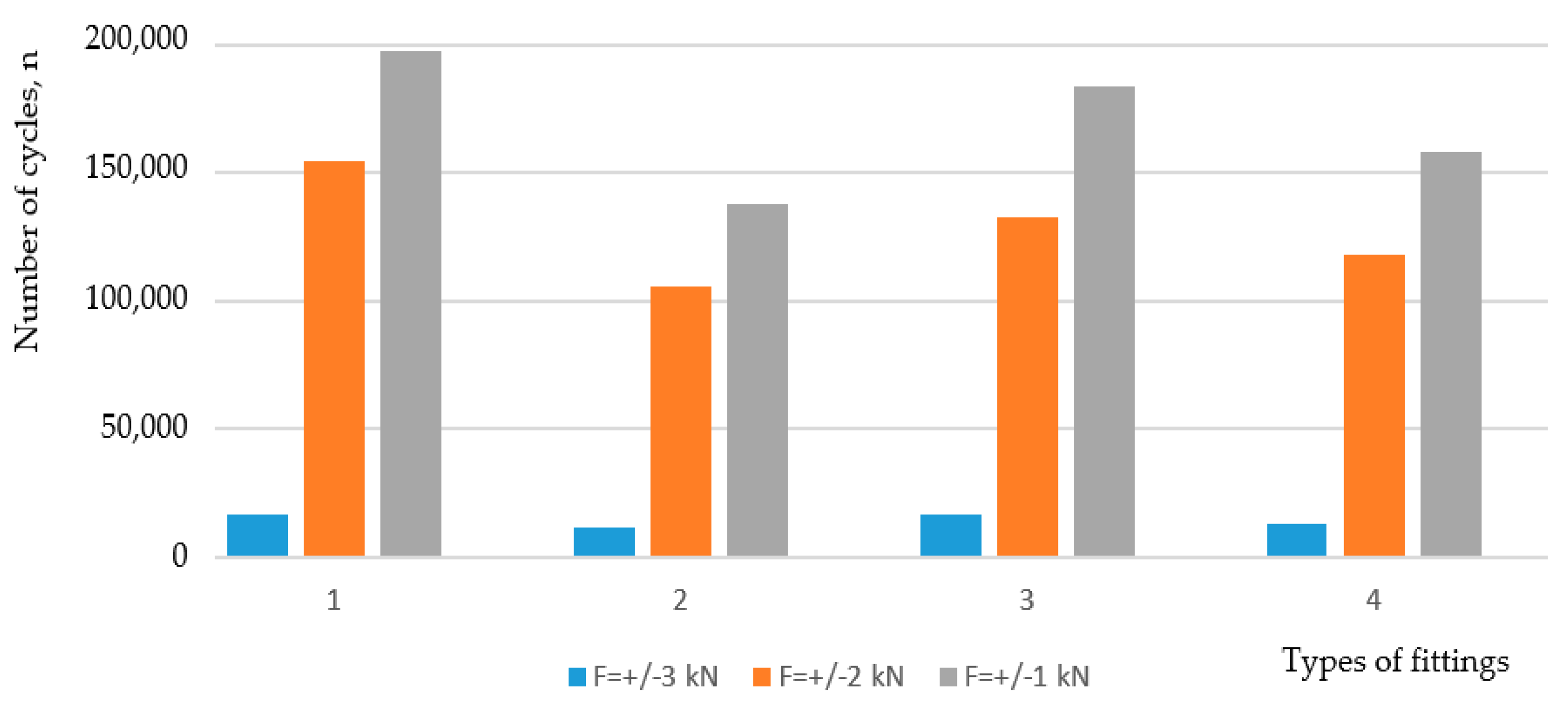

In order to carry out the studies from the point of view of the fatigue behavior of the fittings, nine fittings of each type were made, and these were tested by turn with the help of a fatigue testing machine. Thus, three fittings of the same type were tested for each stress condition, and the results obtained represent an average of the three measured values. After testing the four types of fittings in terms of fatigue behavior, the results shown in

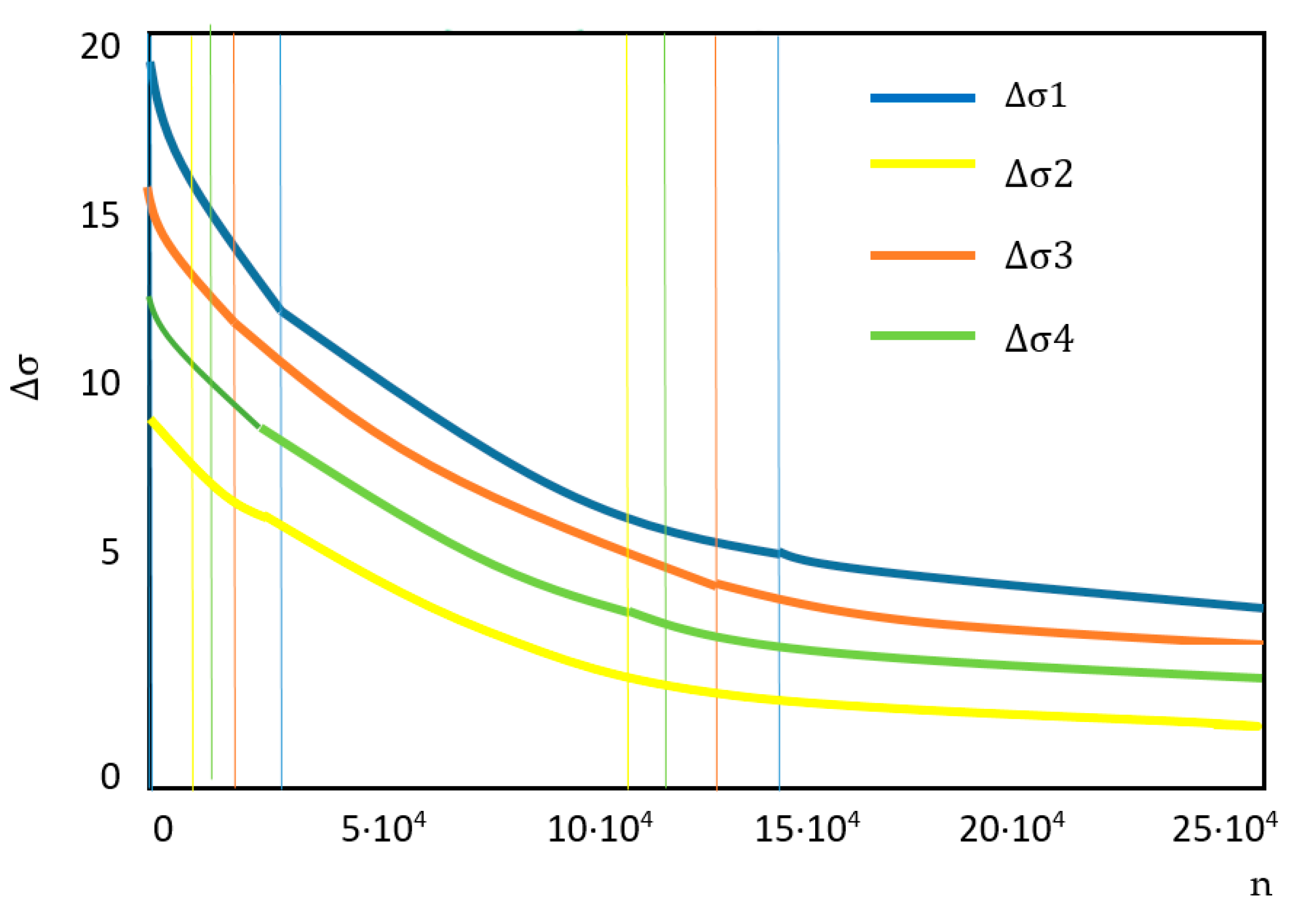

Table 12 were obtained. Given that on a graph in which on the ordinate (vertical axis) we have the

, and on the horizontal we have the number of cycles until breaking, the durability curves are obtained. These durability curves correspond to those specified in relations (2)–(5) and with the help of the calculation program MathCad, by the mathematical processing of the results obtained from the fatigue tests, the values p1 = 2 and r1 = 6.8 were determined for the fittings T1, for which the graph of the function Δσ1 is closest to our points represented by the vector number of cycles noted with n1 = (16210; 154610; 197750) and the force vector denoted F = (3; 2; 1). Under the same conditions, the data obtained for the fittings T2, T3 and T4 were processed and the values p2 = 1.4 and r2 = 5.2 were obtained for the fitting T2, for the fitting T3 the values p3 = 1.9 and r3 = 6.5 respectively for the fitting T4 the values p4 = 1.8 and r4 = 6.1.

Also, using equations (2 ÷ 5) Δσ was calculated, the voltage variation that appeared as a result of the variation of the force applied between a maximum and a minimum for the four types of fittings under the mentioned stress conditions, the results being presented in

Table 13.

After testing the four types of fittings in terms of fatigue behavior, the results shown in

Table 12 were obtained. Also, in

Figure 3, a graphical evolution of the number of cycles until breaking of the samples is presented.

Also, by processing these experimental data, the durability curves were drawn in linear coordinates,

Figure 4, as follows: for the T1 fitting—curve Δσ1, for the T2 fittings—Δσ2 curve, for the T3 fittings—Δσ3 curve, for the T4 fittings—Δσ4 curve.

Figure 4 shows that no durability curve is asymptotic to the horizontal axis. Therefore, these curves will intersect at some point with the horizontal axis, i.e., there is no voltage for which we have an infinite fatigue life, as Wohler’s curve is drawn theoretically, where there is a voltage σ0, for which we record infinite lifespan to fatigue. Also, the closest values observed in the case of durability curves to the real values are obtained in the case of fitting type T2, but also in the case of other types of fittings the difference is very small, falling within the range of 2–9%.

From

Table 12 it is observed that, with the decrease of the test forces of the samples, the number of cycles in which the test tubes yield to the applied fatigue increases. Also, from the same table it is observed that the best behavior in response to fatigue corresponds to the type T1 fitting followed by the fittings T3, T4 and T2, respectively. The fittings of type T2, T3, T4 have the same assembly technology, but have differences in terms of the geometry of the inner and outer bush, respectively. In these conditions it can be concluded that a substantial influence on the fatigue resistance of the transition fittings has the constructive shape of the inner and outer bush, respectively.

Of the transition fittings T2, T3 and T4, the best fatigue resistance corresponds to the T3 fitting, and this demonstrates that constructive differences between the inner and outer bushes can influence the fatigue resistance. Thus, in the case of the inner bush, which has a diameter difference at one end, the fatigue resistance is influenced due to the fact that the presence of a larger diameter for the inner bush towards the end where the welded joint is to be made determines a protection of the HDPE pipe material from the heat released in the joining process by welding. Under these conditions, it is required that the inner bushings of the transition fittings present at the end where the welded joint is made, an addition of material, that would allow the amount of heat released during the welding to be absorbed.

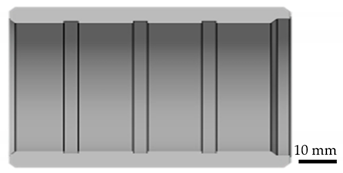

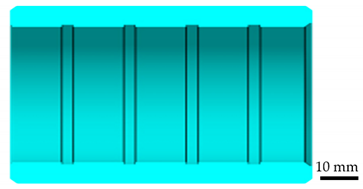

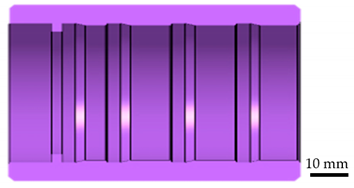

Regarding the geometry of the outer bush, it was observed that it influences the resistance to fatigue in the sense that it is not indicated that on the surface of the bush there to be a very sharp geometric profile that causes an accentuated deformation of the material in the HDPE pipe. Thus, the profile of the channels on the surface of the outer bush must be less sharp and thus the stresses introduced in the material of the HDPE pipes should be as low as possible.

Regarding the T1 type fitting, it had the best fatigue behavior, and this can be explained both by the geometry of the inner and outer bush and by the fact that, in the assembly process of this type of fitting, the assembly process by welding is performed before inserting the HDPE pipe.

Regarding the durability curves drawn in

Figure 4, it is observed that, leading a parallel line to the horizontal, the four durability curves intersect at four points that give us information on the number of cycles until yielding of the four types of fittings. It can be seen from

Figure 4 that the T1 type fitting has a point characterized by the highest number of stress cycles until the fitting will fail.

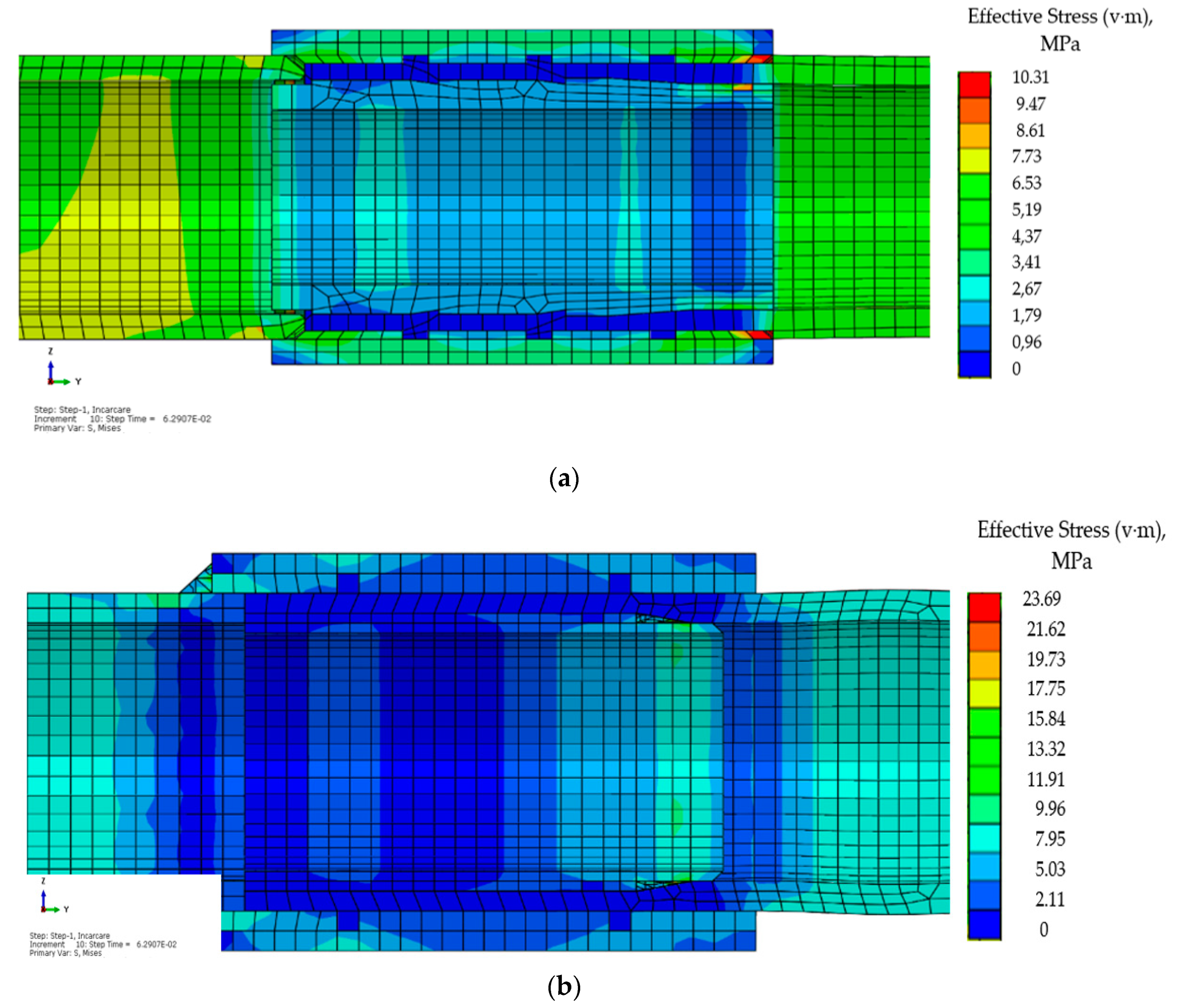

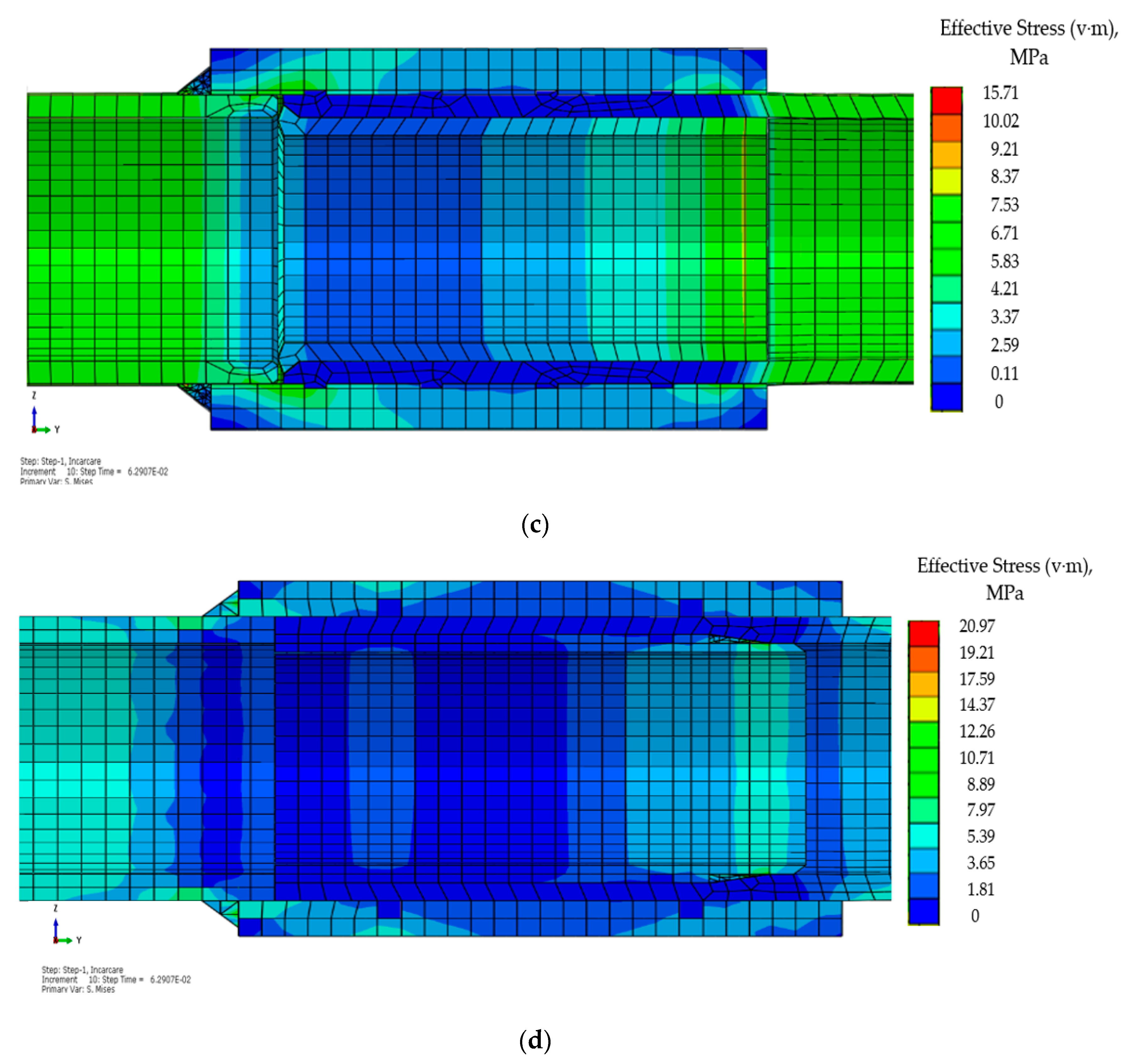

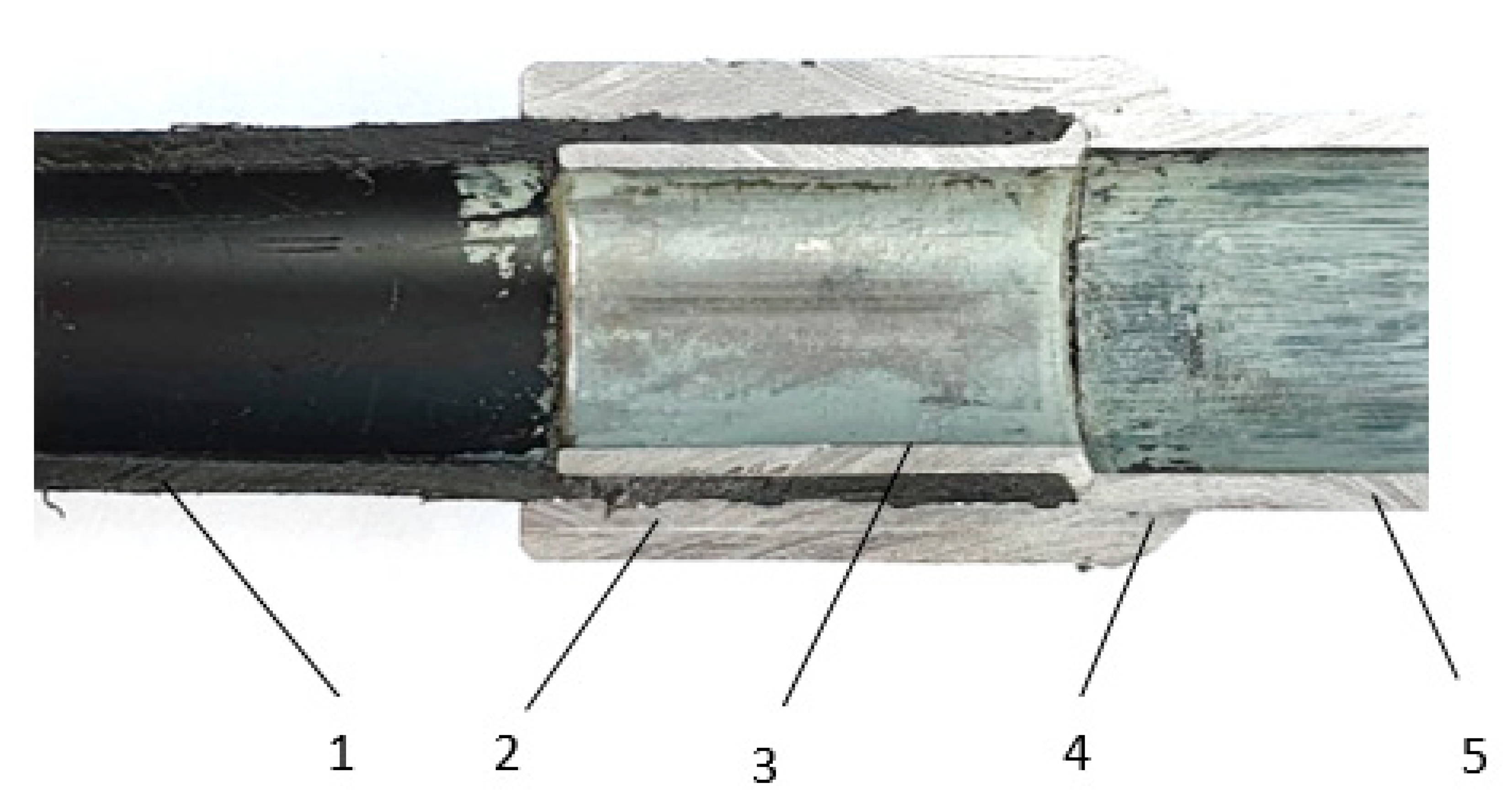

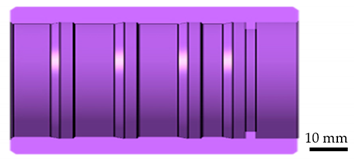

3.4. The Results of the Analysis of the Transition Fitting with an Improved Geometry of the Welded Construction

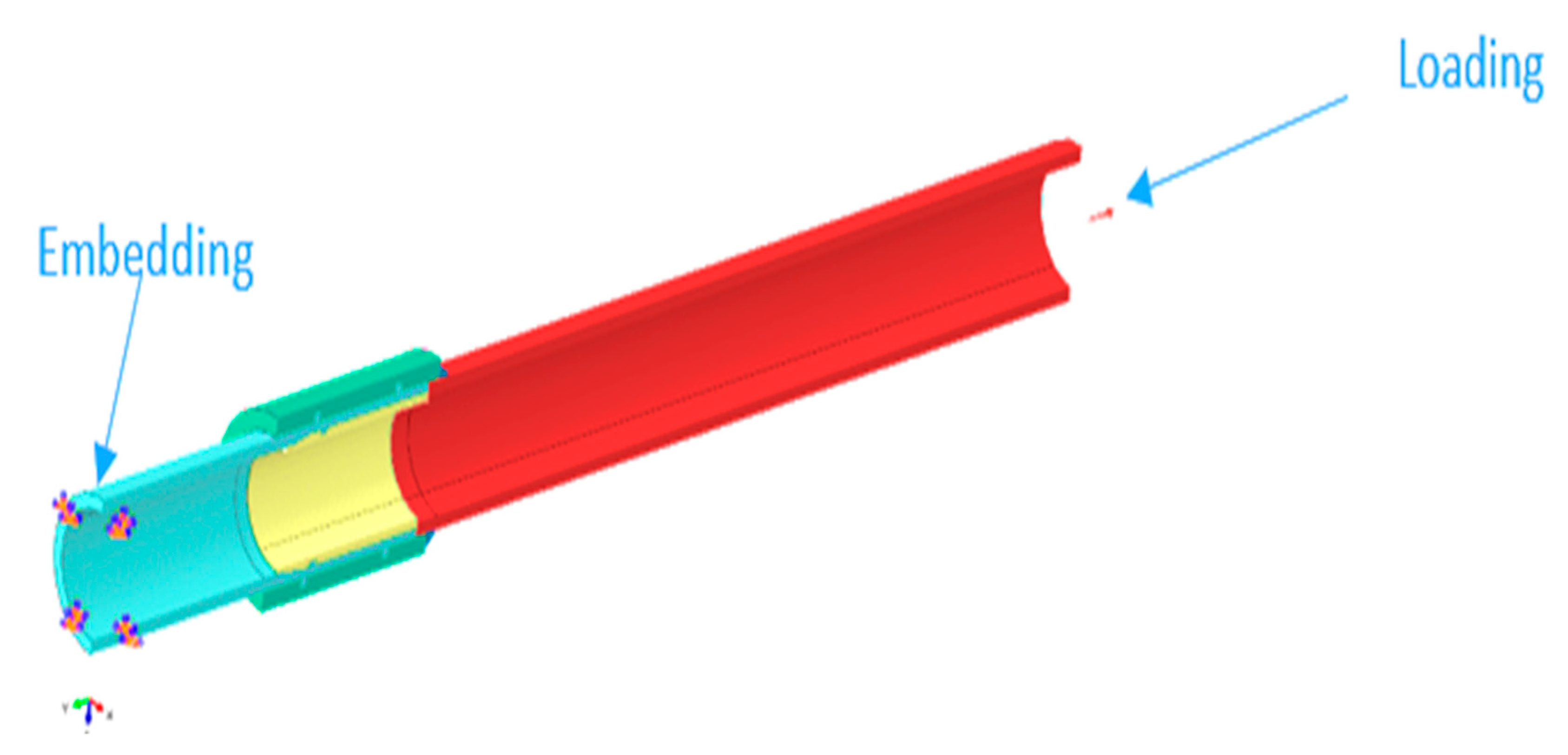

Following the analysis of the experimental research results, it was proposed to make a new transition fitting that has an assembly technology as close as possible to the T1 fitting technology, and, in the same type adopts the constructive elements from the structure of the other types of fittings, that have been shown to positively influence their characteristics.

Thus, for the realization of the new type of transition fitting, the inner bushing which is used to make the fittings T2 and T3, respectively, was chosen along with the outer bush used to make the type T3 fitting. The choice of these types of bushings was made considering the fact that in the experimental research it was demonstrated that the choice of these types of bushings results in an improvement of the behavior of the fittings in operation. The constructive form of the component parts of the new transition fitting (TN) is presented in

Table 14, and a section through this type of transition fitting is shown in

Figure 7.

This new type of transition fitting was subjected to the same tests as the four types of fittings analyzed previously. Thus, the results of the fatigue behavior analysis of this transition fitting are presented in

Table 15.

The analysis of the results presented in

Table 14 shows that the new type of transition fitting has a much better response to applied fatigue compared to the other four types of transition fittings analyzed previously, in the sense that an increase in the number of cycles was obtained, with approximately 50% for the TN fitting compared to the T1 fitting, which had the best fatigue behavior in relation to the T2, T3 and T4 fittings. This demonstrates that the choice of part geometry and an improved assembly technology can allow obtaining fittings with superior characteristics.

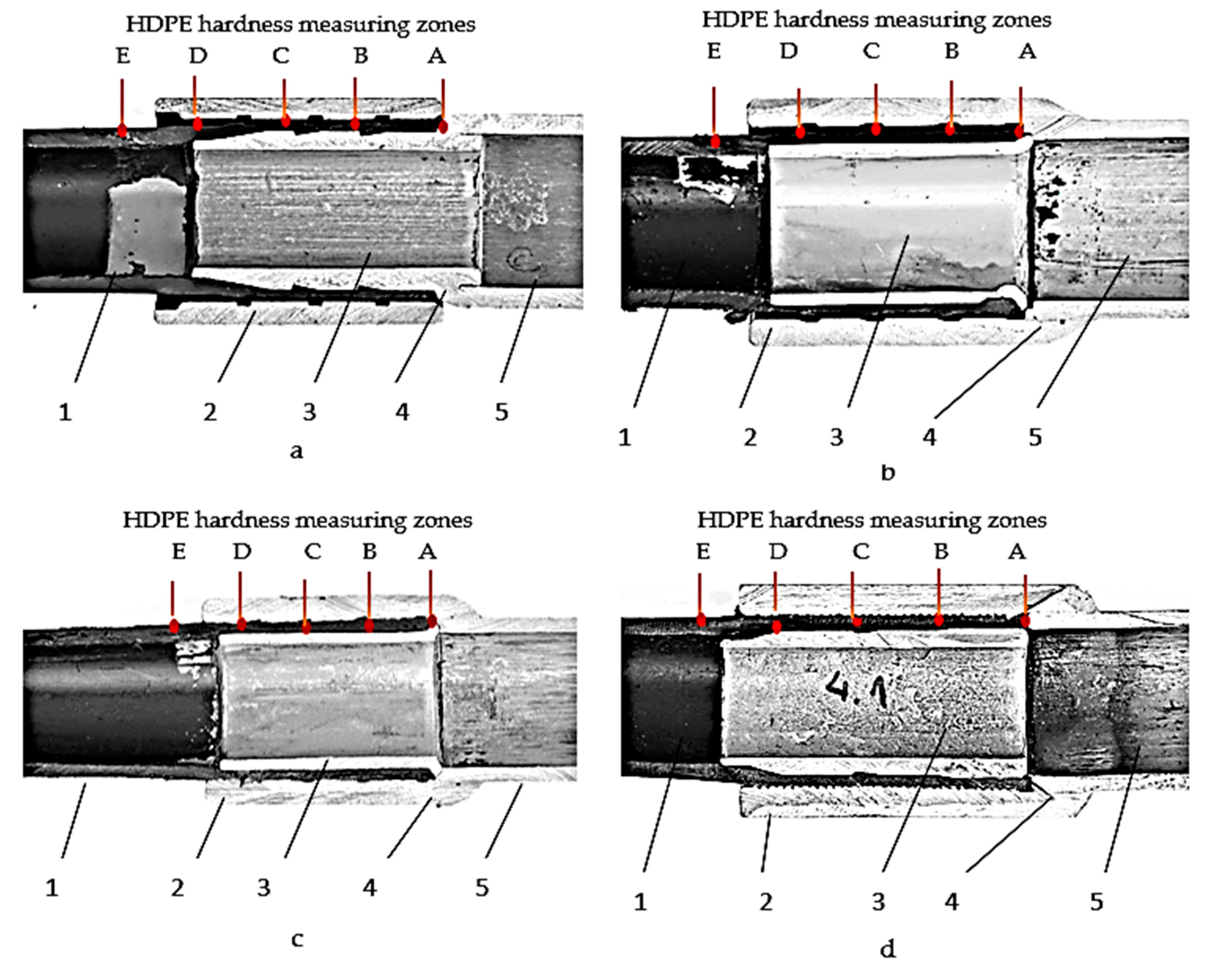

Also, the new type of transition fitting was subjected to hardness tests for HDPE material under the same conditions as T1, T2, T3 and T4 fittings. Following the hardness tests, the highest hardness 58 Sh D for HDPE was obtained, which shows that the new geometry of the inner and outer bushes, causes a very small change in the hardness of the HDPE material, which initially had a hardness of 55 Sh D. This can be explained by the fact that the influence of heat from HAZ on HDPE is very low, and the geometry adopted for the bushings does not cause a large increase in hardness.

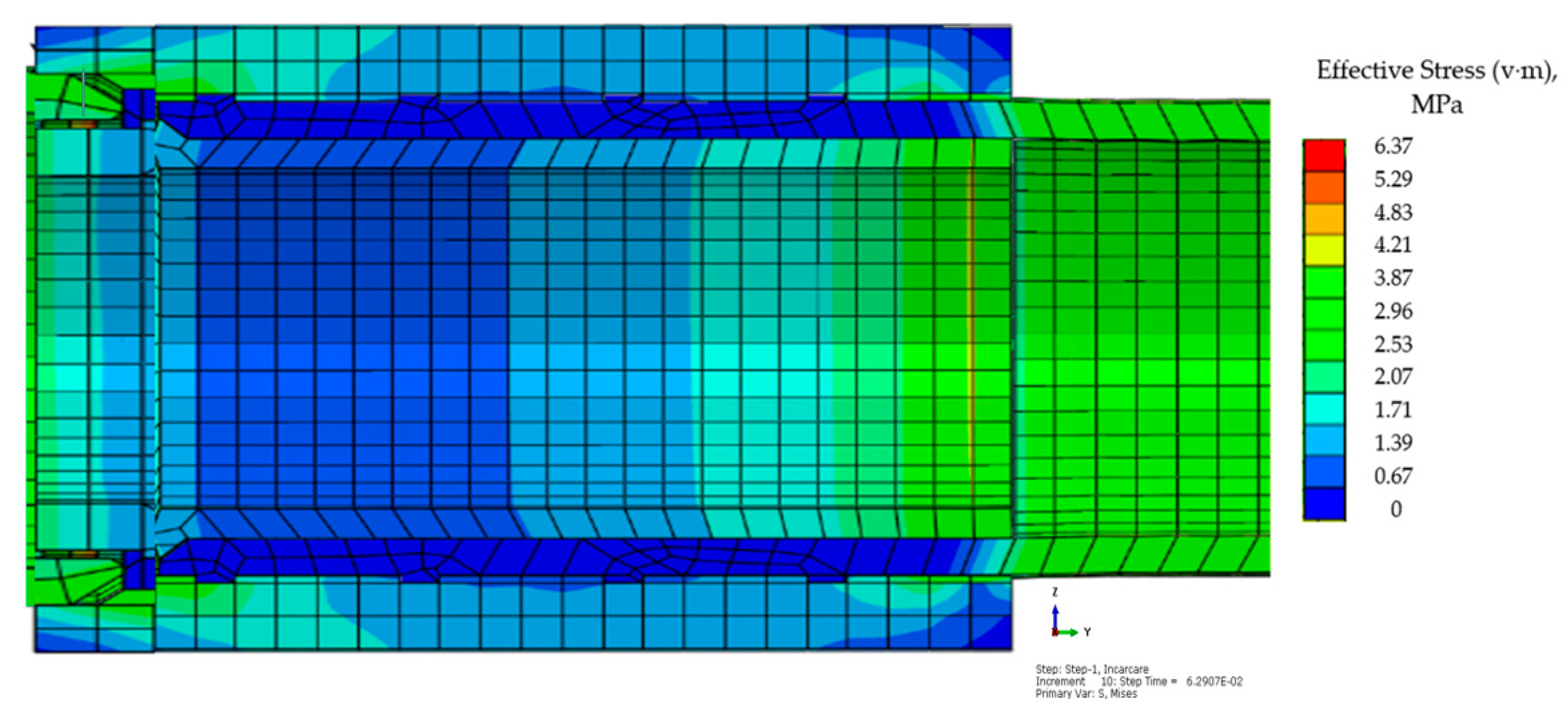

The FEM analysis of the TN transition fitting was performed under the same conditions as in the case of the other four types of transition fittings, this being presented in

Figure 8. From the results presented in

Figure 8 it was observed that the TN fitting has an effective stresses in the material from component parts 6.37 MPa, which demonstrates that this type of fitting has a lower material tension by about 90% compared to the T1 fitting, which was the best of the four initially analyzed.

This much better tensile behavior of the TN fitting can be explained by the fact that the design of the transition fitting has been considerably improved by design and choosing optimal shapes for the inner bushing and the outer bushing, but also by adopting an improved welding assembly technology so that HDPE pipe is not be influenced by the heat released during the welding process.

From what is presented, it is observed that the way the welded joint is formed has a very great influence on the behavior of the fittings in use. Thus, through the design of the welded construction, HAZ must be as restricted as possible, so as not to influence the HDPE pipe. It is also necessary to consider the possibility of replacing this welding technology with an ultrasonic welding process consisting of a rotating sonotrode, which moves around the parts to be welded or that the ultrasonic welding machine that a sonotrode, around which the parts to be welded rotate. This technological solution is possible because ultrasonic welding has a multitude of advantages such as the fact that surface damage is minimal because heat is generated at the interface (very restricted HAZ) and, at the same time, is a clean joining process because it does not generate smoke or sparks during welding and is therefore considered environmentally friendly [

23,

24].

Also, by changing the geometry of the parts in the fitting structure, the HDPE temperature should not exceed 50 °C because above this temperature this type of material quickly loses its ductility. The process of loss of ductility depends on the morphological appearance of the HDPE structures. Furthermore, the increasing trends of the tensile modulus at the higher exposure temperature indicates temperature sensitivity on chemicrystallization [

25].

The results obtained in the studies confirm those recorded in testing the tensile yield strength of HDPE using instrumented indentation tests with a flat-ended cylindrical indenter [

26,

27]. However, unlike previous research, different forms of inner and outer bushings were analyzed, which offer different degrees of deformation for HDPE, thus establishing the geometric shape of the welded construction that allows an optimal deformation of the HDPE pipe.

Regarding the optimal geometry of the surfaces of the inner and outer bushes, theoretical and practical research can be performed using mathematical modeling. These aspects are justified by the fact that, in many previous studies, researchers have mainly analyzed the law of mechanical deformation of flexible pipes by laboratory tests and numerical simulations [

28,

29].

Research has looked at the dynamic stress behavior of transition fittings because, although it was initially established that static load results in increased deformation of HDPE pipes [

30], subsequent research has shown that the dynamic load was more than three times higher than the static load [

31,

32].

Given the conducted studies, the load at which the fittings are required can be reduced if they are covered with expanded polystyrene (EPS) to alleviate the pressure and deformation of surface-buried high density polyethylene (HDPE) flexible pipes [

33]. Thus, considering the proposed solutions, regarding the improvement of the welded construction of the transition fittings, but also the technical solutions proposed by other researchers, conditions are created so that the lifespan and the number of stress cycles until their rupture increase substantially.