Towards Dry Machining of Titanium-Based Alloys: A New Approach Using an Oxygen-Free Environment

Abstract

1. Introduction

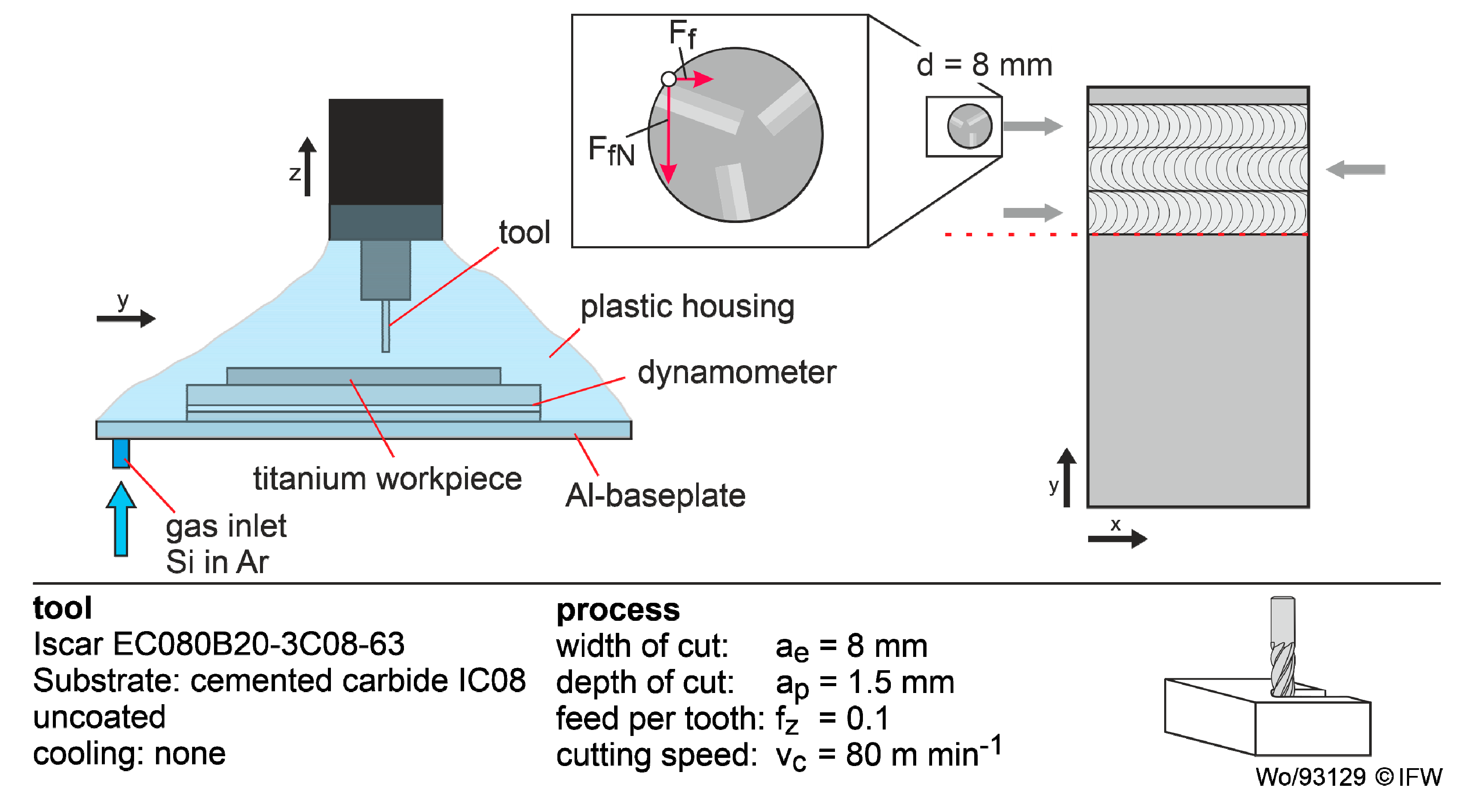

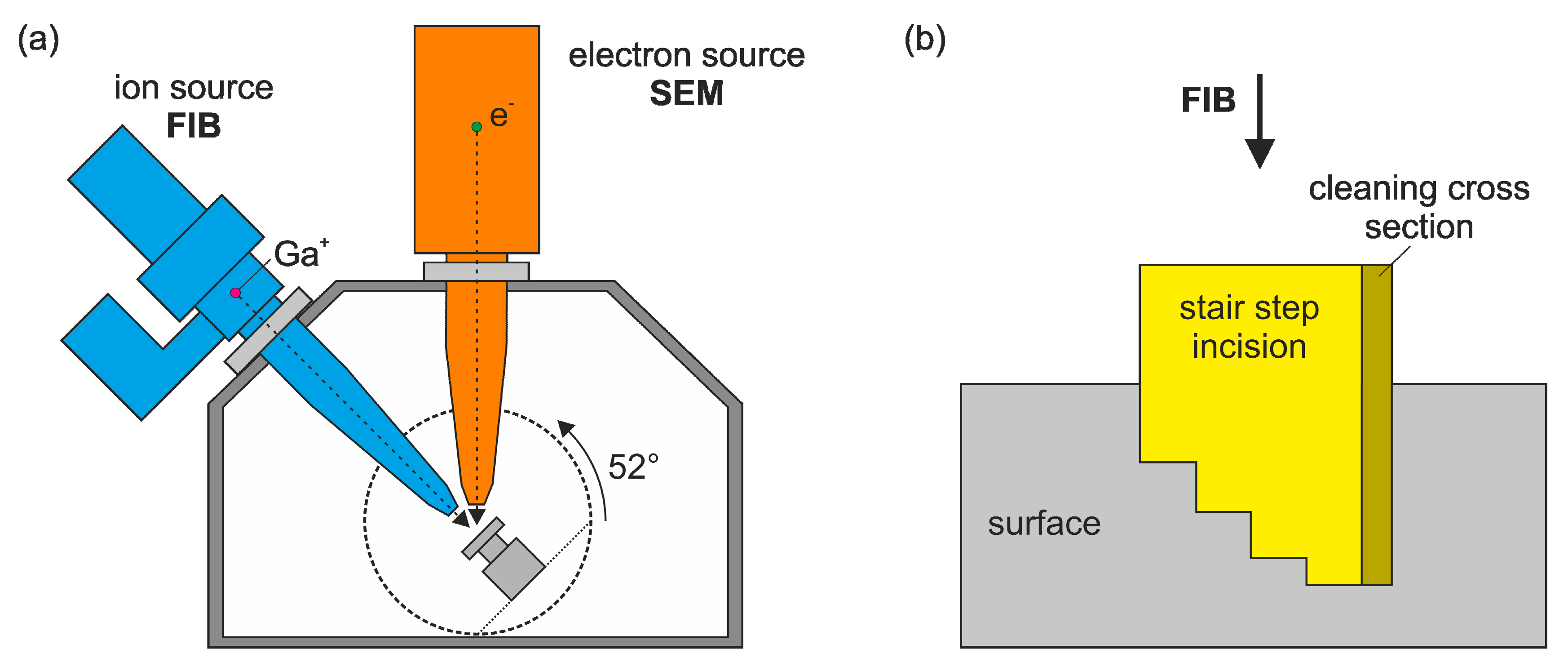

2. Materials and Methods

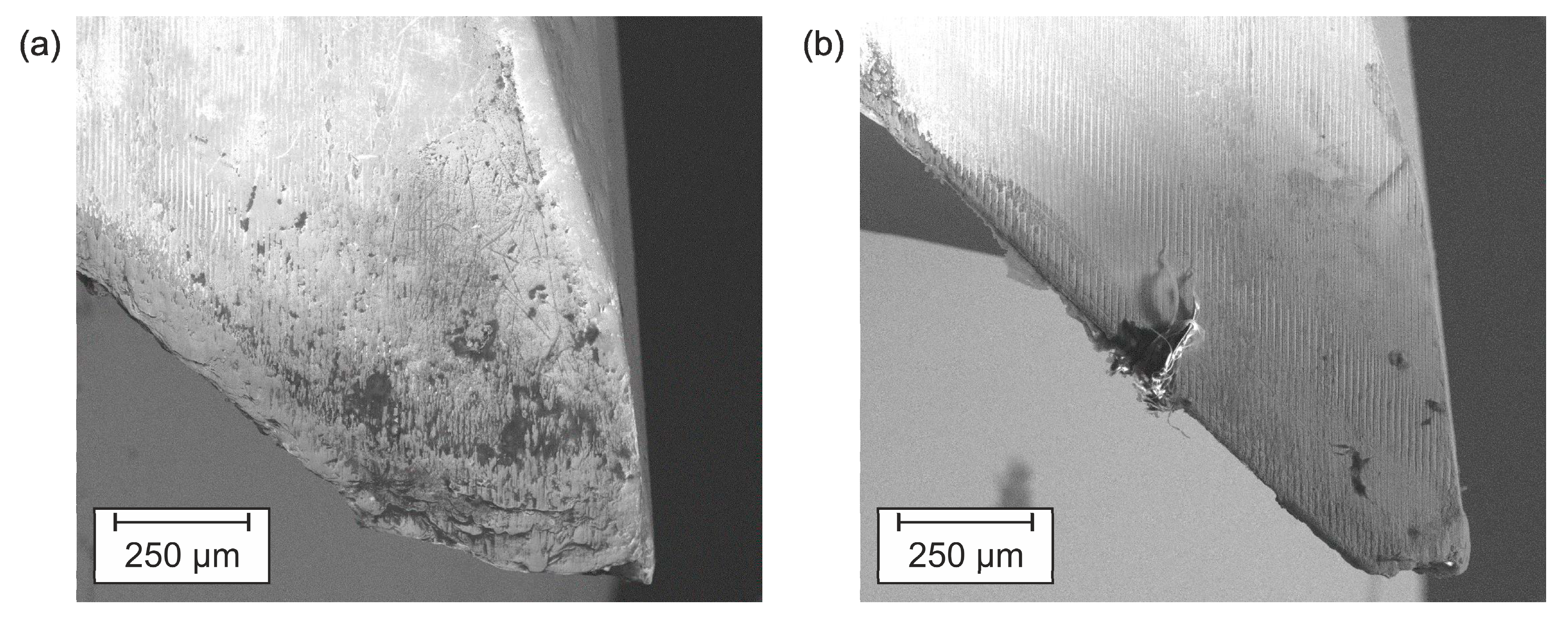

3. Results

4. Discussion

5. Conclusions

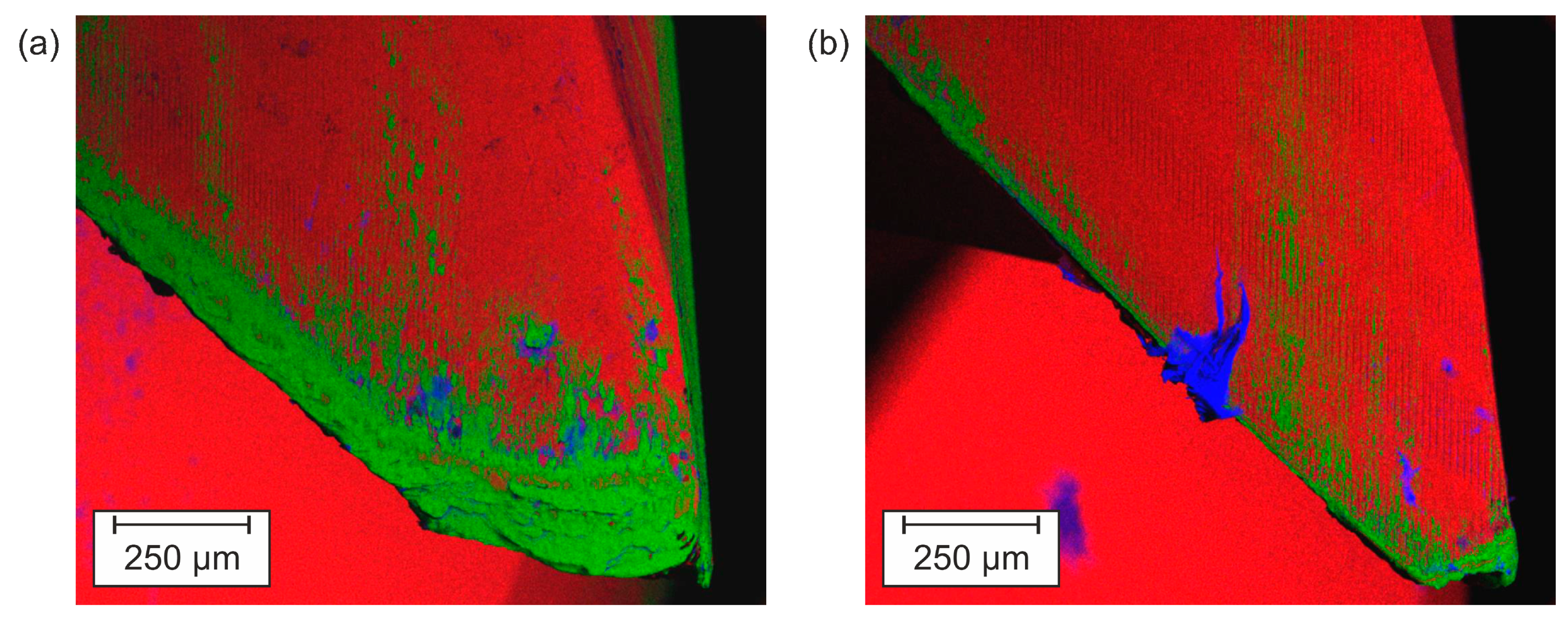

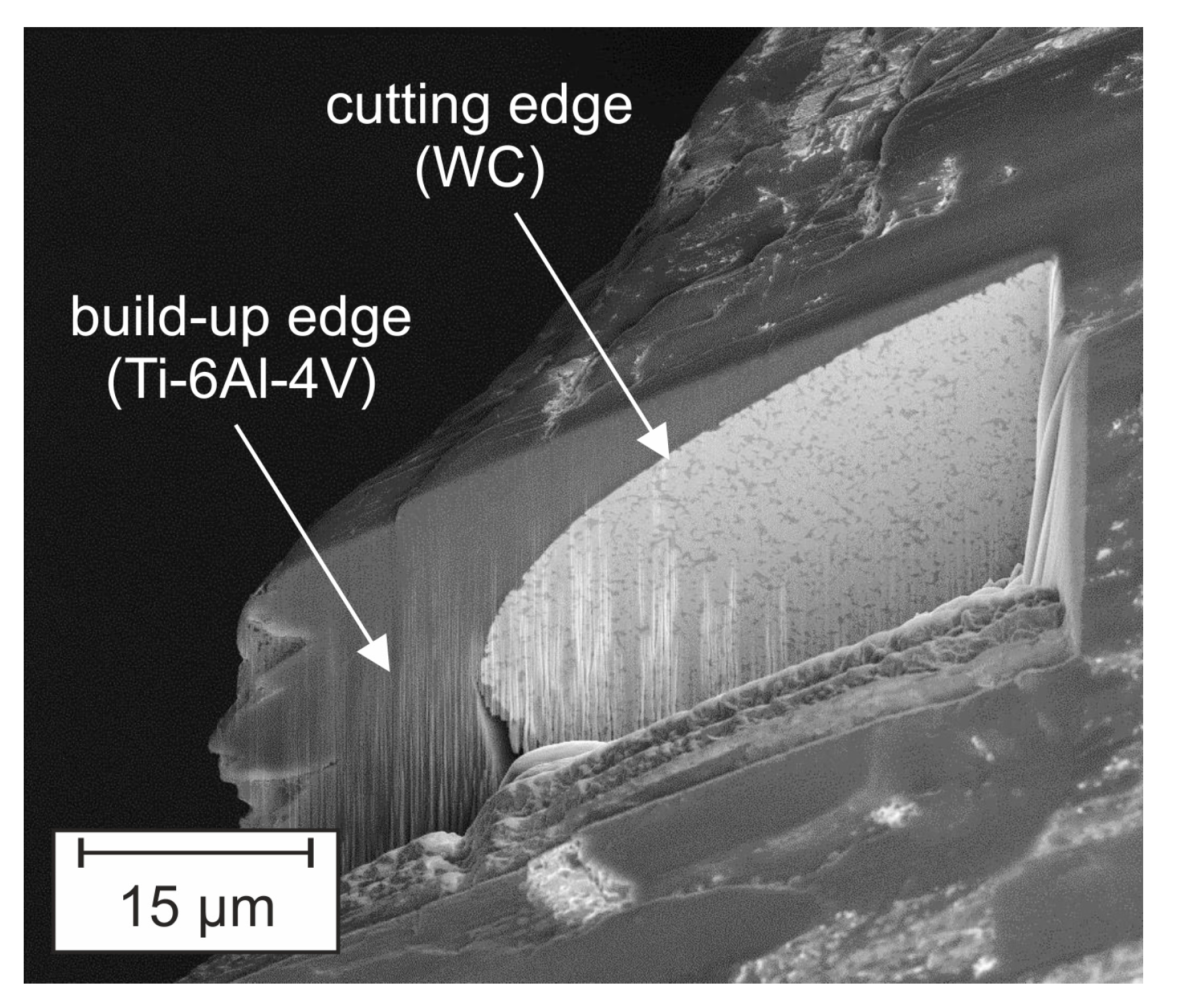

- Tribo-oxidation, which is the dominant wear mechanism upon conventional dry milling in this system, is suppressed upon milling in an oxygen-free environment. Thus, this novel approach renders dry milling viable for advanced machining of Ti-based alloys with cemented carbide tools.

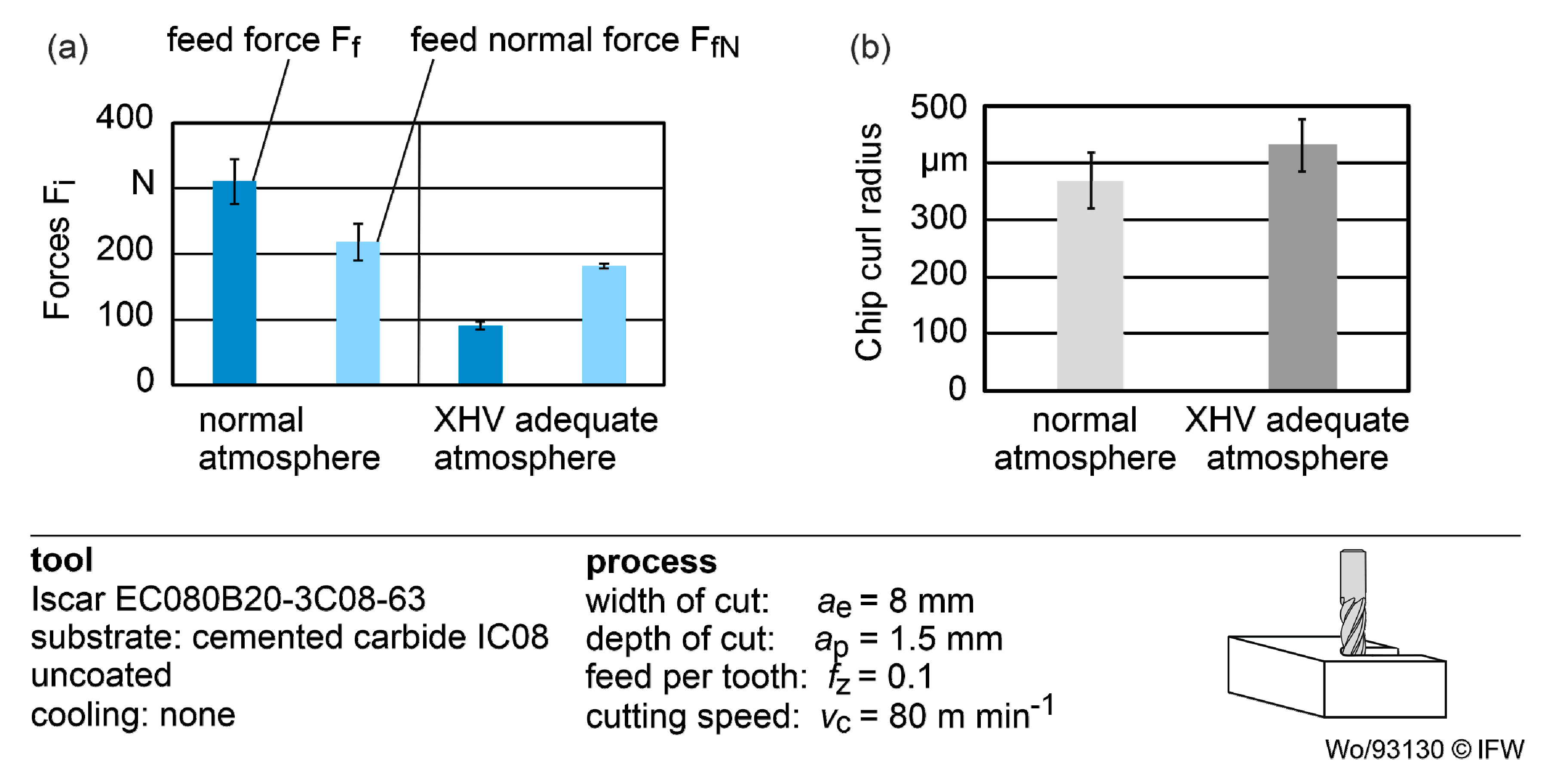

- Cutting forces are lower in the oxygen-free environment and the formation of adhesion is reduced.

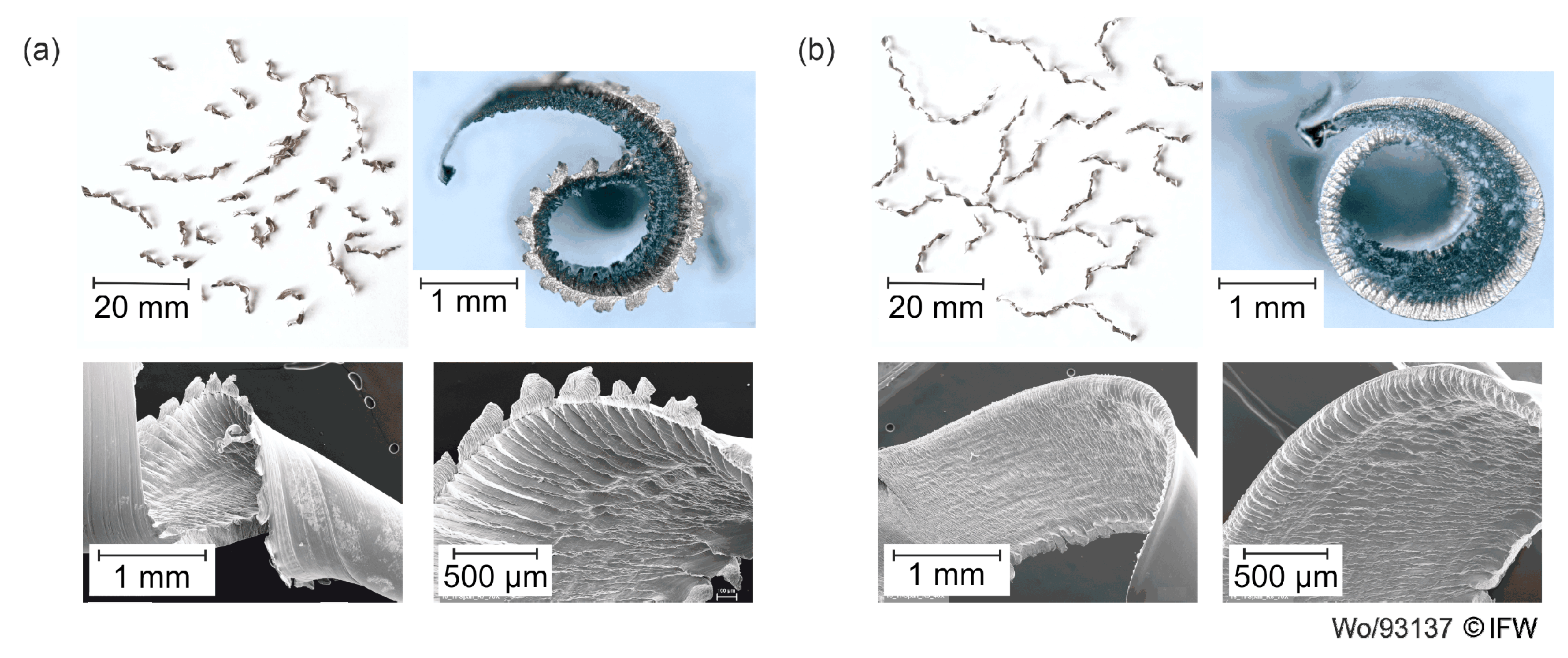

- Chip formation changes in the respective environments due to changes in tool geometry and friction conditions.

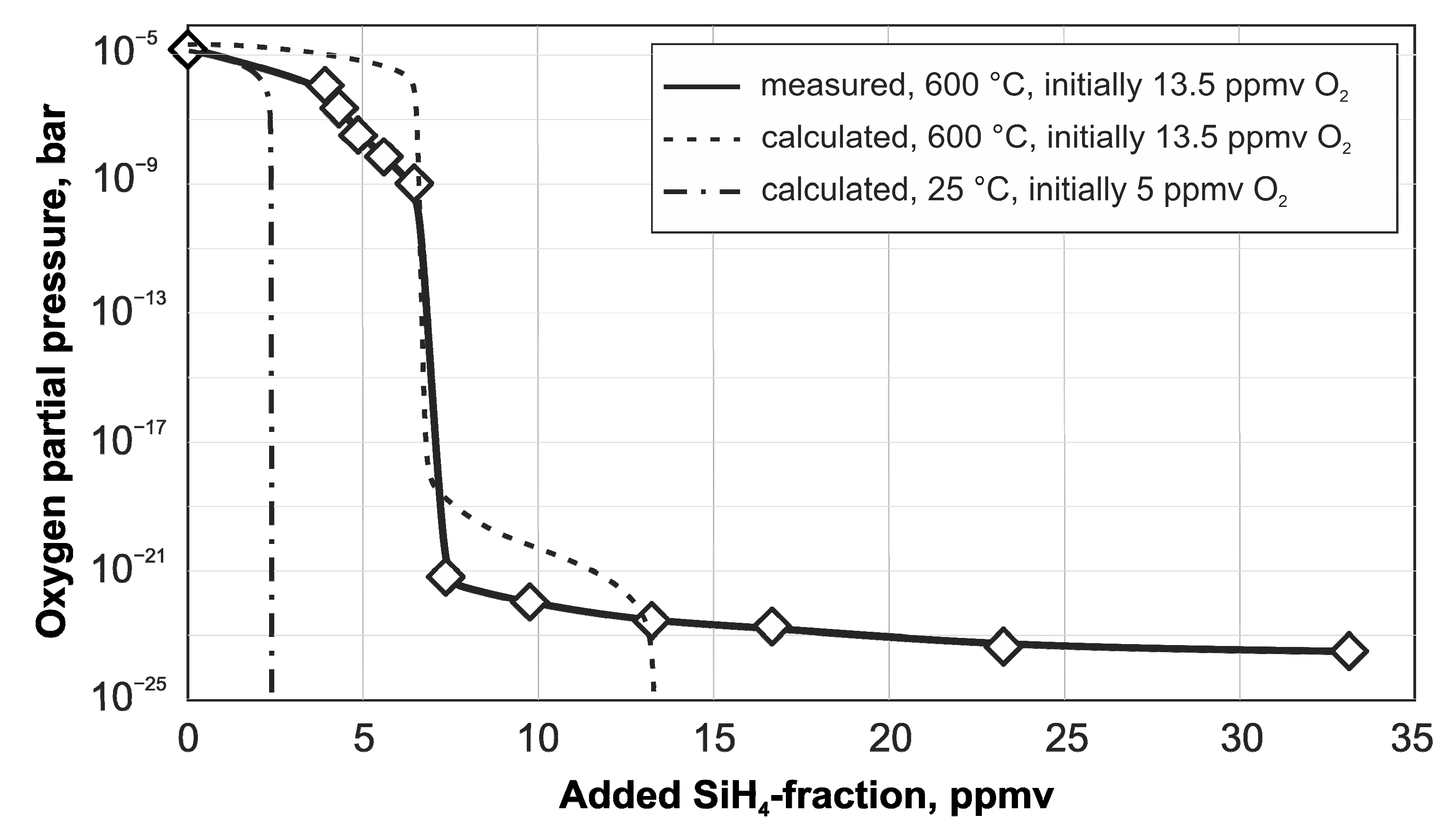

- Oxygen partial pressures corresponding to XHV environments can be easily realized by milling in a SiH4-doped argon atmosphere.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Veiga, C.; Davim, J.P.; Laureiro, A.J.R. Properties an applications of titanium alloys: A brief review. Rev. Adv. Mater. Sci. 2012, 32, 133–148. [Google Scholar]

- Denkena, B.; Dittrich, M.-A.; Jacob, S. Energy Efficiency in Machining of Aircraft Components. Proc. CIRP 2016, 48, 479–482. [Google Scholar] [CrossRef]

- Veiga, C.; Davim, J.P.; Loureiro, A.J.R. Review on machinability of titanium alloys: The process perspective. Rev. Adv. Mater. Sci. 2013, 34, 148–164. [Google Scholar]

- Davim, J.P. Machining of Titanium Alloys, 1st ed.; Springer: Heidelberg, Germany, 2014. [Google Scholar]

- Abele, E.; Fröhlich, B. High speed milling of titanium alloys. Adv. Prod. Eng. Manag. 2008, 3, 131–140. [Google Scholar]

- Pramanik, A. Problems and solutions in machining of titanium alloys. Int. J. Adv. Manuf. Technol. 2014, 70, 919–928. [Google Scholar] [CrossRef]

- Venugopal, K.A.; Paul, S.; Chattopadhyay, A.B. Growth of tool wear in turning of Ti-6Al-4V alloy under cryogenic cooling. Wear 2007, 262, 1071–1078. [Google Scholar] [CrossRef]

- Hartung, P.D.; Kramer, B.M.; von Turkovich, B.F. Tool Wear in Titanium Machining. CIRP Ann. 1982, 31, 75–80. [Google Scholar] [CrossRef]

- Nabhani, F. Wear mechanisms of ultra-hard cutting tools materials. J. Mater. Process. Technol. 2001, 115, 402–412. [Google Scholar] [CrossRef]

- Corduan, N.; Himbart, T.; Polachon, G.; Dessoly, M.; Lambertin, M.; Vigneau, J.; Payoux, B. Wear machanisms of new tool materials for Ti-6Al-4V High performance machining. CIRP Ann. 2003, 52, 73–76. [Google Scholar] [CrossRef]

- Bushlya, V.; Lenrick, F.; Ståhl, J.-E.; M’Saoubi, R. Influence of oxygen on the tool wear in machining. CIRP Ann. 2018, 67, 79–82. [Google Scholar] [CrossRef]

- Wutz, M.; Adam, H.; Walcher, W.; Jousten, K. Handbuch Vakuumtechnik, 12th ed.; Springer Vieweg: Wiesbaden, Germany, 2018. [Google Scholar]

- Lützenkirchen-Hecht, D.; Wulff, D.; Wagner, R.; Frahm, R.; Holländer, U.; Maier, H.J. Thermal anti-oxidation treatment of CrNi-steels as studied by EXAFS in reflection mode: The influence of monosilane additions in the gas atmosphere of a continuous annealing furnace. J. Mater. Sci. 2014, 49, 5454–5461. [Google Scholar] [CrossRef]

- Bergmann, B. Grundlagen zur Auslegung von Schneidkantenverrundungen. Ph.D. Thesis, Leibniz Universität, Hannover, Germany, 2017. [Google Scholar]

- Wyen, C.-F.; Wegener, K. Influence of cutting edge radius on cutting forces in machining titanium. CIRP Ann. 2010, 59, 93–96. [Google Scholar] [CrossRef]

- Zhang, S.; Li, J.F.; Wang, Y.W. Tool life and cutting forces in end milling Inconel 718 under dry and minimum quantity cooling lubrication cutting conditions. J. Clean. Prod. 2012, 32, 81–87. [Google Scholar] [CrossRef]

- Grove, T.; Denkena, B.; Maiß, O.; Krödel, A.; Schwab, H.; Kühn, U. Cutting mechanism and surface integrity in milling of Ti-5553 processed by selective laser melting. J. Mech. Sci. Technol. 2018, 32, 4883–4892. [Google Scholar] [CrossRef]

- Arrazola, P.J.; Özel, T.; Umbrello, D.; Davies, M.; Jawahir, I.S. Recent advances in modelling of metal machining processes. CIRP Ann. 2013, 62, 695–718. [Google Scholar] [CrossRef]

- Cook, N.H. Chip formation in machining titanium. In Proceedings of the Symposium on Machine Grind, Watertown Arsenal, MA, USA, 31 March 1953; pp. 1–7. [Google Scholar]

- Wu, H.M.; To, S. Serrated chip formation and their adiabatic analysis by using the constitutive model of titanium alloy in high speed cutting. J. Alloys Compd. 2015, 629, 368–373. [Google Scholar] [CrossRef]

- Childs, T.H.C. Towards simulating built-up-edge formation in the machining of steel. CIRP J. Manuf. Sci. Technol. 2011, 4, 57–70. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maier, H.J.; Herbst, S.; Denkena, B.; Dittrich, M.-A.; Schaper, F.; Worpenberg, S.; Gustus, R.; Maus-Friedrichs, W. Towards Dry Machining of Titanium-Based Alloys: A New Approach Using an Oxygen-Free Environment. Metals 2020, 10, 1161. https://doi.org/10.3390/met10091161

Maier HJ, Herbst S, Denkena B, Dittrich M-A, Schaper F, Worpenberg S, Gustus R, Maus-Friedrichs W. Towards Dry Machining of Titanium-Based Alloys: A New Approach Using an Oxygen-Free Environment. Metals. 2020; 10(9):1161. https://doi.org/10.3390/met10091161

Chicago/Turabian StyleMaier, Hans Jürgen, Sebastian Herbst, Berend Denkena, Marc-André Dittrich, Florian Schaper, Sebastian Worpenberg, René Gustus, and Wolfgang Maus-Friedrichs. 2020. "Towards Dry Machining of Titanium-Based Alloys: A New Approach Using an Oxygen-Free Environment" Metals 10, no. 9: 1161. https://doi.org/10.3390/met10091161

APA StyleMaier, H. J., Herbst, S., Denkena, B., Dittrich, M.-A., Schaper, F., Worpenberg, S., Gustus, R., & Maus-Friedrichs, W. (2020). Towards Dry Machining of Titanium-Based Alloys: A New Approach Using an Oxygen-Free Environment. Metals, 10(9), 1161. https://doi.org/10.3390/met10091161