Effects of Fe11+ Ions Irradiation on the Microstructure and Performance of Selective Laser Melted 316L Austenitic Stainless Steels

Abstract

1. Introduction

2. Experimental Methods

2.1. Materials Fabrication

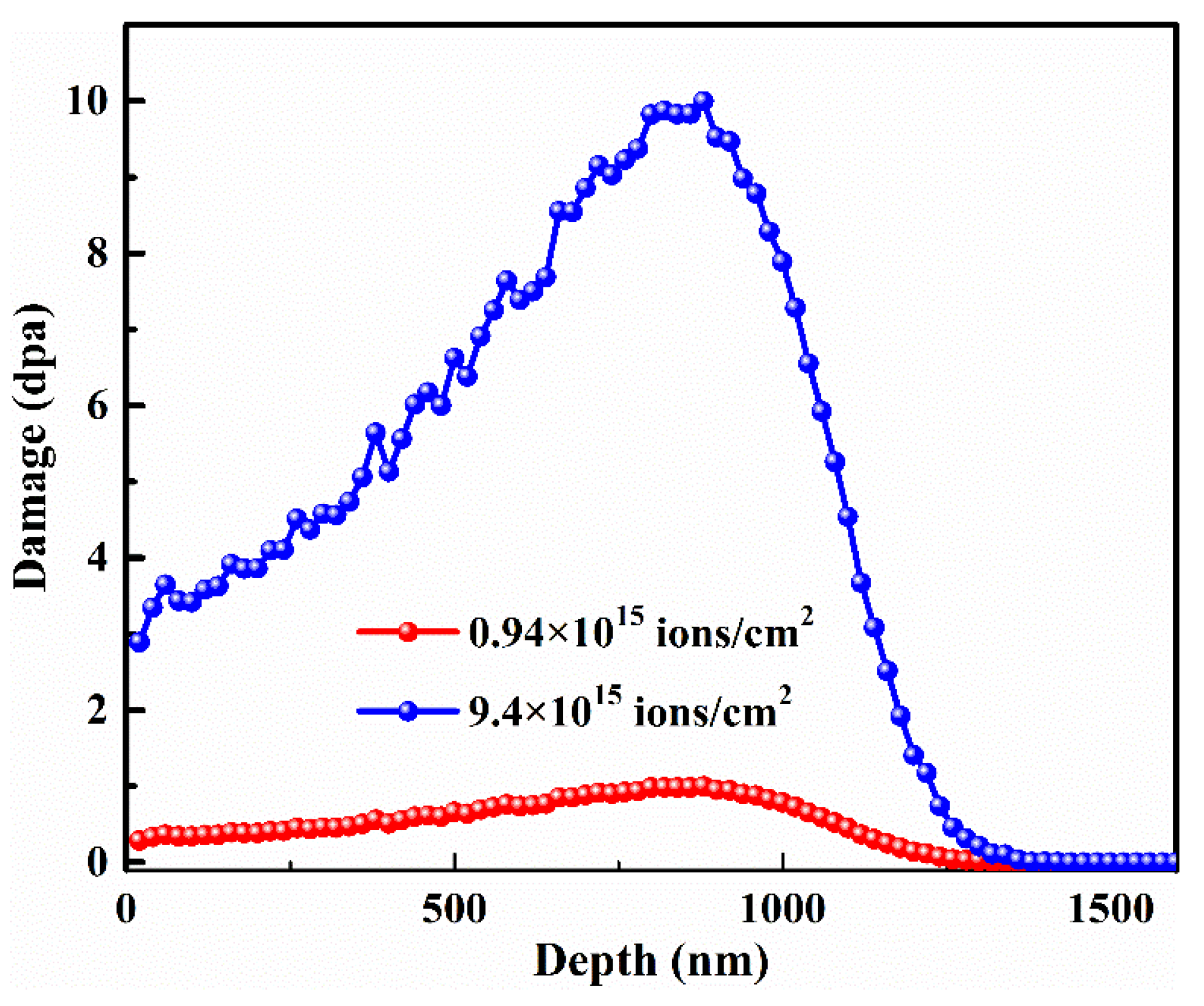

2.2. Irradiation Process

2.3. Characterization Methods

3. Results and Discussion

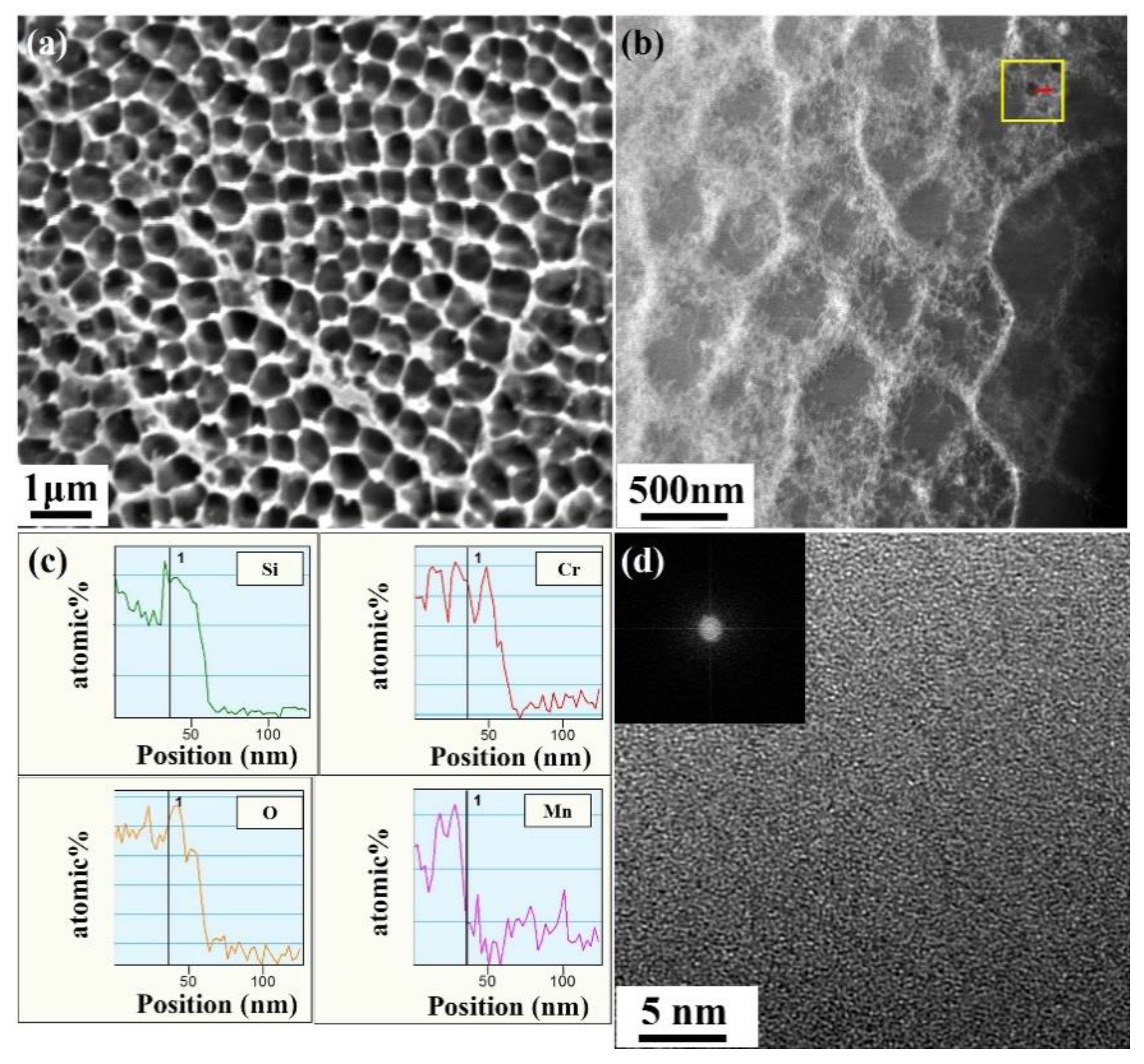

3.1. Microstructure of Pre–Irradiated Samples

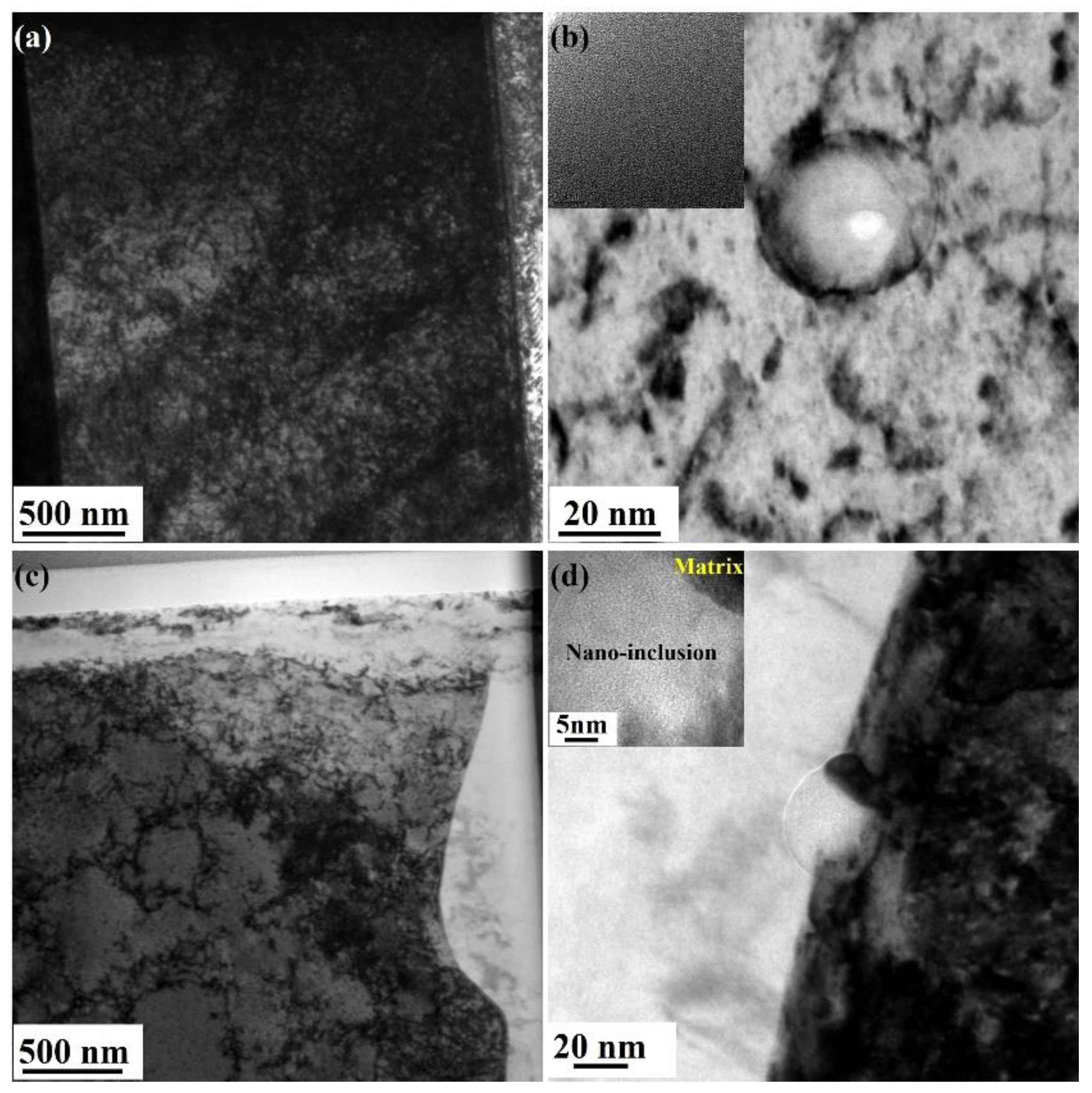

3.2. Microstructure of Post-Irradiated Samples

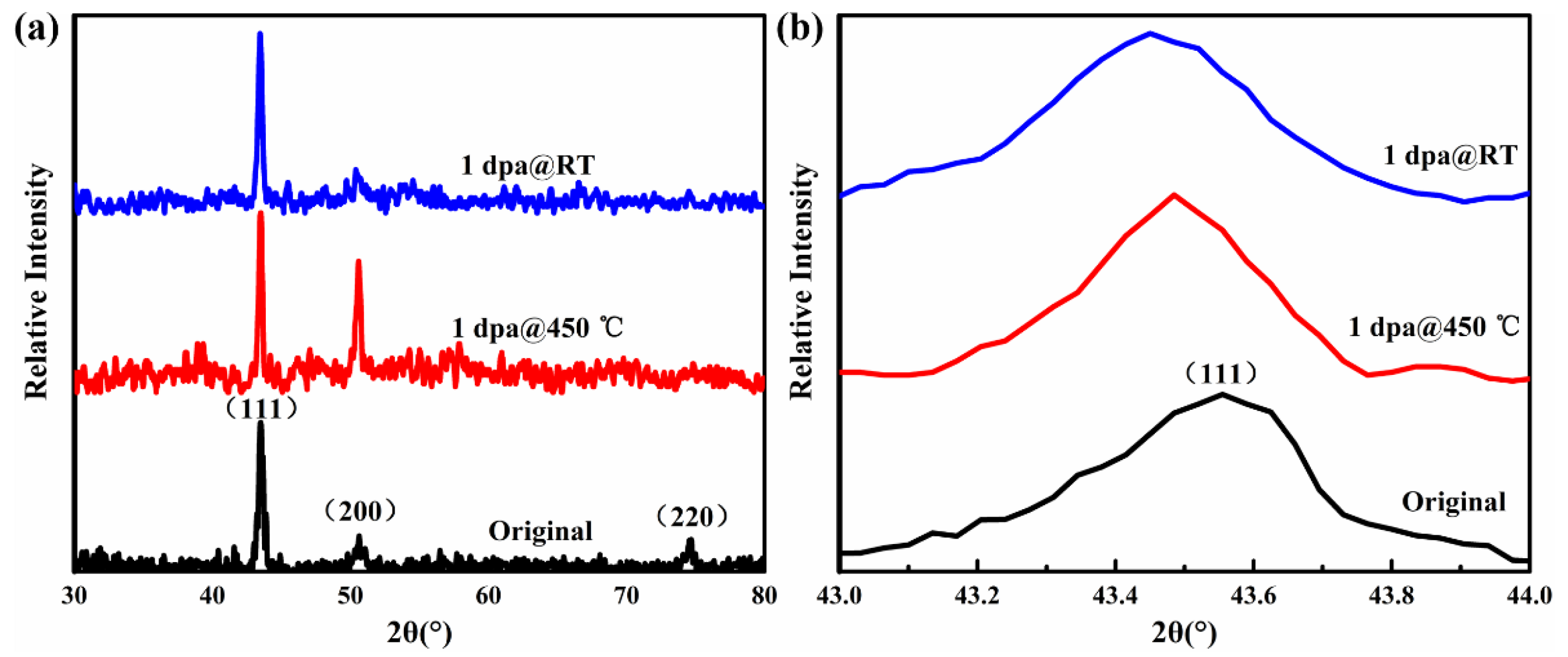

3.3. GIXRD Analysis of Pre- and Post-Irradiated Samples

3.4. Hardness Property Analysis

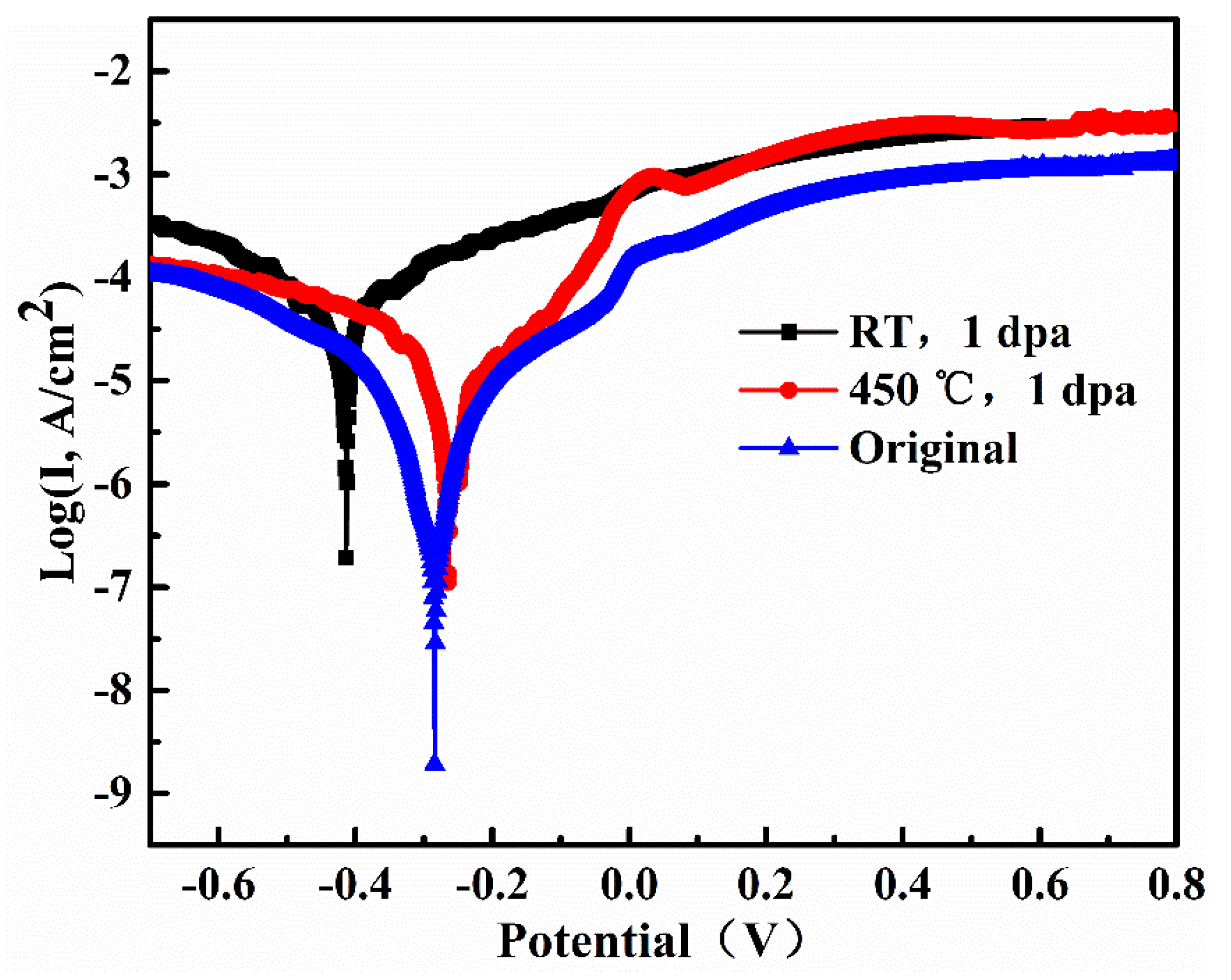

3.5. Corrosion Resistance in 0.9 wt.% NaCl Solution

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Zinkle, S.J.; Was, G.S. Materials challenges in nuclear energy. Acta Mater. 2013, 61, 735–758. [Google Scholar] [CrossRef]

- Şahin, S.; Übeyli, M. A review on the potential use of austenitic stainless steels in nuclear fusion reactors. J. Fusion Energy 2008, 27, 271–277. [Google Scholar] [CrossRef]

- Yang, S.; Yang, Z.; Wang, H.; Watanabe, S.; Shibayama, T. Effect of laser and/or electron beam irradiation on void swelling in SUS316L austenitic stainless steel. J. Nucl. Mater. 2017, 488, 215–221. [Google Scholar] [CrossRef][Green Version]

- Gandy, D.W. Strategy/approach for qualification of nuclear components produced via additive manufacturing. In US DOE Advanced Methods of Manufacturing Workshop; US Department of Energy: Germantown, MD, USA, 2016. [Google Scholar]

- Kruth, J.P.; Mercelis, P.; van Vaerenbergh, J.; Froyen, L.; Rombouts, M. Binding mechanisms in selective laser sintering and selective laser melting. Rapid Prototyp. J. 2005, 11, 26–36. [Google Scholar] [CrossRef]

- Kranz, J.; Herzog, D.; Emmelmann, C. Design guidelines for laser additive manufacturing of lightweight structures in TiAl6V4. J. Laser Appl. 2015, 27, S14001. [Google Scholar]

- Zhong, Y.; Rännar, L.E.; Wikman, S.; Koptyug, A.; Liu, L.; Cui, D.; Shen, Z. Additive manufacturing of ITER first wall panel parts by two approaches: Selective laser melting and electron beam melting. Fusion Eng. Des. 2017, 116, 24–33. [Google Scholar] [CrossRef]

- Yusuf, S.M.; Nie, M.; Chen, Y.; Yang, S.; Gao, N. Microstructure and corrosion performance of 316L stainless steel fabricated by Selective Laser Melting and processed through high-pressure torsion. J. Alloys Compd. 2018, 763, 360–375. [Google Scholar] [CrossRef]

- Zhong, Y.; Liu, L.; Wikman, S.; Cui, D.; Shen, Z. Intragranular cellular segregation network structure strengthening 316L stainless steel prepared by selective laser melting. J. Nucl. Mater. 2016, 470, 170–178. [Google Scholar] [CrossRef]

- Liu, L.; Ding, Q.; Zhong, Y.; Zou, J.; Wu, J.; Chiu, Y.L.; Li, J.; Zhang, Z.; Yu, Q.; Shen, Z. Dislocation network in additive manufactured steel breaks strength–ductility trade-off. Mater. Today 2018, 21, 354–361. [Google Scholar] [CrossRef]

- Lou, X.; Andresen, P.L.; Rebak, R.B. Oxide inclusions in laser additive manufactured stainless steel and their effects on impact toughness and stress corrosion cracking behavior. J. Nucl. Mater. 2018, 499, 182–190. [Google Scholar] [CrossRef]

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive manufacturing of metals. Acta Mater. 2016, 117, 371–392. [Google Scholar] [CrossRef]

- Suryawanshi, J.; Prashanth, K.; Ramamurty, U. Mechanical behavior of selective laser melted 316L stainless steel. Mater. Sci. Eng. A 2017, 696, 113–121. [Google Scholar] [CrossRef]

- Chen, N.; Niu, L.L.; Zhang, Y.; Shu, X.; Zhou, H.B.; Jin, S.; Ran, G.; Lu, G.H.; Gao, F. Energetics of vacancy segregation to [100] symmetric tilt grain boundaries in bcc tungsten. Sci. Rep. 2016, 6, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Jin, K.; Lu, C.; Wang, L.M.; Qu, J.; Weber, W.J.; Zhang, Y.; Bei, H. Effects of compositional complexity on the ion-irradiation induced swelling and hardening in Ni-containing equiatomic alloys. Scr. Mater. 2016, 119, 65–70. [Google Scholar] [CrossRef]

- Yabuuchi, K.; Kuribayashi, Y.; Nogami, S.; Kasada, R.; Hasegawa, A. Evaluation of irradiation hardening of proton irradiated stainless steels by nanoindentation. J. Nucl. Mater. 2014, 446, 142–147. [Google Scholar] [CrossRef]

- Sakaguchi, N.; Endo, M.; Watanabe, S.; Kinoshita, H.; Yamashita, S.; Kokawa, H. Radiation-induced segregation and corrosion behavior on Σ3 coincidence site lattice and random grain boundaries in proton-irradiated type-316L austenitic stainless steel. J. Nucl. Mater. 2013, 434, 65–71. [Google Scholar] [CrossRef]

- Jin, H.H.; Ko, E.; Lim, S.; Kwon, J.; Shin, C. Effect of irradiation temperature on microstructural changes in self-ion irradiated austenitic stainless steel. J. Nucl. Mater. 2017, 493, 239–245. [Google Scholar] [CrossRef]

- Jiao, Z.; Was, G.S. Precipitate behavior in self-ion irradiated stainless steels at high doses. J. Nucl. Mater. 2014, 449, 200–206. [Google Scholar] [CrossRef]

- Sun, X.; Chen, F.; Huang, H.; Lin, J.; Tang, X. Effects of interfaces on the helium bubble formation and radiation hardening of an austenitic stainless steel achieved by additive manufacturing. Appl. Surf. Sci. 2019, 467–468, 1134–1139. [Google Scholar] [CrossRef]

- Song, M.; Wang, M.; Lou, X.; Rebak, R.B.; Was, G.S. Radiation damage and irradiation-assisted stress corrosion cracking of additively manufactured 316L stainless steels. J. Nucl. Mater. 2019, 513, 33–44. [Google Scholar] [CrossRef]

- Stoller, R.E.; Toloczko, M.B.; Was, G.S.; Certain, A.G.; Dwaraknath, S.; Garner, F.A. On the use of SRIM for computing radiation damage exposure. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. Atoms 2013, 310, 75–80. [Google Scholar] [CrossRef]

- Kuleshova, E.A.; Fedotova, S.V.; Gurovich, B.A.; Frolov, A.S.; Maltsev, D.A.; Stepanov, N.V.; Margolin, B.Z.; Minkin, A.J.; Sorokin, A.A. Microstructure degradation of austenitic stainless steels after 45 years of operation as VVER-440 reactor internals. J. Nucl. Mater. 2020, 533, 152124. [Google Scholar] [CrossRef]

- Korepanova, N.; Gu, L.; Zhang, L.; Dai, Y. Evaluation of displacement cross-section for neutron-irradiated 15-15Ti steel and its swelling behavior in CiADS radiation environment. Ann. Nucl. Energy 2019, 133, 937–949. [Google Scholar] [CrossRef]

- Li, X.; Bhushan, B. A review of nanoindentation continuous stiffness measurement technique and its applications. Mater. Charact. 2002, 48, 11–36. [Google Scholar] [CrossRef]

- Chen, F.; Tang, X.; Huang, H.; Liu, J.; Li, H.; Qiu, Y.; Chen, D. Surface damage and mechanical properties degradation of Cr/W multilayer films irradiated by Xe20+. Appl. Surf. Sci. 2015, 357, 1225–1230. [Google Scholar] [CrossRef]

- Saeidi, K.; Gao, X.; Zhong, Y.; Shen, Z.J. Hardened austenite steel with columnar sub-grain structure formed by laser melting. Mater. Sci. Eng. A 2015, 625, 221–229. [Google Scholar] [CrossRef]

- Prashanth, K.G.; Eckert, J. Formation of metastable cellular microstructures in selective laser melted alloys. J. Alloys Compd. 2017, 707, 27–34. [Google Scholar] [CrossRef]

- Chao, Q.; Cruz, V.; Thomas, S.; Birbilis, N.; Collins, P.; Taylor, A.; Hodgson, P.D.; Fabijanic, D. On the enhanced corrosion resistance of a selective laser melted austenitic stainless steel. Scr. Mater. 2017, 141, 94–98. [Google Scholar] [CrossRef]

- Wang, Y.M.; Voisin, T.; McKeown, J.T.; Ye, J.; Calta, N.P.; Li, Z.; Zeng, Z.; Zhang, Y.; Chen, W.; Roehling, T.T.; et al. Additively manufactured hierarchical stainless steels with high strength and ductility. Nat. Mater. 2018, 17, 63–70. [Google Scholar] [CrossRef]

- Saeidi, K.; Gao, X.; Lofaj, F.; Kvetková, L.; Shen, Z.J. Transformation of austenite to duplex austenite-ferrite assembly in annealed stainless steel 316L consolidated by laser melting. J. Alloys Compd. 2015, 633, 463–469. [Google Scholar] [CrossRef]

- Qiu, C.; Al Kindi, M.; Aladawi, A.S.; Al Hatmi, I. A comprehensive study on microstructure and tensile behaviour of a selectively laser melted stainless steel. Sci. Rep. 2018, 8. [Google Scholar] [CrossRef] [PubMed]

- Gigax, J.G.; Kim, H.; Chen, T.; Garner, F.A.; Shao, L. Radiation instability of equal channel angular extruded T91 at ultra-high damage levels. Acta Mater. 2017, 132, 395–404. [Google Scholar] [CrossRef]

- Kaoumi, D.; Motta, A.T.; Birtcher, R.C. A thermal spike model of grain growth under irradiation. J. Appl. Phys. 2008, 104. [Google Scholar] [CrossRef]

- Was, G.S. Fundamentals of Radiation Materials Science: Metals and Alloys, 2nd ed.; Springer: New York, NY, USA, 2016. [Google Scholar]

- Rothman, S.J.; Nowicki, L.J.; Murch, G.E. Self-diffusion in austenitic Fe-Cr-Ni alloys. J. Phys. F Met. Phys. 1980, 10, 383–398. [Google Scholar] [CrossRef]

- Yang, T.; Xia, S.; Guo, W.; Hu, R.; Poplawsky, J.D.; Sha, G.; Fang, Y.; Yan, Z.; Wang, C.; Li, C.; et al. Effects of temperature on the irradiation responses of Al0.1CoCrFeNi high entropy alloy. Scr. Mater. 2018, 144, 31–35. [Google Scholar] [CrossRef]

- Huang, H.F.; Li, J.J.; Li, D.H.; Liu, R.D.; Lei, G.H.; Huang, Q.; Yan, L. TEM, XRD and nanoindentation characterization of Xenon ion irradiation damage in austenitic stainless steels. J. Nucl. Mater. 2014, 454, 168–172. [Google Scholar] [CrossRef]

- Chen, D.; Murakami, K.; Dohi, K.; Nishida, K.; Soneda, N.; Li, Z.; Liu, L.; Sekimura, N. Depth distribution of Frank loop defects formed in ion-irradiated stainless steel and its dependence on Si addition. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. Atoms 2015, 365, 503–508. [Google Scholar] [CrossRef]

- Nix, W.D.; Gao, H. Indentation size effects in crystalline materials: A law for strain gradient plasticity. J. Mech. Phys. Solids 1998, 46, 411–425. [Google Scholar] [CrossRef]

- Huang, H.F.; Li, D.H.; Li, J.J.; Liu, R.D.; Lei, G.H.; He, S.X.; Huang, Q.; Yan, L. Nanostructure variations and their effects on mechanical strength of Ni-17Mo-7Cr alloy under Xenon ion irradiation. Mater. Trans. 2014, 55, 1243–1247. [Google Scholar] [CrossRef]

- Muthukumaran, V.; Selladurai, V.; Nandhakumar, S.; Senthilkumar, M. Experimental investigation on corrosion and hardness of ion implanted AISI 316L stainless steel. Mater. Des. 2010, 31, 2813–2817. [Google Scholar] [CrossRef]

- Hug, E.; Babu, R.P.; Monnet, I.; Etienne, A.; Moisy, F.; Pralong, V.; Enikeev, N.; Abramova, M.; Sauvage, X.; Radiguet, B. Impact of the nanostructuration on the corrosion resistance and hardness of irradiated 316 austenitic stainless steels. Appl. Surf. Sci. 2017, 392, 1026–1035. [Google Scholar] [CrossRef]

| Material | Temperature (°C) | Dose (dpa) | Size (nm) | Density (× 1022/m3) | References |

|---|---|---|---|---|---|

| SLM 316L SS | RT | 1 | 6 | 2.7 | This work |

| 450 | 1 | 8.5 | 1.3 | ||

| CW 316 SS | RT | 0.62 | 5 | 3.7 | [38] |

| SA 304 SS | 350 | 1.25 | 9.6 | 3 | [39] |

| Material | Temperature (°C) | Dose (dpa) | Hardness Enhancement | References |

|---|---|---|---|---|

| SLM 316L SS | RT | 1 | 50% | This work |

| 450 | 1 | 42% | ||

| CW 316 SS | RT | 0.62 | 62% | [38] |

| Material | Temperature (°C) | Dose (dpa) | Jcor (μA/cm2) | Reference |

|---|---|---|---|---|

| Original SLM SS | / | / | 0.80 | This work |

| AISI SS | / | / | 1218.7 | [42] |

| Post-irradiated SLM SS | RT | 1 | 56.7 | This work |

| 450 | 1 | 8.726 | This work |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huan, D.; Li, Y.; Chen, X.; Liu, H. Effects of Fe11+ Ions Irradiation on the Microstructure and Performance of Selective Laser Melted 316L Austenitic Stainless Steels. Metals 2020, 10, 1140. https://doi.org/10.3390/met10091140

Huan D, Li Y, Chen X, Liu H. Effects of Fe11+ Ions Irradiation on the Microstructure and Performance of Selective Laser Melted 316L Austenitic Stainless Steels. Metals. 2020; 10(9):1140. https://doi.org/10.3390/met10091140

Chicago/Turabian StyleHuan, Dajun, Yong Li, Xiaodong Chen, and Hongquan Liu. 2020. "Effects of Fe11+ Ions Irradiation on the Microstructure and Performance of Selective Laser Melted 316L Austenitic Stainless Steels" Metals 10, no. 9: 1140. https://doi.org/10.3390/met10091140

APA StyleHuan, D., Li, Y., Chen, X., & Liu, H. (2020). Effects of Fe11+ Ions Irradiation on the Microstructure and Performance of Selective Laser Melted 316L Austenitic Stainless Steels. Metals, 10(9), 1140. https://doi.org/10.3390/met10091140