Microstructure and Wear Resistance of TiB2/7075 Composites Produced via Rheocasting

Abstract

1. Introduction

2. Materials and Methods

2.1. Material Preparation

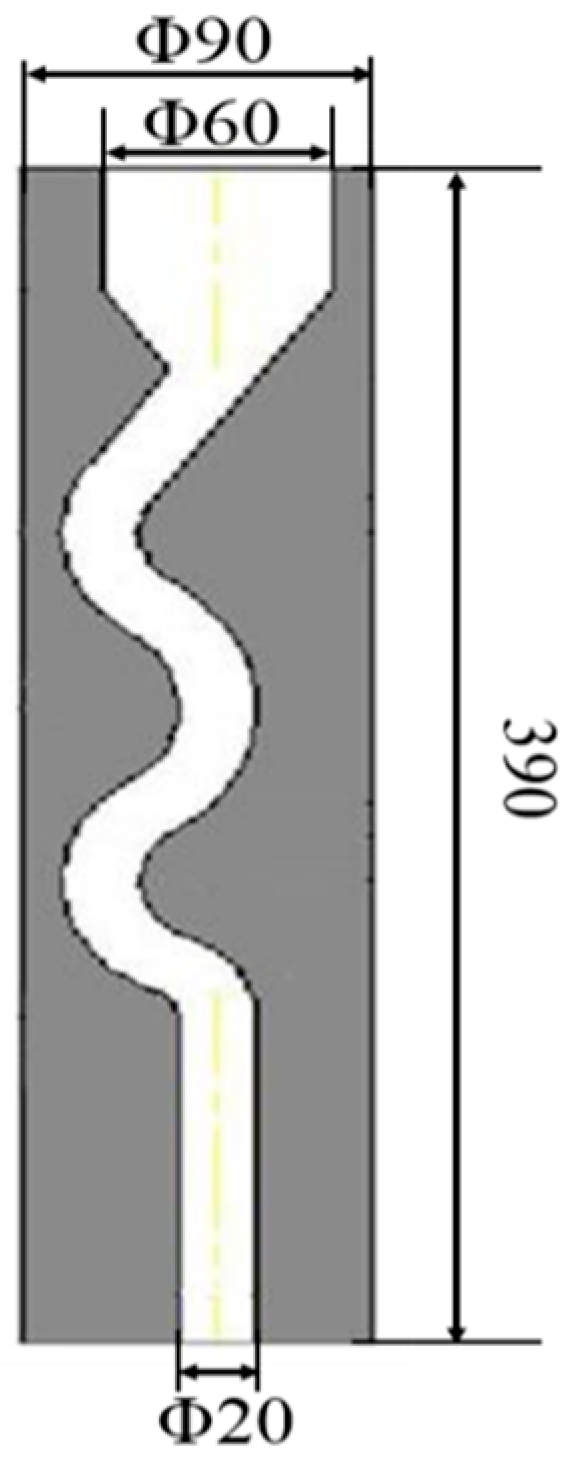

2.2. Rheocasting Process

2.3. Microstructure Analysis

2.4. Hardness and Wear Tests

3. Results and Discussion

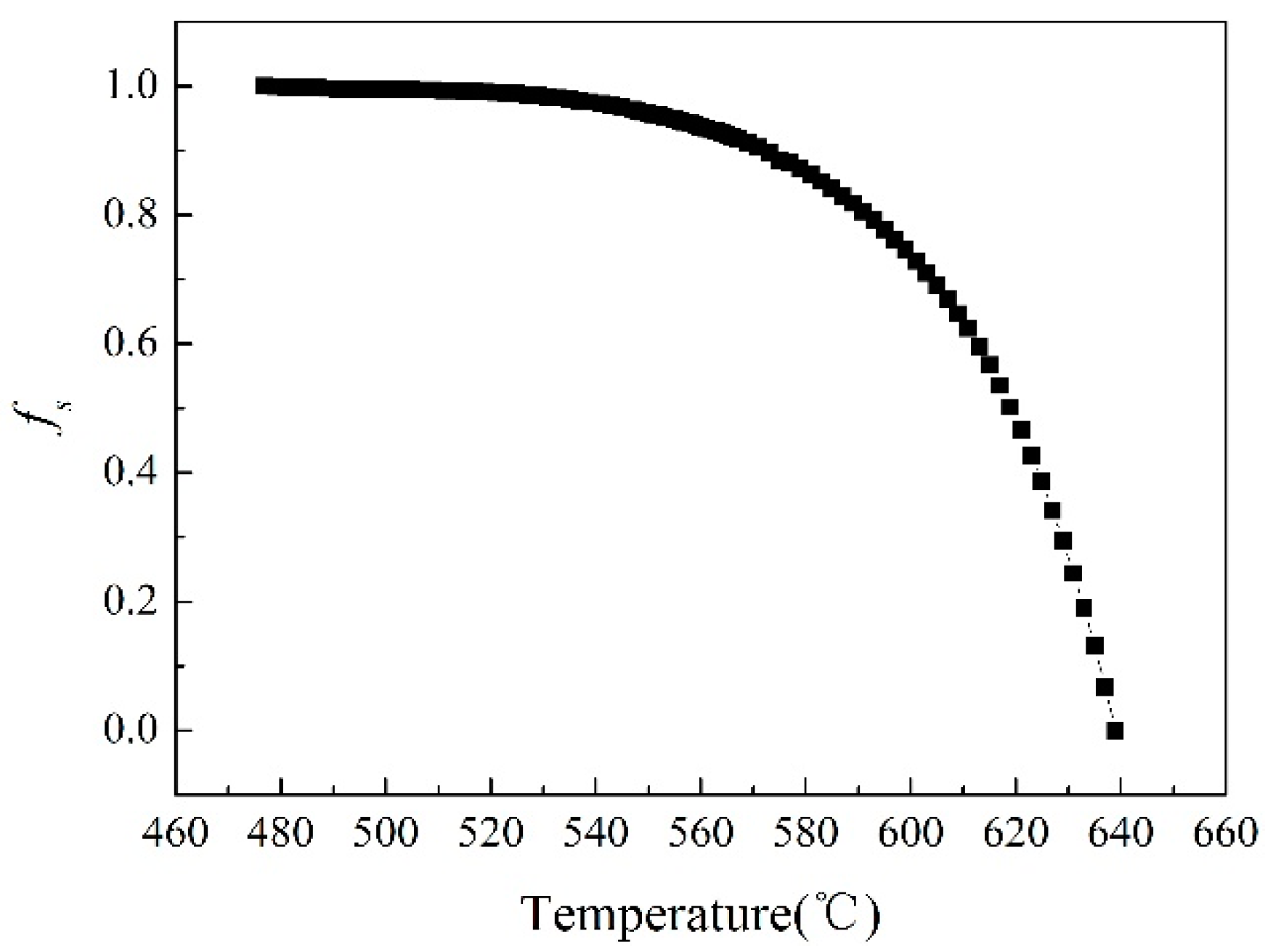

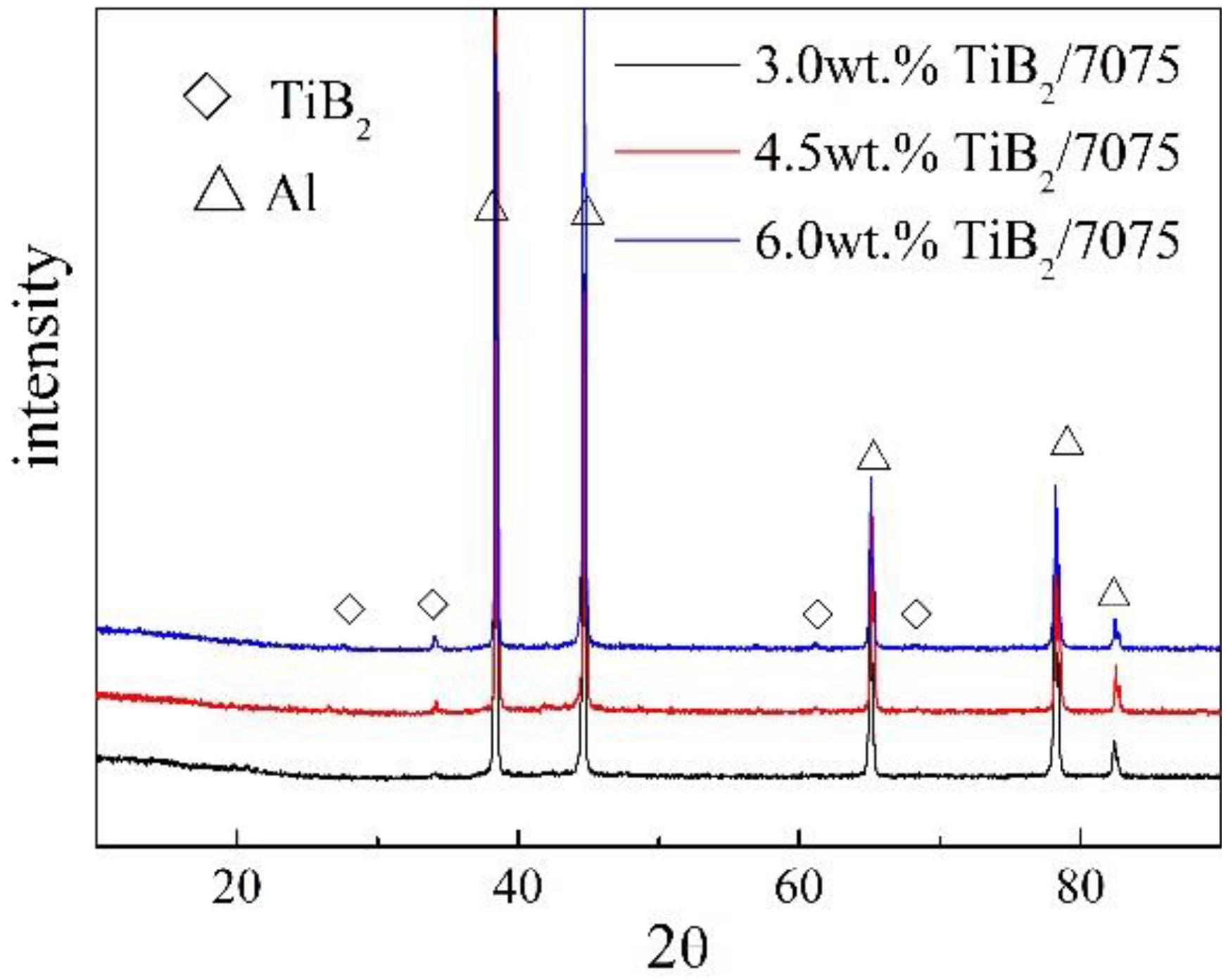

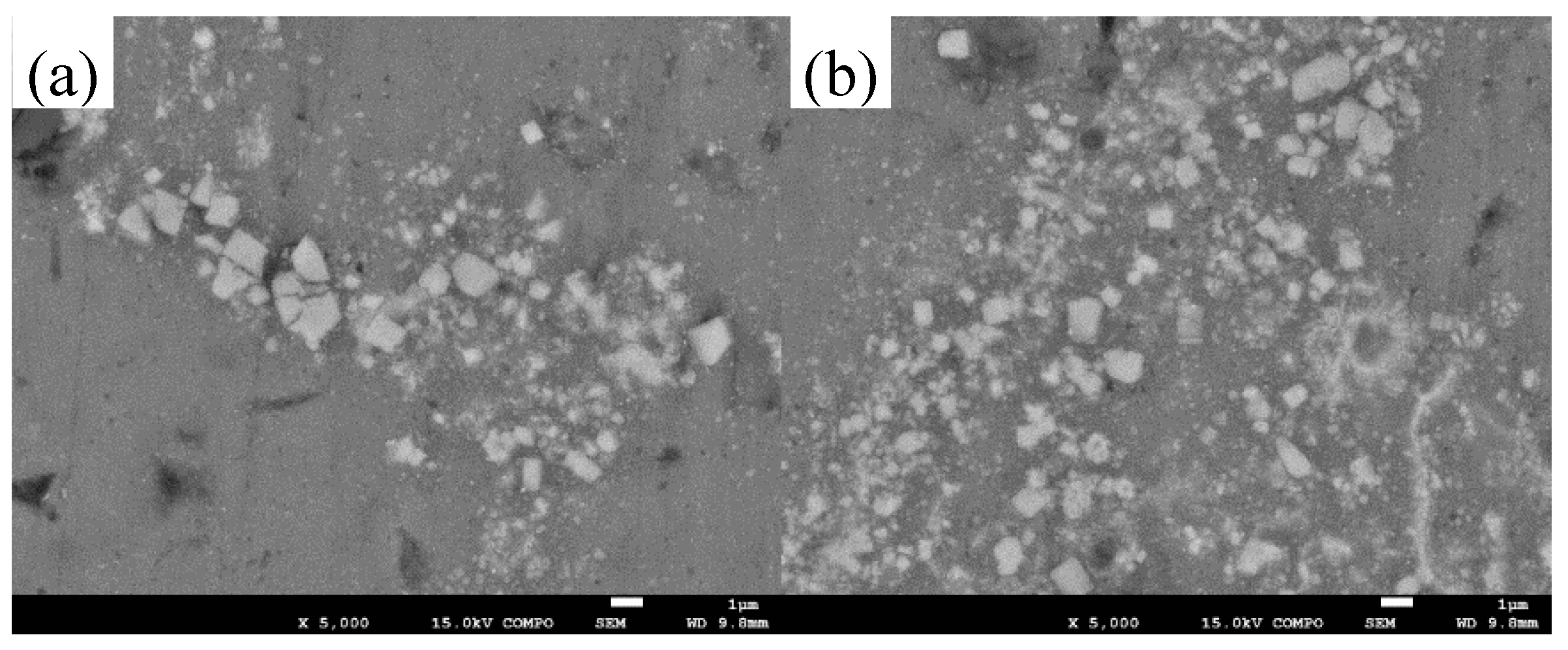

3.1. Processing of Cast In Situ TiB2/7075 Composite

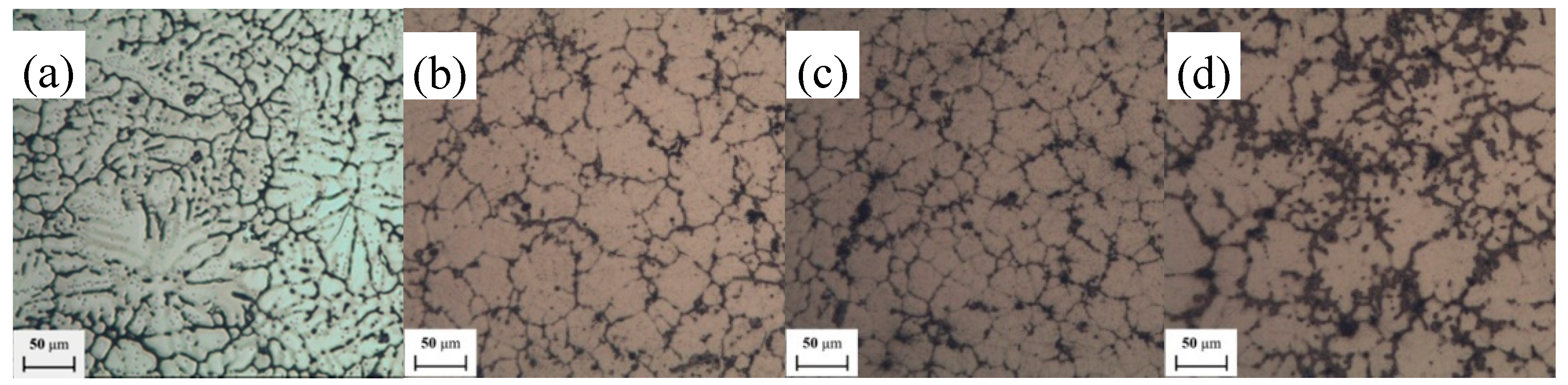

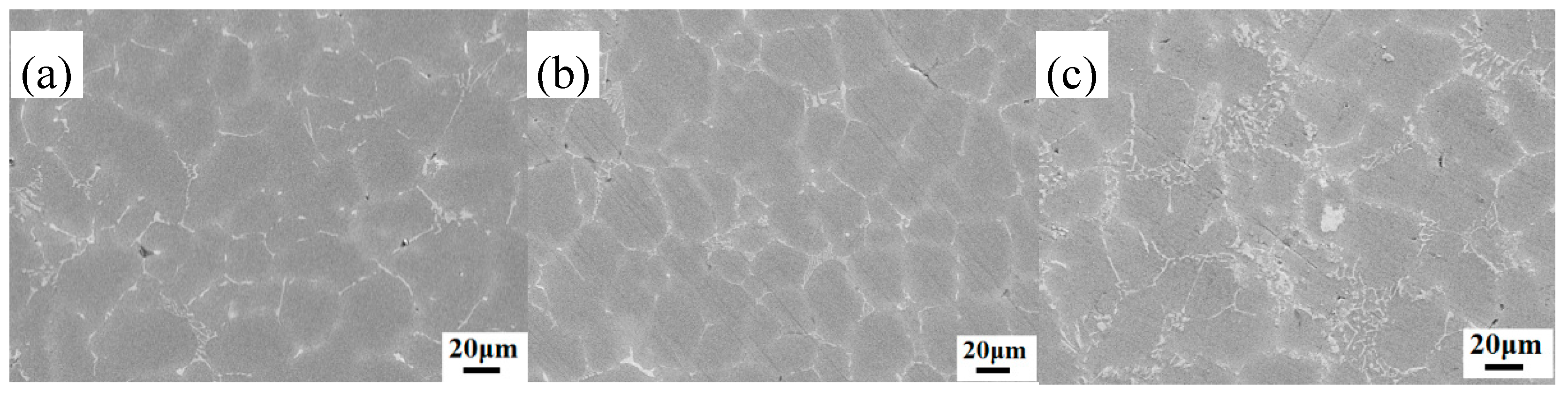

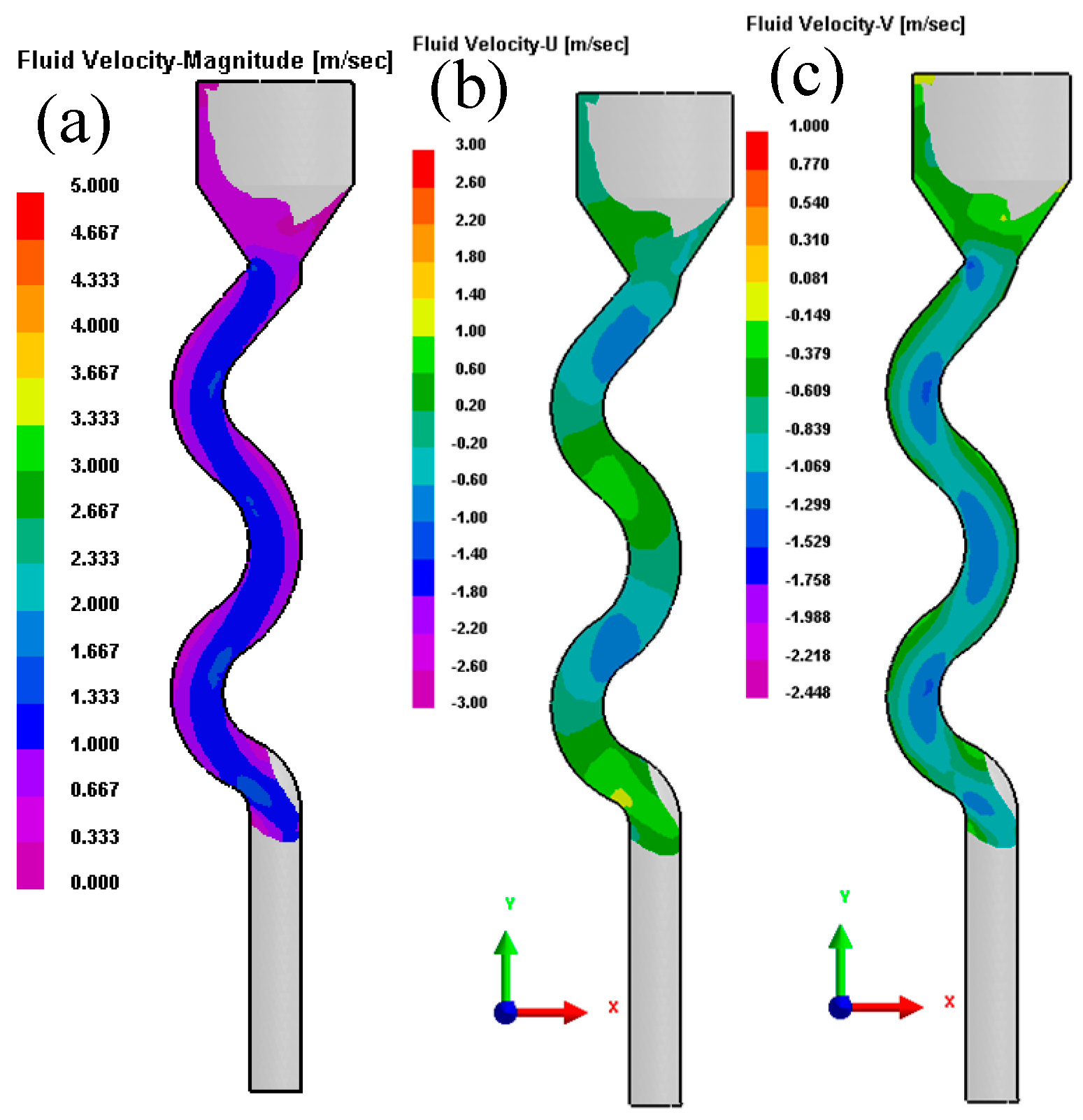

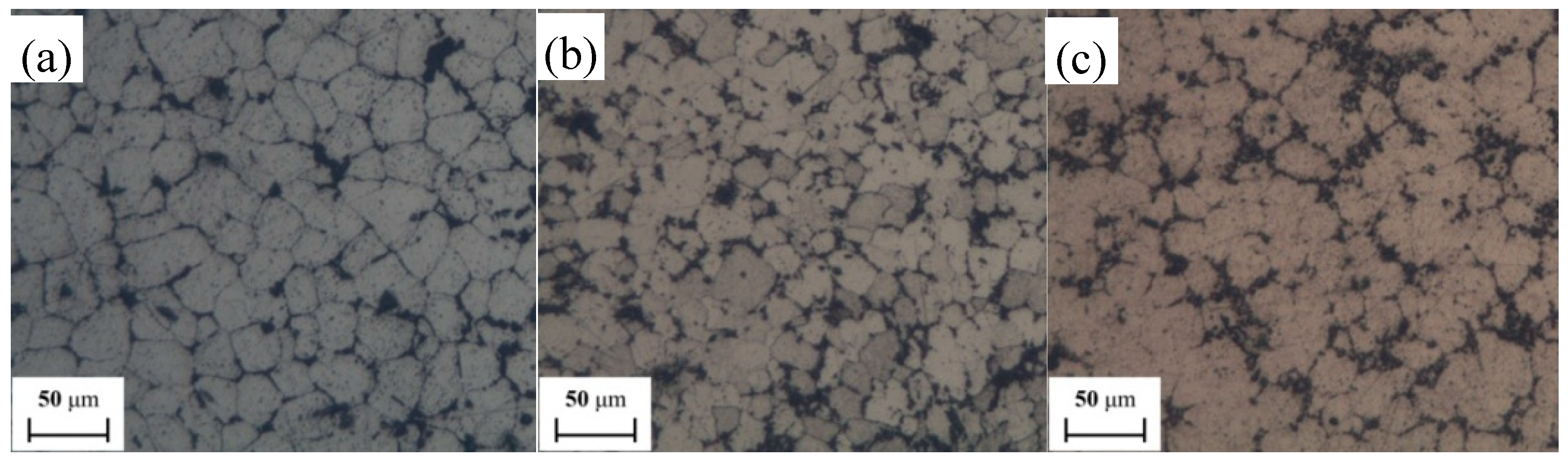

3.2. Rheocasting of TiB2/7075 Composite

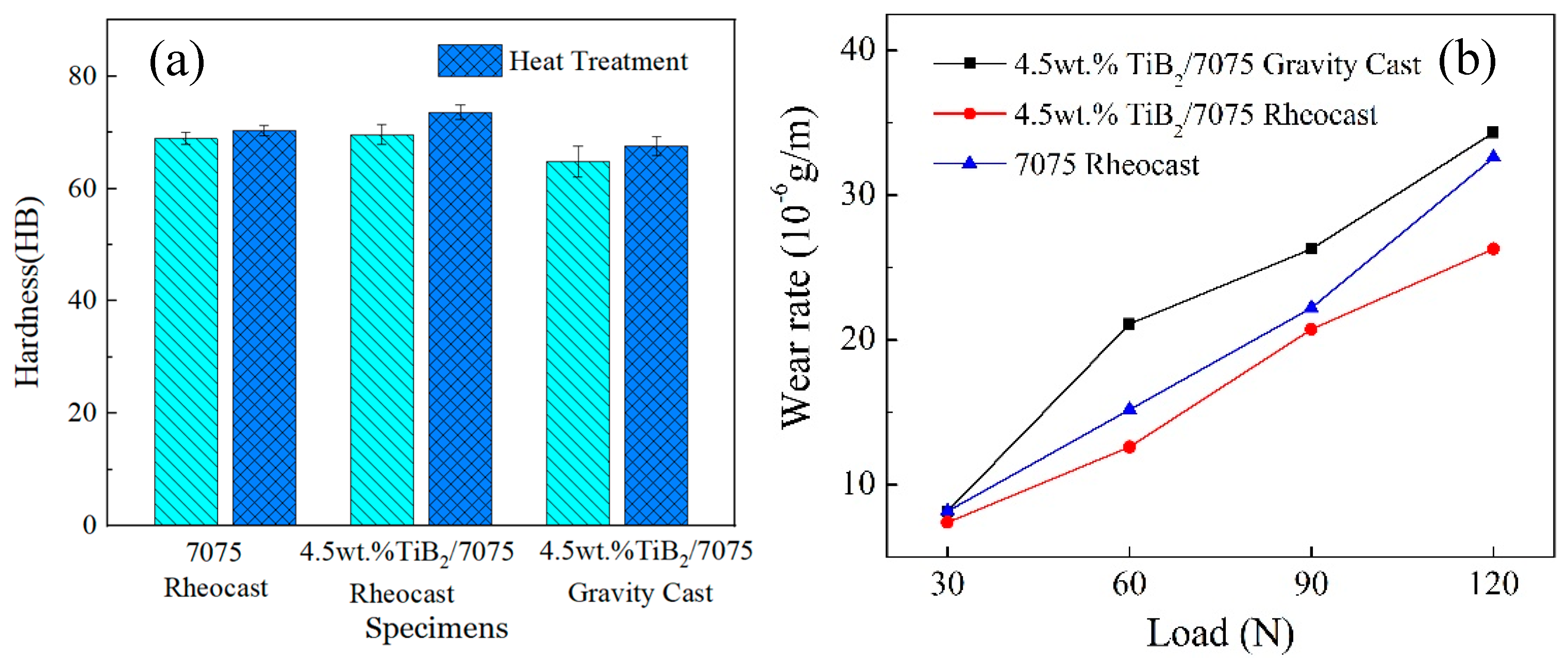

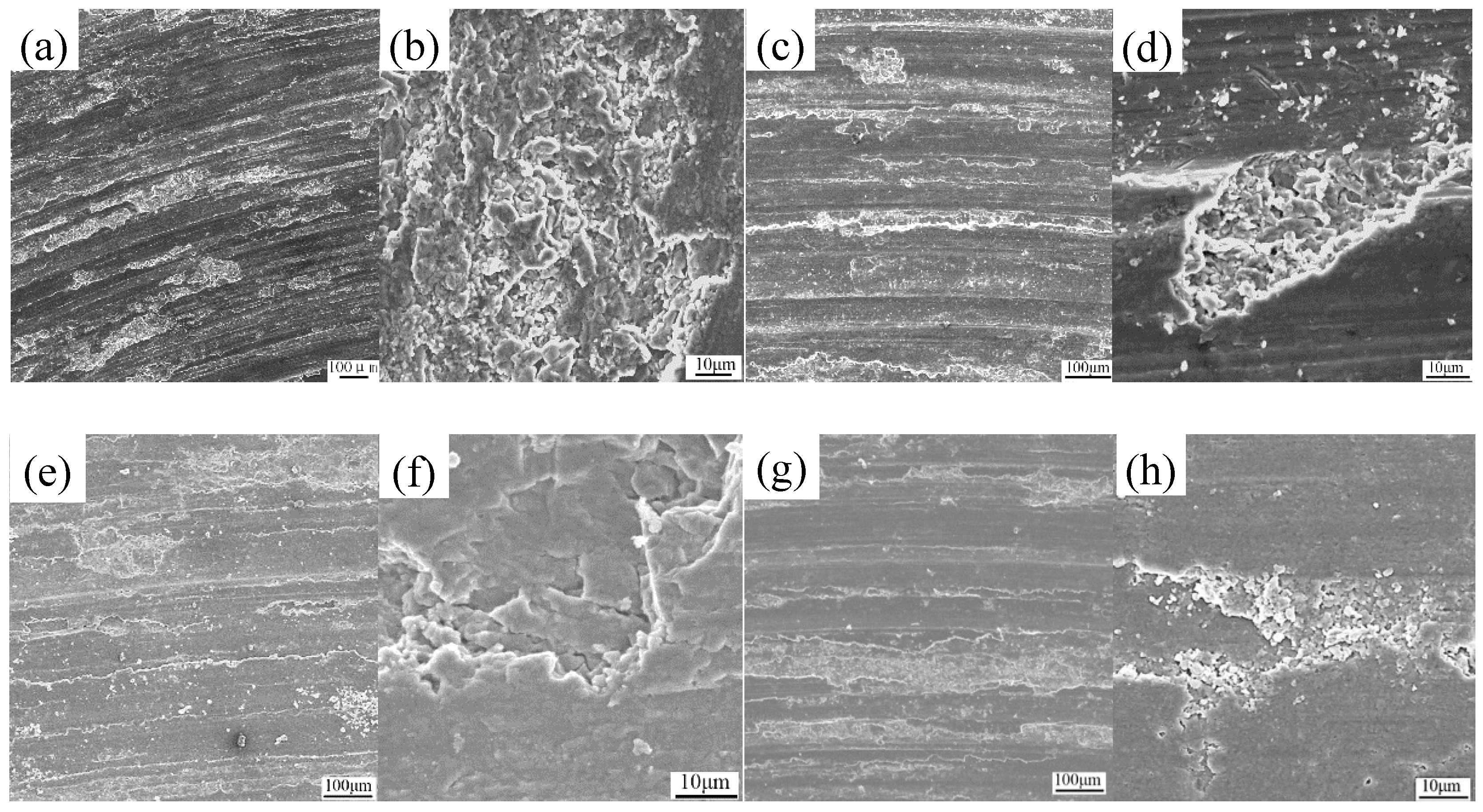

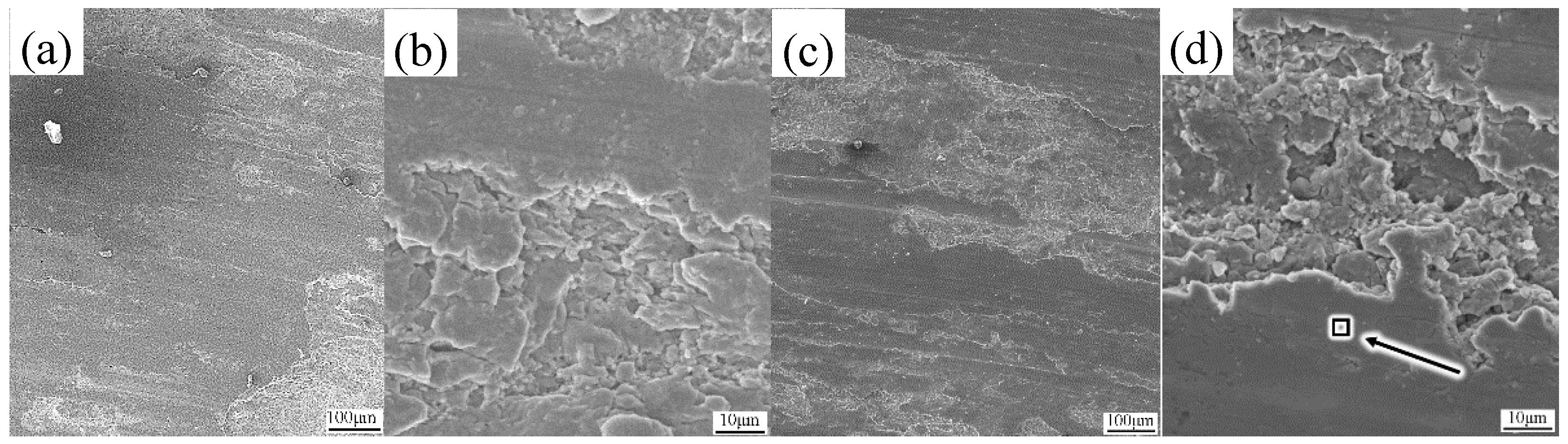

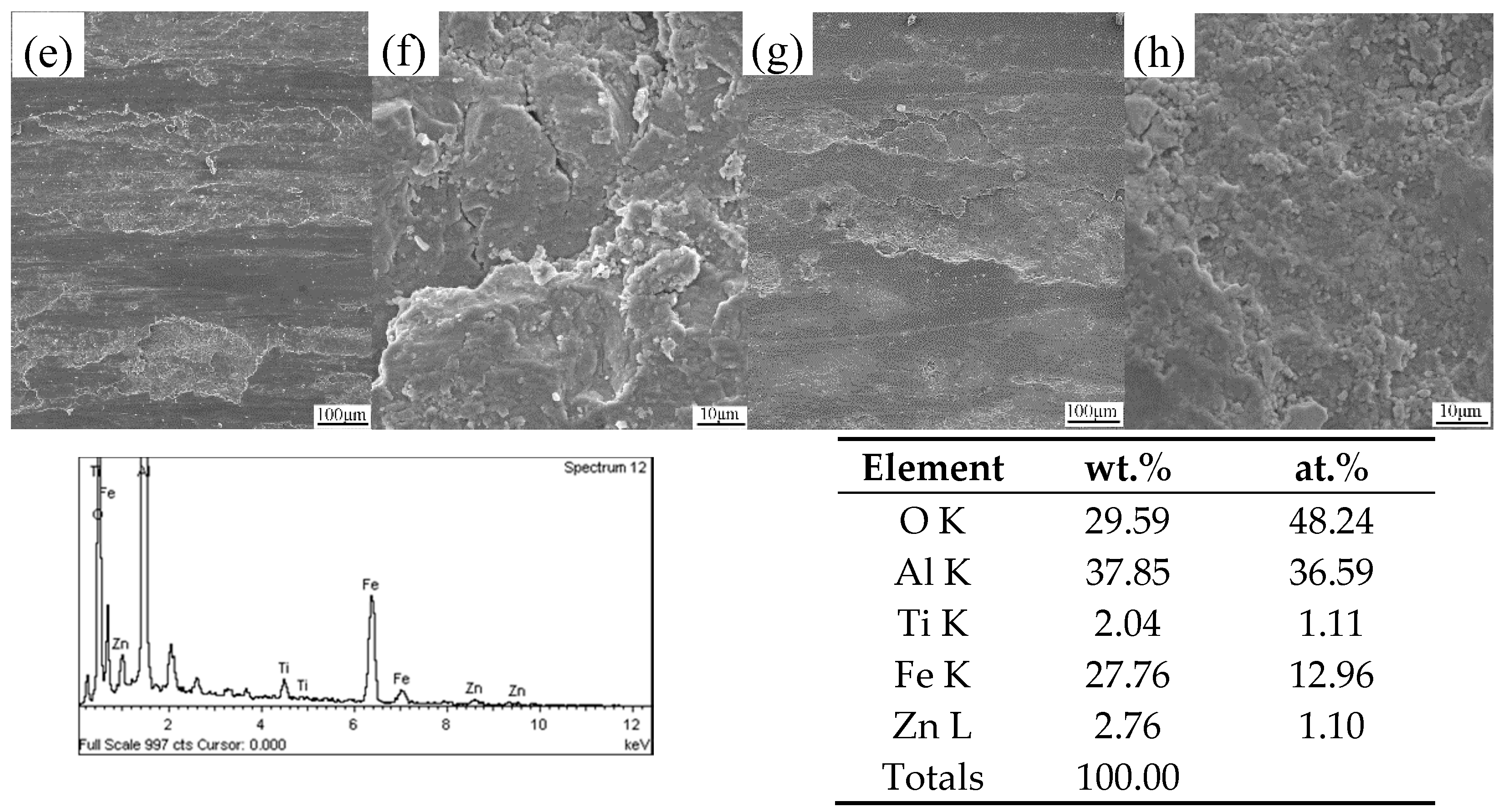

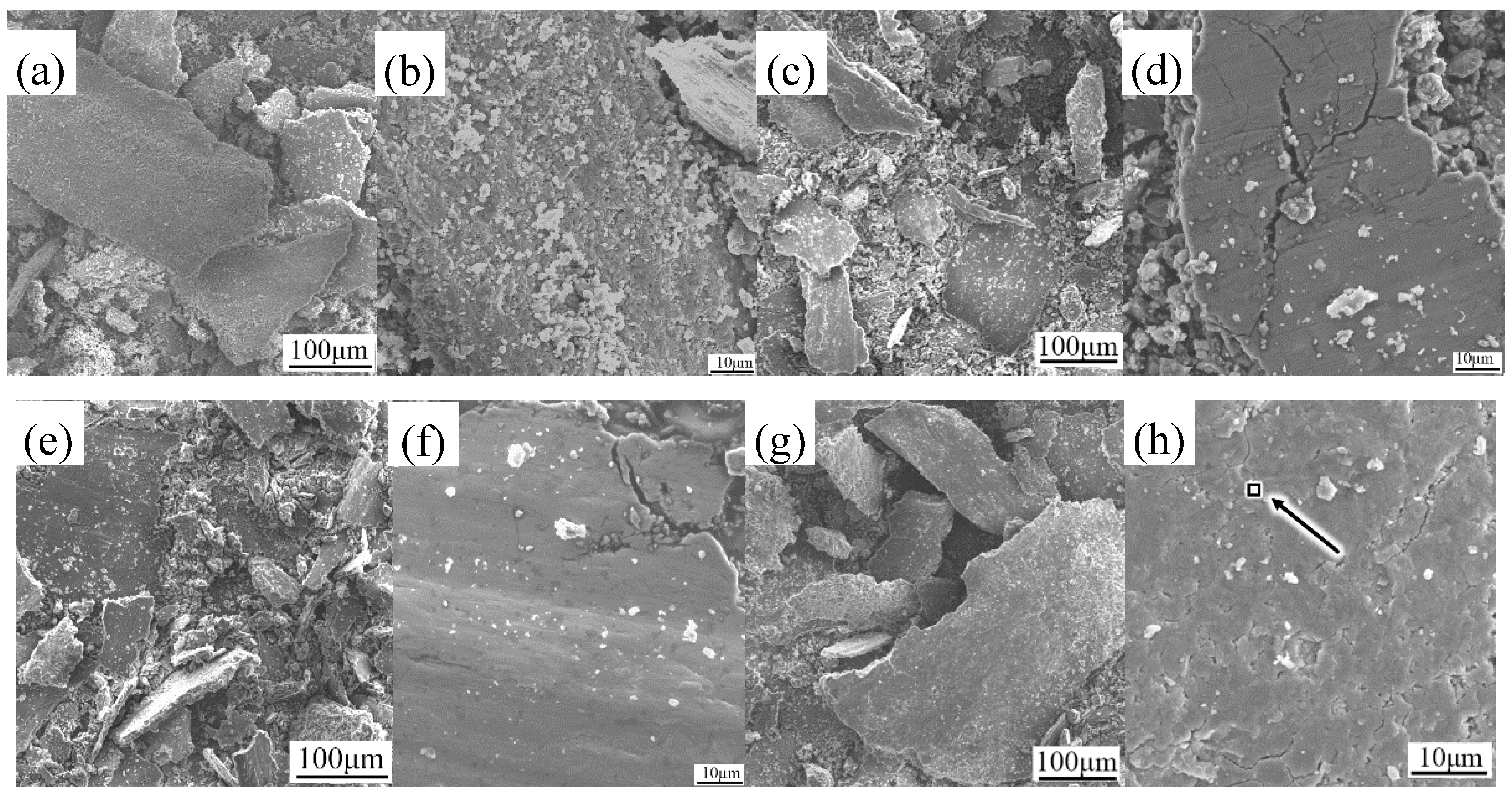

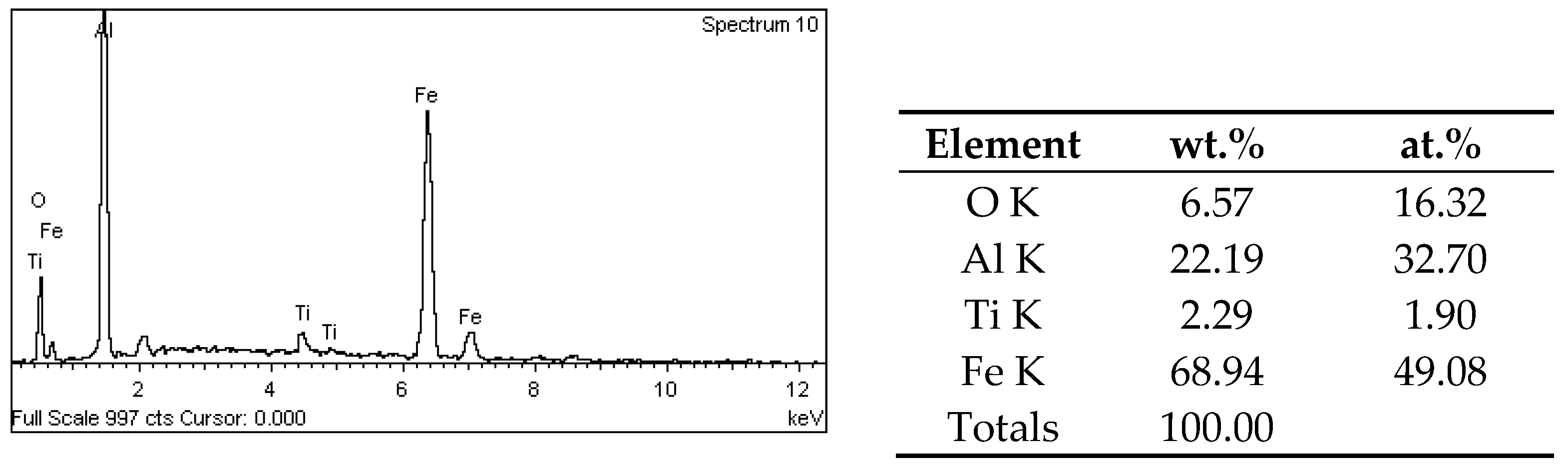

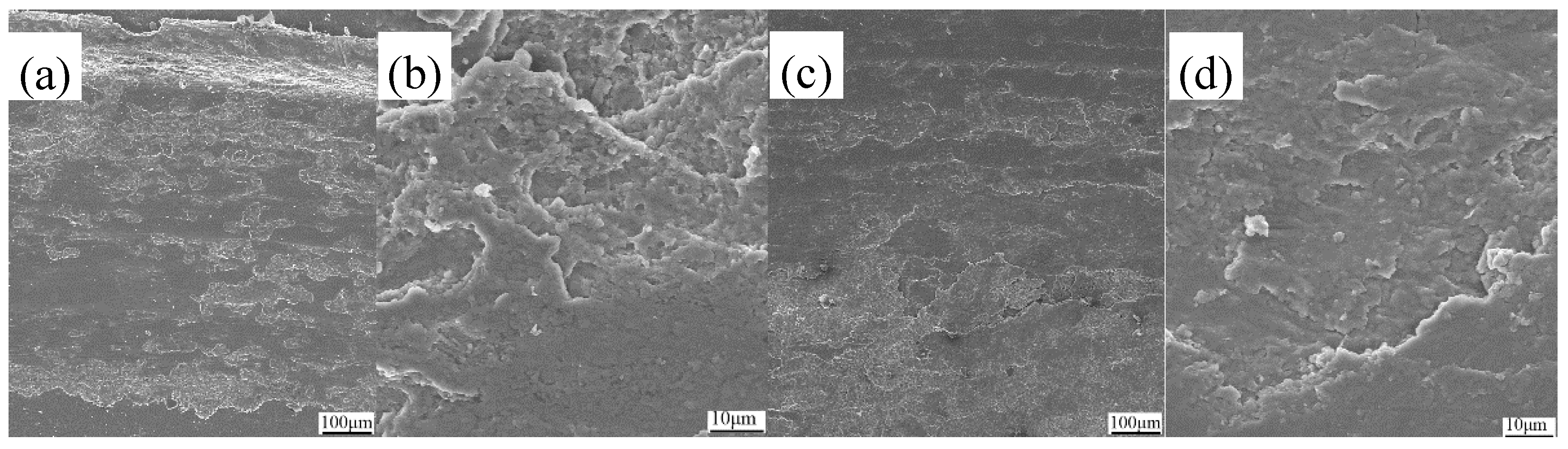

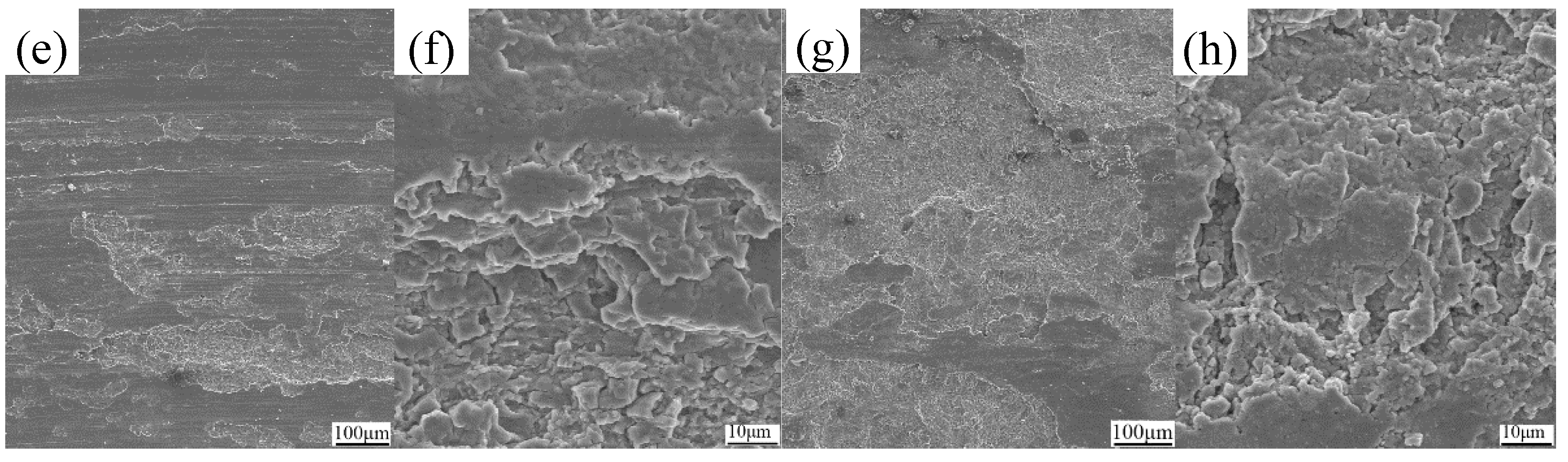

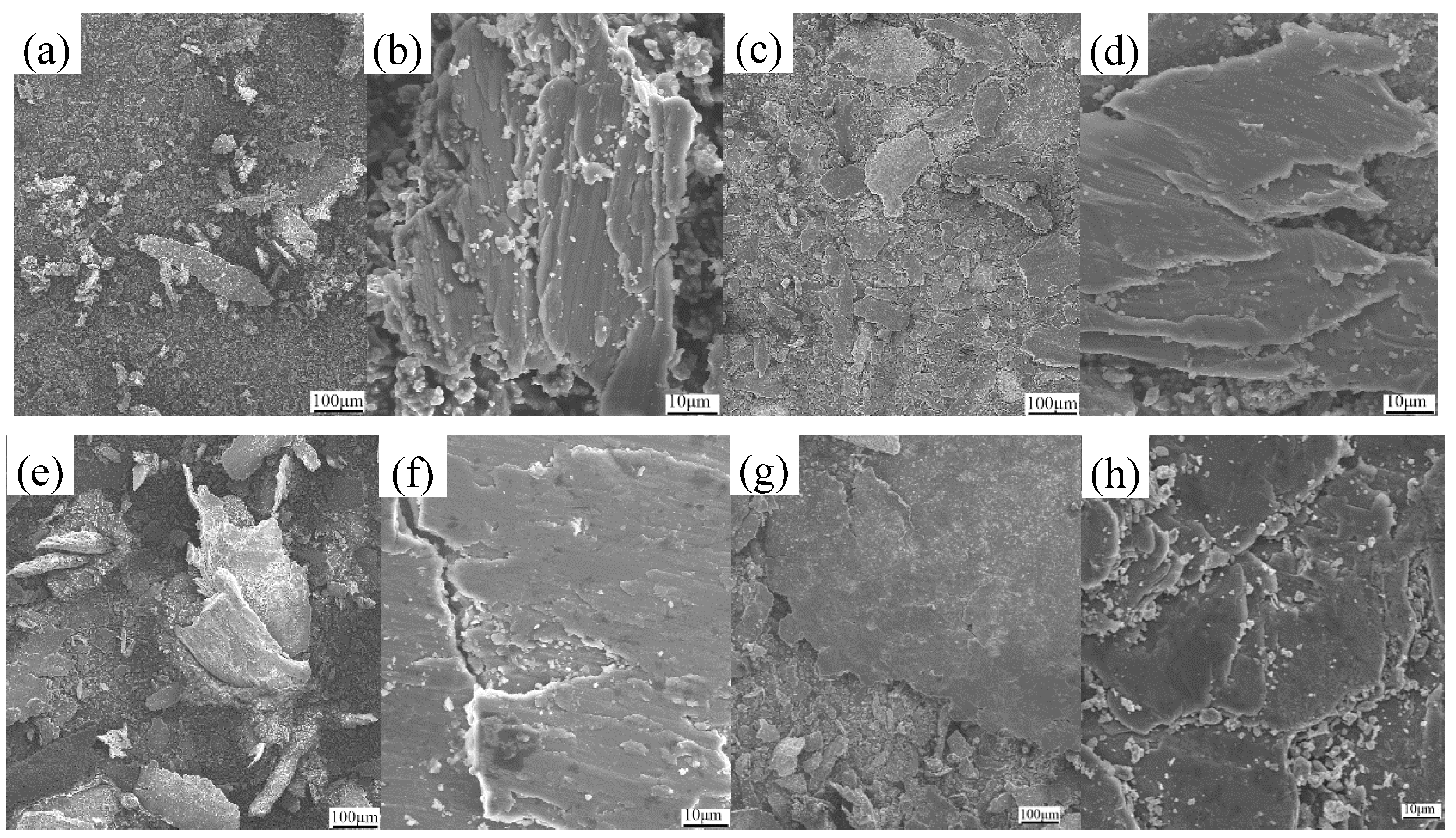

3.3. Wear Resistance

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Spencer, D.B.; Mehrabian, R.; Flemings, M.C. Rheological behavior of Sn-15 pct Pb in the crystallization range. Metall. Trans. 1972, 3, 1925–1932. [Google Scholar] [CrossRef]

- Atkinson, H.V. Modelling the semisolid processing of metallic alloys. Prog. Mater Sci. 2005, 50, 341–412. [Google Scholar] [CrossRef]

- Roh, J.S.; Heo, M.; Jin, C.K.; Park, J.H.; Kan, C.G. Effect of current input method on A356 microstructure in electromagnetically stirred process. Metals 2020, 10, 460. [Google Scholar] [CrossRef]

- Li, L.F.; Li, D.Q.; Feng, J.; Zhang, Y.Z.; Kang, Y.L. Effect of cooling rates on the microstructure and mechanical property of La modified Al7SiMg alloys processed by gravity die casting and semi-solid die casting. Metals 2020, 10, 549. [Google Scholar] [CrossRef]

- Bai, Y.L.; Xu, J.; Zhang, Z.F.; Shi, L.K. Annulus electromagnetic stirring for preparing semisolid A357 aluminum alloy slurry. Trans. Nonferrous Met. Soc. China 2009, 19, 1104–1109. [Google Scholar] [CrossRef]

- Li, G.; Lu, H.X.; Hu, X.G.; Lin, F.; Li, X.W.; Zhu, Q. Current progress in rheoforming of wrought aluminum alloys: A review. Metals 2020, 10, 238. [Google Scholar] [CrossRef]

- Chayong, S.; Atkinson, H.V.; Kapranos, P. Thixoforming 7075 aluminium alloys. Mater. Sci. Eng. A 2005, 390, 3–12. [Google Scholar] [CrossRef]

- Rokni, M.R.; Zarei-Hanzaki, A.; Abedi, H.R.; Haghdadi, N. Microstructure evolution and mechanical properties of backward thixoextruded 7075 aluminum alloy. Mater. Des. 2012, 36, 557–563. [Google Scholar] [CrossRef]

- Guo, H.M.; Yang, X.J.; Wang, J.X.; Hu, B.; Zhu, G.L. Effects of rheoforming on microstructures and mechanical properties of 7075 wrought aluminum alloy. Trans. Nonferrous Met. Soc. China 2010, 20, 355–360. [Google Scholar] [CrossRef]

- Chen, Z.Z.; Mao, W.M.; Wu, Z.C. Mechanical properties and microstructures of Al alloy tensile samples produced by serpentine channel pouring rheo-diecasting process. Trans. Nonferrous Met. Soc. China 2011, 21, 1473–1479. [Google Scholar] [CrossRef]

- Chen, Z.Z.; Mao, W.M.; Wu, Z. Preparation of semi-solid aluminum alloy slurry poured through a water-cooled serpentine channel. Int. J. Miner. Metall. Mater. 2012, 19, 48–53. [Google Scholar] [CrossRef]

- Rogal, Ł.; Dutkiewics, J.; Atkinson, H.V. Characterization of semi-solid processing of aluminium alloy 7075 with Sc and Zr additions. Mater. Sci. Eng. A 2013, 580, 362–373. [Google Scholar] [CrossRef]

- Curle, U.A.; Govender, G. Semi-solid rheocasting of grain refined aluminum alloy 7075. Trans. Nonferrous Met. Soc. China 2010, 20, 832–836. [Google Scholar] [CrossRef]

- Mazahery, A.; Shabani, M.O. Characterization of cast A356 alloy reinforced with nano SiC composites. Trans. Nonferrous Met. Soc. China 2012, 22, 275–280. [Google Scholar] [CrossRef]

- Jiang, J.F.; Wang, Y. Microstructure and mechanical properties of the semisolid slurries and rheoformed component of nano-sized SiC/7075 aluminum matrix composite prepared by ultrasonic-assisted semisolid stirring. Mater. Sci. Eng. A 2015, 639, 350–358. [Google Scholar] [CrossRef]

- Sajjadi, S.A.; Ezatpour, H.R.; Torabi Parizi, M. Comparison of microstructure and mechanical properties of A356 aluminum alloy/Al2O3 composites fabricated by stir and compo-casting processes. Mater. Des. 2012, 34, 106–111. [Google Scholar] [CrossRef]

- Yang, B.; Gan, G.S.; Yang, L.; Sun, M.; Zhang, H.B.; Fang, Z.Z. Microstructural characterization and wear behavior of in situ TiC/7075 composites synthesized by displacement reactions and spray forming. Mater. Sci. Eng. A 2011, 528, 5649–5655. [Google Scholar] [CrossRef]

- Atkinson, H.V.; Liu, D. Microstructural coarsening of semi-solid aluminum alloys. Mater. Sci. Eng. A 2008, 496, 439–466. [Google Scholar] [CrossRef]

- Manson-Whitton, E.D.; Stone, I.C.; Jones, J.R.; Grant, P.S.; Cantor, B. Isothermal grain coarsening of spray formed alloys in the semi-solid state. Acta Mater. 2002, 50, 2517–2535. [Google Scholar] [CrossRef]

- Jiang, J.F.; Wang, Y.; Nie, X.; Xiao, G.F. Microstructure evolution of semisolid billet of nano-sized SiCP/7075 aluminum matrix composite during partial remelting process. Mater. Des. 2016, 96, 36–43. [Google Scholar] [CrossRef]

- Mandal, A.; Murty, B.S.; Chakraborty, M. Sliding wear behaviour of T6 treated A356-TiB2 in-situ composites. Wear 2009, 266, 865–872. [Google Scholar] [CrossRef]

- Mallikarjuna, C.; Shashidhara, S.M.; Mallik, U.S.; Parashivamurthy, K.I. Grain refinement and wear properties evaluation of aluminum alloy 2014 matrix-TiB2 in-situ composites. Mater. Des. 2011, 32, 3554–3559. [Google Scholar] [CrossRef]

- Liu, X.B.; Yang, M.; Zhou, D.K.; Zhao, Y.G. Microstructure and wear resistance of Mg2Si–Al composites fabricated using semi-solid extrusion. Metals 2020, 10, 596. [Google Scholar] [CrossRef]

- Tjong, S.C.; Ma, Z.Y. Microstructural and mechanical characteristics of in situ metal matrix composites. Mater. Sci. Eng. R 2000, 29, 49–113. [Google Scholar] [CrossRef]

- Guan, R.G.; Zhao, Z.Y.; Li, Y.D.; Chen, T.J.; Xu, S.X.; Qi, P.X. Microstructure and properties of squeeze cast A356 alloy processed with a vibrating slope. J. Mater. Process. Technol. 2016, 229, 514–519. [Google Scholar] [CrossRef]

- Zhu, W.; Mao, W.; Tu, Q. Preparation of semi-solid 7075 aluminum alloy slurry by serpentine pouring channel. Trans. Nonferrous Met. Soc. China 2014, 24, 954–960. [Google Scholar] [CrossRef]

- Mohanty, P.S.; Gruzleski, J.E. Mechanism of grain refinement in aluminum. Acta Metall. Mater. 1995, 43, 2001–2012. [Google Scholar] [CrossRef]

- Lu, L.; Lai, M.O.; Chen, F.L. Al-4 wt% Cu Composite reinforced with in-situ TiB2 particles. Acta Mate. 1997, 45, 4297–4309. [Google Scholar] [CrossRef]

- Atsumi, O. Solidification: The Separation Theory and Its Practical Applications; Springer: Berlin, Germany, 1987. [Google Scholar]

- Diler, E.A.; Ipek, R. Main and interaction effects of matrix particle size, reinforcement particle size and volume fraction on wear characteristics of Al-SiCp composites using central composite design. Compos. Part B 2013, 50, 371–380. [Google Scholar] [CrossRef]

- Alipour, M.; Aghdam, B.G.; Rahnoma, H.E.; Emamy, M. Investigation of the effect of Al-5Ti-1B grain refiner on dry sliding wear behavior of an Al-Zn-Mg-Cu alloy formed by strain-induced melt activation process. Mater. Des. 2013, 46, 766–775. [Google Scholar] [CrossRef]

- Siddhalingeshwar, I.G.; Deepthi, D.; Chakraborty, M.; Mitra, R. Sliding wear behavior of in situ Al-4.5Cu-5TiB2 composite processed by single and multiple roll passes in mushy state. Wear 2011, 271, 748–759. [Google Scholar]

- Tjong, S.C.; Lau, K.C. Properties and abrasive wear of TiB2/Al-4%Cu composites produced by hot isostatic pressing. Compos. Sci. Technol. 1999, 59, 2005–2013. [Google Scholar] [CrossRef]

- Abdelgnei, M.A.; Omar, M.Z.; Ghazali, M.J.; Mohammed, M.N.; Rashid, B. Dry sliding wear behaviour of thixoformed Al-5.7Si–2Cu-0.3 Mg alloys at high temperatures using Taguchi method. Wear 2020, 442–443, 203134. [Google Scholar] [CrossRef]

- Yadav, D.K.; Chakrabarty, I. Effect of cooling slope casting and partial remelting treatment on microstructure and mechanical properties of A319-xMg2Si In-Situ composites. Mater. Sci. Eng. A 2020, 791, 139790. [Google Scholar] [CrossRef]

- Wen, S.Z.; Huang, P. Principles of Tribological; Tsinghua University Press: Beijing, China, 2002. (In Chinese) [Google Scholar]

- Imran, M.; Anwar Khan, A.R. Characterization of Al-7075 metal matrix composites: A review. J. Mater. Res. Technol. 2019, 8, 3347–3356. [Google Scholar] [CrossRef]

- Deuis, R.L.; Subramanian, C.; Yellup, J.M. Dry sliding wear of aluminium composites-a review. Compos. Sci. Technol. 1997, 57, 415–435. [Google Scholar] [CrossRef]

| Zn | Mg | Cu | Mn | Si | Cr | Fe | Al |

|---|---|---|---|---|---|---|---|

| 5.52 | 2.36 | 1.51 | 0.15 | 0.18 | 0.25 | 0.26 | - |

| Serpentuator Temperature (°C) | Casting Temperature (°C) | ||

|---|---|---|---|

| 685 | 670 | 655 | |

| 600 | 639 | 628 | 619 |

| 400 | 630 | 624 | - |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, Q.; Yang, B.; Gan, G.; Zhong, Y.; Sun, L.; Zhai, W.; Qiang, W.; Wang, S.; Lu, Y. Microstructure and Wear Resistance of TiB2/7075 Composites Produced via Rheocasting. Metals 2020, 10, 1068. https://doi.org/10.3390/met10081068

Gao Q, Yang B, Gan G, Zhong Y, Sun L, Zhai W, Qiang W, Wang S, Lu Y. Microstructure and Wear Resistance of TiB2/7075 Composites Produced via Rheocasting. Metals. 2020; 10(8):1068. https://doi.org/10.3390/met10081068

Chicago/Turabian StyleGao, Qian, Bin Yang, Guisheng Gan, Yujie Zhong, Liang Sun, Wenyan Zhai, Wei Qiang, Shiqing Wang, and Yongxin Lu. 2020. "Microstructure and Wear Resistance of TiB2/7075 Composites Produced via Rheocasting" Metals 10, no. 8: 1068. https://doi.org/10.3390/met10081068

APA StyleGao, Q., Yang, B., Gan, G., Zhong, Y., Sun, L., Zhai, W., Qiang, W., Wang, S., & Lu, Y. (2020). Microstructure and Wear Resistance of TiB2/7075 Composites Produced via Rheocasting. Metals, 10(8), 1068. https://doi.org/10.3390/met10081068