Improvement of the Crack Propagation Resistance in an α + β Titanium Alloy with a Trimodal Microstructure

Abstract

1. Introduction

2. Experimental Program

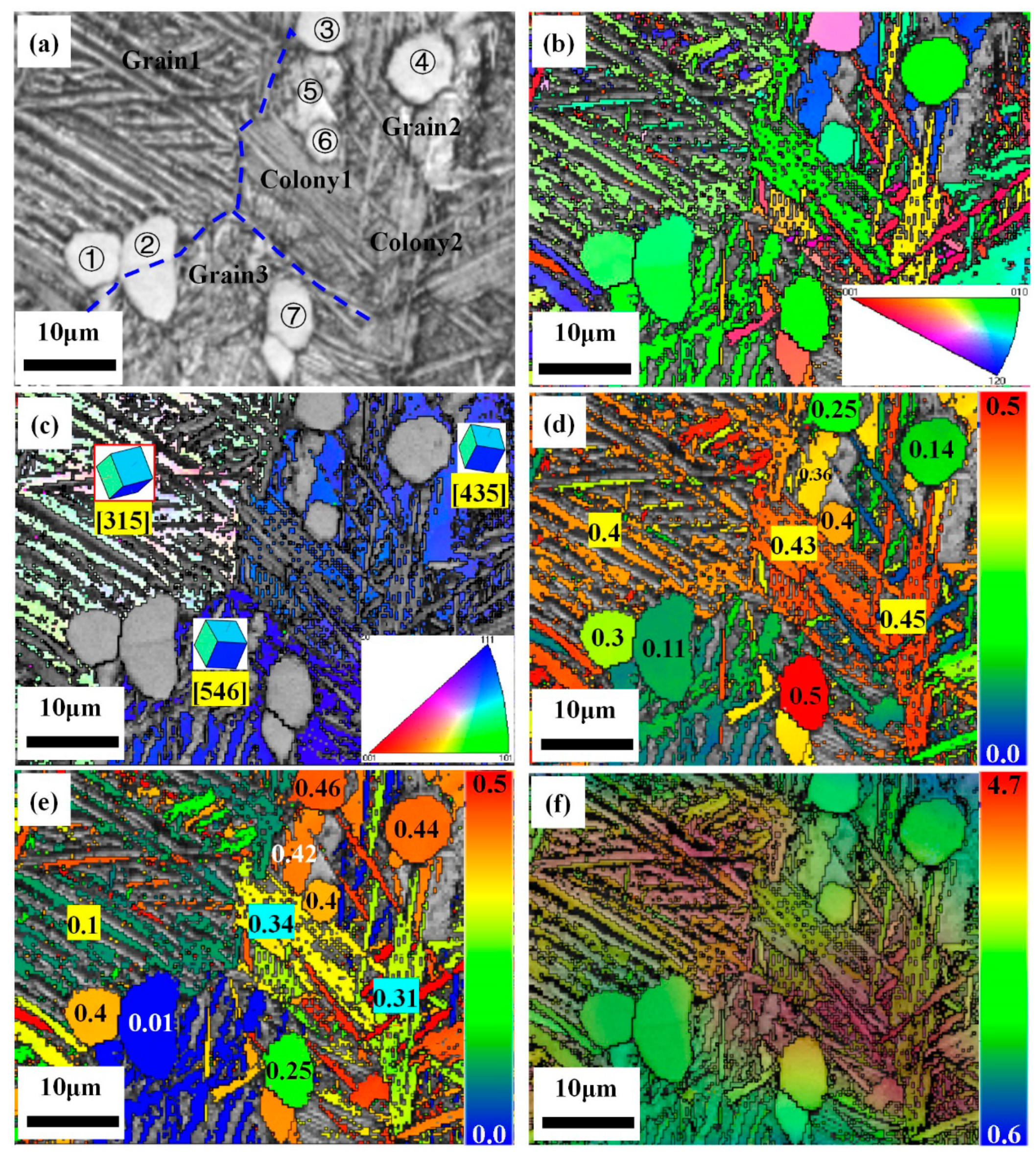

3. Results

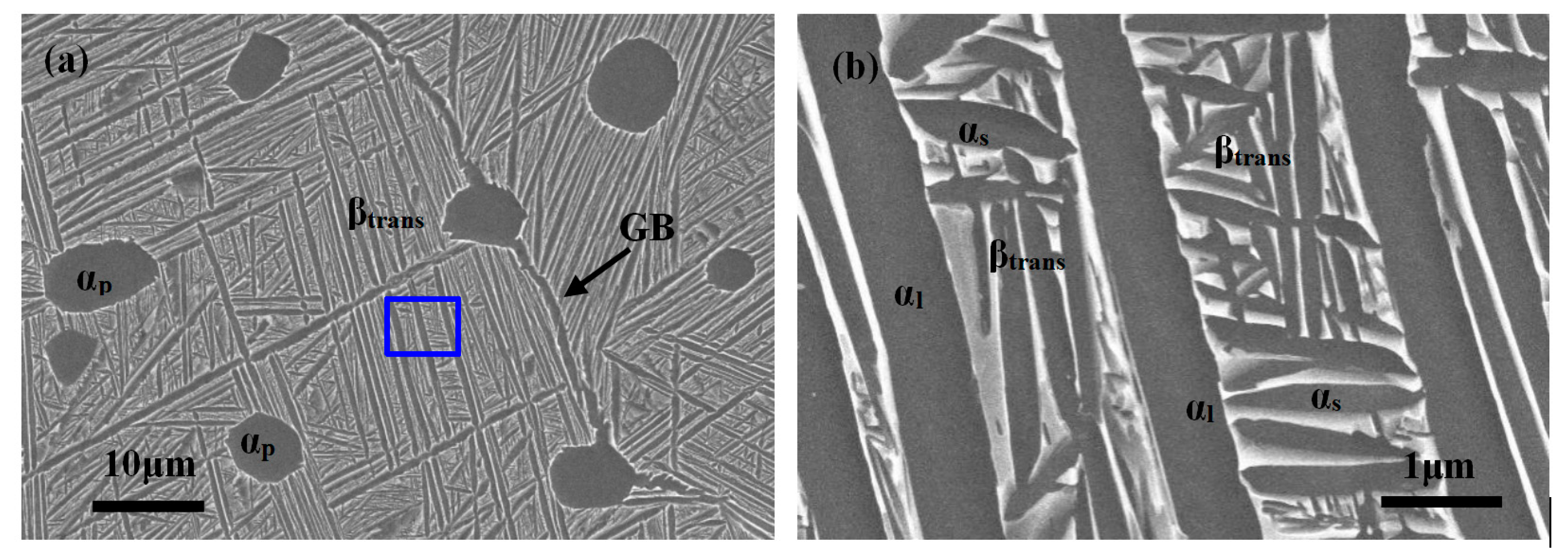

3.1. Microstructures before Deformation

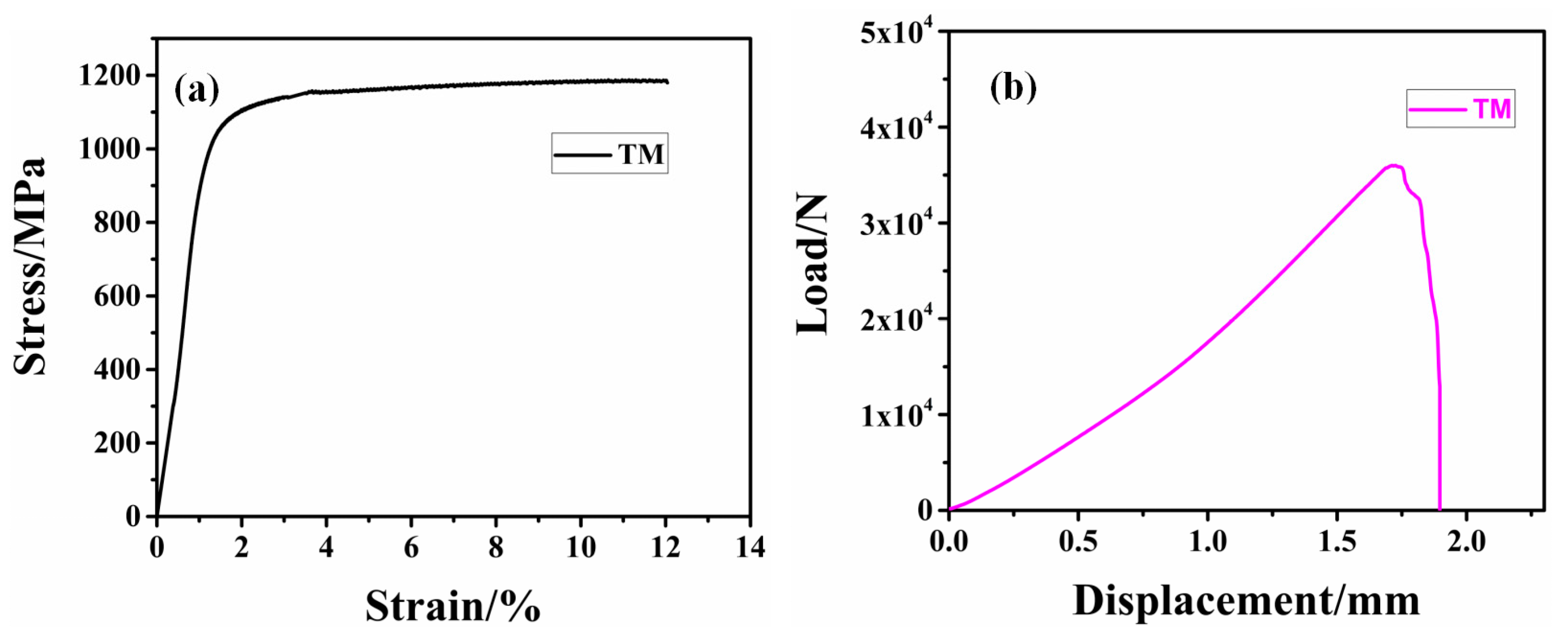

3.2. Mechanical Properties of the Alloy with a TM

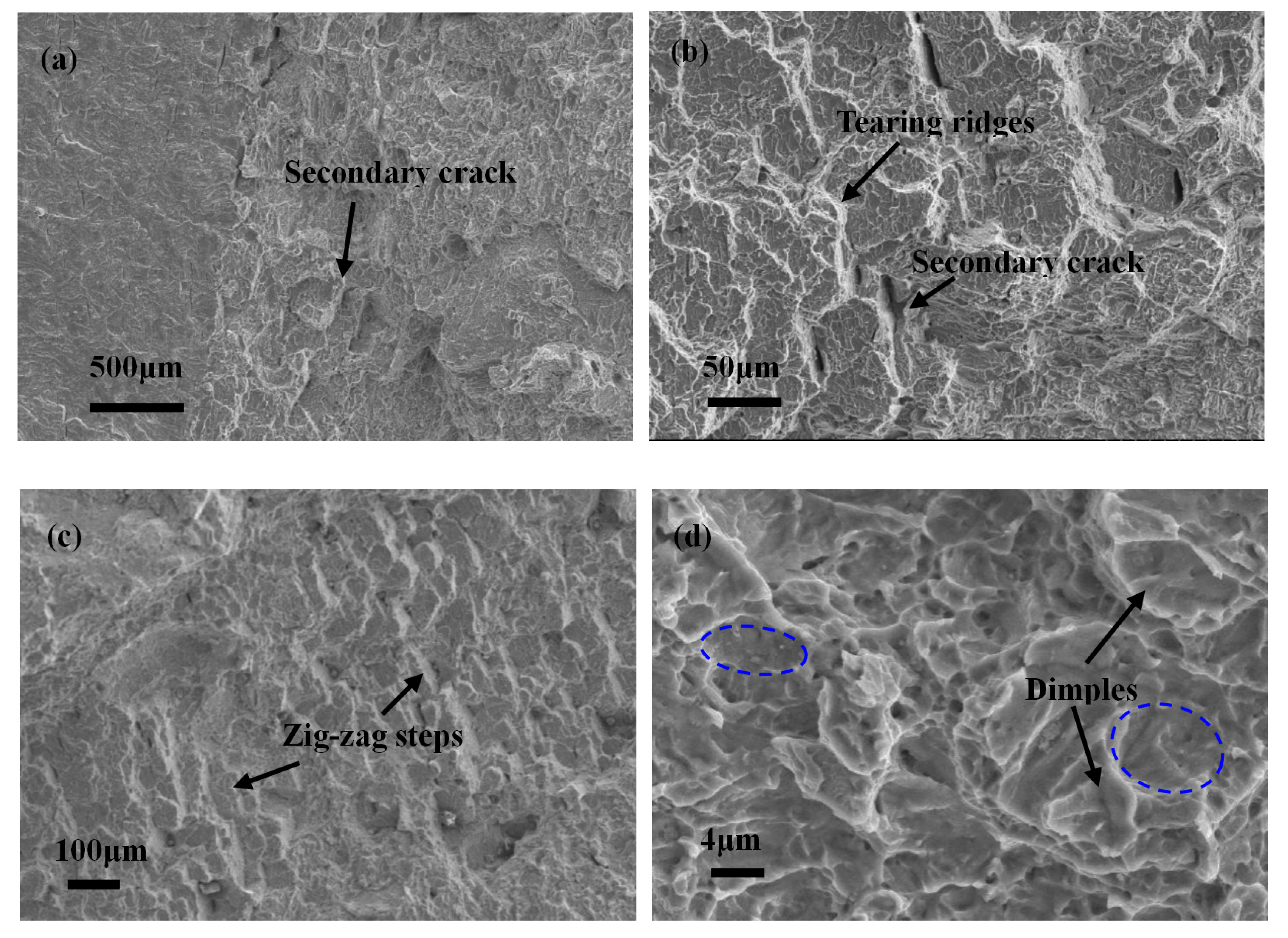

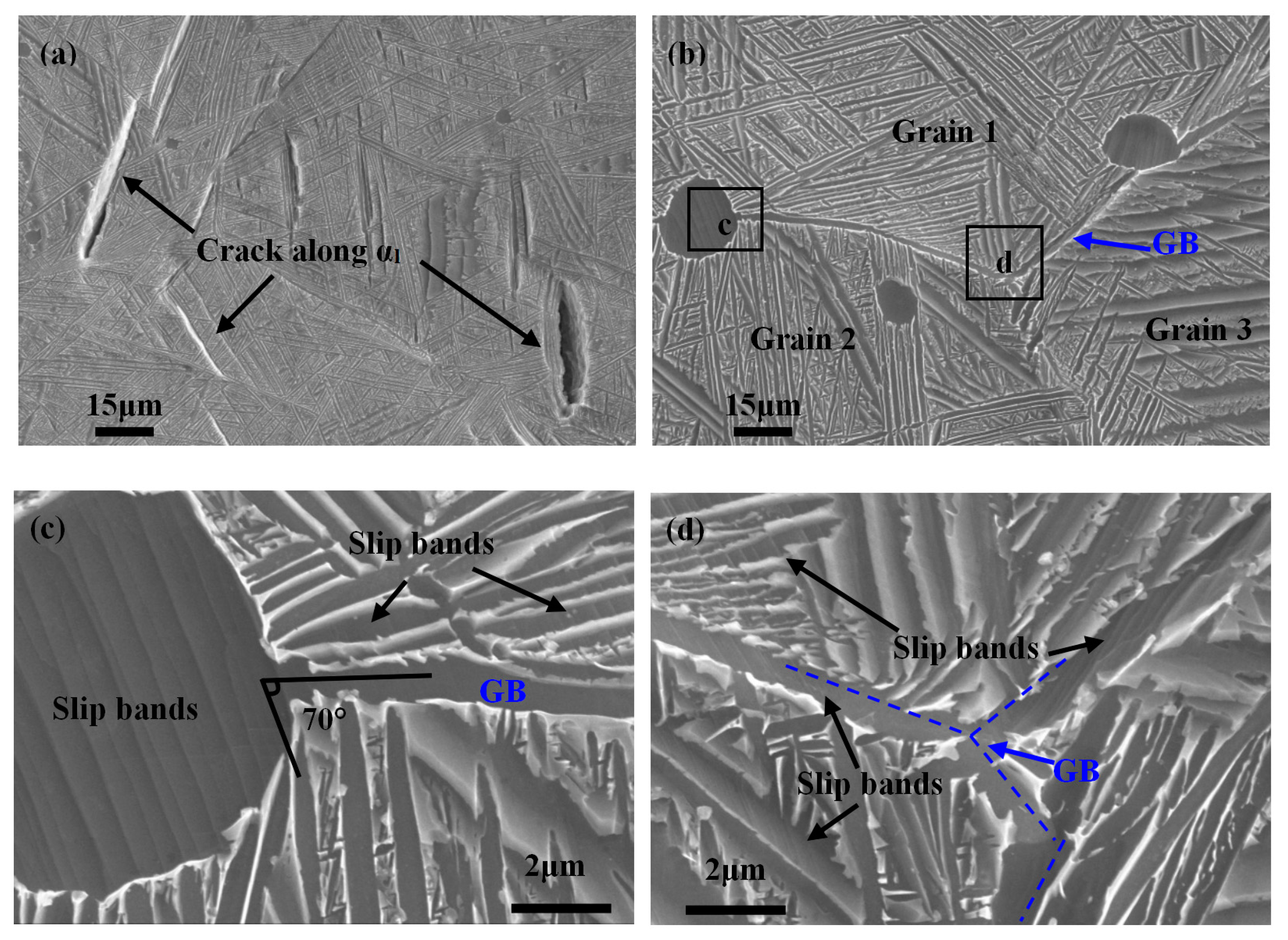

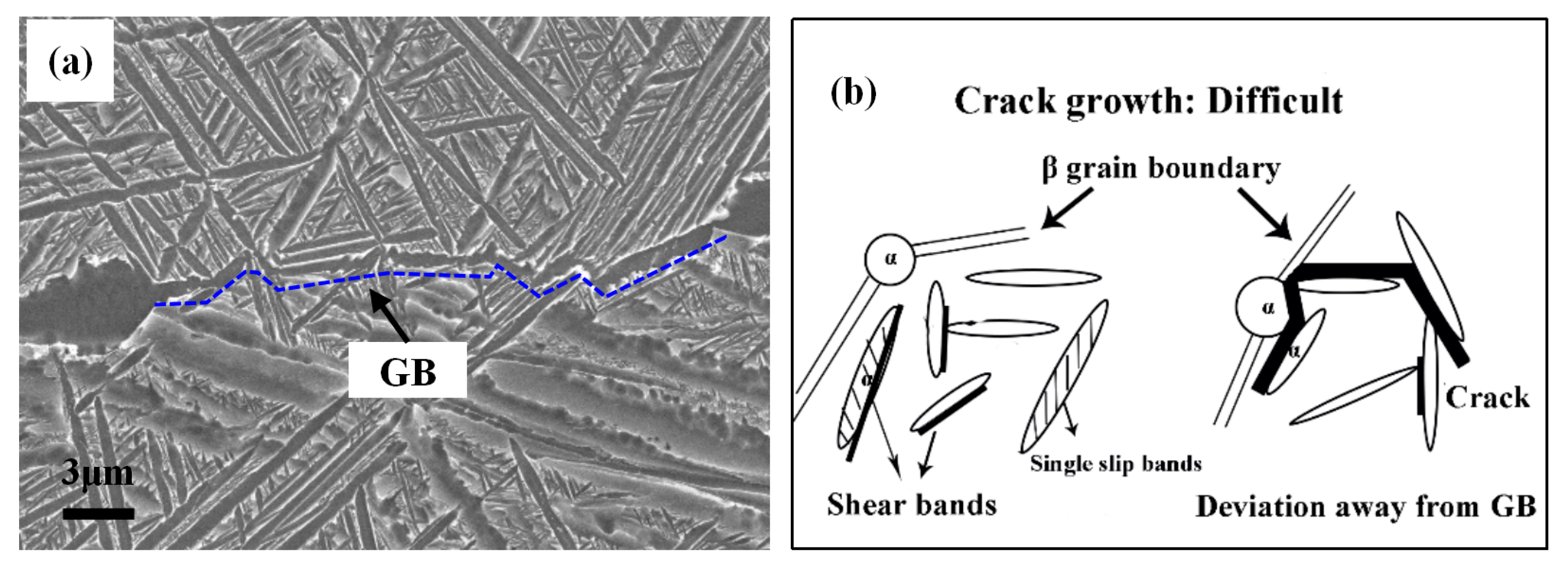

3.3. Fractographic Analyses and the Crack Propagation Behavior

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Banerjee, D.; Williams, J.C. Perspectives on titanium science and technology. Acta Mater. 2013, 61, 844–879. [Google Scholar] [CrossRef]

- Leyens, C.; Peters, M. Titanium and Titanium Alloys: Fundamentals and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2003. [Google Scholar]

- Liu, Y.W.; Chen, F.W.; Xu, G.L.; Cui, Y.W.; Chang, H. Correlation between Microstructure and Mechanical Properties of Heat-Treated Ti-6Al-4V with Fe Alloying. Metals 2020, 10, 854. [Google Scholar] [CrossRef]

- Renon, V.; Henaff, G.; Larignon, C.; Perusin, S.; Villechaise, P. Identification of Relationships between Heat Treatment and Fatigue Crack Growth of αβ Titanium Alloys. Metals 2019, 9, 512. [Google Scholar] [CrossRef]

- He, S.T.; Zeng, W.D.; Xu, J.W.; Chen, W. The effects of microstructure evolution on the fracture toughness of BT-25 titanium alloy during isothermal forging and subsequent heat treatment. Mater. Sci. Eng. A 2019, 745, 203–211. [Google Scholar] [CrossRef]

- Niinomi, M.; Kobayashi, T.; Inagaki, I.; Thompson, A.W. The effect of deformation-induced transformation on the fracture toughness of commercial titanium alloys. Metall. Trans. A 1990, 21, 1733–1744. [Google Scholar] [CrossRef]

- Li, X.H.; He, J.C.; Ji, Y.J.; Zhang, T.C.; Zhang, Y.H. Study of the Microstructure and Fracture Toughness of TC17 Titanium Alloy Linear Friction Welding Joint. Metals 2019, 9, 430. [Google Scholar] [CrossRef]

- Xu, T.W.; Zhang, S.S.; Cui, N.; Cao, L.; Wan, Y. Precipitation Behavior of Ti15Mo Alloy and Effects on Microstructure and Mechanical Performance. J. Mater. Eng. Perform. 2019, 28, 7188–7197. [Google Scholar] [CrossRef]

- Wen, X.; Wan, M.P.; Huang, C.W.; Tan, Y.B.; Lei, M.; Liang, Y.L.; Cai, X. Effect of microstructure on tensile properties, impact toughness and fracture toughness of TC21 alloy. Mater. Des. 2019, 180, 107898. [Google Scholar] [CrossRef]

- Shi, X.H.; Zeng, W.D.; Zhao, Q.Y. The effects of lamellar features on the fracture toughness of Ti-17 titanium alloy. Mater. Sci. Eng. A 2015, 636, 543–550. [Google Scholar] [CrossRef]

- Wen, X.; Wan, M.P.; Huang, C.W.; Lei, M. Strength and fracture toughness of TC21 alloy with multi-level lamellar microstructure. Mater. Sci. Eng. A 2019, 740, 121–129. [Google Scholar] [CrossRef]

- Richards, N.L. Quantitative evaluation of fracture toughness-microstructural relationships in α-β titanium alloys. J. Mater. Eng. Perform. 2004, 13, 218–225. [Google Scholar] [CrossRef]

- Cvijović-Alagić, I.; Gubeljak, N.; Rakin, M.; Cvijović, Z.; Gerić, K. Microstructural morphology effects on fracture resistance and crack tip strain distribution in Ti-6Al-4V alloy for orthopedic implants. Mater. Des. 2014, 53, 870–880. [Google Scholar] [CrossRef]

- Fan, J.K.; Li, J.S.; Kou, H.C.; Hua, K.; Tang, B. The interrelationship of fracture toughness and microstructure in a new near β titanium alloy Ti-7Mo-3Nb-3Cr-3Al. Mater. Charact. 2014, 96, 93–99. [Google Scholar] [CrossRef]

- Hirth, J.P.; Froes, F.H. Interrelations between fracture toughness and other mechanical properties in titanium alloy. Metall. Trans. A 1977, 8A, 1165–1176. [Google Scholar] [CrossRef]

- Gao, P.F.; Cai, Y.; Zhan, M.; Fan, X.G.; Lei, Z.N. Crystallographic orientation evolution during the development of tri-modal microstructure in the hot working of TA15 titanium alloy. J. Alloys Compd. 2018, 741, 734–745. [Google Scholar] [CrossRef]

- Gao, P.F.; Fan, X.G.; Yang, H. Role of processing parameters in the development of tri-modal microstructure during isothermal local loading forming of TA15 titanium alloy. J. Mater. Process. Technol. 2017, 239, 160–171. [Google Scholar] [CrossRef]

- Hosseini, R.; Morakabati, M.; Abbasi, S.M.; Hajari, A. Development of a trimodal microstructure with superior combined strength, ductility and creep-rupture properties in a near α titanium alloy. Mater. Sci. Eng. A 2017, 696, 155–165. [Google Scholar] [CrossRef]

- Tan, C.S.; Sun, Q.Y.; Zhang, G.J. Role of microstructure in plastic deformation and crack propagation behaviour of an α/β titanium alloy. Vacuum 2020. major revise. [Google Scholar]

- Zhang, S.; Liang, Y.L.; Xia, Q.F.; Ou, M.G. Study on Tensile Deformation Behavior of TC21 Titanium Alloy. J. Mater. Eng. Perform. 2019, 28, 1581–1590. [Google Scholar] [CrossRef]

- Jia, R.C.; Zeng, W.D.; He, S.T.; Gao, X.X.; Xu, J.W. The analysis of fracture toughness and fracture mechanism of Ti60 alloy under different temperatures. J. Alloys Compd. 2019, 810, 151899. [Google Scholar] [CrossRef]

- Terlinde, G.; Rathjen, H.J.; Schwalbe, K.H. Microstructure and fracture toughness of the aged, β-Ti Alloy Ti-10V-2Fe-M. Metall. Trans. A 1988, 19, 1037–1049. [Google Scholar] [CrossRef]

- Niinomi, M.; Kobayashi, T. Fracture characteristics analysis related to the microstructures in titanium alloys. Mater. Sci. Eng. A 1996, 213, 16–24. [Google Scholar] [CrossRef]

- Ren, L.; Xiao, W.L.; Chang, H.; Zhao, Y.Q.; Ma, C.L.; Zhou, L. Microstructural tailoring and mechanical properties of a multi-alloyed near β titanium alloy Ti-5321 with various heat treatment. Mater. Sci. Eng. A 2018, 711, 553–561. [Google Scholar] [CrossRef]

- Suresh, S. Fatigue crack deflection and fracture surface contact: Micromechanical models. Metall. Trans. A. 1985, 16, 249–260. [Google Scholar] [CrossRef]

- Xu, J.W.; Zeng, W.D.; Zhou, D.D.; Ma, H.Y.; Chen, W.; He, S.T. Influence of α/β processing on fracture toughness for a two-phase titanium alloy. Mater. Sci. Eng. A 2018, 731, 85–92. [Google Scholar] [CrossRef]

- Tan, C.S.; Sun, Q.Y.; Xiao, L.; Zhao, Y.Q.; Sun, J. Cyclic deformation and microcrack initiation during stress controlled high cycle fatigue of a titanium alloy. Mater. Sci. Eng. A 2018, 711C, 212–222. [Google Scholar] [CrossRef]

- Huang, J.; Wang, Z.R.; Xue, K.M. Cyclic deformation response and micromechanisms of Ti alloy Ti-5Al-5V-5Mo-3Cr-0.5Fe. Mater. Sci. Eng. A 2011, 528, 8723–8732. [Google Scholar] [CrossRef]

- Sangid, M.D. The physics of fatigue crack initiation. Int. J. Fatigue 2013, 57, 58–72. [Google Scholar] [CrossRef]

- Chan, K.S. Toughening mechanisms in titanium aluminides. Metall. Trans. A 1993, 24A, 569–583. [Google Scholar] [CrossRef]

- Ankem, S.; Greene, C.A. Recent developments in microstructure: Property relationships of beta titanium alloys. Mater. Sci. Eng. A 1999, 263, 127–131. [Google Scholar] [CrossRef]

- Bantounas, I.; Lindley, T.C.; Rugg, D.; Dye, D. Effect of microtexture on fatigue cracking in Ti–6Al–4V. Acta Mater. 2007, 55, 5655–5665. [Google Scholar] [CrossRef]

- Ghosh, A.; Sivaprasad, S.; Bhattacharjee, A.; Kar, S.K. Microstructure–fracture toughness correlation in an aircraft structural component alloy Ti-5Al-5V-5Mo-3Cr. Mater. Sci. Eng. A 2013, 568, 61–67. [Google Scholar] [CrossRef]

| Microstructures | Yield Strength/MPa | Tensile Strength/MPa | Elongation/% | Fracture Toughness/MPa·m1/2 |

|---|---|---|---|---|

| TM | 1067 ± 24 | 1186 ± 4 | 12.1 ± 1 | 62 ± 1 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tan, C.; Fan, Y.; Sun, Q.; Zhang, G. Improvement of the Crack Propagation Resistance in an α + β Titanium Alloy with a Trimodal Microstructure. Metals 2020, 10, 1058. https://doi.org/10.3390/met10081058

Tan C, Fan Y, Sun Q, Zhang G. Improvement of the Crack Propagation Resistance in an α + β Titanium Alloy with a Trimodal Microstructure. Metals. 2020; 10(8):1058. https://doi.org/10.3390/met10081058

Chicago/Turabian StyleTan, Changsheng, Yiduo Fan, Qiaoyan Sun, and Guojun Zhang. 2020. "Improvement of the Crack Propagation Resistance in an α + β Titanium Alloy with a Trimodal Microstructure" Metals 10, no. 8: 1058. https://doi.org/10.3390/met10081058

APA StyleTan, C., Fan, Y., Sun, Q., & Zhang, G. (2020). Improvement of the Crack Propagation Resistance in an α + β Titanium Alloy with a Trimodal Microstructure. Metals, 10(8), 1058. https://doi.org/10.3390/met10081058