Tribological Properties of Ti2AlNb Matrix Composites Containing Few-Layer Graphene Fabricated by Spark Plasma Sintering

Abstract

1. Introduction

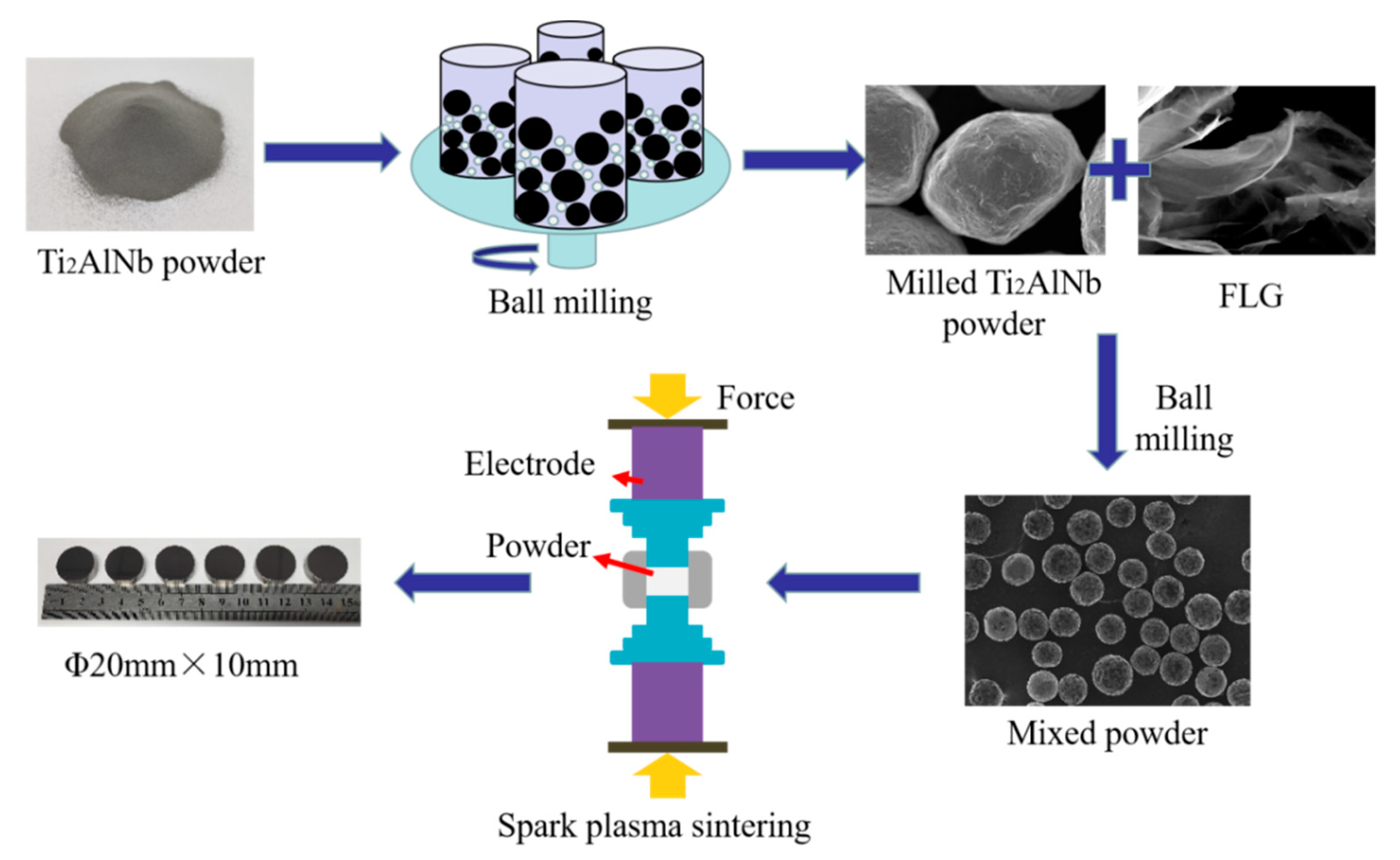

2. Experimental Procedure

2.1. Raw Materials

2.2. Preparation of the FLG/Ti2AlNb Powders

2.3. SPS

2.4. Tribological Measurements

2.5. Characterization

3. Results and Discussion

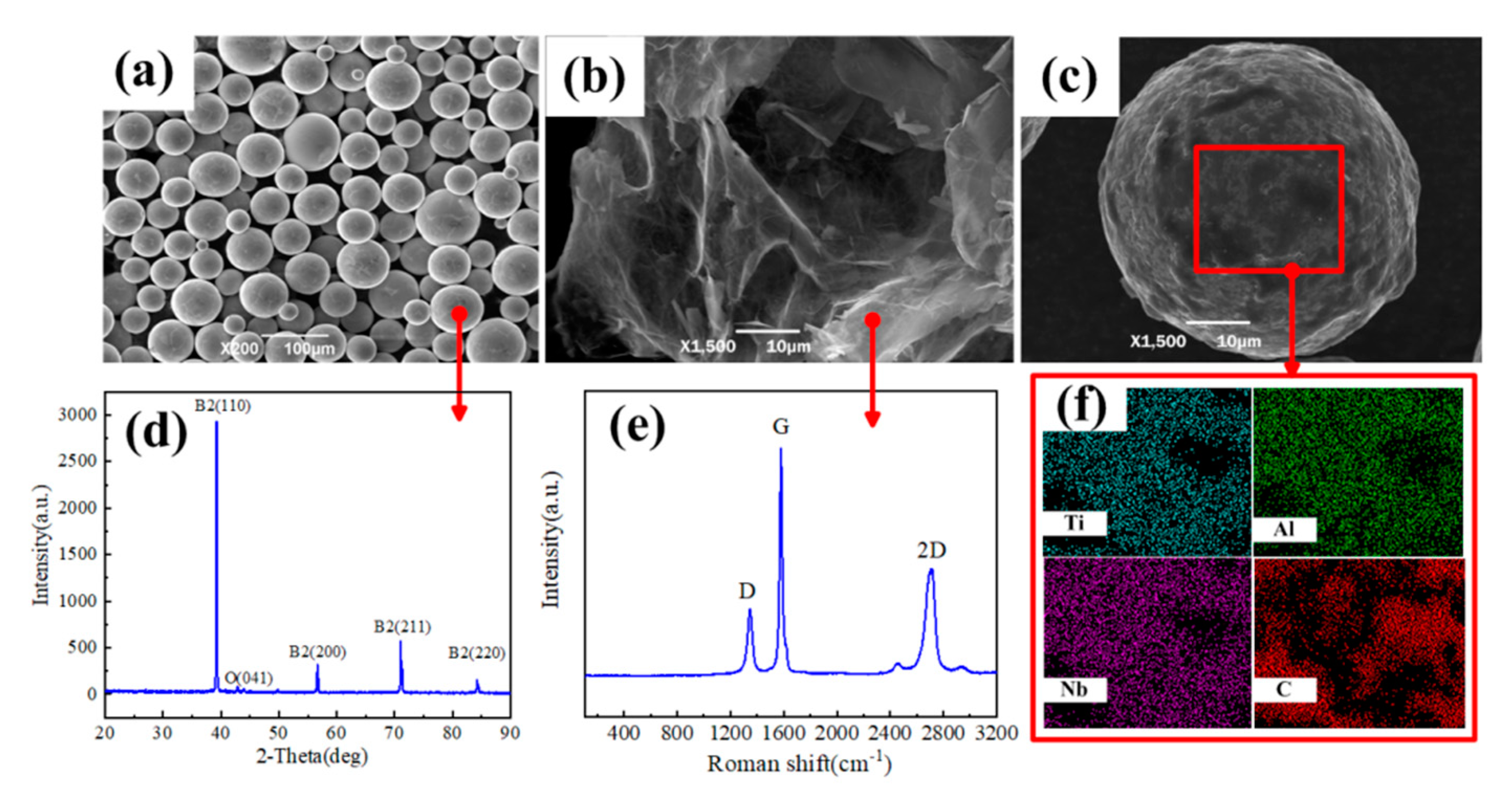

3.1. Microstructures of the Mixed Powders

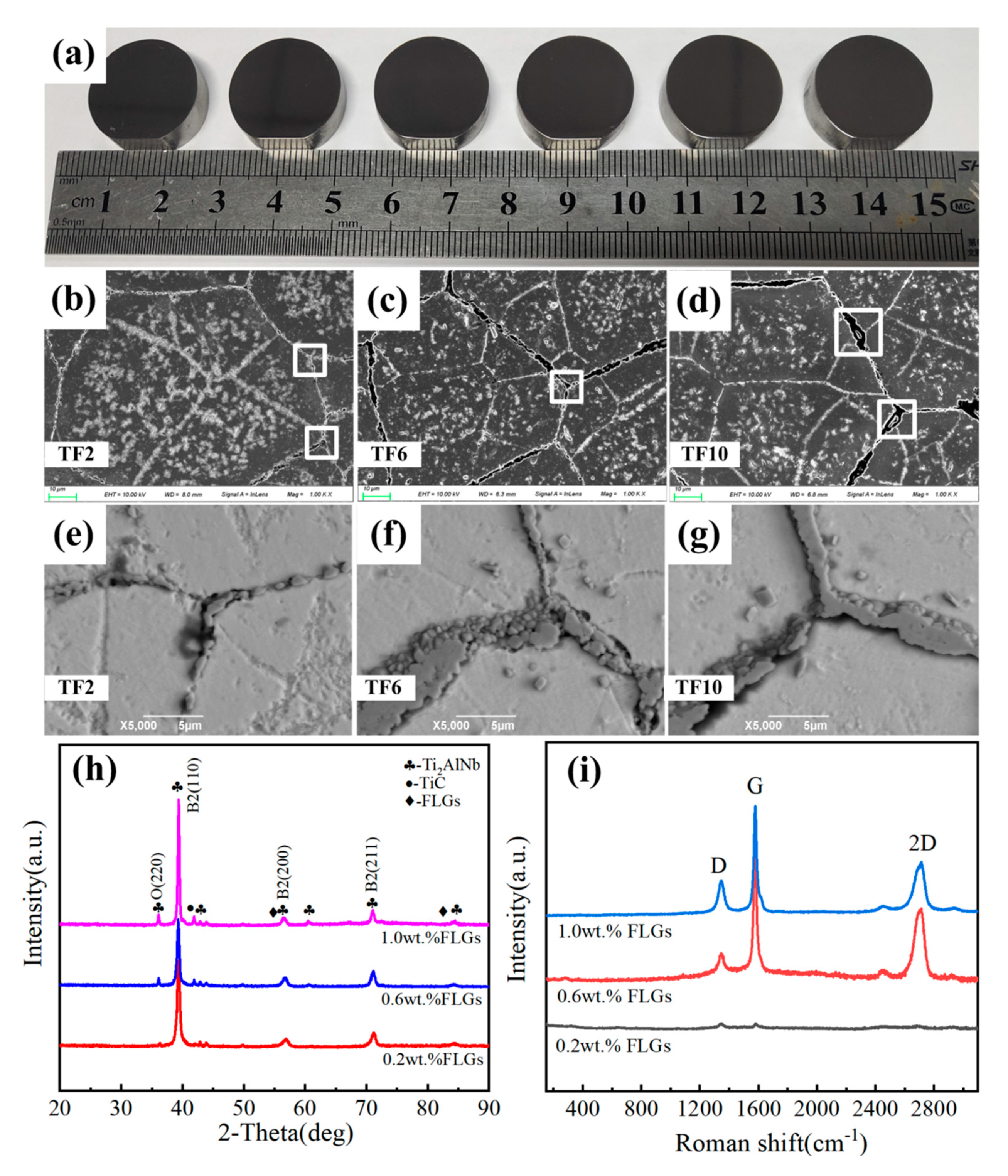

3.2. Microstructure of the FLG/Ti2AlNb Composites

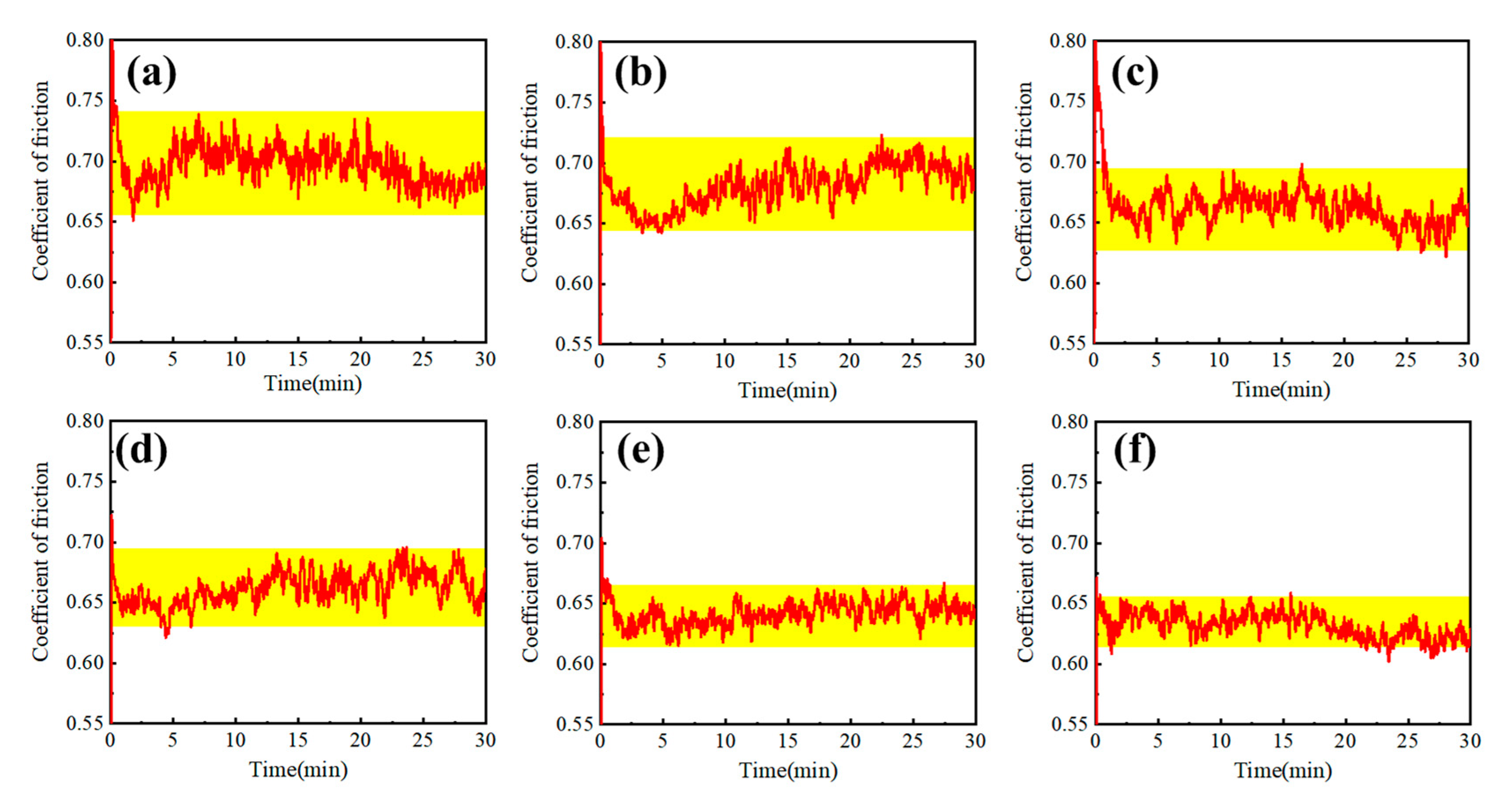

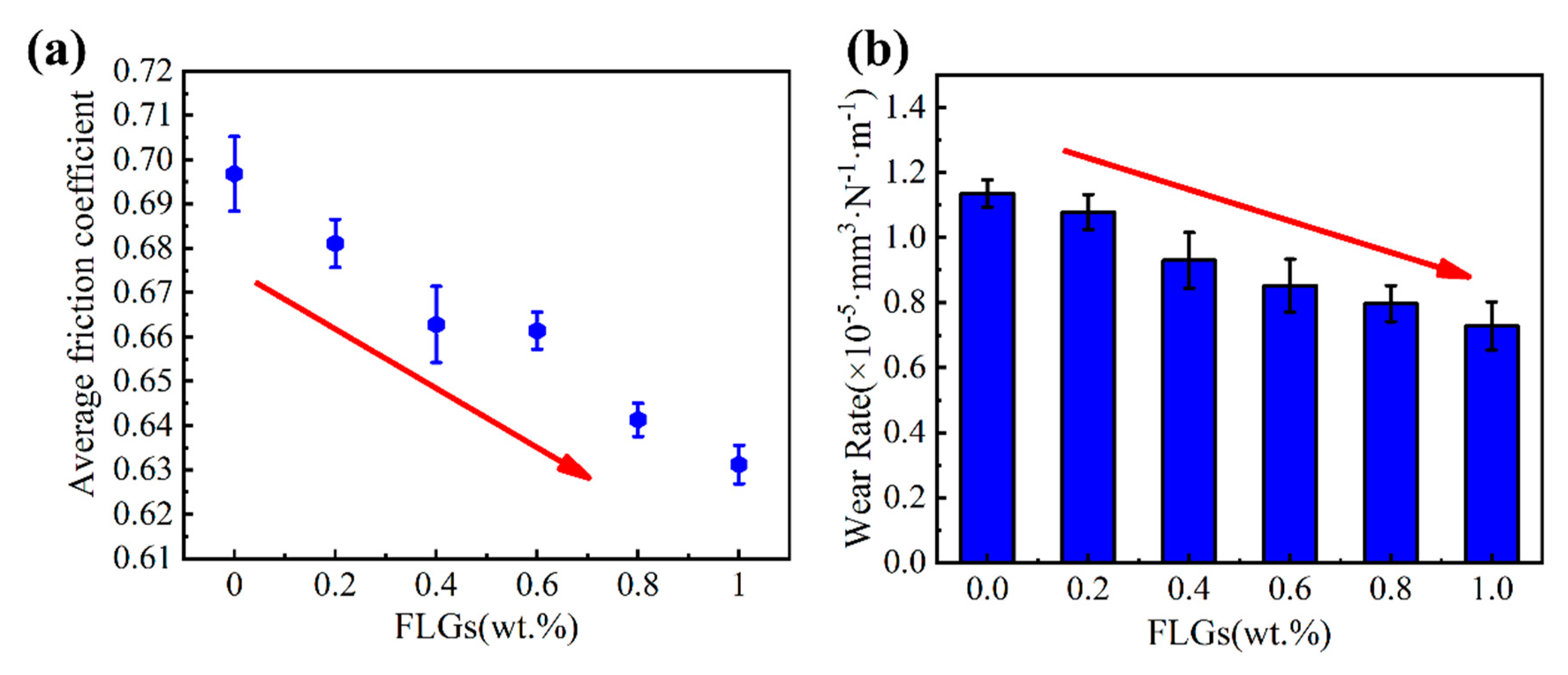

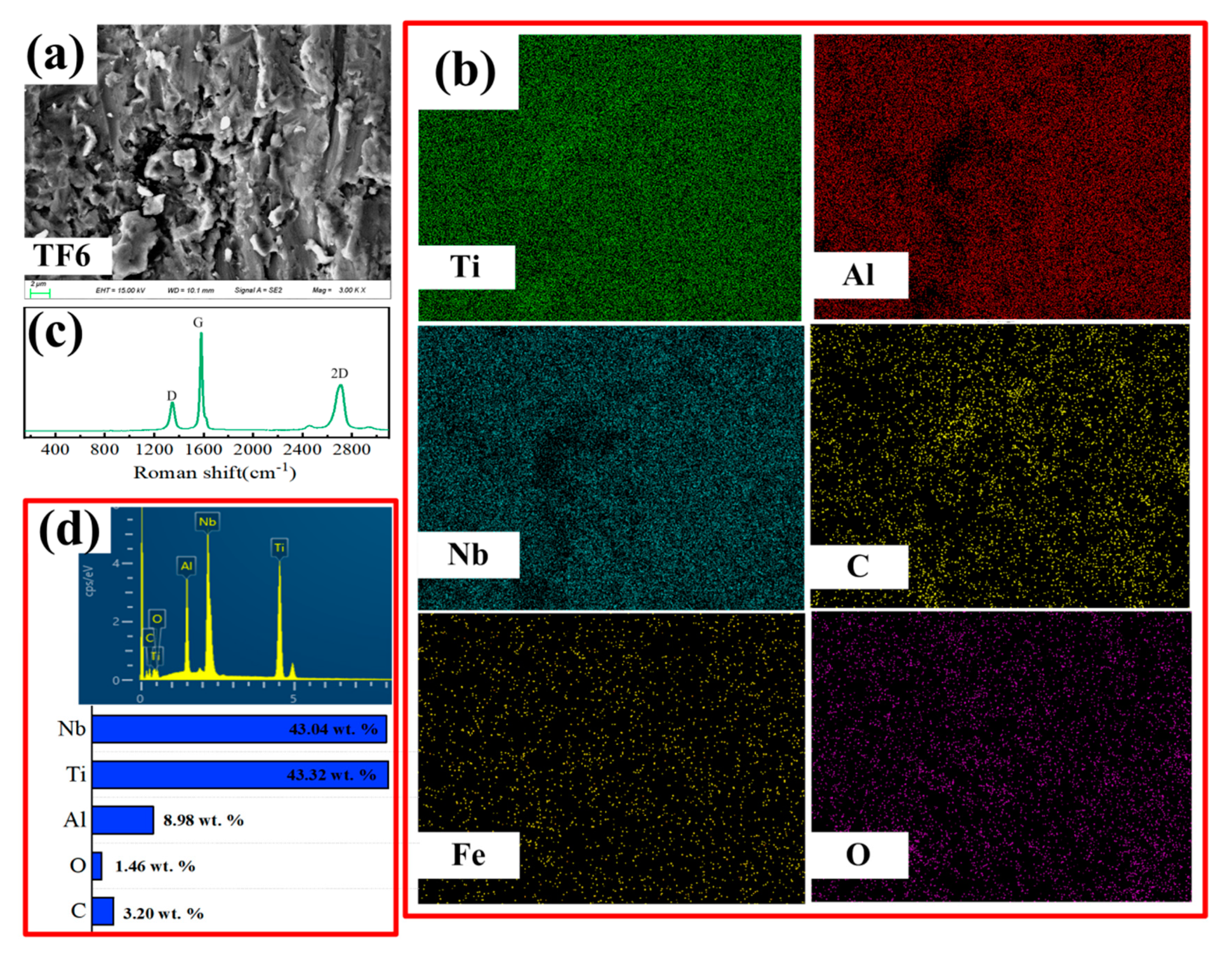

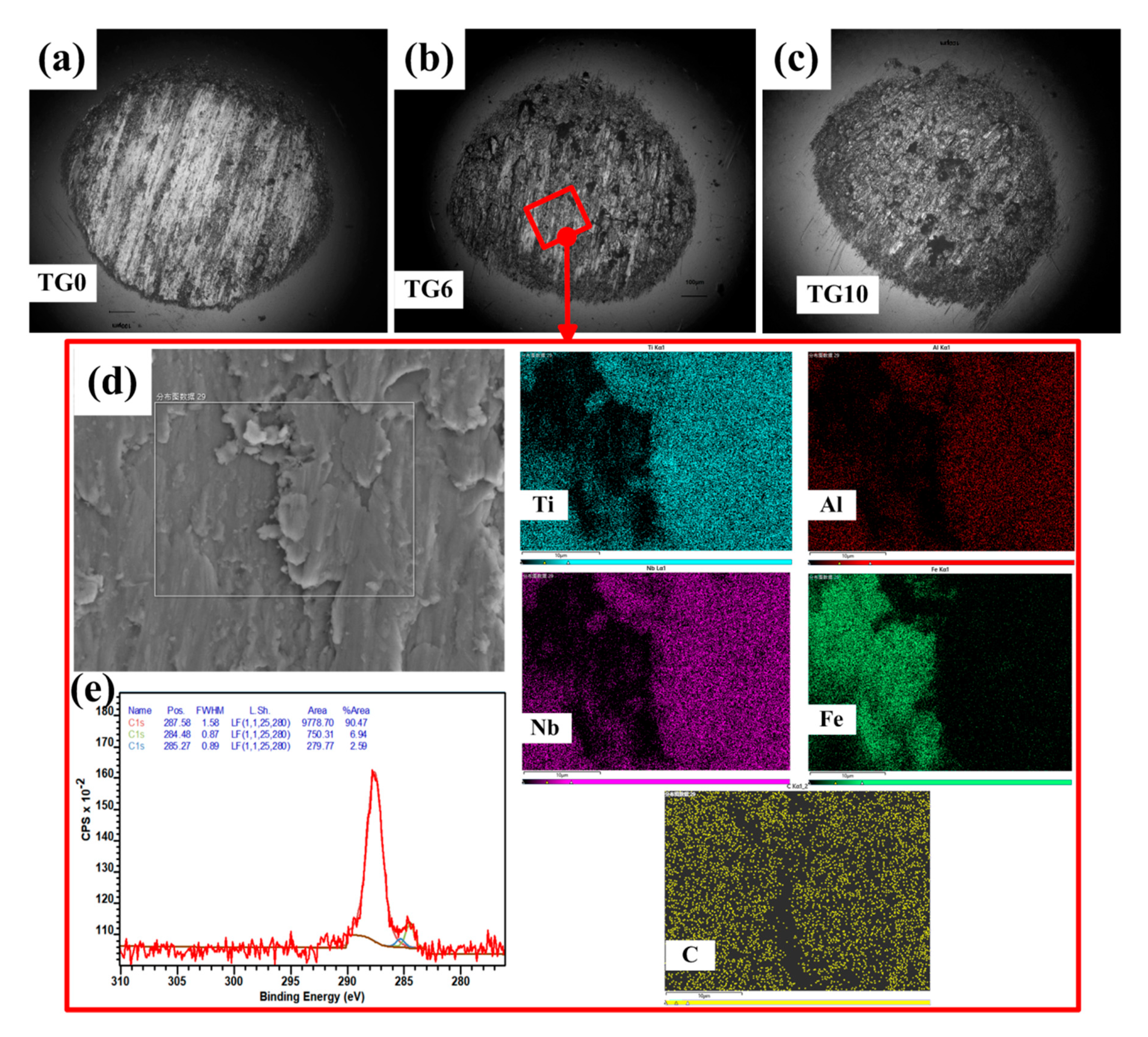

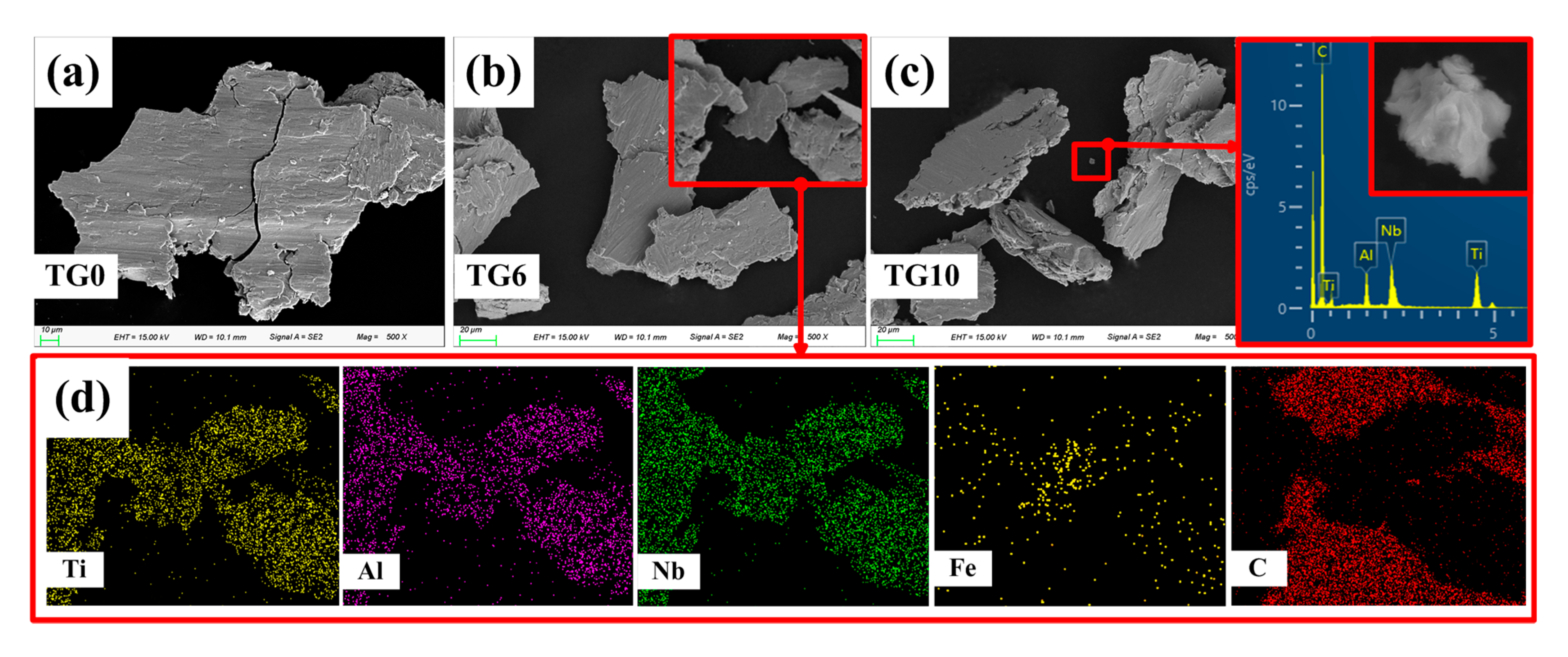

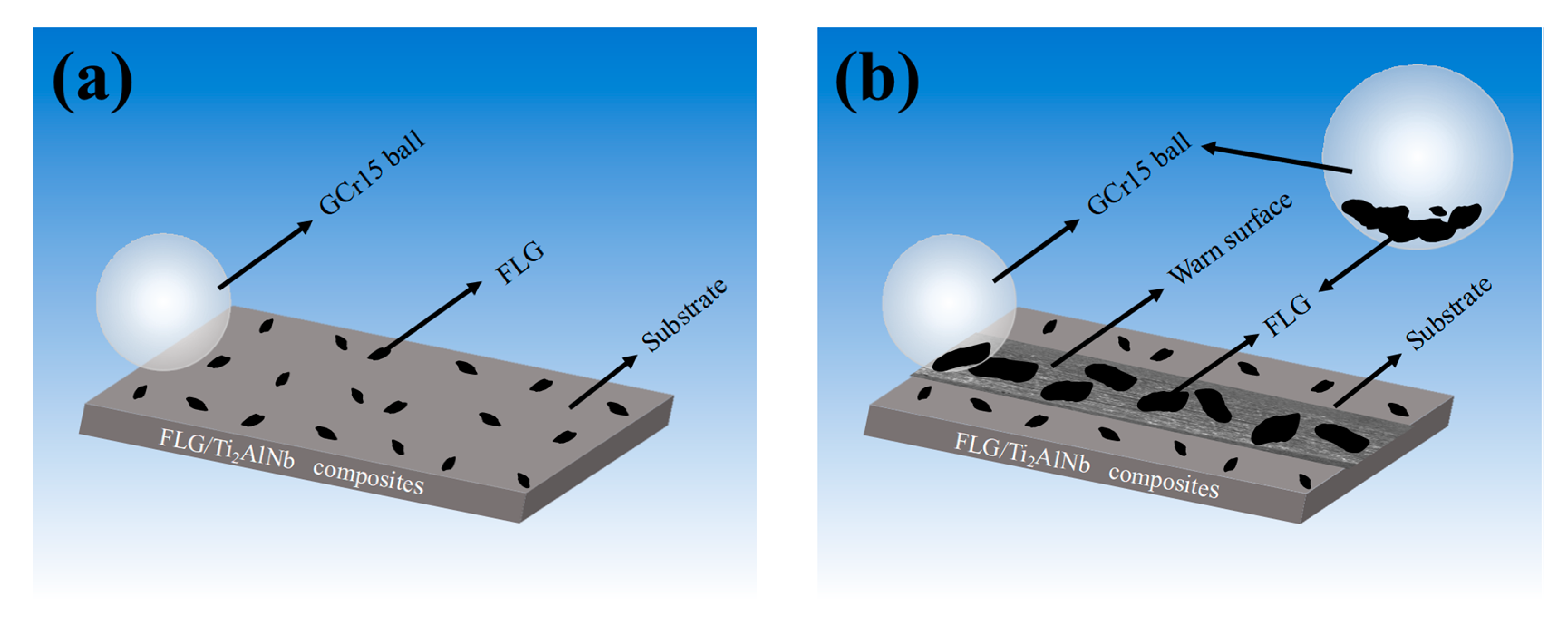

3.3. Tribological Properties and Antifriction Mechanism of the Composites

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Wang, W.; Zeng, W.D.; Sun, Y.L.; Zhou, H.X.; Liang, X.B. Microstructure, Tensile, and Creep Behaviors of Ti-22Al-25Nb (at.%) Orthorhombic Alloy with Equiaxed Microstructure. Materials 2018, 11, 1244. [Google Scholar] [CrossRef]

- Wang, W.; Zhou, H.X.; Wang, Q.J.; Jin, J.; Sun, Y.L.; Wang, K.S. High-Temperature Tribological Behavior of the Ti-22Al-25Nb (at. %) Orthorhombic Alloy with Lamellar O Microstructures. Metals 2019, 9, 5. [Google Scholar] [CrossRef]

- Liu, X.L.; Shi, X.L.; Huang, Y.C.; Lu, G.C.; Deng, X.B.; Yan, Z.; Zhou, H.Y.; Chen, Y.; Xue, B. Tribological behavior of TiAl-multilayer graphene-silver composites at different sliding speeds. Mater. Chem. Phys. 2018, 213, 368–373. [Google Scholar] [CrossRef]

- Su, Y.F.; Zhang, Y.S.; Song, J.J.; Hu, L.T. Tribological behavior and lubrication mechanism of self-lubricating ceramic/metal composites: The effect of matrix type on the friction and wear properties. Wear 2017, 272, 130–138. [Google Scholar] [CrossRef]

- Liu, X.Y.; Shi, X.L.; Wu, C.H.; Yang, K.; Huang, Y.C.; Deng, X.B.; Yan, Z.; Xue, B. Tribological Behavior of M50-MoS2 Self-Lubricating Composites from 150 °C to 450 °C. Mater. Chem. Phys. 2017, 198, 145–153. [Google Scholar] [CrossRef]

- Liu, W.G.; Liu, X.B.; Zhang, Z.G. Development and characterization of composite Ni-Cr-C-CaF2 laser cladding on γ-TiAl intermetallic alloy. J. Alloys Compd. 2009, 470, 25–28. [Google Scholar] [CrossRef]

- Zeng, S.W.; Zhao, A.M.; Jiang, H.T. Oxidation of conventional and nanostructured 8 wt.% yttria-stabilized zirconia coating surface coatings on γ-TiAl. Appl. Surf. Sci. 2015, 332, 362–367. [Google Scholar] [CrossRef]

- Pu, N.W.; Wang, C.A.; Sung, Y.B.; Liu, Y.M. Production of few-layer graphene by supercritical CO2 exfoliation of graphite. Mater. Lett. 2009, 63, 1987–1989. [Google Scholar] [CrossRef]

- Cheng, J.; Li, F.; Liu, W.M. Dry-sliding tribological properties of TiAl/Ti2AlC composites. Tribol. Lett. 2014, 53, 457–467. [Google Scholar] [CrossRef]

- Xu, Z.S.; Shi, X.L.; Zhai, W.Z. Preparation and tribological properties of TiAl matrix composites reinforced by multilayer graphene. Carbon 2014, 67, 168–177. [Google Scholar] [CrossRef]

- Wei, W.; Guoxin, X.; Jianbin, L. Black phosphorus as a new lubricant. Friction 2018, 6, 116–142. [Google Scholar]

- Zhang, Y.Y.; Wang, C.M.; Cheng, Y.; Xiang, Y. Mechanical properties of bilayer graphene sheets coupled by sp3 bonding. Carbon 2011, 49, 4511–4517. [Google Scholar] [CrossRef]

- Xu, Z.S.; Zhang, Q.X.; Jing, P.X.; Zhai, W.Z. High-Temperature Tribological Performance of TiAl Matrix Composites Reinforced by Multilayer Graphene. Tribol. Lett. 2015, 58, 3–11. [Google Scholar] [CrossRef]

- Xu, Z.S.; Chen, L.; Shi, X.L.; Zhang, Q.X.; Ibrahim, A.M.M.; Zhai, W.Z.; Yao, J.; Zhu, Q.S.; Xiao, Y.C. Formation of Friction Layers in Graphene-Reinforced TiAl Matrix Self-Lubricating Composites. ASLE Trans. 2015, 58, 668–678. [Google Scholar] [CrossRef]

- Zhou, H.Y.; Shi, X.L.; Liu, X.Y.; Lu, G.C.; Chen, Y. Tribological Properties and Self-Repairing Functionality of Ti6Al4V-Multilayer Graphene-Ag Composites. J. Mater. Eng. Perform. 2019, 28, 3381–3392. [Google Scholar] [CrossRef]

- Yan, Z.; Shen, Q.; Shi, X.L.; Yang, K.; Zou, J.L.; Huang, Y.C.; Zhang, A.; Ibrahim, A.M.M.; Wang, Z.H. Tribological Behavior of γ-TiAl Matrix Composites with Different Contents of Multilayer Graphene. J. Mater. Eng. Perform. 2017, 26, 2776–2783. [Google Scholar] [CrossRef]

- Yang, Y.F.; Imai, H.; Kondoh, K.; Qian, M. Comparison of spark plasma sintering of elemental and master alloy powder mixtures and prealloyed Ti-6Al-4V powder. Powder Metall. 2014, 50, 41–47. [Google Scholar]

- Wang, F.C.; Zhang, Z.H.; Sun, Y.J.; Liu, Y.; Hu, Z.Y.; Wang, H.; Korznikov, A.V.; Korznikova, E.; Liu, Z.F.; Osamu, S. Rapid and low temperature spark plasma sintering synthesis of novel carbon nanotube reinforced titanium matrix composites. Carbon 2015, 95, 396–407. [Google Scholar] [CrossRef]

- Berman, D.; Erdemir, A.; Sumant, A.V. Few layer graphene to reduce wear and friction on sliding steel surfaces. Carbon 2013, 54, 454–459. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, Q.J.; Mo, W. Metallization and Heat Treatment of Titanium; Metallurgical Industry Press: Beijing, China, 2009; pp. 20–127. [Google Scholar]

- Liu, J.; Wu, M.X.; Yang, Y.; Yang, G.; Yan, H.X.; Jiang, K. Preparation and mechanical performance of graphene platelet reinforced titanium nanocomposites for high temperature applications. J. Alloys Compd. 2018, 765, 1111–1118. [Google Scholar] [CrossRef]

- Mu, X.N.; Cai, H.N.; Zhang, H.M.; Fan, Q.B.; Zhang, Z.H.; Wu, Y.; Ge, Y.X.; Wang, D.D. Interface evolution and superior tensile properties of multi-layer graphene reinforced pure Ti matrix composite. Mater. Des. 2018, 140, 431–441. [Google Scholar] [CrossRef]

- Chase, M.W. NIST-JANAF Themochemical Tables, 4th ed.; American Institute of Physics: College Park, ML, USA, 1998; pp. 1–1951. [Google Scholar]

- Dong, L.L.; Chen, W.T.; Deng, N.; Zheng, C.H. A novel fabrication of graphene by chemical reaction with a green reductant. Chem. Eng. J. 2016, 306, 754–762. [Google Scholar] [CrossRef]

- Dong, L.L.; Xiao, B.; Jin, L.H.; Lu, J.W.; Liu, Y.; Fu, Y.Q.; Zhao, Y.Q.; Wu, G.H.; Zhang, Y.S. Mechanisms of simultaneously enhanced strength and ductility of titanium matrix composites reinforced with nanosheets of graphene oxides. Ceram. Int. 2019, 45, 19370–19379. [Google Scholar] [CrossRef]

- Zhou, H.T.; Su, Y.J.; Liu, N.; Kong, F.T.; Wang, X.P.; Zhang, X.; Chen, Y.Y. Modification of microstructure and properties of Ti-47Al-2Cr-4Nb-0.3W alloys fabricated by SPS with trace multilayer graphene addition. Mater. Charact. 2018, 138, 1–10. [Google Scholar] [CrossRef]

- Zhang, F.M.; Liu, T.F. Nanodiamonds reinforced titanium matrix nanocomposites with network architecture. Compos. Part B 2019, 165, 143–154. [Google Scholar] [CrossRef]

- Kumar, S.; Sarma, V.S.; Murty, B.S. Influence of in situ formed TiB2 particles on the abrasive wear behaviour of Al-4Cu alloy. Mater. Sci. Eng. A 2007, 465, 160–164. [Google Scholar] [CrossRef]

- Tijo, D.; Waghmare, D.T.; Kaladharan, D.; Masanta, M. Effect of TiC content on Sliding Wear Behavior of TiC-Ti Metal Matrix Composite. Mater. Today Proc. 2018, 5, 19848–19853. [Google Scholar] [CrossRef]

- Zheng, B.W.; Dong, F.Y.; Yuan, X.G.; Huang, H.J.; Zhang, Y.; Zuo, X.J.; Luo, L.S.; Wang, L.; Su, W.D.; Liaw, P.K.; et al. Microstructure and tribological behavior of in situ synthesized (TiB+TiC)/Ti6Al4V (TiB/TiC¼1/1) composites. Tribol. Int. 2020, 145, 106177. [Google Scholar] [CrossRef]

- Wang, Y.; Lei, K.; Ruan, Y.; Dong, W. Microstructure and wear resistance of c-BN/Ni–Cr–Ti composites prepared by spark plasma sintering. Int. J. Refract. Met. Hard Mater. 2016, 54, 98–103. [Google Scholar] [CrossRef]

- Wang, L.; Cheng, J.; Qiao, Z.H.; Yang, J.; Liu, W.M. Tribological behaviors of in situ TiB2 ceramic reinforced TiAl-based composites under sea water environment. Ceram. Int. 2017, 43, 4314–4323. [Google Scholar] [CrossRef]

- Shi, X.L.; Xu, Z.S.; Wang, M.; Zhai, W.Z.; Yao, J.; Song, S.Y. Tribological behavior of TiAl matrix self-lubricating composites containing silver from 25 to 800 °C. Wear 2013, 303, 486–494. [Google Scholar] [CrossRef]

- Balandin, A.A.; Ghosh, S.; Bao, W.; Calizo, I.; Teweldebrhan, D.; Miao, F. Superior thermal conductivity of single-layer graphene. Nano Lett. 2008, 8, 902–907. [Google Scholar] [CrossRef]

| C | Si | Mn | S | Mo | P | Cr | Ni | Cu |

|---|---|---|---|---|---|---|---|---|

| 0.95–1.05 | 0.15–0.35 | 0.20–0.40 | 0.020 | ≤0.10 | 0.027 | 1.30–1.65 | ≤0.30 | ≤0.25 |

| Sample | Theoretical Density (g/cm3) | Actual Density (g/cm3) | Densification (%) | Porosity (%) |

|---|---|---|---|---|

| TF0 | 5.210 | 5.092 | 97.74 | 2.26 |

| TF2 | 5.197 | 5.168 | 99.45 | 0.55 |

| TF4 | 5.183 | 5.166 | 99.67 | 0.33 |

| TF6 | 5.170 | 5.157 | 99.75 | 0.25 |

| TF8 | 5.157 | 5.146 | 99.79 | 0.21 |

| TF10 | 5.143 | 5.122 | 99.58 | 0.42 |

| Composite Materials | Based Alloy | Reinforced Phase | Content | Wear Properties | Anti-Friction Effect of Average Unit Mass Fraction | |

|---|---|---|---|---|---|---|

| Present Work | Ti2AlNb | FLG (wt.%) | 0 | Wear Rate (×10−5 mm3·N−1·m−1) | 6.81 | 73.49% |

| 0.2 | 5.34 | |||||

| 0.4 | 4.22 | |||||

| 0.6 | 4.06 | |||||

| 0.8 | 4.19 | |||||

| 1.0 | 3.47 | |||||

| [28] | Ti | TiC (%) | 30 | Wear Mass Loss (m/mg) | 4.38 | 0.07% |

| 40 | 2.55 | |||||

| 50 | 1.5 | |||||

| 60 | 0.92 | |||||

| [29] | Ni-Cr-Ti | C-BN (wt.%) | 20 | Wear Mass Loss (m/mg) | 2.35 | 2.23% |

| 25 | 0.75 | |||||

| 30 | 0.2 | |||||

| 35 | 0.5 | |||||

| 40 | 1.5 | |||||

| [30] | Ti-46Al-2Cr-2Nb | TiB2 | 0 | Wear Rate (×10−5 mm3·N−1·m−1) | 15.3 | 2.25% |

| 20 | 8.22 | |||||

| 40 | 1.98 | |||||

| [31] | Ti6Al4V | TiB+TiC (%) | 0 | Wear Rate (×10−5 mm3·N−1·m−1) | 6.81 | 7.35% |

| 2 | 5.34 | |||||

| 4 | 4.22 | |||||

| 6 | 4.06 | |||||

| 8 | 4.19 | |||||

| 10 | 3.47 | |||||

| Samples | TF0 | TF2 | TF4 | TF6 | TF8 | TF10 |

|---|---|---|---|---|---|---|

| Ultimate compressive strength | 1407.70 | 1515.38 | 1445.37 | 1463.13 | 1398.68 | 1389.93 |

| Enhancement effect | - | 7.1% | 2.6% | 3.8% | −0.6% | −1.2% |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, W.; Han, Z.; Wang, Q.; Wei, B.; Xin, S.; Gao, Y. Tribological Properties of Ti2AlNb Matrix Composites Containing Few-Layer Graphene Fabricated by Spark Plasma Sintering. Metals 2020, 10, 924. https://doi.org/10.3390/met10070924

Wang W, Han Z, Wang Q, Wei B, Xin S, Gao Y. Tribological Properties of Ti2AlNb Matrix Composites Containing Few-Layer Graphene Fabricated by Spark Plasma Sintering. Metals. 2020; 10(7):924. https://doi.org/10.3390/met10070924

Chicago/Turabian StyleWang, Wei, Ziru Han, Qingjuan Wang, Baojia Wei, Shewei Xin, and Yuan Gao. 2020. "Tribological Properties of Ti2AlNb Matrix Composites Containing Few-Layer Graphene Fabricated by Spark Plasma Sintering" Metals 10, no. 7: 924. https://doi.org/10.3390/met10070924

APA StyleWang, W., Han, Z., Wang, Q., Wei, B., Xin, S., & Gao, Y. (2020). Tribological Properties of Ti2AlNb Matrix Composites Containing Few-Layer Graphene Fabricated by Spark Plasma Sintering. Metals, 10(7), 924. https://doi.org/10.3390/met10070924