Electrospinning: A Powerful Tool to Improve the Corrosion Resistance of Metallic Surfaces Using Nanofibrous Coatings

Abstract

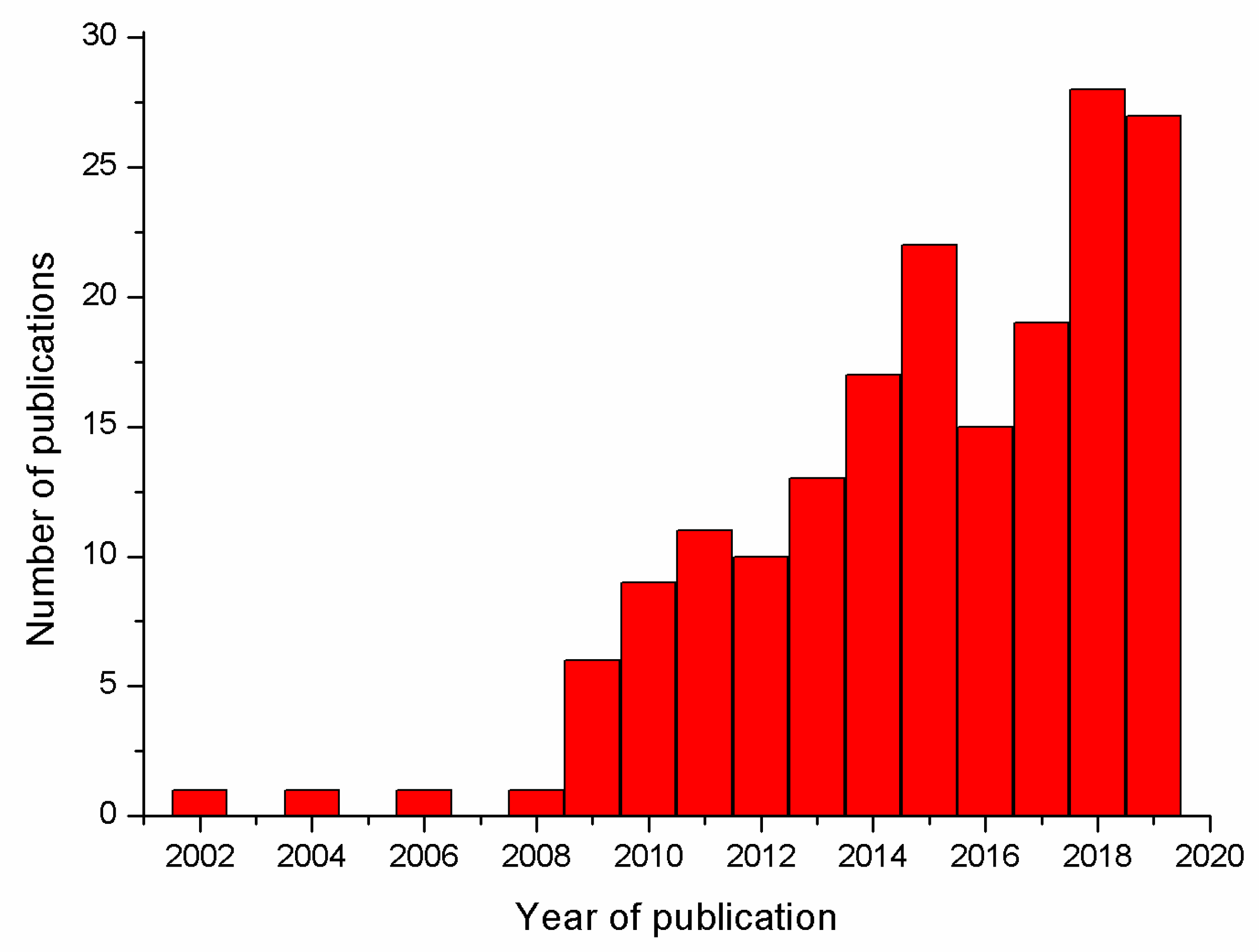

1. Introduction

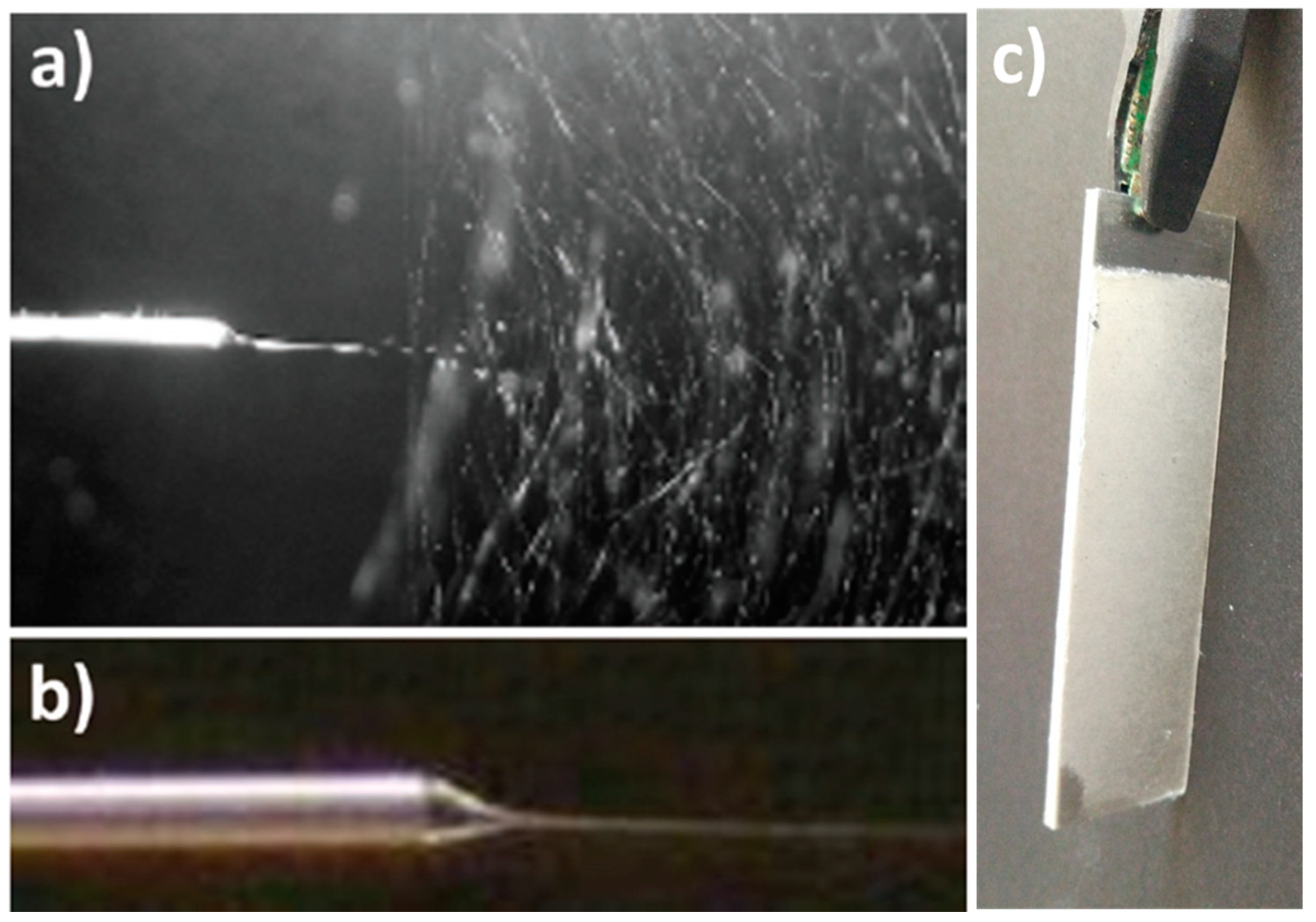

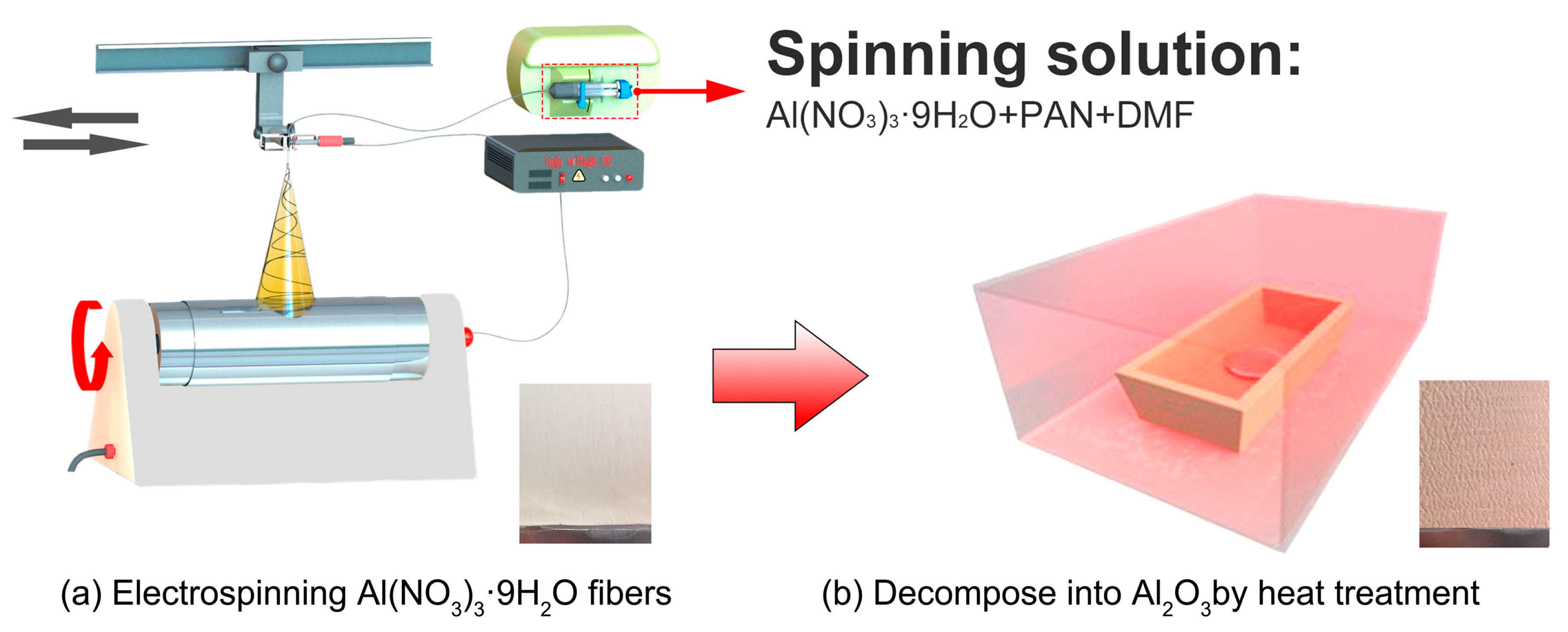

2. Fundamentals of the Electrospinning Process

3. Electrospun Coatings for Corrosion Protection

3.1. Electrospun Coatings of Entirely Polymeric Fibres

3.2. Electrospun Protective Self-Healing Coatings

3.3. Combination of Electrospinning Process with Other Deposition Techniques

4. Emerging Trends of Electrospun Coatings: The Case of Biocorrosion

4.1. Release of Active Compounds

4.2. Surface Texturing: Antifouling Surfaces

5. Summary Table

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Cohen, U.; Koch, F.B.; Sard, R. Electroplating of Cyclic Multilayered Alloy (CMA) Coatings. J. Electrochhem. Soc. 1983, 130, 1987–1995. [Google Scholar] [CrossRef]

- Solmaz, R.; Kardaş, G. Electrochemical deposition and characterization of NiFe coatings as electrocatalytic materials for alkaline water electrolysis. Electrochim. Acta 2009, 54, 3726–3734. [Google Scholar] [CrossRef]

- Mansfeld, F. Evaluation of Anodized Aluminum Surfaces with Electrochemical Impedance speculated. J. Electrochem. Soc. 1988, 135, 828–833. [Google Scholar] [CrossRef]

- Chong, K.Z.; Shih, T.S. Conversion-coating treatment for magnesium alloys by a permanganate-phosphate solution. Mater. Chem. Phys. 2003, 80, 191–200. [Google Scholar] [CrossRef]

- Shan, C.X.; Hou, X.; Choy, K.-L. Corrosion resistance of TiO2 films grown on stainless steel by atomic layer deposition. Surf. Coat. Technol. 2008, 202, 2399–2402. [Google Scholar] [CrossRef]

- Conceicao, T.F.; Scharnagl, N.; Blawert, C.; Dietzel, W.; Kainer, K.U. Corrosion protection of magnesium alloy AZ31 sheets by spin coating process with poly(ether imide) [PEI]. Corros. Sci. 2010, 52, 2066–2079. [Google Scholar] [CrossRef]

- Wang, D.; Bierwagen, G.P. Sol-gel coatings on metals for corrosion protection. Prog. Org. Coat. 2009, 64, 327–338. [Google Scholar] [CrossRef]

- Shchukin, D.G.; Zheludkevich, M.; Yasakau, K.; Lamaka, S.; Ferreira, M.G.S.; Möhwald, H. Layer-by-layer assembled nanocontainers for self-healing corrosion protection. Adv. Mater. 2006, 18, 1672–1678. [Google Scholar] [CrossRef]

- Ishizaki, T.; Hieda, J.; Saito, N.; Saito, N.; Takai, O. Corrosion resistance and chemical stability of super-hydrophobic film deposited on magnesium alloy AZ31 by microwave plasma-enhanced chemical vapor deposition. Electrochim. Acta 2010, 55, 7094–7101. [Google Scholar] [CrossRef]

- Jehn, H.A. Improvement of the corrosion resistance of PVD hard coating-substrate systems. Surf. Coat. Technol. 2000, 125, 212–217. [Google Scholar] [CrossRef]

- Bertrand, G.; Mahdjoub, H.; Meunier, C. A study of the corrosion behaviour and protective quality of sputtered chromium nitride coatings. Surf. Coat. Technol. 2000, 126, 199–209. [Google Scholar] [CrossRef]

- Li, D.; Xia, Y. Electrospinning of nanofibres: Reinventing the wheel? Adv. Mater. 2004, 16, 1151–1170. [Google Scholar] [CrossRef]

- Rivero, P.J.; Garcia, J.A.; Quintana, I.; Rodriguez, R. Design of nanostructured functional coatings by usingwet-chemistry methods. Coatings 2018, 8, 76. [Google Scholar] [CrossRef]

- Frenot, A.; Chronakis, I.S. Polymer nanofibres assembled by electrospinning. Curr. Opin. Colloid Interface Sci. 2003, 8, 64–75. [Google Scholar] [CrossRef]

- Yee, W.A.; Kotaki, M.; Liu, Y.; Lu, X. Morphology, polymorphism behavior and molecular orientation of electrospun poly(vinylidene fluoride) fibres. Polymer 2007, 48, 512–521. [Google Scholar] [CrossRef]

- Lee, K.Y.; Jeong, L.; Kang, Y.O.; Lee, S.J.; Park, W.H. Electrospinning of polysaccharides for regenerative medicine. Adv. Drug Deliv. Rev. 2009, 61, 1020–1032. [Google Scholar] [CrossRef] [PubMed]

- Xu, X.; Yang, Q.; Wang, Y.; Yu, H.; Chen, X.; Jing, X. Biodegradable electrospun poly(l-lactide) fibres containing antibacterial silver nanoparticles. Eur. Polym. J. 2006, 42, 2081–2087. [Google Scholar] [CrossRef]

- Ma, M.; Hill, R.M.; Lowery, J.L.; Fridrikh, S.V.; Rutledge, G.C. Electrospun poly(styrene-block-dimethylsiloxane) block copolymer fibres exhibiting superhydrophobicity. Langmuir 2005, 21, 5549–5554. [Google Scholar] [CrossRef]

- Jia, Y.-T.; Gong, J.; Gu, X.-H.; Kim, H.-Y.; Dong, J.; Shen, X.-Y. Fabrication and characterization of poly (vinyl alcohol)/chitosan blend nanofibres produced by electrospinning method. Carbohydr. Polym. 2007, 67, 403–409. [Google Scholar] [CrossRef]

- López-Rubio, A.; Fabra, M.J.; Martínez-Sanz, M. Food packaging based on nanomaterials. Nanomaterials 2019, 9, 1224. [Google Scholar] [CrossRef]

- Bhardwaj, N.; Kundu, S.C. Electrospinning: A fascinating fibre fabrication technique. Biotechnol. Adv. 2010, 28, 325–347. [Google Scholar] [CrossRef] [PubMed]

- Rivero, P.J.; Urrutia, A.; Goicoechea, J.; Rodríguez, Y.; Corres, J.M.; Arregui, F.J.; Matías, I.R. An antibacterial submicron fibre mat with in situ synthesized silver nanoparticles. J. Appl. Polym. Sci. 2012, 126, 1228–1235. [Google Scholar] [CrossRef]

- Reneker, D.H.; Yarin, A.L. Electrospinning jets and polymer nanofibres. Polymer 2008, 49, 2387–2425. [Google Scholar] [CrossRef]

- Jiang, T.; Carbone, E.J.; Lo, K.W.-H.; Laurencin, T.C. Electrospinning of polymer nanofibres for tissue regeneration. Prog. Polym. Sci. 2015, 46, 1–24. [Google Scholar] [CrossRef]

- Pillay, V.; Dott, C.; Choonara, Y.E.; Tyagi, C.; Tomar, L.; Kumar, P.; Ndesendo, V.M. A review of the effect of processing variables on the fabrication of electrospun nanofibres for drug delivery applications. J. Nanomater. 2013, 2013, 1–22. [Google Scholar] [CrossRef]

- Wang, X.; Hsiao, B.S. Electrospun nanofibre membranes. Curr. Opin. Chem. Eng. 2016, 12, 62–81. [Google Scholar] [CrossRef]

- Deitzel, J.M.; Kleinmeyer, J.; Harris, D.; Tan, N.C.B. The effect of processing variables on the morphology of electrospun nanofibres and textiles. Polymer 2001, 42, 261–272. [Google Scholar] [CrossRef]

- Zhang, C.; Yuan, X.; Wu, L.; Han, Y.; Sheng, J. Study on morphology of electrospun poly(vinyl alcohol) mats. Eur. Polym. J. 2005, 41, 423–432. [Google Scholar] [CrossRef]

- Demir, M.M.; Yilgor, I.; Yilgor, E.; Erman, B. Electrospinning of polyurethane fibres. Polymer 2002, 43, 3303–3309. [Google Scholar] [CrossRef]

- Megelski, S.; Stephens, J.S.; Chase, D.B.; Rabolt, J.F. Micro- and nanostructured surface morphology on electrospun polymer fibres. Macromolecules 2002, 35, 8456–8466. [Google Scholar] [CrossRef]

- Katti, D.S.; Robinson, K.W.; Ko, F.K.; Laurencin, C.T. Bioresorbable nanofibre-based systems for wound healing and drug delivery: Optimization of fabrication parameters. J. Biomed. Mater. Res. Part B Appl. Biomater. 2004, 70, 286–296. [Google Scholar] [CrossRef] [PubMed]

- Jaworek, A.; Krupa, A.; Lackowski, M.; Sobczyk, A.T.; Czech, T.; Ramakrishna, S.; Sundarrajan, S.; Pliszka, D. Nanocomposite fabric formation by electrospinning and electrospraying technologies. J. Electrost. 2009, 67, 435–438. [Google Scholar] [CrossRef]

- Wannatong, L.; Sirivat, A.; Supaphol, P. Effects of solvents on electrospun polymeric fibres: Preliminary study on polystyrene. Polym. Int. 2004, 53, 1851–1859. [Google Scholar] [CrossRef]

- Geng, X.; Kwon, O.-H.; Jang, J. Electrospinning of chitosan dissolved in concentrated acetic acid solution. Biomaterials 2005, 26, 5427–5432. [Google Scholar] [CrossRef]

- Agarwal, P.; Mishra, P.K.; Srivastava, P. Statistical optimization of the electrospinning process for chitosan/polylactide nanofabrication using response surface methodology. J. Mater. Sci. 2012, 47, 4262–4269. [Google Scholar] [CrossRef]

- Doshi, J.; Reneker, D.H. Electrospinning process and applications of electrospun fibres. J. Electrost. 1995, 35, 151–160. [Google Scholar] [CrossRef]

- Ki, C.S.; Baek, D.H.; Gang, K.D.; Lee, K.H.; Um, I.C.; Park, Y.H. Characterization of gelatin nanofibre prepared from gelatin-formic acid solution. Polymer 2005, 46, 5094–5102. [Google Scholar] [CrossRef]

- Casper, C.L.; Yang, W.; Farach-Carson, M.C.; Rabolt, J.F. Understanding the Effects of Processing Parameters on Electrospun Fibres and Applications in Tissue Engineering. ACS Symp. Ser. 2006, 918, 205–216. [Google Scholar]

- Casper, C.L.; Stephens, J.S.; Tassi, N.G.; Chase, D.B.; Rabolt, J.F. Controlling surface morphology of electrospun polystyrene fibres: Effect of humidity and molecular weight in the electrospinning process. Macromolecules 2004, 37, 573–578. [Google Scholar] [CrossRef]

- Stodolak-Zych, E.; Rapacz-Kmita, A.; Dudek, M. Potential of Superhydrophobic Layer on the Implant Surface. In Solid State Phenomena; Elsevier Science: Amsterdam, The Netherlands, 2015; Volume 227, pp. 511–514. [Google Scholar]

- Castro, J.; Krishnan, K.G.; Jamaludeen, S.; Venkataragavan, P.; Gnanavel, S. Degradation and Corrosion Behavior of Electrospun PHBV Coated AZ-31 Magnesium Alloy for Biodegradable Implant Applications. J. Bio Tribo Corros. 2017, 3, 52. [Google Scholar] [CrossRef]

- Palumbo, G.; Cusanno, A.; Garcia-Romeu, M.L.; Bagudanch, I.; Negrini, N.C.; Villa, T.; Farè, S. Single Point Incremental Forming and Electrospinning to produce biodegradable magnesium (AZ31) biomedical prostheses coated with porous PCL. Mater. Today: Proc. 2019, 7, 394–401. [Google Scholar] [CrossRef]

- Nafi, A.W.; Afifi, A.; Abidin, N.I.Z.; Aziz, H.A.; Kalantari, N.K. Effect of the poly l-lactic acid coating on the corrosion of magnesium in hank’s solution. Sains Malays. 2018, 47, 169–179. [Google Scholar] [CrossRef]

- Hanas, T.; Kumar, T.S.S.; Perumal, G.; Doble, M. Tailoring degradation of AZ31 alloy by surface pre-treatment and electrospun PCL fibrous coating. Mater. Sci. Eng. C 2016, 65, 43–50. [Google Scholar] [CrossRef] [PubMed]

- Hanas, T.; Kumar, T.S.S. Tailoring Biodegradation of Fine Grained AZ31 Alloy Implants by Nanofibrous Coatings. in Mater. Today Proc. 2017, 4, 6697–6703. [Google Scholar] [CrossRef]

- Abdal-hay, A.; Barakat, N.A.M.; Lim, J.K. Influence of electrospinning and dip-coating techniques on the degradation and cytocompatibility of Mg-based alloy. Colloids Surf. A Physicochem. Eng. Asp. 2013, 420, 37–45. [Google Scholar] [CrossRef]

- Rezk, A.I.; Mousa, H.M.; Lee, J.; Park, C.H.; Kim, C.S. Composite PCL/HA/simvastatin electrospun nanofibre coating on biodegradable Mg alloy for orthopedic implant application. J. Coat. Technol. Res. 2019, 16, 477–489. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhang, Z.; Yu, L.; Tang, Q. Electrospinning of polyaniline microfibres for anticorrosion coatings: An avenue of enhancing anticorrosion behaviors. Synth. Met. 2016, 212, 84–90. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhang, Z.; Yu, L. Corrosion protection of carbon steel by electrospun film containing polyaniline microfibres. React. Funct. Polym. 2016, 102, 20–26. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhang, Z.; Yu, L.; Jiang, T. Hydrophobic polystyrene/electro-spun polyaniline coatings for corrosion protection. Synth. Met. 2017, 234, 166–174. [Google Scholar] [CrossRef]

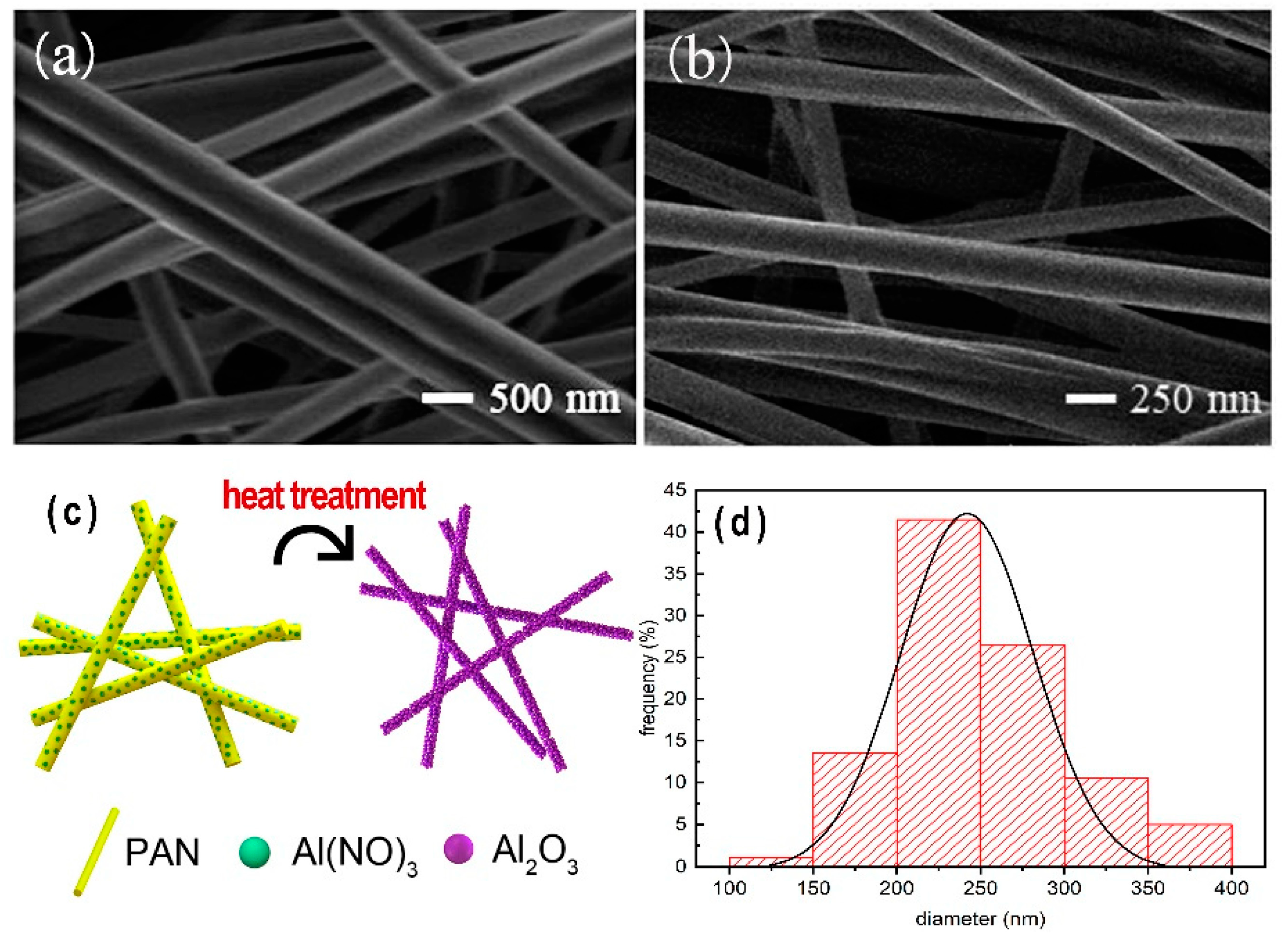

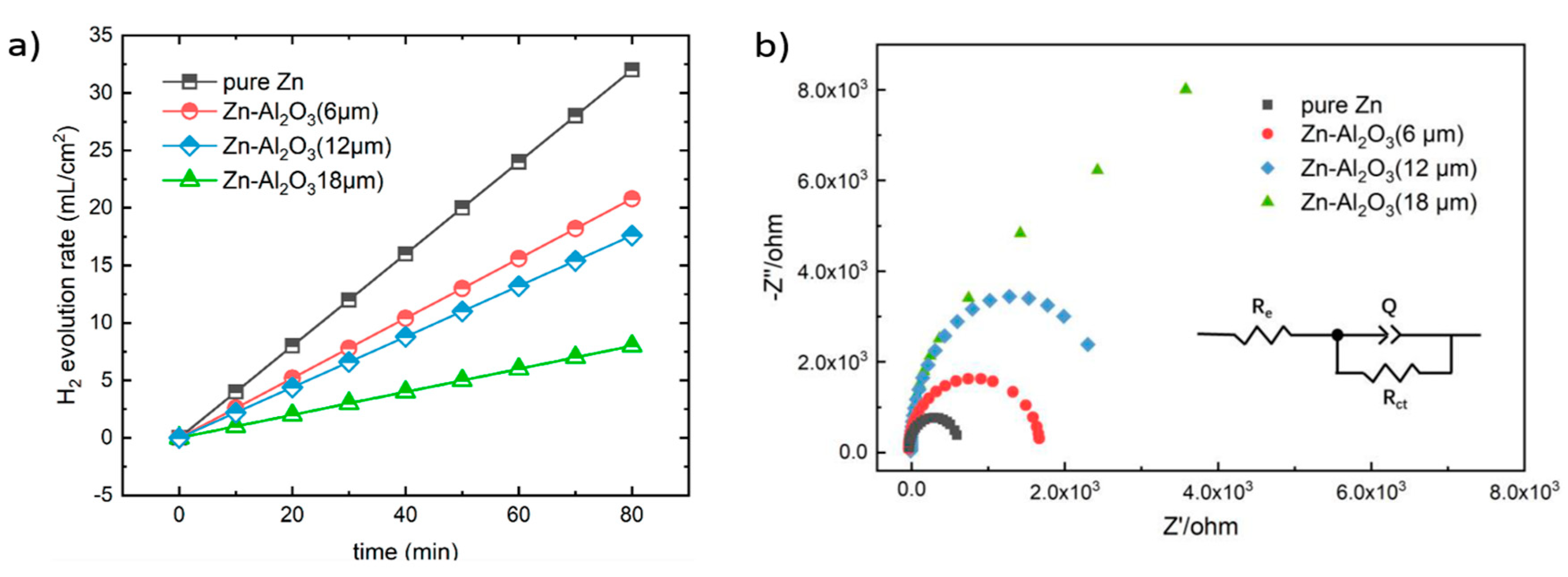

- Yu, Y.; Zuo, Y.; Zhang, Z.; Wu, L.; Ning, C.; Zuo, C. Al2O3 coatings on zinc for anti-corrosion in alkaline solution by electrospinning. Coatings 2019, 9, 692. [Google Scholar] [CrossRef]

- Firouzi, A.; del Gaudio, C.; Lamastra, F.R.; Montesperelli, G.; Bianco, A. Electrospun polymeric coatings on aluminum alloy as a straightforward approach for corrosion protection. J. Appl. Polym. Sci. 2015, 132, 41250. [Google Scholar] [CrossRef]

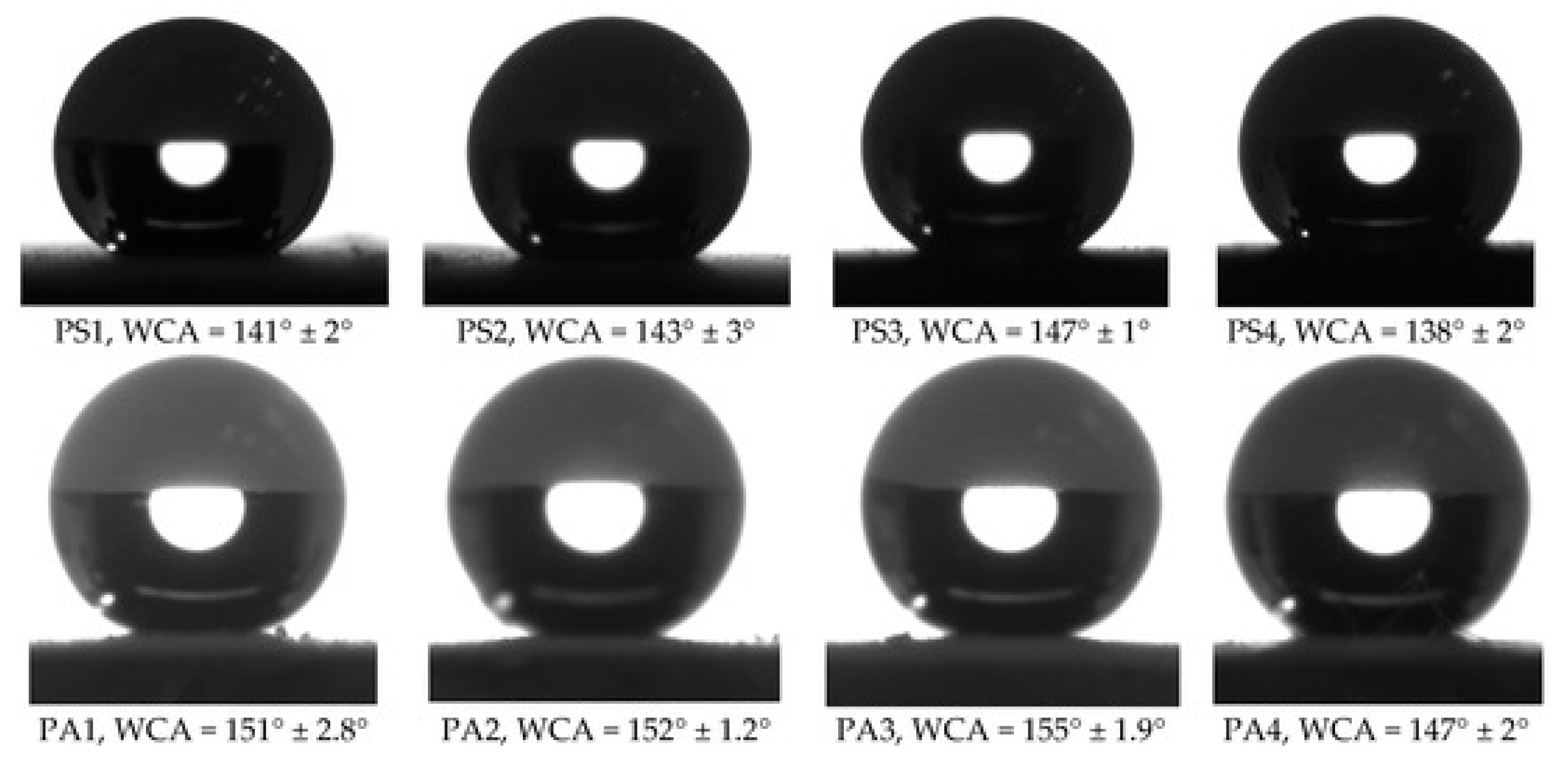

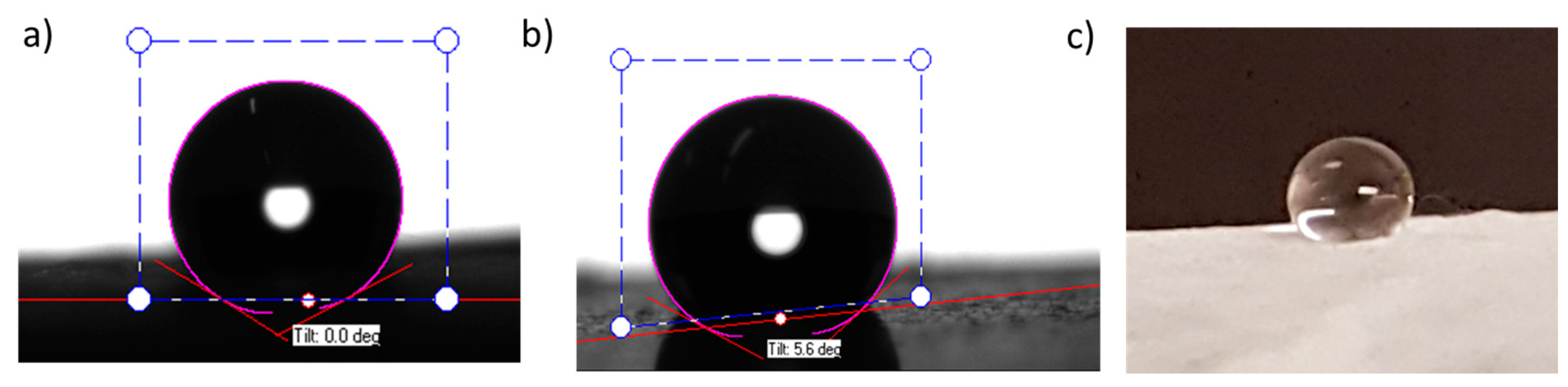

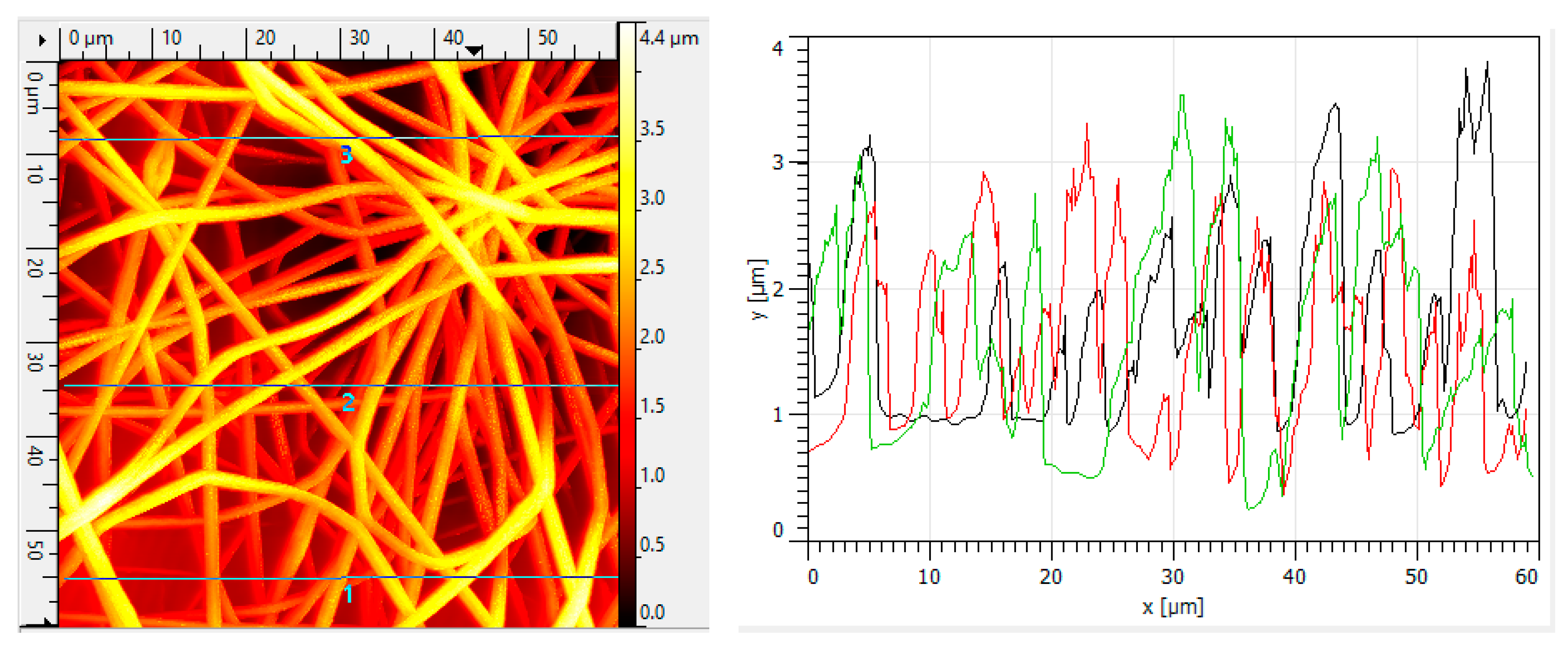

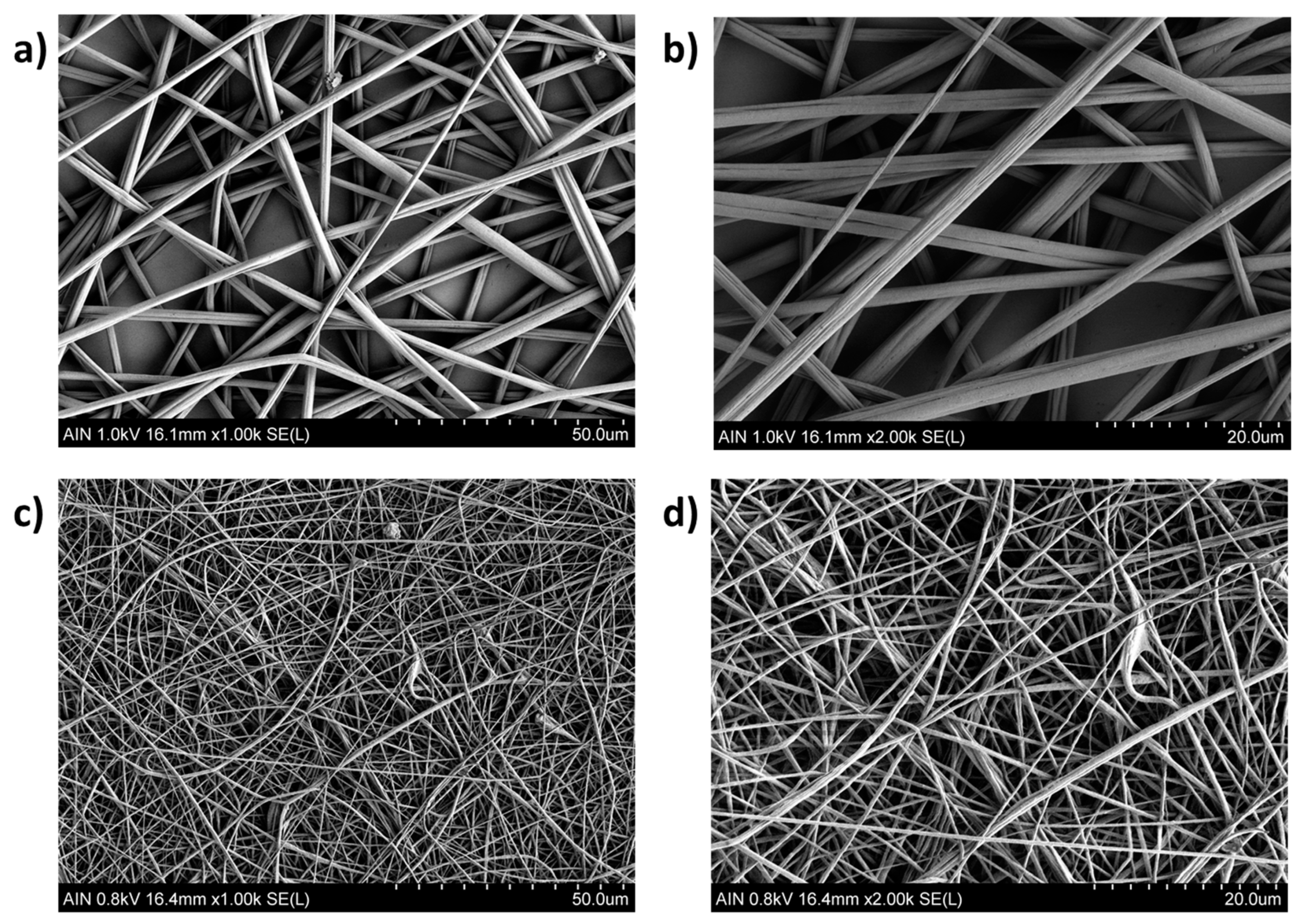

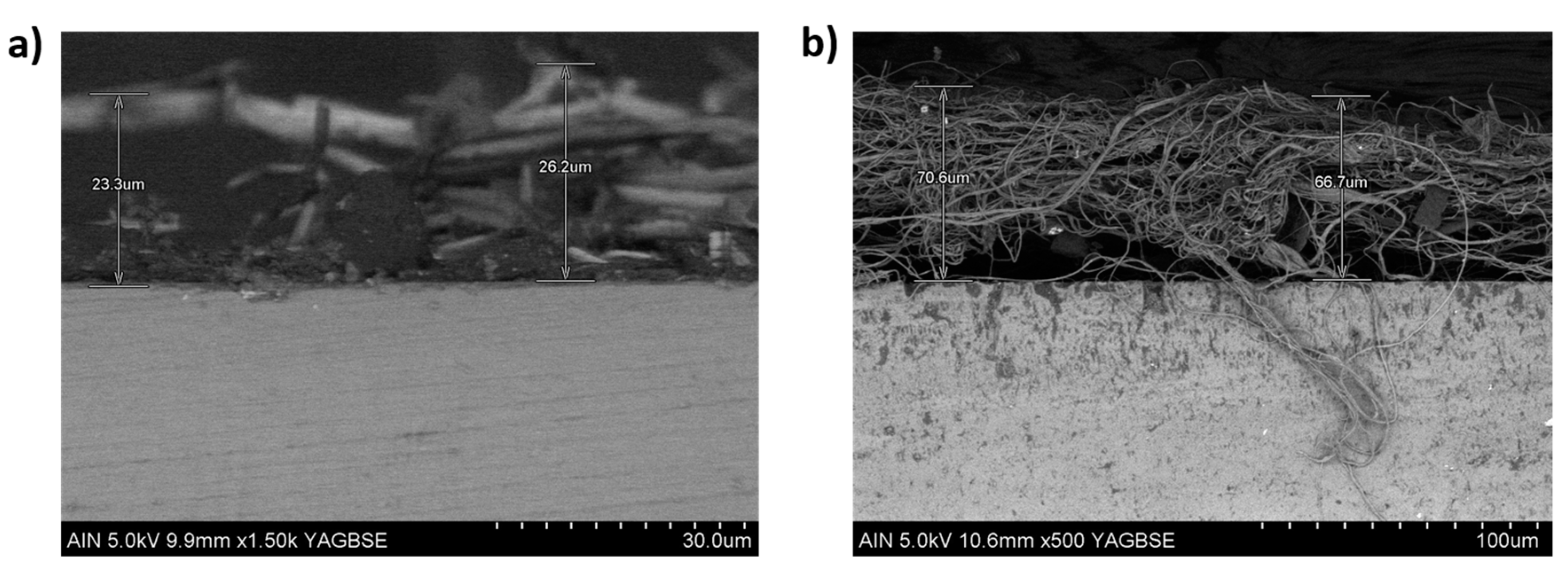

- Rivero, P.J.; Yurrita, D.; Berlanga, C.; Palacio, J.F.; Rodríguez, R. Functionalized electrospun fibres for the design of novel hydrophobic and anticorrosive surfaces. Coatings 2018, 8, 300. [Google Scholar] [CrossRef]

- Liu, F.; Hashim, N.A.; Liu, Y.; Abed, M.R.M.; Li, K. Progress in the production and modification of PVDF membranes. J. Memb. Sci. 2011, 375, 1–27. [Google Scholar] [CrossRef]

- Cui, M.; Xu, C.; Shen, Y.; Tian, H.; Feng, H.; Li, J. Electrospinning superhydrophobic nanofibrous poly(vinylidene fluoride)/stearic acid coatings with excellent corrosion resistance. Thin Solid Film. 2018, 657, 88–94. [Google Scholar] [CrossRef]

- Zhao, Y.; Xing, C.; Zhang, Z.; Yu, L. Superhydrophobic polyaniline/polystyrene micro/nanostructures as anticorrosion coatings. React. Funct. Polym. 2017, 119, 95–104. [Google Scholar] [CrossRef]

- Es-Saheb, M.; Sherif, E.M.; El-zatahry, A.; Rayes, M.M.E.; Khalil, K.A. Corrosion passivation in aerated 3.5% NaCl solutions of brass by nanofibre coatings of polyvinyl chloride and polystyrene. Int. J. Electrochem. Sci. 2012, 7, 10442–10455. [Google Scholar]

- Es-saheb, M.; Elzatahry, A.A.; Sherif, E.-S.M.; Alkaraki, A.S.; kenawy, E.-R. A novel electrospinning application for polyvinyl chloride nanofibre coating deposition as a corrosion inhibitor for aluminum, steel, and brass in chloride solutions. Int. J. Electrochem. Sci. 2012, 7, 5962–5976. [Google Scholar]

- Sherif, E.-S.M.; Es-Saheb, M.; El-Zatahry, A.; Alkaraki, A.S. Coating electrospun polyvinyl alcohol and polyvinyl chloride fibres as corrosion passivation applications. Int. J. Electrochem. Sci. 2012, 7, 6154–6167. [Google Scholar]

- Li, J.; Guan, P.; Li, M.; Zhang, Y.; Cheng, P.; Jia, R. Anticorrosive superhydrophobic polystyrene-coated mesh for continuous oil spill clean-u. New J. Chem. 2017, 41, 4862–4868. [Google Scholar] [CrossRef]

- Radwan, A.B.; Abdullah, A.M.; Mohamed, A.M.A.; Al-Maadeed, M.A. New electrospun polystyrene/Al2O3 nanocomposite superhydrophobic coatings; Synthesis, characterization, and application. Coatings 2018, 8, 65. [Google Scholar] [CrossRef]

- Polat, N.H.; Kap, Ö.; Farzaneh, A. Anticorrosion coating for magnesium alloys: Electrospun superhydrophobic polystyrene/SiO2 composite fibres. Turkish J. Chem. 2018, 42, 672–683. [Google Scholar]

- Grignard, B.; Vaillant, A.; De Coninck, J.; Piens, M.; Jonas, A.M.; Detrembleur, C.; Jérôme, C. Electrospinning of a functional perfluorinated block copolymer as a powerful route for imparting superhydrophobicity and corrosion resistance to aluminum substrates. Langmuir 2011, 27, 335–342. [Google Scholar] [CrossRef] [PubMed]

- Firouzi, A.; Impagnatiello, A.; del Gaudio, C.; Lamastra, F.R.; Bianco, A.; Montesperelli, G. Electrospun protective self-healing coatings for light alloys: A better understanding of the intrinsic potential of the technology. J. Appl. Polym. Sci. 2015, 132, 42728. [Google Scholar] [CrossRef]

- Dieleman, C.D.; Denissen, P.J.; Garcia, S.J. Long-Term Active Corrosion Protection of Damaged Coated-AA2024-T3 by Embedded Electrospun Inhibiting Nanonetworks. Adv. Mater. Interfaces 2018, 5, 1800176. [Google Scholar] [CrossRef]

- Gaballah, S.; Shehata, N.; Shaaban, M.; Nosier, S.; Hefnawy, A.; Hamed, A.; Samir, E. Corrosion inhibition of aluminum in hydrochloric acid solution using ceria doped polyvinyl chloride nanofibre. Int. J. Electrochem. Sci. 2017, 12, 1094–1105. [Google Scholar] [CrossRef]

- Dong, Y.; Li, S.; Zhou, Q. Self-healing capability of inhibitor-encapsulating polyvinyl alcohol/polyvinylidene fluoride coaxial nanofibres loaded in epoxy resin coatings. Prog. Org. Coat. 2018, 120, 49–57. [Google Scholar] [CrossRef]

- Doan, T.Q.; Leslie, L.S.; Kim, S.Y.; Bhargava, R.; White, S.R.; Sottos, N.R. Characterization of core-shell microstructure and self-healing performance of electrospun fibre coatings. Polymer 2016, 107, 263–272. [Google Scholar] [CrossRef]

- Ji, X.; Wang, W.; Li, W.; Zhao, X.; Liu, A.; Wang, X.; Liu, S. pH-responsible self-healing performance of coating with dual-action core-shell electrospun fibres. J. Taiwan Inst. Chem. Eng. 2019, 104, 227–239. [Google Scholar] [CrossRef]

- Menchaca, C.; Castaneda, I.; Soto-Quintero, A.; Guardián, R.; Cruz, R.; García-Sánchez, M.A.; Uruchurtu, J. Characterization of a “Smart” hybrid varnish electrospun nylon benzotriazole copper corrosion protection coating. Int. J. Corros. 2012, 2012, 925958. [Google Scholar] [CrossRef]

- Radwan, A.B.; Mohamed, A.M.A.; Abdullah, A.M.; Al-Maadeed, M.A. Corrosion protection of electrospun PVDF-ZnO superhydrophobic coating. Surf. Coat. Technol. 2016, 289, 136–143. [Google Scholar] [CrossRef]

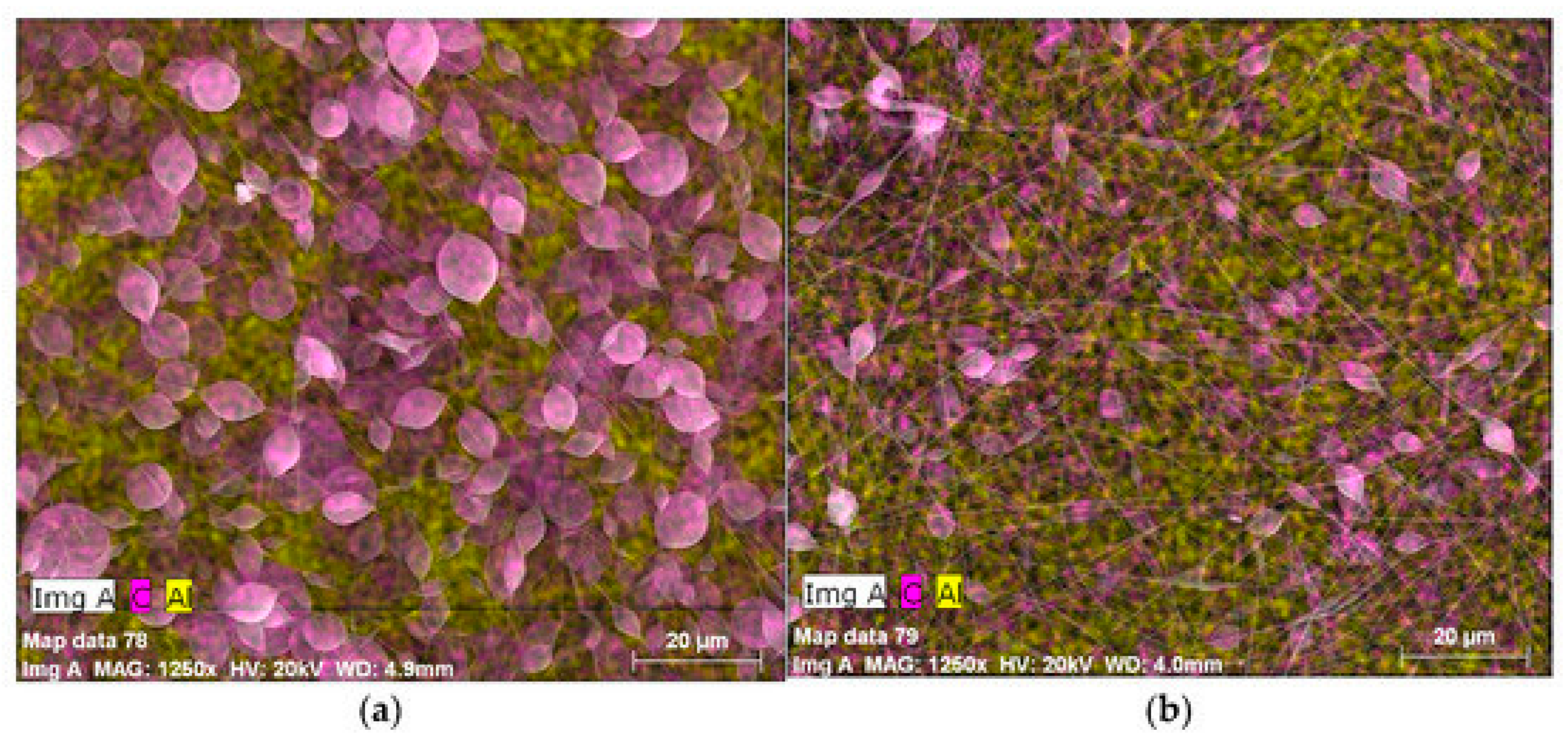

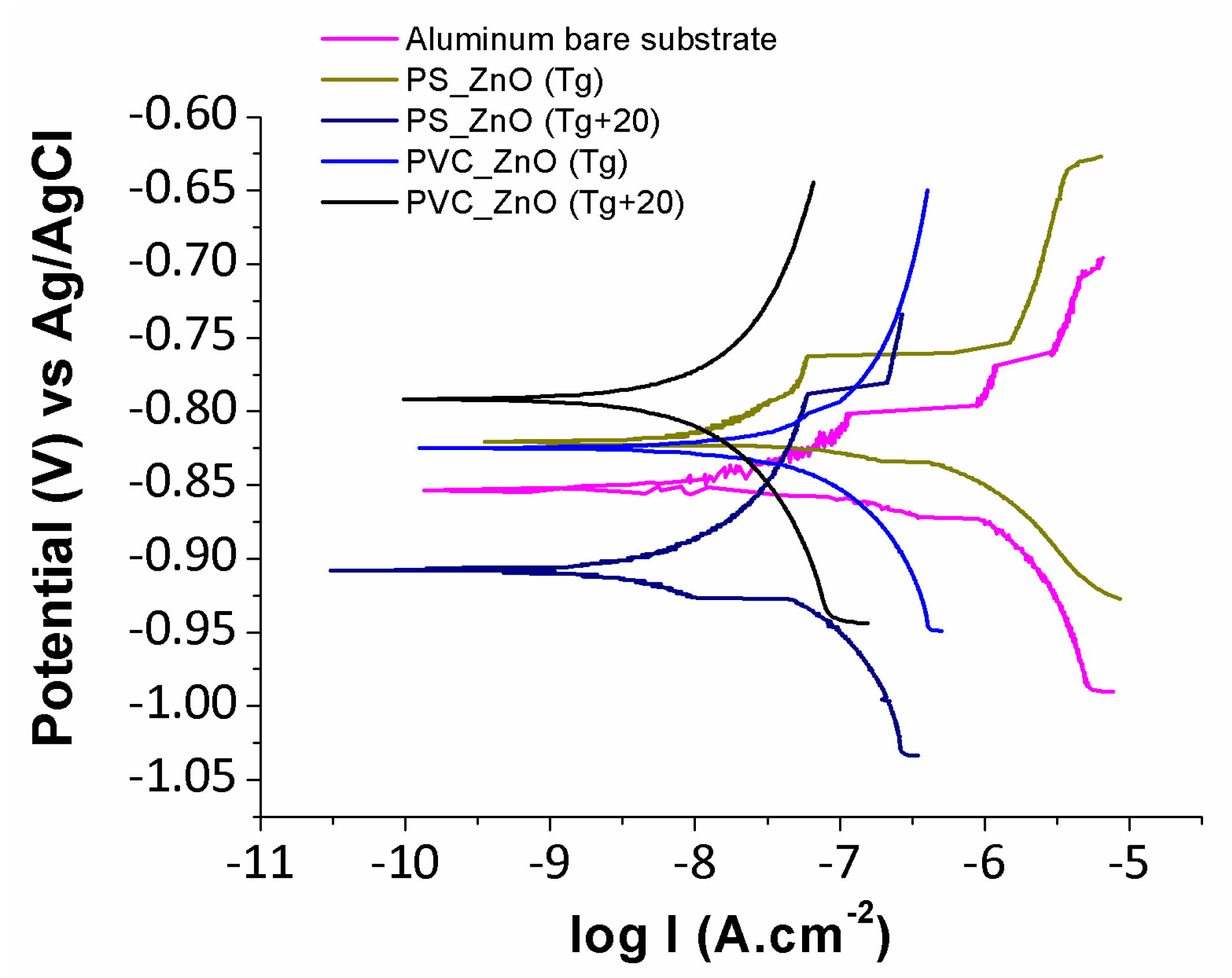

- Iribarren, A.; Rivero, P.J.; Berlanga, C.; Larumbe, S.; Miguel, A.; Fernandez-Palacio, J.; Rodriguez, R. Multifunctional protective PVC-ZnO nanocomposite coatings deposited on aluminum alloys by electrospinning. Coatings 2019, 9, 216. [Google Scholar] [CrossRef]

- Rivero, P.J.; Iribarren, A.; Larumbe, S.; Palacio, J.F.; Rodríguez, R. A comparative study of multifunctional coatings based on electrospun fibres with incorporated ZnO nanoparticles. Coatings 2019, 9, 367. [Google Scholar] [CrossRef]

- Wang, X.; Ding, B.; Yu, J.; Wang, M. Engineering biomimetic superhydrophobic surfaces of electrospun nanomaterials. Nano Today 2011, 6, 510–530. [Google Scholar] [CrossRef]

- Augustine, R.; Kalarikkal, N.; Thomas, S. Effect of zinc oxide nanoparticles on the in vitro degradation of electrospun polycaprolactone membranes in simulated body fluid. Int. J. Polym. Mater. Polym. Biomater. 2016, 65, 28–37. [Google Scholar] [CrossRef]

- Asmatulu, R.; Ceylan, M.; Nuraje, N. Study of superhydrophobic electrospun nanocomposite fibres for energy systems. Langmuir 2011, 27, 504–507. [Google Scholar] [CrossRef] [PubMed]

- Zhong, Z.; Qin, J.; Ma, J. Cellulose acetate/hydroxyapatite/chitosan coatings for improved corrosion resistance and bioactivity. Mater. Sci. Eng. C 2015, 49, 251–255. [Google Scholar] [CrossRef]

- Nejad, H.B.; Garrison, K.L.; Mather, P.T. Comparative analysis of shape memory-based self-healing coatings. J. Polym. Sci. Part B Polym. Phys. 2016, 54, 1415–1426. [Google Scholar] [CrossRef]

- Covelo, A.; Genescá, J.; Barba, A.; Menchaca, C.; Uruchurtu, J.; Hernández, M. Corrosion behavior of hybrid sol-gel films reinforced with electrospun nanofibres. In Solid Sate Phenomena; Elsevier Science: Amsterdam, The Netherlands, 2015; Volume 227, pp. 119–122. [Google Scholar]

- Starkey, R.L.; Wight, K.M. Anaerobic Corrosion of Iron in Soil. In Final Report of the American Gas Association; Corrosion Iron Research Fellowship; American Gas Association: New York, NY, USA, 1945. [Google Scholar]

- Iverson, W.P. Microbial Corrosion of Metals. Adv. Appl. Microbiol. 1987, 32, 1–36. [Google Scholar]

- Melchers, R.E. The effect of corrosion on the structural reliability of steel offshore structures. Corros. Sci. 2005, 47, 2391–2410. [Google Scholar] [CrossRef]

- Melchers, R.; Jeffrey, R. The critical involvement of anaerobic bacterial activity in modelling the corrosion behaviour of mild steel in marine environments. Electrochim. Acta 2008, 54, 80–85. [Google Scholar] [CrossRef]

- Enning, D.; Venzlaff, H.; Garrelfs, J.; Dinh, H.T.; Meyer, V.; Mayrhofer, K.J.J.; Hassel, A.W.; Stratmann, M.; Widdel, F. Marine sulfate-reducing bacteria cause serious corrosion of iron under electroconductive biogenic mineral crust. Environ. Microbiol. 2012, 14, 1772–1787. [Google Scholar] [CrossRef] [PubMed]

- Vigneron, A.; Alsop, E.B.; Chambers, B.; Lomans, B.P.; Head, I.M.; Tsesmetzis, N. Complementary microorganisms in highly corrosive biofilms from an offshore oil production facility. Appl. Environ. Microbiol. 2016, 82, 2545–2554. [Google Scholar] [CrossRef] [PubMed]

- Díez, B.; Amariei, G.; Rosal, R. Electrospun Composite Membranes for Fouling and Biofouling Control. Ind. Eng. Chem. Res. 2018, 57, 14561–14570. [Google Scholar] [CrossRef]

- Su, Q.; Zhang, J.; Zhang, L.Z. Fouling resistance improvement with a new superhydrophobic electrospun PVDF membrane for seawater desalination. Desalination 2020, 476, 114246. [Google Scholar] [CrossRef]

- Matin, A.; Khan, Z.; Zaidi, S.M.J.; C, M. Boyce. Biofouling in reverse osmosis membranes for seawater desalination: Phenomena and prevention. Desalination 2011, 281, 1–16. [Google Scholar] [CrossRef]

- Chan, W.Y.; Chian, K.S.; Tan, M.J. In vitro metal ion release and biocompatibility of amorphous Mg 67Zn28Ca5 alloy with/without gelatin coating. Mater. Sci. Eng. C 2013, 33, 5019–5027. [Google Scholar] [CrossRef]

- Bakhsheshi-Rad, H.R.; Akbari, M.; Ismail, A.F.; Aziz, M.; Hadisi, Z.; Pagan, E.; Chen, X. Coating biodegradable magnesium alloys with electrospun poly-L-lactic acid-åkermanite-doxycycline nanofibres for enhanced biocompatibility, antibacterial activity, and corrosion resistance. Surf. Coatings Technol. 2019, 377, 124898. [Google Scholar] [CrossRef]

- Xu, L.; Yu, G.; Zhang, E.; Pan, F.; Yang, K. In vivo corrosion behavior of Mg-Mn-Zn alloy for bone implant application. J. Biomed. Mater. Res. Part A 2007, 83A, 703–711. [Google Scholar] [CrossRef]

- Donlan, R.M. Biofilms and device-associated infections. Emerg. Infect. Dis. 2001, 7, 277–281. [Google Scholar] [CrossRef]

- Ramage, G.; Martínez, J.P.; López-Ribot, J.L. Candida biofilms on implanted biomaterials: A clinically significant problem. FEMS Yeast Res. 2006, 6, 979–986. [Google Scholar] [CrossRef]

- Hays, G.F. World Corrosion Organization; Corrodia; NACE International: Houston, TX, USA, 2010. [Google Scholar]

- Beavers, J.A.; Thompson, N.G. External corrosion of oil and natural gas pipelines. ASM Handb. 2006, 13, 1015–1025. [Google Scholar]

- Mansfield, E.; Sowards, J.W.; Crookes-Goodson, W.J. Findings and recommendations from the NIST Workshop on alternative fuels and materials: Biocorrosion. J. Res. Natl. Inst. Stand. Technol. 2015, 120, 28. [Google Scholar] [CrossRef] [PubMed]

- Artifon, W.; Pasini, S.M.; Valério, A.; González, S.Y.G.; Souza, S.G.; Souza, S.G. Harsh environment resistant-antibacterial zinc oxide/Polyetherimide electrospun composite scaffolds. Mater. Sci. Eng. C 2019, 103, 109859. [Google Scholar] [CrossRef] [PubMed]

- Heitz, E.; Flemming, H.C.; Sand, W. Microbially Influenced Corrosion of Materials: Scientific and Engineering Aspects; Springer: Berlin/Heidelberg, Germany, 1996. [Google Scholar]

- Libert, M.F.; Bildstein, O. La biocorrosion: Nouvelles approches. Actual. Chim. 2015, 400, 105–107. [Google Scholar]

- Videla, H.A.; Herrera, L.K. Microbiologically influenced corrosion: Looking to the future. Int. Microbiol. 2005, 8, 169–180. [Google Scholar]

- Oren, A. Chemolithotrophy. In Encyclopedia of Life Sciences; John Wiley & Sons Ltd.: Chichester, UK, 2009. [Google Scholar]

- Kip, N.; van Veen, J.A. The dual role of microbes in corrosion. ISME J. 2015, 9, 542–551. [Google Scholar] [CrossRef]

- Ehrlich, H.L.; Newman, D.K.; Kappler, A. Ehrlich’s Geomicrobiology; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar]

- Morrison, C.; Heitmann, E.; Armiger, W.; Dodds, D.; Koffas, M. Electrochemical Bioreactor Technology for Biocatalysis and Microbial Electrosynthesis. Adv. Appl. Microbiol. 2018, 105, 51–86. [Google Scholar]

- Juzeliūnas, E.; Ramanauskas, R.; Lugauskas, A.; Leinartas, K.; Samuleviciene, M.; Sudavičius, A.; Juškėnas, R. Microbially influenced corrosion of zinc and aluminium—Two-year subjection to influence of Aspergillus niger. Corros. Sci. 2007, 49, 4098–4112. [Google Scholar] [CrossRef]

- Dai, X.; Wang, H.; Ju, L.K.; Cheng, G.; Cong, H.; Newby, B.M.Z. Corrosion of aluminum alloy 2024 caused by Aspergillus niger. Int. Biodeterior. Biodegrad. 2016, 115, 1–10. [Google Scholar] [CrossRef]

- Jirón-Lazos, U.; Corvo, F.; de la Rosa, S.C.; García-Ochoa, E.M.; Bastidas, D.M.; Bastidas, J.M. Localized corrosion of aluminum alloy 6061 in the presence of Aspergillus niger. Int. Biodeterior. Biodegrad. 2018, 133, 17–25. [Google Scholar] [CrossRef]

- Herrera, L.K.; Videla, H.A. Role of iron-reducing bacteria in corrosion and protection of carbon steel. Int. Biodeterior. Biodegrad. 2009, 63, 891–895. [Google Scholar] [CrossRef]

- Wen, S.; Hu, Y.; Zhang, Y.; Huang, S.; Zuo, Y.; Min, Y. Dual-functional core-shell electrospun mats with precisely controlled release of anti-inflammatory and anti-bacterial agents. Mater. Sci. Eng. C 2019, 100, 514–522. [Google Scholar] [CrossRef] [PubMed]

- De-Paula, M.M.M.; Afewerki, S.; Viana, B.C.; Webster, T.J.; Lobo, A.O.; Marciano, F.R. Dual effective core-shell electrospun scaffolds: Promoting osteoblast maturation and reducing bacteria activity. Mater. Sci. Eng. C 2019, 103, 109778. [Google Scholar] [CrossRef] [PubMed]

- Lee, M.W.; An, S.; Lee, C.; Liou, M.; Yarin, A.L.; Yoon, S.S. Self-healing transparent core-shell nanofibre coatings for anti-corrosive protection. J. Mater. Chem. A 2014, 2, 7045–7053. [Google Scholar] [CrossRef]

- Poinern, G.E.J.; Brundavanam, S.; Fawcett, D. Biomedical Magnesium Alloys: A Review of Material Properties, Surface Modifications and Potential as a Biodegradable Orthopaedic Implant. Am. J. Biomed. Eng. 2013, 2, 218–240. [Google Scholar] [CrossRef]

- Witte, F.; Fischer, J.; Nellesen, J.; Crostack, H.-A.; Kaese, V.; Pisch, A.; Beckmann, F.; Windhagen, H. In vitro and in vivo corrosion measurements of magnesium alloys. Biomaterials 2006, 27, 1013–1018. [Google Scholar] [CrossRef] [PubMed]

- Song, G.L.; Atrens, A. Corrosion Mechanisms of Magnesium Alloys. Adv. Eng. Mater. 1999, 1, 11–33. [Google Scholar] [CrossRef]

- Bakhsheshi-Rad, H.R.; Ismail, A.F.; Aziz, M.; Hadisi, Z.; Omidi, M.; Chen, X. Antibacterial activity and corrosion resistance of Ta2O5 thin film and electrospun PCL/MgO-Ag nanofibre coatings on biodegradable Mg alloy implants. Ceram. Int. 2019, 45, 11883–11892. [Google Scholar] [CrossRef]

- Kim, J.; Mousa, H.M.; Park, C.H.; Kim, C.S. Enhanced corrosion resistance and biocompatibility of AZ31 Mg alloy using PCL/ZnO NPs via electrospinning. Appl. Surf. Sci. 2017, 396, 249–258. [Google Scholar] [CrossRef]

- Zomorodian, A.; Garcia, M.P.; Silva, T.M.E.; Fernandes, J.C.S.; Fernandes, M.H.; Montemor, M.F. Corrosion resistance of a composite polymeric coating applied on biodegradable AZ31 magnesium alloy. Acta Biomater. 2013, 9, 8660–8670. [Google Scholar] [CrossRef]

- de Rincón, O.T.; Pérez, O.; Paredes, E.; Caldera, Y.; Urdaneta, C.; Sandoval, I. Long-term performance of ZnO as a rebar corrosion inhibitor. Cem. Concr. Compos. 2002, 24, 79–87. [Google Scholar] [CrossRef]

- John, S.; Joseph, A.; Jose, A.J.; Narayana, B. Enhancement of corrosion protection of mild steel by chitosan/ZnO nanoparticle composite membranes. Prog. Org. Coat. 2015, 84, 28–34. [Google Scholar] [CrossRef]

- Hwang, S.H.; Song, J.; Jung, Y.; Kweon, O.Y.; Song, H.; Jang, J. Electrospun ZnO/TiO2 composite nanofibres as a bactericidal agent. Chem. Commun. 2011, 47, 9164–9166. [Google Scholar] [CrossRef] [PubMed]

- Singh, S.; Singh, S.K.; Chowdhury, I.; Singh, R. Understanding the Mechanism of Bacterial Biofilms Resistance to Antimicrobial Agents. Open Microbiol. J. 2017, 11, 53–62. [Google Scholar] [CrossRef] [PubMed]

- Brown, D.C.; Turner, R.J. Biofilms and Microbiologically Influenced Corrosion in the Petroleum Industry. ACS Symp. Ser. 2019, 1323, 187–203. [Google Scholar]

- Nasreen, S.A.A.N.; Sundarrajan, S.; Nizar, S.A.S.; Balamurugan, R.; Ramakrishna, S. In situ polymerization of PVDF-HEMA polymers: Electrospun membranes with improved flux and antifouling properties for water filtration. Polym. J. 2014, 46, 167–174. [Google Scholar] [CrossRef]

- Son, H.Y.; Ryu, J.H.; Lee, H.; Nam, Y.S. Bioinspired templating synthesis of metal-polymer hybrid nanostructures within 3D electrospun nanofibres. ACS Appl. Mater. Interfaces 2013, 5, 6381–6390. [Google Scholar] [CrossRef]

| Coating | Metallic Substrate | Corrosion Tests | Reference |

|---|---|---|---|

| PHBV | Magnesium alloy (AZ31) | Tafel polarization curves and immersion test | [41] |

| PLLA | Pure magnesium and Magnesium alloy (AZ91) | Hydrogen evolution after immersion test in Hank’s solution | [43] |

| PCL | Magnesium alloy (AZ31) | Weight loss and immersion test | [44] |

| PCL | Magnesium alloy (AZ31) | Immersion test | [45] |

| PLA | Die casting magnesium alloy (AM50) | Tafel polarization curves, immersion test and weight loss in SBF | [46] |

| PCL/HA-NPs/simvastatin | Magnesium alloy (AZ31) | Tafel polarization curves and Electrochemical Impedance Spectroscopy (EIS) | [47] |

| PANI/PMMA | Q325 carbon steel | Tafel polarization curves and Electrochemical Impedance Spectroscopy (EIS) | [48] |

| PANI/PMMA | Q235 carbon steel | Tafel polarization curves and Electrochemical Impedance Spectroscopy (EIS) | [49] |

| PANI/PMMA (primer) and PS (topcoat) | Q235 carbon steel | Tafel polarization curves and Electrochemical Impedance Spectroscopy (EIS) | [50] |

| PAN-Al2O3 | Zinc sheet | Hydrogen evolution, Tafel polarization curves and Electrochemical Impedance Spectroscopy (EIS) | [51] |

| PVA/glyoxal | Aluminium alloy (AA6082) | Electrochemical Impedance Spectroscopy (EIS) | [52] |

| PVDF/SA | Aluminium sheets | Tafel polarization curves and Electrochemical Impedance Spectroscopy (EIS) | [55] |

| PANI-PFOA/PS | Q235 carbon steel | Tafel polarization curves and Electrochemical Impedance Spectroscopy (EIS) | [56] |

| PVC PS | Brass | Cyclic potentiodynamic polarization and Electrochemical Impedance Spectroscopy (EIS) | [57] |

| PVC | Aluminium, copper and brass | Cyclic potentiodynamic polarization and Electrochemical Impedance Spectroscopy (EIS) | [58] |

| PVA PVC | Aluminium | Cyclic potentiodynamic polarization and Electrochemical Impedance Spectroscopy (EIS) | [59] |

| PS | Aluminium | Potentiodynamic polarization curves | [60] |

| PS/Al2O3 | Commercial aluminium foil | Electrochemical Impedance Spectroscopy (EIS) | [61] |

| PS/mod-SiO2 | Magnesium alloy (AZ31) | Potentiodynamic polarization curves | [62] |

| (PFDA-co-AA)-b-PAN) | Aluminium alloy (AA2024T3) | Acetic acid salt spray test | [63] |

| PVA/glyoxal doped with cerium nitrate and cerium acetylacetone | Aluminium alloy (AA6082) | Electrochemical Impedance Spectroscopy (EIS) | [64] |

| PVA/GA doped with CeCl3 and Li2CO3 | Aluminium alloy (AA2024-T3) | Electrochemical Impedance Spectroscopy (EIS) | [65] |

| PVC/Ceria NPs | Aluminium | Cyclic potentiodynamic polarization and Electrochemical Impedance Spectroscopy (EIS) | [66] |

| PVA@PVDF doped with MBT | Q345 carbon steel | Scanning Kelvin Probe (SKF) and Electrochemical Impedance Spectroscopy (EIS) | [67] |

| PDMS/PDES@PVA DBTL@PVA | Carbon steel | Linear polarization | [68] |

| PVA@(OA+BTA) | Carbon steel | Electrochemical Impedance Spectroscopy (EIS) | [69] |

| Nylon/BTA | Copper | Electrochemical Impedance Spectroscopy (EIS) | [70] |

| PVDF-ZnO | Aluminium alloy | Tafel polarization curves and Electrochemical Impedance Spectroscopy (EIS) | [71] |

| PVC-ZnO | Aluminium alloy (AA6061-T6) | Tafel polarization curves and pitting corrosion | [72] |

| PVC-ZnO PS-ZnO | Aluminium alloy (AA6061-T6) | Tafel polarization curves and pitting corrosion | [73] |

| CA nanofibres and HAP/CHI solution by dip-coating | 304 stainless steel | Electrochemical polarization curves and electrochemical impedance | [77] |

| PCL and epoxy resin by spin-coating | Carbon steel | Linear sweep voltammetry | [78] |

| TPOZ+GPTMS and PVA doped with Ce(NO3)3 and CeO2 | Aluminium alloy (AA2024-T3) | Electrochemical Impedance spectroscopy (EIS) | [79] |

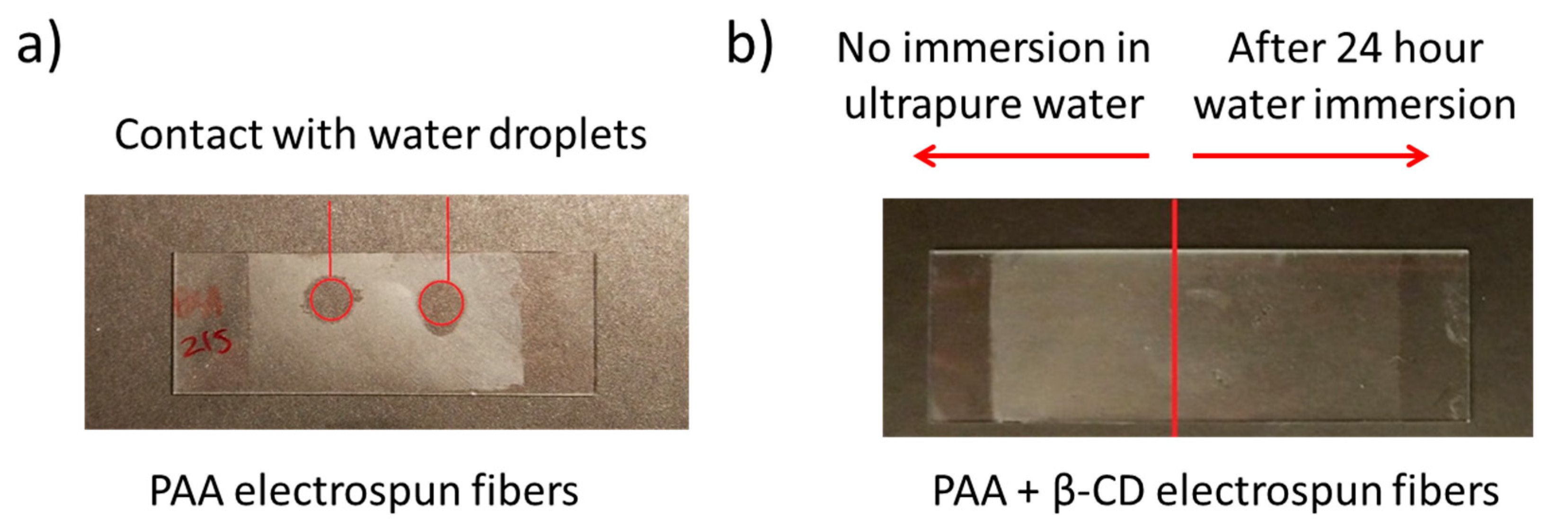

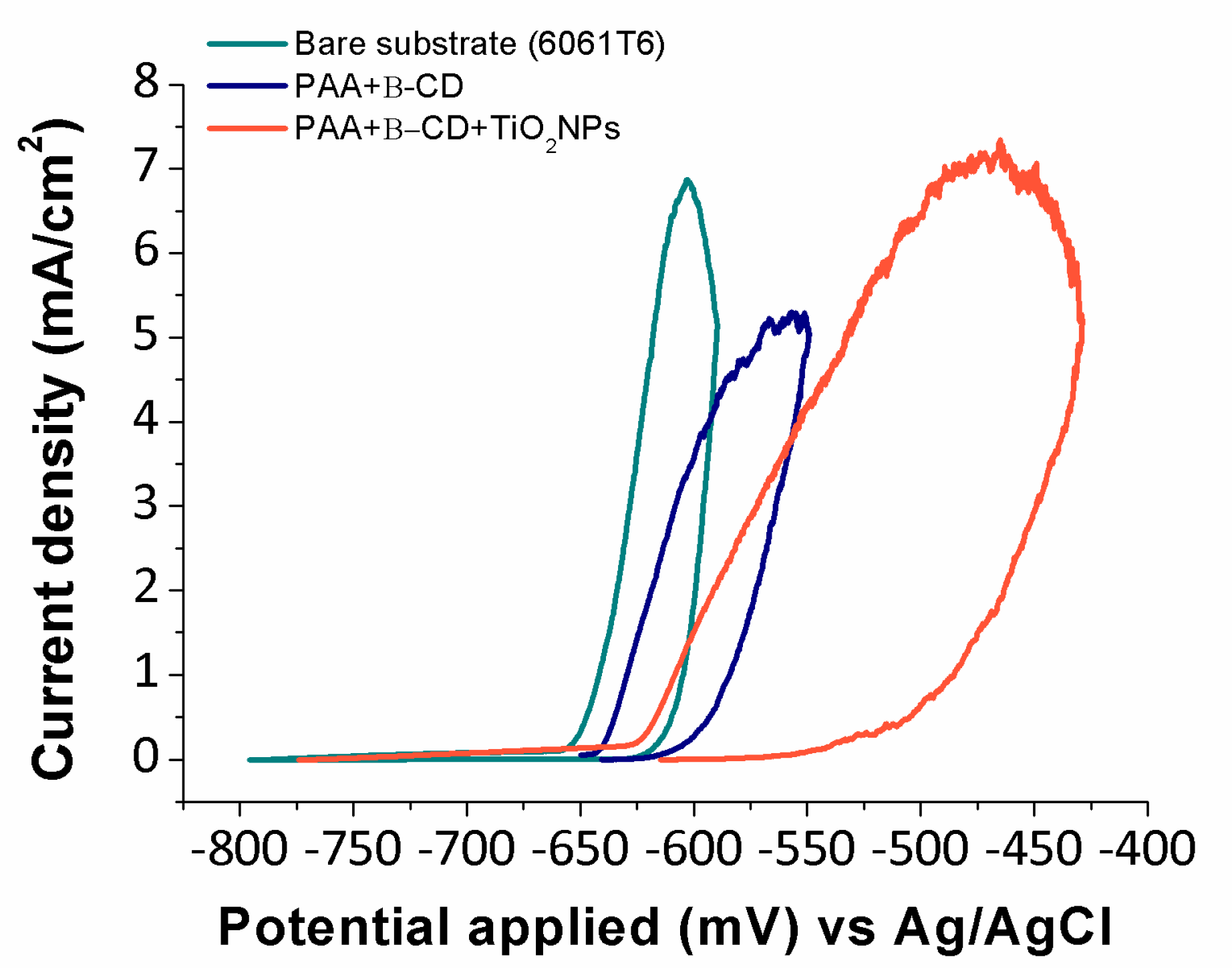

| PAA/β-CD/TiO2NPs and CVD-silanization process | Aluminium alloy (AA6061-T6) | Tafel polarization curves and cyclic potentiodynamic polarization curves | [53] |

| Sputtering Ta2O5 and PCL/MgO-Ag | As-cast Mg-Ca-Zn specimen | Tafel polarization curves and Electrochemical Impedance Spectroscopy (EIS) | [115] |

| Gelatin | As-cast Mg-Ca-Zn specimen | Metal ion concentration and pH monitoring | [89] |

| PLLA-AKT-DOXY | As-cast Mg-Ca specimen | Tafel polarization curves, Electrochemical Impedance Spectroscopy (EIS) and hydrogen evolution | [90] |

| PCL/ZnO | Magnesium alloy (AZ31) | Tafel polarization curves and Electrochemical Impedance Spectroscopy (EIS) | [116] |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rivero, P.J.; Redin, D.M.; Rodríguez, R.J. Electrospinning: A Powerful Tool to Improve the Corrosion Resistance of Metallic Surfaces Using Nanofibrous Coatings. Metals 2020, 10, 350. https://doi.org/10.3390/met10030350

Rivero PJ, Redin DM, Rodríguez RJ. Electrospinning: A Powerful Tool to Improve the Corrosion Resistance of Metallic Surfaces Using Nanofibrous Coatings. Metals. 2020; 10(3):350. https://doi.org/10.3390/met10030350

Chicago/Turabian StyleRivero, Pedro J., Deyo Maeztu Redin, and Rafael J. Rodríguez. 2020. "Electrospinning: A Powerful Tool to Improve the Corrosion Resistance of Metallic Surfaces Using Nanofibrous Coatings" Metals 10, no. 3: 350. https://doi.org/10.3390/met10030350

APA StyleRivero, P. J., Redin, D. M., & Rodríguez, R. J. (2020). Electrospinning: A Powerful Tool to Improve the Corrosion Resistance of Metallic Surfaces Using Nanofibrous Coatings. Metals, 10(3), 350. https://doi.org/10.3390/met10030350