1. Introduction

A surface roughness appearing as a result of cutting processes has a big impact on functional properties of their products, as well as the quality of products in use. Therefore, determining a co-dependency between the set input and/or measurable process parameters occurring during machining and parameters of surface roughness contributes to the managing of the process in terms of a timely prediction of the process from the aspect of a satisfactory product quality.

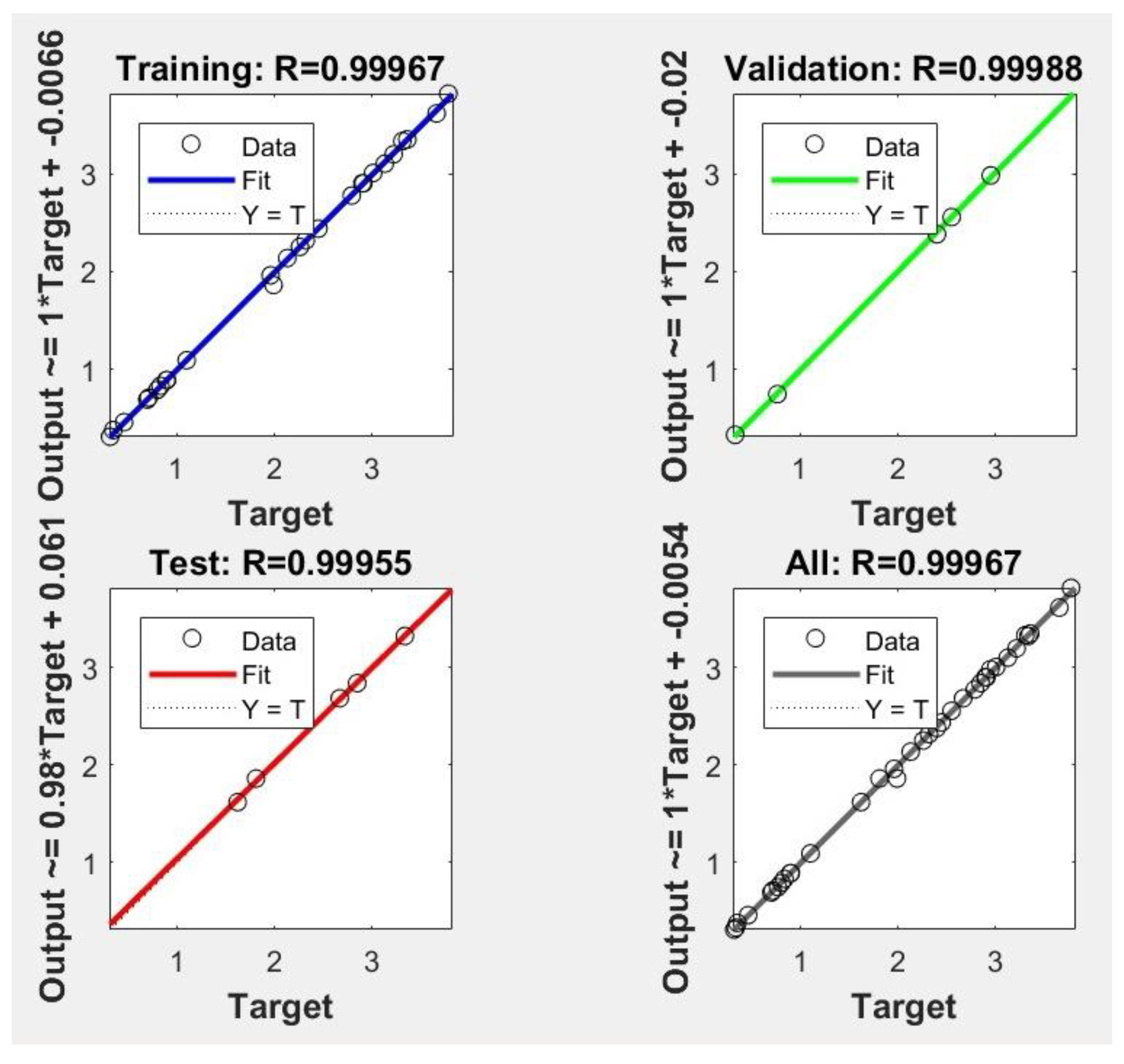

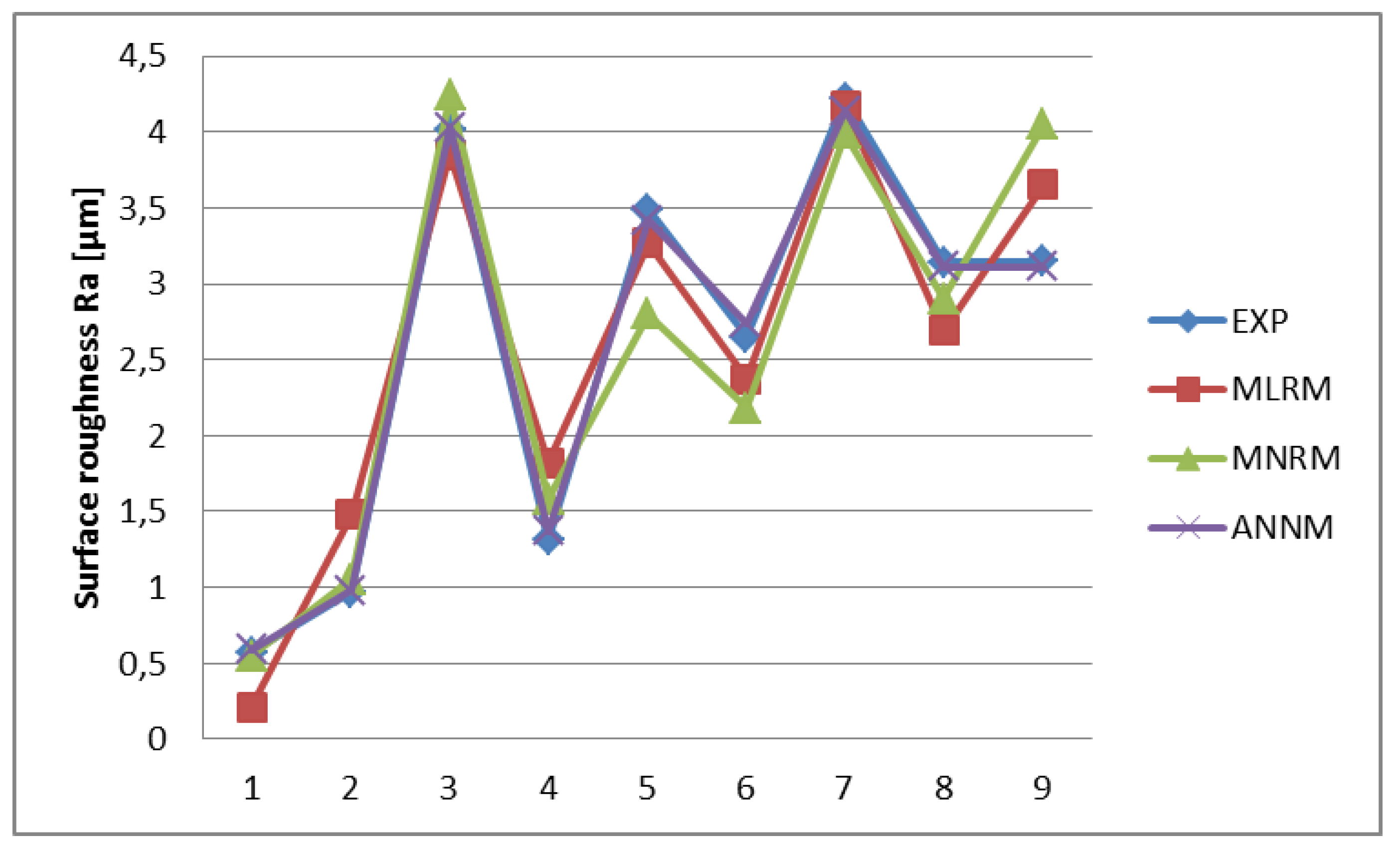

A large number of experimental research projects have tried to establish a co-dependency between surface roughness and input parameters for machining processes. The model for predicting the surface roughness, using an arithmetic mean surface roughness deviation (Ra), was developed by applying a multiple regression model and the models based on artificial neural networks (ANNs).

Rodrigues et al. [

1] used a regression analysis for developing a model linking a speed

n (rev/min), feed

f (mm/rev), and a depth of a cut

a (mm) with the surface roughness using an arithmetic mean deviation

Ra (μm), by conducting a full plan of the experiment, as well as by varying referred parameters at three levels, when turning a construction steel using tools made of high speed steel (HSS). The corrected determination coefficient in this case was 66.1%, indicating a strong correlation between the surface roughness and referred parameters.

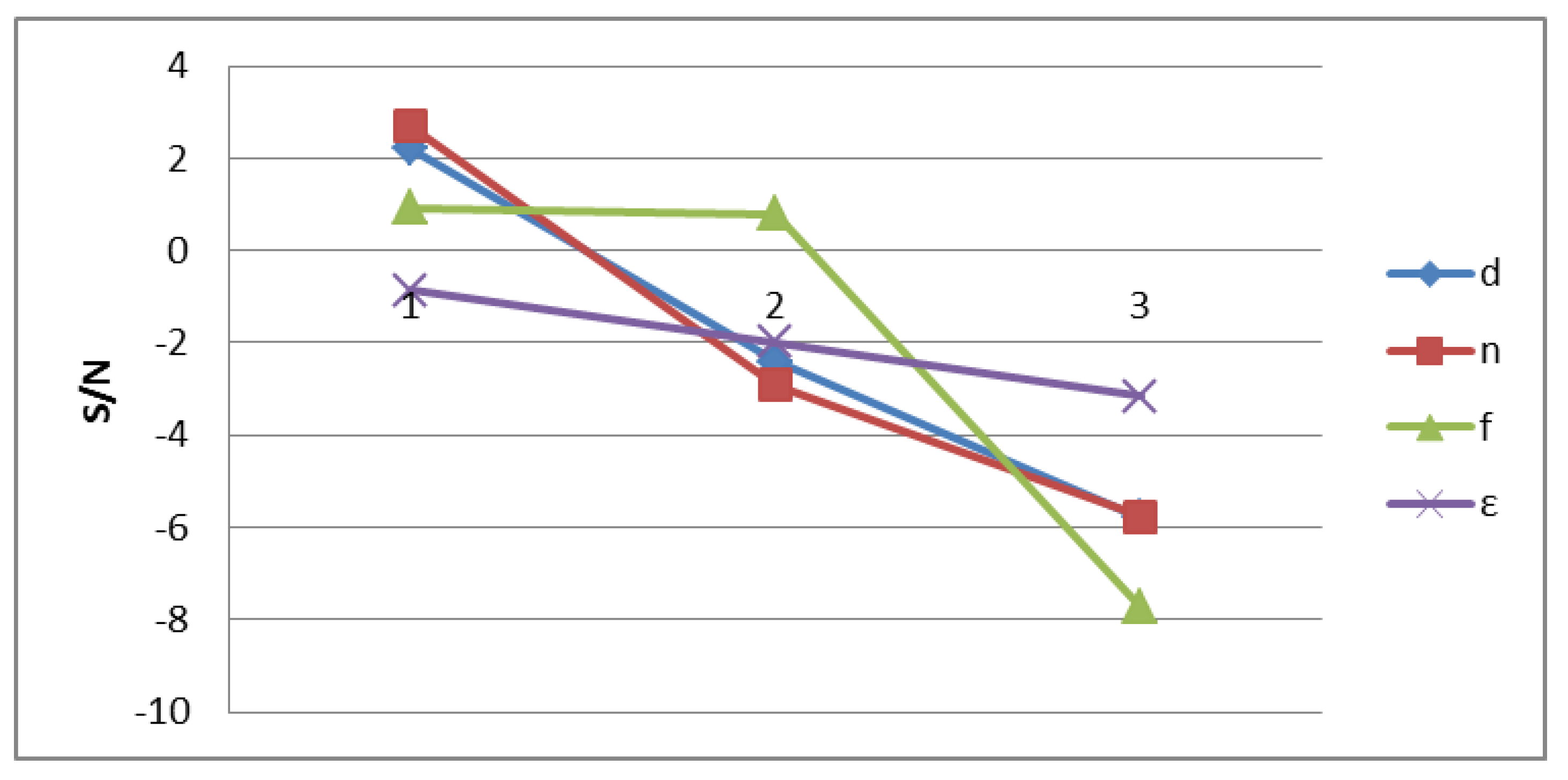

By applying the Taguchi design of experiment, Çiçek et al. [

2] created an optimal combination of machining parameters from the aspect of the surface roughness, when drilling austenitic stainless steel AISI 316 with twist drills made of high speed steel (HSS), subjected to conventional and cryogenic treatments, by varying feed

f (mm/rev) and cutting speed

vc (m/min) at two levels. Apart from establishing an optimal combination, by means of a multiple regression analysis, they developed a regression model linking the referred parameters with the surface roughness through an arithmetic mean deviation

Ra (μm), with the determination coefficient of 96.3%.

Based on the application of Taguchi design in an experiment when drilling OHNS material, tool steel broadly used in tool manufacturing, with high speed steel (HSS) twist drills, and a regression analysis, using commercially available software MINITAB 13, Kumar and Packiaraj [

3] developed models linking an arithmetic mean deviation of a surface roughness

Ra (μm) and a deviation of a hole diameter from a nominal value Δ

D (mm) to a cutting speed

vc (m/min), feed

f (mm/rev), and a twist drill diameter

d (mm). The developed models yielded good results, and the analysis of variances showed that feed and cutting speed have key impacts on a surface roughness and the deviation of a hole diameter from its nominal value, which is necessary to create such a combination of these parameters that should reduce variations affecting the quality of a hole made in OHNS material.

With the application of Taguchi design in an experiment, analysis of variance, and a regression analysis, Ficici et al. [

4] researched the impact of tool modifications (twist drill cutting edge grinding in μm), cutting speed

vc (m/min), and feed

f (mm/rev) on the roughness of a hole when drilling austenitic stainless steel AISI 304 with twist drills made of high speed steel (HSS). By conducting the experiment and through data analysis, they found an optimal combination of the parameters, while alternative analysis provided them with data showing that the tool modifications, cutting speed

vc (m/min), and feed

f (mm/rev) affect a surface roughness in drilling process at the levels of 74.25%, 13.72%, and 6.25%, respectively. With the development of the regression model, they connected the above parameters to the surface roughness through an arithmetic mean deviation

Ra (μm), and both by conducting the confirmation experiment and using an optimal combination of parameters, they determined that the prediction error is 4.34%.

Based on the results of the experiment conducted by an BBD (Box Behnken Design) experiment, Kumari et al. [

5] developed a mathematical model linking the speed

n (rev/min), the velocity of an auxiliary motion

vf (mm/min), and the concentration of cooling agents (%) to an arithmetic mean deviation of surface roughness

Ra (μm), when drilling stainless steel SS 304 with twist drills made of high speed steel (HSS), while Xiao et al. [

6], by applying Taguchi design of experiment and with an acceptable prediction error, developed a regression model for predicting surface roughness in case of stainless steel turning.

Based on applying a genetic programming, Brezocnik et al. [

7] developed models for predicting surface roughness that produced good results in the comparison with the experimental ones, using a speed, feed, depth of cut, and vibrations between the tools and the work piece as independent variables, with the surface roughness as a dependable variable expressed in an arithmetic mean deviation, while, by applying a regression analysis, Sekulic et al. [

8] developed a model for predicting surface roughness when milling steel X210CR12 hardness 58 HRC, which was used as a basis for the model development with the application of a genetic algorithm (GA) and a newly developed grey wolf optimizer algorithm (GWO) with a prediction accuracy calculated at 91.8%.

Akkuş and Asilturk [

9] developed a model for predicting a surface roughness based on ANNs when turning tempered steel AISI 4140. Testing of the subject model gave favourable results with a mean square deviations of 0.0497795. Given the comparison of the results of the referred model with the data of the fuzzy model and a mathematical model, developed through the same research, it can be concluded that artificial intelligence can be successfully used for the prediction purposes.

By conducting Taguchi design of experiment and by using inputs for a cutting speed

vc (m/min), speed

n (rev/min) and the depth of a cut

a (mm), varied at three levels, when turning AA 6351 alloy, Konanki and Sadineni [

10] developed a model for predicting a surface roughness based on ANNs, via an arithmetic mean deviation

Ra (μm), with an average testing error of 2.24%. The predicted model’s values were very close to the experimental values confirming that acceptable prediction model was developed.

Rashid and Lani [

11] used a multiple regression and ANNs for developing the model of a surface roughness when milling aluminium. By conducting the experiment, using full factorial plan and setting multiple regression coefficients, they developed a model connecting a surface roughness expressed in an arithmetic mean deviation of the profile roughness

Ra (μm), speed

n (rev/min), velocity of the auxiliary motion

vf (mm/min) and the depth of a cut

a (mm) with a prediction accuracy of 86.7%. The prediction by means of ANNs gave the best results, with a mean error of 6.42%, which proved that the ANN predicted a surface roughness with a 93.58% accuracy.

Given the case of turning a composite material with an aluminium metal matrix, based on both, the results of experiments obtained by CCD (Central Composite Design) and by applying regression analysis and ANN with multiple outputs, Tamang and Chandrasekaran [

12] developed models connecting a cutting speed

vc (m/min), velocity of the auxiliary motion

vf (mm/min) and the depth of cut

a (mm) with both an arithmetic mean deviation of a surface roughness

Ra (μm) and a machining tool wear

VB (mm). By comparing their prediction results of developed models, they got data showing that ANNs yield a higher prediction accuracy of about 92% for a tool wear prediction and around 95% for the predicting a surface roughness.

Given the application of a regression analysis and ANNs on the results obtained by conducting a full design of the experiment when turning red brass, Hanief and Wani [

13] developed models linking the cutting speed

vc (m/min), feed

f (mm/rev) and the depth of a cut

a (mm) to the arithmetic mean deviation of a surface roughness

Ra (μm). Maximal prediction errors for the obtained models were 9.9% and 9.5%, respectively, an advantage was therefore given to the model obtained through the application of ANNs.

The referred models yield good approximations of experimental results, but they do not consider an impact character of the size of a tool wear on the surface roughness.

Based on the experimental research of turning and drilling of soft annealed pearlite-ferrite steel, Nedić et al. [

14] established the presence of a polynomial dependency in the form of the third degree polynomial, between an arithmetic mean deviation of a surface roughness

Ra (μm) and a machining tool wear

VB (mm).

Krivokapić et al. [

15] drew a conclusion that the development of a model for an indirect monitoring of a tool wear during steel machining, and the establishment of a correlation between the surface roughness and the provider of information about the tool wear phenomena (axial force and torque), allows surface roughness prediction based on a tool wear data.

Mathew et al. [

16] showed that a tool wear span

VB (mm), when milling EN-8 medium carbon steel, can be connected with the level of an acoustic emission expressed through a mean stress value

AE (mV), while Lin et al. [

17] showed that it is possible to use ANNs for the surface roughness prediction based on a vibration signal when milling medium carbon steel S45C.

Bhaskaran et al. [

18] researched the impact of a tool wear when milling high-alloy steel AISI-D3, with hardness of 60 HRC, on the signal of an acoustic emission and a surface roughness of the work piece and showed that exceedances of certain limits leads to sudden increases in certain parameters of acoustic emissions, as well as in the value of a surface roughness.

Spaić and Marinović [

19], by applying ANNs, established a model for an axial drilling force

F3 (N) depending on the width of a wear band

VB (mm), based on experimental results obtained when drilling high strength and hardness steel EN 42CrMo4 with twist drills made of high speed steel. The paper showed that ANNs can be used for predicting axial cutting force as a provider of information on cutting tools’ wear.

Xu et al. [

20] showed that a tool wear

VB (mm), when drilling aluminium alloys, can be predicted by ANNs using process input parameters, such as a cut depth

a (mm), speed

n (rev/min), and a feed

f (mm/rev), complemented by the values of measurable process parameters, such as an axial cutting force

F3 (N) and torque

M (Nm).

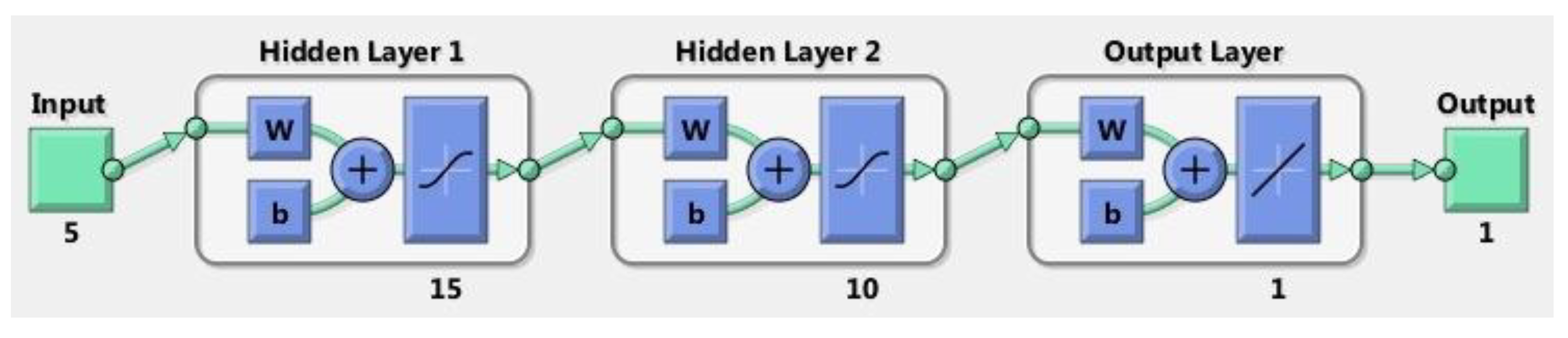

Given the application of a regression analysis and ANNs, when drilling steel for enhancement EN 42CrMo4 hardness 17 HRC, Vučurević et al. [

21] developed models for the prediction of the surface roughness, using a twist drill diameter

d (mm), speed

n (rev/min), feed

f (mm/rev), installation angle of the work piece

ε (

o) and an axial drill force

F3 (N) as input parameters. Regarding the development of the model establishing a connection between the machining parameters and an axial drilling force, which is in correlation with a machining tool wear, with the surface roughness expressed in arithmetic mean deviation

Ra (μm), they came to a conclusion that it is possible to develop models for the surface roughness prediction based on an axial drilling force that is in correlation with a tool’s wear. Based on a comparative analysis of the results obtained from the model, they found out that application of ANNs provides better prediction results.

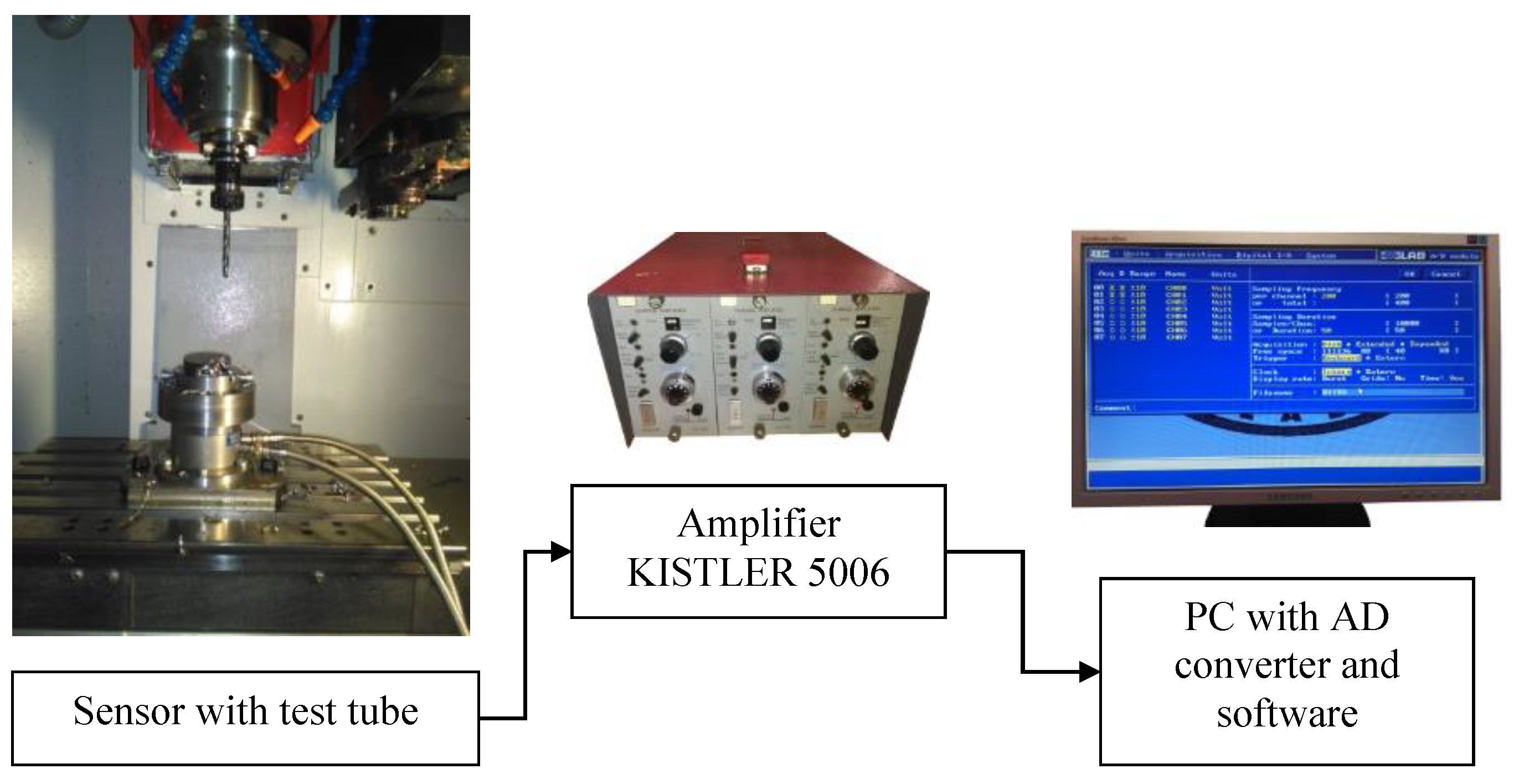

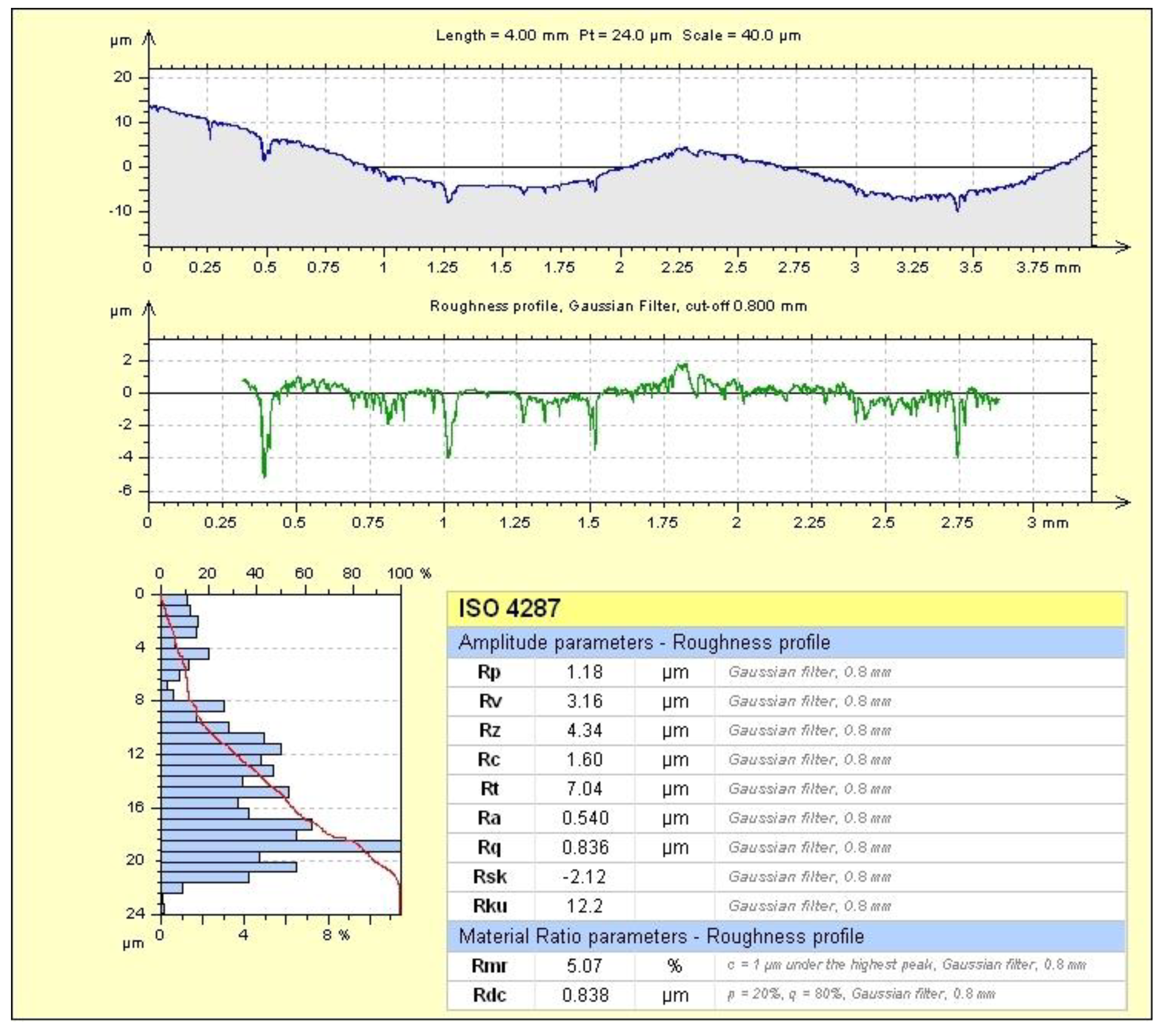

Taking into consideration the aforementioned, an opportunity to develop a model of a multiple regression and ANN model, to include process input parameters (nominal twist drill diameter, speed, feed, and angle of installation of the work piece) and a torque as a measurable parameter of the machining related to machining tool wear, has appeared.

The goal of this paper, based on the experimental results obtained by using the Taguchi design of experiment, is to obtain a model which, for given values of input parameters (nominal twist drill diameter, speed, feed, angle of installation of the work piece) and measurable parameter (torque), will be able to predict the surface roughness.

This paper achieves the inclusion of tool wear in the models of surface roughness prediction through torque, as a measurable parameter during the machining process, which is correlated with tool wear, which was not the case in previous studies. The basic novelty of the paper is the ability to monitor and predict the process from the aspect of mean arithmetic deviation of surface roughness without stopping the process and measuring it, using an adequate model that includes torque as a measurable parameter.