Abstract

A high-throughput method for the discovery of structural materials requires a large number of samples with highly reproducible properties. We propose using spherical micro-samples, which can be quickly produced by molten metal single droplet processes with high geometrical reproducibility. However, geometrical reproducibility does not automatically yield in the reproducibility of specific properties that are governed by the microstructure and thermal history of the samples. This work evaluates the reproducibility of two different steels (AISI D3 and 5140) in their as-synthesized state without additional heat treatment. By determining a set of well-established high-throughput descriptors by electrochemical analysis, particle-oriented peening, and micro machining, we show that high reproducibility can be achieved. Additionally, the determined properties correlate well with their austenitic (AISI D3) and martensitic (AISI5140) state. The AISI D3 shows an improved corrosion resistance, increased cutting forces during machining, and a higher deformation during particle-oriented peening. The reproducibility of the sample synthesis indicates that this type of sample is well suited for high-throughput methods to find new structural materials.

1. Introduction

High-throughput methods for material development allow for the efficient exploration of completely unknown search domains in material research. For structural materials, such search domains consist of not only the composition of an alloy but also the treatment of the material through thermal, mechanical, or thermomechanical processes [1]. As a consequence, fast and flexible synthesis and treatment processes are required to provide the experimental basis for a high-throughput method. In addition, the properties of structural materials, in contrast to functional materials, are determined by their composition, specific microstructure, and interacting elements (e.g., grains, grain boundaries, and precipitates). A high-throughput sample for structural materials should therefore be small on one hand in order to achieve high efficiency, and large enough in all three spatial dimensions on the other hand to represent the microstructure in the sample volume, thus enabling the determined properties to be mapped onto bulk material. This is not possible with the thin-film techniques established for functional materials [2].

Due to these requirements, there are only a few approaches for establishing a high-throughput method for structural materials. A frequently used sample type is that of diffusion couples [3,4,5,6]. Due to their continuous concentration gradients, these can resolve entire binary or ternary systems on small samples. However, the disadvantage of this sample type is that heat treatment, which leads to further diffusion of the elements, is only possible to a limited extent, and that all local compositions must be heat treated in the same way. In addition, the characteristic values that can be determined on the polished cross-sections are limited. Typically, nanoindentation [7,8] is carried out as a mechanical characterization procedure, which cannot adequately represent interactions of microstructural elements of complex alloys due to the local resolution of analysis. A similar strategy is followed by approaches that produce graded samples by in-situ powder mixing in laser metal deposition processes [9].

A much more flexible high-throughput method is obtained by using discrete single samples instead of graded samples [1]. Such discrete samples can be individually heat treated and tested [10], so that individual sample states can be transformed or destructively tested without affecting neighboring states. Spherical micro-samples, which can be synthesized in large numbers in a short period of time by a drop-on-demand process, are considered as easily producible sample forms without directional dependence of the properties. For such spherical micro-samples, we have developed a process in previous works [11], through which a reproducible droplet generation at high melt temperatures of up to 1600 °C is possible for the first time. Based on quantitative investigations of the microstructure by evaluating secondary dendrite arm spacing, we were also able to verify the reproducibility of droplet cooling, which essentially determines the microstructure, and validate a cooling model for the droplets [11].

For the characterization of material samples in high-throughput methods, new test procedures are required that are adapted to the sample shape [6]. The approach of using descriptors that map the desired conventional material properties, either individually or in combination, is a common approach in high-throughput methods. Steinbacher et al. [12] have proposed a set of such descriptors for a wide range of physical, chemical, mechanical, and technological properties and have demonstrated their sensitivity on commercially available spheres with a diameter of 800 µm with high geometric and microstructural reproducibility for different heat treatment conditions, thus demonstrating that a high-throughput method based on single samples is possible.

The aim of this work is to investigate whether the spherical micro-samples produced by the single droplet generation process also show such high reproducibility on the basis of specific descriptors that can be used in a high-throughput method. The focus here is on the as-synthesized state, which is the basis for subsequent heat treatment of the spheres.

2. Materials and Methods

2.1. Sample Synthesis

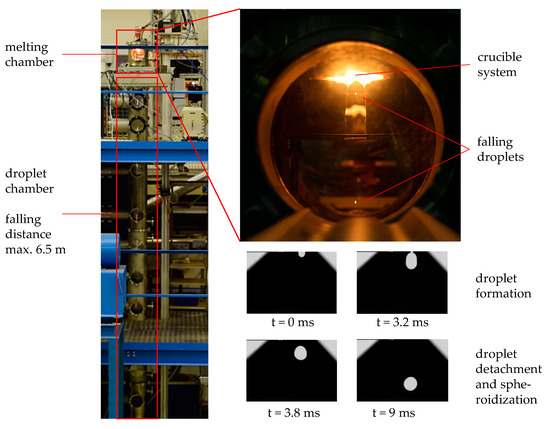

Spherical micro-samples were generated from two different materials using drop-on-demand single droplet generation process. The formed melt droplets were completely solidified during free fall at a fall distance of 6.5 m in an argon atmosphere before they were quenched in oil (Durixol WX61). Figure 1 illustrates the top part of the droplet generator used for the synthesis of samples. The droplets are formed at the nozzle via sending a pressure pulse through a solenoid valve; they detach the crucible with a pressure drop caused by closing the valve. The process is optimized and controlled via computer using a self-developed Matlab script. The formation and detachment process is observed thoroughly during the process using high speed camera ‘i-speed 210’ (Vizaar Industrial Imaging, Albstadt, Germany). The image series in Figure 1 demonstrates the appearance of a X210Cr12 droplet at the nozzle and its further detachment during the synthesis.

Figure 1.

High-temperature drop-on-demand facility for spherical micro-sample synthesis.

Two steel types X210Cr12 (AISI D3) and 41Cr4 (AISI 5140) were used as feedstock material. The process conditions of sample synthesis are summarized in Table 1. Additionally, the chemical composition of the feedstock materials is shown in Table 2.

Table 1.

Process conditions for sample synthesis.

Table 2.

Chemical composition of feedstock material.

The samples were cleaned and dried. The following high-throughput descriptors were determined on each of the five independent samples of both alloys.

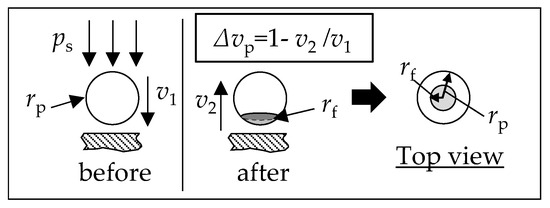

2.2. Descriptor 1: Particle-Oriented Peening

In order to analyze the reproducibility of the particles, particle-oriented peening is used [16]. In this process, individual particles are accelerated using compressed air (jet pressure ps = 4 bar) to impact on a contact plate of higher hardness (hardened 100Cr6; 63 HRC), which is located at a constant distance of a = 80 mm in front of the nozzle outlet. Due to the high velocity impact, the particles are deformed according to their material properties (e.g., hardness or yield strength) [17]. As shown in Figure 2, both the plastic deformation as the ratio of the particle radius rp to the radius of the flattened surface rf and the velocity reduction Δvp (ratio of the velocities before and after the impact) due to the impact are examined. The former quantities are determined by means of a light microscope (Zeiss SteREO.V12 microscope, REOObjective.435200-0000-000, Carl Zeiss Microscopy GmbH, Jena, Germany) before and after the implementation of the process. The velocity of the approaching particle (before the impact) v1 and the rebounding particle (after the impact) v2 are determined using a system consisting of a light barrier (manufactured by “FOS Messtechnik GmbH”), two stroboscopes (“HELIO-STROB micro2” manufactured by “ELMED Messtechnik GmbH”, exposure frequency: 4000 Hz), and a monochrome camera (type “DMK 5 37BUX250” manufactured by “The Imaging Source Europe GmbH”) (cf. [12]).

Figure 2.

Scheme of the particle-oriented peening process, including all considered variables.

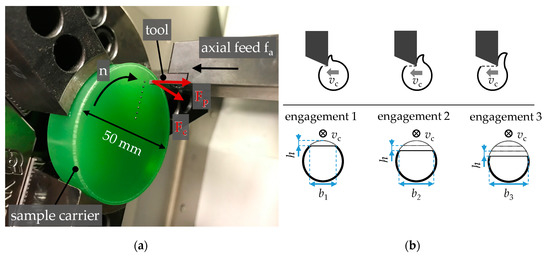

2.3. Descriptor 2: Micro Machining

Cutting process monitoring techniques provide measurands such as process forces that are directly influenced by the mechanical properties of the machined material [18]. Micro machining processes like micro turning operate with low material removal rates in the range of a few microns to a few ten microns, and have therefore been utilized to investigate the reproducibility of the mechanical behavior of spherical micro-samples in cutting experiments. The micro-samples were embedded to two-thirds in cold-curing epoxy resin to allow clamping on a conventional CNC precision lathe as displayed in Figure 3a. Machining was carried out by axial feed face turning of each sample individually at a constant cutting speed of 60 m/min and a feed rate fa of 10 µm per revolution, which equals to the uncut chip thickness hcu. Process forces in cutting and feed direction were measured using a dynamometer attached to the tool holder. The eccentrical sample arrangement on the carrier leads to an intermittent cut with a continuous increase of the cutting width b as well as the length of cut with each tool engagement as displayed in Figure 3b. The descriptors, namely, specific cutting force F’c and specific thrust force F’p, were calculated as described in [12] by dividing the maximum force value of each tool engagement of a sample by the corresponding cutting width bx.

Figure 3.

(a) Machining setup and (b) cutting conditions for axial feed turning of spherical micro-samples.

2.4. Descriptor 3: Electro Chemistry

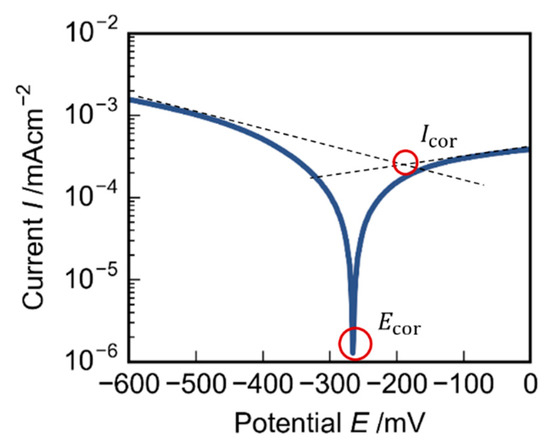

Electrochemical measurements show a high sensitivity to microstructure properties like grain size [19], phase composition [20], and carbides [21]. For this reason, electrochemical measurements can be used to check the reproducibility of the given samples with respect to its microstructure. Linear Sweep Voltammetry (LSV) measurements of embedded micro-samples were performed using a scanning flow cell [22]. The measurements were used to collect electrochemical descriptors, namely, corrosion current and corrosion potential.

A potential is applied between the sample (the working electrode) and a so called counter electrode during LSV measurements. The potential increases with a given scan rate in Vs−1 and the current is measured (Figure 4). The corrosion potential is the potential at which anodic and cathodic currents are equal and the overall measured currents equals zero. (One should note that during potentiodynamic measurements, the faradaic currents are overlaid by a capacitive current. This is due to the charging of the double layer. Since the scan rate is very low and the capacitive current should not show significant differences for different samples, this current can be neglected). For the determination of the corrosion current density, the linear courses of the anodic and cathodic currents are extended, and the intersection of both lines indicates the value of the corrosion current (Tafel plot).

Figure 4.

Linear Sweep Voltammetry (LSV) measurement in 0.1 M phosphate buffer with 0.1 M NaCl. Scan rate: 0.001 Vs−1. Corrosion current determined by the Tafel method and corrosion potential are marked.

The measurements were carried out at room temperature with a scan rate of 0.001 Vs−1 (Figure 4) using a Metrohm Autolab potentiostat with the PGSTAT204 module. A 0.1 M phosphate buffer solution (pH = 7.5) with 0.1 M NaCl [23] was used as the electrolyte solution.A platinum wire was applied as counter electrode and an Ag/AgCl electrode (3 M KCl; eDAQ) as the reference electrode. All potentials are referred to the Ag/AgCl electrode.

3. Results

3.1. Sample Synthesis

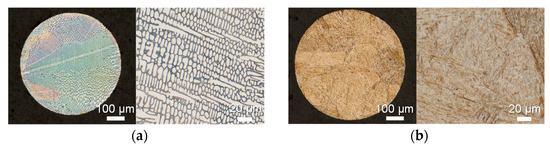

After being synthesized, the spherical micro-samples were cleaned with ethanol and dried for four hours at a temperature of 80 °C. The particles were then embedded, ground, polished, and etched in order to check the homogeneity of their microstructure. Figure 5 shows the microsection of the spheres used for this study from two alloys. Due to high carbon and chromium content, the X210Cr12 solidifies with a mainly austenitic microstructure. Between the dendritic structure, primary carbides are formed from the remaining melt during solidification. In comparison, the 41Cr4 steel develops a fully martensitic microstructure.

Figure 5.

Micrographs of synthesized samples: (a) X210Cr12 and (b) 41Cr4.

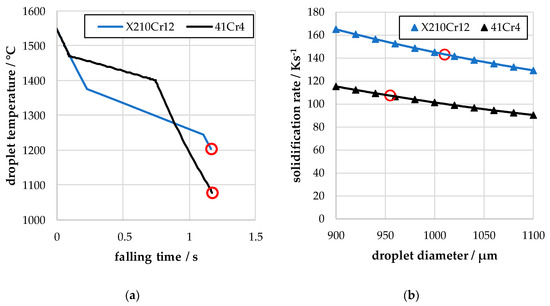

The thermal history of droplets from both alloys was calculated using a previously developed droplet cooling model [24]. Figure 6a shows the thermal histories for the process conditions from Table 1 and the experimental falling distance of 6.5m before the droplets are quenched. Both alloys are fully solid in the argon atmosphere before they are collected in oil. The solidification rate as a function of droplet diameter is shown in Figure 6b. A small variation in droplet diameter (e.g., ±10 µm) will only have a minor effect on the solidification rate (process conditions are marked with red circles). We conclude that microstructure development should be highly reproducible due to this wide process window.

Figure 6.

(a) Calculated thermal histories from droplet cooling model for experimental process conditions and a falling distance of 6.5 m red circles indicate impact time in quenchant. (b) Average solidification rates for both alloys, red circles mark experimental conditions.

3.2. Particle-Oriented Peening

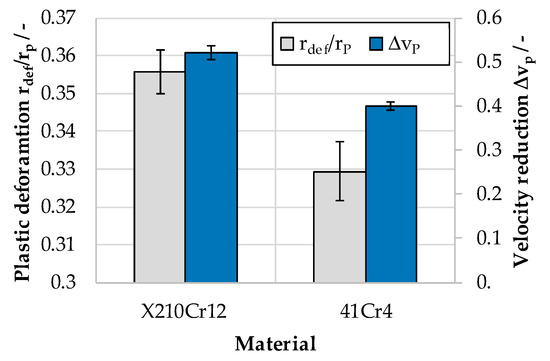

Figure 7 illustrates the plastic deformations rdef/rp and the velocity reductions ∆vp determined for the investigated materials. In each case, the mean values of five experiments are shown. In order to analyze the results deviation, the error bars are used to visualize the maximum and minimum determined value of the test series. While the X210Cr12 shows a plastic deformation of about 0.355 and velocity reductions of about 0.521, the values determined for 41Cr4 are significantly lower. A plastic deformation of 0.330 and a velocity reduction of 0.400 were calculated for 41Cr4. For both of the presented results variables, maximal relative standard deviations of 3% were determined.

Figure 7.

Determined plastic deformation and velocity reduction due to impact in particle-oriented peening.

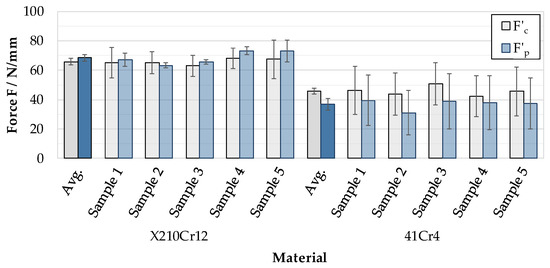

3.3. Micro Machining

Figure 8 represents the average specific and thrust forces (displayed in opaque bars) obtained in cutting experiments for the two sample materials as well as the individual mean forces for each sample (displayed in dotted bars). The standard deviation of each sample represents the standard deviation of the forces obtained for 15 individual tool engagements, while the standard deviation of the average force (“Avg.”) represents the standard deviation of the mean forces of five samples respectively. The X210Cr12 alloy shows distinctively higher cutting and thrust forces than the 41Cr4, indicating a higher shear strength of the X210Cr12 compared to 41Cr4. Compared to the results of the particle-oriented peening, it can be assumed that the material behavior for shear-dominated loading mechanisms differs from the behavior under impact/normal loading, where the 41Cr4 alloy shows the smallest plastic deformation and therefore a higher resistance to normal strain.

Figure 8.

Averaged and individual results of cutting force F’c and specific thrust force F’p measurements obtained during micro machining.

The overall mean force averaged over five samples shows distinctively low standard deviations (below 8%) for each investigated alloy, indicating a high reproducibility of the sample’s mechanical behavior under shear-dominated loads. The average specific forces obtained for individual samples, consisting of 15 subsequent tool engagements, show a higher standard deviation, which is caused by the varying accordance of the maximum cutting width with the average cutting width depending on the effective depth of cut. However, the standard deviations for the individual samples are comparable the two alloys, indicating a high process stability and reproducible behavior of the force measurements. Further investigations will require calculation optimization of the exact cutting width for the individual tool engagements.

3.4. Electro Chemistry

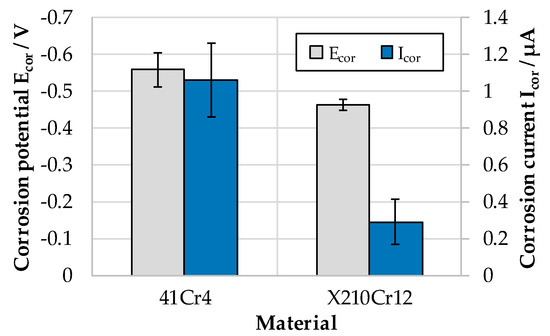

The corrosion potential of all four samples indicate significant differences (Figure 9). The 41Cr4 shows a lower potential (−0.56 V) compared to the X210Cr12 (−0.46 V). This difference can be expected, since a higher corrosion potential indicates a better protection against corrosion. Higher corrosion potentials are related to a more noble material and/or a lower anodic current and thus lower dissolution by oxidation (assuming the same cathodic current). Chromium enhances the passivity of steel, and an increasing element content leads to a more protective passive film [25,26,27].

Figure 9.

Corrosion potential and corrosion current for both steels. Error bars show the standard deviation of each of the five independent samples per material.

The corrosion current also shows very clear differences and a high reproducibility for all samples (Figure 10). 41Cr4 samples shows higher corrosion current compared to that of X210Cr12 due to the lower chromium content. These electrochemical descriptors show high reproducibility and expected behavior for the two materials. Both materials can be significantly distinguished by the measurements and the determined characteristic values.

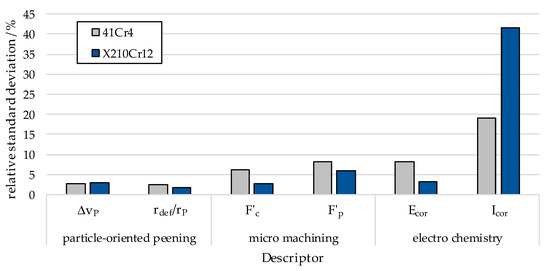

Figure 10.

Relative standard deviation of determined descriptors for both materials.

4. Discussion

In this work, we have synthesized spherical micro-samples from the steels 41Cr4 and X210Cr12 with a high-temperature drop-on-demand droplet generator. While the 41Cr4 showed a martensitic microstructure, the X210Cr12 was obtained in a mainly austenitic state, which should result in very different mechanical and corrosion properties. Based on the droplet cooling model, we were able to show that the solidification rate of the droplets in this process is not sensitive to process conditions. To show the reproducibility of different properties, generated particles were subjected to a fast deformation by particle-oriented peening, micro machining, and electrochemical analysis. Two descriptors were determined for each analysis.

Particle-oriented peening showed a smaller sample deformation and a smaller velocity reduction for the martensitic 41Cr4, compared to the austenitic X210Cr12. This is consistent with the higher hardness of the martensitic state. Less deformation of the sample consumes less kinetic energy and therefore yields in less velocity reduction. For micro machining, increased cutting and specific thrust forces were determined for the X210Cr12, which results from its increased shear strength. Finally, the increased chromium content of the X210Cr12 leads to more corrosion resistance and hence an increased corrosion potential; a strongly reduced corrosion current was observed. We conclude that the determined descriptors are consistent with expected properties of the two chosen alloys.

To evaluate the reproducibility of properties, the relative standard deviation of the descriptors was determined (Figure 10). The particle-oriented peening descriptors show very good reproducibility, with standard deviations smaller than 5%. The micro machining of individual spheres shows good reproducibility, which is in the same order of the corrosion potential Ecor. The corrosion current shows an increased standard deviation, which is due to the low values of corrosion current and the resolution of the measurement device and not to the low reproducibility of samples since the corrosion potential is reproducible.

Since we were able to show that the descriptors are sensitive enough to clearly distinguish the two alloys and at the same time a high degree of reproducibility was determined for five out of the six descriptors, we conclude that this also means that the produced samples have reproducible properties.

5. Conclusions

The aim of this study was to examine spherical micro-samples of two steels produced with a high-temperature drop-on-demand process with regard to the reproducibility of their mechanical, technological, and corrosion properties. These samples can only provide the basis for a high-throughput method if they are proved to be reproducible. To assess the reproducibility, established high-throughput descriptors were used to evaluate the samples with regard to their relative standard deviation. It was found that the standard deviation is comparable to that obtained by Steinbacher et al. on high-precision spheres of 100Cr6. Thus, the high temperature droplet generation is a suitable method to produce sufficiently reproducible material samples for high-throughput. Future work will continue the investigations shown here and extend them by defined heat treatment steps. In the next step, mapping of descriptors to descriptors [28,29] is necessary to obtain a complete high-throughput method.

Author Contributions

Conceptualization, review, and editing, N.E.; methodology and supervision, C.H., D.M., and M.B.; investigation and writing, A.T., S.I.M., N.W., and I.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research is funded by Deutsche Forschungsgemeinschaft (DFG, German Research Foundation)—project number 276397488-SFB 1232, and the support is gratefully acknowledged.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Ellendt, N.; Mädler, L. High-Throughput Exploration of Evolutionary Structural Materials. HTM J. Heat Treatment Mater. 2018, 73, 3–12. [Google Scholar] [CrossRef]

- Otani, M.; Itaka, K.; Wong-Ng, W.; Schenck, P.; Koinuma, H. Development of a high-throughput thermoelectric screening tool for combinatorial thin film libraries. Appl. Surf. Sci. 2007, 254, 765–767. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhao, J.C. Extracting interdiffusion coefficients from binary diffusion couples using traditional methods and a forward-simulation method. Intermetallics 2013, 34, 132–141. [Google Scholar] [CrossRef]

- Zhao, J.C. The diffusion-multiple approach to designing alloys. Annu. Rev. Mater. Res. 2005, 35, 51–73. [Google Scholar] [CrossRef]

- Zhao, J.C. Combinatorial approaches as effective tools in the study of phase diagrams and composition–structure–property relationships. Prog. Mater Sci. 2006, 51, 557–631. [Google Scholar] [CrossRef]

- Zhao, J.C.; Zheng, X.; Cahill, D.G. High-throughput measurements of materials properties. JOM 2011, 63, 40–44. [Google Scholar] [CrossRef]

- Lucca, D.; Herrmann, K.; Klopfstein, M. Nanoindentation: Measuring methods and applications. CIRP Ann. 2010, 59, 803–819. [Google Scholar] [CrossRef]

- Shuman, D.J.; Costa, A.L.; Andrade, M.S. Calculating the elastic modulus from nanoindentation and microindentation reload curves. Mater. Charact. 2007, 58, 380–389. [Google Scholar] [CrossRef]

- Knoll, H.; Ocylok, S.; Weisheit, A.; Springer, H.; Jägle, E.; Raabe, D. Combinatorial Alloy Design by Laser Additive Manufacturing. Steel Res. Int. 2017, 88. [Google Scholar] [CrossRef]

- Sonnenberg, H.; Clausen, B. Short-Term Characterization of Spherical 100Cr6 Steel Samples Using Micro Compression Test. Materials 2020, 13, 733. [Google Scholar] [CrossRef]

- Imani Moqadam, S.; Mädler, L.; Ellendt, N. A High Temperature Drop-On-Demand Droplet Generator for Metallic Melts. Micromachines 2019, 10, 477. [Google Scholar] [CrossRef] [PubMed]

- Steinbacher, M.; Alexe, G.; Baune, M.; Bobrov, I.; Bosing, I.; Clausen, B.; Czotscher, T.; Epp, J.; Fischer, A.; Langstädtler, L.; et al. Descriptors for High-throughput in Structural Materials Development. High-Throughput 2019, 8, 22. [Google Scholar] [CrossRef] [PubMed]

- Bogaard, R.H.; Desai, P.D.; Li, H.H.; Ho, C.Y. Thermophysical properties of stainless steels. Thermochim. Acta 1993, 218, 373–393. [Google Scholar] [CrossRef]

- Jirková, H.; David, A.; Bohuslav, M. Unconventional structure of X210Cr12 steel obtained by thixoforming. J. Alloys Compd. 2010, 504, S500–S503. [Google Scholar] [CrossRef]

- Ross, R.B. Metallic Materials Specification Handbook; Springer Science & Business Media: Boston, MA, USA, 2013. [Google Scholar]

- Kämmler, J.; Wielki, N.; Guba, N.; Ellendt, N.; Meyer, D. Shot peening using spherical micro specimens generated in high-throughput processes. Materialwiss. Werkstofftech. 2019, 50, 5–13. [Google Scholar] [CrossRef]

- Toenjes, A.; Wielki, N.; Meyer, D.; von Hehl, A. Analysis of Different 100Cr6 Material States Using Particle-Oriented Peening. Metals 2019, 9, 1056. [Google Scholar] [CrossRef]

- Beinhauer, A.; Heinzel, C.; Riemer, O. Determination of material properties by evaluation of machinability in multi-scale precision turning. In Proceedings of the 17th euspen International Conference & Exhibition, Hannover, Germany, 29 May–2 June 2017; pp. 130–131. [Google Scholar]

- Ralston, K.; Birbilis, N. Effect of grain size on corrosion: A review. Corrosion 2010, 66, 075005. [Google Scholar] [CrossRef]

- Bösing, I.; Bobrov, I.; Epp, J.; Baune, M.; Thöming, J. Influence of Systematically Changed Martensite Content on the Passive Film Properties of Austenitic Stainless Steel in Neutral Electrolyte. Int. J. Electrochem. Sci. 2020, 15, 319–333. [Google Scholar] [CrossRef]

- Bösing, I.; Cramer, L.; Steinbacher, M.; Zoch, H.W.; Thöming, J.; Baune, M. Influence of heat treatment on the microstructure and corrosion resistance of martensitic stainless steel. AIP Adv. 2019, 9. [Google Scholar] [CrossRef]

- Schuppert, A.K.; Topalov, A.A.; Katsounaros, I.; Klemm, S.O.; Mayrhofer, K.J. A scanning flow cell system for fully automated screening of electrocatalyst materials. J. Electrochem. Soc. 2012, 159, F670. [Google Scholar] [CrossRef]

- Bösing, I.; Thöming, J.; Baune, M. Electrolyte composition for distinguishing corrosion mechanisms in steel alloy screening. Int. J. Corros. 2017. [Google Scholar] [CrossRef]

- Imani Moqadam, S.; Mädler, L.; Ellendt, N. Microstructure Adjustment of Spherical Microsamples for High-Throughput Analysis Using a Drop-on-Demand Droplet Generator. Materials 2019, 12, 3769. [Google Scholar] [CrossRef]

- Osozawa, K.; Engell, H.-J. The anodic polarization curves of iron-nickel-chromium alloys. Corros. Sci. 1966, 6, 389–393. [Google Scholar] [CrossRef]

- Sieradzki, K.; Newman, R. A percolation model for passivation in stainless steels. J. Electrochem. Soc. 1986, 133, 1979–1980. [Google Scholar] [CrossRef]

- Potgieter, J.; Olubambi, P.; Cornish, L.; Machio, C.; Sherif, E.-S.M. Influence of nickel additions on the corrosion behaviour of low nitrogen 22% Cr series duplex stainless steels. Corros. Sci. 2008, 50, 2572–2579. [Google Scholar] [CrossRef]

- Huhn, S.; Sonnenberg, H.; Eggersglüß, S.; Clausen, B.; Drechsler, R. Revealing properties of structural materials by combining regression-based algorithms and nano indentation measurements. In Proceedings of the IEEE Symposium Series on Computational Intelligence (SSCI), Honolulu, HI, USA, 27 November–1 December 2017; pp. 1–6. [Google Scholar] [CrossRef]

- Drechsler, R.; Eggersglüß, S.; Ellendt, N.; Huhn, S.; Mädler, L. Exploring superior structural materials using multi-objective optimization and formal techniques. In Proceedings of the International Symposium on Embedded Computing and System Design (ISED), Patna, India, 15–17 December 2016; pp. 13–17. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).