2. Materials and Experimental Methods

The Peltier modules investigated are single-stage, marketed under different brands, manufactured with a

p-

n series of Bismuth Telluride semiconductor material (

), and assembled between plates made of ceramic stuff that can be assumed as

. The number of pairs and some geometric features of these modules, are shown in

Table 1, assuming for all devices, the semiconductor pillars as parallelepipeds with a square base.

The geometric dimensions shown in

Table 1 were obtained using a caliper, measuring the thickness of the whole module, the thickness of the ceramic plate, and the size of the pillars (height and base side). The agreement between the measured dimensions of the pillars and the dimensions of the whole module (height

L and width

W) was verified by evaluating with a blade gauge the gap between the pillars and the thickness of the connecting copper elements to which the

p-

n semiconductors are soldered to form the junctions. The filling factor, reported in the last column of

Table 1, is the ratio between the sum of the cross-sections of all the semiconductor elements and the entire surface area of the ceramic plates. The filling factor can be useful to take into account the spreading-constriction thermal resistance between pillars and ceramic plates.

The modules named a.1, a.2, and a.3 have the same number of pairs, with some differences in the total thickness and size of the pillar, but quite a similar filling factor and assembly features. Therefore, based on the performances declared by the manufacturer, similar values of the figure of merit were expected for these three modules. Modules b and c are totally different from each other and from the previous ones, in particular as regards the dimensions of the pillar, the filling factor, and assembly characteristics; therefore, for the latter, rather different figures of merits are foreseen.

As known, the dimensionless figure of merit

zT can be evaluated in a real device by measuring the electrical quantities at the accessible external connections, since it can be obtained as the ratio between the total developed Seebeck voltage and the total ohmic voltage drop. Separating the two contributions is not trivial and is traditionally performed with a time-domain transient approach called the “Harman method” [

23]. The idea behind the method is that when a dc current, which flows through the device, is switched off, the sudden voltage drop experienced at the device terminals is due to the ohmic voltage that disappears with the current, while the thermoelectric voltage persists due to the thermal inertia of the device, which prevents fast temperature variations. Based on this criterion, the figure of merit and the ohmic series resistance of the tested thermoelectric modules were measured using a commercial time-domain Harman type instrument [

25] produced by RMT (Moscow, Russia), named z-meter model DX 4090. The DX 4090 instrument also estimates the characteristic time and the maximum temperature difference that can be reached between the junctions of the Peltier device under test.

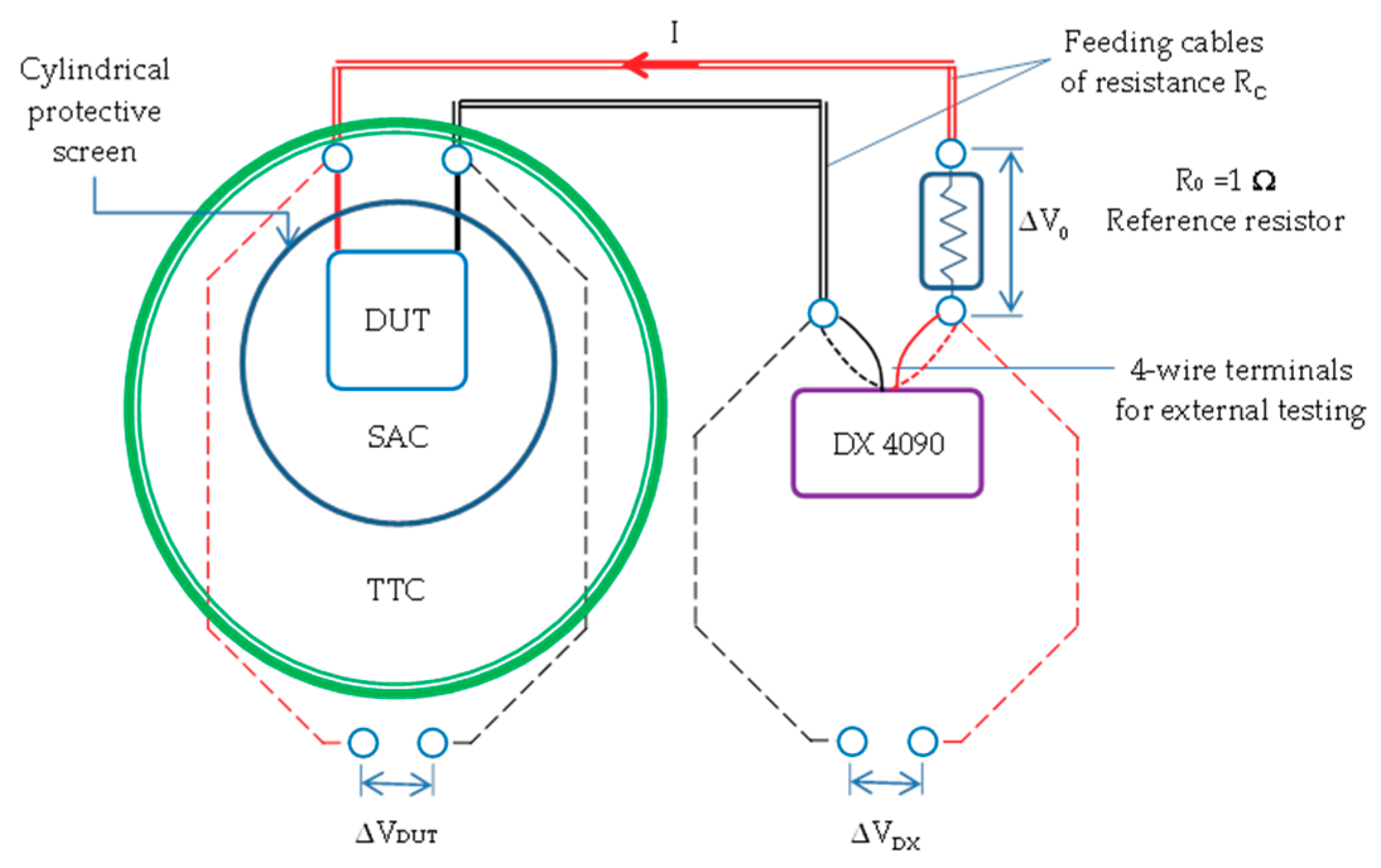

Figure 1 shows the scheme of the experimental arrangement, whose main parts are the Thermostatic Test Chamber (TTC), capable of operating from 203 K to 473 K with a stability of the set-point within ±0.1 K and the above-mentioned z-meter (DX 4090). Only the Peltier modules investigated were inserted in TTC while the other measurement tools such as the reference resistor (Fluke 742A-1,

R0 = 1) shown in

Figure 1, the voltmeters (Agilent 34420A 7½ Digit) and the thermocouples measurement bench (NI cDAQ-9178, TB-9212) not shown in the figure, were placed outside the TTC and kept in thermal equilibrium with the laboratory. For achieving a Still Air Chamber (SAC) inside TTC, a protective cylindrical screen has been arranged around the Device Under Test (DUT), avoiding on its exposed surfaces the air turbulences induced by the internal fan. At each established TTC set points chosen in the range 363 K, 213 K, the assigned test reference temperature was that picked on the inner surface of the cylindrical screen of SAC.

During the tests, the actual output current

I set by the DX 4090 was checked to measure the voltage drop

V0 at the potential leads of the reference resistor

R0. This output current allows identifying the resistance

RC of the feeding cables (double red and black lines in

Figure 1) by measuring the voltage drop

VDX and

VDUT at the external connections of the DX 4090 and of the DUT, as shown in

Figure 1. In this way, the resistance

R’ measured by the DX 4090 is influenced by the resistances

R0 and

RC, and the figure of merit z’ obtained is altered as if the

p-

n series of the DUT was more resistive.

The corrected values for the resistance

R of the

p-

n series (including, in this case, the resistance of connecting leads assembled at the factory) can be found subtracting

R0 and

RC, while the revised value

z is obtained considering for this case the equality

, so

With the correct

R value of the DUT, by subtracting the ohmic component

from the measured voltage drop

VDUT (or subtracting

from

VDX) it was possible to identify the total Seebeck voltage

produced at

p-

n junctions, associating to it the junction temperature difference

which produces this voltage, namely:

where,

is the number of thermoelectric pairs, and ε represents the equivalent Seebeck coefficient of the single junction of the assembled pillar series.

Since the direct measurement of the actual junction temperature of an assembled thermoelectric module is not an easy task, to obtain from the Seebeck voltage expressed by Equation (3), the junction temperature difference was estimated on the basis of the temperature difference measured on the outside surfaces of the ceramic plates, introducing suitable corrections.

Different solutions were considered to identify the temperature of the outside surfaces of the ceramic plates. Around room temperature, with feeding currents less than 50 mA, a good temperature uniformity on these plates was verified using an infrared camera (FLIR 6753sc, cooled array 640 × 512 px, NETD < 18 mK). The operating range of the IR camera (253–623 K) has unfortunately inhibited its use in carrying out experiments down to 213 K. So, the surface temperatures were measured using type K thermocouples with exposed welded tip junctions (made using 0.076 mm diameter wires), placed in contact with the ceramic plate using a thin, highly reflective aluminum adhesive tape. The expected deviation between

and

(

) was estimated taking into account both the thermal resistance of the ceramic layers (

) and the pillars footprint area on the ceramic surface as spreading effect determined by the filling factors shown in

Table 1.

Considering the actual ceramic thickness of the investigated Peltier modules, assuming feeding current in the range 25–40 mA, with some hypotheses on the maximum heat flux, exchanged at the junction (less than 0.1 W with I = 40 mA), a maximum deviation between and was estimated of the same order of accuracy expected in the temperature measurements. Despite this, in all experimental tests, a temperature correction in the range 0.05–0.1 K was nevertheless applied on the measured .

3. Experimental Results

All Peltier modules were tested in the range from 363 K to 213 K, covering the gap with temperature steps of about 30 K. Investigations were performed at a steady-state, checking the stability of the set-point imposed on the basis of the temperature measured inside the SAC. As mentioned in the previous section, the measured quantities were the voltage drops V0, VDX, and VDUT, as well as the resistance of the module and the figure of merit , the latter two measured using the DX 40490 (z-meter). The measurement protocol of the DX 4090 provides for polarity inversion; therefore, the voltage drops VDX and VDUT, obtained at each reference temperature Tref, were obtained by averaging the measured values with current I and −I, respectively. Following this approach for all modules, at each Tref, the measurement was repeated twice, waiting between the two measurements for the time necessary for the temperature to return to the set-point value.

The

p-

n series resistance

R, the dimensionless figure of merit

zT at

Tref, and the Seebeck voltage

obtained by Equations (1)–(3) are summarized for the Peltier modules in

Table 2,

Table 3,

Table 4,

Table 5 and

Table 6, specifying the test current

I imposed by the DX 4090.

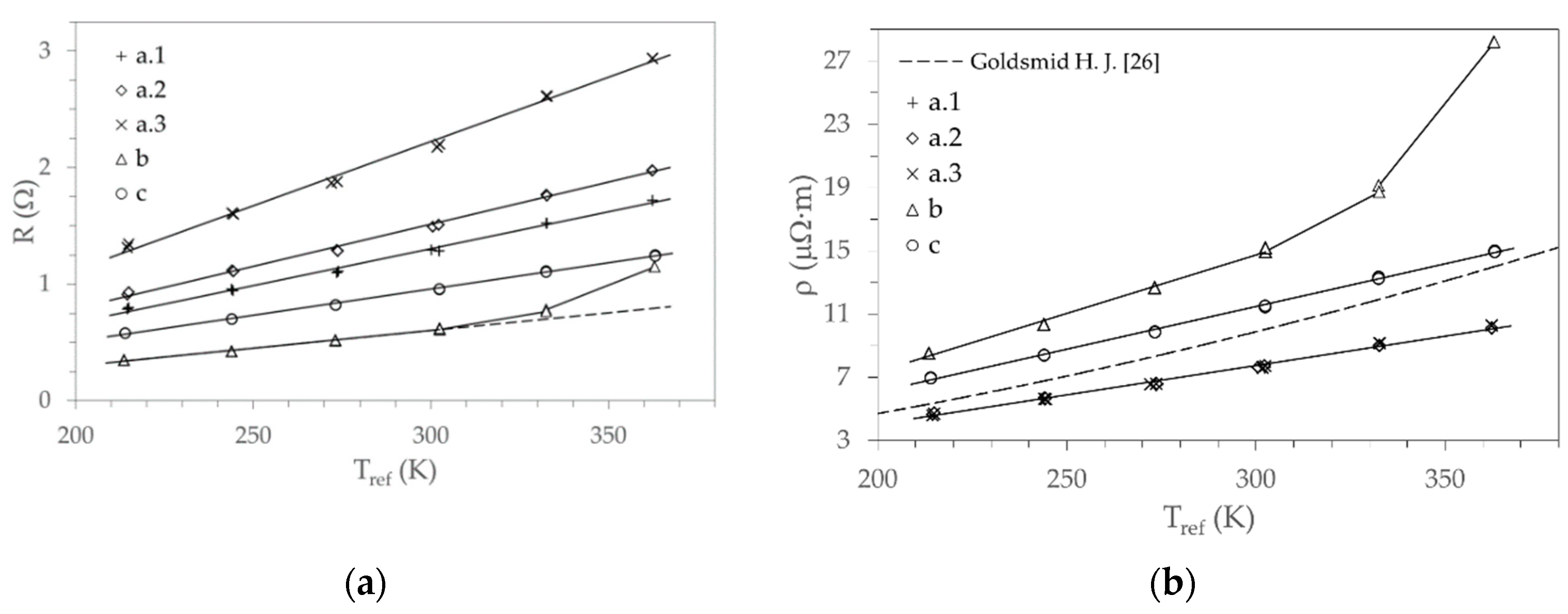

The obtained

p-

n series resistance

R, in addition to the resistance of the semiconductor pillars, includes at each junction both the resistance of the soldering material and the connecting copper element. For all the modules tested, the trend of resistance

R as a function of the reference temperature of the test is shown in

Figure 2a. The trends are almost linear for all modules, with the exception of module

b for which a deviation from the linear trend is observed for temperatures higher than the ambient one. Assuming that the assembled thermoelectric materials have common and comparable properties,

Figure 2b shows their equivalent electrical resistivity obtained by means of the geometry of the pillars reported in

Table 1. This resistivity is fairly similar for modules a.1, a.2, and a.3, while it assumes quite different values for modules

b and

c. In particular, the dependence of resistivity on temperature for module

b deviates from linearity when the ambient temperature is exceeded. The dashed line shown in

Figure 2b provides a comparison with the values found in the literature [

14], which represent a possible trend of the average electrical resistivity for the

p and

n doped

bulk materials. The latter can be assumed in agreement with the measured trends for the grouped modules “a” and module c, while the same cannot be said for module b.

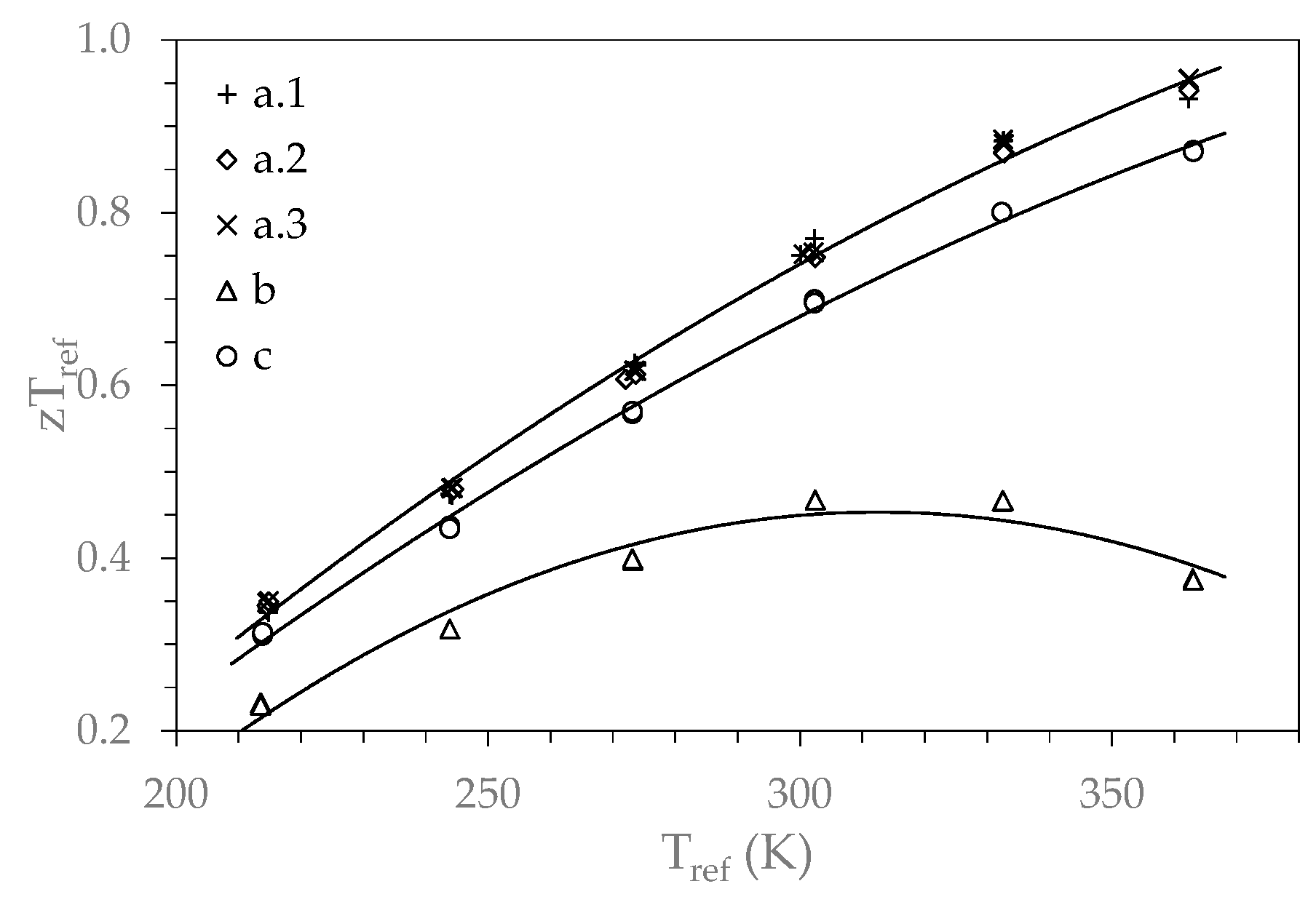

The similar behavior for the Peltier modules “a” is confirmed by the dimensionless figure of merit shown in

Figure 3. For these modules, the measured trends

zTref as the temperature changes are practically coincident and not so different from that obtained for module

c. On the other hand, for module

b the resulting figure of merit shows significantly different values and trends.

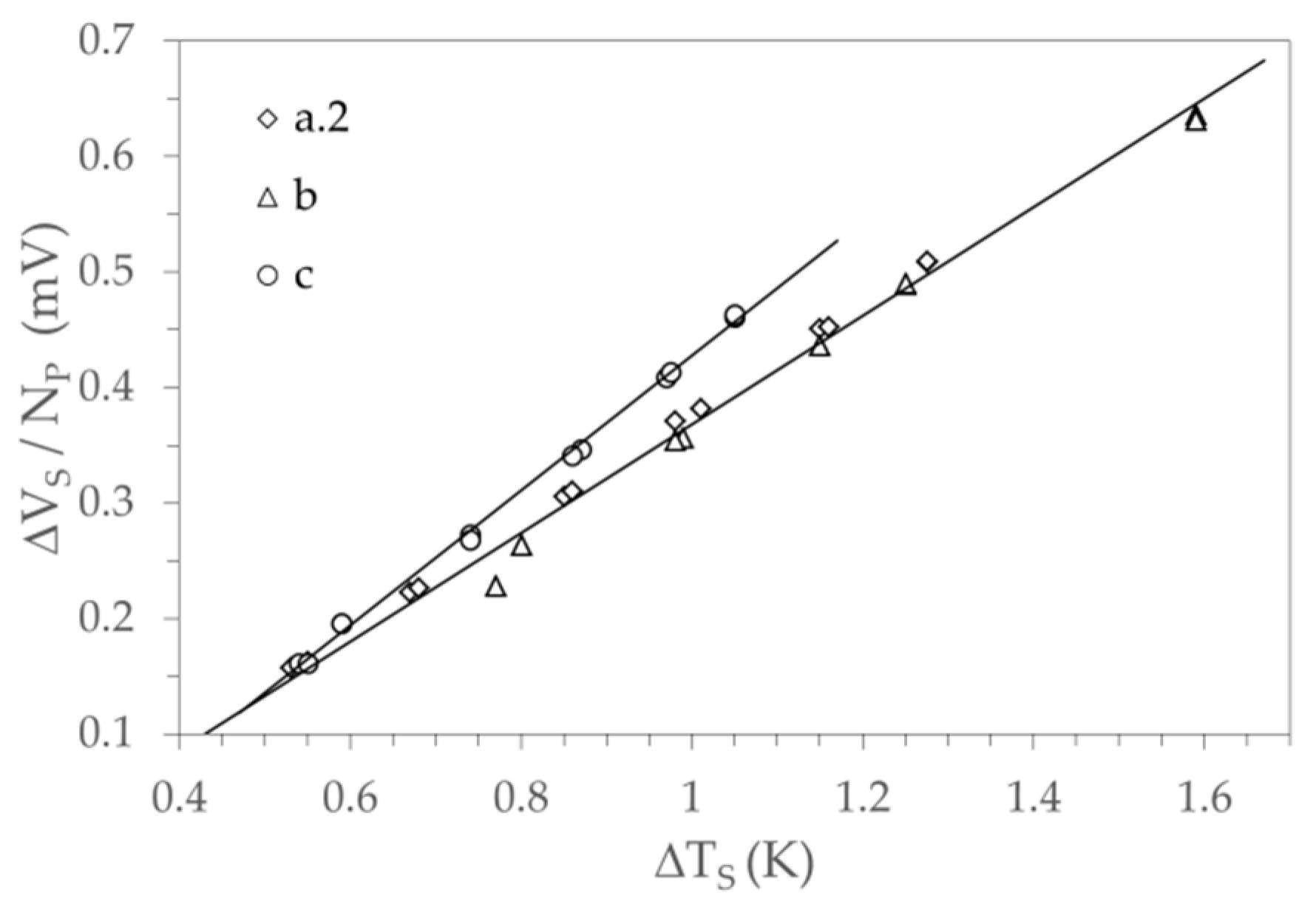

Since the values of zTref and found for the devices grouped as “a” are similar, it is possible to assume that their Seebeck coefficients are also similar. Therefore, in the following to estimate the Seebeck coefficient from the temperature difference measured on the ceramic plates, only modules a.2, b, and c were considered.

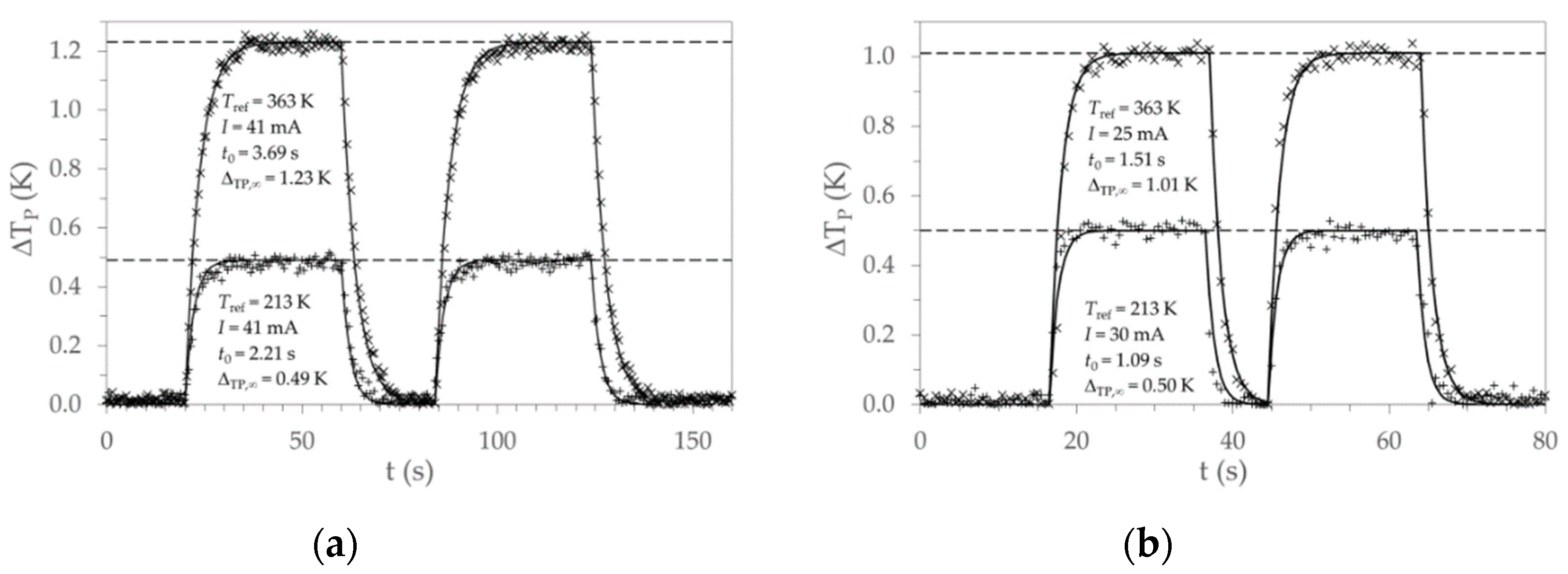

Figure 4 shows the trend over time of the temperature difference

for tests at maximum (363 K) and minimum temperature (213 K).

Figure 4a,b refer to Peltier modules a.2 and c, respectively. Such a transient temperature difference is caused by the feeding current

I, the characteristic time

estimated using the DX 4090 is a useful parameter for the evaluation of the asymptotic value

. In fact, assuming the time

as the parameter that characterizes the response to a step input of a first-order linear system (RC lumped model), it was possible to obtain the best fit of the values

and evaluate the asymptotic temperature differences

shown in

Figure 4a,b with dashed lines. The agreement with the measured values is pointed out through the trends calculated with

and

, represented in the previous figures by the solid lines that reproduce the two sequential transients established by the measurement protocol of the DX 4090.

Since the estimated

are systematically lower than the actual values of the temperature difference

of the junctions, as mentioned at the end of the previous section, a temperature correction

has been imposed, such that

. In the performed tests,

was assigned to modules a.2 and c, and

to module b, due to the higher temperature noise noticed. Using the total Seebeck voltage measured at the leads of these modules,

Figure 5 shows the Seebeck voltage of a single pair as a function of the estimated Seebeck temperature difference

for the junctions. In

Figure 5, it is possible to observe the linear trend of the Seebeck voltage with a greater slope in the case of module

c compared to modules a.2 and b. The same slope found for the latter two modules suggests similar Seebeck coefficients for both devices.

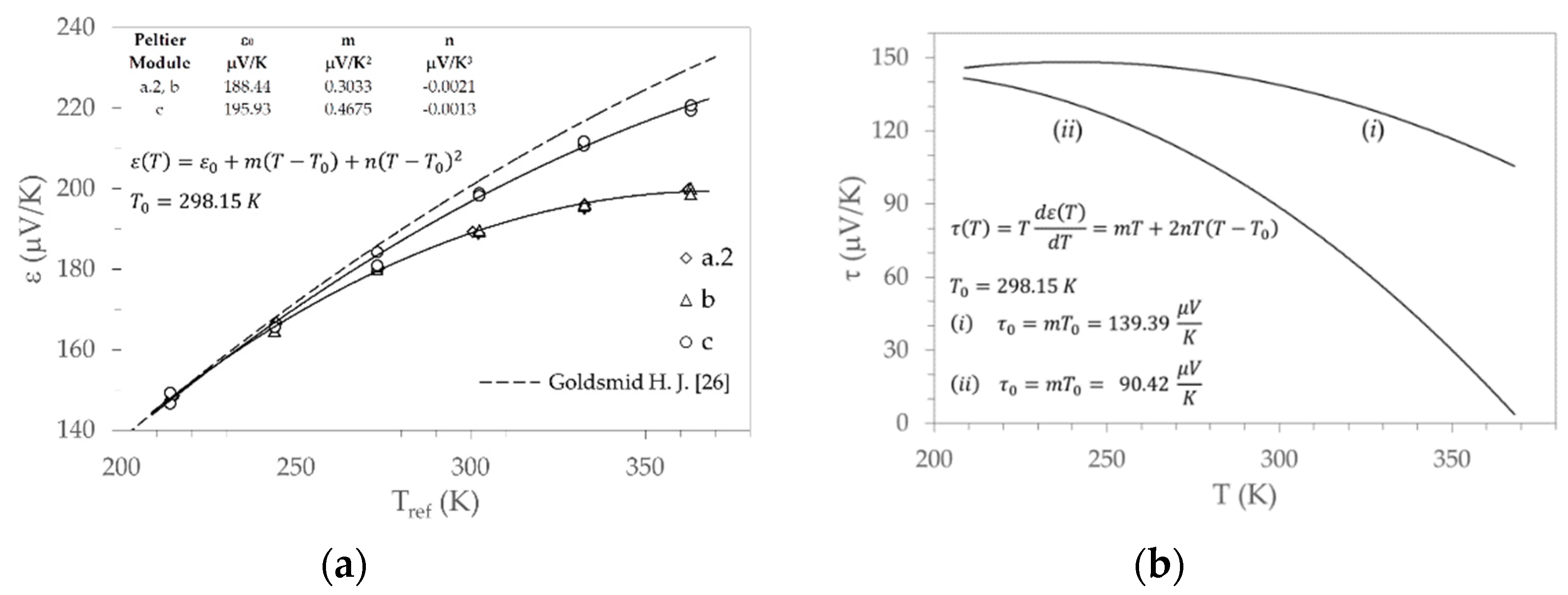

In fact, the equivalent Seebeck coefficients of the single junction resulting from Equation (3) and shown in

Figure 6a as a function of the reference temperature of the test, highlight the same values for modules a.2 and b, and higher values with a different trend for module c. In this figure, the solid lines indicate the second-order polynomial fit, whose equation, coefficients, and reference temperature

are shown inside the diagram box. The dashed line in the figure represents the theoretical trend proportional to

, as mentioned by Goldsmid [

26] for the thermoelectric power of

.

From the equations for

, two temperature-dependent relationships were obtained for the Thomson coefficients

for module c, and modules a.2 and b marked, hereafter as (

i) and (

ii) respectively.

Figure 6b shows the trends for the Thomson coefficient with respect to temperature, and inside the diagram box the reported relationship refers to both cases (

i) and (

ii); parameters

m and

n are those shown in

Figure 6a, while

is the Thomson coefficient at the reference temperature

.

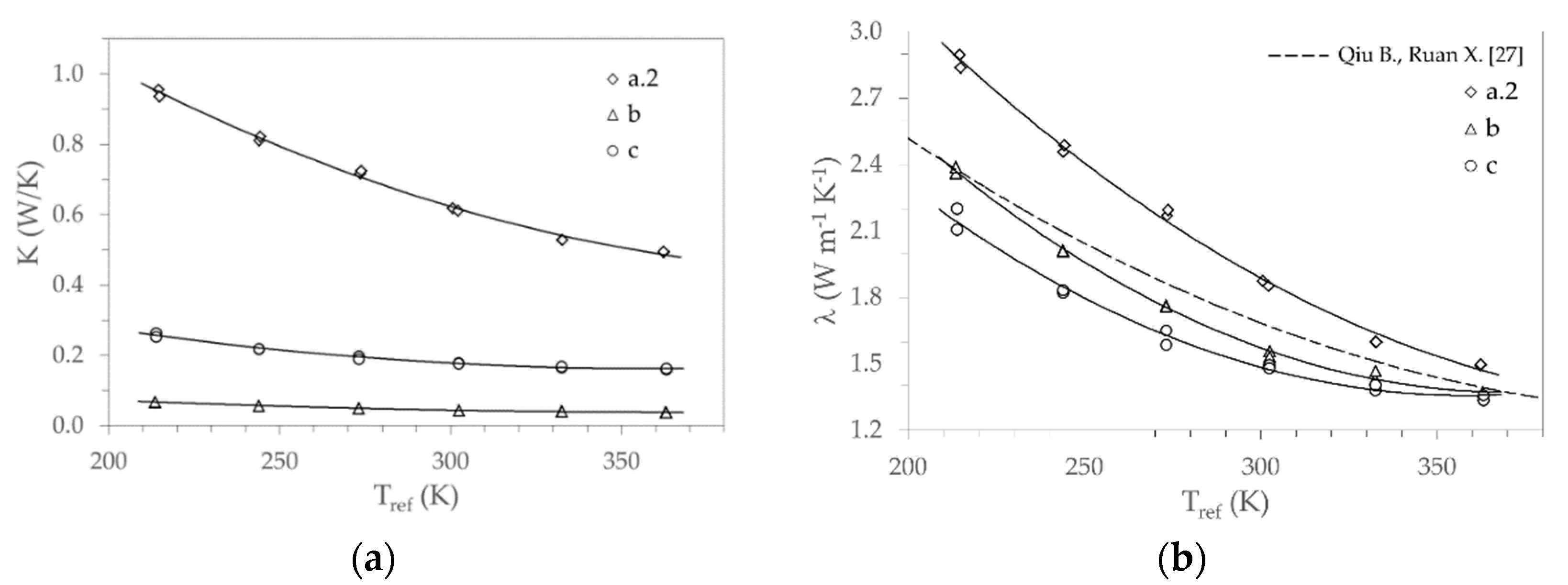

Finally, with the measured electric resistance

R and the Seebeck coefficient estimated, from the well know relation that expresses the figure of merit

, the thermal conductance

was obtained for modules a.2, b, and c, as shown in

Figure 7a. Then, using the pillars geometry reported in

Table 1, the equivalent thermal conductivity of the assembled thermoelectric materials was estimated.

Figure 7b displays the values found against the reference temperature of the test, and the dashed line represents the trend of the average thermal conductivity with respect to the temperature for

p and

n doped Bi

2Te

3 bulk materials found in the literature [

27].

4. Discussion

The results of the tests performed on various commercial Peltier modules, described in the previous section, make it possible to highlight the temperature dependence of their thermoelectric properties, in particular for the Seebeck coefficient , the electric resistivity , and the thermal conductivity . These properties were mentioned as equivalent, because they were not obtained through investigations carried out directly on semiconductor materials, but indirectly through the same materials assembled in thermoelectric modules. Despite this, the values found and the comparison with the literature data gave them adequate reliability.

The temperature dependence of the thermoelectric properties makes it difficult to predict the actual performance of a device when used in the various temperature ranges. Furthermore, the impact of the Thomson effect on the performance of a device is not always so clear, especially when this effect overlaps the Joule effect caused by electrical resistivity if the latter also depends on the temperature.

The analysis was focused on the temperature dependence of the Seebeck coefficient

that is responsible for the Thomson coefficients

previously identified as (

i) and (

ii). The temperature dependence of the electrical resistivity

and of the thermal conductivity

was also considered, adopting the values obtained for module

c and a.2, in the cases (

i) and (

ii), respectively. Assuming in the temperature range investigated there is a linear and a quadratic trend for the resistivity and conductivity respectively, and taking into account what is specified for temperature dependence of the Seebeck coefficient (see

Figure 6a), the general relationship of dependence on the temperature adopted for these properties (

is the generic one) can be written as:

where

is the value (

) of the considered property at the reference temperature

. In

Table 7, for a reference temperature

the coefficients

,

, and

are displayed for both cases (

i) and (

ii). For cases (

i) and (

ii), the geometry of the pillars and the number of pairs are those reported in

Table 1 referring, respectively, to modules c and a.2. The effect produced by the temperature dependence of the thermoelectric properties was obtained by assuming the steady-state conditions and a one-dimensional thermal and electric field along pillars and solving the following governing equation:

where

j is the current density, and the term in round brackets is the Thomson coefficient. The first term of Equation (5) represents the heat flux due to the Fourier conduction, while the second and the third terms characterize the heat generation due respectively to the Thomson and Joule effects. Dirichlet boundary conditions were imposed at the cold (

and hot (

side, thus the heat fluxes at these boundaries can be calculated as:

where in both equations, the terms in round brackets are the Peltier coefficients on the cold and hot sides,

is the cross-section of the pillar (

), while in both equations the first and second terms represent Peltier and Fourier heat fluxes on the cold and hot sides respectively. The coefficient of performance (

) of the device can be expressed by:

The solution for Equation (5) at any location

was obtained numerically by discretization of the computational domain

). The domain was meshed with more than one hundred and one-dimensional elements; the set of equations was solved with a recursive finite differences algorithm (see, for example [

28]), adopting a three-point approximation of the temperature gradient.

For both types of modules, (i) and (ii), using three different currents, , , and two cases were examined with constant hot side temperatures equal to and respectively. is current with which is obtained when the cold side is kept at the temperature , and , , are the Seebeck coefficient and the electrical resistivity at .

To explore these scenarios, the temperature of the cold side was varied in steps of 1 K from to assuming , with , the figure of merit and the thermal conductivity at , respectively. For each assigned , the temperature distribution along the pillars was calculated by solving Equation (5), and therefore determining the heat fluxes on the cold and hot sides with Equations (6) and (7), and the coefficient of performance with Equation (8).

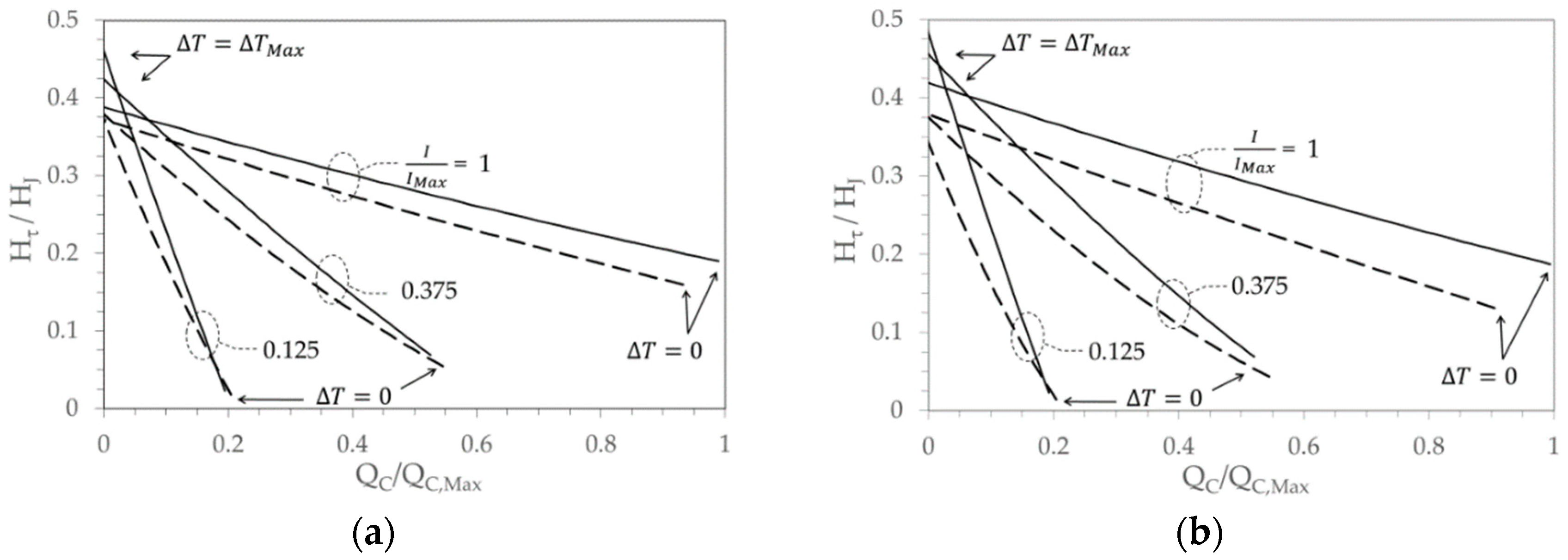

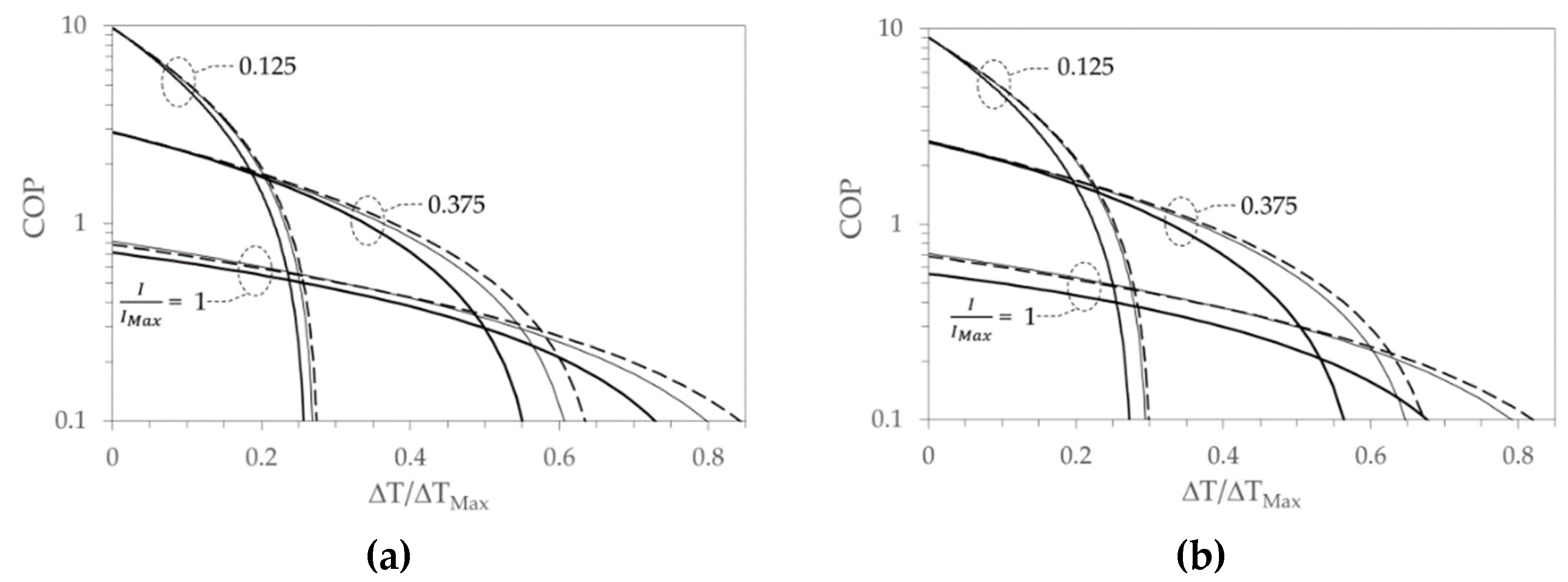

Positive Thomson heat (second term of Equation (5)) plays the role of reducing heat generation by Joule effect (third term of Equation (5)), and both cases (

i) and (

ii) show a positive Thomson heat at the cold side.

Figure 8, for the cases at

and

, shows the ratio between Thomson heat and Joule effect calculated on the cold side as a function of the relative cooling capacity

for different values of the relative feeding current

.

Since the Joule effect is always positive, the graphs in

Figure 8 suggest an enhancement of the cooling capacity induced by the Thomson effect, in particular for high values of

when the cooling capacity decreases. By increasing the cooling capacity,

goes to zero, and the Thomson heat is minimum, but its value increases with the current. To clarify the real role assumed by the Thomson effect in improving the cooling capacity, it is more interesting to compare the experimental results obtained with an ideal circumstance. In this ideal case all the thermoelectric properties are assumed independent of the temperature (i.e.,

), and, therefore, the Thomson effect is zero, and the heat generation by Joule effect along the pillars with a fixed current is constant.

To underline the Thomson effect in relation to the temperature dependence of electrical resistivity and thermal conductivity, it can also be useful to make a comparison with another hypothetical scenario. In this scenario, the Seebeck coefficient is temperature dependent, as established in the cases (

i) and (

ii), while the electrical resistivity and the thermal conductivity are both independent of temperature (i.e.,

). Thes scenarios, for both cases (

i) and (

ii), is shown in

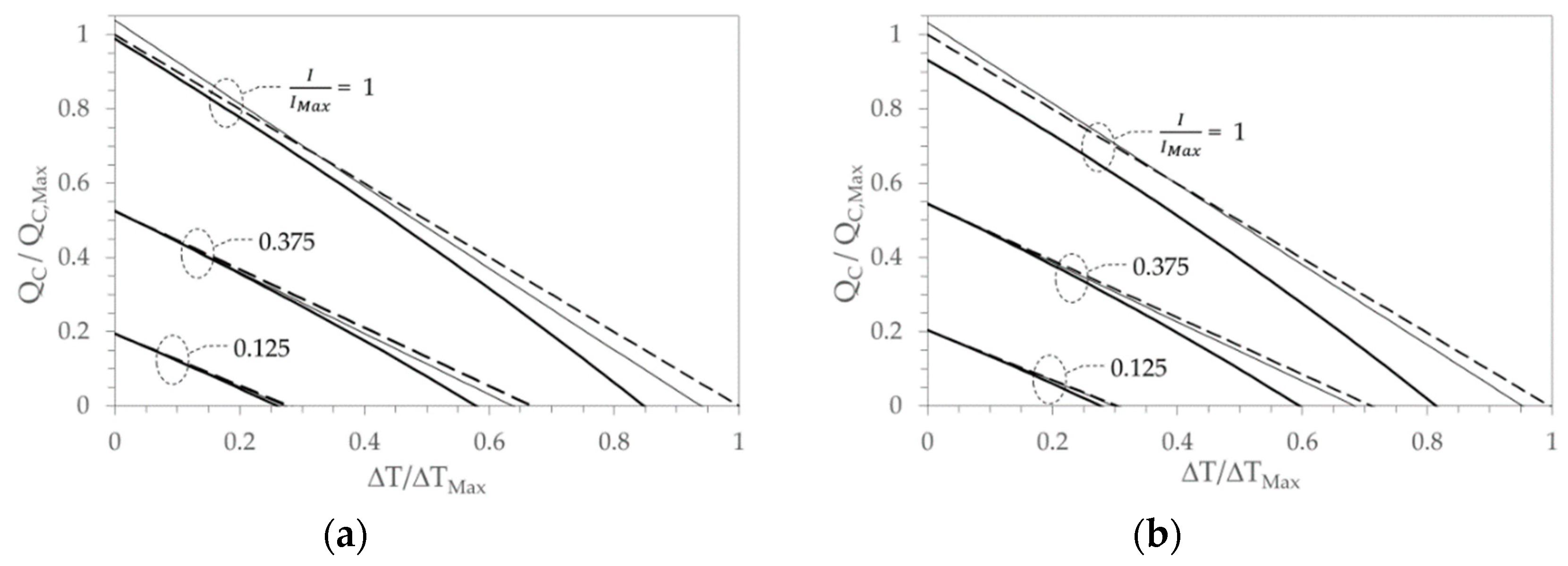

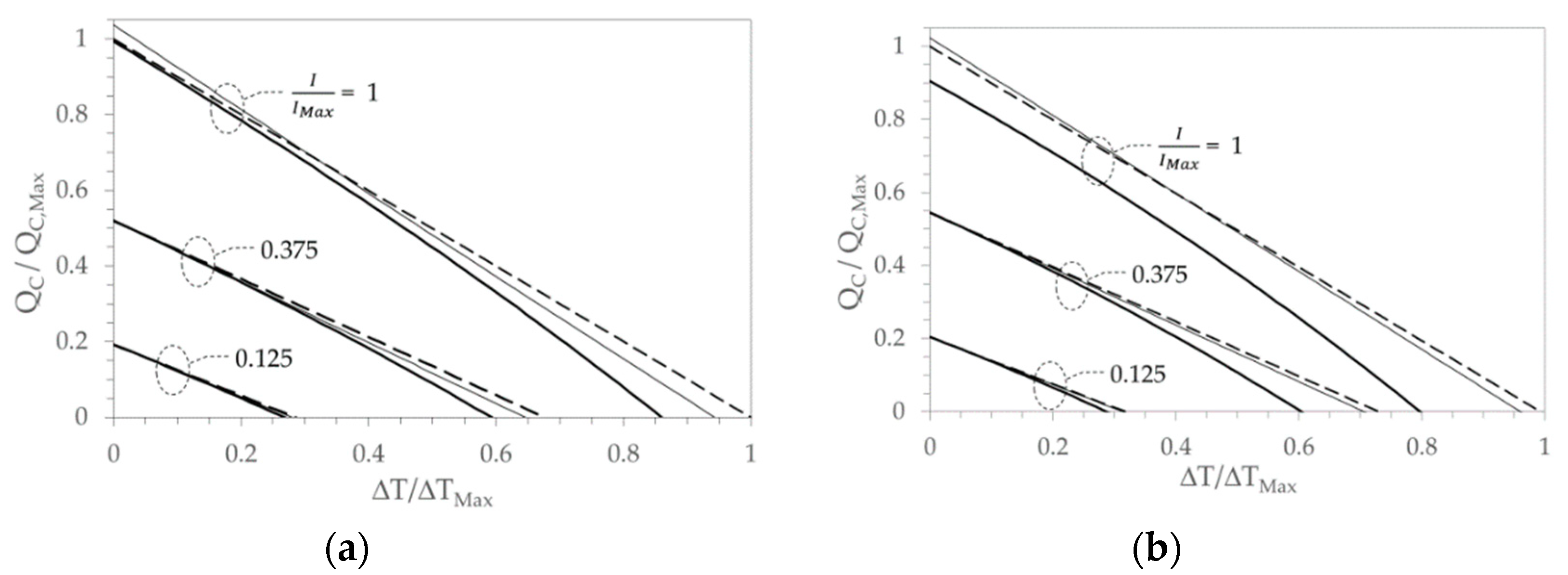

Figure 9, with

, and in

Figure 10, with

. In the two figures, the trends of the relative cooling capacity

as a function of the relative temperature difference

, compared for different values of the relative feeding current

, are quite similar. With the adoption of the previous defined

, the maximum temperature difference depends on the temperature of the hot side chosen, named

.

In the previous diagrams, it can be seen that the results obtained with the temperature-independent properties, represented by the dashed lines, show a linear trend with respect to the relative temperature difference

The slope depends on the feeding current, i.e.,

, and reproduces the typical trend proposed in datasheets of commercial devices. On the contrary, the experimental results obtained, represented by the thick solid lines, show the influence of the temperature-dependent thermoelectric properties with an overall reduced cooling capacity, in particular for both high feeding currents, and temperature differences. With a low feeding current there are no significant differences regardless of the assumptions about the thermoelectric properties, while at high currents, a reduced cooling capacity is observed for all the temperature differences between the junctions. When

approaches zero, the reduced cooling capacity is caused by the different temperature gradients resulting on the cold side. The temperature gradient is influenced by the temperature profile along the pillars, which depends on the electrical resistivity and thermal conductivity. Furthermore, the thermal gradient on the cold side in the case of temperature-dependent properties is higher than that found in the ideal case of temperature-independent properties. In this way, with the same Peltier heat flux for

, the Fourier heat conduction increases. Therefore, with regard to case (

ii),

Figure 9b and

Figure 10b show at the higher current a greater deviation from ideal conditions due to the higher thermal conductivity value (see

Table 7), compared with

Figure 9a and

Figure 10a, which refer to case (

i). At the lower currents investigated, this fact was negligible.

The assumption that only the Seebeck coefficient depends on the temperature allows us to better highlight the contribution of the Thomson effect. On the cold side, as shown in

Figure 8a,b, the magnitude of the Thomson heat compared with the heat generation by Joule effect is greater at higher

and with lower cooling capacities. In addition, the Thomson heat, although reduced, does not vanish at smaller

and with greater cooling capacity, and when the temperature difference approaches zero, it clearly increases with the feeding current. The thin solid lines in

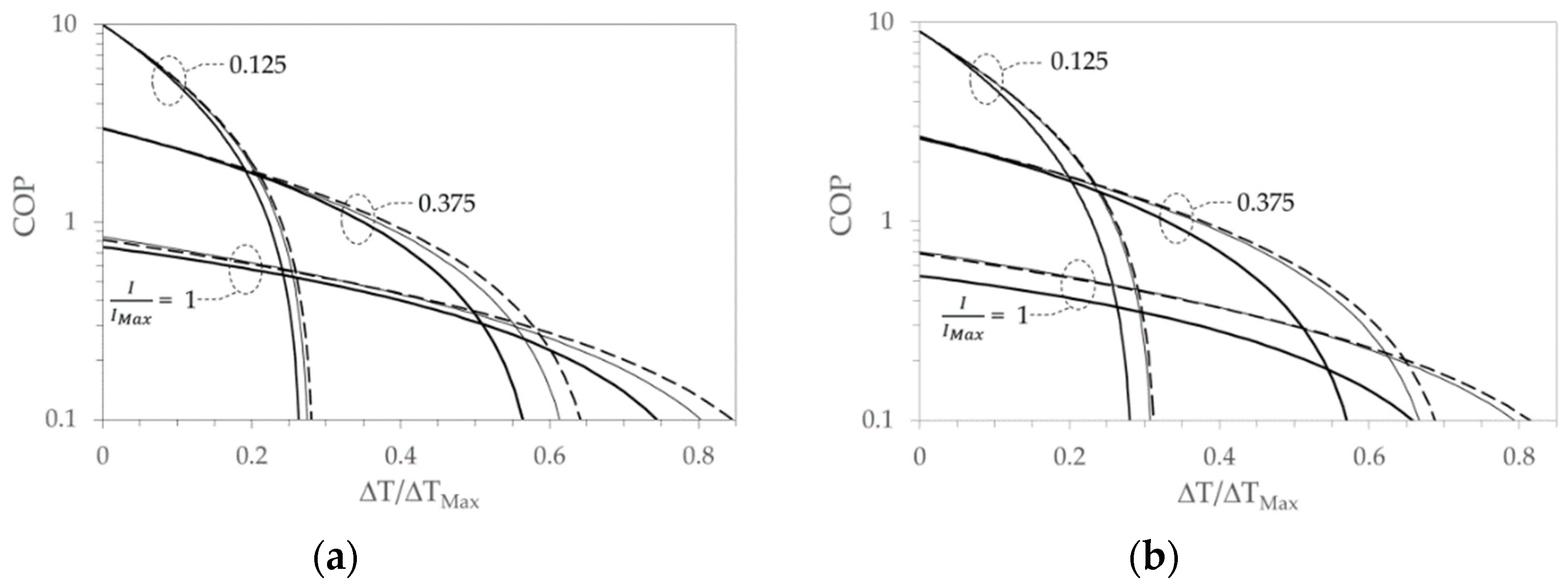

Figure 9a,b shows these evidence. At the lowest current set, the effect induced by Thomson heat is practically undetectable and its influence is observable due to the increase in the feeding current. At higher temperature differences, the trend of the cooling capacity shifts toward the ideal condition (temperature-independent properties), but remains even lower. Otherwise, with higher feeding current and at the lower temperature difference, the cooling capacity exceeds that obtained in the ideal condition because on the cold side, the heat generated by Joule effect is reduced due to the heat absorbed by the Thomson effect, and consequently the local thermal gradient and the Fourier heat contribution are reduced. A further confirmation of this is given by the coefficients of performance reported in

Figure 11 and

Figure 12, for which it is difficult to highlight an improvement in the performance of the device compared with the event that only the Seebeck coefficient is temperature-dependent (solid thin lines). Under these conditions, for the thermoelectric modules investigated, only with the maximum current, a small improvement in the performance was observed.