Multi-Objective Optimization of Cutting Parameters in Turning AISI 304 Austenitic Stainless Steel

Abstract

1. Introduction

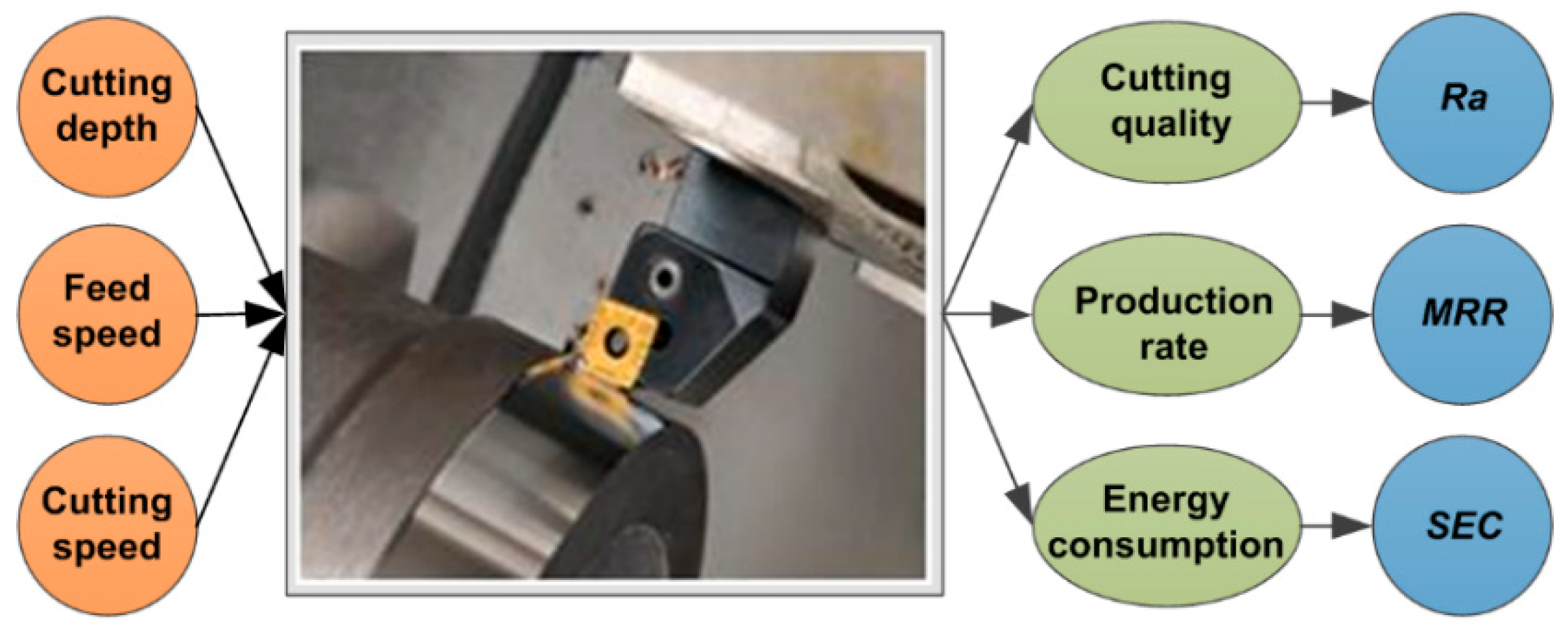

2. Multi-Objective Optimization Framework of Turning Parameters

2.1. Cutting Quality

2.2. Production Rate

2.3. Energy Consumption

3. Optimization Example

3.1. Experimental Details

3.1.1. Workpiece Material and Cutting Tool

3.1.2. Experimental Equipment

3.1.3. Design of Experiments

3.2. Grey Relational Analysis

3.3. Process Modelling and ANOVA

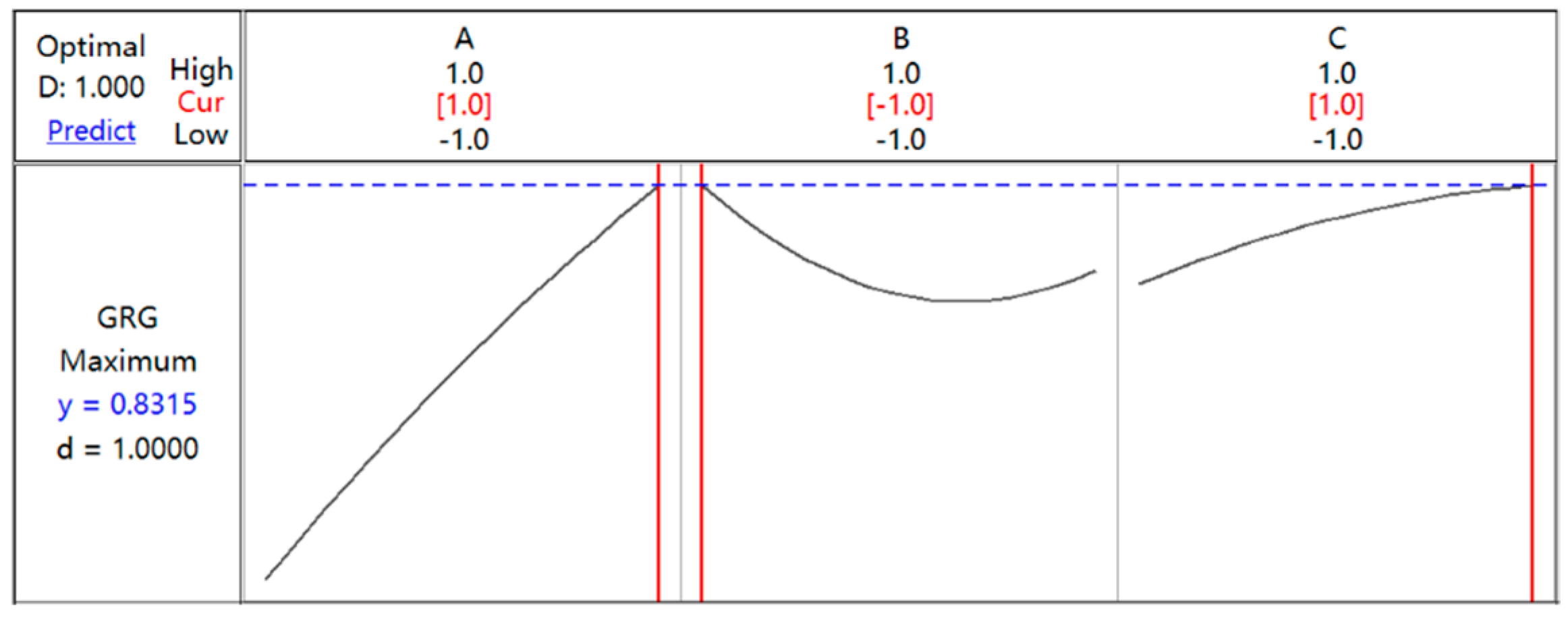

3.4. Optimization Results and Comparative Analysis

4. Conclusions

- (1)

- In order to effectively balance the cutting quality, production rate, and energy consumption in turning process, Ra, MRR, and SEC are featured as optimization objectives of turning parameters for sustainable manufacturing.

- (2)

- The complex multi-objective optimization problem can be transformed to a single objective optimization problem with grey relational analysis, which simplifies the optimization procedure.

- (3)

- The coefficient of determination R-sq of the GRG model is 97.21%. This means that the regression model based on RSM can be used to predict the value of GRG with high accuracy.

- (4)

- In this optimization example, the optimal combination of cutting parameters in turning AISI 304 austenitic stainless steel is: ap = 2.2 mm, f = 0.15 mm/rev, and v = 90 m/s. Compared with the initial turning parameters, Ra decreases 66.90%, MRR increases 8.82%, and SEC decreases 81.46%.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Öktem, H.; Erzurumlu, T.; Kurtaran, H. Application of response surface methodology in the optimization of cutting conditions for surface roughness. J. Mater. Process. Technol. 2005, 170, 11–16. [Google Scholar] [CrossRef]

- Zhao, G.; Liu, Z.; He, Y.; Cao, H.; Guo, Y. Energy consumption in machining: Classification, prediction, and reduction strategy. Energy 2017, 133, 142–157. [Google Scholar] [CrossRef]

- Camposeco-Negrete, C.; de Dios Calderón-Nájera, J. Sustainable machining as a mean of reducing the environmental impacts related to the energy consumption of the machine tool: A case study of AISI 1045 steel machining. Int. J. Adv. Manuf. Technol. 2019, 102, 27–41. [Google Scholar] [CrossRef]

- Kumar, S. Measurement and uncertainty analysis of surface roughness and material removal rate in micro turning operation and process parameters optimization. Measurement 2019, 140, 538–547. [Google Scholar] [CrossRef]

- Zhou, T.; He, L.; Wu, J.; Du, F.; Zou, Z. Prediction of surface roughness of 304 stainless steel and multi-objective optimization of cutting parameters based on GA-GBRT. Appl. Sci. 2019, 9, 3684–3705. [Google Scholar] [CrossRef]

- Li, H.; Wang, J. Determination of optimum parameters in plane grinding by using grey relational analysis. Chin. Mech. Eng. 2011, 22, 631–635. [Google Scholar]

- Kuram, E.; Ozcelik, B. Multi-objective optimization using Taguchi based grey relational analysis for micro-milling of Al 7075 material with ball nose end mill. Measurement 2013, 46, 1849–1864. [Google Scholar] [CrossRef]

- Tuo, J.; Liu, F.; Zhang, H.; Liu, P.; Cai, W. Connotation and Assessment Method for Inherent Energy Efficiency of Machine tool. J. Mech. Eng. 2018, 54, 167–175. [Google Scholar] [CrossRef]

- Vijayaraghavan, A.; Dornfeld, D. Automated energy monitoring of machine tool. CIRP Ann. 2010, 59, 21–24. [Google Scholar] [CrossRef]

- Kara, S.; Li, W. Unit process energy consumption models for material removal processes. CIRP Ann. 2011, 60, 37–40. [Google Scholar] [CrossRef]

- Li, L.; Yan, J.; Xing, Z. Energy requirements evaluation of milling machines based on thermal equilibrium and empirical modelling. J. Clean. Prod. 2013, 52, 113–121. [Google Scholar] [CrossRef]

- Zhang, H.; Kong, L.; Li, T.; Chen, J. SCE modeling and influence trend analysis of cutting parameters. Chin. Mech. Eng. 2015, 26, 1098–1103. [Google Scholar]

- Camposeceo-Negrete, C. Optimization of cutting parameters using response surface method for minimizing energy consumption and maximizing cutting quality in turning of AISI 6061 T6 aluminum. J. Clean. Prod. 2015, 91, 109–117. [Google Scholar] [CrossRef]

- Zhao, G.; Guo, Y.; Zhu, P.; Zhao, Y. Energy consumption characteristics and influence on surface quality in milling. Proc. CIRP 2018, 71, 111–115. [Google Scholar] [CrossRef]

- Zhou, L.; Li, J.; Li, F.; Mendis, G.; Sutherland, J.W. Optimization parameters for energy efficiency in end milling. Proc. CIRP 2018, 69, 312–317. [Google Scholar] [CrossRef]

- Li, C.; Xiao, Q.; Tang, Y.; Li, L. A method integrating Taguchi, RSM and MOPSO to CNC machining parameters optimization for energy saving. J. Clean. Prod. 2016, 135, 263–275. [Google Scholar] [CrossRef]

- Yan, J.; Li, L. Multi-objective optimization of milling parameters—The trade-offs between energy, production rate and cutting quality. J. Clean. Prod. 2013, 52, 462–471. [Google Scholar] [CrossRef]

- Li, X.; Liu, Z.; Liang, X. Tool wear, surface topography, and multi-objective optimization of cutting parameters during machining AISI 304 austenitic stainless steel flange. Metals 2019, 9, 972–987. [Google Scholar] [CrossRef]

- Liu, N.; Wang, S.; Zhang, Y.; Lu, W. A novel approach to predicting surface roughness based on specific cutting energy consumption when slot milling Al-7075. Int. J. Mech. Sci. 2016, 118, 13–20. [Google Scholar] [CrossRef]

- Fang, X.; Safi-Jahanshaki, H. A new algorithm for developing a reference model for predicting surface roughness in finish machining of steels. Int. J. Prod. Res. 1997, 35, 179–197. [Google Scholar] [CrossRef]

- Hu, S.; Liu, F.; He, Y.; Hu, T. An on-line approach for energy efficiency monitoring of machine tool. J. Clean. Prod. 2012, 27, 133–140. [Google Scholar] [CrossRef]

- Nayak, S.K.; Patro, J.K.; Dewangan, S.; Gangopadhyay, S. Multi-objective optimization of machining parameters during dry turning of AISI 304 austenitic stainless steel using grey relational analysis. Proc. Mater. Sci. 2014, 6, 701–708. [Google Scholar] [CrossRef]

- Baş, D.; Boyaci, I.H. Modeling and optimization I: usability of response methodology. J. Food Eng. 2007, 78, 836–845. [Google Scholar] [CrossRef]

| Composition | C | Mn | Si | P | S | Ni | Cr | Mo | Cu | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| wt% | 0.065 | 1.78 | 0.3 | 0.027 | 0.02 | 8.1 | 18.2 | 0.13 | 0.14 | 71.2 |

| Specific Heat Capacity | Elastic Modulus | Coefficient of Thermal Expansion | Thermal Conductivity | Density |

|---|---|---|---|---|

| (J·kg−1·K−1) | (GPa) | (10−6·K−1) | (W·m−1·K−1) | (g/cm3) |

| 500 | 194 | 17.3 | 16.3 | 7.93 |

| Parameters | Range | Level 1 | Level 2 | Level 3 | Level 4 | Level 5 |

|---|---|---|---|---|---|---|

| ap (mm) | 0.2–2.2 | 0.2 | 0.7 | 1.2 | 1.7 | 2.2 |

| f (mm/rev) | 0.15–0.35 | 0.15 | 0.20 | 0.25 | 0.30 | 0.35 |

| v (m/min) | 50–90 | 50 | 60 | 70 | 80 | 90 |

| No. | ap | f | v | d | n | Ra | MRR | SEC |

|---|---|---|---|---|---|---|---|---|

| (mm) | (mm/rev) | (m/min) | (mm) | (r/min) | (μm) | (mm3/s) | (J/mm3) | |

| 1 | 0.2 | 0.15 | 50 | 47.40 | 336 | 1.0325 | 24.9116 | 73.8180 |

| 2 | 0.2 | 0.20 | 60 | 46.97 | 407 | 1.5835 | 39.8676 | 56.2968 |

| 3 | 0.2 | 0.25 | 70 | 46.55 | 479 | 2.3270 | 58.1238 | 46.4650 |

| 4 | 0.2 | 0.30 | 80 | 46.13 | 621 | 3.0725 | 89.6062 | 39.1952 |

| 5 | 0.2 | 0.35 | 90 | 45.71 | 627 | 3.9995 | 104.5854 | 34.9219 |

| 6 | 0.7 | 0.15 | 60 | 45.29 | 422 | 0.9995 | 103.4517 | 25.0040 |

| 7 | 0.7 | 0.20 | 70 | 43.87 | 508 | 1.6190 | 160.7579 | 19.7991 |

| 8 | 0.7 | 0.25 | 80 | 42.44 | 600 | 2.3195 | 229.4776 | 16.4892 |

| 9 | 0.7 | 0.30 | 90 | 41.03 | 699 | 3.0820 | 309.9726 | 14.3977 |

| 10 | 0.7 | 0.35 | 50 | 39.60 | 402 | 3.8170 | 200.6044 | 13.6178 |

| 11 | 1.2 | 0.15 | 70 | 38.17 | 584 | 0.8830 | 203.4855 | 18.3305 |

| 12 | 1.2 | 0.20 | 80 | 35.74 | 713 | 1.6265 | 309.4723 | 14.9285 |

| 13 | 1.2 | 0.25 | 90 | 33.32 | 860 | 2.4110 | 433.9042 | 13.2391 |

| 14 | 1.2 | 0.30 | 50 | 30.93 | 515 | 3.1150 | 288.6046 | 12.3712 |

| 15 | 1.2 | 0.35 | 60 | 46.98 | 407 | 3.8100 | 409.7492 | 1.4578 |

| 16 | 1.7 | 0.15 | 80 | 44.56 | 572 | 0.7810 | 327.3309 | 1.9894 |

| 17 | 1.7 | 0.20 | 90 | 41.14 | 697 | 1.4180 | 489.3811 | 1.5024 |

| 18 | 1.7 | 0.25 | 50 | 37.67 | 423 | 2.1520 | 338.5855 | 2.3185 |

| 19 | 1.7 | 0.30 | 60 | 34.28 | 557 | 3.0020 | 484.5907 | 1.4280 |

| 20 | 1.7 | 0.35 | 70 | 30.90 | 721 | 3.8335 | 655.8941 | 1.1752 |

| 21 | 2.2 | 0.15 | 90 | 46.85 | 612 | 0.7980 | 472.1559 | 2.4545 |

| 22 | 2.2 | 0.20 | 50 | 42.40 | 376 | 1.4105 | 348.2292 | 3.1293 |

| 23 | 2.2 | 0.25 | 60 | 37.03 | 516 | 1.7555 | 517.5645 | 2.1792 |

| 24 | 2.2 | 0.30 | 70 | 32.58 | 684 | 2.8110 | 718.1025 | 1.4547 |

| 25 | 2.2 | 0.35 | 80 | 43.53 | 585 | 3.6870 | 974.7890 | 1.1535 |

| Contrast Sequence | Ra | MRR | SEC |

|---|---|---|---|

| 1 | 0.9219 | 0.0000 | 0.0000 |

| 2 | 0.7507 | 0.0157 | 0.2411 |

| 3 | 0.5197 | 0.0350 | 0.3764 |

| 4 | 0.2880 | 0.0681 | 0.4765 |

| 5 | 0.0000 | 0.0839 | 0.5353 |

| 6 | 0.9321 | 0.0827 | 0.6718 |

| 7 | 0.7396 | 0.1430 | 0.7434 |

| 8 | 0.5220 | 0.2154 | 0.7890 |

| 9 | 0.2851 | 0.3001 | 0.8177 |

| 10 | 0.0567 | 0.1850 | 0.8285 |

| 11 | 0.9683 | 0.1880 | 0.7636 |

| 12 | 0.7373 | 0.2996 | 0.8104 |

| 13 | 0.4936 | 0.4306 | 0.8337 |

| 14 | 0.2748 | 0.2776 | 0.8456 |

| 15 | 0.0589 | 0.4051 | 0.9958 |

| 16 | 1.0000 | 0.3184 | 0.9885 |

| 17 | 0.8021 | 0.4890 | 0.9952 |

| 18 | 0.5740 | 0.3302 | 0.9840 |

| 19 | 0.3099 | 0.4839 | 0.9962 |

| 20 | 0.0516 | 0.6643 | 0.9997 |

| 21 | 0.9947 | 0.4708 | 0.9821 |

| 22 | 0.8044 | 0.3404 | 0.9728 |

| 23 | 0.6972 | 0.5186 | 0.9859 |

| 24 | 0.3693 | 0.7298 | 0.9959 |

| 25 | 0.0971 | 1.0000 | 1.0000 |

| Contrast Sequence | GRCMRR | GRCRa | GRCSEC | GRG | Sort |

|---|---|---|---|---|---|

| 1 | 0.3333 | 0.8648 | 0.3333 | 0.5105 | 20 |

| 2 | 0.3369 | 0.6673 | 0.3972 | 0.4671 | 22 |

| 3 | 0.3413 | 0.5100 | 0.4450 | 0.4321 | 23 |

| 4 | 0.3492 | 0.4125 | 0.4885 | 0.4167 | 24 |

| 5 | 0.3531 | 0.3333 | 0.5183 | 0.4016 | 25 |

| 6 | 0.3528 | 0.8805 | 0.6037 | 0.6123 | 12 |

| 7 | 0.3685 | 0.6576 | 0.6609 | 0.5623 | 16 |

| 8 | 0.3892 | 0.5112 | 0.7032 | 0.5345 | 17 |

| 9 | 0.4167 | 0.4115 | 0.7329 | 0.5204 | 19 |

| 10 | 0.3802 | 0.3464 | 0.7446 | 0.4904 | 21 |

| 11 | 0.3811 | 0.9404 | 0.6790 | 0.6668 | 8 |

| 12 | 0.4165 | 0.6556 | 0.7251 | 0.5991 | 13 |

| 13 | 0.4675 | 0.4968 | 0.7504 | 0.5716 | 15 |

| 14 | 0.4090 | 0.4081 | 0.7641 | 0.5271 | 18 |

| 15 | 0.4567 | 0.3470 | 0.9917 | 0.5984 | 14 |

| 16 | 0.4231 | 1.0000 | 0.9775 | 0.8002 | 2 |

| 17 | 0.4945 | 0.7164 | 0.9905 | 0.7338 | 4 |

| 18 | 0.4274 | 0.5400 | 0.9689 | 0.6454 | 10 |

| 19 | 0.4921 | 0.4201 | 0.9925 | 0.6349 | 11 |

| 20 | 0.5983 | 0.3452 | 0.9994 | 0.6476 | 9 |

| 21 | 0.4858 | 0.9895 | 0.9654 | 0.8136 | 1 |

| 22 | 0.4312 | 0.7188 | 0.9484 | 0.6995 | 6 |

| 23 | 0.5095 | 0.6228 | 0.9725 | 0.7016 | 5 |

| 24 | 0.6492 | 0.4422 | 0.9918 | 0.6944 | 7 |

| 25 | 1.0000 | 0.3564 | 1.0000 | 0.7855 | 3 |

| Source | DF | SS | MS | F | P |

|---|---|---|---|---|---|

| Regression model | 8 | 0.324835 | 0.040604 | 69.81 | <0.001 |

| Error | 16 | 0.009307 | 0.000582 | - | - |

| Total | 24 | 0.334142 | - | - | - |

| S = 0.0241181 | R-sq = 97.21% | R-sq (adj) = 95.82% | |||

| Items | ap | f | v | Ra | MRR | SEC |

|---|---|---|---|---|---|---|

| (mm) | (mm/rev) | (m/min) | (μm) | (mm3/s) | (J/mm3) | |

| Initial parameters | 1.2 | 0.25 | 90 | 2.4110 | 433.9042 | 13.2391 |

| Optimal parameters | 2.2 | 0.15 | 90 | 0.7980 | 472.1559 | 2.4545 |

| Promotion | - | - | - | 66.90% | 8.82% | 81.46% |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Su, Y.; Zhao, G.; Zhao, Y.; Meng, J.; Li, C. Multi-Objective Optimization of Cutting Parameters in Turning AISI 304 Austenitic Stainless Steel. Metals 2020, 10, 217. https://doi.org/10.3390/met10020217

Su Y, Zhao G, Zhao Y, Meng J, Li C. Multi-Objective Optimization of Cutting Parameters in Turning AISI 304 Austenitic Stainless Steel. Metals. 2020; 10(2):217. https://doi.org/10.3390/met10020217

Chicago/Turabian StyleSu, Yu, Guoyong Zhao, Yugang Zhao, Jianbing Meng, and Chunxiao Li. 2020. "Multi-Objective Optimization of Cutting Parameters in Turning AISI 304 Austenitic Stainless Steel" Metals 10, no. 2: 217. https://doi.org/10.3390/met10020217

APA StyleSu, Y., Zhao, G., Zhao, Y., Meng, J., & Li, C. (2020). Multi-Objective Optimization of Cutting Parameters in Turning AISI 304 Austenitic Stainless Steel. Metals, 10(2), 217. https://doi.org/10.3390/met10020217