Improving Hydrogen Embrittlement Resistance of Hot-Stamped 1500 MPa Steel Parts That Have Undergone a Q&P Treatment by the Design of Retained Austenite and Martensite Matrix

Abstract

1. Introduction

2. Materials and Methods

3. Results

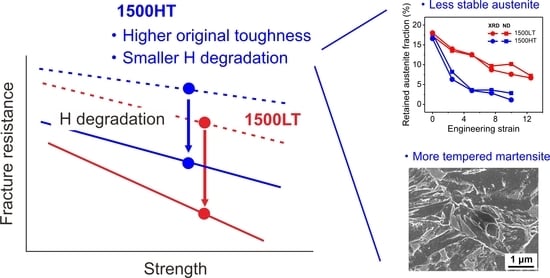

4. Discussion

4.1. Hydrogen

4.2. Retained Austenite

4.3. Martensite Matrix

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Wang, L.; Speer, J.G. Quenching and Partitioning Steel Heat Treatment. Metallogr. Microstruct. Anal. 2013, 2, 268–281. [Google Scholar] [CrossRef]

- Huang, M.X.; Liang, Z.Y.; Luo, Z.C. Critical Assessment 15: Science of deformation and failure mechanisms in twinning induced plasticity steels. Mater. Sci. Technol. 2015, 31, 1265–1270. [Google Scholar] [CrossRef]

- Yi, H.L.; Sun, L.; Xiong, X.C. Challenges in the formability of the next generation of automotive steel sheets. Mater. Sci. Technol. 2018, 34, 1112–1117. [Google Scholar] [CrossRef]

- Speer, J.; Matlock, D.K.; De Cooman, B.C.; Schroth, J.G. Carbon partitioning into austenite after martensite transformation. Acta Mater. 2003, 51, 2611–2622. [Google Scholar] [CrossRef]

- Speer, J.G.; Edmonds, D.V.; Rizzo, F.C.; Matlock, D.K. Partitioning of carbon from supersaturated plates of ferrite, with application to steel processing and fundamentals of the bainite transformation. Curr. Opin. Solid State Mater. Sci. 2004, 8, 219–237. [Google Scholar] [CrossRef]

- Pierce, D.T.; Coughlin, D.R.; Clarke, K.D.; De Moor, E.; Poplawsky, J.; Williamson, D.L.; Mazumder, B.; Speer, J.G.; Hood, A.; Clarke, A.J. Microstructural evolution during quenching and partitioning of 0.2C–1.5Mn-1.3Si steels with Cr or Ni additions. Acta Mater. 2018, 151, 454–469. [Google Scholar] [CrossRef]

- Liu, L.; He, B.B.; Cheng, G.J.; Yen, H.W.; Huang, M.X. Optimum properties of quenching and partitioning steels achieved by balancing fraction and stability of retained austenite. Scr. Mater. 2018, 150, 1–6. [Google Scholar] [CrossRef]

- He, B.B.; Liu, L.; Huang, M.X. Room-Temperature Quenching and Partitioning Steel. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2018, 49, 3167–3172. [Google Scholar] [CrossRef]

- Xiong, Z.; Jacques, P.J.; Perlade, A.; Pardoen, T. Ductile and intergranular brittle fracture in a two-step quenching and partitioning steel. Scr. Mater. 2018, 157, 6–9. [Google Scholar] [CrossRef]

- Xiong, Z.; Jacques, P.J.; Perlade, A.; Pardoen, T. Characterization and Control of the Compromise between Tensile Properties and Fracture Toughness in a Quenched and Partitioned Steel. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2019, 50, 3502–3513. [Google Scholar] [CrossRef]

- Wang, Z.; Huang, M.X. The Role of Retained Austenite Stability on Low-Temperature Mechanical Behaviors of a Quenching and Partitioning Steel. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2019, 50, 5650–5655. [Google Scholar] [CrossRef]

- Wang, Z.; Huang, M.X. Optimising the strength-ductility-toughness combination in ultra-high strength quenching and partitioning steels by tailoring martensite matrix and retained austenite. Int. J. Plast. 2020, 134, 102851. [Google Scholar] [CrossRef]

- Mehner, T.; Scharf, I.; Frint, P.; Schubert, F.; Mašek, B.; Wagner, M.F.-X.; Lampke, T. Hydrogen embrittlement of a quenching and partitioning steel during corrosion and zinc electroplating. Mater. Sci. Eng. A 2019, 744, 247–254. [Google Scholar] [CrossRef]

- Wang, Z.; Luo, Z.C.; Huang, M.X. Revealing hydrogen-induced delayed fracture in ferrite-containing quenching and partitioning steels. Materialia 2018, 4, 260–267. [Google Scholar] [CrossRef]

- Yang, J.; Song, Y.; Lu, Y.; Gu, J.; Guo, Z. Effect of ferrite on the hydrogen embrittlement in quenched-partitioned-tempered low carbon steel. Mater. Sci. Eng. A 2017, 712, 630–636. [Google Scholar] [CrossRef]

- Nagumo, M. Fundamentals of Hydrogen Embrittlement; Springer: Berlin/Heidelberg, Germany, 2016; pp. 1–239. [Google Scholar] [CrossRef]

- Zhu, X.; Zhang, K.; Li, W.; Jin, X. Effect of retained austenite stability and morphology on the hydrogen embrittlement susceptibility in quenching and partitioning treated steels. Mater. Sci. Eng. A 2016, 658, 400–408. [Google Scholar] [CrossRef]

- Zhu, X.; Li, W.; Hsu, T.Y.; Zhou, S.; Wang, L.; Jin, X. Improved resistance to hydrogen embrittlement in a high-strength steel by quenching-partitioning-tempering treatment. Scr. Mater. 2015, 97, 21–24. [Google Scholar] [CrossRef]

- Ryu, J.H.; Chun, Y.S.; Lee, C.S.; Bhadeshia, H.K.D.H.; Suh, D.W. Effect of deformation on hydrogen trapping and effusion in TRIP-assisted steel. Acta Mater. 2012, 60, 4085–4092. [Google Scholar] [CrossRef]

- Zhu, X.; Li, W.; Zhao, H.; Jin, X. Effects of cryogenic and tempered treatment on the hydrogen embrittlement susceptibility of TRIP-780 steels. Int. J. Hydrogen Energy 2013, 38, 10694–10703. [Google Scholar] [CrossRef]

- Hu, X.H.; Sun, X.; Hector, L.G.; Ren, Y. Individual phase constitutive properties of a TRIP-assisted QP980 steel from a combined synchrotron X-ray diffraction and crystal plasticity approach. Acta Mater. 2017, 132, 230–244. [Google Scholar] [CrossRef]

- Hou, Z.R.; Opitz, T.; Xiong, X.C.; Zhao, X.M.; Yi, H.L. Bake-partitioning in a press-hardening steel. Scr. Mater. 2019, 162, 492–496. [Google Scholar] [CrossRef]

- Liu, H.; Lu, X.; Jin, X.; Dong, H.; Shi, J. Enhanced mechanical properties of a hot stamped advanced high-strength steel treated by quenching and partitioning process. Scr. Mater. 2011, 64, 749–752. [Google Scholar] [CrossRef]

- Wojdyr, M. Fityk: A general-purpose peak fitting program. J. Appl. Crystallogr. 2010, 43, 1126–1128. [Google Scholar] [CrossRef]

- Toby, B.H. EXPGUI, a graphical user interface for GSAS. J. Appl. Crystallogr. 2001, 34, 210–213. [Google Scholar] [CrossRef]

- Ungár, T.; Dragomir, I.; Révész, Á.; Borbély, A. The contrast factors of dislocations in cubic crystals: The dislocation model of strain anisotropy in practice. J. Appl. Crystallogr. 1999, 32, 992–1002. [Google Scholar] [CrossRef]

- Ungár, T.; Borbély, A. The effect of dislocation contrast on X-ray line broadening: A new approach to line profile analysis. Appl. Phys. Lett. 1996, 69, 3173–3175. [Google Scholar] [CrossRef]

- Wang, M.; Huang, M.X. Abnormal trip effect on the work hardening behavior of a quenching and partitioning steel at high strain rate. Acta Mater. 2020, 188, 551–559. [Google Scholar] [CrossRef]

- Warren, B.E.; Averbach, B.L. The effect of cold-work distortion on X-ray patterns. J. Appl. Phys. 1950, 21, 595–599. [Google Scholar] [CrossRef]

- ASTM. Standard Practice for X-ray Determination of Retained Austenite in Steel with Near Random Crystallographic Orientatio; ASTM: West Conshohocken, PA, USA, 2009; Volume 3, pp. 1–7. [Google Scholar] [CrossRef]

- Miyamoto, G.; Oh, J.C.; Hono, K.; Furuhara, T.; Maki, T. Effect of partitioning of Mn and Si on the growth kinetics of cementite in tempered Fe-0.6 mass% C martensite. Acta Mater. 2007, 55, 5027–5038. [Google Scholar] [CrossRef]

- He, B.B.; Huang, M.X.; Ngan, A.H.W.; van der Zwaag, S. Effect of Free Surface on the Stability of Individual Retained Austenite Grains in a Duplex Stainless Steel. Metall. Mater. Trans. A 2014, 45, 4875–4881. [Google Scholar] [CrossRef]

- Tirumalasetty, G.K.; Van Huis, M.A.; Kwakernaak, C.; Sietsma, J.; Sloof, W.G.; Zandbergen, H.W. Deformation-induced austenite grain rotation and transformation in TRIP-assisted steel. Acta Mater. 2012, 60, 1311–1321. [Google Scholar] [CrossRef]

- Verlinden, B.; Bocher, P.; Girault, E.; Aernoudt, E. Austenite texture and bainite/austenite orientation relationships in TRIP steel. Scr. Mater. 2001, 45, 909–916. [Google Scholar] [CrossRef]

- Yuan, L.; Ponge, D.; Wittig, J.; Choi, P.; Jiménez, J.A.; Raabe, D. Nanoscale austenite reversion through partitioning, segregation and kinetic freezing: Example of a ductile 2 GPa Fe-Cr-C steel. Acta Mater. 2012, 60, 2790–2804. [Google Scholar] [CrossRef]

- Bouaziz, O.; Zurob, H.; Huang, M. Driving Force and Logic of Development of Advanced High Strength Steels for Automotive Applications. Steel Res. Int. 2013, 84, 937–947. [Google Scholar] [CrossRef]

- Koyama, M.; Tasan, C.C.; Akiyama, E.; Tsuzaki, K.; Raabe, D. Hydrogen-assisted decohesion and localized plasticity in dual-phase steel. Acta Mater. 2014, 70, 174–187. [Google Scholar] [CrossRef]

- Fan, Y.H.; Zhang, B.; Yi, H.L.; Hao, G.S.; Sun, Y.Y.; Wang, J.Q.; Han, E.-H.; Ke, W. The role of reversed austenite in hydrogen embrittlement fracture of S41500 martensitic stainless steel. Acta Mater. 2017, 139, 188–195. [Google Scholar] [CrossRef]

- Yoo, J.; Jo, M.C.; Kim, D.W.; Song, H.; Koo, M.; Sohn, S.S.; Lee, S. Effects of Cu addition on resistance to hydrogen embrittlement in 1 GPa-grade duplex lightweight steels. Acta Mater. 2020, 196, 370–383. [Google Scholar] [CrossRef]

- Sojka, J.; Vodárek, V.; Schindler, I.; Ly, C.; Jérôme, M.; Váňová, P.; Ruscassier, N.; Wenglorzová, A. Effect of hydrogen on the properties and fracture characteristics of TRIP 800 steels. Corros. Sci. 2011, 53, 2575–2581. [Google Scholar] [CrossRef]

- Louthan, M.R. Hydrogen embrittlement of metals: A primer for the failure analyst. J. Fail. Anal. Prev. 2008, 8, 289–307. [Google Scholar] [CrossRef]

- Hidalgo, J.; Celada-Casero, C.; Santofimia, M.J. Fracture mechanisms and microstructure in a medium Mn quenching and partitioning steel exhibiting macrosegregation. Mater. Sci. Eng. A 2019, 754, 766–777. [Google Scholar] [CrossRef]

- Turk, A.; Joshi, G.R.; Gintalas, M.; Callisti, M.; Rivera-Díaz-del-Castillo, P.E.J.; Galindo-Nava, E.I. Quantification of hydrogen trapping in multiphase steels: Part I—Point traps in martensite. Acta Mater. 2020, 194, 118–133. [Google Scholar] [CrossRef]

- Turk, A.; Pu, S.D.; Bombač, D.; Rivera-Díaz-del-Castillo, P.E.J.; Galindo-Nava, E.I. Quantification of hydrogen trapping in multiphase steels: Part II—Effect of austenite morphology. Acta Mater. 2020, 197, 253–268. [Google Scholar] [CrossRef]

- Pérez Escobar, D.; Depover, T.; Duprez, L.; Verbeken, K.; Verhaege, M. Combined thermal desorption spectroscopy, differential scanning calorimetry, scanning electron microscopy and X-ray diffraction study of hydrogen trapping in cold deformed TRIP steel. Acta Mater. 2012, 60, 2593–2605. [Google Scholar] [CrossRef]

- Jacques, P.; Furnémont, Q.; Pardoen, T.; Delannay, F. On the role of martensitic transformation on damage and cracking resistance in TRIP-assisted multiphase steels. Acta Mater. 2001, 49, 139–152. [Google Scholar] [CrossRef]

- Lacroix, G.; Pardoen, T.; Jacques, P.J. The fracture toughness of TRIP-assisted multiphase steels. Acta Mater. 2008, 56, 3900–3913. [Google Scholar] [CrossRef]

- Bhadeshia, H.K.D.H. Prevention of Hydrogen Embrittlement in Steels. ISIJ Int. 2016, 56, 24–36. [Google Scholar] [CrossRef]

- Krauss, G. Tempering of Lath Martensite in Low and Medium Carbon Steels: Assessment and Challenges. Steel Res. Int. 2017, 88, 1–18. [Google Scholar] [CrossRef]

- Jiang, F.; Masumura, T.; Hirata, K.; Tsuchiyama, T.; Takaki, S. A new diffraction line profile breadth analysis approach for evaluating plastic lattice strain anisotropy in cold-worked nickel under various strain paths. Int. J. Plast. 2019, 112, 89–107. [Google Scholar] [CrossRef]

- Harjo, S.; Kawasaki, T.; Tomota, Y.; Gong, W.; Aizawa, K.; Tichy, G.; Shi, Z.; Ungár, T. Work Hardening, Dislocation Structure, and Load Partitioning in Lath Martensite Determined by In Situ Neutron Diffraction Line Profile Analysis. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2017, 48, 4080–4092. [Google Scholar] [CrossRef]

- Xiao, L.; Fan, Z.; Jinxiu, Z.; Mingxing, Z.; Mokuang, K.; Zhenqi, G. Lattice-parameter variation with carbon content of martensite. I. X-ray-diffraction experimental study. Phys. Rev. B 1995, 52, 9970–9978. [Google Scholar] [CrossRef]

- Geng, W.T.; Wang, V.; Xu, J.; Ishikawa, N. Hydrogen trapping in carbon supersaturated—Iron and its decohesion effect in martensitic steel. Scr. Mater. 2018, 149, 1–15. [Google Scholar] [CrossRef]

- Horn, R.M.; Ritchie, R.O. Mechanisms of tempered martensite embrittlement in low alloy steels. Metall. Trans. A 1978, 9, 1039–1053. [Google Scholar] [CrossRef]

| Element | C | Si | Mn | P | S | Al | N | Fe + Others |

|---|---|---|---|---|---|---|---|---|

| wt% | 0.3 | 1.57 | 2.94 | 0.0036 | 0.0039 | 0.022 | ≤0.004 | bal. |

| Retained Austenite | |||||

|---|---|---|---|---|---|

| Materials | Volume fraction (%) | Lattice parameter (Å) | Carbon concentration (wt%) calculated from the empirical equation: aγ = 3.556 + 0.0453 xC+ 0.00095 xMn | ||

| 1500LT | 17.2 | 3.59884 | 0.884 | ||

| 1500HT | 17.8 | 3.59646 | 0.831 | ||

| Martensite Matrix | |||||

| Materials | Volume fracture (%) | Lattice parameter (Å) | Dislocation density (1016 m2) | q value | M value |

| 1500LT | 82.8 | 2.86400 | 1.44 | 1.84 | 6.08 |

| 1500HT | 82.2 | 2.86298 | 0.801 | 1.84 | 5.52 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Z.; Huang, M. Improving Hydrogen Embrittlement Resistance of Hot-Stamped 1500 MPa Steel Parts That Have Undergone a Q&P Treatment by the Design of Retained Austenite and Martensite Matrix. Metals 2020, 10, 1585. https://doi.org/10.3390/met10121585

Wang Z, Huang M. Improving Hydrogen Embrittlement Resistance of Hot-Stamped 1500 MPa Steel Parts That Have Undergone a Q&P Treatment by the Design of Retained Austenite and Martensite Matrix. Metals. 2020; 10(12):1585. https://doi.org/10.3390/met10121585

Chicago/Turabian StyleWang, Zhou, and Mingxin Huang. 2020. "Improving Hydrogen Embrittlement Resistance of Hot-Stamped 1500 MPa Steel Parts That Have Undergone a Q&P Treatment by the Design of Retained Austenite and Martensite Matrix" Metals 10, no. 12: 1585. https://doi.org/10.3390/met10121585

APA StyleWang, Z., & Huang, M. (2020). Improving Hydrogen Embrittlement Resistance of Hot-Stamped 1500 MPa Steel Parts That Have Undergone a Q&P Treatment by the Design of Retained Austenite and Martensite Matrix. Metals, 10(12), 1585. https://doi.org/10.3390/met10121585