Constitutive Model and Flow Behavior of B1500HS High-Strength Steel During the Hot Deformation Process

Abstract

1. Introduction

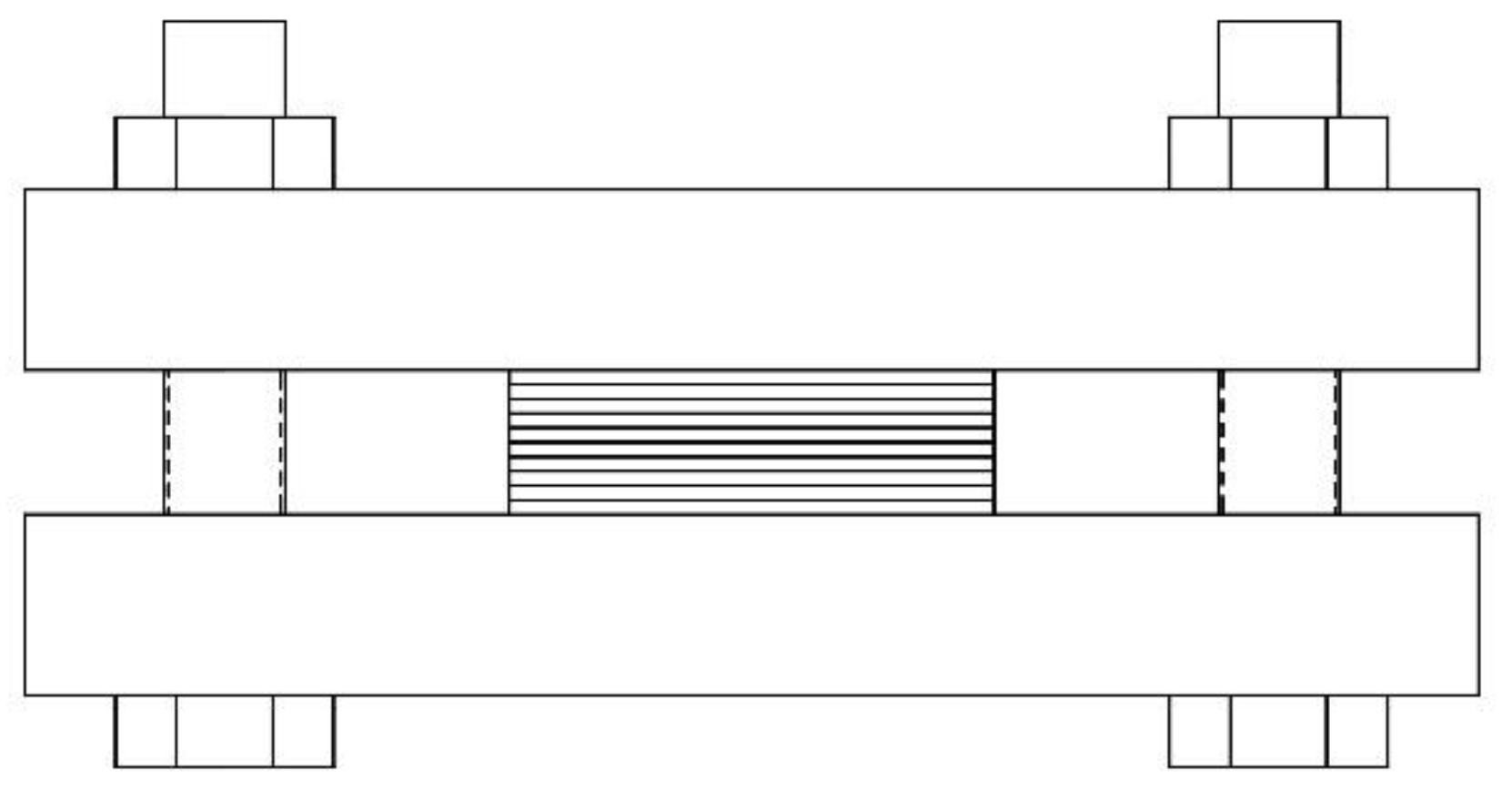

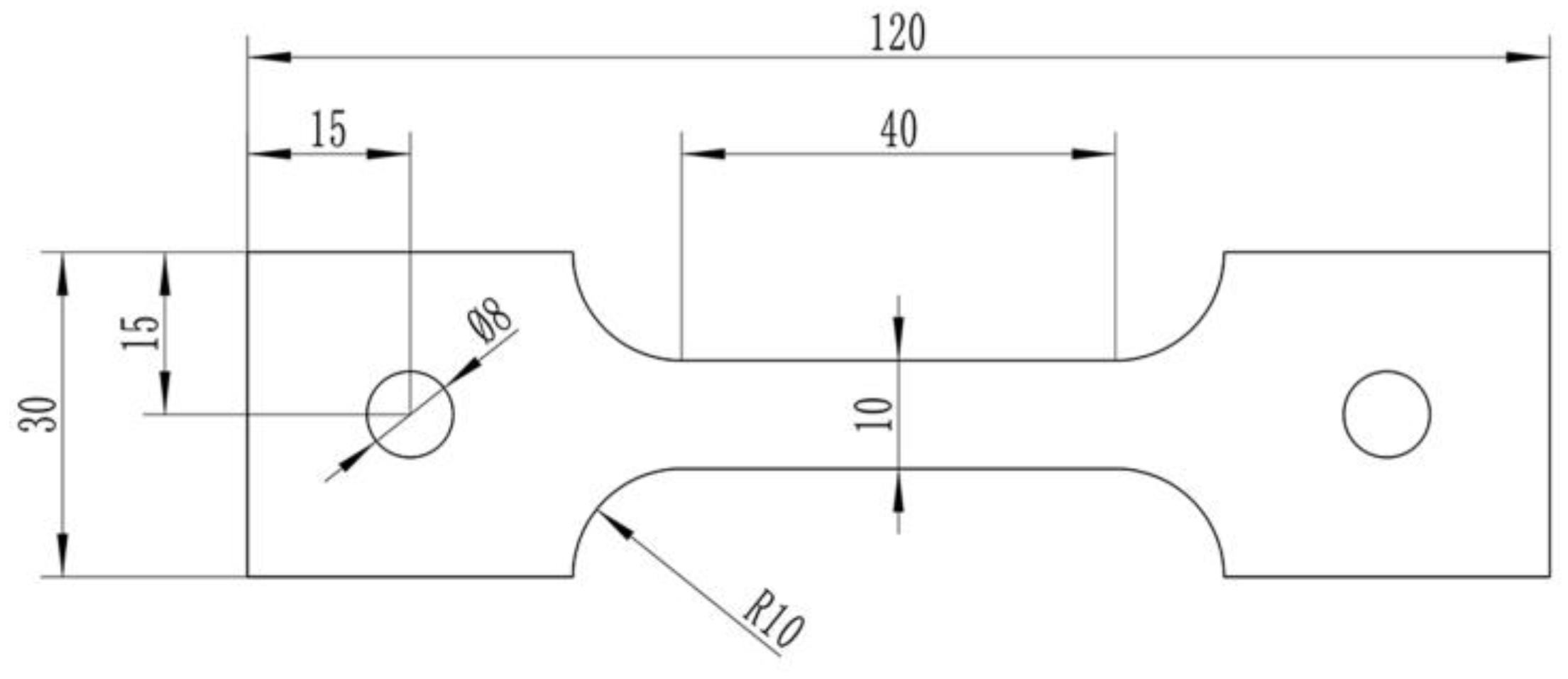

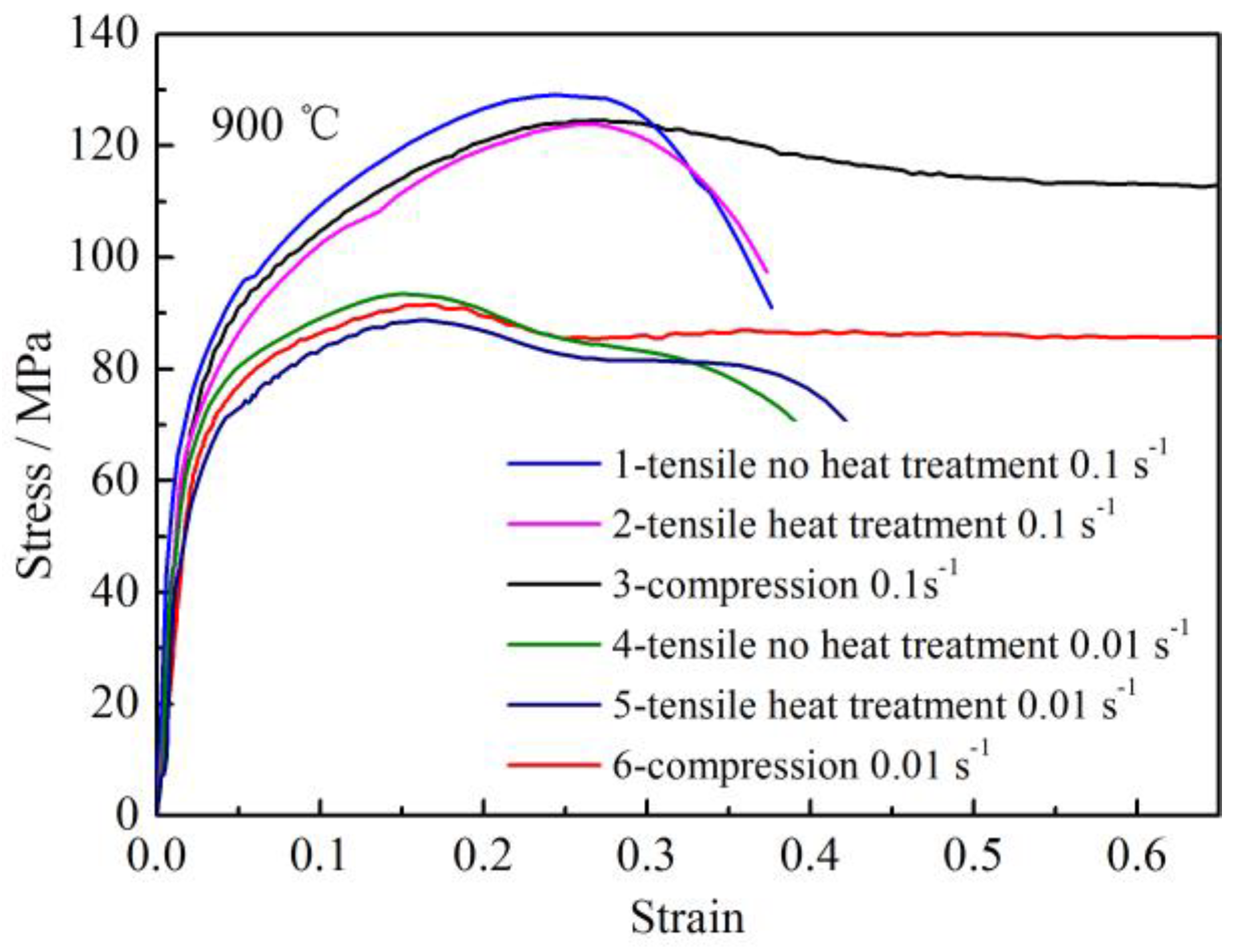

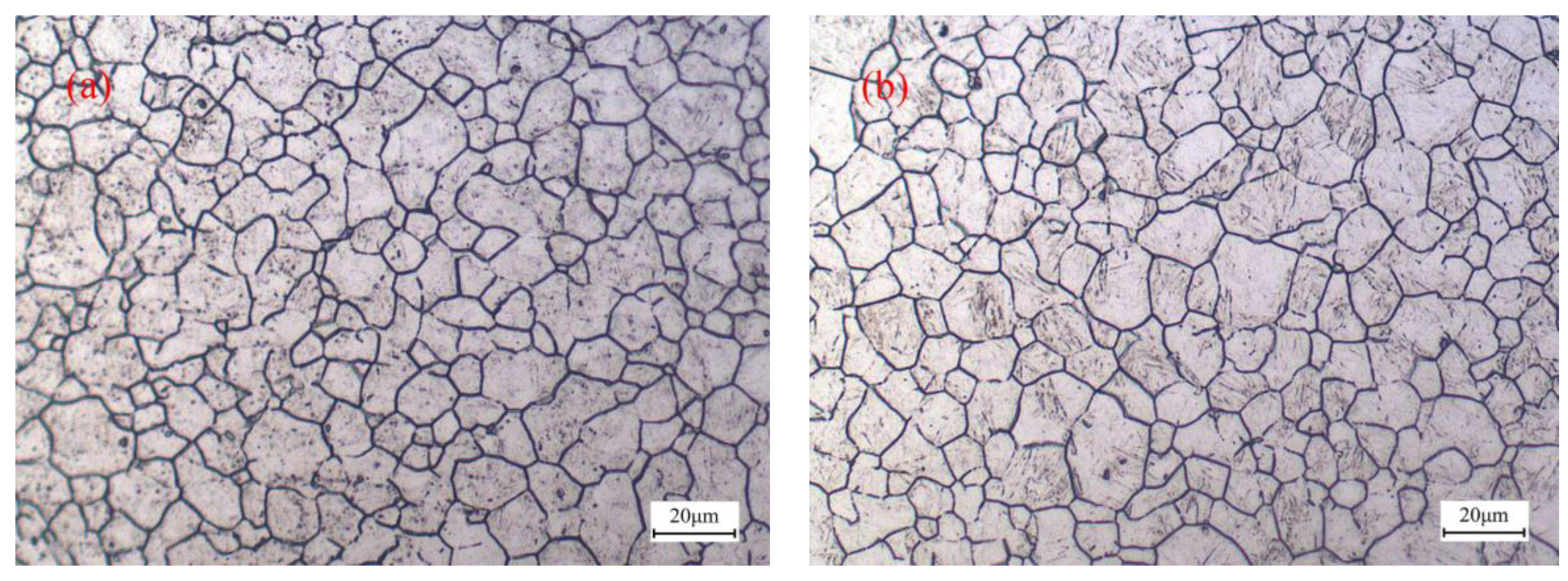

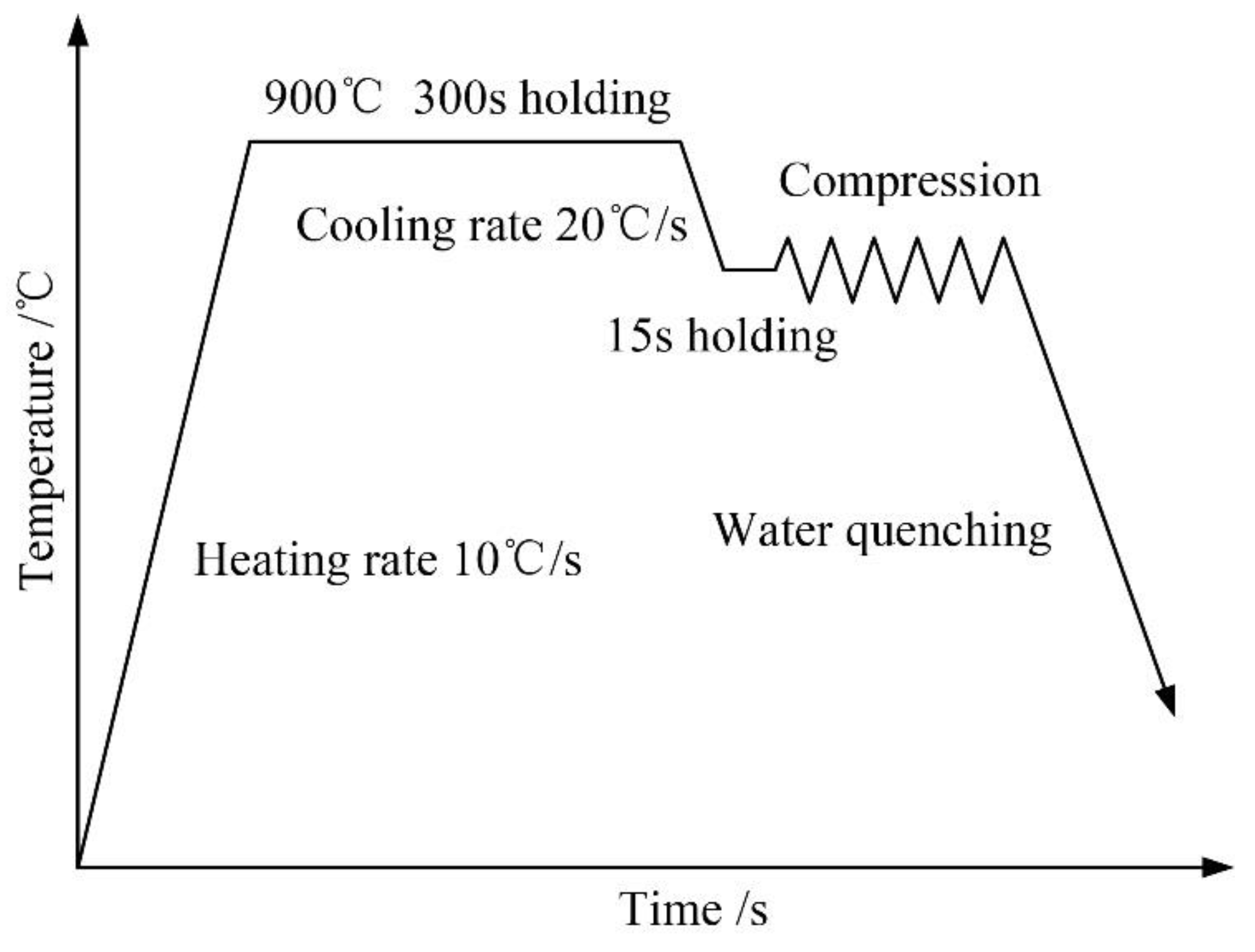

2. Materials and Methods

3. Results and Discussion

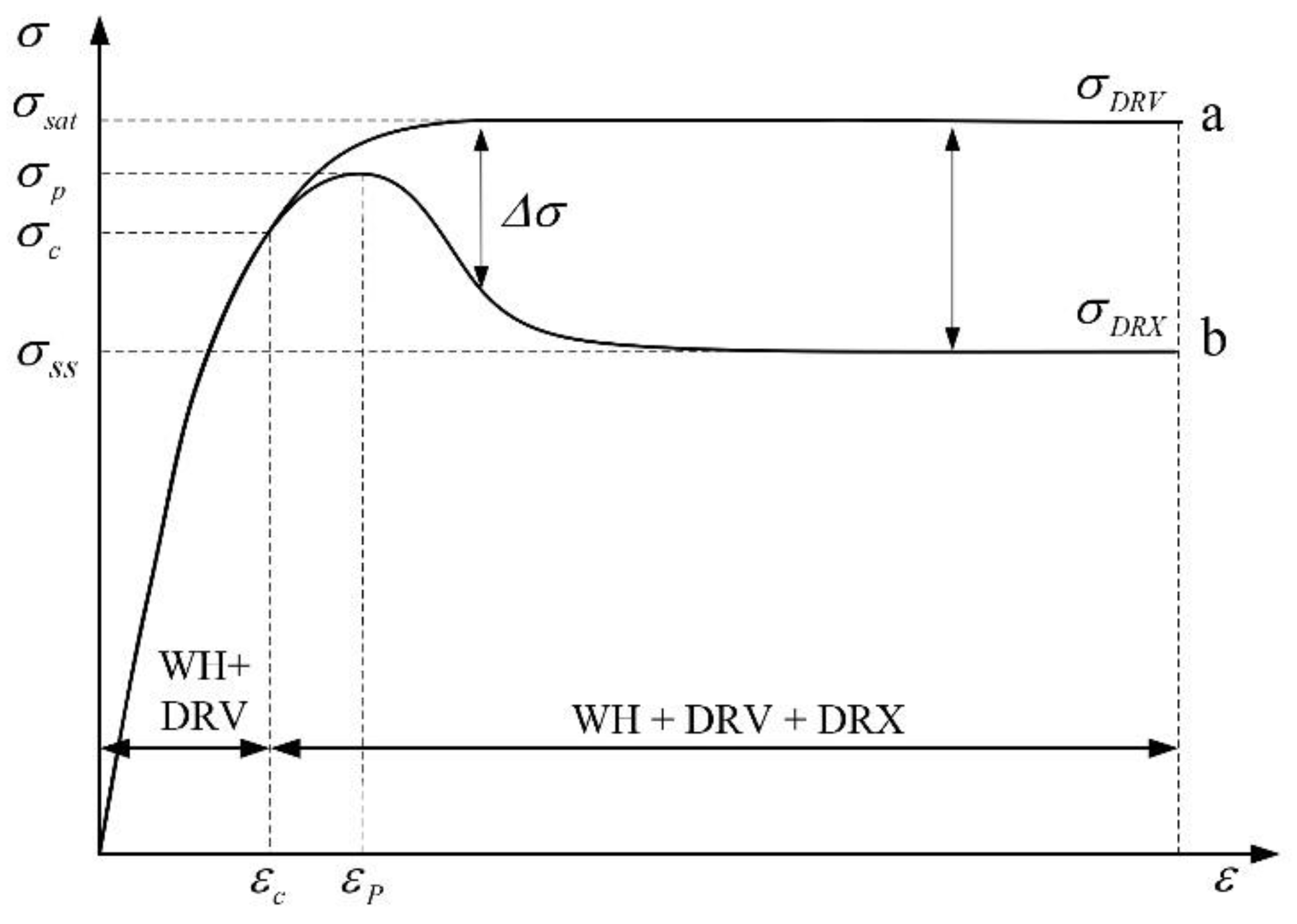

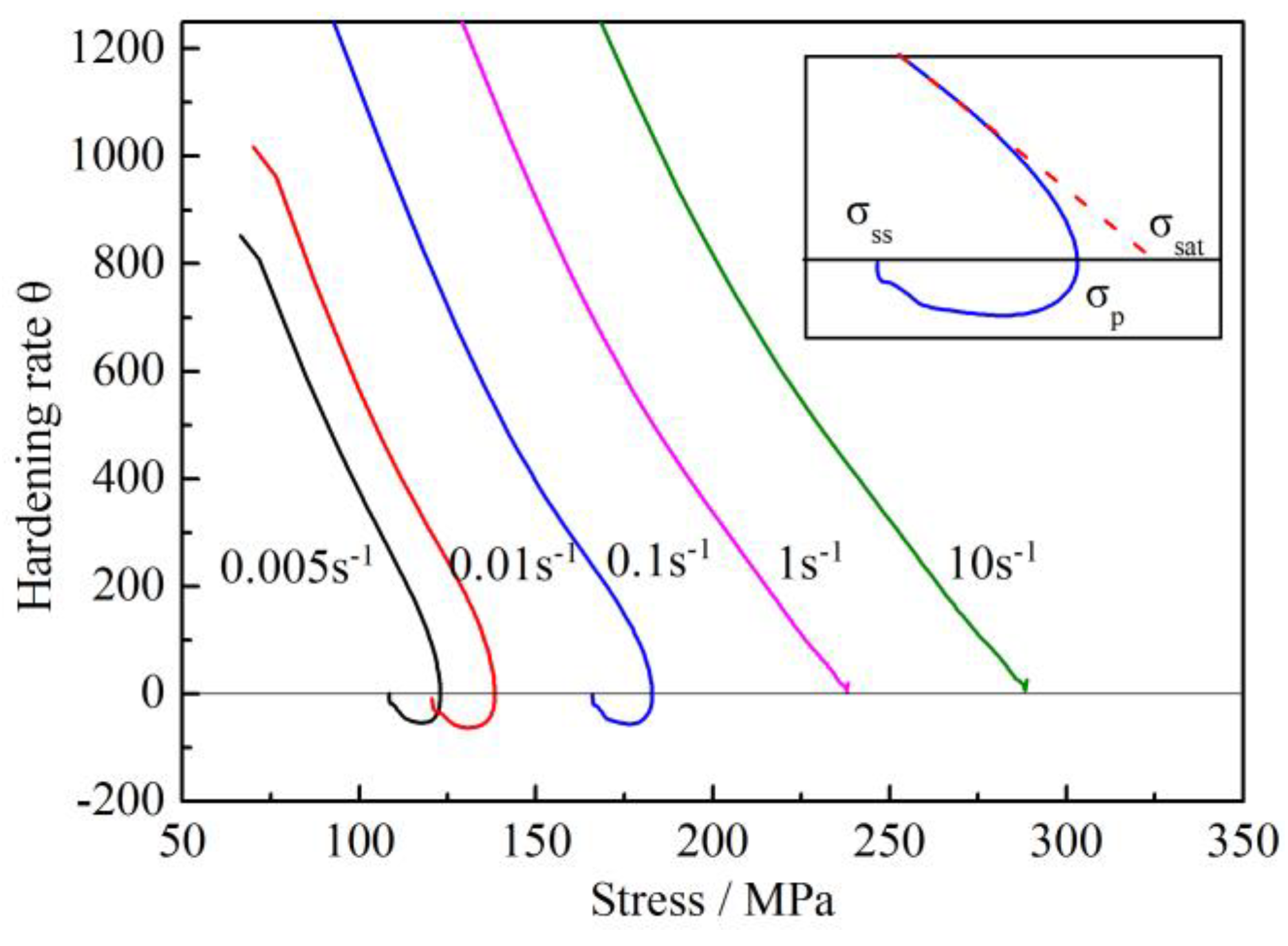

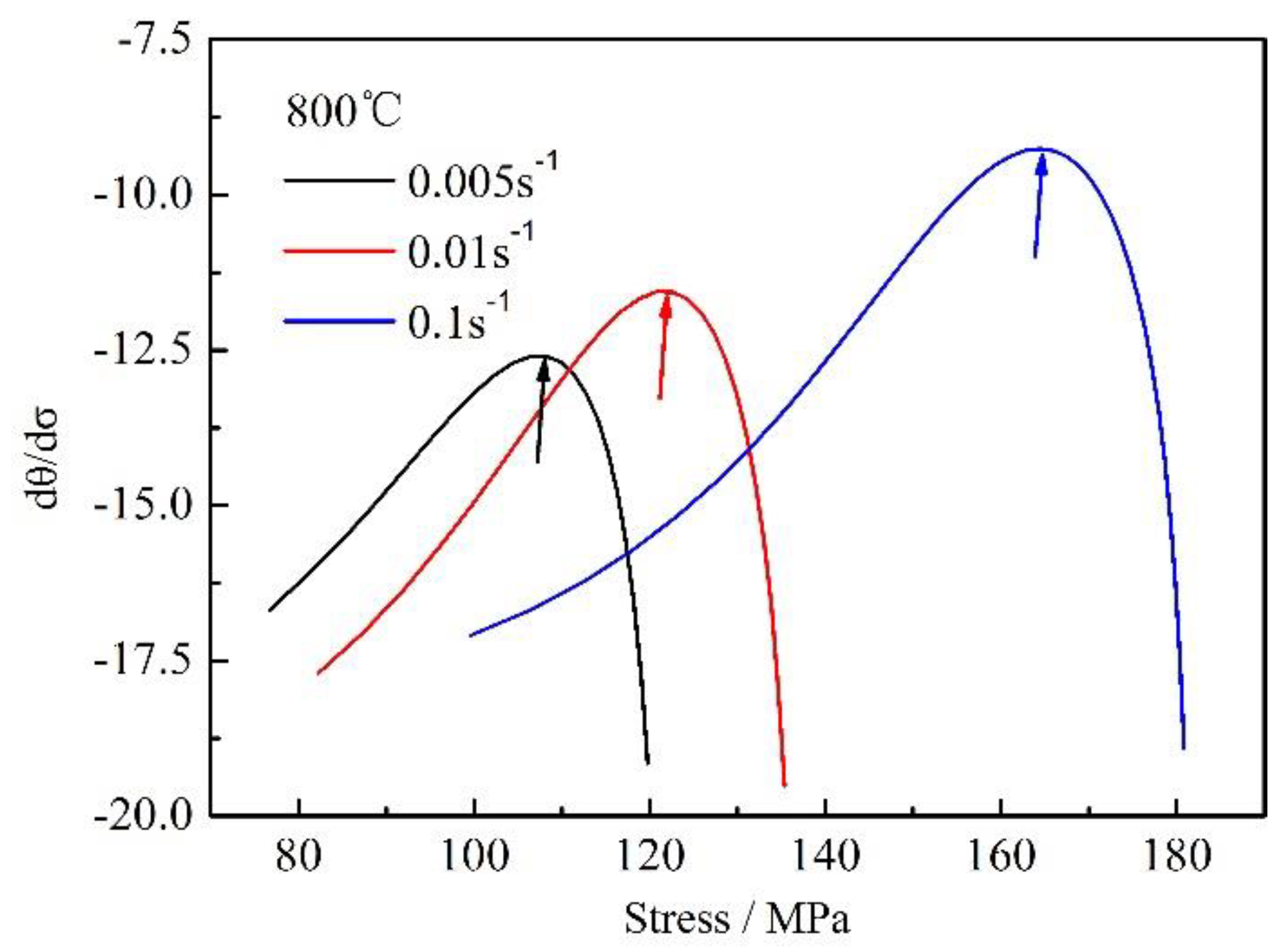

3.1. Discussion on Softening Mechanism and Construction Method of the Constitutive Model

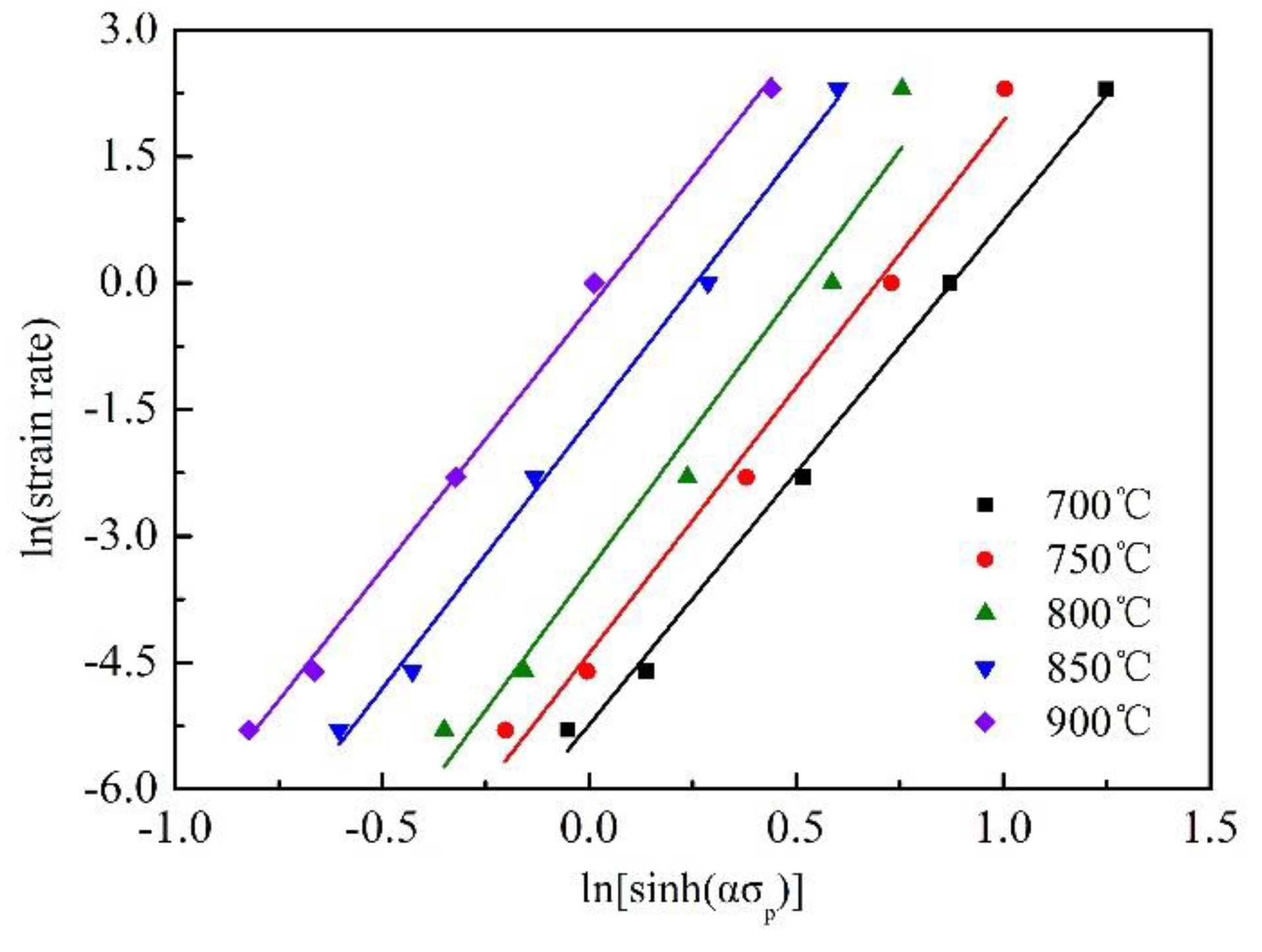

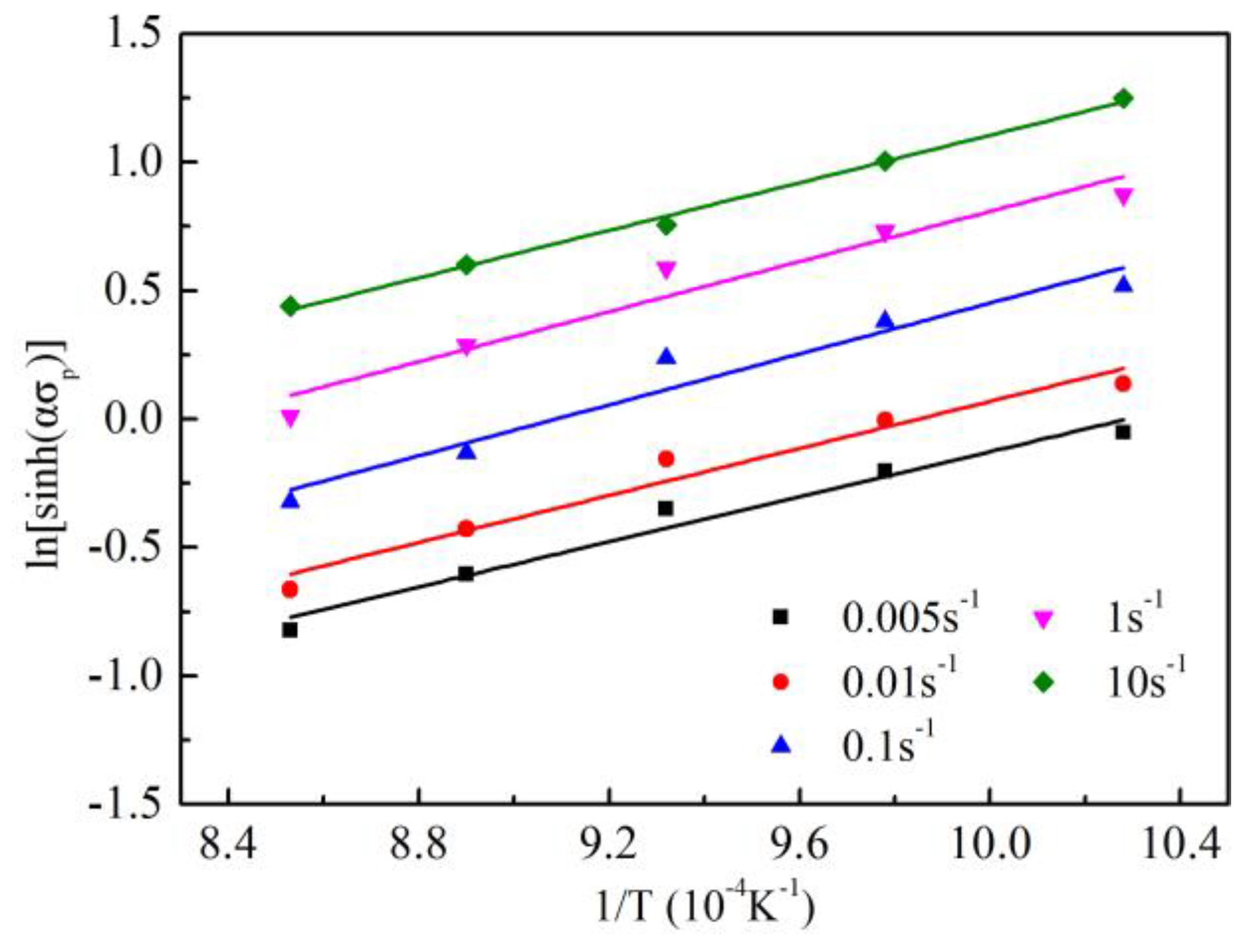

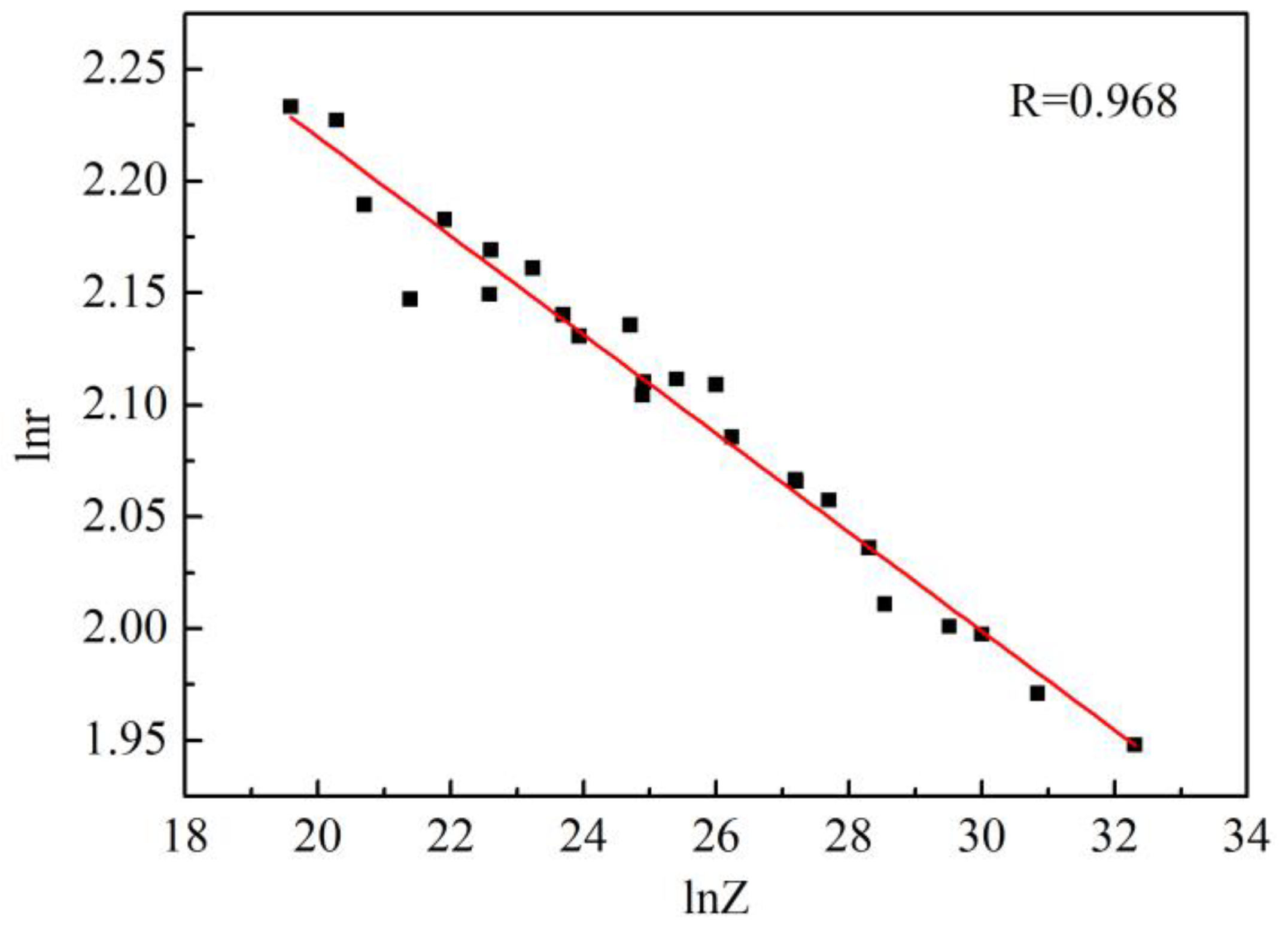

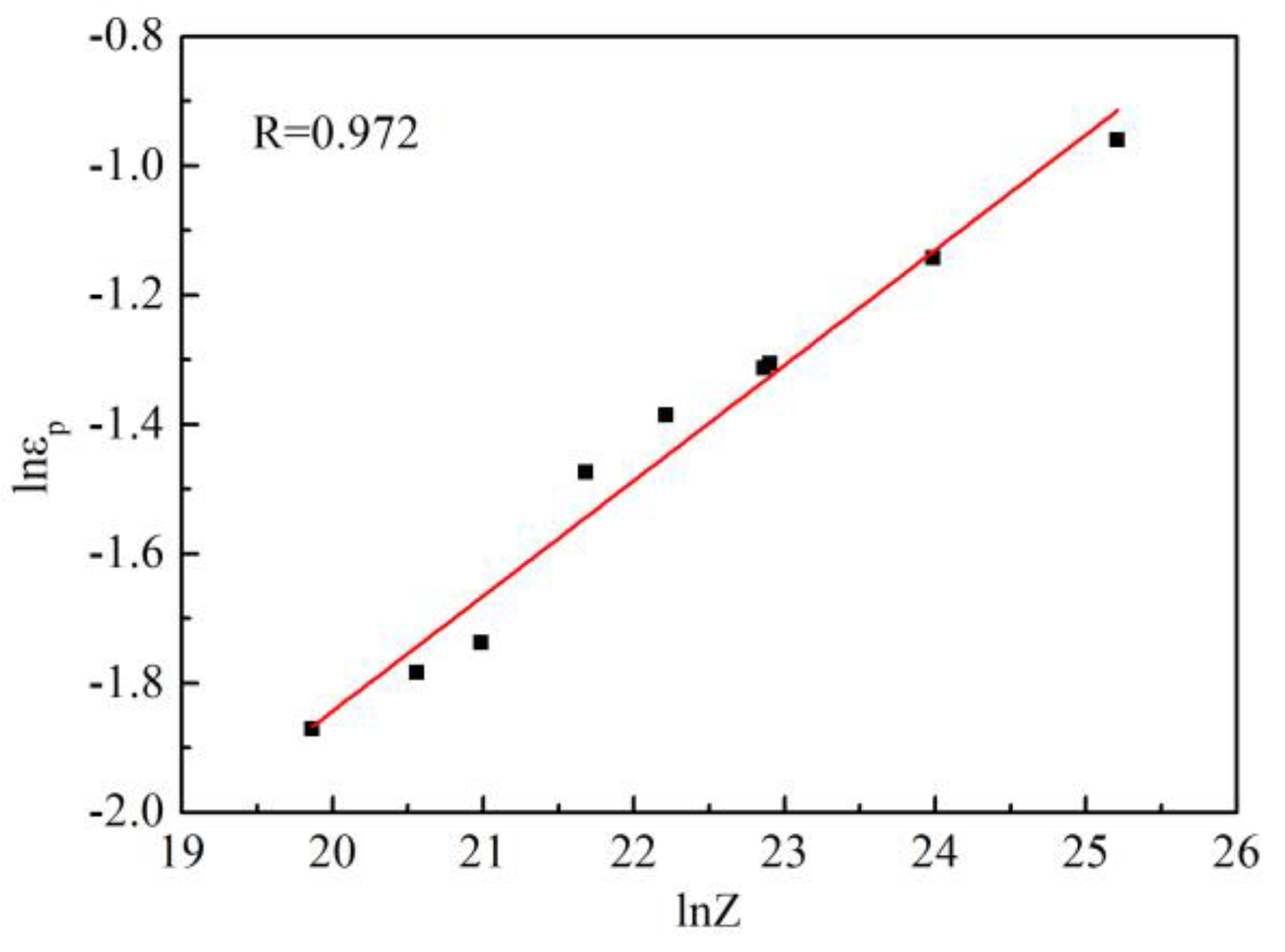

3.2. Zener–Hollomon Factor

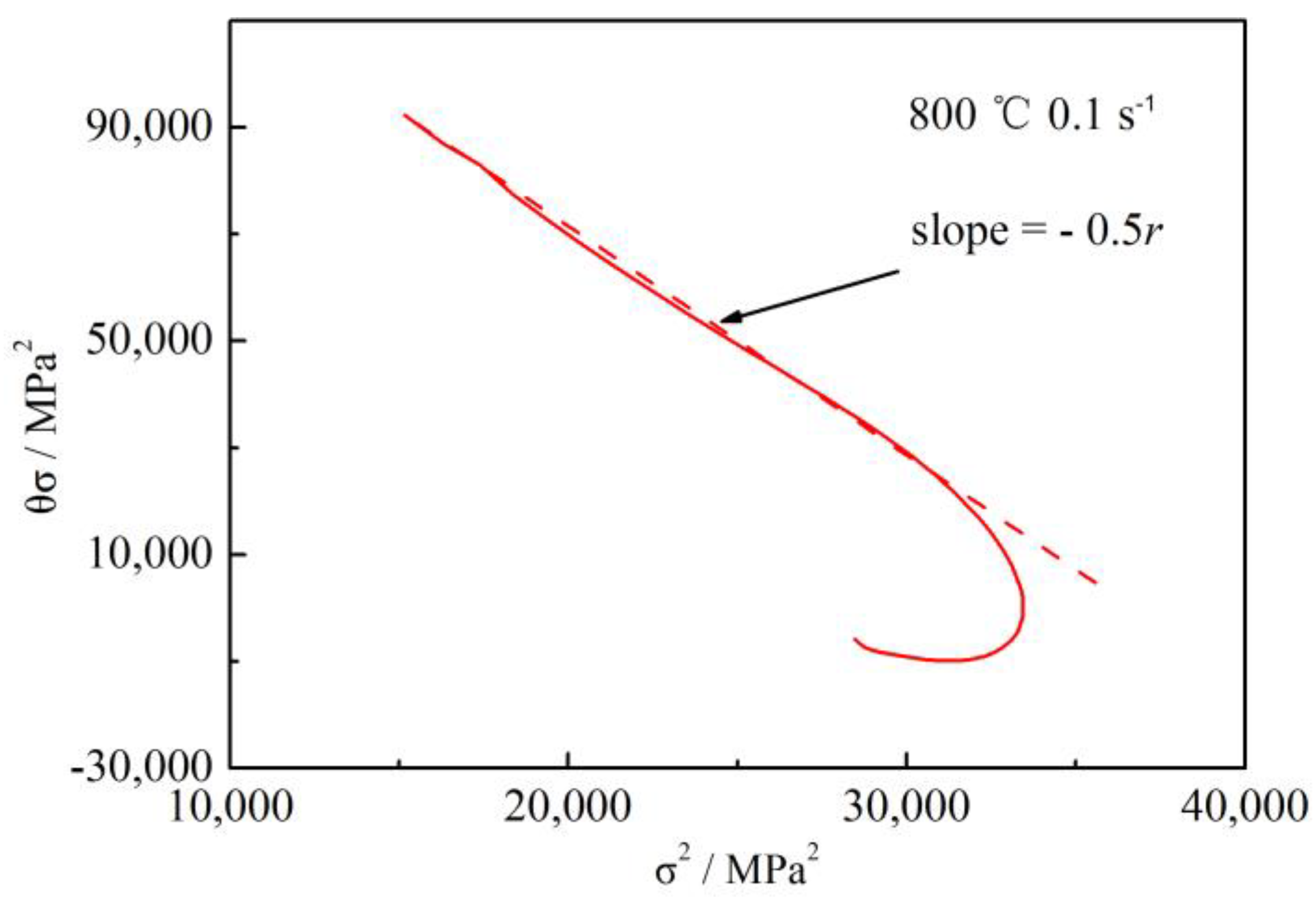

3.3. Constitutive Model of Dynamic Recovery

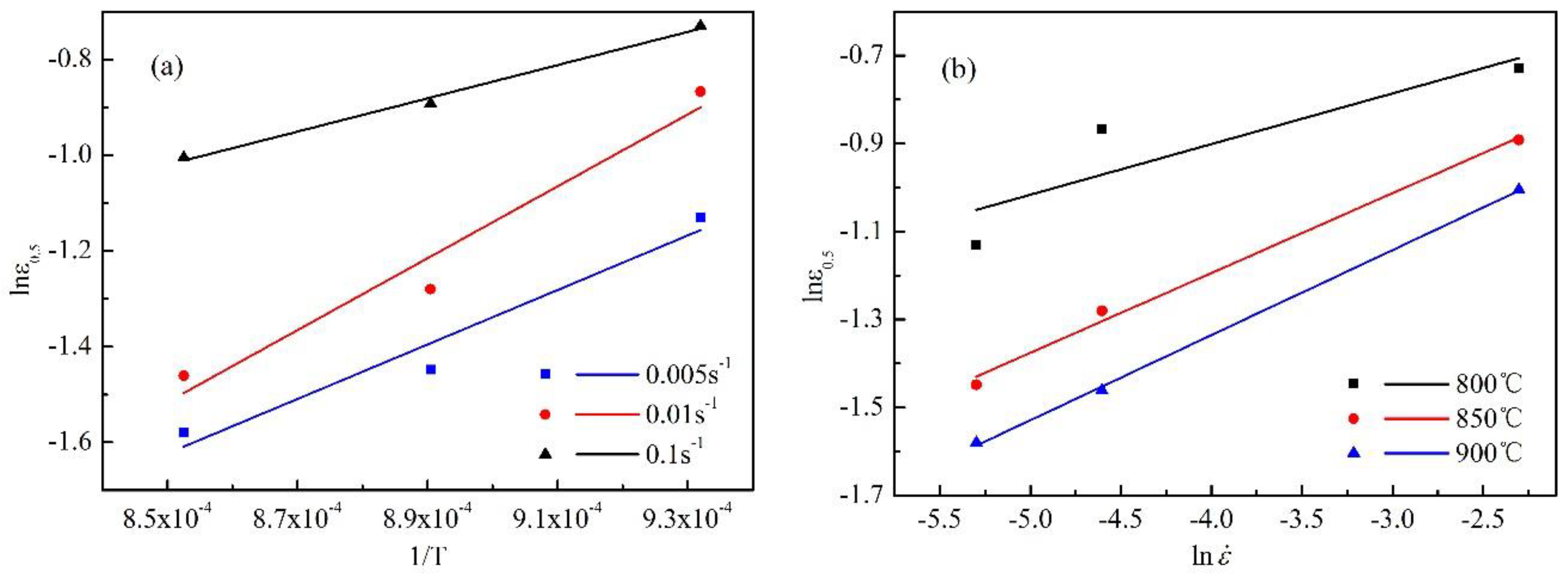

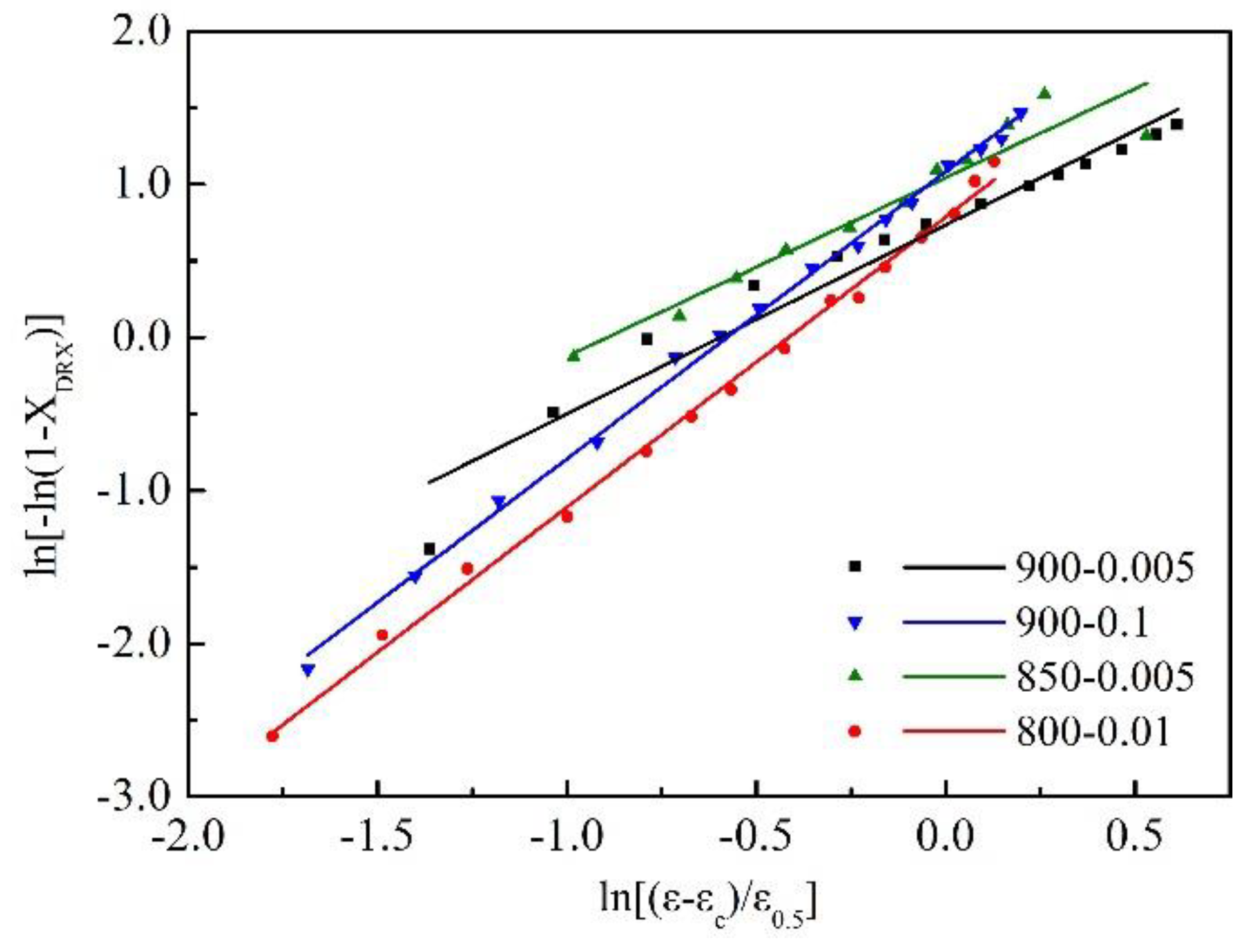

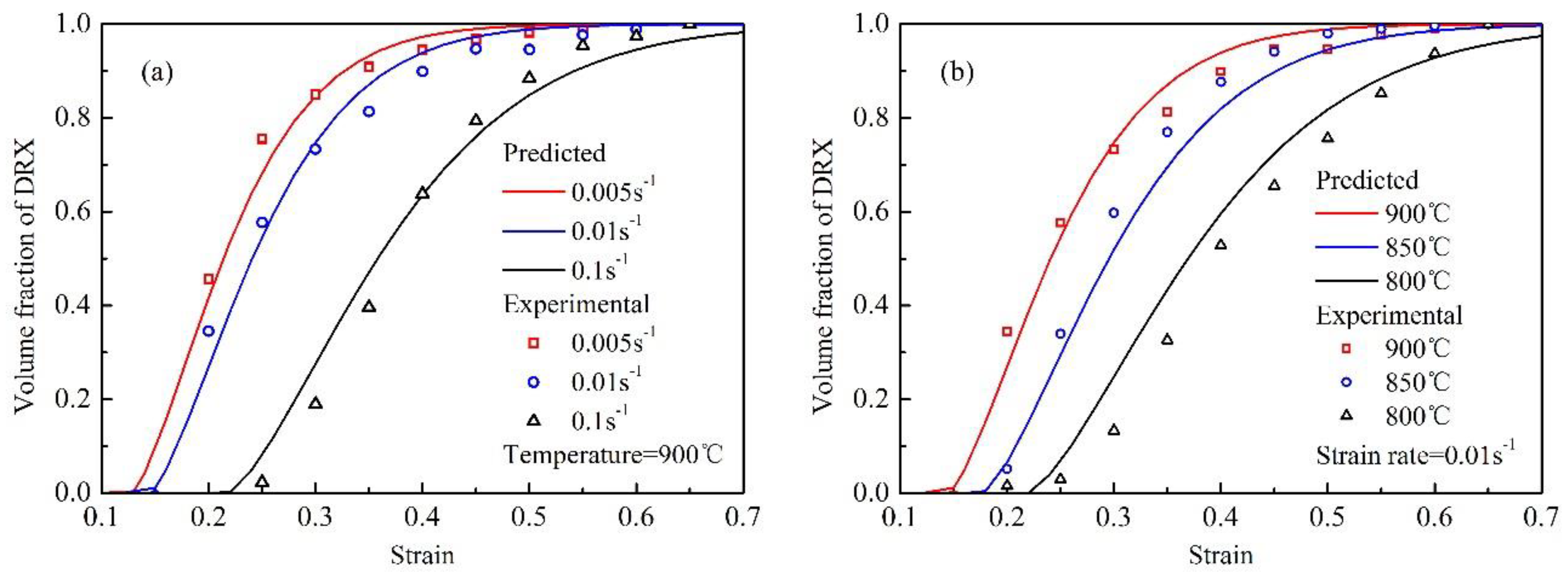

3.4. Constitutive Model of Dynamic Recrystallization

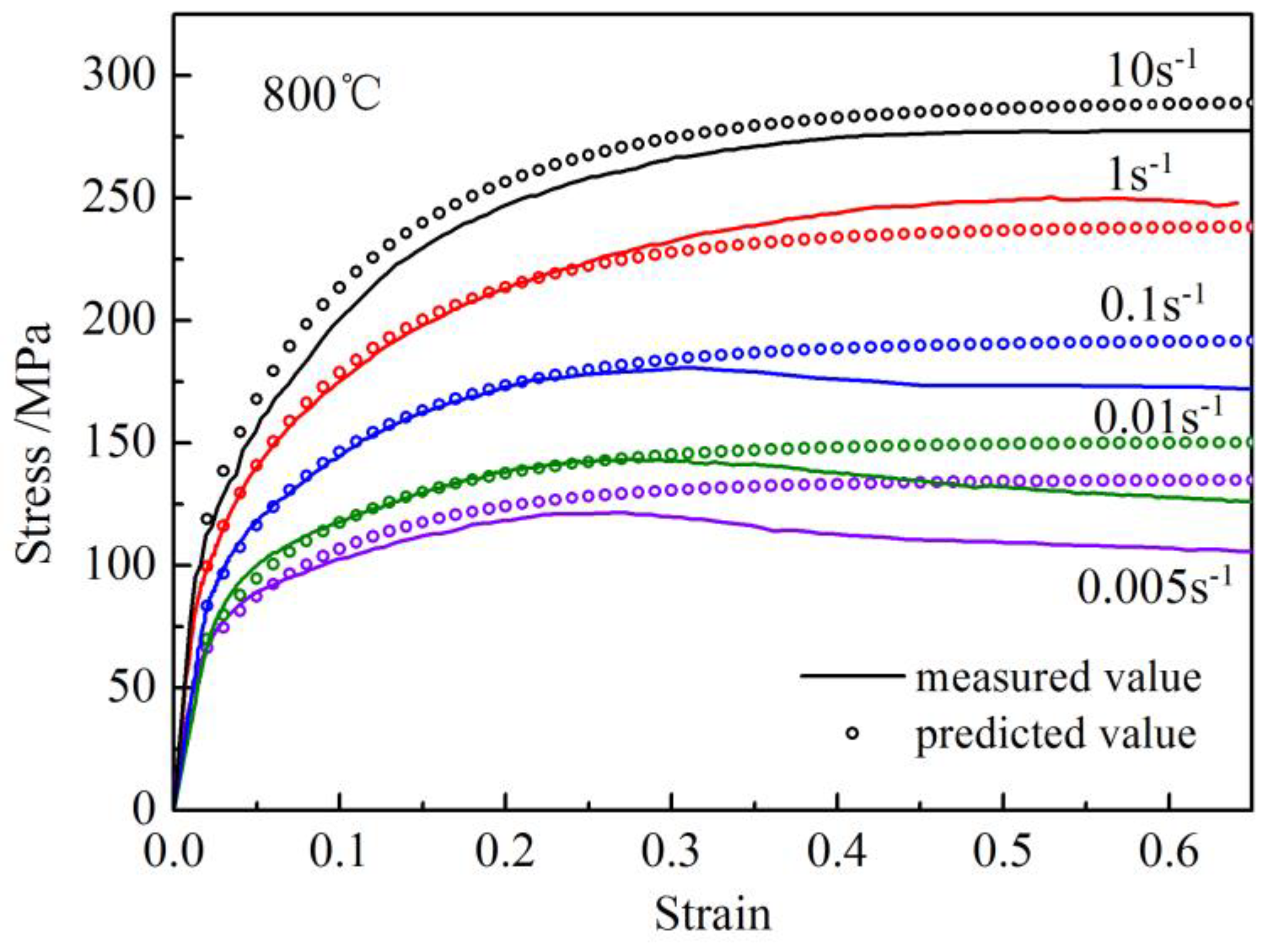

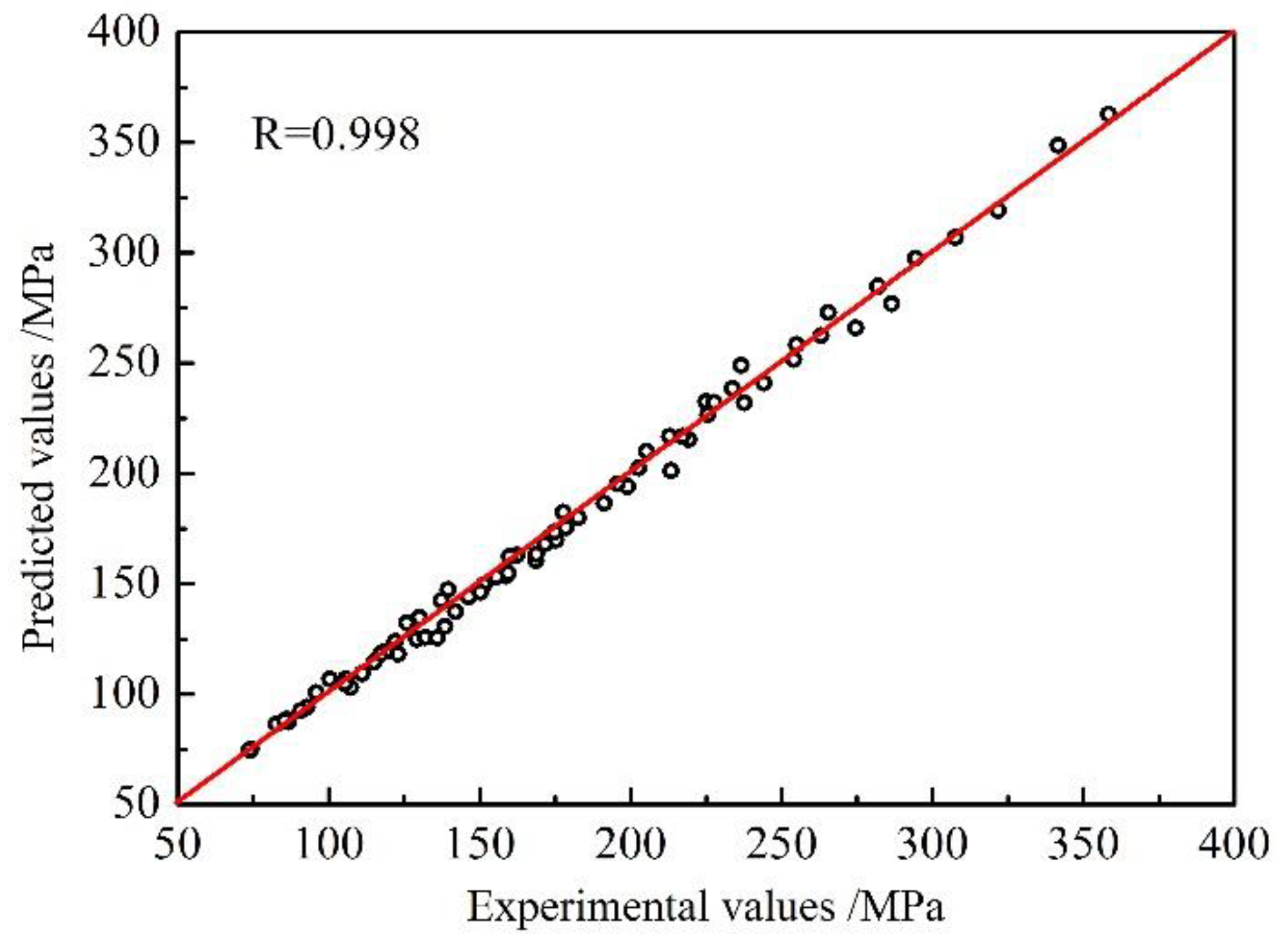

3.5. Verification of the Constitutive Model

4. Conclusions

- (1)

- The flow stress–strain curves of B1500HS high-strength steel under a temperature range of 700–900 °C and a strain rate range of 0.005–10 s−1 were measured using hot compression tests. According to the flow stress–strain curves, the softening mechanisms of material under different deformation conditions were analyzed.

- (2)

- By analyzing the curves of and , parameters used in the solving of the constitutive model such as , , , and were obtained, and the mathematical expressions between these parameters and the Zener–Hollomon factor were also established. Based on dislocation density theory and the dynamic recrystallization kinetics equation, constitutive models corresponding to different softening mechanisms were constructed.

- (3)

- The flow stress–strain curves of B1500HS high-strength steel predicted by the established constitutive models were compared with the experimental results. In addition, the correlation coefficient between the predicted value and the experimental value was solved. It can be concluded that the constitutive models are reliable to reflect the hot deformation process of B1500HS high-strength steel.

Author Contributions

Funding

Conflicts of Interest

References

- Bok, H.H.; Lee, M.G.; Pavlina, E.J.; Barlat, F.; Kim, H.D. Comparative study of the prediction of microstructure and mechanical properties for a hot-stamped b-pillar reinforcing part. Int. J. Mech. Sci. 2011, 53, 744–752. [Google Scholar] [CrossRef]

- Kim, H.Y.; Park, J.K.; Lee, M.G. Phase transformation-based finite element modeling to predict strength and deformation of press-hardened tubular automotive part. Int. J. Adv. Manuf. Technol. 2014, 70, 1787–1801. [Google Scholar] [CrossRef]

- Bobbili, R.; Madhu, V. An Investigation into hot deformation characteristics and processing maps of high-strength armor steel. J. Mater. Eng. Perform. 2015, 24, 4728–4735. [Google Scholar] [CrossRef]

- Salari, S.; Naderi, M.; Bleck, W. Constitutive modeling during simultaneous forming and quenching of a boron bearing steel at high temperatures. J. Mater. Eng. Perform. 2015, 24, 808–815. [Google Scholar] [CrossRef]

- Mirzadeh, H.; Parsa, M.H.; Ohadi, D. Hot deformation behavior of austenitic stainless steel for a wide range of initial grain size. Mater. Sci. Eng. A 2013, 569, 54–60. [Google Scholar] [CrossRef]

- Li, H.; He, L.; Zhao, G.Q.; Zhang, L. Constitutive relationships of hot stamping boron steel B1500HS. Mater. Sci. Eng. A 2013, 580, 330–348. [Google Scholar] [CrossRef]

- Güler, H.; Ertan, R.; Özcan, R. Investigation of the hot ductility of a high-strength boron steel. Mater. Sci. Eng. A 2014, 608, 90–94. [Google Scholar] [CrossRef]

- Güler, H.; Ertan, R.; Özcan, R. Characteristics of 30MnB5 boron steel at elevated temperatures. Mater. Sci. Eng. A 2013, 578, 417–421. [Google Scholar] [CrossRef]

- Mejía, I.; Altamirano, G.; Bedolla-Jacuinde, A.; Cabrera, J.M. Modeling of the hot flow behavior of advanced ultra-high strength steels (A-UHSS) microalloyed with boron. Mater. Sci. Eng. A 2014, 610, 116–125. [Google Scholar] [CrossRef]

- Montazeri-Pour, M.; Parsa, M.H. Constitutive analysis of tensile deformation behavior for AA1100 aluminum subjected to multi-axial incremental forging and shearing. Mech. Mater. 2016, 94, 117–131. [Google Scholar] [CrossRef]

- Rakhshkhorshid, M.; Hashemi, S.H. Experimental study of hot deformation behavior in API X65 steel. Mater. Sci. Eng. A 2013, 573, 37–44. [Google Scholar] [CrossRef]

- Estrin, Y.; Mecking, H. A unified phenomenological description of work hardening and creep based on one-parameter models. Acta Metall. 1984, 32, 57–70. [Google Scholar] [CrossRef]

- Lin, Y.C.; Chen, X.M. A critical review of experimental results and constitutive descriptions for metals and alloys in hot working. Mater. Des. 2011, 32, 1733–1759. [Google Scholar] [CrossRef]

- Xu, M.; Mi, Z.L.; Li, H.; Tang, D.; Jiang, H.T. Constitutive model based on dislocation density theory for hot deformation behavior of ultra-high strength dual phase steel DP1000. Chin. J. Mater. Res. 2017, 31, 576–584. [Google Scholar]

- Anjabin, N.; Taheri, A.K.; Kim, H.S. Constitutive modeling of hot deformation behavior of the AA6063 alloy with different precipitates. Metall. Mater. Trans. A 2013, 44, 5853–5860. [Google Scholar] [CrossRef]

- Feng, D.; Zhang, X.M.; Liu, S.D.; Deng, Y.L. Constitutive equation and hot deformation behavior of homogenized Al–7.68Zn–2.12Mg–1.98Cu–0.12Zr alloy during compression at elevated temperature. Mater. Sci. Eng. A 2014, 608, 63–72. [Google Scholar] [CrossRef]

- Schikorra, M.; Donati, L.; Tomesani, L.; Tekkaya, A.E. Microstructure analysis of aluminum extrusion: Prediction of microstructure on AA6060 alloy. J. Mater. Process. Technol. 2008, 201, 156–162. [Google Scholar] [CrossRef]

- Wen, D.X.; Lin, Y.C.; Zhou, Y. A new dynamic recrystallization kinetics model for a Nb containing Ni-Fe-Cr-base superalloy considering influences of initial δ phase. Vacuum 2017, 141, 316–327. [Google Scholar] [CrossRef]

- Jonas, J.J.; Quelennec, X.; Jiang, L.; Martin, E. The avrami kinetics of dynamic recrystallization. Acta Mater. 2009, 57, 2748–2756. [Google Scholar] [CrossRef]

- Lin, Y.C.; Chen, M.S.; Zhong, J. Prediction of 42CrMo steel flow stress at high temperature and strain rate. Mech. Res. Commun. 2008, 35, 142–150. [Google Scholar] [CrossRef]

- Mirzadeh, H.; Najafizadeh, A. Prediction of the critical conditions for initiation of dynamic recrystallization. Mater. Des. 2010, 31, 1174–1179. [Google Scholar] [CrossRef]

| C | Si | Mn | Cr | Ni | Mo | B | Al | Ti | Cu | V | S | P |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.23 | 0.25 | 1.35 | 0.19 | 0.028 | 0.04 | 0.003 | 0.04 | 0.03 | 0.016 | 0.004 | 0.006 | 0.015 |

| Temperature/°C | Strain Rate/s−1 | Softening Mechanism |

|---|---|---|

| 750 | 0.005–0.01 | DRV + DRX |

| 800–850 | 0.005–0.1 | |

| 900 | 0.005–1 | |

| 700 | 0.005–10 | DRV |

| 750 | 0.1–10 | |

| 800–850 | 1–10 | |

| 900 | 10 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, M.; Duan, Y.; Yao, D.; Guan, Y.; Yang, L. Constitutive Model and Flow Behavior of B1500HS High-Strength Steel During the Hot Deformation Process. Metals 2020, 10, 64. https://doi.org/10.3390/met10010064

Li M, Duan Y, Yao D, Guan Y, Yang L. Constitutive Model and Flow Behavior of B1500HS High-Strength Steel During the Hot Deformation Process. Metals. 2020; 10(1):64. https://doi.org/10.3390/met10010064

Chicago/Turabian StyleLi, Muyu, Yongchuan Duan, Dan Yao, Yingping Guan, and Liu Yang. 2020. "Constitutive Model and Flow Behavior of B1500HS High-Strength Steel During the Hot Deformation Process" Metals 10, no. 1: 64. https://doi.org/10.3390/met10010064

APA StyleLi, M., Duan, Y., Yao, D., Guan, Y., & Yang, L. (2020). Constitutive Model and Flow Behavior of B1500HS High-Strength Steel During the Hot Deformation Process. Metals, 10(1), 64. https://doi.org/10.3390/met10010064