Low-Frequency Ultrasound Assisted in Improvement in Cell Development and Production of Parasporal Crystals from Bacillus thuringiensis HD1

Simple Summary

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Effect of Ultrasound on B. thuringiensis HD1 Cells

2.2.1. B. thuringiensis Stains and Culture

2.2.2. Ultrasound Treatments

2.3. Preparation of Parasporal Crystals

2.4. Determination of Cell Membrane Permeability

2.5. Characterization of B. thuringiensis Cell Morphology

2.6. Characterization of B. thuringiensis Parasporal Crystals

2.7. Determination of Germination Activity of B. thuringiensis Spores

2.8. Analysis of Inositol Concentration

2.9. Insecticidal Activity of B. thuringiensis Parasporal Crystals

2.9.1. Insects

2.9.2. Mortality of S. zeamais

2.10. Statistical Analysis

3. Results

3.1. Effect of LFU on Growth of B. thuringiensis and Its Parasporal Crystal Production

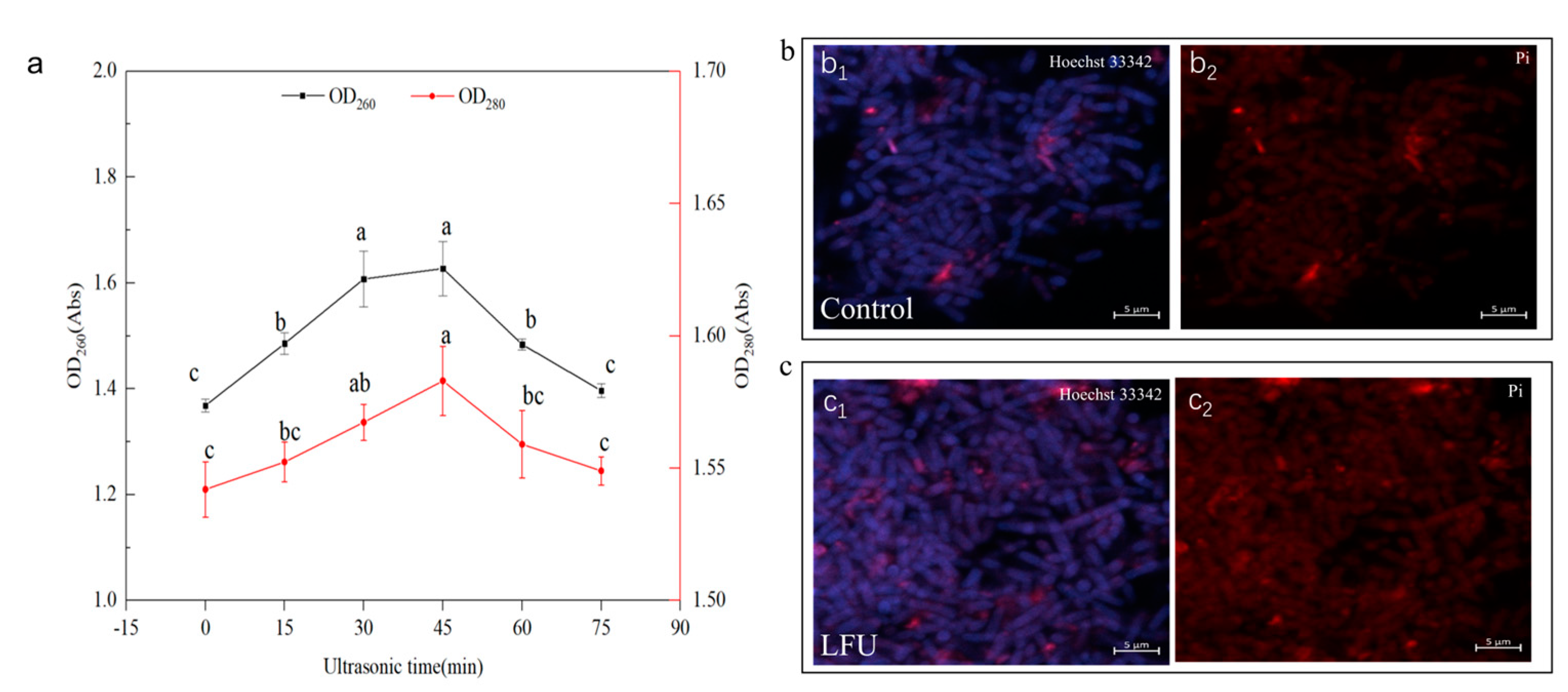

3.2. Effect of LFU on Permeability of B. thuringiensis Cell Membrane

3.3. Effect of LFU on Morphology of B. thuringiensis Cells

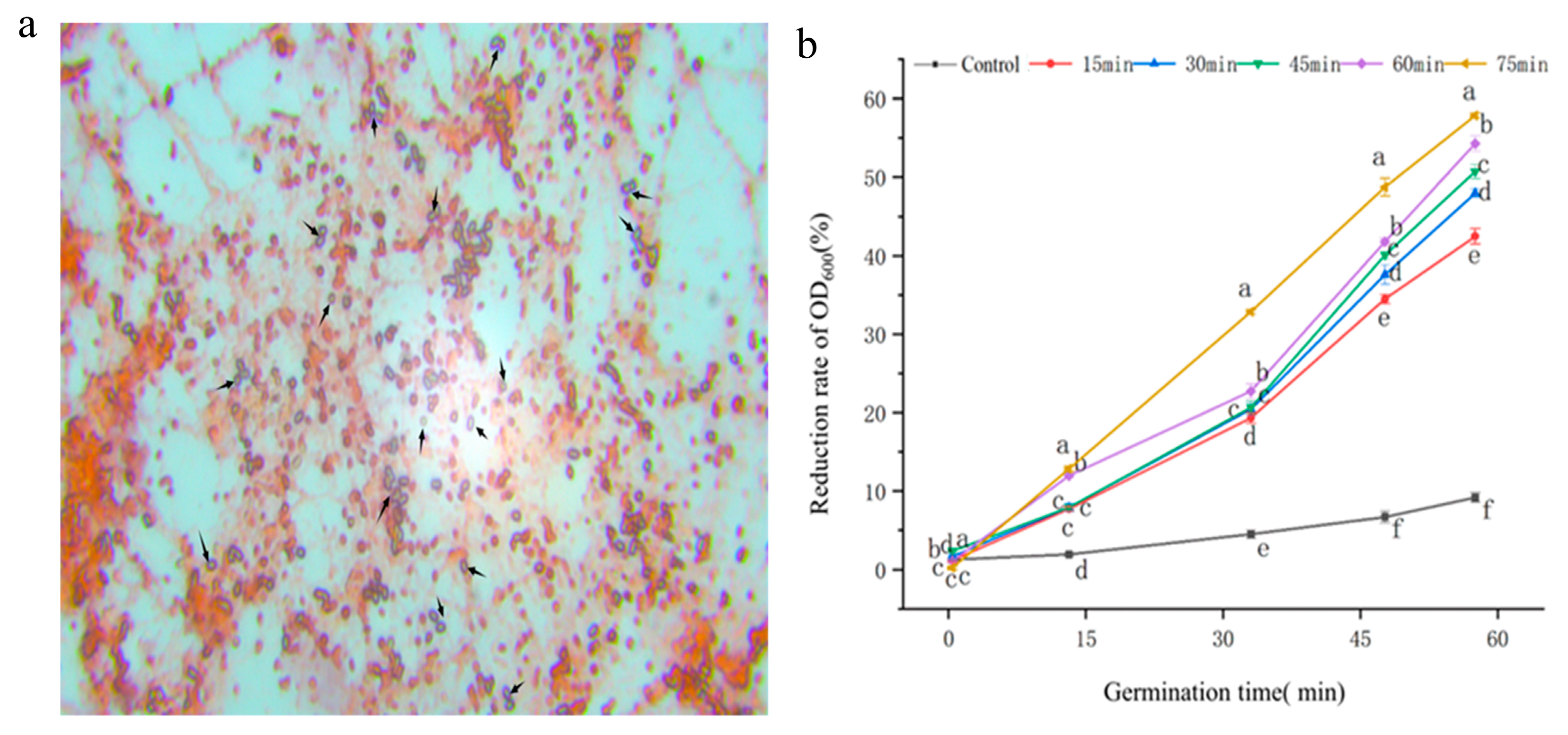

3.4. LFU Stimulates B. thuringiensis Spore Germination

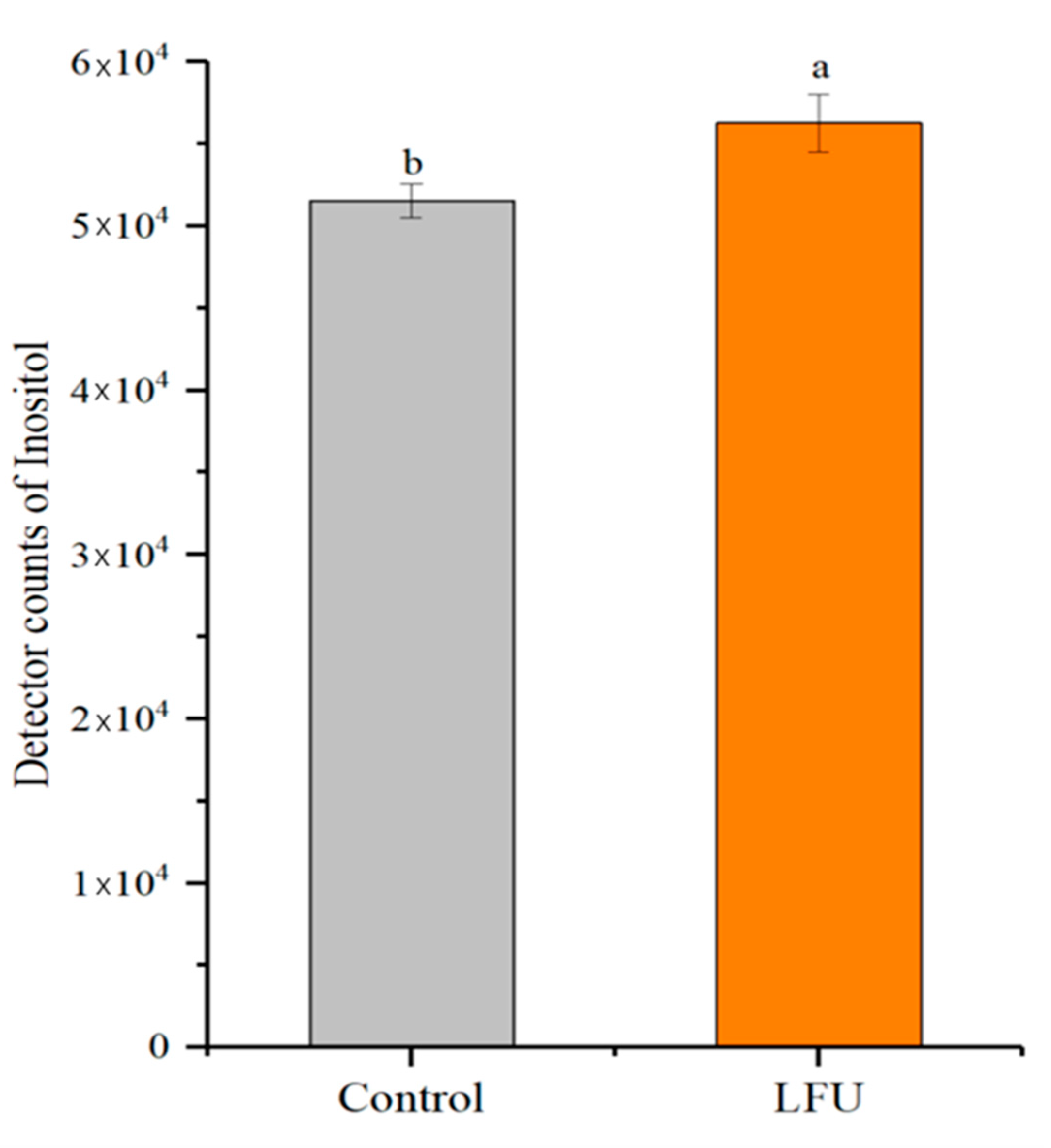

3.5. Effect of LFU on Inositol Concentration of B. thuringiensis Fermentation

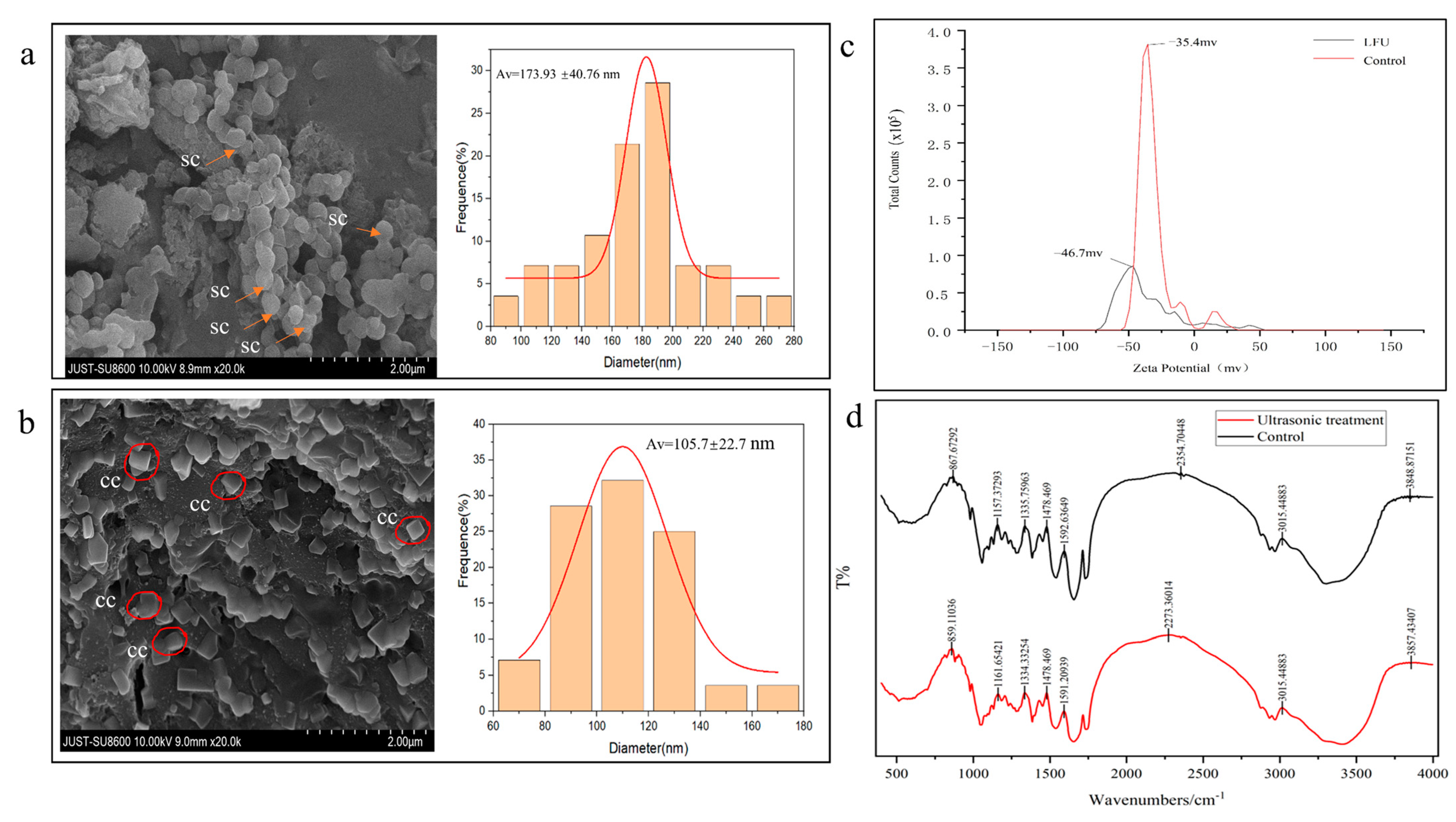

3.6. Effect of LFU on Physicochemical Characteristics of B. thuringiensis Parasporal Crystals

3.7. The Pesticidal Activities of B. thuringiensis Parasporal Crystals Against S. zeamais

4. Discussions

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| LFU | Low-frequency ultrasound |

| FESEM | Field emission scanning electron microscopy |

| CLSM | Laser confocal scanning electron microscope |

| FTIR | Fourier transform infrared |

| LC50 | Lethal concentration to 50% |

| KT50 | Half knock-down time |

| SD | Standard deviation |

| SE | Standard error |

| Con | Concentration |

| LCL | Lower confidence limit |

| UCL | Upper confidence limit |

| χ2 | Chi-square test |

| Cry | Crystalline |

| Cyt | Cytolytic |

References

- Loutfi, H.; Fayad, N.; Pellen, F.; Le Jeune, B.; Chakroun, M.; Benfarhat, D.; Lteif, R.; Kallassy, M.; Le Brun, G.; Abboud, M. Morphological Study of Bacillus thuringiensis Crystals and Spores. Appl. Sci. 2021, 11, 155. [Google Scholar] [CrossRef]

- Ehling-Schulz, M.; Lereclus, D.; Koehler, T.M. The Bacillus cereus Group: Bacillus Species with Pathogenic Potential. Microbiol Spectr. 2019, 7, 10.1128. [Google Scholar] [CrossRef]

- Palma, L.; Muñoz, D.; Berry, C.; Murillo, J.; Caballero, P. Bacillus thuringiensis Toxins: An Overview of Their Biocidal Activity. Toxins 2014, 6, 3296–3325. [Google Scholar] [CrossRef] [PubMed]

- Romeis, J.; Naranjo, S.E.; Meissle, M.; Shelton, A.M. Genetically engineered crops help support conservation biological control. Biol. Control. 2019, 130, 136–154. [Google Scholar] [CrossRef]

- Jian, J.; Liao, X.; Mo, Z.; Li, S.; Li, L.; Chen, S.; Huang, Z.; Chen, J.; Dai, W.; Sun, S. Feasibility of low-intensity ultrasound treatment with hydroxylamine to accelerate the initiation of partial nitrification and allow operation under intermittent aeration. J. Environ. Sci. 2024, 139, 446–459. [Google Scholar] [CrossRef] [PubMed]

- Abedi, M.H.; Yao, M.S.; Mittelstein, D.R.; Bar-Zion, A.; Swift, M.B.; Lee-Gosselin, A.; Barturen-Larrea, P.; Buss, M.T.; Shapiro, M.G. Ultrasound-controllable engineered bacteria for cancer immunotherapy. Nat. Commun. 2022, 13, 1585. [Google Scholar] [CrossRef]

- Cui, S.; Wu, Y.; Cui, Z.; He, P.; Huang, N.; Xu, W.; Hu, J. Low-frequency ultrasound-assisted biosynthesis and characterization of ZnO nanoparticles using Bacillus thuringiensis against Tribolium castaneum (Coleoptera, Tenebrionidae). Mater. Lett. 2023, 341, 134158. [Google Scholar] [CrossRef]

- Chuanyun, D.; Bochu, W.; Chuanren, D.; Sakanishi, A. Low ultrasonic stimulates fermentation of riboflavin producing strain Ecemothecium ashbyii. Colloid Surface B 2003, 30, 37–41. [Google Scholar] [CrossRef]

- Huang, G.; Chen, S.; Tang, Y.; Dai, C.; Sun, L.; Ma, H.; He, R. Stimulation of low intensity ultrasound on fermentation of skim milk medium for yield of yoghurt peptides by Lactobacillus paracasei. Ultrason. Sonochemistry 2019, 51, 315–324. [Google Scholar] [CrossRef]

- Laussmann, T.; Pikzack, C.; Thiel, U.; Mayr, G.W.; Vogel, G. Diphospho-myo-inositol phosphates during the life cycle of Dictyostelium and Polysphondylium. Eur. J. Biochem. 2000, 267, 2447–2451. [Google Scholar] [CrossRef]

- Michell, R.H. Inositol derivatives: Evolution and functions. Nat. Rev. Mol. Cell Bio. 2008, 9, 151–161. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Shen, C.; Xia, D.; Wang, J.; Tang, Q. Characterization of the Expression and Functions of Two Odorant-Binding Proteins of Sitophilus zeamais Motschulsky (Coleoptera: Curculionoidea). Insects 2019, 10, 409. [Google Scholar] [CrossRef]

- Laura Peschiutta, M.; Achimon, F.; Daniela Brito, V.; Paola Pizzolitto, R.; Alberto Zygadlo, J.; Paula Zunino, M. Fumigant toxicity of essential oils against Sitophilus zeamais (Motschulsky) (Coleoptera: Curculionidae): A systematic review and meta-analysis. J. Pest Sci. 2022, 95, 1037–1056. [Google Scholar] [CrossRef]

- Mounsef, J.R.; Salameh, D.; Awad, M.K.; Chamy, L.; Brandam, C.; Lteif, R. A simple method for the separation of Bacillus thuringiensis spores and crystals. J. Microbiol. Methods 2014, 107, 147–149. [Google Scholar] [CrossRef] [PubMed]

- Tran, H.N.H.; Graham, L.; Adukwu, E.C. In vitro antifungal activity of Cinnamomum zeylanicum bark and leaf essential oils against Candida albicans and Candida auris. Appl. Microbiol. Biotechnol. 2020, 104, 8911–8924. [Google Scholar] [CrossRef]

- Dananjaya, S.H.S.; Kumar, R.S.; Yang, M.; Nikapitiya, C.; Lee, J.; De Zoysa, M. Synthesis, characterization of ZnO-chitosan nanocomposites and evaluation of its antifungal activity against pathogenic Candida albicans. Int. J. Biol. Macromol. 2018, 108, 1281–1288. [Google Scholar] [CrossRef] [PubMed]

- Zhao, L.; Duan, F.; Gong, M.; Tian, X.; Guo, Y.; Jia, L.; Deng, S. (+)-Terpinen-4-ol Inhibits Bacillus cereus Biofilm Formation by Upregulating the Interspecies Quorum Sensing Signals Diketopiperazines and Diffusing Signaling Factors. J. Agric. Food Chem. 2021, 69, 3496–3510. [Google Scholar] [CrossRef]

- Pan, X.; Wang, Y.; Chen, Z.; Pan, D.; Cheng, Y.; Liu, Z.; Lin, Z.; Guan, X. Investigation of Antibacterial Activity and Related Mechanism of a Series of Nano-Mg(OH)2. ACS Appl. Mater. Interfaces 2013, 5, 1137–1142. [Google Scholar] [CrossRef]

- Hasanin, M.; Elbahnasawy, M.A.; Shehabeldine, A.M.; Hashem, A.H. Ecofriendly preparation of silver nanoparticles-based nanocomposite stabilized by polysaccharides with antibacterial, antifungal and antiviral activities. Biometals 2021, 34, 1313–1328. [Google Scholar] [CrossRef]

- Talukdar, P.K.; Sarker, M.R. The serine proteases CspA and CspC are essential for germination of spores of Clostridium perfringens SM101 through activating SleC and cortex hydrolysis. Food Microbiol. 2020, 86, 103325. [Google Scholar] [CrossRef]

- Tehri, N.; Kumar, N.; Raghu, H.V.; Vashishth, A. Biomarkers of bacterial spore germination. Ann. Microbiol. 2018, 68, 513–523. [Google Scholar] [CrossRef]

- Abbott, W.S. A method of computing the effectiveness of an insecticide. J. Econ. Entomol. 1925, 18, 265–267. [Google Scholar] [CrossRef]

- de Oliveira, J.L.; Gómez, I.; Sánchez, J.; Soberón, M.; Polanczyk, R.A.; Bravo, A. Performance insights into spray-dryer microencapsulated Bacillus thuringiensis cry pesticidal proteins with gum arabic and maltodextrin for effective pest control. Appl. Microbiol. Biotechnol. 2024, 108, 181. [Google Scholar] [CrossRef] [PubMed]

- Jouzani, G.S.; Valijanian, E.; Sharafi, R. Bacillus thuringiensis: A successful insecticide with new environmental features and tidings. Appl. Microbiol. Biotechnol. 2017, 101, 2691–2711. [Google Scholar] [CrossRef]

- Cao, X.; Che, Z.; Zhou, B.; Guan, B.; Chen, G.; Zeng, W.; Liang, Z. Investigations in ultrasound-assisted anticoagulant production by marine Bacillus subtilis ZHX. Ultrason. Sonochemistry 2020, 64, 104994. [Google Scholar] [CrossRef]

- Patil, U.; Mokashe, N.; Shaha, J.; Arthekar, S.; Jagatap, H. Ultrasound-assisted improvements in biocatalytic activity and production of organic-solvent stable protease from Bacillus circulans MTCC 7942. Ultrason. Sonochemistry 2018, 40, 201–205. [Google Scholar] [CrossRef]

- Dai, C.; Shu, Z.; Xu, X.; Yan, P.; Dabbour, M.; Kumah Mintah, B.; Huang, L.; He, R.; Ma, H. Enhancing the growth of thermophilic Bacillus licheniformis YYC4 by low-intensity fixed-frequency continuous ultrasound. Ultrason. Sonochemistry 2023, 100, 106611. [Google Scholar] [CrossRef]

- Wei, Q.; Yao, J.; Chen, R.; Yang, S.; Tang, Y.; Ma, X. Low-frequency ultrasound and nitrogen limitation induced enhancement in biomass production and lipid accumulation of Tetradesmus obliquus ACHB-12. Bioresour. Technol. 2022, 358, 127387. [Google Scholar] [CrossRef] [PubMed]

- Pitt, W.G.; Ross, S.A. Ultrasound increases the rate of bacterial cell growth. Biotechnol. Prog. 2003, 19, 1038–1044. [Google Scholar] [CrossRef]

- Chen, J.; Zhai, W.; Li, Y.; Guo, Y.; Zhu, Y.; Lei, G.; Li, J. Enhancing the biomass and riboflavin production of Ashbya gossypii by using low-intensity ultrasound stimulation. Biochem. Eng. J. 2022, 181, 108394. [Google Scholar] [CrossRef]

- Contreras, A.; Jones, M.K.; Eldon, E.D.; Klig, L.S. Inositol in Disease and Development: Roles of Catabolism via myo-Inositol Oxygenase in Drosophila melanogaster. Int. J. Mol. Sci. 2023, 24, 4185. [Google Scholar] [CrossRef]

- Fu, B.; Huang, X.; Ma, J.; Chen, Q.; Zhang, Q.; Yu, P. Characterization of an inositol-producing Lactobacillus plantarum strain and the assessment of its probiotic potential and antibacterial activity. LWT 2022, 153, 112553. [Google Scholar] [CrossRef]

- Chatree, S.; Thongmaen, N.; Tantivejkul, K.; Sitticharoon, C.; Vucenik, I. Role of Inositols and Inositol Phosphates in Energy Metabolism. Molecules 2020, 25, 5079. [Google Scholar] [CrossRef] [PubMed]

- Sieiro, C.; Pichardo-Gallardo, Á.; Areal-Hermida, L.; Almuiña-González, R.; Villa, T.G. Parasporal Crystal Toxins in Bacillus thuringiensis. In Developmental Biology in Prokaryotes and Lower Eukaryotes; Springer: Cham, Switzerland, 2021; pp. 125–148. [Google Scholar] [CrossRef]

- Yang, T.; Wu, Z.; Li, L.; Jiang, M.; Fang, X.; Huang, W.; Zhou, Y. Identification and analysis of toxins in novel Bacillus thuringiensis strain Bt S3076-1 against Spodoptera frugiperda and Helicoverpa armigera (Lep.: Noctuidae). Arch. Microbiol. 2023, 205, 168. [Google Scholar] [CrossRef] [PubMed]

- Nazari, B.; Mohammadifar, M.A.; Shojaee-Aliabadi, S.; Feizollahi, E.; Mirmoghtadaie, L. Effect of ultrasound treatments on functional properties and structure of millet protein concentrate. Ultrason. Sonochemistry 2018, 41, 382–388. [Google Scholar] [CrossRef] [PubMed]

- Kong, J.; Yu, S. Fourier Transform Infrared Spectroscopic Analysis of Protein Secondary Structures. Acta Biochim. Biophys. Sin. 2007, 39, 549–559. [Google Scholar] [CrossRef]

- Tian, S.; Huang, S.; Zhu, Y.; Zhang, G.; Lian, J.; Liu, Z.; Zhang, L.; Qin, X. Effect of low-intensity ultrasound on partial nitrification: Performance, sludge characteristics, and properties of extracellular polymeric substances. Ultrason. Sonochemistry 2021, 73, 105527. [Google Scholar] [CrossRef]

- Wang, S.; Zhou, B.; Shen, Y.; Wang, Y.; Peng, Y.; Niu, L.; Yang, X.; Li, S. Effect of ultrasonic pretreatment on the emulsification properties of Clanis Bilineata Tingtauica Mell protein. Ultrason. Sonochemistry 2021, 80, 105823. [Google Scholar] [CrossRef]

- Kasozi, L.C.; Derera, J.; Tongoona, P.; Gasura, E. Seed generation effect on quality of genetic information from maize (Zea mays L.) diallel cross for maize weevil (Sitophilus zeamais Motschulsky) resistance. Euphytica 2021, 217, 114. [Google Scholar] [CrossRef]

- Chattopadhyay, P.; Banerjee, G. Recent advancement on chemical arsenal of Bt toxin and its application in pest management system in agricultural field. 3 Biotech 2018, 8, 201. [Google Scholar] [CrossRef]

- Thomas, D.J.; Morgan, J.A.; Whipps, J.M.; Saunders, J.R. Plasmid transfer between the Bacillus thuringiensis subspecies kurstaki and tenebrionis in laboratory culture and soil and in lepidopteran and coleopteran larvae. Appl. Environ. Microbiol. 2000, 66, 118–124. [Google Scholar] [CrossRef] [PubMed]

| Con (mg/kg Flour) | 7-day Mortality (%) ± SD | Slope Function (Slope) | LC50 ± SE (mg/kg) | LCL–UCL (mg/kg) | χ2 |

|---|---|---|---|---|---|

| Control | 24.44 ± 7.70 e | −4.851 ± 1.003 | 10.795 | 7.718–13.314 | 12.808 * |

| 10 | 36.11 ± 12.73 c | ||||

| 20 | 56.11 ± 5.36 b | ||||

| 30 | 90.56 ± 10.05 a | ||||

| 40 | 91.67 ± 8.33 da | ||||

| 50 | 97.22 ± 4.81 a |

| Exposure Time (days) | Mortality (%) ± SD | Slope Function (Slope) | KT50 ± SE (days) | LCL–UCL (days) | χ2 |

|---|---|---|---|---|---|

| 0 | 0.00 e | −3.083 ± 0.534 | 4.855 | 4.075–5.657 | 11.718 * |

| 2 | 20 ± 6.67 d | ||||

| 4 | 36.35 ± 3.38 cd | ||||

| 6 | 51.11 ± 7.40 bc | ||||

| 8 | 56.42 ± 10.62 b | ||||

| 10 | 90.56 ± 10.05 a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cui, S.; Shen, K.; Xiong, S.; Li, X.; Wang, Y.; Geng, X.; Lu, Y. Low-Frequency Ultrasound Assisted in Improvement in Cell Development and Production of Parasporal Crystals from Bacillus thuringiensis HD1. Insects 2025, 16, 507. https://doi.org/10.3390/insects16050507

Cui S, Shen K, Xiong S, Li X, Wang Y, Geng X, Lu Y. Low-Frequency Ultrasound Assisted in Improvement in Cell Development and Production of Parasporal Crystals from Bacillus thuringiensis HD1. Insects. 2025; 16(5):507. https://doi.org/10.3390/insects16050507

Chicago/Turabian StyleCui, Sufen, Kaihui Shen, Shiqi Xiong, Xiao Li, Yue Wang, Xueqing Geng, and Yujie Lu. 2025. "Low-Frequency Ultrasound Assisted in Improvement in Cell Development and Production of Parasporal Crystals from Bacillus thuringiensis HD1" Insects 16, no. 5: 507. https://doi.org/10.3390/insects16050507

APA StyleCui, S., Shen, K., Xiong, S., Li, X., Wang, Y., Geng, X., & Lu, Y. (2025). Low-Frequency Ultrasound Assisted in Improvement in Cell Development and Production of Parasporal Crystals from Bacillus thuringiensis HD1. Insects, 16(5), 507. https://doi.org/10.3390/insects16050507