A Critical Review of Approaches to the Design of Floating-Liner Apparatus for Instantaneous Piston Assembly Friction Measurement

Abstract

1. Introduction

2. The Development of Instantaneous Piston-Friction Measurement

3. Main Design Challenges in the Floating-Liner Method

- Methods of sealing the cylinder/crankcase interface.

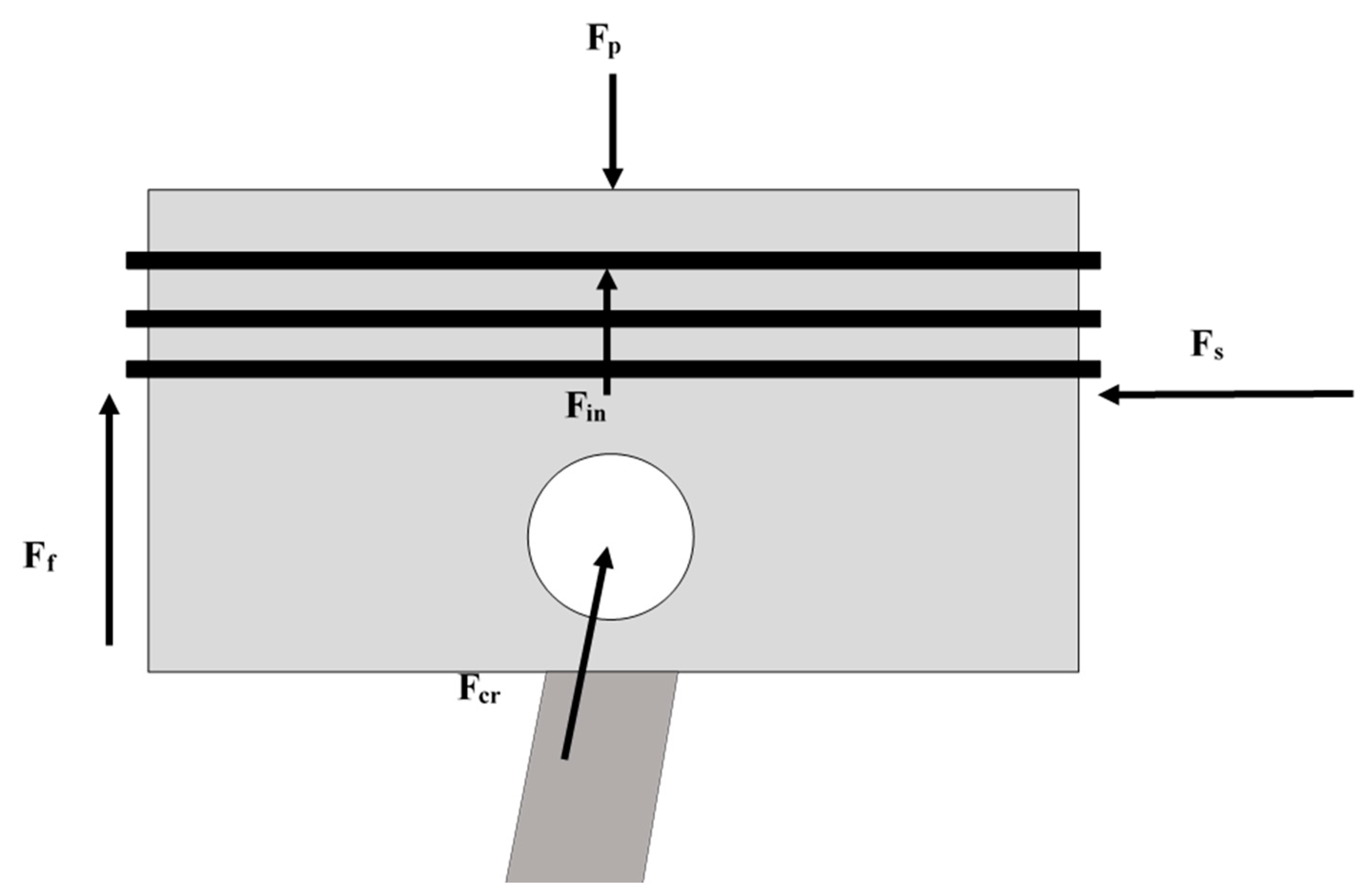

- Balancing of forces acting on the cylinder.

- Approaches to cylinder restraint.

- Sensor requirements.

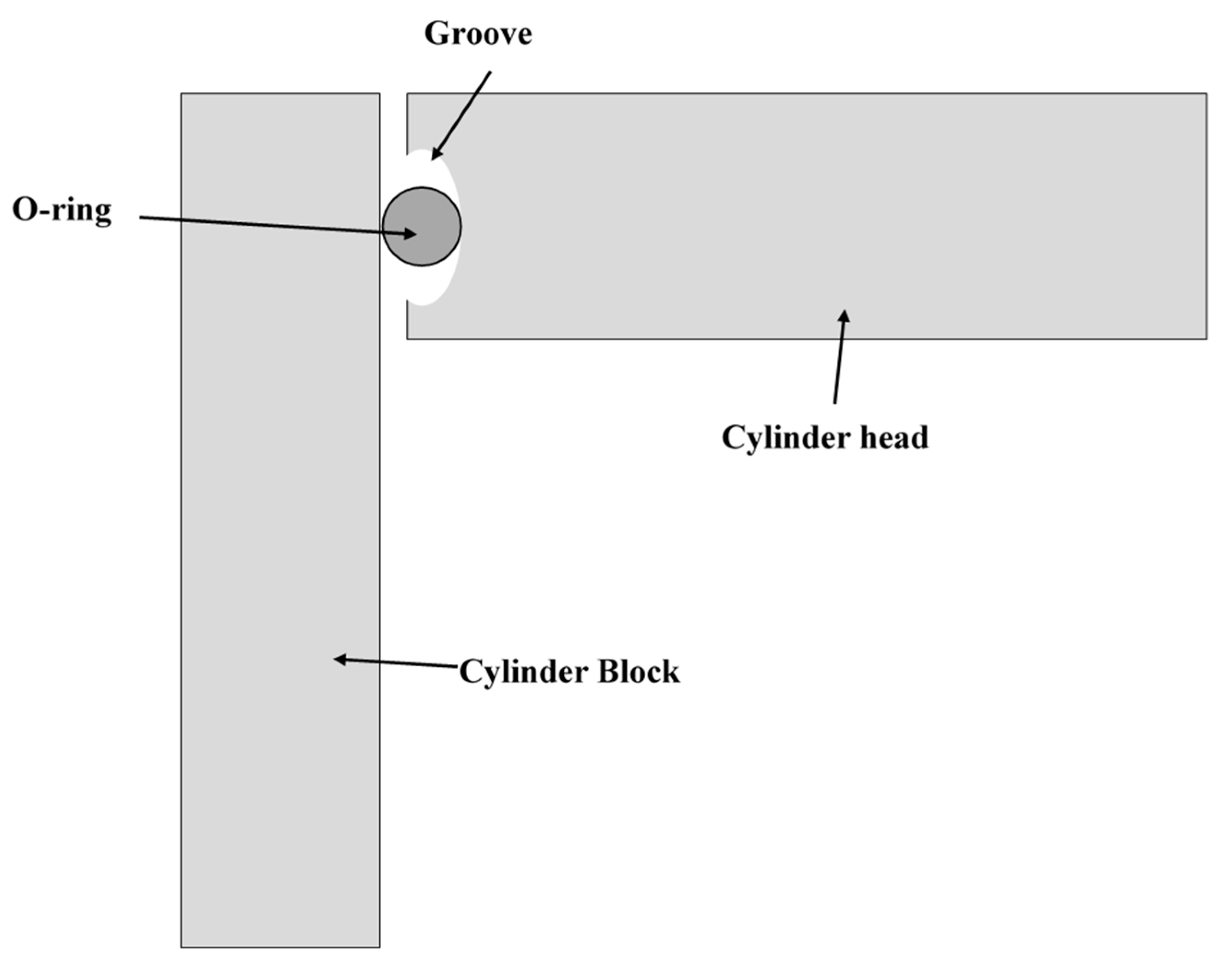

3.1. Methods of Sealing the Cylinder Crankcase Interface

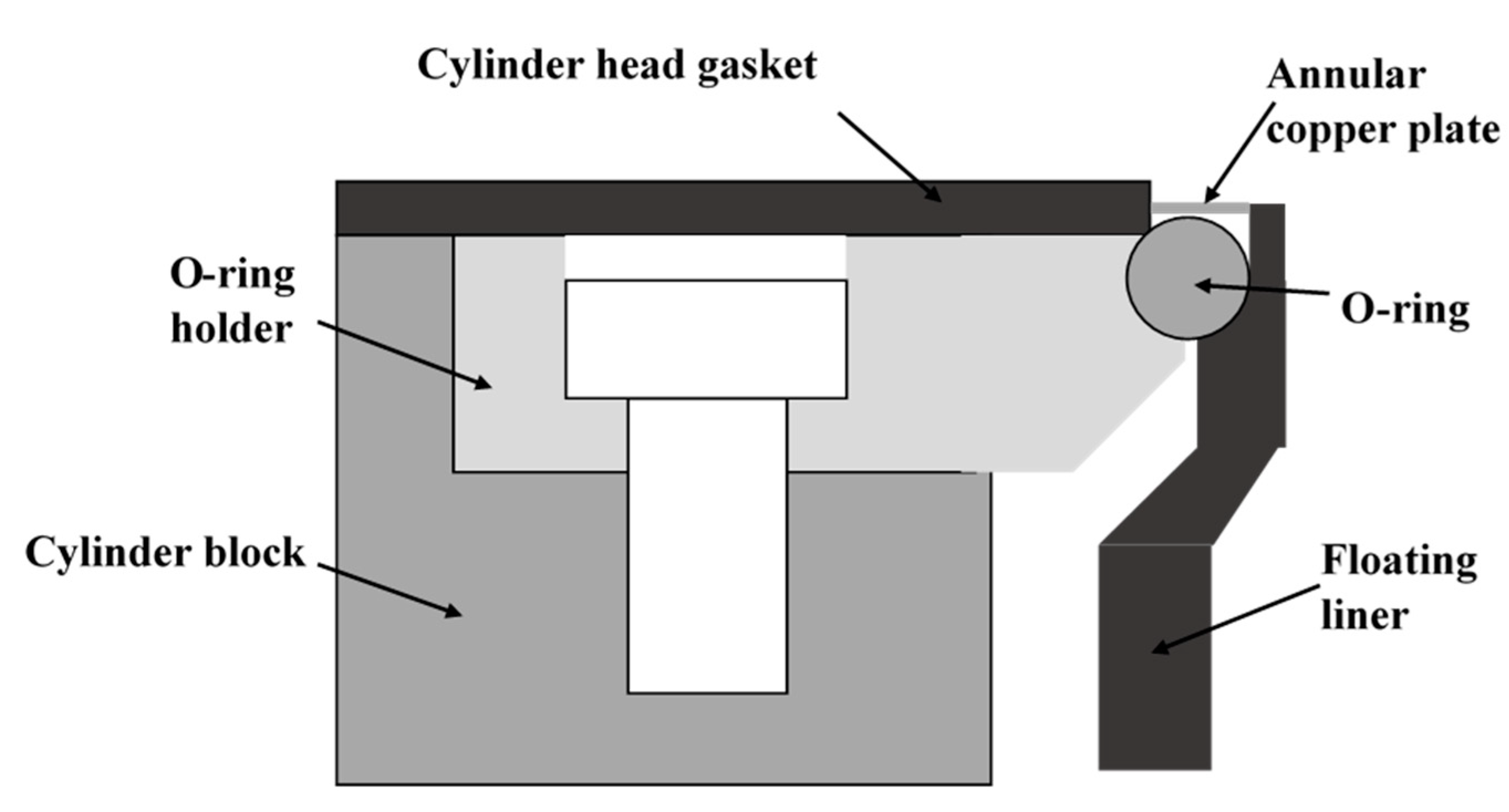

3.1.1. O-Ring Seals

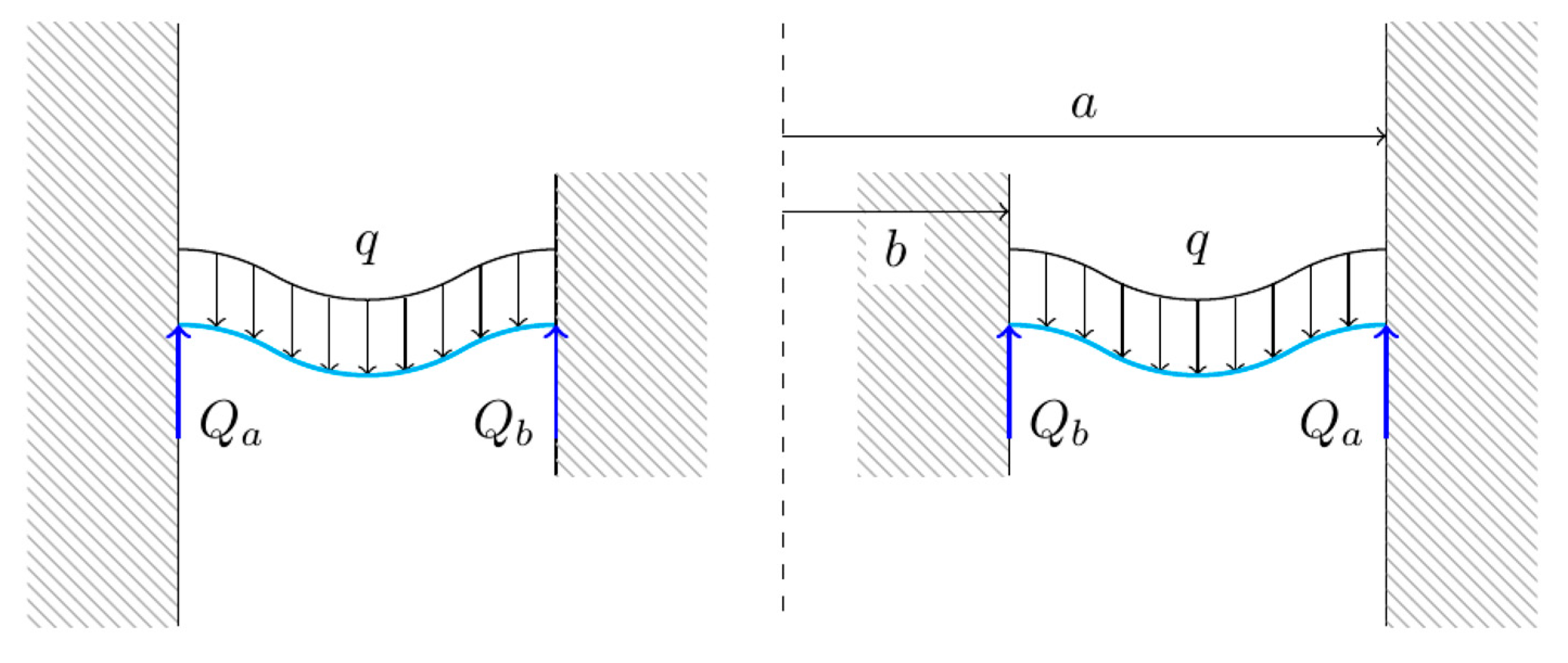

3.1.2. Hydrostatic Seals

3.1.3. Gas-Restriction Seals

3.1.4. Annular/Force Balancing Seals

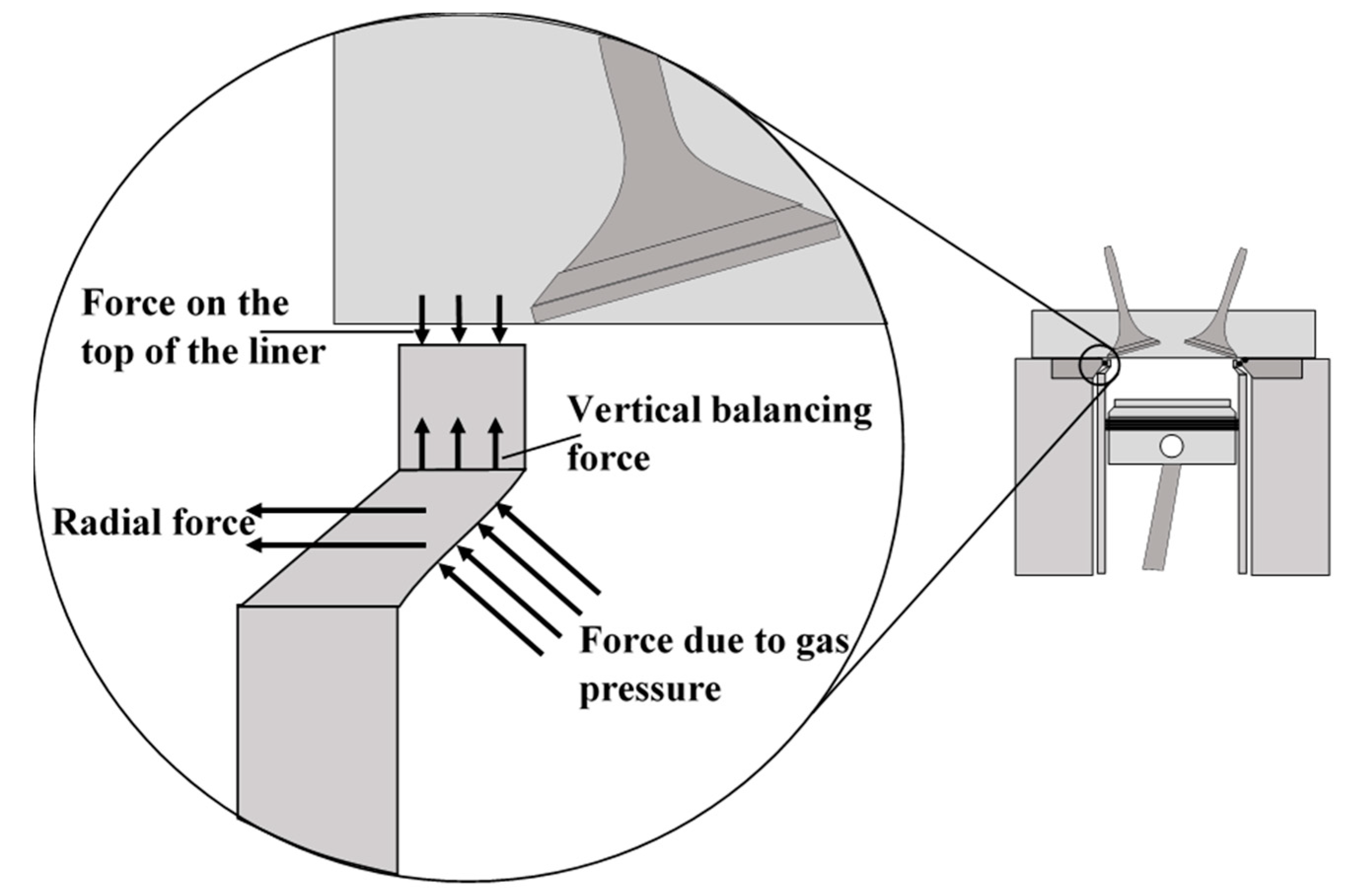

3.2. Force Balancing of the Floating-Liner

3.2.1. Liner Geometry Force Balancing

3.2.2. Electronic Chamber Pressure Balancing

3.2.3. Gas Chamber Pressure Balancing

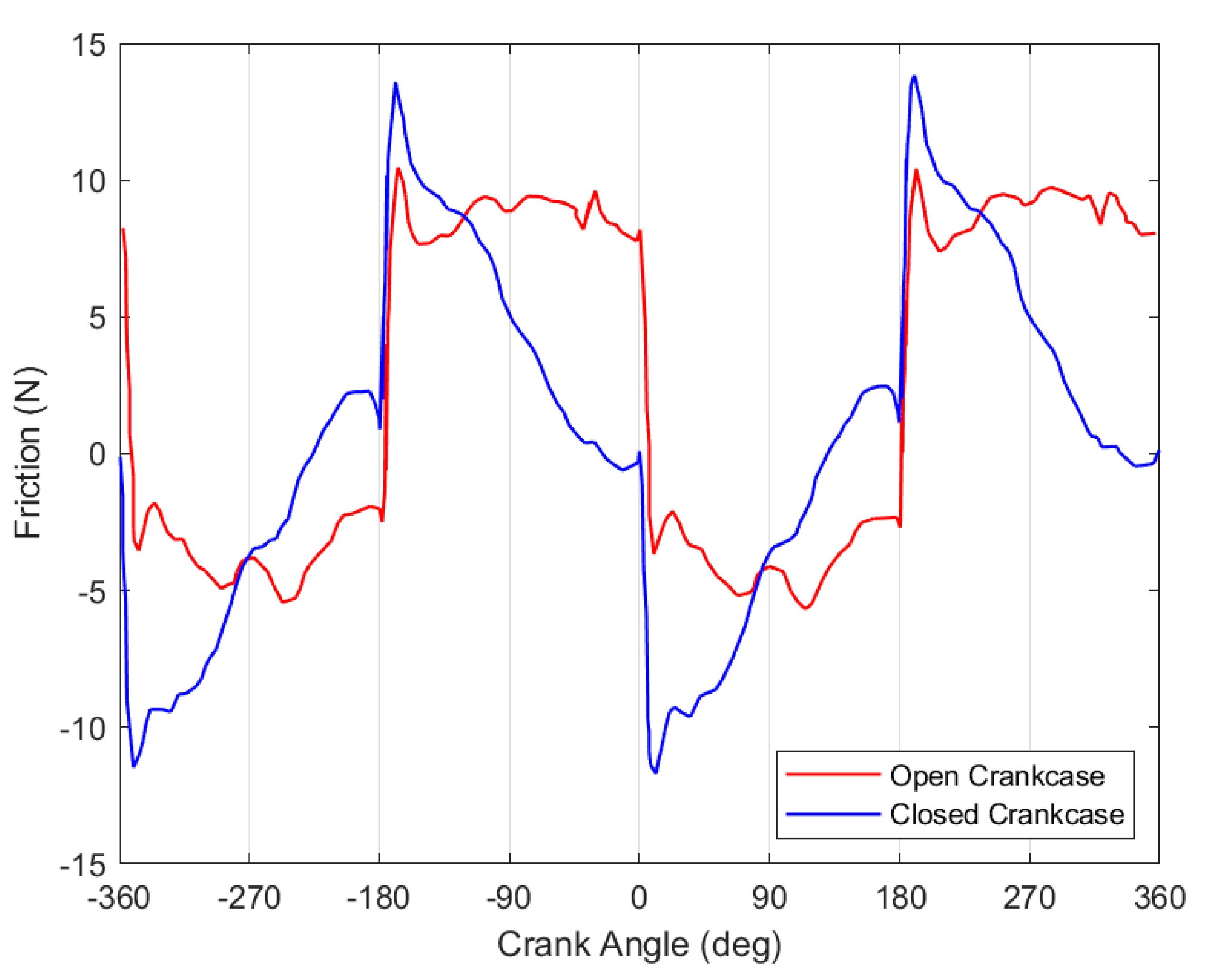

4. Design Challenges Associated with Firing Operation of the Floating-Liner Method

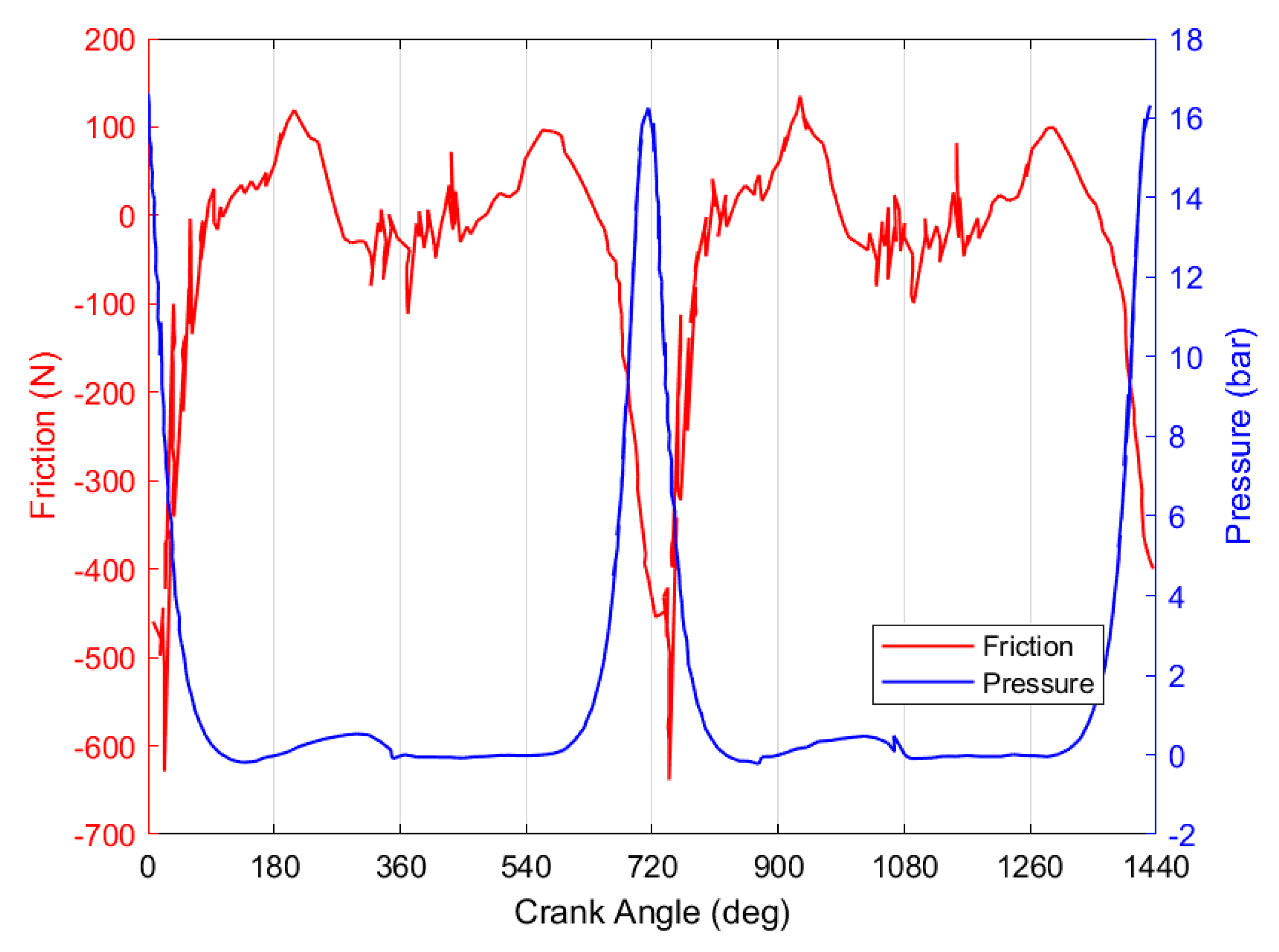

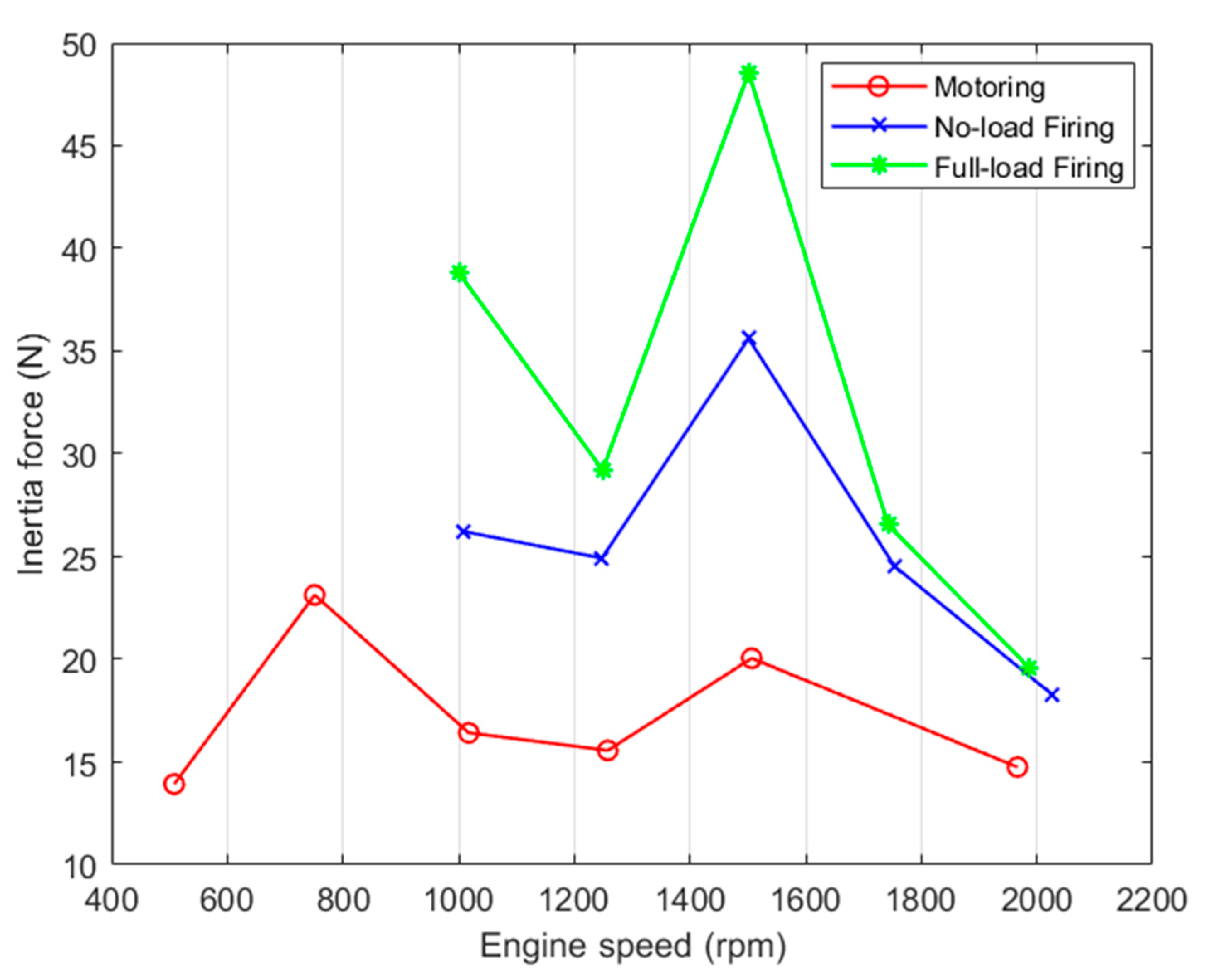

4.1. Correction of Friction Data for Engine Vibrations

4.2. Protection of Polymer Seals

4.3. Choosing Firing Floating-Liner Instrumentation

4.4. Force Transducer Issues

4.4.1. Measurement Range

4.4.2. Frequency Response

4.4.3. Zero Offset

5. Discussion: Major Configurations of Floating-Liner Techniques

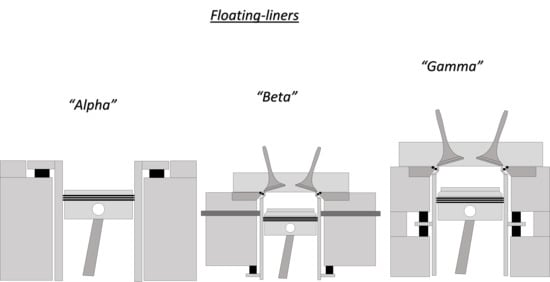

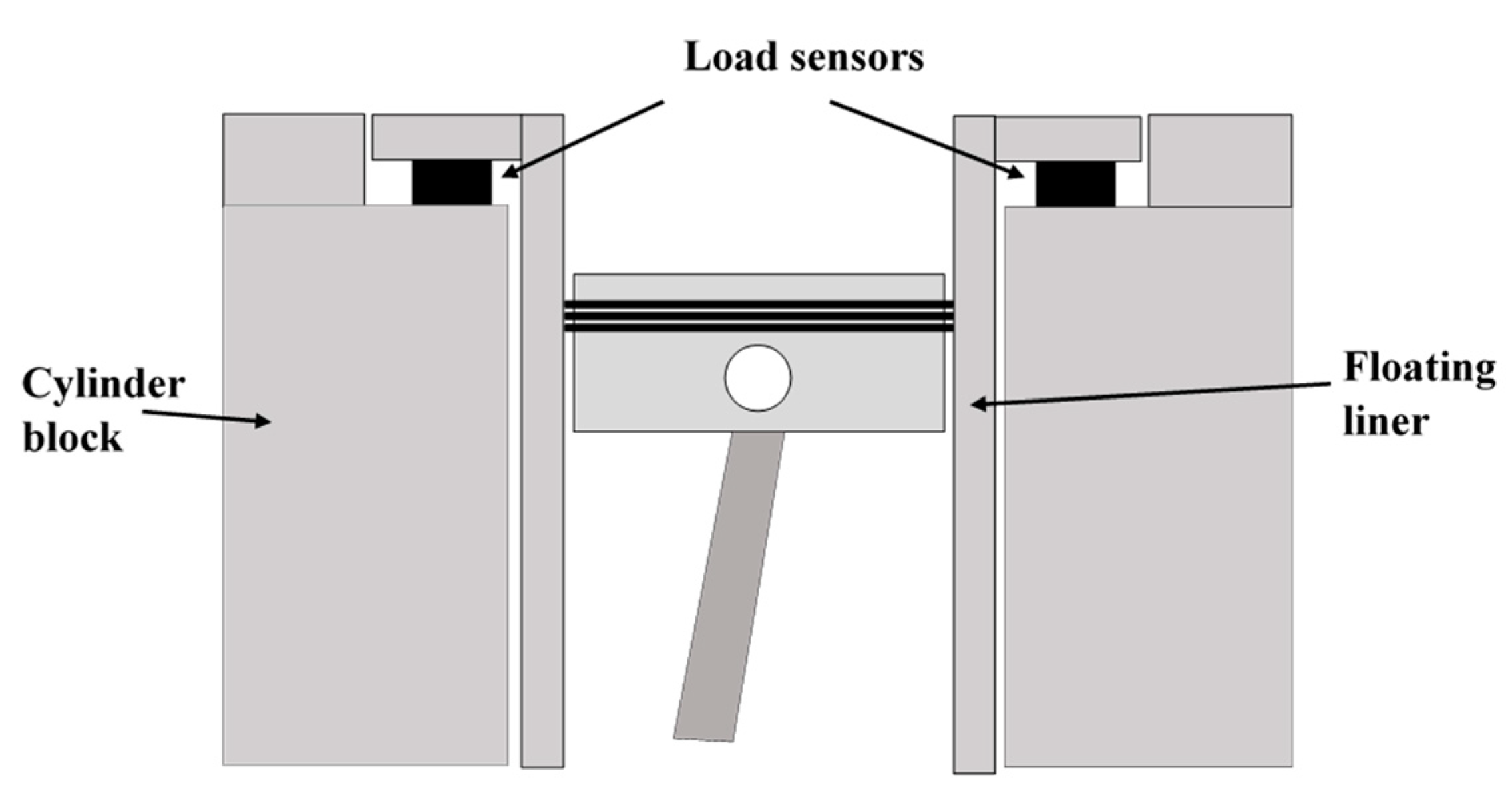

5.1. Alpha

5.1.1. Applications

5.1.2. Advantages

- Simple design.

- Easy access to the liner and the piston, so it could be used effectively with interchangeable liners, pistons and piston rings.

- Inexpensive when compared with the other designs.

- Able to be based on a wide range of reciprocating engines due to its simplicity, as a cranking mechanism and a liner are only the main components needed from an engine to build this type of floating-liner.

5.1.3. Disadvantages

- Cannot be pressurized.

- Cannot be fired.

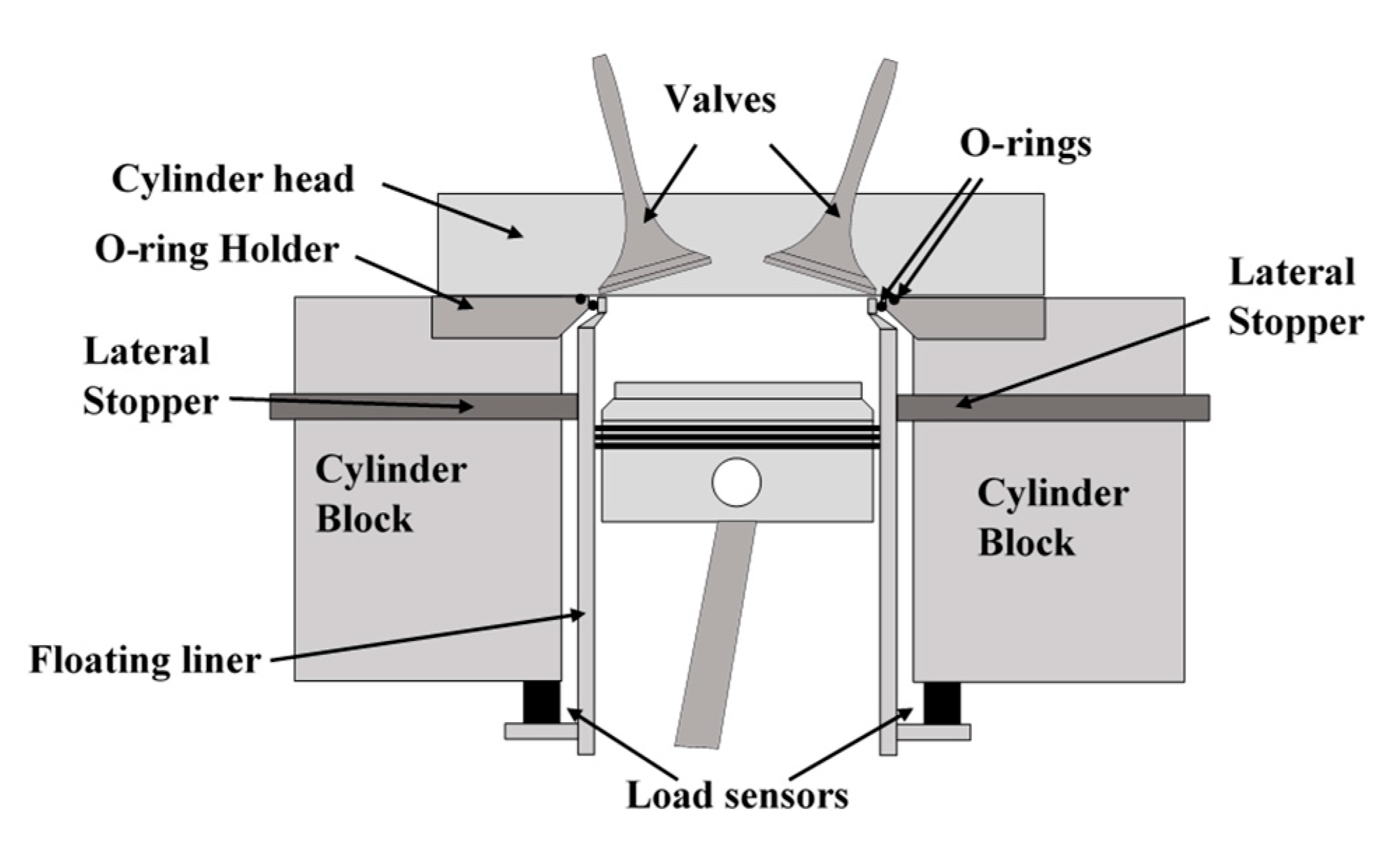

5.2. Beta

5.2.1. Applications

5.2.2. Advantages

- The arrangement can be used in firing conditions.

- Due to the sensors being placed at the base of the liner, the arrangement offers space to modify the head for sealing.

- Motoring of the system is possible.

- Motoring can involve pressurization and heated lubricants and/or external liner heaters.

5.2.3. Disadvantages

- The arrangement requires a high level of modification of the engine, especially the engine block and cylinder head for sealing gas pressure.

- The system requires lateral restriction of the motion of the liner.

- The arrangement is relatively difficult to assemble and disassemble to change the liner, piston rings, etc.

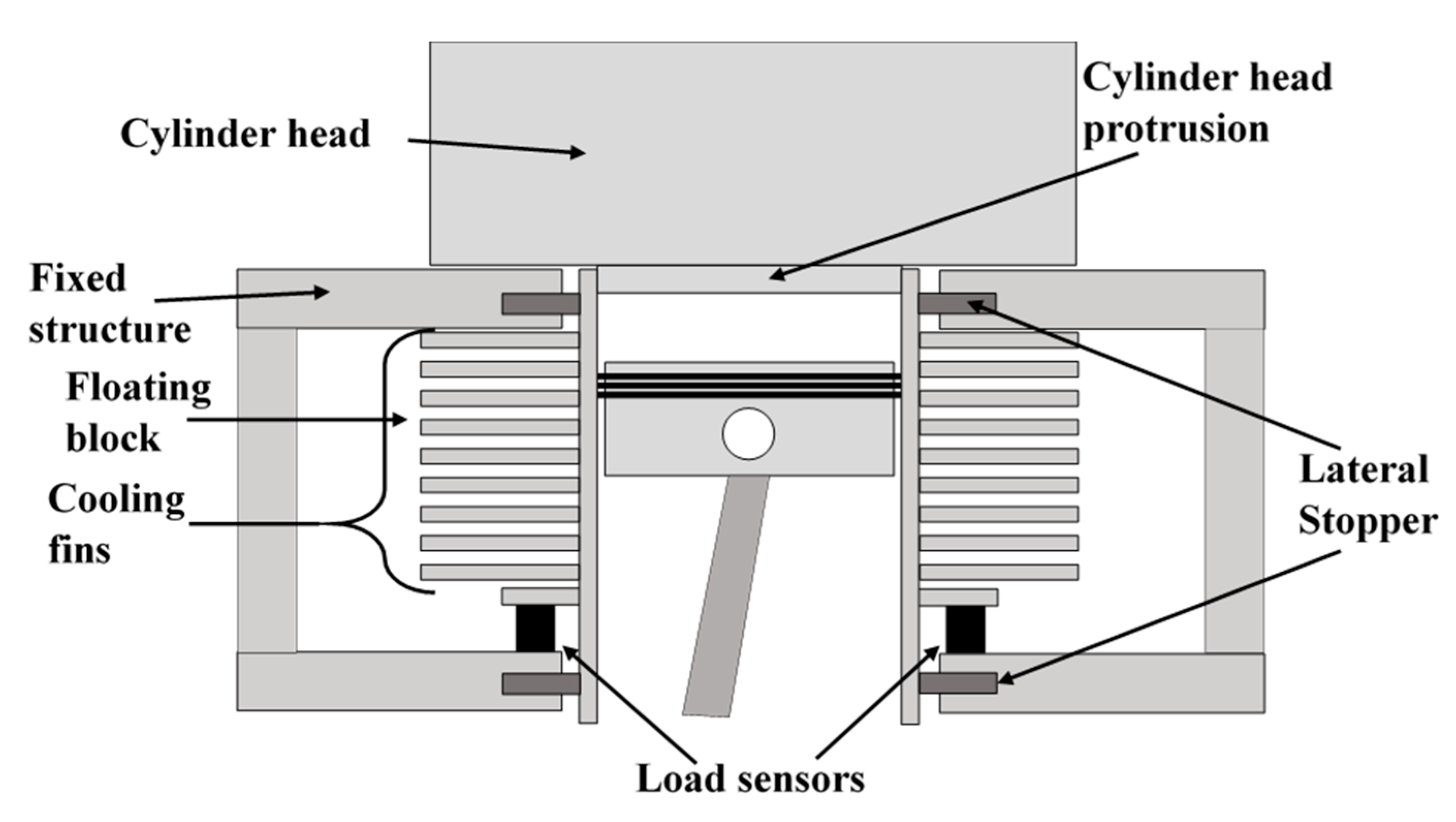

5.3. Gamma

5.3.1. Applications

5.3.2. Advantages

- The arrangement does not require lateral support.

- The system can be used in motoring and firing condition.

- The arrangement can be pressurized and heated using lubrication oil and/or external liner heaters.

5.3.3. Disadvantages

- The approach requires manufacturing or modification of both the liner and cylinder block.

- Harder to be used in firing condition as the liner and the cylinder block are manufactured.

- It is less convenient to use the approach with pre-manufactured cylinder liners.

6. Conclusions

- With the advancement in today’s machining precision, annular/force balancing sealing is a promising method of sealing the combustion chamber.

- Gas chamber pressure balancing can be an intuitive way to avoid modifying piston crown, leading to using many stock pistons for research without modifying them.

- Designing of floating-liner system mainly depends on the nature of the study required to be conducted.

- Non-pressurized (such as Alpha) floating-liner systems are simple to build and operate. However, they do not replicate the full range of behavior of the mechanical and fluid components in the piston assembly or the effects resulting from combustion and, therefore, represent the behavior of operating engines in a limited way.

- Pressurized systems (such as Beta and Gamma) are becoming increasingly common, but their design remains challenging. They have the potential to replicate the full spectrum of phenomena that arise in firing engines during service.

- Firing floating-liners are the most challenging in design and operation, especially regarding excessive engine vibrations, sealing the combustion chamber, and the instrumentation used. However, it gives the most realistic results if it is built properly.

- Pressurized and heated floating-liners are good alternatives and have fewer issues than the firing ones, yet can give a good simulation to the firing conditions.

- A range of standardized approaches, reviewed in this paper, can be adopted to develop effective designs of both pressurized and non-pressurized floating-liner arrangements.

7. Proposals for Further Work

- It will be of value to compare the output of established piston assembly lubrication models with detailed data collected from floating-liner systems to test the level of compatibility between accurate experimental friction measurements and well established (industry standard) simulation tools.

- It may be of more value to evaluate power loss from friction data, rather than to present friction data in its own right, as power loss data is more meaningful in a broader context.

- It is clearly possible to incorporate other types of tribological sensor in floating-liner systems, to evaluate oil consumption, lubricating film thickness, cylinder temperature distributions, etc. Such multi-sensor systems will have considerable value in commercial settings.

- Design improvements can only be reliably detected at different sites if the same test equipment is used for all evaluations, so it may make sense to identify a standardized design of floating-liner systems so that direct comparisons can be made between data collected by different organizations.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

References

- Fontaras, G.; Samaras, Z. On the way to 130 g CO2/km—Estimating the future characteristics of the average European passenger car. Energy Policy 2010, 38, 1826–1833. [Google Scholar] [CrossRef]

- Holmberg, K.; Andersson, P.; Erdemir, A. Global energy consumption due to friction in passenger cars. Tribol. Int. 2012, 47, 221–234. [Google Scholar] [CrossRef]

- Jost, H.P. Tribology Micro & Macro Economics: A Road to Economic Savings. Tribol. Lubr. Technol. 2005, 61, 18–22. [Google Scholar]

- Holmberg, K.; Erdemir, A. Global impact of friction on energy consumption, economy and environment. FME Trans. 2015, 43, 181–185. [Google Scholar]

- Fessler, R.R.; Fenske, G.R. Multiyear Program Plan: Reducing Friction and Wear in Heavy Vehicles. 1999. Available online: https://www.osti.gov/biblio/771210 (accessed on 16 January 2021).

- Ting, L.L. A Review of Present information on Piston Ring Tribology. SAE Trans. 1985, 94, 1135–1146. [Google Scholar]

- Patton, K.J.; Nitschke, R.G.; Heywood, J.B. Development and Evaluation of a Friction Model for Spark-Ignition Engines. SAE Trans. 1989, 98, 1441–1461. [Google Scholar]

- Kovach, J.T.; Tsakiris, E.A.; Wong, L.T. Engine Friction Reduction for Improved Fuel Economy; SAE: Warrendale, PA, USA, 1982. [Google Scholar]

- Koch, F.; Geiger, U.; Hermsen, F. PIFFO Piston Friction Force Measurements during Engine Operation; SAE: Warrendale, PA, USA, 1996. [Google Scholar]

- Richardson, D.E. Review of Power Cylinder Friction for Diesel Engines. J. Eng. Gas Turbines Power 2000, 122, 506–519. [Google Scholar] [CrossRef]

- Betz, G.; Gabele, H.; Assmus, H.O. Friction Power and Noise Behaviour of the Piston Assembly. In Proceedings of the Second International Conference on Combustion Engines–Reduction of Friction and Wear, London, UK, 19–20 September 1989; pp. 35–58. [Google Scholar]

- Goenka, P.K.; Meernik, P.R. Lubrication analysis of piston skirts. SAE Trans. 1992, 101, 886–895. [Google Scholar]

- Harikumar, Y.; Mahadevan, R.; Muralitharan, N.; Manivasagam, S. Rengarajan Predictive Technique Approach for Diesel Engine Piston Ring Pack Design Optimization and Experimental Verification; SAE: Warrendale, PA, USA, 2005. [Google Scholar]

- Winklhofer, E.; Loesch, S.; Satschen, S.; Thonhauser, B. Reduction of Friction Losses by Means of Cylinder Liner Offset in a Floating Liner Single Cylinder Engine. Int. J. Automot. Eng. 2018, 9, 304–309. [Google Scholar] [CrossRef][Green Version]

- Mike, T.N.; Dennis, N.A.; Donald, J.P.; Simon, C.T.; Spyros, I. Tseregounis Overview of Techniques for Measuring Friction Using Bench Tests and Fired Engines. SAE Trans. 2000, 109, 890–900. [Google Scholar]

- Nagano, Y.; Ito, A.; Okamoto, D.; Yamasaka, K. A Study on the Feature of Several Types of Floating Liner Devices for Piston Friction Measurement; SAE: Warrendale, PA, USA, 2019. [Google Scholar]

- Nagar, P.; Miers, S. Friction between Piston and Cylinder of an IC Engine: A Review; SAE: Warrendale, PA, USA, 2011. [Google Scholar]

- Uras, H.M.; Patterson, D.J. Effect of Some Piston Variables on Piston and Ring Assembly Friction. SAE Trans. 1987, 96, 16–26. [Google Scholar]

- Uras, H.M.; Patterson, D.J. Measurement of Piston and Ring Assembly Friction Instantaneous IMEP Method; SAE: Warrendale, PA, USA, 1983. [Google Scholar]

- Uras, H.M.; Patterson, D.J. Oil and Ring Effects on Piston-Ring Assembly Friction by the Instantaneous IMEP Method; SAE: Warrendale, PA, USA, 1985. [Google Scholar]

- Uras, H.M.; Patterson, D.J. Effect of Some Lubricant and Engine Variables on Instantaneous Piston and Ring Assembly Friction; SAE: Warrendale, PA, USA, 1984. [Google Scholar]

- Mufti, R.A.; Priest, M. Experimental Evaluation of Piston-Assembly Friction under Motored and Fired Conditions in a Gasoline Engine. J. Tribol. 2005, 127, 826–836. [Google Scholar] [CrossRef]

- Mufti, R.A. Total and Component Friction in a Motored and Firing Engine. Ph.D. Thesis, University of Leeds, Leeds, UK, 2004. [Google Scholar]

- Hawkes, C.J. Friction of piston rings. Trans. Ne Coast Inst. Civ. Engrs. Shipbuild. 1936, 52, 49. [Google Scholar]

- Barros, A.F. Piston ring friction-rig measurements with low viscosity oils. J. Inst. Pet. 1960, 46, 1. [Google Scholar]

- Eilon, S.; Saunders, O.A. A study of piston-ring lubrication. Proc. Inst. Mech. Eng. 1957, 171, 427–462. [Google Scholar] [CrossRef]

- Stanton, T.E. The friction of pistons and piston rings. Engineer 1925, 139, 72. [Google Scholar]

- Tischbein, H.W. The Friction of Piston Rings. NACA Technical Memorandums No. 1069. 1945. Available online: https://digital.library.unt.edu/ark:/67531/metadc63676/ (accessed on 16 January 2021).

- Forbes, J.E.; Taylor, E.S. A Method for Studying Piston Friction. NACA Report; 1943. Available online: https://ntrs.nasa.gov/citations/19930093197 (accessed on 16 January 2021).

- Leary, W.A.; Jovellanos, J.U. A Study of Piston and Ring Friction. NACA Report. 1944. Available online: https://digital.library.unt.edu/ark:/67531/metadc61997/m1/8/ (accessed on 16 January 2021).

- Livengood, J.C.; Wallour, C. A Study of Piston-Ring Friction. 1947. Available online: https://digital.library.unt.edu/ark:/67531/metadc55407/ (accessed on 16 January 2021).

- Rogowski, A.R. Method of Measuring the Instantaneous Friction of Piston Rings in a Firing Engine; SAE: Warrendale, PA, USA, 1961. [Google Scholar]

- Furuhama, S.; Takiguchi, M. Measurement of Piston Frictional Force in Actual Operating Diesel Engine. SAE Trans. 1979, 88, 2896–2914. [Google Scholar]

- Nakayama, K.; Yasutake, Y.; Takiguti, M.; Furuhama, S. Effect of Piston Motion on Piston Skirt Friction of a Gasoline Engine; SAE: Warrendale, PA, USA, 1997. [Google Scholar]

- Urabe, M.; Tomomatsu, T.; Ishiki, K.; Takiguchi, M.; Someya, T. Variation of Piston Friction Force and Ring Lubricating Condition in a Diesel Engine with EGR; SAE: Warrendale, PA, USA, 1998. [Google Scholar]

- Teraguchi, S.; Suzuki, W.; Takiguchi, M.; Sato, D. Effects of Lubricating Oil Supply on Reductions of Piston Slap Vibration and Piston Friction. SAE Trans. 2001, 110, 579–584. [Google Scholar]

- Kikuchi, T.; Ito, S.; Nakayama, Y. Piston friction analysis using a direct-injection single-cylinder gasoline engine. JSAE Rev. 2003, 24, 53–58. [Google Scholar] [CrossRef]

- Madden, D.; Kim, K.; Takiguchi, M. Part 1: Piston Friction and Noise Study of Three Different Piston Architectures for an Automotive Gasoline Engine. SAE Trans. 2006, 115, 257–263. [Google Scholar]

- Kim, K.; Shah, P.; Takiguchi, M.; Aoki, S. Part 3: A Study of Friction and Lubrication Behavior for Gasoline Piston Skirt Profile Concepts; SAE: Warrendale, PA, USA, 2009. [Google Scholar]

- Cerrato, R.; Gozzelino, R. Ricci A Single Cylinder Engine for Crankshaft Bearings and Piston Friction Losses Measurement; SAE: Warrendale, PA, USA, 1984. [Google Scholar]

- Mollenhauer, K.; Bruchner, K. Contribution to the Determination of the Influence of Cylinder Pressure and Engine Speed on Engine Friction. MTZ 1980, 41, 265–268. [Google Scholar]

- Sherrington, I.; Smith, E.H. The measurement of piston-ring friction by the floating liner method. Imeche. Exp. Methods Engine Res. Dev. 1988, 1–11. [Google Scholar]

- Richez, M.F.; Constans, B.; Winquist, K. Paper V(ii) Theoretical and experimental study of ring-liner friction. In Tribology of Reciprocating Engines; Dowson, D., Taylor, C.M., Godet, M., Berthe, D., Eds.; Elsevier Ltd.: Amsterdam, The Netherlands, 1993; pp. 122–131. [Google Scholar]

- Gore, M.; Howell-Smith, S.J.; King, P.D.; Rahnejat, H. Measurement of In-Cylinder Friction Using the Floating Liner Principle. In Proceedings of the ASME 2012 Internal Combustion Engine Division Spring Technical Conference, Torino, Piemonte, Italy, 6–9 May 2012; American Society of Mechanical Engineers Digital Collection: New York City, NY, USA, 2012; pp. 901–906. [Google Scholar]

- Gore, M.; Theaker, M.; Howell-Smith, S.; Rahnejat, H.; King, P.D. Direct measurement of piston friction of internal-combustion engines using the floating-liner principle. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2014, 228, 344–354. [Google Scholar] [CrossRef]

- Law, T.; MacMillan, D.; Shayler, P.J.; Kirk, G.; Pegg, I.; Stark, R. A New Floating-Liner Test Rig Design to Investigate Factors Influencing Piston-Liner Friction; SAE: Warrendale, PA, USA, 2012. [Google Scholar]

- Furuhama, S.; Sasaki, S. New device for the measurement of piston frictional forces in small engines. SAE Trans. 1983, 781–792. [Google Scholar]

- Clarke, D.G.; Sherrington, I.; Smith, E.H. Design Considerations for a ’Floating Liner’ Method of Measuring Piston/Piston Ring Friction in Internal Combustion Engines. In Proceedings of the Proc. of Eurotrib 89, 5th International Congress on Tribology, Helsinki, Finland, 14 June 1989; pp. 432–438. [Google Scholar]

- Clarke, D.G.; Sherrington, I.; Smith, E.H. The floating liner method applied to measure instantaneous piston assembly friction in a motored engine. In Proceedings of the Proc. of Nordtrib 90, 4th Nordic Symposium on Tribology, Lubrication, Friction and Wear, Hirthals, Denmark, 10–13 June 1990; Technical University of Denmark Copenhagen, Denmark: Hirtshals, Denmark, 1990; pp. 473–483. [Google Scholar]

- Young, W.C.; Budynas, R.G.; Sadegh, A.M. Roarks Formulas for Stress and Strain; McGraw-Hill’s AccessEngineering; McGraw Hill Book Company: New York City, NY, USA, 2011. [Google Scholar]

- Rahnejat, H. Multi-Body Dynamics: Vehicles, Machines and Mechanisms; Professional Engineering Publisher: London, UK, 1998. [Google Scholar]

- Ha, K. Liner Mounting Structure for Measuring Piston Friction. US6487999B2, 3 December 2002. [Google Scholar]

- Ha, K.; Kim, J.; Cho, M.; Oh, D.Y. Development of Piston Friction Force Measurement System; SAE: Warrendale, PA, USA, 2002. [Google Scholar]

- Yun, J.E.; Kim, S.S. New Device for Piston-Ring Assembly Friction Force Measurement in IDI Diesel Engine. JSME Int. J. Ser. B Fluids Therm. Eng. 1993, 36, 723–729. [Google Scholar] [CrossRef][Green Version]

- Sato, T.; Kurita, H.; Ito, A.; Iwasaki, H. Friction Measurement of Al-17%Si Monolithic Cylinder with Using Newly Developed Floating Liner Device. SAE Int. J. Engines 2014, 8, 135–142. [Google Scholar] [CrossRef]

- Westerfield, Z.; Liu, Y.; Kim, D.; Tian, T. A Study of the Friction of Oil Control Rings Using the Floating Liner Engine. SAE Int. J. Engines 2016, 9, 1807–1824. [Google Scholar] [CrossRef]

- Kirner, C.; Halbhuber, J.; Uhlig, B.; Oliva, A.; Graf, S.; Wachtmeister, G. Experimental and simulative research advances in the piston assembly of an internal combustion engine. Tribol. Int. 2016, 99, 159–168. [Google Scholar] [CrossRef]

- Ishiki, K.; Oshida, S.; Takiguchi, M.; Urabe, M. A Study of Abnormal Wear in Power Cylinder of Diesel Engine with EGR Wear Mechanism of Soot Contaminated in Lubricating Oil; SAE: Warrendale, PA, USA, 2000. [Google Scholar]

- Cater, M.; Bolander, N.W.; Sadeghi, F. A Novel Suspended Liner Test Apparatus for Friction and Side Force Measurement with Corresponding Modeling; SAE: Warrendale, PA, USA, 2006. [Google Scholar]

- Tamura, K.; Kasai, M.; Nakamura, Y.; Enomoto, T. Influence of Shear-Thinning of Polymer-Containing Engine Oils on Friction at the Piston Ring-Cylinder Liner Interface; SAE: Warrendale, PA, USA, 2013. [Google Scholar]

- Liao, K.; Chen, H.; Tian, T. The Study of Friction between Piston Ring and Different Cylinder Liners using Floating Liner Engine Part 1; SAE: Warrendale, PA, USA, 2012. [Google Scholar]

- Westerfield, Z.; Totaro, P.; Kim, D.; Tian, T. An Experimental Study of Piston Skirt Roughness and Profiles on Piston Friction Using the Floating Liner Engine; SAE: Warrendale, PA, USA, 2016. [Google Scholar]

- O’Rourke, B.; Stanglmaier, R.; Radford, D. Development of a Floating-Liner Engine for Improving the Mechanical Efficiency of High Performance Engines; SAE: Warrendale, PA, USA, 2006. [Google Scholar]

- Winklhofer, E.; Loesch, S.; Satschen, S. High Precision Piston to Liner Friction Measurement. In Proceedings of the JSAE Annual Congress Proceedings, Pacifico Yokohama, Japan, 25–27 May 2016; pp. 1864–1869. [Google Scholar]

| Ref. | Cylinder Capacity (L) | Engine Load | Engine Speed (rev min−1) | Natural Frequency (Hz) | Maximum Friction (N) | Instrumentation Used |

|---|---|---|---|---|---|---|

| [55] | 0.11 0.11 0.11 | 300 kPa (IMEP) 500 kPa (IMEP) 900 kPa (IMEP) | 3000 3000 3000 | - | 50 100 130 | Load washers, crankcase pressure sensor, thermocouple near the cylinder bore surface |

| [45] | 0.449 0.449 | 30 Nm 72 Nm | 2500 2500 | - | 125 370 | Quartz piezoelectric miniature force transducers model 9131B, Kistler Holding AG, 4 accelerometers |

| [56] | 0.496 | 200 kPa (IMEP) | 1500 | - | 35 | piezoelectric sensors, thermocouple on the liner |

| [57] | 0.500 | 600 kPa (IMEP) | 2000 | - | 65 | - |

| [54] | 0.619 0.619 0.619 | No Load No Load No Load | 1000 1500 2000 | 25 25 25 | 280 270 260 | Strain gauge M-M, WK-06-125-AD-350, Pizeo-accelerometer (Brul & kjaer 4393) sensor |

| [54] | 0.619 0.619 0.619 | 100% Load 100% Load 100% Load | 1000 1500 2000 | 25 25 25 | 320 250 270 | Strain gauge M-M, WK-06-125-AD-350, Piezo-accelerometer (Brul & kjaer 4393) sensor |

| [35] | 1.052 | 50% load | 2000 | - | 280 | Load washer |

| [58] | 1.052 | 75% load | 1200 | - | 280 | Load washer |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Youssef, A.M.; Calderbank, G.; Sherrington, I.; Smith, E.H.; Rahnejat, H. A Critical Review of Approaches to the Design of Floating-Liner Apparatus for Instantaneous Piston Assembly Friction Measurement. Lubricants 2021, 9, 10. https://doi.org/10.3390/lubricants9010010

Youssef AM, Calderbank G, Sherrington I, Smith EH, Rahnejat H. A Critical Review of Approaches to the Design of Floating-Liner Apparatus for Instantaneous Piston Assembly Friction Measurement. Lubricants. 2021; 9(1):10. https://doi.org/10.3390/lubricants9010010

Chicago/Turabian StyleYoussef, Abdelrahman M., Graham Calderbank, Ian Sherrington, Edward H. Smith, and Homer Rahnejat. 2021. "A Critical Review of Approaches to the Design of Floating-Liner Apparatus for Instantaneous Piston Assembly Friction Measurement" Lubricants 9, no. 1: 10. https://doi.org/10.3390/lubricants9010010

APA StyleYoussef, A. M., Calderbank, G., Sherrington, I., Smith, E. H., & Rahnejat, H. (2021). A Critical Review of Approaches to the Design of Floating-Liner Apparatus for Instantaneous Piston Assembly Friction Measurement. Lubricants, 9(1), 10. https://doi.org/10.3390/lubricants9010010