Effect of Laser-Textured Groove Patterns on Friction Reduction and Stress Distribution in High-Speed Steel Surfaces

Abstract

1. Introduction

2. Materials and Methods

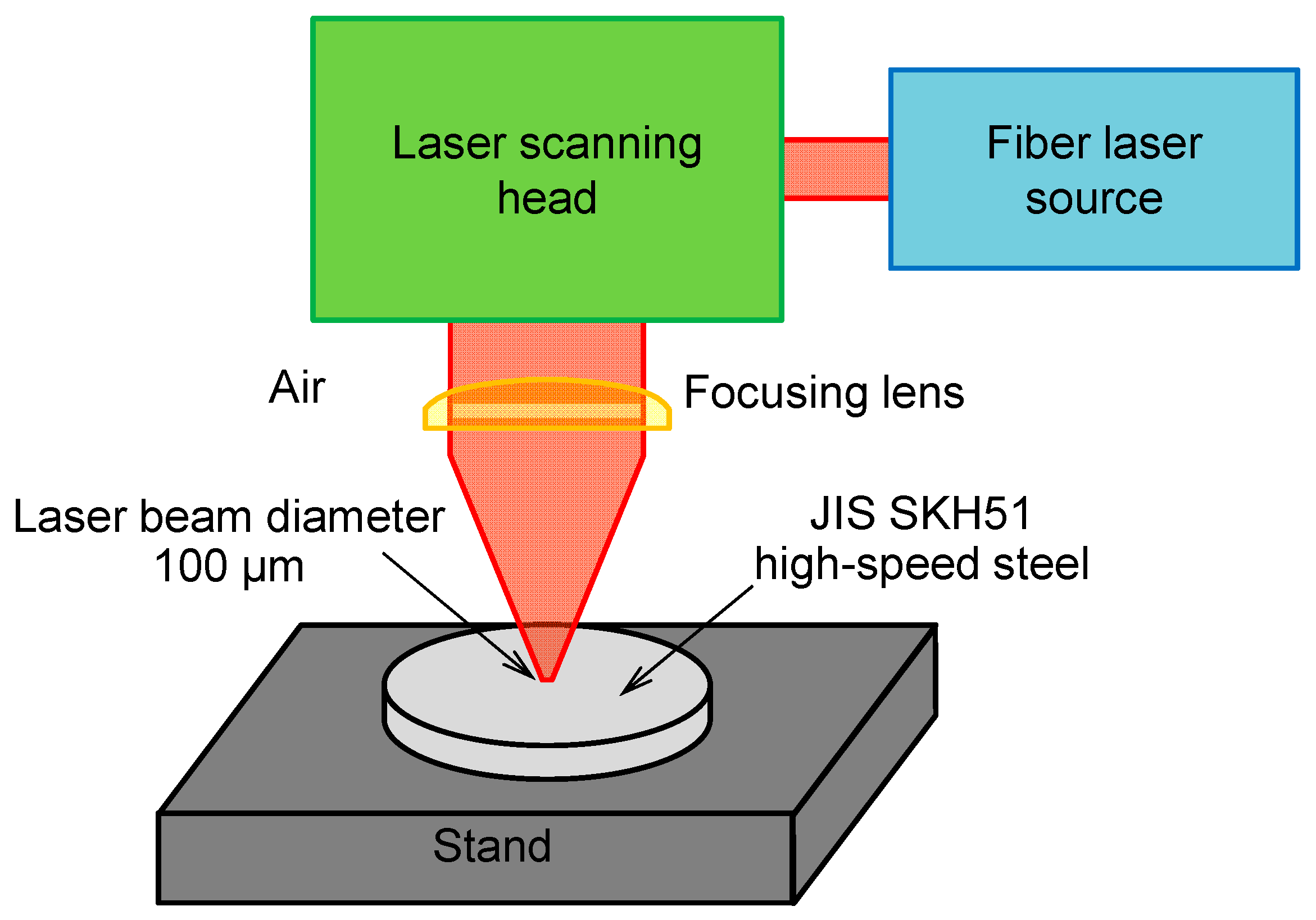

2.1. Micro-Groove Fabrication

2.2. Friction Test

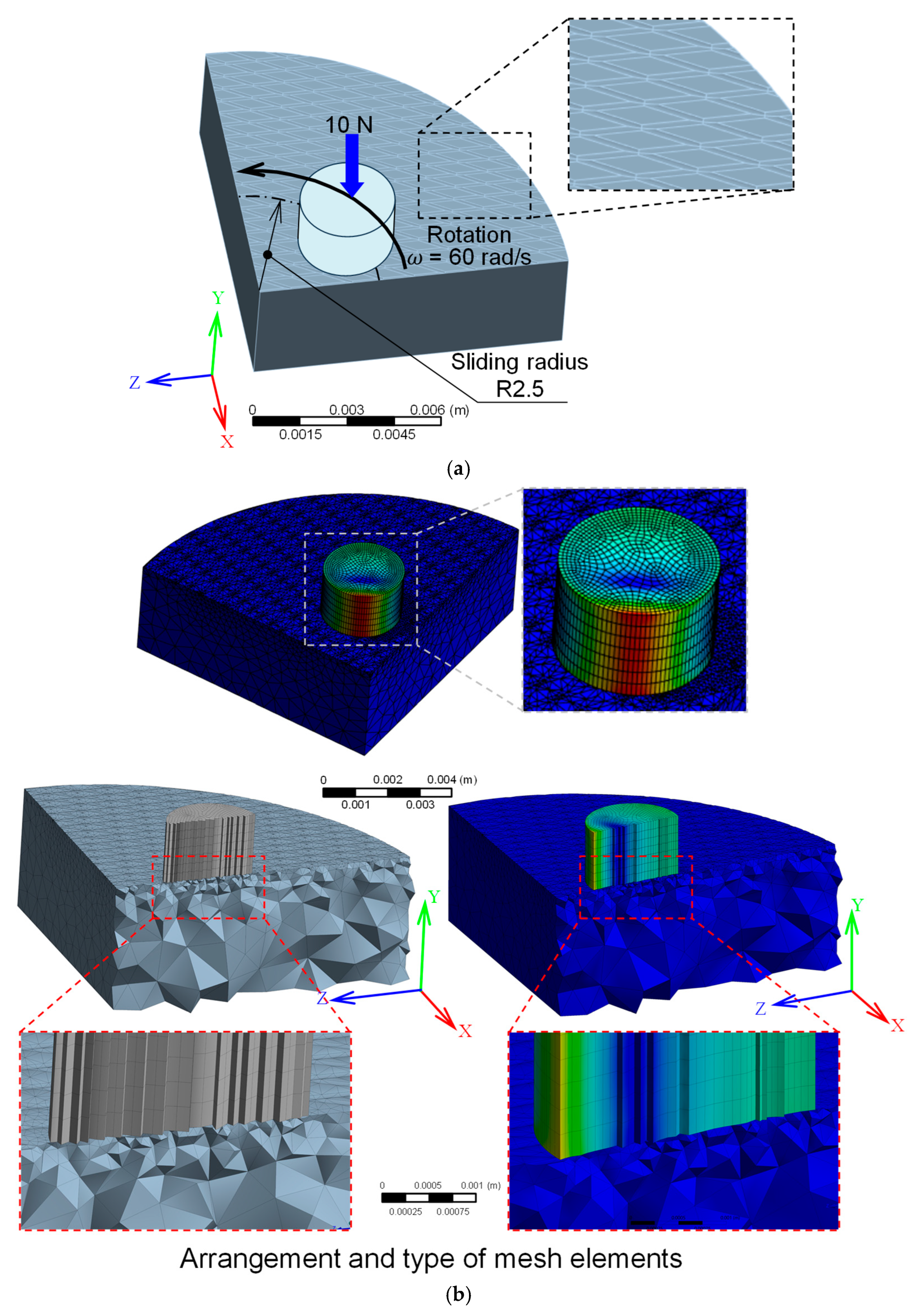

2.3. Numerical Simulation of Pin-on-Disc Test

- •

- Pin constraints: The movement of the pin was allowed in all directions, and the rotational displacement was restricted about the Z- and X- axes while allowing rotation around the disc axis (Y-axis) to simulate the circular sliding motion.

- •

- Disc constraints: The disc was fully constrained in all translational and rotational directions to remain fixed during the simulation, reflecting its stationary role in the model.

- •

- Contact definition: A surface-to-surface contact interaction was defined between the pin and disc using an elastic contact condition and penalty-based tangential contact model to allow frictional sliding. Because the friction force was not the primary focus of the simulation. A constant friction coefficient of 0.25 was assigned to all surface configurations to enable a controlled comparative analysis of the crosshatch angle effects. This represents a simplification of the complex tribological interactions compared to the reality in which friction coefficients vary with contact pressure, sliding velocity, temperature, and lubrication conditions [47,48]. By maintaining identical friction parameters across all cases, the resulting differences in contact pressure and stress distribution can be directly attributed to the surface texture geometry without interference from the varying friction variables [49]. This approach allows for clear isolation of texture-induced effects on contact mechanics.

3. Results and Discussion

3.1. Effect of Laser Power and Number of Passes on Width and Depth of Micro-Grooves

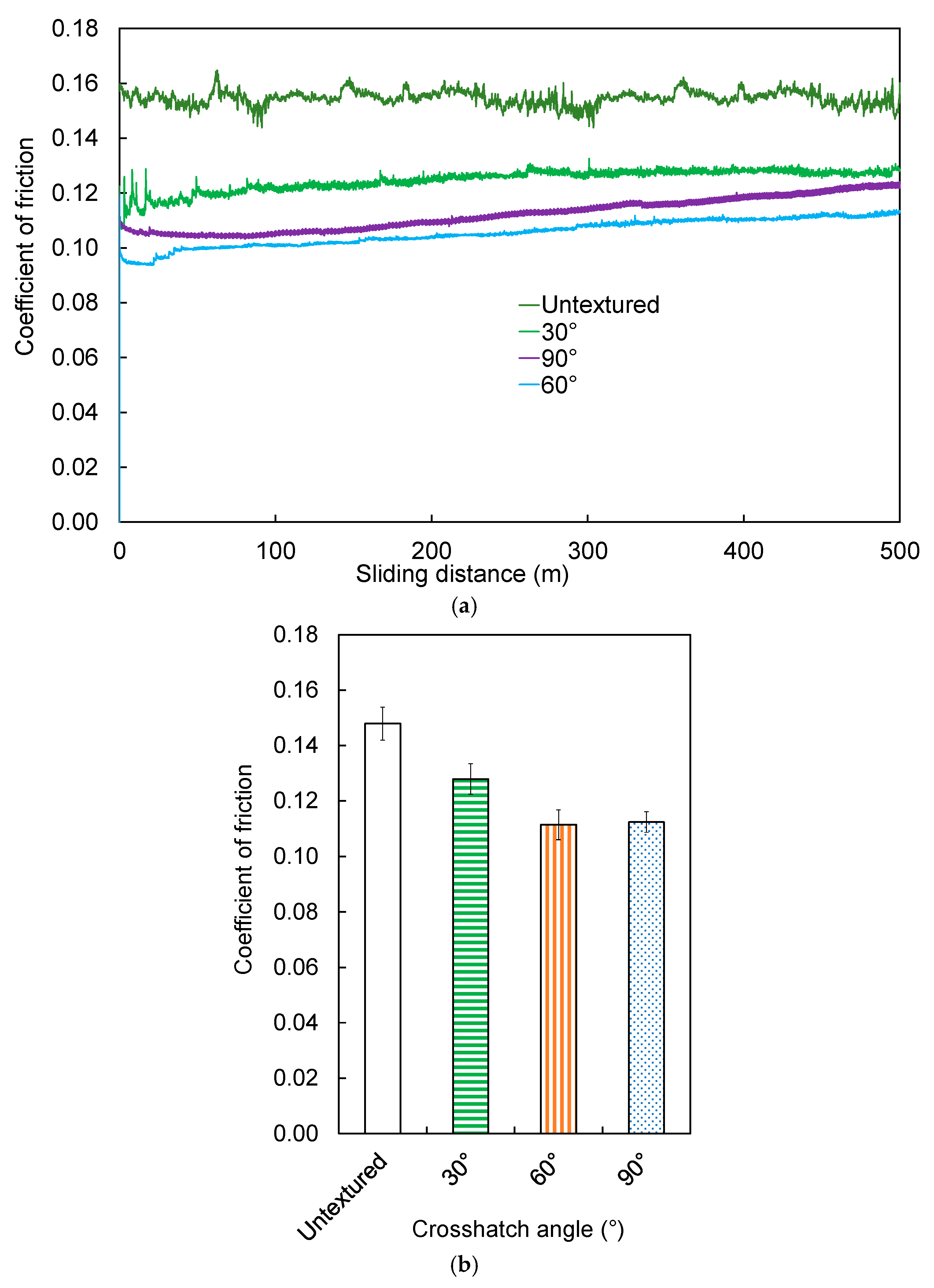

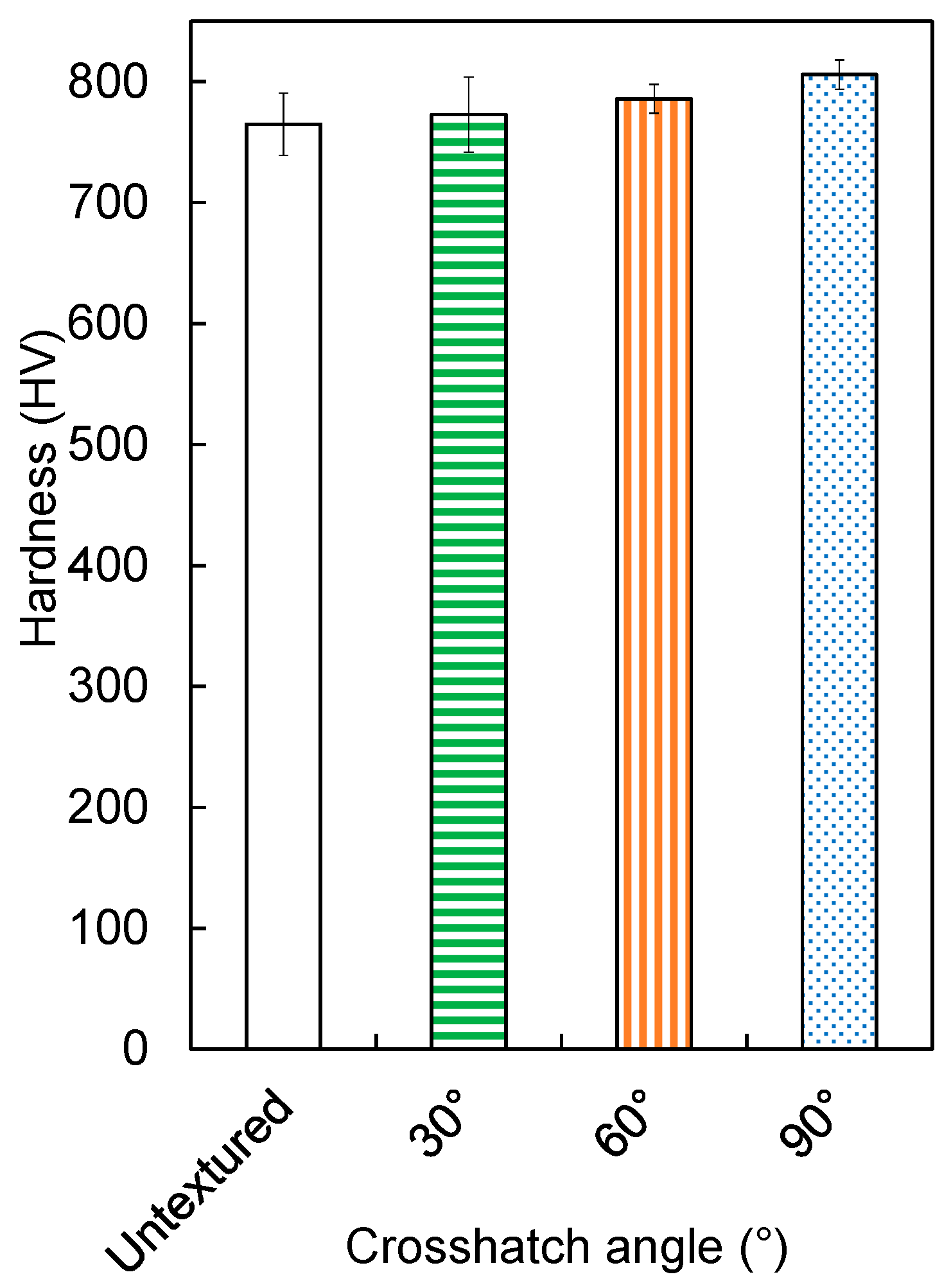

3.2. Effect of Groove Crosshatch Angles on Friction and Wear of High-Speed Steel Surfaces

3.3. Numerical Simulation of Contact Behavior

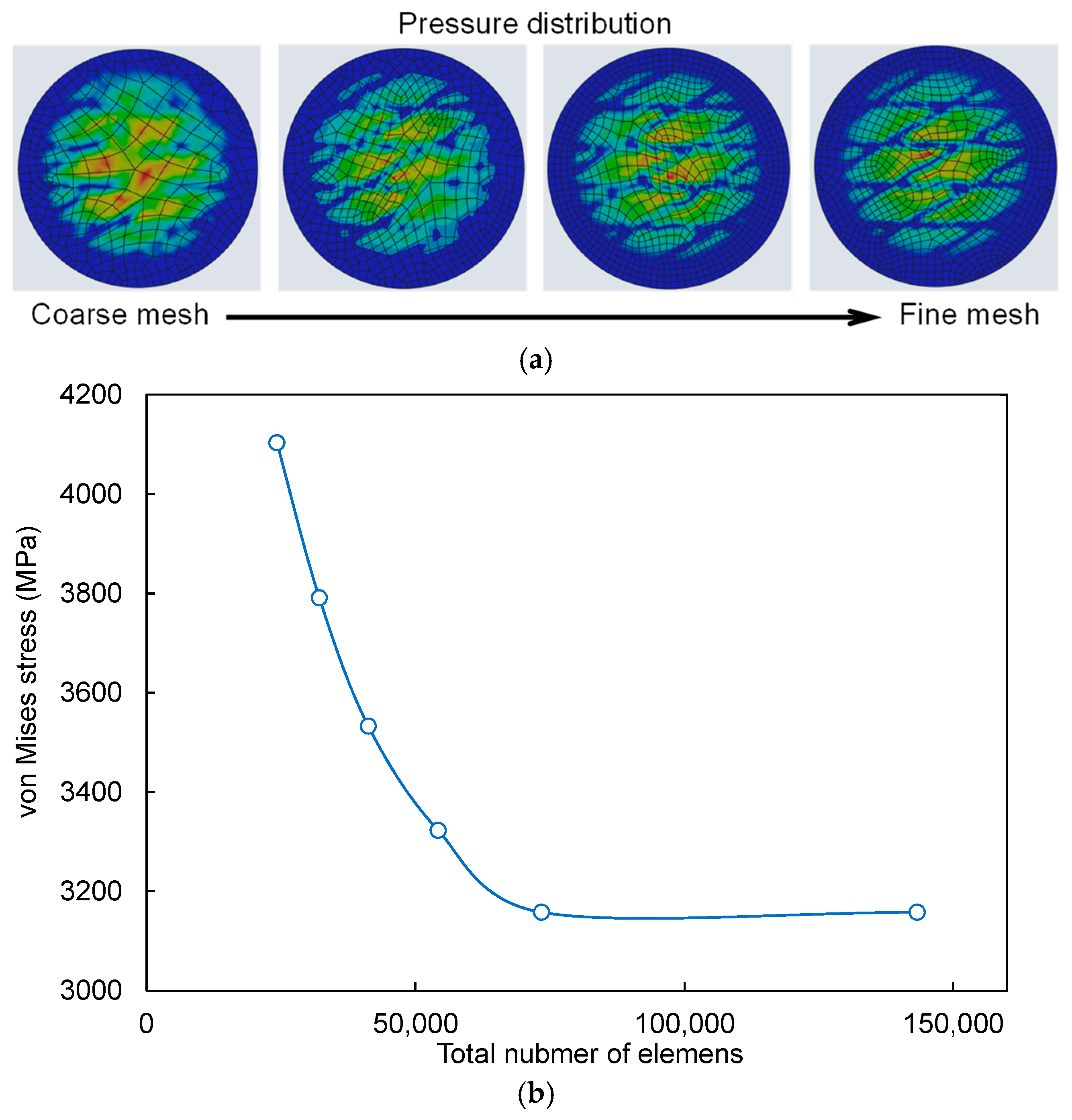

3.3.1. Mesh Independence Study

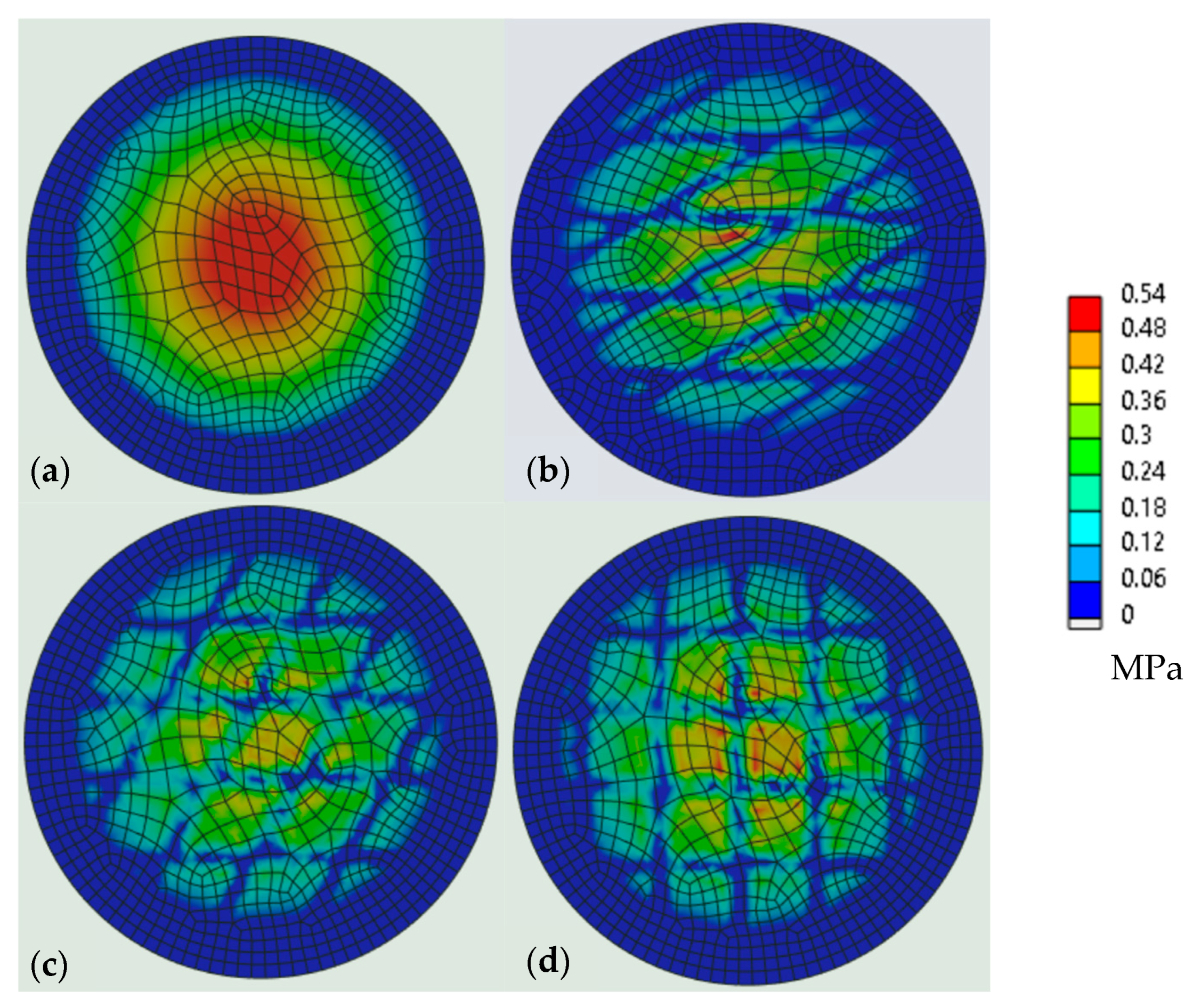

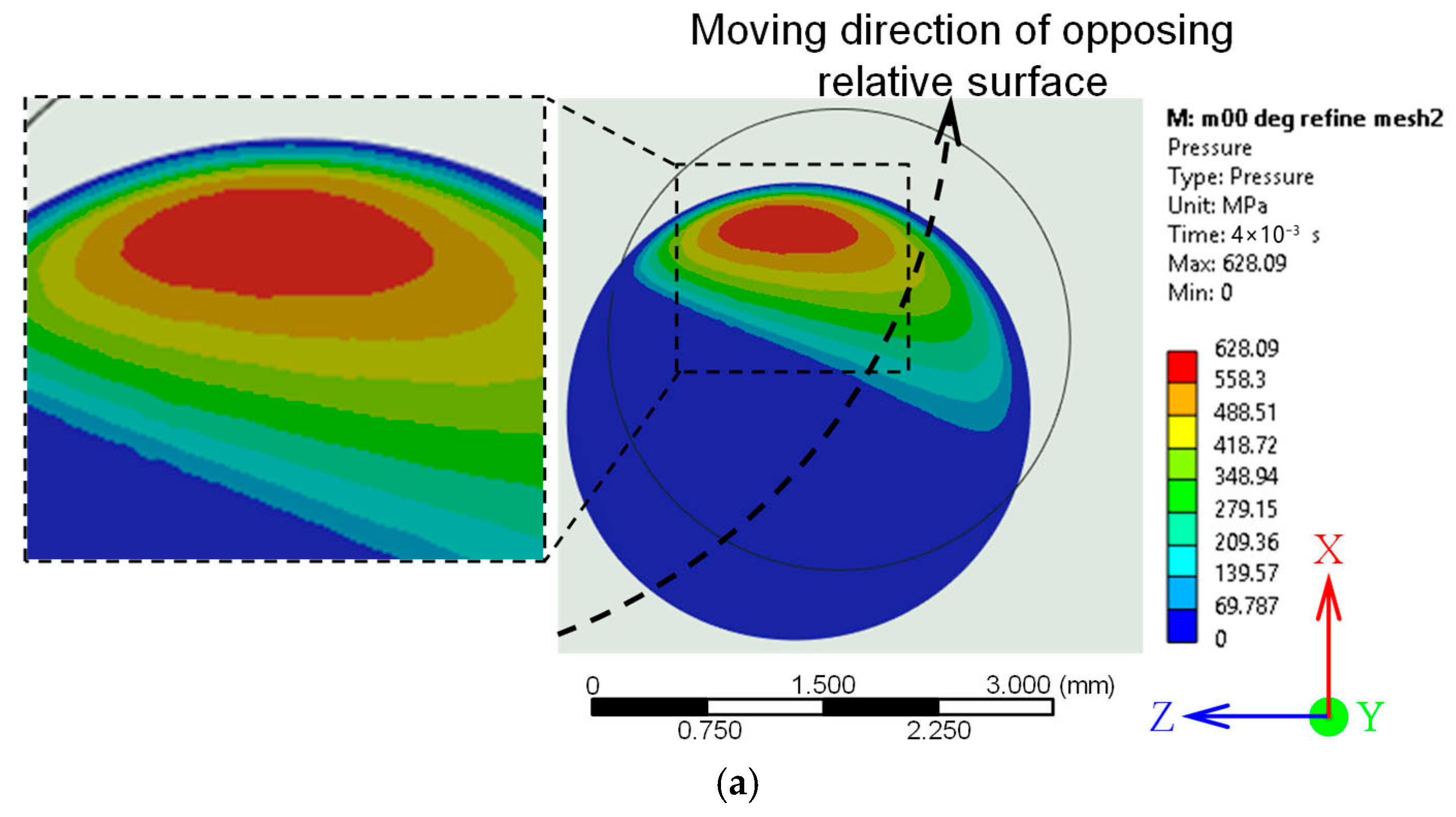

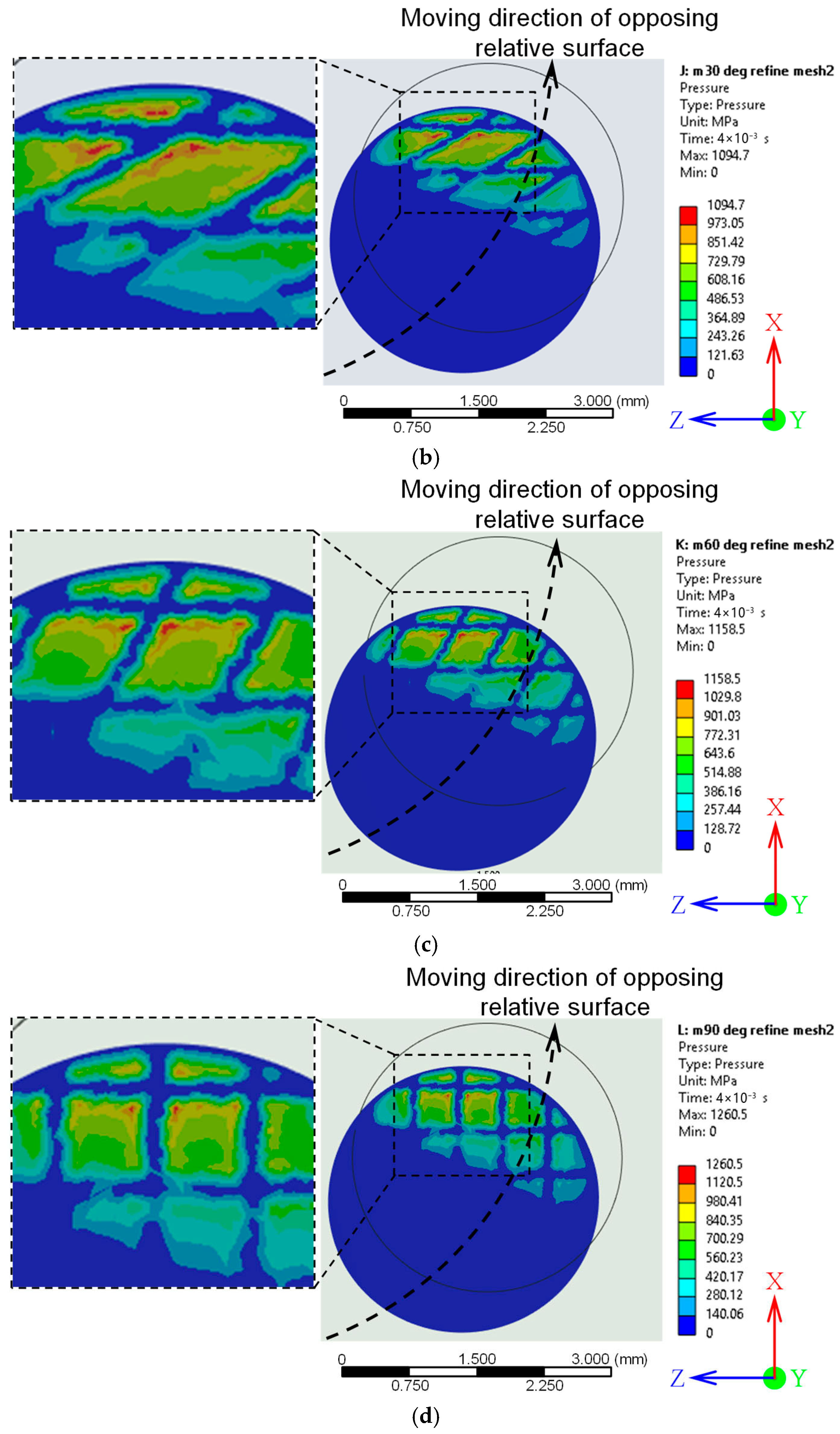

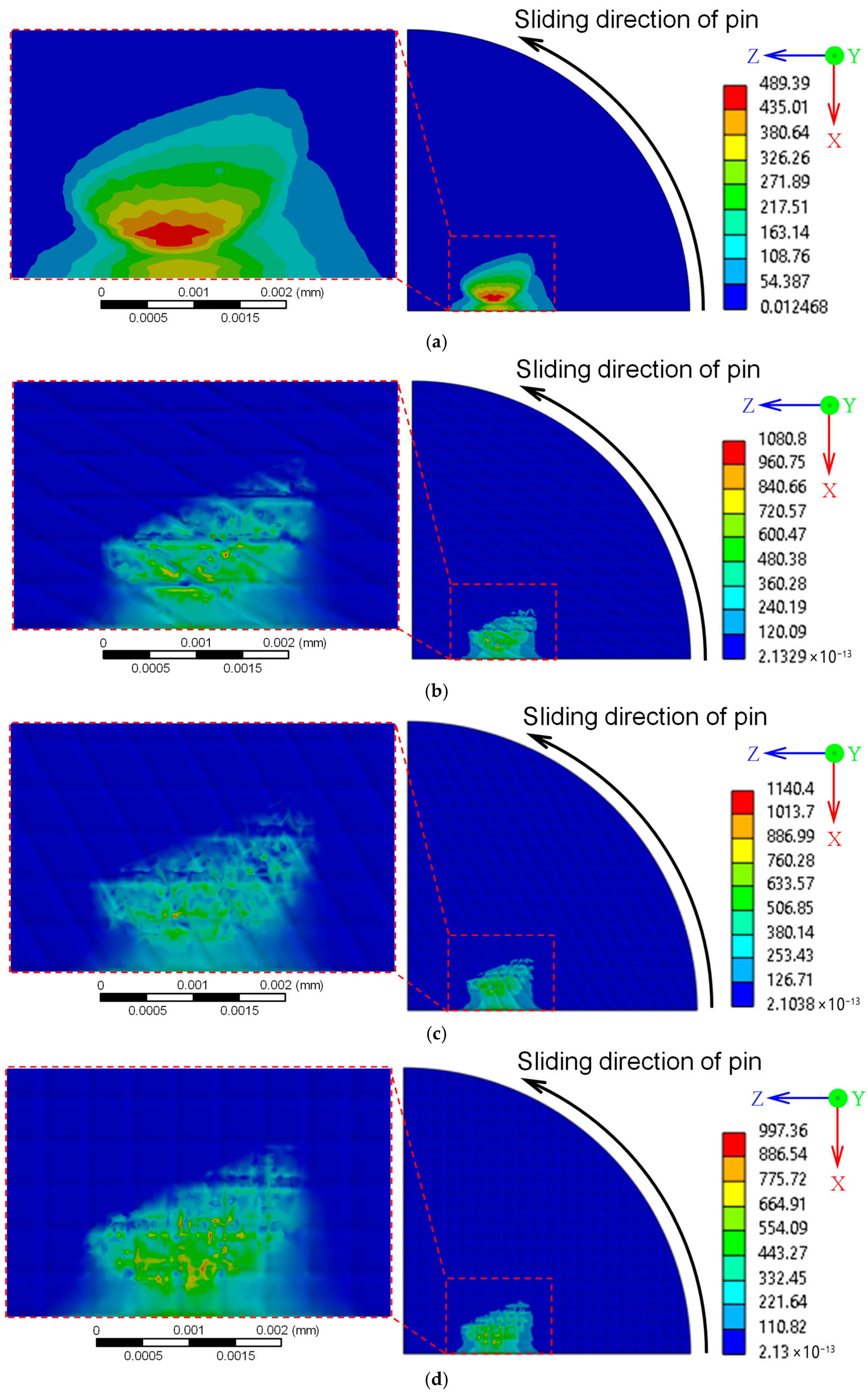

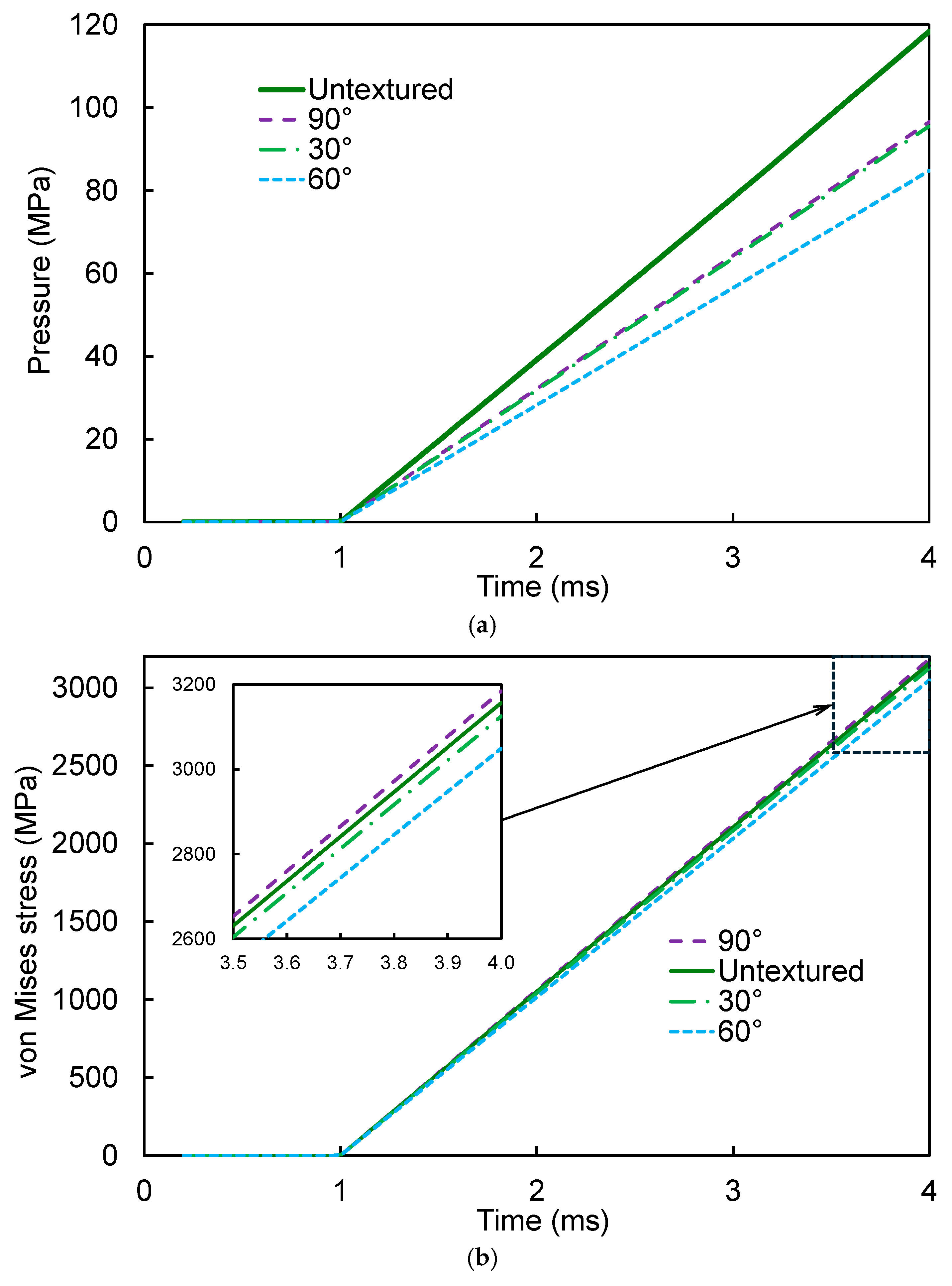

3.3.2. Contact Pressure Distribution and Stress Concentration

4. Conclusions

- (1)

- A higher laser power led to a simultaneous increase in the groove width and depth, whereas increasing the number of passes primarily increased the groove depth with minimal influence on the groove width. The numerical predictions closely matched the experimental measurements, confirming the reliability of the predictive model for groove geometry.

- (2)

- Laser processing at 20 W with three passes produced grooves with an average width of 115.62 μm and a depth of 15.07 μm, resulting in an aspect ratio of 0.13, which is close to the target value of 0.1 with minimal variation.

- (3)

- Among the tested geometries, the 60° crosshatch pattern achieved the lowest average coefficient of friction of 0.111, representing a 25% reduction compared with the untextured surface, which had a friction coefficient of 0.148. It was also superior to the 30° pattern, which had a coefficient of 0.127, and the 90° pattern, which had a friction coefficient of 0.112.

- (4)

- Variations in the crosshatch angle produced small differences in the total contact area but significantly affected the distribution of flat contact zones. A more uniform and well-distributed flat contact area contributed to improved friction performance.

- (5)

- Pin-on-disc testing over a sliding distance of 500 m showed no measurable material loss from the SKH51 surface, with only minor surface scratching observed.

- (6)

- Finite element analysis revealed that the laser-textured surfaces disrupted the uniform pressure distribution of the untextured surfaces, producing heterogeneous, localized high-stress zones along the groove edges. The orientation of laser-textured micro-grooves significantly influenced both average contact pressure and von Mises stress during sliding contact. Among the tested configurations, the 60° crosshatch angle exhibited the lowest average contact pressure (84.79 MPa) and average von Mises stress (3048.9 MPa), with a reduction in contact pressure of approximately 28% compared to the untextured surface (118.38 MPa). The 60° crosshatch pattern provided the most balanced combination of load redistribution, reduced mean pressure and average stress, which may reduce friction during service.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Nielsen, C.V.; Bay, N. Review of Friction Modeling in Metal Forming Processes. J. Mater. Process. Technol. 2018, 255, 234–241. [Google Scholar] [CrossRef]

- Tamaoki, K.; Manabe, K.; Kataoka, S.; Aizawa, T. Continuous Dry Cylindrical and Rectangular Deep Drawing by Electroconductive Ceramic Dies. J. Manuf. Sci. Eng. 2013, 135, 031010. [Google Scholar] [CrossRef]

- Abe, Y.; Mori, K.; Hatashita, F.; Shiba, T.; Daodon, W.; Osakada, K. Improvement of Seizure Resistance in Ironing of Stainless Steel Cup with Cermet Die Having Fine Lubricant Pockets. J. Mater. Process. Technol. 2016, 234, 195–207. [Google Scholar] [CrossRef]

- Zhai, W.; Bai, L.; Zhou, R.; Fan, X.; Kang, G.; Liu, Y.; Zhou, K. Recent Progress on Wear-Resistant Materials: Designs, Properties, and Applications. Adv. Sci. 2021, 8, 2003739. [Google Scholar] [CrossRef] [PubMed]

- Hacisalihoglu, I.; Yildiz, F.; Alsaran, A. Wear Performance of Different Nitride-Based Coatings on Plasma Nitrided AISI M2 Tool Steel in Dry and Lubricated Conditions. Wear 2017, 384–385, 159–168. [Google Scholar] [CrossRef]

- Kumar, A.; Kaur, M.; Joseph, A.; Jhala, G. Surface Engineering Analysis of Plasma-Nitrided Die Steels. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2019, 234, 917–931. [Google Scholar] [CrossRef]

- Podgornik, B.; Hogmark, S.; Sandberg, O. Proper Coating Selection for Improved Galling Performance of Forming Tool Steel. Wear 2006, 261, 15–21. [Google Scholar] [CrossRef]

- Trzepieciński, T. Approaches for Preventing Tool Wear in Sheet Metal Forming Processes. Machines 2023, 11, 616. [Google Scholar] [CrossRef]

- Bay, N.; Azushima, A.; Groche, P.; Ishibashi, I.; Merklein, M.; Morishita, M.; Nakamura, T.; Schmid, S.; Yoshida, M. Environmentally Benign Tribo-Systems for Metal Forming. CIRP Ann. 2010, 59, 760–780. [Google Scholar] [CrossRef]

- Adamus, J.; Więckowski, W.; Lacki, P. Analysis of the Effectiveness of Technological Lubricants with the Addition of Boric Acid in Sheet Metal Forming. Materials 2023, 16, 5125. [Google Scholar] [CrossRef]

- Dhage, S.; Jayal, A.D.; Sarkar, P. Effects of Surface Texture Parameters of Cutting Tools on Friction Conditions at Tool-Chip Interface during Dry Machining of AISI 1045 Steel. Procedia Manuf. 2019, 33, 794–801. [Google Scholar] [CrossRef]

- Guo, D.; Wang, D.; Wu, S.; Qi, H.; Saetang, V. Investigation on Turning of Inconel 718 Using Differently Coated Microtextured Tools. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2025, 239, 754–764. [Google Scholar] [CrossRef]

- Etsion, I. State of the Art in Laser Surface Texturing. J. Tribol. 2005, 127, 248. [Google Scholar] [CrossRef]

- Costa, H.L.; Hutchings, I.M. Effects of Die Surface Patterning on Lubrication in Strip Drawing. J. Mater. Process. Technol. 2009, 209, 1175–1180. [Google Scholar] [CrossRef]

- Tang, W.; Zhou, Y.; Zhu, H.; Yang, H. The Effect of Surface Texturing on Reducing the Friction and Wear of Steel under Lubricated Sliding Contact. Appl. Surf. Sci. 2013, 273, 199–204. [Google Scholar] [CrossRef]

- Byun, J.W.; Shin, H.S.; Kwon, M.H.; Kim, B.H.; Chu, C.N. Surface Texturing by Micro ECM for Friction Reduction. Int. J. Precis. Eng. Manuf. 2010, 11, 747–753. [Google Scholar] [CrossRef]

- Costa, H.; Hutchings, I. Some Innovative Surface Texturing Techniques for Tribological Purposes. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2014, 229, 429–448. [Google Scholar] [CrossRef]

- Mankeekar, T.; Bähre, D.; Durneata, D.; Hall, T.; Lilischkis, R.; Natter, H.; Saumer, M. Fabrication of Micro-Structured Tools for the Production of Curved Metal Surfaces by Pulsed Electrochemical Machining. Int. J. Adv. Manuf. Technol. 2021, 119, 2825–2833. [Google Scholar] [CrossRef]

- Zhu, H.; Jiang, Z.; Han, J.; Saetang, V.; Xu, K.; Liu, Y.; Zhang, Z.; Huang, S.; Zhou, J. Fabrication of Oxide-Free Dimple Structure on Germanium via Electrochemical Jet Machining Enhanced by Opposing Laser Irradiation. J. Manuf. Process. 2022, 85, 623–635. [Google Scholar] [CrossRef]

- Singh, M.; Jain, V.K.; Ramkumar, J. Micro-Texturing on Flat and Cylindrical Surfaces Using Electric Discharge Micromachining. J. Micromanuf. 2020, 4, 127–137. [Google Scholar] [CrossRef]

- Su, X.; Shi, L.; Huang, W.; Wang, X. A Multi-Phase Micro-Abrasive Jet Machining Technique for the Surface Texturing of Mechanical Seals. Int. J. Adv. Manuf. Technol. 2016, 86, 2047–2054. [Google Scholar] [CrossRef]

- Kasem, H.; Stav, O.; Grützmacher, P.; Gachot, C. Effect of Low Depth Surface Texturing on Friction Reduction in Lubricated Sliding Contact. Lubricants 2018, 6, 62. [Google Scholar] [CrossRef]

- Mao, B.; Siddaiah, A.; Liao, Y.; Menezes, P.L. Laser Surface Texturing and Related Techniques for Enhancing Tribological Performance of Engineering Materials: A Review. J. Manuf. Process. 2020, 53, 153–173. [Google Scholar] [CrossRef]

- Daodon, W.; Saetang, V. Improvement of Frictional Property of AISI D2 Tool Steel Surface against JIS SPFC 980Y Advanced High-Strength Steel by Using Laser Texturing Process. Lubricants 2023, 11, 68. [Google Scholar] [CrossRef]

- Kovalchenko, A.; Ajayi, O.; Erdemir, A.; Fenske, G.; Etsion, I. The Effect of Laser Surface Texturing on Transitions in Lubrication Regimes during Unidirectional Sliding Contact. Tribol. Int. 2005, 38, 219–225. [Google Scholar] [CrossRef]

- Ryk, G.; Etsion, I. Testing Piston Rings with Partial Laser Surface Texturing for Friction Reduction. Wear 2006, 261, 792–796. [Google Scholar] [CrossRef]

- Wang, S.; Wang, W.; Xu, Y.; Zhang, X.; Chen, C.; Geng, P.; Ma, N. Effect of Nanosecond Pulsed Laser Parameters on Texturing Formation of Metallic Surface: Experiment and Modelling. J. Mater. Res. Technol. 2023, 26, 7775–7788. [Google Scholar] [CrossRef]

- Zhu, H.; Shen, Y.; Sun, H.; Zhang, Z.; Jin, C.; Ge, S.; Xu, K.; Liu, Y.; Wang, J.; Gu, Q. Ultrafast Laser-Driven Precision Removal of Silver Coatings on Ceramic Substrates: Synergistic Experimental Investigation and TTM Simulation. Int. J. Heat Mass Transf. 2026, 255, 127758. [Google Scholar] [CrossRef]

- Zhu, H.; Mao, D.; Lu, X.; Zhang, Z.; Xu, K.; Liu, Y.; Wang, J.; Saetang, V. Synergistic Post-Processing of Micro-Through-Slot Sidewalls in Si Wafers via Hybrid Laser-Electrochemical-Abrasive Method: Mechanism Investigation and Process Simulation. J. Manuf. Process. 2025, 149, 486–501. [Google Scholar] [CrossRef]

- Fouathiya, A.; Meziani, S.; Sahli, M.; Barrière, T. Experimental Investigation of Microtextured Cutting Tool Performance in Titanium Alloy via Turning. J. Manuf. Process. 2021, 69, 33–46. [Google Scholar] [CrossRef]

- Schneider, J.; Braun, D.; Greiner, C. Laser Textured Surfaces for Mixed Lubrication: Influence of Aspect Ratio, Textured Area and Dimple Arrangement. Lubricants 2017, 5, 32. [Google Scholar] [CrossRef]

- Geiger, M.; Popp, U.; Engel, U. Excimer Laser Micro Texturing of Cold Forging Tool Surfaces-Influence on Tool Life. CIRP Ann. 2002, 51, 231–234. [Google Scholar] [CrossRef]

- Popp, U.; Engel, U. Microtexturing of Cold-Forging Tools-Influence on Tool Life. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2006, 220, 27–33. [Google Scholar] [CrossRef]

- Wagner, K.; Völkl, R.; Engel, U. Tool Life Enhancement in Cold Forging by Locally Optimized Surfaces. J. Mater. Process. Technol. 2008, 201, 2–8. [Google Scholar] [CrossRef]

- Meng, F.; Zhou, R.; Davis, T.; Cao, J.; Wang, Q.J.; Hua, D.; Liu, J. Study on Effect of Dimples on Friction of Parallel Surfaces under Different Sliding Conditions. Appl. Surf. Sci. 2010, 256, 2863–2875. [Google Scholar] [CrossRef]

- Wang, Z.; Li, Y.; Bai, F.; Wang, C.; Zhao, Q. Angle-Dependent Lubricated Tribological Properties of Stainless Steel by Femtosecond Laser Surface Texturing. Opt. Laser Technol. 2016, 81, 60–66. [Google Scholar] [CrossRef]

- Wang, H.; Tian, L.; Zheng, J.; Yang, D.; Zhang, Z. The Synergetic Effects of Laser Texturing and Super-Hydrophobic Coatings on Improving Wear Properties of Steel. Tribol. Int. 2022, 173, 107657. [Google Scholar] [CrossRef]

- Wu, Z.; Yuan, C.; Guo, Z.; Huang, Q. Effect of the Groove Parameters on the Lubricating Performance of the Water-Lubricated Bearing under Low Speed. Wear 2023, 522, 204708. [Google Scholar] [CrossRef]

- Meng, R.; Deng, J.; Duan, R.; Liu, Y.; Zhang, G. Modifying Tribological Performances of AISI 316 Stainless Steel Surfaces by Laser Surface Texturing and Various Solid Lubricants. Opt. Laser Technol. 2019, 109, 401–411. [Google Scholar] [CrossRef]

- Segu, D.Z.; Chae, Y.; Lee, S.-J.; Kim, C.-L. Synergistic Influences of Laser Surface Texturing and ZrO2-MoDTC Hybrid Nanofluids for Enhanced Tribological Performance. Tribol. Int. 2023, 183, 108377. [Google Scholar] [CrossRef]

- Niu, Y.; Pang, X.; Yue, S.; Shangguan, B.; Zhang, Y. The Friction and Wear Behavior of Laser Textured Surfaces in Non-Conformal Contact under Starved Lubrication. Wear 2021, 476, 203723. [Google Scholar] [CrossRef]

- Phun, C.; Daodon, W.; Septham, K.; Kumkhuntod, P.; Zhu, H.; Saetang, V. Laser-Fabricated Micro-Dimples for Improving Frictional Property of SKH51 Tool Steel Surfaces. Lubricants 2023, 11, 456. [Google Scholar] [CrossRef]

- Online Materials Information Resource–MatWeb. Available online: http://www.matweb.com (accessed on 24 December 2024).

- Karunathilaka, N.; Tada, N.; Uemori, T.; Hanamitsu, R.; Kawano, M. Effect of Contact Pressure Applied on Tool Surface during Cold Forging on Fatigue Life of Tool Steel. Procedia Manuf. 2018, 15, 488–495. [Google Scholar] [CrossRef]

- Properties and Selection: Irons, Steels, and High-Performance Alloys. In Metals Handbook, 10th ed.; ASM International: Materials Park, OH, USA, 1990; Volume 1.

- Torres Pérez, A.; García-Atance Fatjó, G.; Hadfield, M.; Austen, S. A Model of Friction for a Pin-On-Disc Configuration with Imposed Pin Rotation. Mech. Mach. Theory 2011, 46, 1755–1772. [Google Scholar] [CrossRef]

- Bhushan, B. Modern Tribology Handbook/Vol. 1, Principles of Tribology; CRC Press LLC: Boca Raton, FL, USA, 2001. [Google Scholar]

- Zmitrowicz, A. Models of Kinematics Dependent Anisotropic and Heterogeneous Friction. Int. J. Solids Struct. 2006, 43, 4407–4451. [Google Scholar] [CrossRef]

- Greenwood, J.A.; Williamson, J.B.P. Contact of Nominally Flat Surfaces. Proc. R. Soc. Lond. Ser. A. Math. Phys. Sci. 1966, 295, 300–319. [Google Scholar] [CrossRef]

- Etsion, I.; Halperin, G.; Brizmer, V.; Kligerman, Y. Experimental Investigation of Laser Surface Textured Parallel Thrust Bearings. Tribol. Lett. 2004, 17, 295–300. [Google Scholar] [CrossRef]

- Abe, Y.; Sugiura, M.; Ando, T.; Kumkhuntod, P.; Septham, K.; Daodon, W.; Mori, K. Improvement of Seizure Resistance in Ironing of Aluminum Alloy Sheets and Stainless Steel Cups by Utilizing Laser Textured Die Having Lubricant Pockets. Metals 2023, 13, 803. [Google Scholar] [CrossRef]

- Shimizu, T.; Kobayashi, H.; Vorholt, J.; Yang, M. Lubrication Analysis of Micro-Dimple Textured Die Surface by Direct Observation of Contact Interface in Sheet Metal Forming. Metals 2019, 9, 917. [Google Scholar] [CrossRef]

- Yuan, S.; Huang, W.; Wang, X. Orientation Effects of Micro-Grooves on Sliding Surfaces. Tribol. Int. 2011, 44, 1047–1054. [Google Scholar] [CrossRef]

- Wang, X.; Wang, J.; Zhang, B.; Huang, W. Design Principles for the Area Density of Dimple Patterns. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2014, 229, 538–546. [Google Scholar] [CrossRef]

| Properties | JIS SKH51 | AISI 304 | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Modulus of elasticity (GPa) | 207 | 193 | ||||||||||

| Poisson’s ratio | 0.29 | 0.29 | ||||||||||

| Densities (10−3 g/mm3) | 8.14 | 8.00 | ||||||||||

| Tensile strength (MPa) | 2302 | 505 | ||||||||||

| Yield strength (MPa) | 1600 | 215 | ||||||||||

| Hardness (HV) | 783 | 129 | ||||||||||

| Chemical composition (wt.%) | ||||||||||||

| C | Si | Mn | P | S | Cr | Mo | W | V | Ni | |||

| JIS SKH51 | 0.80–0.88 | max 0.45 | max 0.40 | max 0.03 | max 0.03 | 3.8−4.5 | 4.7−5.2 | 5.9−6.7 | 1.7–2.1 | - | ||

| AISI 304 | 0.08 | 0.60 | 1.50 | - | - | 18.5 | - | - | - | 10 | ||

| Parameter | Value |

|---|---|

| Laser wavelength (nm) | 1064 |

| Laser pulse duration, τ (ns) | 100 |

| Laser pulse repetition rate, f (kHz) | 100 |

| Laser scanning speed, v (mm/s) | 10 |

| Laser beam diameter at 1/e2 (μm) | 100 |

| Average laser power, P (W) | 10, 15, 20 and 25 |

| Number of passes, n | 1 and 3 |

| Friction Test | |

|---|---|

| Disk material | JIS SKH51 |

| Pin material | AISI 304 |

| Sliding speed (mm/s) | 150 |

| Sliding distance (m) | 500 |

| Groove densities (%) | 36 |

| Crosshatch angle (°) | 30, 60 and 90 |

| Normal load (N) | 10 |

| Total Number of Elements | Von Mises Stress (MPa) | Error (%) |

|---|---|---|

| 24,231 | 4103.28 | - |

| 32,120 | 3791.26 | 8.230 |

| 41,234 | 3532.67 | 7.320 |

| 54,231 | 3322.68 | 6.320 |

| 73,425 | 3157.84 | 5.220 |

| 143,294 | 3157.80 | 0.001 |

| Crosshatch Angles (°) | Average Pressure (MPa) | Average Von Mises Stress (MPa) |

|---|---|---|

| Untextured | 118.38 | 3156.9 |

| 30 | 95.53 | 3125.0 |

| 60 | 84.79 | 3048.9 |

| 90 | 96.52 | 3184.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Saetang, V.; Vengsungnle, P.; Zhu, H.; Qi, H.; Maskong, H.; Daodon, W. Effect of Laser-Textured Groove Patterns on Friction Reduction and Stress Distribution in High-Speed Steel Surfaces. Lubricants 2025, 13, 419. https://doi.org/10.3390/lubricants13090419

Saetang V, Vengsungnle P, Zhu H, Qi H, Maskong H, Daodon W. Effect of Laser-Textured Groove Patterns on Friction Reduction and Stress Distribution in High-Speed Steel Surfaces. Lubricants. 2025; 13(9):419. https://doi.org/10.3390/lubricants13090419

Chicago/Turabian StyleSaetang, Viboon, Ponthep Vengsungnle, Hao Zhu, Huan Qi, Haruetai Maskong, and Witthaya Daodon. 2025. "Effect of Laser-Textured Groove Patterns on Friction Reduction and Stress Distribution in High-Speed Steel Surfaces" Lubricants 13, no. 9: 419. https://doi.org/10.3390/lubricants13090419

APA StyleSaetang, V., Vengsungnle, P., Zhu, H., Qi, H., Maskong, H., & Daodon, W. (2025). Effect of Laser-Textured Groove Patterns on Friction Reduction and Stress Distribution in High-Speed Steel Surfaces. Lubricants, 13(9), 419. https://doi.org/10.3390/lubricants13090419