1. Introduction

The analysis of structural changes in colloidal systems determined by the interpretation of changes in viscoelastic properties during mechanical excitations is important due to the durability and stability of these systems. The explanation of the mechanisms of interaction of individual elements of the colloidal system and determination of the kinetics of structural changes under the influence of mechanical excitations will allow the determination of rheological parameters characterising structural changes and will contribute to acquiring new knowledge about the characteristics of structural changes in colloidal systems. Finding a correlation between lubricant components and changes in their structure as a result of interactions occurring under the influence of mechanical forces will contribute to the identification of mechanisms of these interactions. So far, the literature has described the interactions between the components of simple colloidal systems that characterise changes in their structure under the influence of small mechanical, temperature, or variable chemical constraints. However, analysing and describing the mechanism of changes in the chemical structure of multi-component colloidal systems under the influence of high loads and large temperature changes can be an important contribution to the development of science about the chemical structure of colloidal systems. Identifying changes in the structure of lubricants will allow us to broaden the knowledge about processes affecting the formation of the structure during mechanical excitations of substances with varied chemical composition [

1,

2,

3].

It was assumed that the components of colloidal systems may be converted under the influence of mechanical excitations performed in tests carried out in the technological system, and the emerging new chemical compounds may change the chemical structure. Identification and description of mechanisms of changes in the chemical structure of the studied systems will be a research problem of this application. The full identification of changes in the structure of colloidal systems under the influence of mechanical excitations can only be realised through the use of complementary research techniques.

The innovative nature of the research will consist of assessing the change in rheological properties of lubricants determined using diffusion microrheology (DWS). On the basis of changes in rheological parameters, the change in the chemical structure of the tested lubricants will be assessed. The characteristics of changes in the chemical structure of the tested materials after mechanical and thermal excitations using rheological tests are an innovative method of assessing the quality of lubricants.

Diffusion spectroscopy DWS is used to study liquid and solid samples in a wide range of frequencies and viscoelasticity. It uses the technique of a diffusing wave to study optically turbid media. It allows the measurement of the dynamics of samples and local intermolecular displacements. In transmission mode, scattered light is detected after passing through an L-shaped cuvette. The time fluctuations of the detected intensity are measured using the ICF correlation intensity function. However, in the back-scattering mode, the light scatters towards the incident beam, and its fluctuations are measured [

3,

4].

The module of elasticity and viscosity is calculated from the MSD function by means of a generalised Stokes–Einstein equation with the knowledge of the radius of the molecule/marker. The MSD correlation function is determined on the basis of coordinates of the phase particles dispersed at a given time and related to the value of the diffusion coefficient with the following relationship: <Δr

2(t)> = 4 Dt [

5,

6,

7]. Knowledge of the MSD correlation function allows for determining the diffusion coefficient in the tested liquid, and, consequently, for calculating the viscosity of the studied liquid. For non-Newtonian liquids, the dependence of the MSD correlation function on time is not a straight line. For samples exhibiting elastic properties, the MSD function is constant, i.e., independent of time. For Newtonian liquids, the correlation function is linearly time-dependent. While for viscoelastic liquids, the slope of the MSD function assumes intermediate values between viscous and elastic properties, and the slope coefficient of the curve assumes the value of 0 < n < 1. The MSD function is characterised by the occurrence of the so-called

plateau, for which the value of thermal energy is equal to the cumulated energy in the structure of the studied substance. The location of the plateau indicates the size of the elastic properties of the medium being tested. The smaller the value of the plateau, the more elastic the tested sample.

Studies conducted using optical microrheometry (DWS) give a lot of valuable information about the changes occurring in the dispersion microstructure, characterise its stability, and allow monitoring of the quality of dispersion systems in changing conditions. They ensure not only the correlative knowledge of dispersion stability but also lead to a deeper understanding of the dispersion microstructure.

Changes in the physical properties of the emulsion are characterised by diffusion spectroscopy [

8,

9,

10]. There are many cases of using this technique to evaluate rheological properties to monitor and predict the dispersion stability and changes in the emulsion microstructure [

11,

12]. This technique can also be successfully applied to characterise ceramic sludges, colloidal suspensions, and biopolymer gels, such as yoghurt [

13,

14,

15]. Using diffusion spectroscopy, information on the quantitative transition of sol into gel, viscoelastic properties, and characteristics of changes in the microstructure of aluminium oxide suspensions can be obtained [

13]. It was also used to monitor changes in the mechanical properties of soft composite materials, such as dispersions, latex polystyrene gels, casein gels, and biopolymer solutions [

16]. And also to study the movement of particles in concentrated fluids, such as colloids or microemulsions, characterised by high dispersion of particles [

17]. Using the DWS technique, research was also conducted, which gave a number of interesting pieces of information about the heterogeneity of biopolymer materials [

18].

Diffusion microrheology was used to assess the quality changes in dextran solutions. The G’ and G” modules were determined from frequency. The results of the discussed parameters were used to assess changes in the structure of the tested solutions [

19]. The DWS technique was used to assess the temperature-dependent gelling process in colloidal dispersions. The change in the structure of colloidal dispersions with temperature was determined, the gelation point was determined, and the rate of aggregation of particles suspended in the dispersion was studied. The viscoelastic properties were discussed using the Maxwell and Kelvin–Voigt models [

20]. Optical microrheology can be used to determine the dynamics of particle motion, changing the structure and mechanical properties of dual emulsions based on the value of the MSD function in time and changes in the G’ and G” module values from frequency in order to facilitate the understanding of emulsion destabilisation processes [

1]. Optical microrheology was used to assess the rheological and microstructural characteristics of submicron emulsions deposited on a modified matrix based on waxy maize starch. Based on the results of the MSD curve in time and the G’ and G” modules on frequency, the change in structure of the studied emulsion was assessed, and the structure destabilisation mechanism was confirmed [

21]. Optical microrheology is also used to study the dynamics and structure of complex fluids. Based on the changes in the G’ and G” module values on frequency, the changes in the structural properties of the colloidal dispersions, polymers, and biomaterials were assessed. Dynamic phenomena related to the tested fluid were evaluated, and relaxation modes of the adsorbed polymers were also studied [

22]. Microrheology properties of complex fluids and gels can be characterised using optical microrheology. Structural changes were evaluated based on the results of the G’ and G” modules. It was found that the results of the MSD function can be used to characterise the technological process and to monitor changes in structure over time [

23]. Optical microrheology was used to study the viscoelastic properties of soft materials. Changes in the structure over time were evaluated based on the results of the G’ and G” modules. The DWS technique allows us to obtain information about the medium quickly and in a wide frequency range, which is fundamental for characterising and monitoring structural changes over time [

16].

The DWS technique has also been used to evaluate structural changes in paraffin emulsions [

24] and vegetable greases after tribological tests in which silicon-containing substances were used as thickeners or as additives [

25,

26,

27].

The Raman spectroscopy will be used as a complementary technique to tests carried out using DWS diffusing rheometry. This technique will be used to determine the structural changes in the tested lubricating greases subjected to variable extortions during the tests carried out.

Raman spectroscopy is an analytical technique that makes it possible to examine molecular vibrations in chemical compounds, thereby providing insight into their structure through the identification of functional groups. It can also be applied for quantitative or semi-quantitative evaluation of the content of a given substance in a sample. The method is widely used to monitor the course of chemical reactions by analysing the spectra of products and mixtures, as well as to investigate interactions between solution components (such as cation–solvent systems) or to study the mechanisms of catalyst activity. Because each compound produces a distinct Raman spectrum determined by its molecular structure, the method can be used for a broad range of materials in different physical states—including gases, liquids, aqueous and non-aqueous solutions, pastes, solids, powders, and single crystals—across wide temperature and pressure ranges. Another advantage of this technique is that sample preparation is usually straightforward and does not require special cells. Furthermore, Raman spectroscopy is particularly useful for aqueous systems, as the low polarisability of water results in only weak Raman scattering [

28,

29].

The technique has been extensively applied to diverse materials. For example, it has been used to analyse the structure of polymer solutions [

30], revealing changes in molecular organisation at different temperatures. Raman studies have also focused on colloidal systems [

31], paraffin waxes and polymer microemulsions under variable thermal conditions [

32], phase transitions in hydrocarbons [

33], as well as crystallinity changes in polymer blends subjected to heating [

28]. Additionally, it has been employed to investigate structural modifications in aqueous polymer solutions, base oils, and lubricants under different operating conditions [

29].

In conclusion, Raman spectroscopy provides valuable information on how the chemical structure of materials evolves when exposed to temperature or mechanical stress. Monitoring these changes over time makes it possible to evaluate the influence of process conditions on the molecular state of a material and to characterise the stability of studied systems on a microscopic level.

So far, no reports have been published on the comprehensive assessment of lubricant microstructures using DWS diffusion spectrometry enriched with Raman spectroscopy. The use of these two analytical techniques will allow explaining the behaviour of multicomponent dispersion systems subjected to mechanical and thermal excitations. Analysis of the previously described cases and own works of Raman spectroscopy allows one to state that it is possible to identify and explain changes in the structure of lubricants and correlate them with changes in rheological properties investigated by means of DWS diffusing rheometry.

On the basis of changes in rheological parameters, including the correlation function MSD, the microstructure of the tested lubricants will be evaluated in relation to the different content of thickener in the dispersed phase, having an influence on the consistency of the tested systems. The obtained results will be the basis for finding a correlation between the stability of the microstructure and the parameters determined from the correlation function MSD—the diffusion coefficient and the modules characterising the viscoelastic properties of the tested dispersion systems.

In the paper [

34], the dynamics of molecules in gels with the use of casein micelles was carried out using the diffusing microrheology technique. The acidified milk, the skimmed milk with kargenine, and the skimmed milk with agar were tested. The rheological tests using the DWS technique allowed for the evaluation of the gel strength and the particle dynamics in connection with the gel microrheology. And also to determine the change in the reaction of the system to stress and the dynamics of particles dispersed in gels. In the literature [

35] can also find the application of the DWS technique to measure the instability of the colloidal structure. This article describes the destabilisation of model substances in the form of skim milk and emulsions. The changes in the diffusion coefficient were determined, and the gel point was determined on the basis of changes in the MSD function in time. The paper [

36] was also published, in which the authors use the DWS technique to study the properties of gelling and aggregating systems. The article presents an example of the application of diffusing microrheology to measure the size of colloidal particles of food suspensions. The gel point was determined on the basis of the results of measurements of the viscoelastic properties, i.e., modules G’ and G”. The process of destabilisation of colloidal systems in time was also investigated. The behaviour of intermolecular forces in the particle aggregation process was discussed.

A very important aspect is the use of optical microrheology (DWS) to study the dynamics of changes in the microstructure of complex fluids and polymers, as presented in [

37]. Based on the changes in the values of the G’ and G” modules with frequency, the changes in the structural properties of colloidal dispersions, polymers, and biomaterials were evaluated. The dynamic phenomena related to the tested fluid and the study of the relaxation modes of adsorbed polymers were evaluated.

In [

38], DWS spectroscopy was used to examine the rheological properties of high-viscosity silicone oil. The change in the structure of the tested oil in time was evaluated on the basis of the measurement results of the G’ and G” modules, and a mathematical model describing the nonlinear viscoelastic properties was proposed.

The DWS technique was also used to study the interactions between thermoaggressive microgel particles [

39]. The changes in the microstructure of gels were evaluated on the basis of the results of the MSD function in time, the dynamics of particle movement, and the gelation point was determined based on the measurements of G’ and G” modules from frequency.

The next work [

40] describes the use of optical microrheology to study the structure of supramolecular solutions. The movement of the particles of the dispersed phase was observed. The change in the structure of solutions was evaluated on the basis of the test results of the G’ and G” modules in time and the data obtained from the MSD function.

The article [

41] describes the possibility of using DWS optical microrheology to evaluate the rheological properties of complex fluids and gels. The changes in the structure were evaluated on the basis of the research results of the G’ and G” modules. It was found that the results of the MSD function can be used to characterise the technological process and monitor the changes in the structure of fluids and gels over time.

Interesting research results were presented by the authors in [

42] concerning the characteristics of the temperature-dependent gelling process in colloidal dispersions using DWS diffusing spectroscopy. The change in the structure of colloidal dispersions with temperature was evaluated, the gel point was determined, and the rate of aggregation of particles suspended in the dispersion was examined. The viscoelastic properties were discussed using the Maxwell and Kelvin–Voigt models. A coordinate dependent on temperature (G’ = G”) and frequency was used to calculate the activation energy representing the critical energy of the interaction during gel formation.

In work [

43], the authors have evaluated the fluid mechanics using the results of rheological tests carried out with the use of the DWS technique. The viscoelastic properties were tested, i.e., the modules G’ and G”, to evaluate the microstructure and dynamics of the tested fluids. The MSD function was used by the authors to track the dynamics of individual fluid molecules.

In reference [

44], the authors used optical microrheology to evaluate the rheological characteristics (the viscoelastic properties) of soft materials. The changes in the structure of the tested samples over time were evaluated on the basis of the test results of the G’ and G” modules. The DWS technique allows you to obtain information about the medium quickly and over a wide frequency range and is essential for many industrial applications, e.g., for rapid characterisation and monitoring of a technological process.

The tests of the viscoelastic properties of complex liquids using the DWS diffusing spectroscopy have been described in [

45]. The changes in the structure of the liquid in time were evaluated, and the dynamics of particle motion were tested using the results of the G’ and G” modules, and the MSD correlation function over time.

Several publications have used the DWS technique to evaluate changes in the structure of greases produced on different base oils based on determining the rheological parameters [

20,

46,

47,

48,

49].

An important contribution to this field was made by Nassef et al., who investigated the elastic and rheological properties of environmentally friendly lubricants. Their work demonstrated that bio-based greases exhibit favourable viscoelastic behaviour and stability under load, confirming the potential of ecological lubricants as a sustainable alternative for industrial applications [

50].

In article [

32], the authors analyse lubrication systems with biopolymer thickeners. Tribological tests have shown that eco-friendly lubricants can achieve a lubricating film and friction comparable to oil-based lubricants obtained from petroleum processing, depending on the type of thickener.

In article [

51], the authors present a two-stage modification (transesterification + epoxidation) that significantly improves the thermal and oxidative stability as well as the tribological properties of the resulting grease, resulting in lower wear and better friction compared to commercial greases.

In paper [

2], the authors describe aqueous solutions of colloidal gels with silica nanoparticles, which are characterised by a low friction coefficient (a decrease of over 97% compared to compositions without silica additives) and evident low wear thanks to their self-repairing and nano-bearing properties.

The aim of this study was to investigate the change in the microstructure of vegetable lubricants, carried out using diffusing spectroscopy and Raman and FTIR spectroscopy, based on rheological parameters and characteristic bands of vegetable oil, intended for use in the food industry, developed at the Łukasiewicz Research Network—Institute for Sustainable Technologies in Radom.

2. Materials and Methods

A set of model lubricating greases was formulated using environmentally safe components as both the continuous and dispersed phases. Three types of vegetable oils—rapeseed, sunflower, and abyssinian—served as the liquid medium, where amorphous silica of a specific particle size (7–40 nm) was used as a thickener. These three lubricating compositions were then modified by introducing the AW/EP additive (BCH 351) into their structure [

52,

53,

54,

55,

56]. The rapeseed oil employed in the grease formulations was characterised by the following physicochemical properties: density of 0.813 g/cm

3, kinematic viscosity of 44.13 cSt at 40 °C, peroxide value of 2.36 meq O

2/kg, iodine value of 108.78 g I

2/100 g, saponification value of 132.55 mg KOH/g, and acid value of 1.23 mg KOH/g. The sunflower oil used for preparation of the compositions exhibited a density of 0.756 g/cm

3, kinematic viscosity of 32.44 cSt at 40 °C, peroxide value of 1.87 meq O

2/kg, iodine value of 113.34 g I

2/100 g, saponification value of 156.23 mg KOH/g, and acid value of 1.43 mg KOH/g. In turn, the abyssinian oil incorporated in the formulations showed a density of 0.711 g/cm

3, a kinematic viscosity of 41.27 cSt at 40 °C, a peroxide value of 2.09 meq O

2/kg, an iodine value of 142.88 g I

2/100 g, a saponification value of 187.71 mg KOH/g, and an acid value of 1.79 mg KOH/g [

57,

58,

59,

60,

61,

62,

63].

Aerosil

®-type modified silica [

64,

65,

66] was employed as the dispersed phase in the formulations. The vegetable base oils and the silica thickener were combined using a high-speed homogeniser operating at 18,000 rpm for 30 min under ambient conditions. The resulting grease compositions were further enhanced by the incorporation of a 1.5% share of a modifying additive (BCH), selected to improve both the physicochemical and rheological behaviour of the lubricants. These ingredients were used to prepare vegetable-based greases corresponding to the second consistency class. The consistency of the obtained lubricants was evaluated according to the PN-ISO 2137:2021 standard [

67] with the use of a laser penetrometer manufactured by the Lukasiewicz Research Network–Institute for Sustainable Technologies. All formulations were subsequently analysed in terms of rheological and spectroscopic properties, and the experimental data were carried out three times and subjected to statistical treatment using Student’s

t-test.

BCH 351 is a multifunctional additive for vegetable oil-based industrial lubricants, e.g., rapeseed oil, castor oil, etc. The product contains antioxidants, corrosion inhibitors, and EP/AW additives. It is a yellow liquid with a specific gravity at 20 °C of 1.02 g/cm3, and a viscosity at 40 °C of 85 mm2/s. The additive includes branched alkyl-3,5-ditert- butyl-4-hydroxyhydrocinnamate, butylated triphenyl phosphate, and N-alkylated benzotriazole.

The compositions prepared in this way, which were marked with the symbols: 1A (based on rapeseed oil), 1B (based on rapeseed oil and modified of BCH additive), 2A (based on sunflower oil), 2B (based on sunflower oil and modified of BCH additive), 3A (based on Abyssinian oil) and 3B (based on Abyssinian oil and modified of BCH additive) carried out the rheological and spectral tests. The chemical composition of the tested greases is presented in

Table 1.

The developed lubricants have been designed for use in food industry equipment, such as gearboxes, bearings and friction points in machines that come into contact with food, where non-toxic and biodegradable agents are required, as well as in environmentally friendly applications, e.g., in agriculture, municipal machinery and transport, where it is important to reduce the negative impact on the environment; in addition, they can be used in special operating conditions where the properties of lubricants with moderate elasticity and tribological stability under variable loads are beneficial, as confirmed by rheological and spectroscopic tests.

Next, the prepared compositions will be evaluated using Raman and FTIR spectroscopy, and the structure of the tested lubricants by DWS diffusion spectroscopy.

Rheological tests. The rheological behaviour of the lubricants was examined using an optical rheometer (DWS RheoLab, LS Instruments AG, Fribourg, Switzerland). This instrument applies Diffusing Wave Spectroscopy (DWS) to determine rheological parameters of complex systems such as suspensions, emulsions, or foams. The technique relies on the concept that, in optically turbid samples, the propagation of light can be described as a diffusion process. By tracking fluctuations in the scattered light, the device enables microrheological analysis of materials, capturing static intermolecular displacements across a broad frequency spectrum and viscoelastic range [

68,

69,

70,

71,

72,

73].

The rheometer allows measurements in two configurations: transmission and backscattering [EU Patent 1720000]. In transmission mode, the scattered light is detected after passing through the entire sample, and its temporal intensity variations are analysed. In backscattering mode, in contrast, the light scattered back in the direction of the incident beam is collected, and its intensity fluctuations are recorded [

42,

74,

75].

The mean square displacement (MSD) correlation function under static conditions was determined, and rheological measurements were performed at 293 K. Based on the analysis of the obtained parameters, changes in the viscoelastic behaviour of the initial lubricant samples were evaluated. To ensure accurate results, preliminary procedures were carried out, including device calibration, selection of the appropriate measurement mode, and adjustment of the cuvette thickness. Prior to testing, the instrument was calibrated using a standard polystyrene emulsion with a particle size of 222 nm in water. Subsequently, the refractive indices of the individual base oils were determined, measurement time and temperature were set, and the spectrometer cuvette was prepared with the addition of a scattering marker (titanium dioxide, particle size 360 nm). Choosing the correct cuvette thickness is critical, as valid measurements require that the ratio of the optical path length (L) to the transport mean free path (l*) falls between 7 and 30; outside of this range, measurements cannot be performed reliably. Tests were conducted in both transmission and backscattering geometries to identify the optimal optical path and ensure accurate data collection. Finally, the lubricant samples were homogenised and placed in a cuvette with a 1 mm optical path for the rheological analyses [

40,

43,

76,

77,

78,

79].

Spectral tests. The structural changes in the lubricants will be investigated using a Raman spectrometer. The Raman spectroscopy will be used to monitor the qualitative changes occurring in the tested materials. Analysis of Raman spectra will consist of evaluation of band decay in the range of 1440–1470 cm

−1 and approximately 1300 cm

−1, corresponding to the vibrations coming from changes in the range of bands characteristic of unsaturated systems derived from vegetable base oil (3010, 1656, and 1268 cm

−1) [

80,

81,

82,

83]. The Raman spectra will be obtained using a Raman NRS 5100 confocal Raman micro-spectrometer (Jasco Corporation, Tokyo, Japan) equipped with an excitation laser with a wavelength of 532.12 nm and a CCD detector. The working conditions of the spectrometer are as follows: diffraction grating 600 lines/mm, laser power 5.0 mW, numerical aperture 40 μm, resolution 13.72 cm

−1, lens magnification 20×, and exposure time 200 s. The calibration of the Raman spectrometer will be carried out using a silicon reference plate [

84,

85].

Fourier spectroscopy spectra were carried out with a Jasco FTIR 6200 spectrometer (Jasco Corporation, Tokyo, Japan), in the reflection mode, using a Pike attachment with a diamond crystal, an exposure time of one spectrum—30 s, and a measurement range from 650 cm−1 to 4000 cm−1 during the test.

3. Results

Spectral tests of lubricating compositions. The lubricating greases prepared on vegetable oils were subjected to spectral testing using Raman spectroscopy and FTIR spectroscopy to evaluate the chemical structure of lubricating compositions.

The results of the chemical structure of lubricating compositions prepared with different types of vegetable base oils using the FTIR technique are shown in

Figure 1.

In the FTIR spectra of vegetable oil-based lubricants with the addition of BCH, numerous new minor peaks appeared in the range of 1500–1600 cm

−1, along with a more pronounced peak at 966 cm

−1. The bands in the 1500–1600 cm

−1 region may originate from aromatic groups present in the BCH structure (C=C stretching vibrations in aromatic rings) as well as from carboxylate groups (COO

−), whose asymmetric stretching vibrations also fall within this range [

86]. The presence of these groups promotes the formation of a stable lubricating structure, enhancing the anti-wear properties of the grease and its resistance to degradation. The more intense peak at 966 cm

−1, in turn, indicates the presence of C=C double bonds in a trans configuration or unsaturated cyclic fragments [

87].

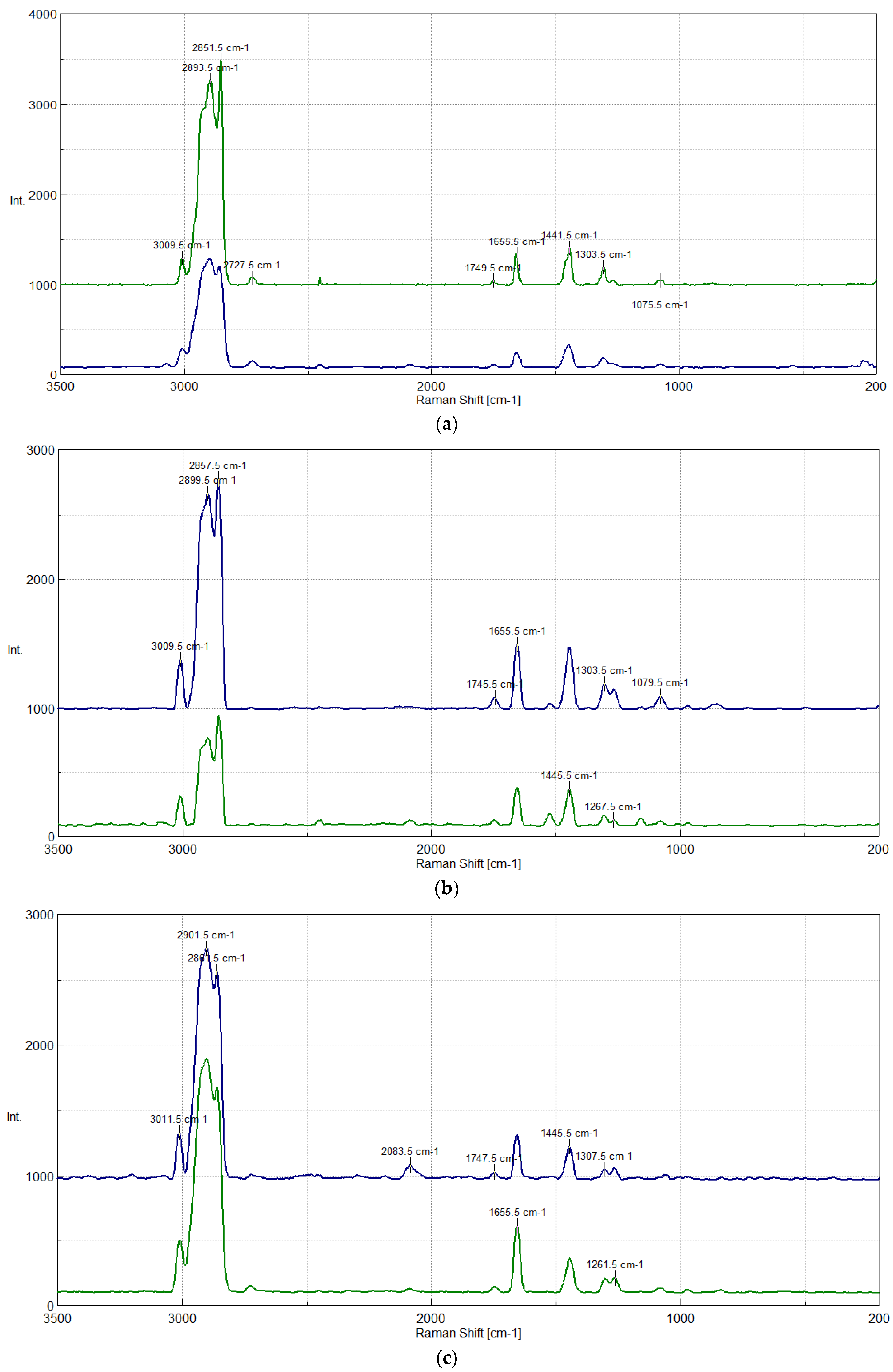

Spectral tests with a Raman spectrometer were carried out for all lubricating compositions made with different vegetable oils. The results obtained are shown in

Figure 2a–c.

For tested lubricating compositions, characteristic bands occurring in the fatty acids of vegetable oils were plotted, such as bands excited by stretching vibrations of C=C groups, CH

2 scissor vibrations at 1656 and 1442 cm

−1, respectively, and bands of stretching vibrations of =C-H and C-H of CH

3 and CH

2 groups occurring near 3011 and 2928, 2896 and 2854 cm

−1. In the spectral range of 3011–2854 cm

−1, intense bands were observed corresponding to stretching vibrations of C–H bonds in aliphatic groups. The peak at 3011 cm

−1 is assigned to =C–H stretching vibrations originating from double bonds in unsaturated fatty acids (such as oleic and linoleic acid). The bands at 2928, 2896, and 2854 cm

−1 correspond to stretching vibrations of C–H bonds in CH

2 and CH

3 groups present in long-chain fatty acids. The peak at 1656 cm

−1 arises from C=C stretching vibrations, which are typical of alkenes found in the structure of unsaturated fatty acids. The band at 1442 cm

−1 is attributed to CH

2 scissoring (deformation) vibrations, further confirming the presence of long-chain fatty acids in the form of triacylglycerols. The prominent band at 1748 cm

−1 indicates the presence of carbonyl (C=O) stretching vibrations, typical for esters—in this case, corresponding to the ester linkage between fatty acids and glycerol (triacylglycerols). This band does not suggest the presence of free fatty acids or oxidation products, but rather reflects the natural chemical structure of rapeseed oil. Additional bands observed at 1305 and 1264 cm

−1 can be attributed to complex deformation vibrations of C–H groups and C–O stretching vibrations associated with ester functionalities. The band at 1085 cm

−1 is assigned to C–O–C stretching vibrations—indicative of ester bridges linking glycerol to fatty acid residues. The band at 1524 cm

−1 may result from combination modes involving C=C and C–H vibrations, which are characteristic of more complex unsaturated systems. The 1085 cm

−1 band may also partially arise from the presence of amorphous silica (Aerosil), which exhibits Si–O–Si stretching vibrations in this same spectral region. However, due to the dominant presence of oil, the signal is most likely derived primarily from ester C–O–C bridges [

88].

To evaluate structural changes in the investigated lubricants, spectral bands corresponding to the stretching vibrations of unsaturated C=C groups at 1656 cm−1 and saturated CH2 groups at 1442 cm−1 were selected, as these peaks are well separated and have clearly defined boundaries. The peak intensity was quantified by integrating the area under the curve. On this basis, the ratio of C=C double bonds to C–C single bonds in the fatty acid chains of the vegetable oils was calculated. For composition 1A, the I1656/I1442 intensity ratio was 1.213; for composition 2B, it was 1.175; for composition 1B, it reached 1.088; for composition 3A, the value was 0.884; for composition 2A, it was 1.411; and for composition 3B, the ratio was 0.692.

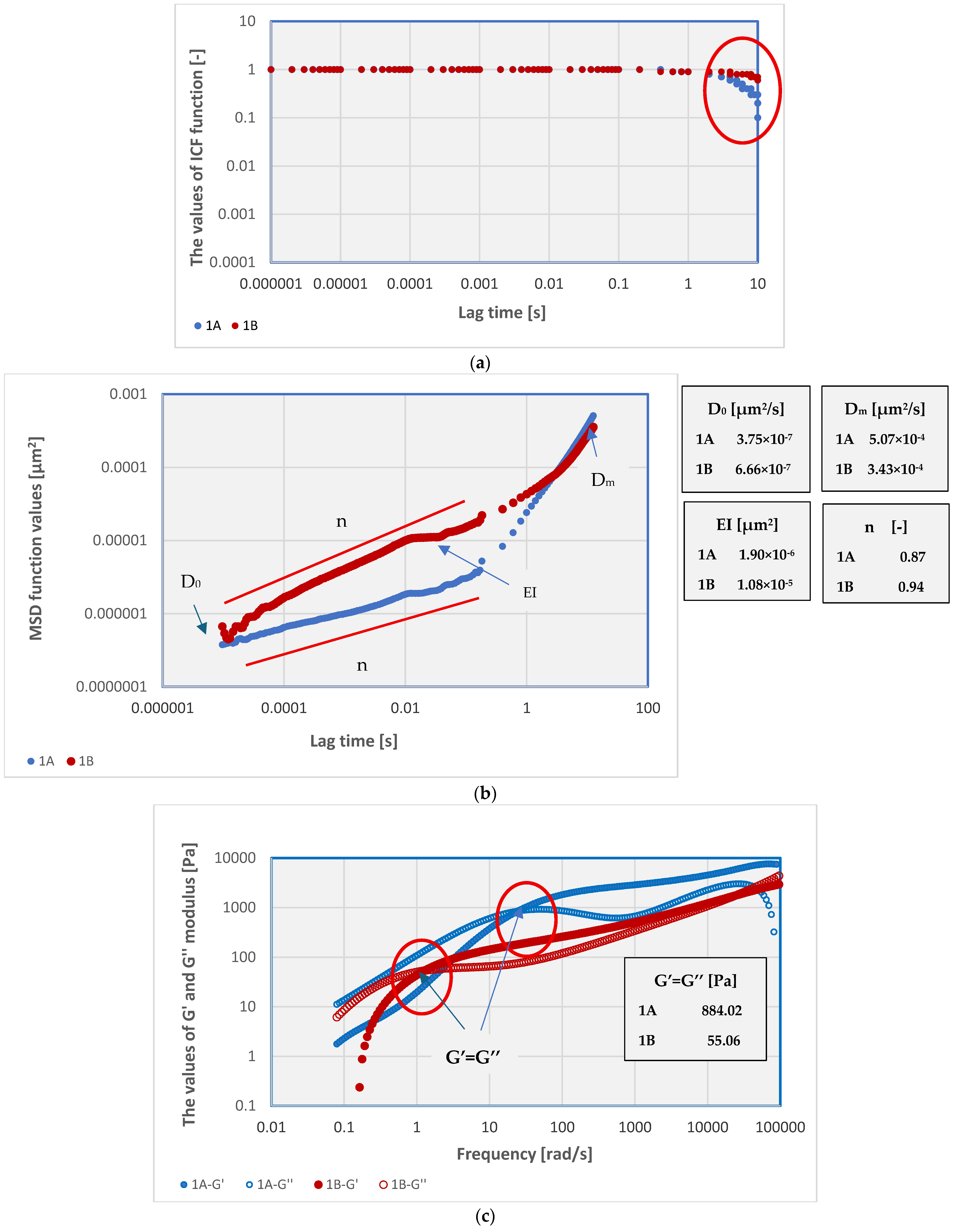

Then, for the produced lubricating compositions, the rheological properties were tested using a DWS diffusion spectrometer. The results of the tests are presented in

Figure 3,

Figure 4 and

Figure 5.

The carried out tests made it possible to determine the dependence of the correlation function ICF on time, the dependence of the mean square displacement—MSD—on time, and the dependence of the modules G’ and G” on frequency. On the basis of the determined dependencies, the diffusion coefficients D

0 and D

m characteristic for determining the changes in viscoelastic properties of tested lubricating greases were calculated. The elasticity index, the slope coefficient of the MSD curve, and the point at which the G’ and G” moduli equalise were also calculated. The values of these parameters indicate a change in the structure of the tested lubricating compositions. The results of the tests of the rheological properties of lubricating compositions produced on the rapeseed oil basis are presented in

Figure 3a–c.

The application of the DWS technique was aimed at proving that it is possible to determine a change in the chemical structure of tested lubricating compositions on the basis of calculated values of ICF, MSD functions and G’ and G” modules, as well as on the basis of calculated values of parameters determined from these functions, which, in connection with spectral tests carried out on a Raman spectrometer, will make it possible to explain that changes in rheological parameters are related to changes in the structure of the tested lubricating compositions.

The introduction of a multifunctional additive into the chemical structure of a lubricating grease produced on the basis of rapeseed oil leads to a change in the rheological properties of the tested grease. Much higher values of the ICF function were observed for the grease modified with the BCH additive compared to the base grease at higher values of lag time, which indicates a change in the microstructure of the tested lubricant. The calculated value of the diffusion coefficient D0 takes on a higher value for the additive-modified grease and the diffusion coefficient Dm a lower value, indicating a different chemical structure to the base grease and a change in structure of the modified grease over time. A much steeper slope of the MSD correlation function was observed in relation to the base grease, indicating a change in structure towards the higher viscosity substance. The higher value of the elasticity index for the additive-modified grease indicates a change in structure and stronger viscoelastic properties of this grease, especially at higher lag time values of the MSD function, resulting in a stronger structure and less susceptibility to degradation.

The results of the G’ and G” moduli confirm that the intersection of both moduli occurs at a much lower value at low frequency; this changes with increasing frequency, indicating a strengthening of the structure of the additive-modified grease and an increase in its resistance to structure changes under increasing mechanical forcing.

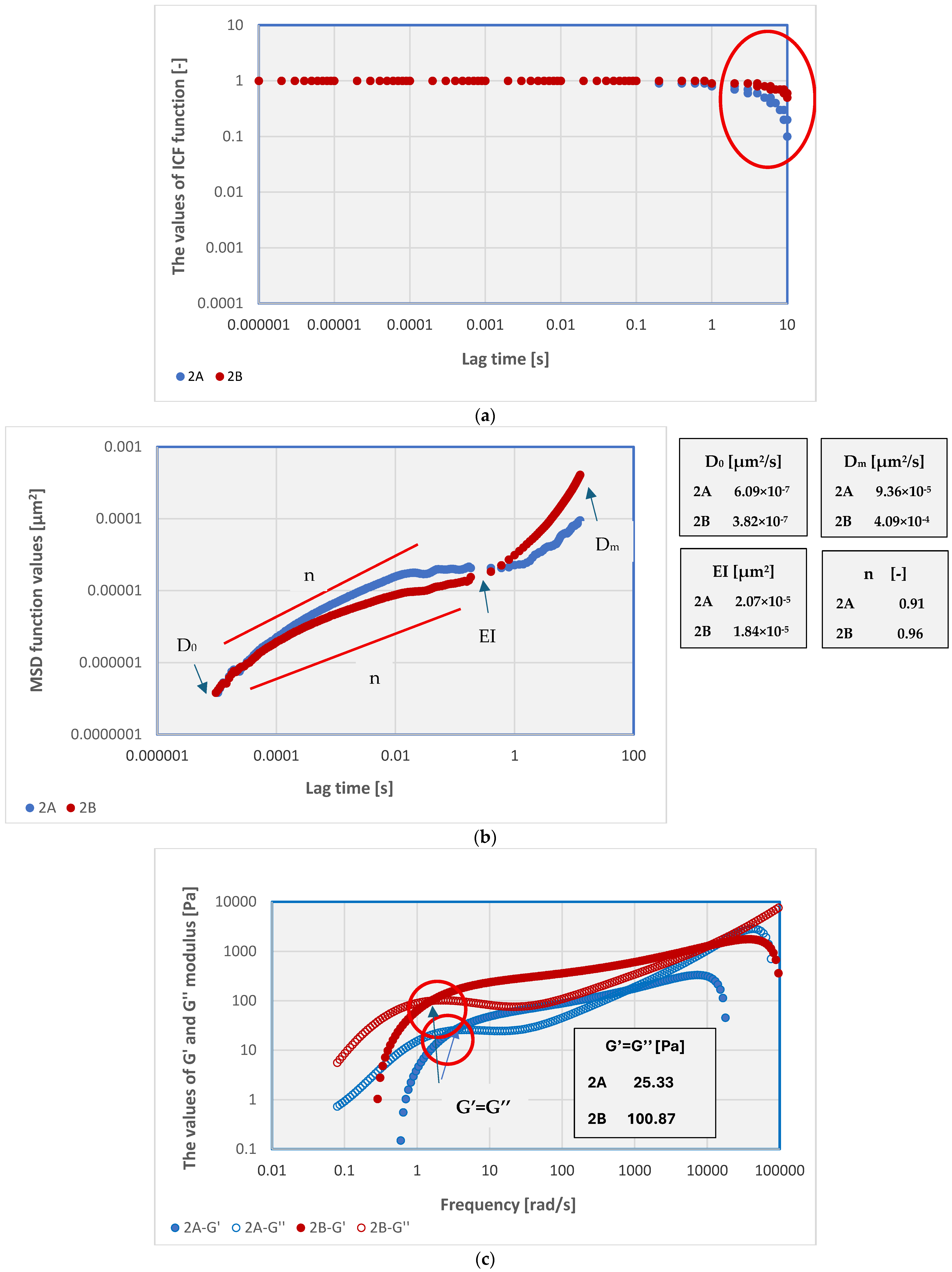

The results of rheological tests on the grease produced from sunflower oil are shown in

Figure 4.

The introduction of a multifunctional additive into the chemical structure of a sunflower oil-based grease leads to a change in the viscoelastic properties of the tested grease. Higher values of the ICF function were observed for the lubricant modified with the BCH additive compared to the base lubricant, especially at deceleration times above 1 s, which indicates a change in the microstructure of the tested lubricant. The calculated value of the diffusion coefficient D0 is characterised by a higher value for the modified grease relative to the results obtained for the base grease and a higher value of the diffusion coefficient Dm at higher lag time values for the additive-modified grease, indicating a change in chemical structure over time. A significantly higher slope coefficient of the MSD correlation function was observed in relation to the base grease, indicating a change in structure towards a higher viscosity fluid. The lower value of the elasticity index for the additive-modified grease indicates a change in structure and weaker viscoelastic properties of this grease, resulting in a weaker structure and greater susceptibility to degradation under applied load, moving towards a Newtonian fluid structure.

This behaviour is also evidenced by the results of the G’ and G’’’ moduli; in this case, a low stability of the sample is observed on the graph. The shape of the graph of both moduli assumes variable values, first increasing, then decreasing to increase again, indicating a change in structure and low stability of the test sample, even though the intersection occurs at a much higher value of G” and G’’’ modulus.

The results of the rheological tests of the grease produced with abyssinian oil are shown in

Figure 5.

The introduction of the multifunctional additive to the chemical structure of the abyssinian oil-based grease caused a change in the rheological characteristics of the tested grease. Higher values of the ICF function were observed for the lubricant modified with the BCH additive compared to the base lubricant, especially at higher lag times of the ICF correlation function, which indicates structural changes in the tested lubricant caused by the action of the modifying additive. The calculated values of diffusion coefficients assume lower values for the modified lubricant with the BCH additive over a wide range of MSD function lag times. Such values are indicative of a change in the chemical structure of the tested lubricant, to which the multifunctional additive was introduced, and a strengthening of its structure, characterised by higher values of the MSD correlation function. The structure of the lubricant, strengthened by the additive used, is not susceptible to changes under mechanical forces. A higher slope factor of the MSD correlation function was observed for the grease modified with the additive compared to the base grease, indicating a change in structure towards a higher viscosity fluid. The lower value of the elasticity index for grease with an additive indicates a change in the structure and viscoelasticity of this grease, resulting in a stronger, more stable structure and less susceptibility to degradation under applied load.

This behaviour is also evidenced by the results of the G’ and G” modules; the point of intersection of both modules for modified grease with the additive occurs at higher values of both parameters, which indicates a change in structure and greater resistance of the grease to degradation of its structure during its work under high mechanical forcing.

Comparison of the obtained results of rheological tests of the tested lubricating compositions with spectral tests indicates that the parameters determined from rheological tests can be the basis for evaluating changes in the chemical structure of vegetable greases.

The introduction of BCH 351 into the lubricant structure resulted in a noticeable improvement in rheological and tribological parameters, including increased wear resistance and increased load-bearing capacity of the lubricant, as confirmed by rheological test results showing a change in microstructure characteristics towards a stronger structure and a shift in the intersection point of the G’ and G” modules towards higher values. In addition, the presence of an antioxidant and corrosion inhibitor reduced the susceptibility of lubricants to degradation, and in the case of rapeseed and abyssinian oil-based lubricants, a clear increase in structural elasticity and reduced susceptibility to lubricating film destruction under dynamic loads was observed. In summary, BCH 351 acts as a package that enhances the resistance of eco-friendly greases to both wear and extreme pressure (AW/EP) loads, while increasing their chemical and operational stability.

The BCH 351 additive significantly improved the viscoelastic properties and microstructure of the tested lubricants, as in its presence the plateau of the mean particle displacement (MSD) function decreased, and the elastic modulus G’ reached higher values than in the case of reference lubricants, which indicates a more coherent and rigid structure and a more durable silica network in the oil matrix. At the same time, the shift in the G’ and G” intersection point towards higher frequencies confirmed that the structure of the lubricant with the additive was more resistant to deformation and liquefaction, thus maintaining stability even under difficult operating conditions. FTIR analyses suggest that BCH 351 interacts with both the surface of silica particles and the functional groups of the base oil, stabilising its oxidation products, which further reduces chemical degradation. As a result, this additive plays a dual role—it strengthens the structural network of the grease, increasing its elasticity and mechanical resistance, while at the same time improving its chemical stability, which translates into less susceptibility to leakage, better consistency retention, and more effective protection of surfaces against wear.

Higher values of the elastic modulus G’ and lower values of the mean square displacement (MSD) in lubricants modified with the BCH 351 additive indicate stiffening and stabilisation of the microstructure, which translates into better lubricating film retention under load, and thus greater wear resistance and higher load-bearing capacity. FTIR and Raman analyses, in turn, showed changes in the bands characteristic of C=C bonds and carbonyl groups, which indicate interactions of the additive with unsaturated fatty acids and their oxidation products, which can be interpreted as a slowdown in oxidation processes and an improvement in the chemical stability of lubricants. In addition, the shift in the intersection point of the G’ and G” modules towards higher frequencies confirms that lubricants with BCH additive retain their grease-like properties over a wider range of conditions, which in practice means less susceptibility to softening, leakage, or loss of consistency during operation of machines exposed to vibration and shock. As a result, the rheological and spectral results are not just laboratory characteristics but are closely related to key performance properties such as wear resistance, load-carrying capacity, and oxidative stability, confirming the practical significance of the obtained results.

Rapeseed oil mainly contains oleic acid (C18:1, ~60%) and smaller amounts of linoleic acid (C18:2) and α-linolenic acid (C18:3), giving it a moderate level of unsaturation and a relatively high proportion of monounsaturated acids. This composition promotes oxidative stability and provides a favourable balance between the fluidity of the oil and its chemical resistance. Sunflower oil, on the other hand, is characterised by a high content of linoleic acid (over 60%), which increases its polyunsaturation and thus its susceptibility to auto-oxidation processes. This has a negative effect on the durability of the lubricant structure and reduces its oxidative stability, although at the same time, the presence of polyunsaturated fatty acids promotes the formation of polymeric oxidation products, which can act as a temporary protective layer under friction conditions. Abyssinian oil differs significantly from the other two—it contains a high proportion of long-chain monounsaturated acids, such as erucic acid (C22:1), which promotes the formation of a more rigid network in the grease and improves rheological properties but may reduce fluidity at low temperatures.

Our results indicate that rapeseed oil-based lubricants showed the best balance between structural stability and wear resistance. This is confirmed by DWS measurements, which showed lower mean particle displacement (MSD) values and a higher elastic modulus G’, indicating a more coherent and flexible silica network in this oil base. Sunflower oil-based lubricants were more susceptible to oxidative degradation, which is reflected in changes in FTIR spectra (stronger carbonyl bands associated with oxidation products). Abyssinian oil, on the other hand, allowed for the production of greases with high elasticity but slightly poorer tribological stability under long-term load.

It can be concluded that it is the balance in the degree of unsaturation of rapeseed oil—moderate polyene content and high proportion of monounsaturated acids—that promotes the formation of a stable and flexible lubricant microstructure, which in practice translates into better wear resistance and longer service life compared to lubricants based on sunflower or Abyssinian oil.

Research results indicate that eco-friendly vegetable oil-based lubricants differ significantly in terms of microstructure and rheological properties depending on the base oil used, the type of thickener, and the modifying additives introduced into the lubricant structure. For example, oils with a very high polyene content (such as linseed oil) quickly form oxidised polymer compounds during operation, which deposit on friction surfaces and reduce wear. On the other hand, oils rich in monounsaturated acids (rapeseed oil, Abyssinian oil) oxidise more slowly, which promotes long-term grease stability, although they provide a thinner natural protective layer. Therefore, the optimal choice of oil base is a compromise between oxidative resistance and the ability to form boundary layers. The results obtained by the authors suggest that Abyssinian oil (Crambe abyssinica), containing mainly long-chain monounsaturated acids, promotes the formation of a more durable lubricant microstructure than sunflower oil rich in polyunsaturated esters—this is consistent with expectations regarding the higher oxidative stability of Abyssinian oil. At the same time, sunflower oil-based grease may exhibit better anti-wear properties at the beginning of operation due to the aforementioned oxidation mechanism that forms protective deposits, but at the cost of faster degradation of the structure in the long term.

However, the rapeseed oil, with an intermediate polyene content, produces a lubricant with intermediate properties, confirming that the fatty acid composition strongly influences the balance between the elasticity of the lubricant structure and its chemical stability [

50,

51,

87].

An important factor shaping the microstructure of grease is the type of thickener used. The greases tested used an ashless thickener in the form of amorphous silica. The literature emphasises that silica causes the formation of an extensive three-dimensional network of particles in the oil due to its large specific surface area and interfacial interaction capabilities. Modified silica is hydrophobic, which facilitates its dispersion in oil and the formation of a stable structure even with gentle mixing. Importantly, from an environmental point of view, silica is non-toxic and thermally stable [

8,

12,

46]. These characteristics make amorphous silica an attractive thickener for biodegradable plastic lubricants, providing them with high temperature resistance and high chemical stability [

8]. The results obtained by the authors confirm the high efficiency of the silica thickener—lubricants thickened with silica showed better structural stability and lubricating properties compared to traditional soap thickeners, which is consistent with the reports of other authors. Kozdrach et al. found that vegetable oil-based grease thickened with amorphous silica has the highest resistance to scuffing compared to other greases thickened with lithium, aluminium, or calcium soaps [

17,

55].

The literature also shows that the effectiveness of silicate modifiers may depend on the type of base oil—for example, in rapeseed lubricants, the addition of silica resulted in a greater improvement in wear resistance than in lubricants based on linseed or soybean oil [

14,

15,

16,

17]. The authors explain this by differences in fatty acid composition: rapeseed oil (rich in monounsaturated acids) interacts better with hydrophobic (organically modified) silica particles, while oils with very high polyunsaturated content may interact less effectively. As a result, silica in rapeseed grease forms a more tightly bound network—the thickener particles are more strongly bound to the oil chain due to van der Waals interactions, which translates into improved grease performance. Another interesting conclusion is that the presence of reactive atoms (such as Si in silica or Al in aluminium thickeners) capable of chemisorption on oil molecules increases the resistance of the grease to mechanical and thermal stress. Our observations correlate with this conclusion—greases thickened with pure silica showed high consistency stability in long-term shear and elevated temperature tests, which indicates a permanent bond between the dispersed phase and the base oil [

16,

17,

18,

19,

20].

In addition to thickeners, modifying additives play a key role—anti-wear (AW), anti-seize (EP), antioxidants, and others—which in environmentally friendly lubricants must be as non-toxic and ash-free as possible. However, additives containing heavy metals or chlorine are avoided in the composition of environmentally friendly lubricants, which is why alternatives are being sought, including polymer additives, ceramic nanoparticles or boron compounds. This study used the BCH 351 additive, which acts as an anti-wear and structure-forming modifier. It is a multifunctional polymer-based additive containing active elements such as nitrogen, boron, and phosphorus, which change the chemical structure of the lubricant, improving its rheological and tribological properties. The results of the authors’ research clearly indicate the beneficial effect of this additive on the microstructure and properties of vegetable lubricants. The use of polymer additives increases the lubricant’s resistance to oxidation and raises its yield stress.

The mechanism of action of polymer additives is explained by the presence of hydrophilic and hydrophobic groups, which allow them to bind to silica particles and, on the other hand, anchor themselves in the oil matrix. This creates a kind of bridge between the thickener and the oil, stiffening the lubricant network and at the same time preventing oxidation (the polymer captures radicals or shields reactive sites). This leads to an increase in dynamic viscosity in low shear ranges and increased elasticity of the lubricant structure (increase in pour point). We observed a very similar effect for the BCH 351 additive—lubricants with this additive showed higher G’ modulus and pour point values than similar lubricant compositions without the additive, which indicates a strengthening of the structure and an increase in its resistance to flow under load. It can be concluded that BCH 351 works by synergistically binding with the silica network or by forming reactive layers on friction surfaces that protect against wear. The latter mechanism is typical for many AW/EP additives—e.g., borate additives in lithium and polyurea greases react under friction conditions to form a glassy layer of borates on the surface, which drastically reduces wear and friction.

In the case of BCH 351, it is likely that a protective layer forms during operation—this may be confirmed by FTIR analysis of lubricants after testing, where new bands indicating oxidised or chemically activated components of the lubricating film would be expected. Indeed, FTIR spectral analysis carried out as part of our work (and in the literature) reveals certain changes in the chemical structure of the lubricant under the influence of the additive and mechanical loads. In the samples used in the article, FTIR analysis showed changes in the intensity of characteristic functional group bands after the introduction of the BCH 351 additive into the lubricant structure (e.g., in the carbonyl and hydroxyl ranges), suggesting interactions of the additive with both the oil matrix and silica particles. It can be assumed that the BCH 351 additive forms hydrogen bonds or other interactions with the silica surface (as seen in slight shifts in the Si–OH bands) and also stabilises oxidised oil products (C=O signals), preventing their further degradation. This multidimensional action of the additive translates into improved chemical stability of the lubricant and active wear prevention [

17,

18,

19,

20,

85,

86,

87].

In order to better understand the impact of the described additive and the vegetable oil bases used on the structural condition of the lubricant, the DWS (diffuse light scattering) optical microrheology method was used. Analysis of the correlation intensity function and mean particle displacement (MSD) allows conclusions to be drawn about the ‘stiffening’ or ‘loosening’ of the grease microstructure under the influence of changes in the chemical composition of the greases. The rheological parameters determined by the DWS technique, such as the intensity correlation function, the MSD function over time, and the G’ and G” modules, constitute a unique ‘fingerprint’ of the grease microstructure. In other words, each lubricant is characterised by a specific shape of these curves and parameter values, which can be used to identify factors affecting the stability or destabilising the structure of the lubricant. For example, the difference in the MSD function curve between the lubricant with BCH 351 additive and the reference lubricant observed in the authors’ research revealed significant differences in the dynamics of dispersed particles. The modified lubricant showed lower values of the average displacement of particles in a steady state (lower plateau values of the MSD function) and a lower rate of increase in MSD as a function of delay time, which indicates a reduction in the freedom of movement of particles in the thickener network.

This behaviour is typical for systems with stronger elastic properties—silica thickener particles and dispersion markers are ‘trapped’ in a stiffer structure, and their movements are more restricted. Conversely, for lubricants without additives (especially those based on lower viscosity or more loosening oils), the MSD function reached higher plateau values, indicating weaker elastic properties and greater susceptibility of the lubricant structure to deformation. It is known from the literature that the plateau phase of the MSD function correlates with the range of elastic deformations—the longer and lower the plateau (smaller displacements), the more stable and elastic the grease network [

20,

46,

57,

63]. The results achieved in the publication fit this pattern: the addition of BCH 351 lowered the plateau level of the MSD correlation function, indicating an increase in the cohesion and elasticity of the microstructure of the tested lubricants. Analysis of the G’ and G” module values obtained by the DWS method confirmed these conclusions.

In all tested lubricants, the G’ modulus exceeded the G” modulus in low and medium frequency ranges, which means that the lubricants behaved like structured (solid-like) systems under typical operating conditions. However, differences were observed in the position of the G’=G” intersection point (the point at which the lubricant transitions from an elastic to a viscous regime). Lubricants with the addition of BCH 351 were characterised by a shift in the intersection point of both G’=G” modules towards higher frequencies, which indicates that their structure only liquefies at higher frequencies. In other words, this additive increased the frequency range in which the lubricants behave like solids, which indicates a strengthening of the thickener network. For comparison, the lubricant without the additive showed an earlier (at a lower frequency) equalisation of the G’ and G” modules, which means lower resistance of the structure to stress—it liquefied more easily under load. Such changes are critical from a practical point of view: a lubricant with a higher G’ in the low frequency range will maintain its consistency better (less tendency to leak or soften at rest), while a sufficiently high G” in the high frequency range ensures the ability to flow under extreme load (which allows the lubricating film to be renewed in the friction zone).

The authors’ research and literature data show that silica-thickened lubricants behave in this way: they are pseudoplastic and thixotropic—they retain their shape under low loads and shear under high loads but do not completely lose their structural cohesion. The silica network provides vegetable lubricants with high elasticity and cohesion, and the addition of BCH 351 increases this parameter, shifting the yield point towards higher values. In practice, this means that lubricants with the addition of BCH 351 retain their structural stability over a wider range of conditions (e.g., vibrations, impact loads), which can prevent leaks and loss of lubricating properties in difficult applications [

17,

18,

19].

A comparison with literature data confirms the validity of the chosen concept of producing environmentally friendly lubricants using vegetable oils, silica thickeners, and BCH additives. The rheological properties measured using the DWS method showed a close relationship with the structure of the lubricants and their performance. Differences in composition affect elasticity, stability, and lubricating properties: base oils with varying degrees of unsaturation determine the grease’s resistance to oxidation and its ability to form a film; silica thickener provides a three-dimensional network that guarantees the load-bearing capacity of the lubricating film, while the BCH 351 additive strengthens this network and improves the performance of the tested lubricants. The changes in rheological parameters determined by the DWS method (decrease in MSD values, increase in G’ module values, changes in diffusion coefficients) were reflected in the microstructure of the lubricants and promise to improve their behaviour under working conditions—lubricants with the additive and a suitable oil base maintain their consistency and protect against wear even at elevated temperatures and high loads.

These results are consistent with the trends described in the literature for biodegradable lubricants modified with polymers or nanoadditives [

2,

13,

19,

27]. It can therefore be concluded that the use of vegetable oils as the dispersing phase and modified silica as the dispersed phase of environmentally friendly plastic lubricants, in combination with a compatible BCH additive, is a promising solution for the chemical composition of environmentally friendly lubricants. Such lubricants are characterised by the desired structural flexibility and mechanical stability, as well as high-performance properties—good adhesion and load resistance—while maintaining the eco-friendly nature of the lubricant compositions. In a broader context, the results obtained contribute to a deeper understanding of the structure-property correlations in new-generation plastic lubricants and indicate directions for optimising the production of environmentally friendly lubricants.