Modeling and Prediction of Tribological Performance of Surface Textures on Spherical Hydrostatic–Hydrodynamic Bearings

Abstract

1. Introduction

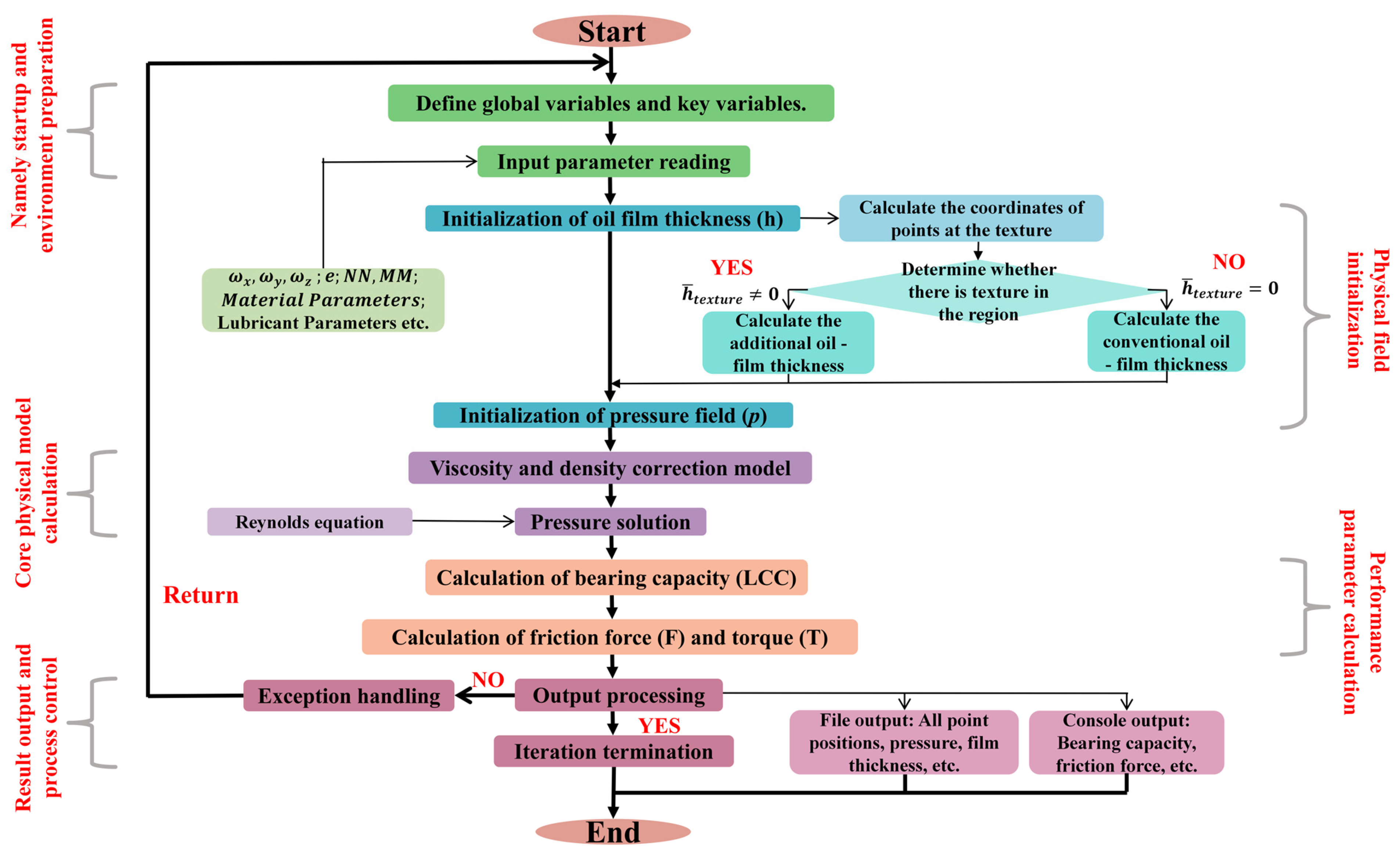

2. Mathematical Model

2.1. Bearing Geometry and Representation

2.2. Lubrication Model

2.3. The Load Carrying Capacity of SHHBs

2.4. Friction

3. Numerical Simulation Procedure

3.1. Mesh Sensitivity Test

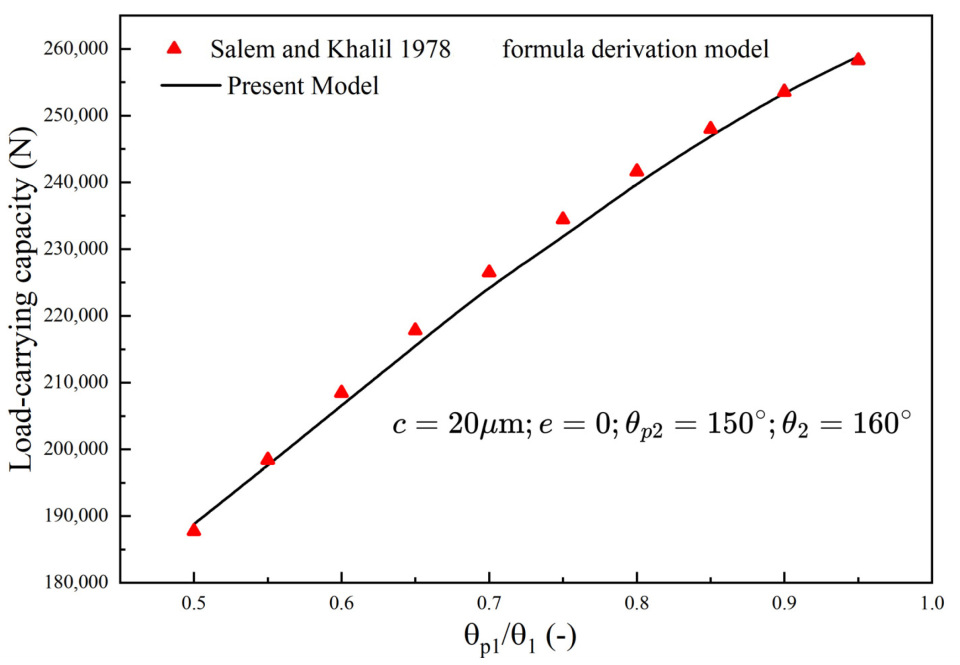

3.2. Numerical Simulation Validation

4. Results and Discussion of Numerical Calculations

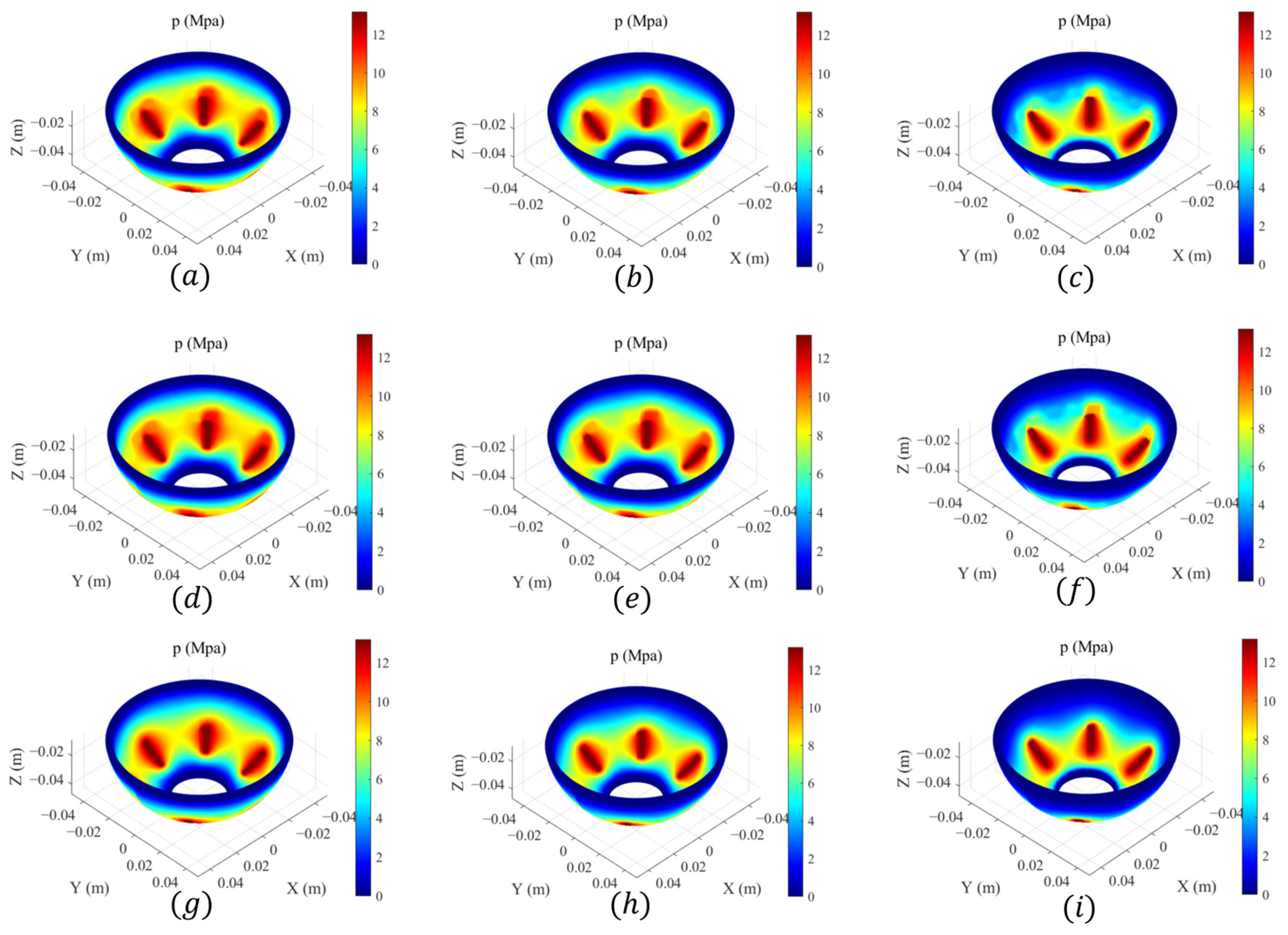

4.1. Influence of Texture Parameters

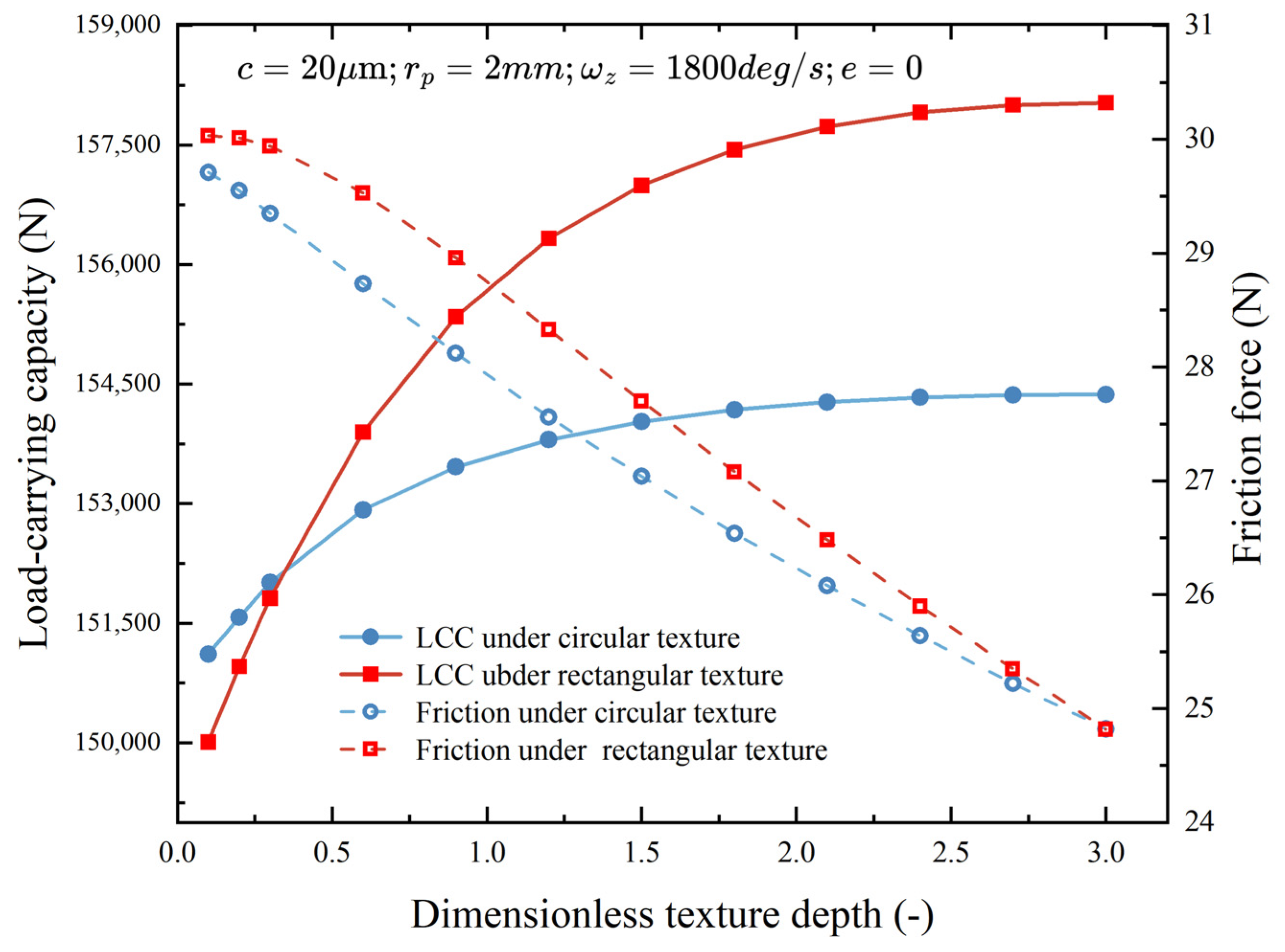

4.1.1. Effect of Dimensionless Depth of Textures

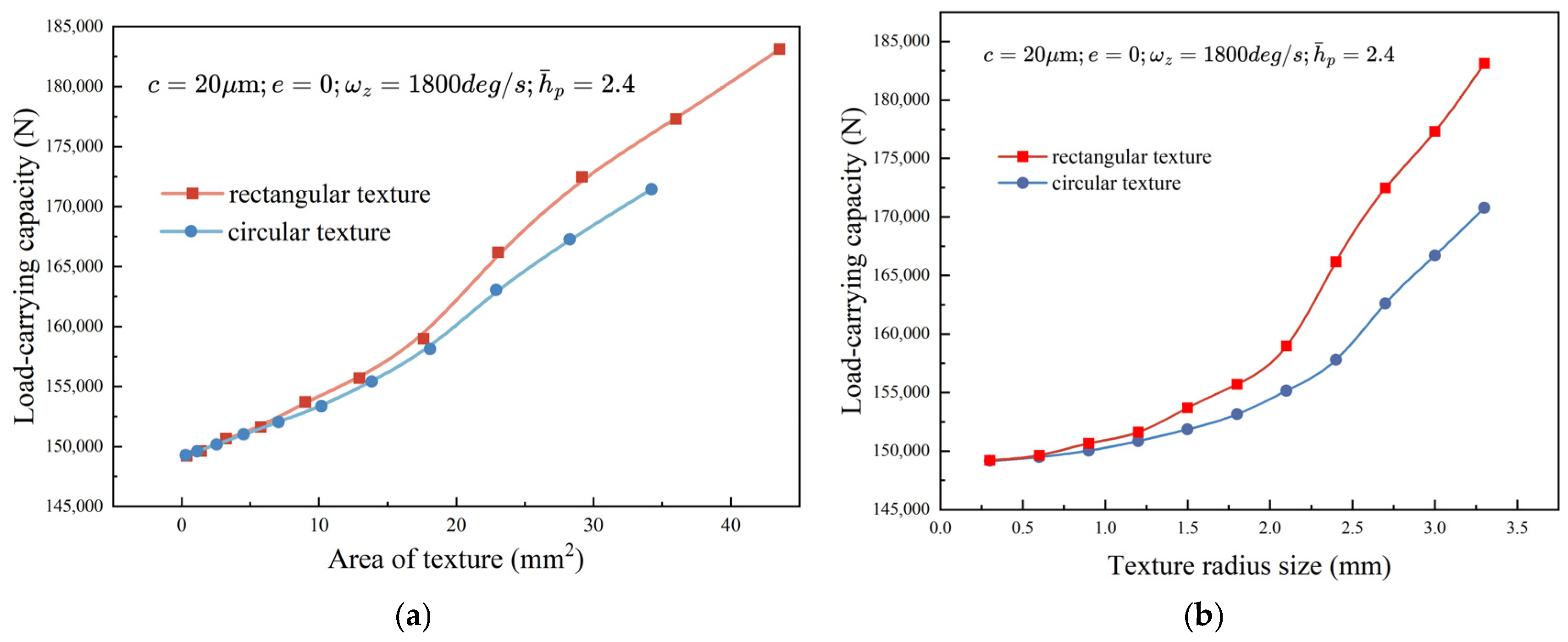

4.1.2. Effect of Texture Size

4.2. Effect of Radial Clearance

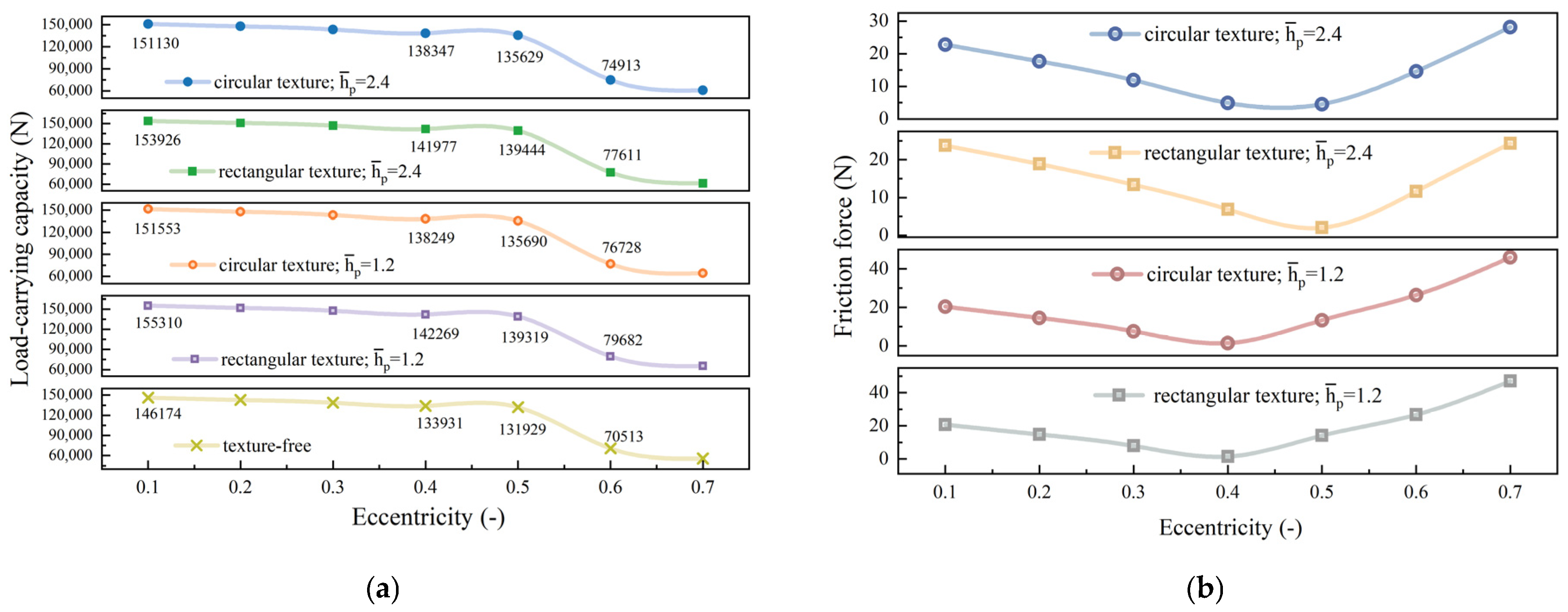

4.3. Effect of Eccentricity

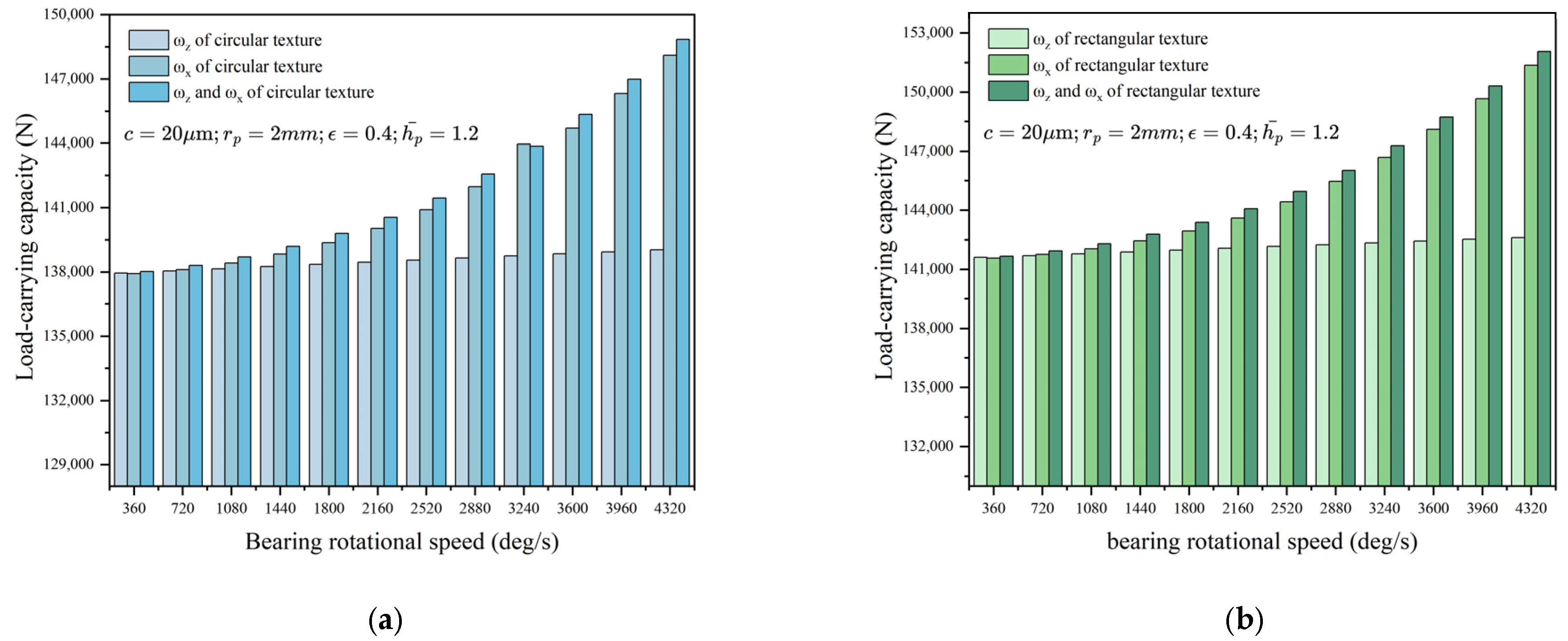

4.4. Effect of Rotational Speed

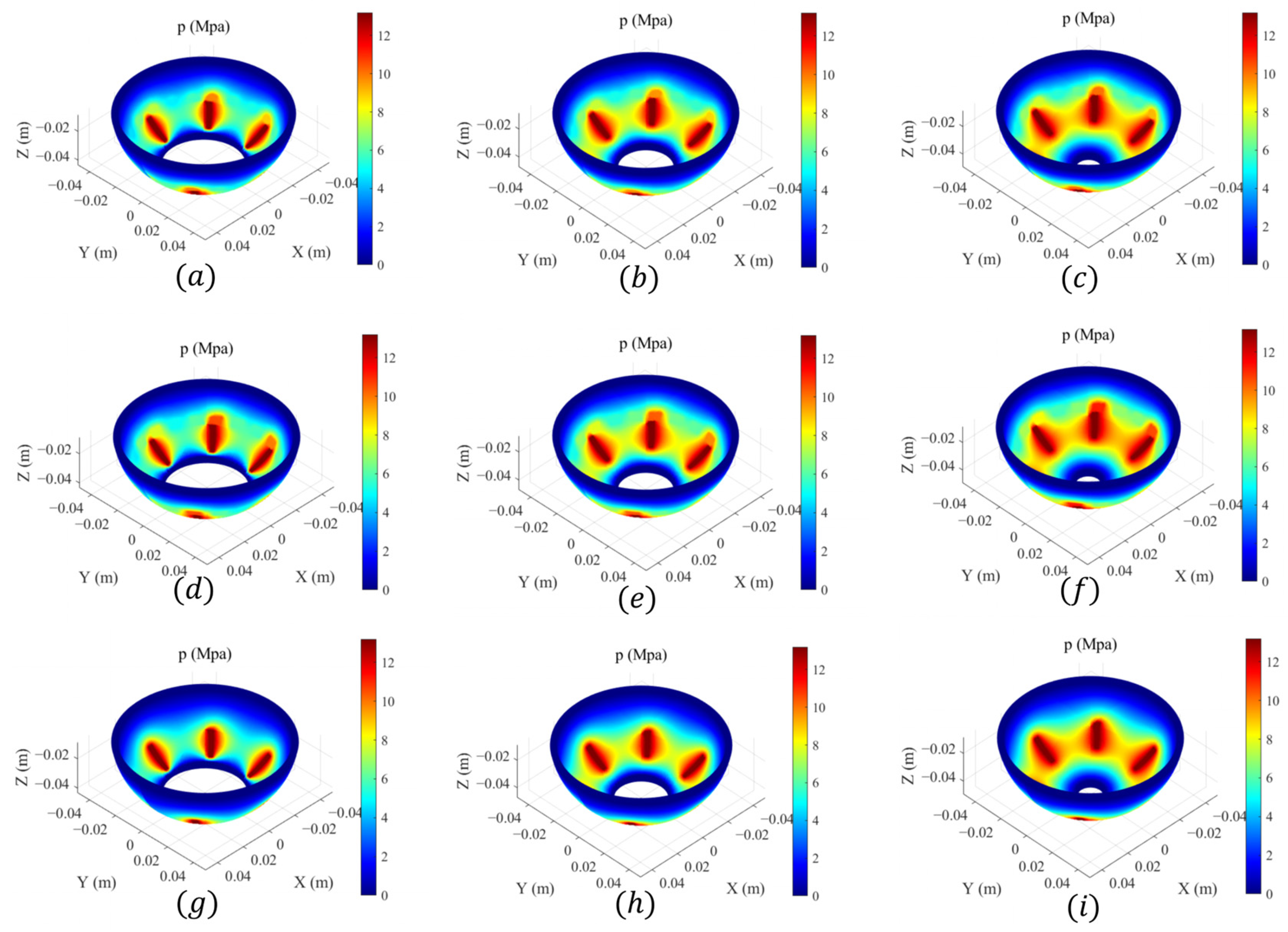

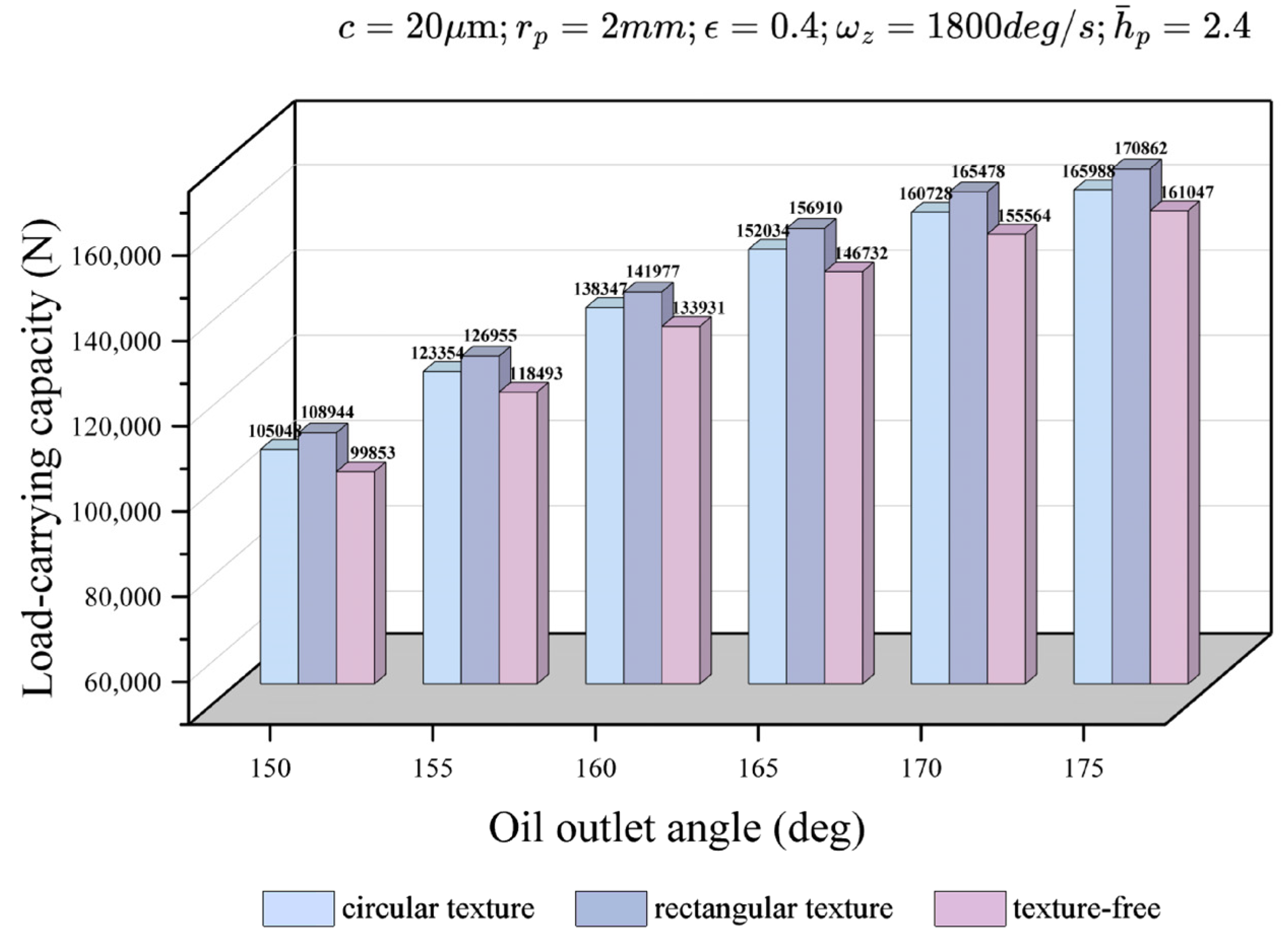

4.5. Effect of Outlet Angle

5. Conclusions

- The presence of textures can improve the load-carrying capacity of the bearing, and the larger the texture radius, the better the load-carrying capacity. When the texture radius is fixed and the dimensionless depth of the texture is changed, the load-carrying capacity of SHHBs tends to be stable when .

- Under certain conditions, when only the radial clearance is changed, the load-carrying capacity of the bearing decreases sharply when the radial clearance reaches , which is 60% lower than that when the radial clearance is .

- To reduce the friction force during bearing operation, different radial clearances should be selected for different dimensionless depths. There exists such a rule: the minimum friction force obtained under different radial clearances corresponds to a decreasing radial clearance value as the dimensionless depth decreases.

- Under certain conditions, when only the eccentricity is changed, the load-carrying capacity of SHHBs drops to 50% of that when the eccentricity is 0.1, when the eccentricity equals 0.6. Considering both friction force and load-carrying capacity, the eccentricity should be set within 0.5.

- The load-carrying capacity of SHHBs gradually increases with the increase of rotational speed, and the influence of rotational speed in the x-axis direction on the bearing’s load-carrying capacity is greater than that in the z-axis direction.

- As the oil outlet angle increases, the effective contact area between SHHBs and the rotor increases, and the load-carrying capacity of the bearing also increases gradually.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Bearing radius | Normalized shaft speed | ||

| film thickness | Total bearing load-carrying capacity | ||

| Polar angle | Contact stress arm length of pits and peaks | ||

| Azimuthal angle | Coefficient of friction | ||

| Fluid pressure | Frictional torque in directions | ||

| Time | Total frictional force | ||

| Oil supply pressure | Fluid shear stress | ||

| Lubricant viscosity | Normalized film thickness | ||

| Pit depth | Bearing rotational speed in directions | ||

| Pit radius | Normalized texture film thickness | ||

| Pit aspect ratio | Normalized local Cartesian coordinate system | ||

| Normalized clearance | Bearing center coordinates | ||

| Radial clearance | Normalized film pressure | ||

| Oil outlet width | coordinate of the center of a single texture | ||

| Synthetic torque | Normalized bearing center coordinates | ||

| Shaft speed | Local Cartesian coordinate system | ||

| Film pressure | Load-carrying capacity in directions |

References

- Gao, W.; Li, Y.; Li, C.; Xu, Y.; Liu, Z. Numerical prediction of drag force on spherical elements inside high-speed ball bearing with under-race lubrication. Mech. Syst. Signal Process. 2025, 224, 112024. [Google Scholar] [CrossRef]

- Puoza, J.C. Research progress of surface texturing and thermal diffusion technology to improve tribological properties of materials. Prog. Eng. Sci. 2025, 2, 100034. [Google Scholar] [CrossRef]

- Ji, J.; Fu, Y.; Bi, Q. The influence of partially textured slider with orientation ellipse dimples on the behavior of hydrodynamic lubrication. Ind. Lubr. Tribol. 2014, 66, 161–167. [Google Scholar] [CrossRef]

- Qiu, M.; Delic, A.; Raeymaekers, B. The effect of texture shape on the load-carrying capacity of gas-lubricated parallel slider bearings. Tribol. Lett. 2012, 48, 315–327. [Google Scholar] [CrossRef]

- Huang, Y.-L.; Zhong, L.; Wang, G.-R.; Wei, G.; Peng, S.-C. Research status and progress of surface texture lubrication and friction reduction. Surf. Technol. 2021, 50, 217–232. [Google Scholar] [CrossRef]

- Gu, C.; Meng, X.; Xie, Y.; Yang, Y. Effects of surface texturing on ring/liner friction under starved lubrication. Tribol. Int. 2016, 94, 591–605. [Google Scholar] [CrossRef]

- Kumar, M.; Tyagi, R. Tribological performance of bearing steel with bi-triangular and circular textures under lubricated sliding. J. Mater. Eng. Perform. 2022, 31, 4519–4530. [Google Scholar] [CrossRef]

- Tang, Z.; Liu, X.; Liu, K. Effect of surface texture on the frictional properties of grease lubricated spherical plain bearings under reciprocating swing conditions. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2017, 231, 125–135. [Google Scholar] [CrossRef]

- Manser, B.; Belaidi, I.; Hamrani, A.; Khelladi, S.; Bakir, F. Texture shape effects on hydrodynamic journal bearing performances using mass-conserving numerical approach. Tribol.—Mater. Surf. Interfaces 2019, 14, 33–50. [Google Scholar] [CrossRef]

- Hingawe, N.D.; Bhore, S.P. Multi-objective optimization of the design parameters of texture bottom profiles in a parallel slider. Friction 2020, 8, 726–745. [Google Scholar] [CrossRef]

- Sharma, S. Lubrication characteristics of Newtonian-lubricated hydrodynamic bearing with partial and fully textured surface. In Machines, Mechanism and Robotics; Kumar, R., Chauhan, V.S., Talha, M., Pathak, H., Eds.; Springer: Singapore, 2022; pp. 1635–1643. [Google Scholar] [CrossRef]

- Yu, Y.; Zhou, L.; Ruan, W.; Xu, P.; Shen, J. Characteristic analysis and optimization of special-shaped micro-textured multi-oil wedge sliding bearing. J. Northwestern Polytech. Univ. 2023, 41, 222–229. [Google Scholar] [CrossRef]

- Gu, C.; Cui, Y.; Zhang, D. Research on the optimal design approach of the surface texture for journal bearings. Lubricants 2024, 12, 111. [Google Scholar] [CrossRef]

- Zhang, H.; Hafezi, M.; Dong, G.; Liu, Y. A design of coverage area for textured surface of sliding journal bearing based on genetic algorithm. J. Tribol. 2018, 140, 061702. [Google Scholar] [CrossRef]

- Dass, T.D.; Gunakala, S.R.; Comissiong, D.; Azamathulla, H.M.; Martin, H.; Ramachandran, S. Investigating journal bearing characteristics incorporating variable viscosity, couple-stress lubricant, slip-velocity, magnetic fluid, and sinusoidal surface-texturing. Results Eng. 2024, 22, 102338. [Google Scholar] [CrossRef]

- Manser, B.; Khelladi, S.; Deligant, M.; Ragueb, H.; Belaidi, I.; Bakir, F. Performance of hydrodynamic textured journal bearing with the combined influence of elastic deformation and pseudo-plastic lubricant. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2023, 237, 1–18. [Google Scholar] [CrossRef]

- Turali, N.; Saleem, S.S. Investigation of the synergetic effect of oleophilic textured surfaces and MoS2 at different loads on the tribological performance of Ti64 alloy. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2024, 239, 1–15. [Google Scholar] [CrossRef]

- Tomar, A.K.; Sharma, S.C. An investigation into surface texture effect on hole-entry hybrid spherical journal bearing performance. Tribol. Int. 2020, 151, 106417. [Google Scholar] [CrossRef]

- Agrawal, N.; Sharma, S.C. Micro-grooved hybrid spherical thrust bearing with non-Newtonian lubricant behaviour. Int. J. Mech. Sci. 2023, 240, 107940. [Google Scholar] [CrossRef]

- Wang, F.; Niel, L. Lubrication theory for spherical bearings. In Encyclopedia of Tribology; Wang, Q.J., Chung, Y.W., Eds.; Springer: Boston, MA, USA, 2013; pp. 2121–2133. [Google Scholar] [CrossRef]

- Brizmer, V.; Kligerman, Y. A laser surface textured journal bearing. J. Tribol. 2012, 134, 031702. [Google Scholar] [CrossRef]

- Gupta, J.L.; Deheri, G.M. Effect of roughness on the behaviour of squeeze film in a spherical bearing. Tribol. Trans. 1996, 39, 99–102. [Google Scholar] [CrossRef]

- Xu, C.; Jiang, S. Analysis of the static characteristics of a self-compensation hydrostatic spherical hinge. J. Tribol. 2015, 137, 041701. [Google Scholar] [CrossRef]

- Gu, C.; Meng, X.; Xie, Y.; Zhang, D. Mixed lubrication problems in the presence of textures: An efficient solution to the cavitation problem with consideration of roughness effects. Tribol. Int. 2016, 103, 516–528. [Google Scholar] [CrossRef]

- Wang, F.C.; Brockett, C.; Williams, S.; Udofia, I.; Fisher, J.; Jin, Z.M. Lubrication and friction prediction in metal-on-metal hip implants. Phys. Med. Biol. 2008, 53, 1277. [Google Scholar] [CrossRef]

- Wang, F.C.; Zhao, S.X.; Quiñonez, A.F.; Xu, H.; Mei, X.S.; Jin, Z.M. Nonsphericity of bearing geometry and lubrication in hip joint implants. J. Tribol. 2009, 131, 031201. [Google Scholar] [CrossRef]

- Salem, E.; Khalil, F. Variable-viscosity effects in externally pressurized spherical oil bearings. Wear 1978, 50, 221–235. [Google Scholar] [CrossRef]

- Zachariadis, D.C. Axial wedge effect in tilted hydrodynamic journal bearings. Tribol. Trans. 2008, 51, 173–181. [Google Scholar] [CrossRef]

| Parameters | Values |

|---|---|

| Oil supply groove starting angle | |

| Oil supply groove termination angle | |

| Number of oil supply ports | |

| Z-axis coordinate of the center of a single texture | |

| Bearing radius | |

| Inner boundary spherical angle | |

| oil outlet angle | |

| Texture shape | circle and rectangle |

| Oil supply pressure | |

| Oil outlet width | |

| Density | |

| Viscosity |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, H.; Gu, C.; Zhang, D. Modeling and Prediction of Tribological Performance of Surface Textures on Spherical Hydrostatic–Hydrodynamic Bearings. Lubricants 2025, 13, 408. https://doi.org/10.3390/lubricants13090408

Xu H, Gu C, Zhang D. Modeling and Prediction of Tribological Performance of Surface Textures on Spherical Hydrostatic–Hydrodynamic Bearings. Lubricants. 2025; 13(9):408. https://doi.org/10.3390/lubricants13090408

Chicago/Turabian StyleXu, Huanlin, Chunxing Gu, and Di Zhang. 2025. "Modeling and Prediction of Tribological Performance of Surface Textures on Spherical Hydrostatic–Hydrodynamic Bearings" Lubricants 13, no. 9: 408. https://doi.org/10.3390/lubricants13090408

APA StyleXu, H., Gu, C., & Zhang, D. (2025). Modeling and Prediction of Tribological Performance of Surface Textures on Spherical Hydrostatic–Hydrodynamic Bearings. Lubricants, 13(9), 408. https://doi.org/10.3390/lubricants13090408