Optimizing the Artificial Aging Process of Lubricating Oils Contaminated by Alternative Fuel Using Design of Experiments Methodology

Abstract

1. Introduction

2. Materials and Methods

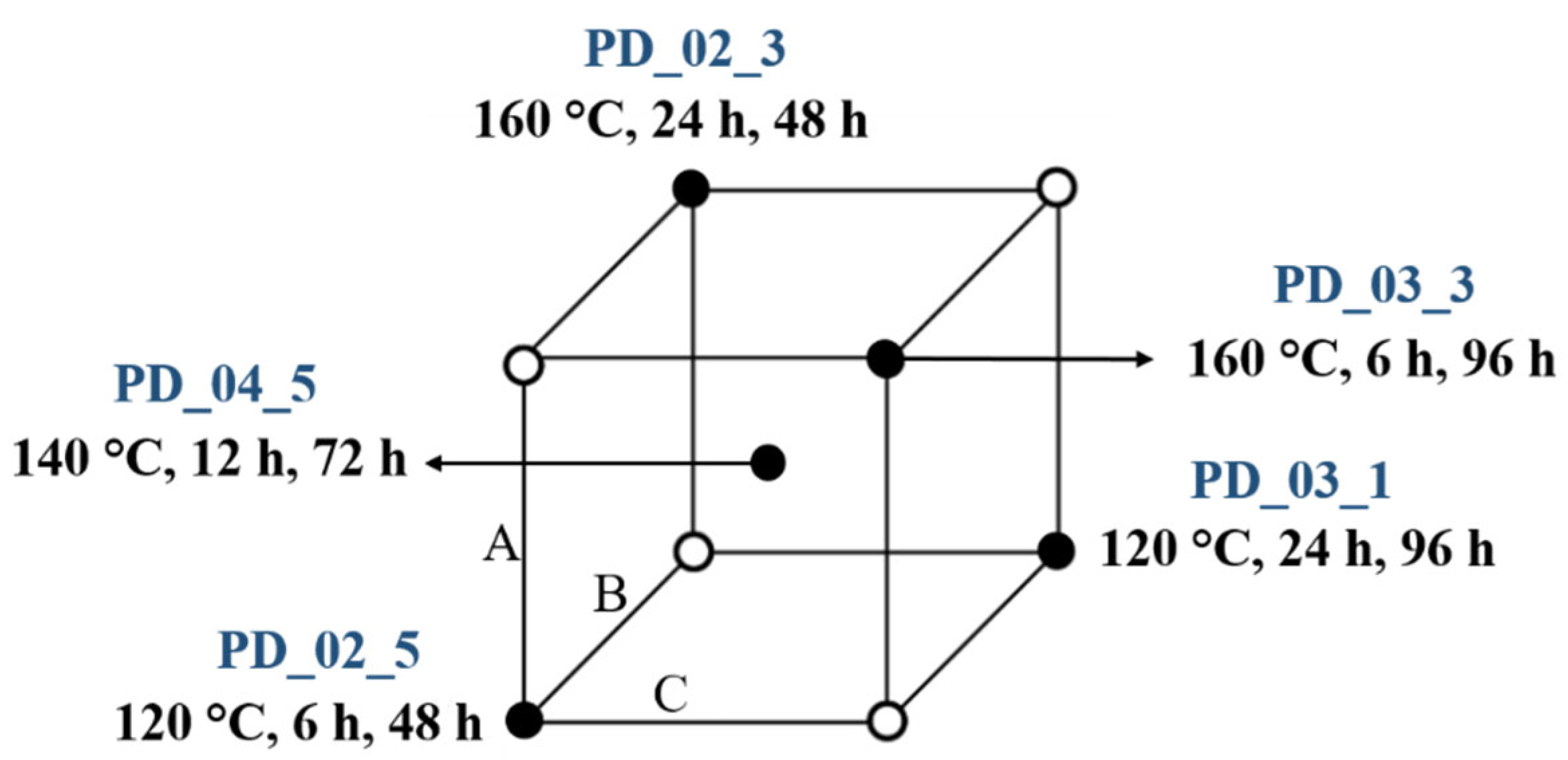

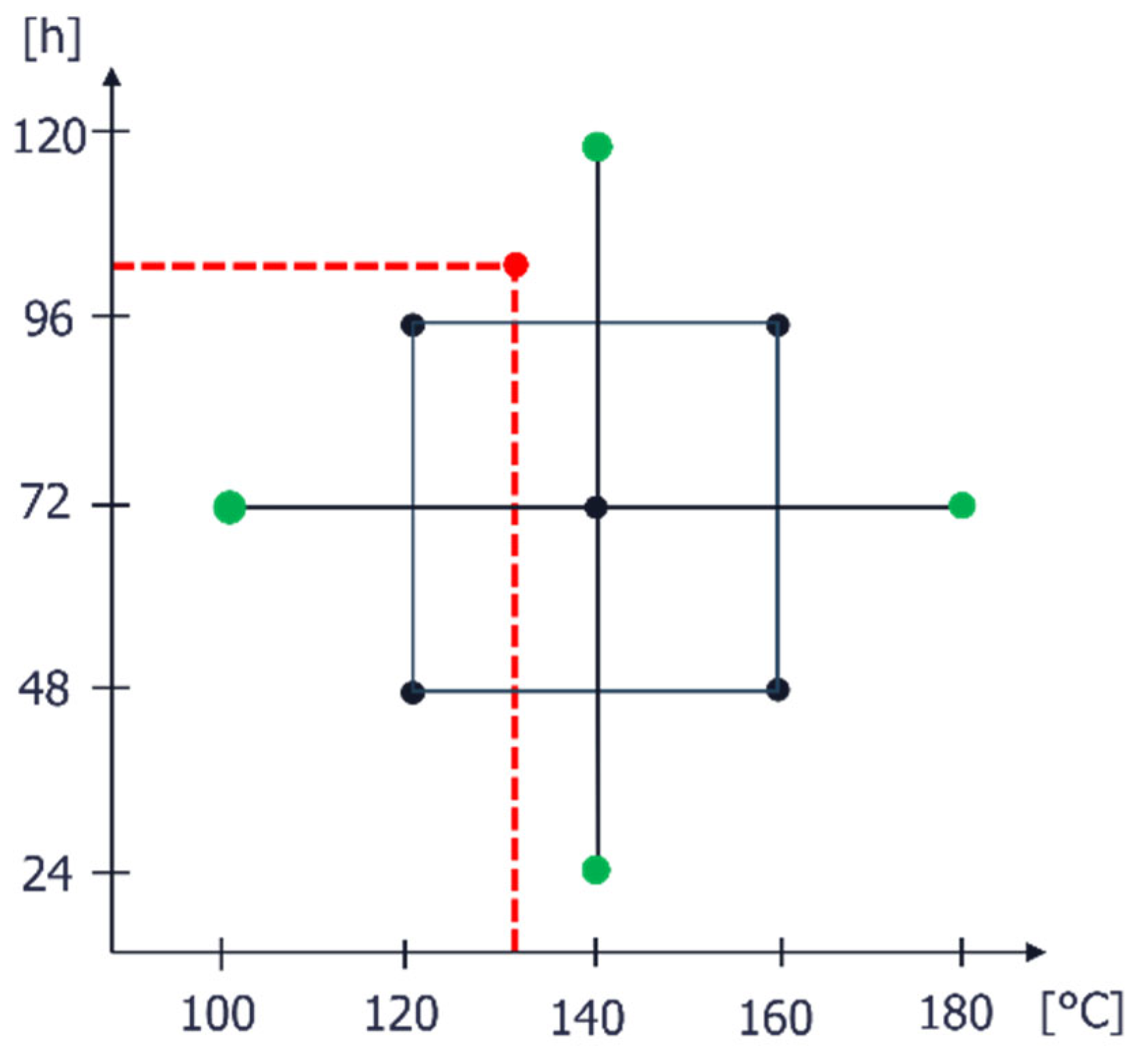

2.1. Design of Experiment—Fractional Factorial

2.2. Artificial Oil Aging Methodology

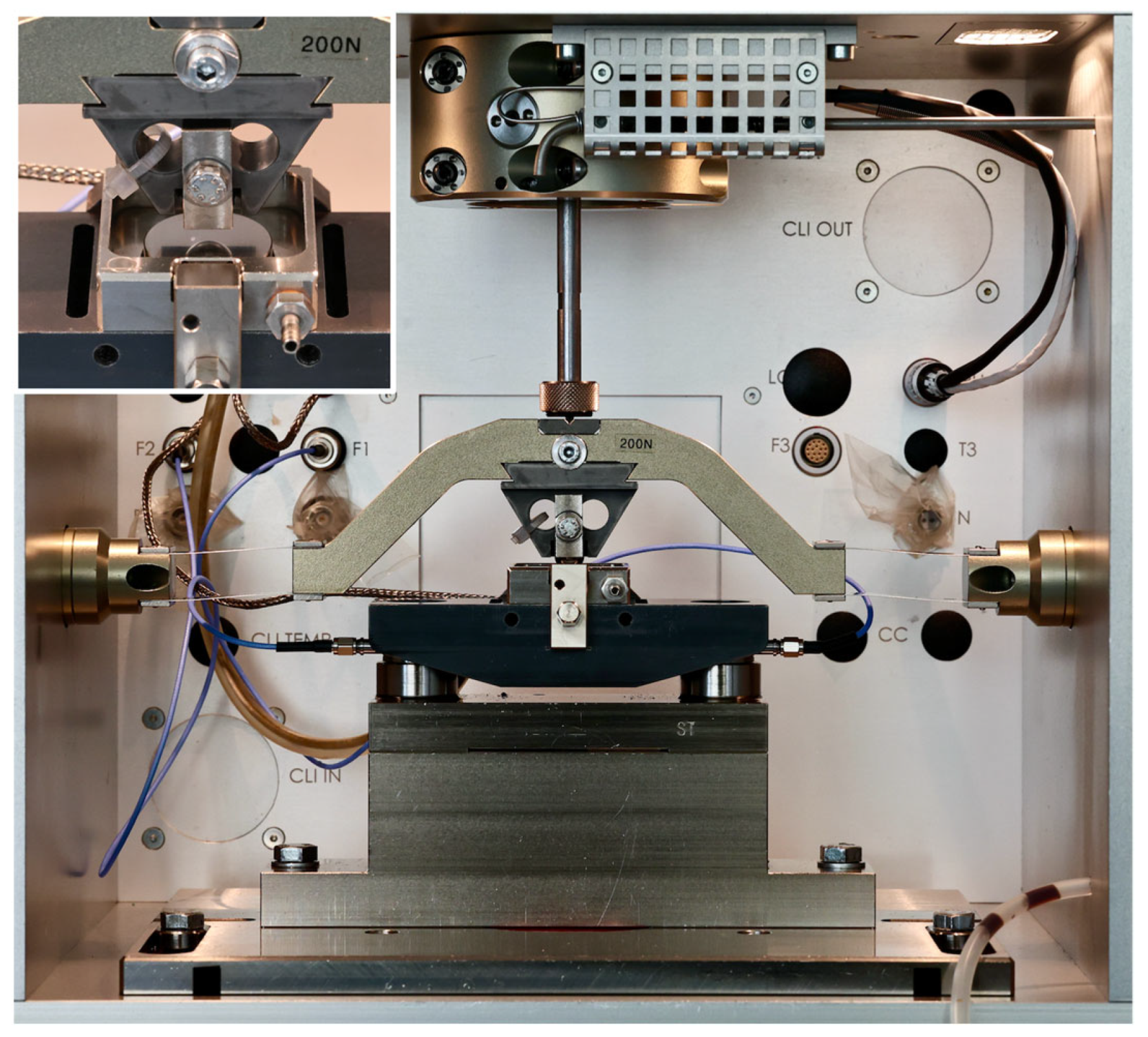

2.3. Friction and Wear Tests

2.4. Wear Analysis

2.5. Oil Analysis

2.6. Surface/Tribofilm Analysis

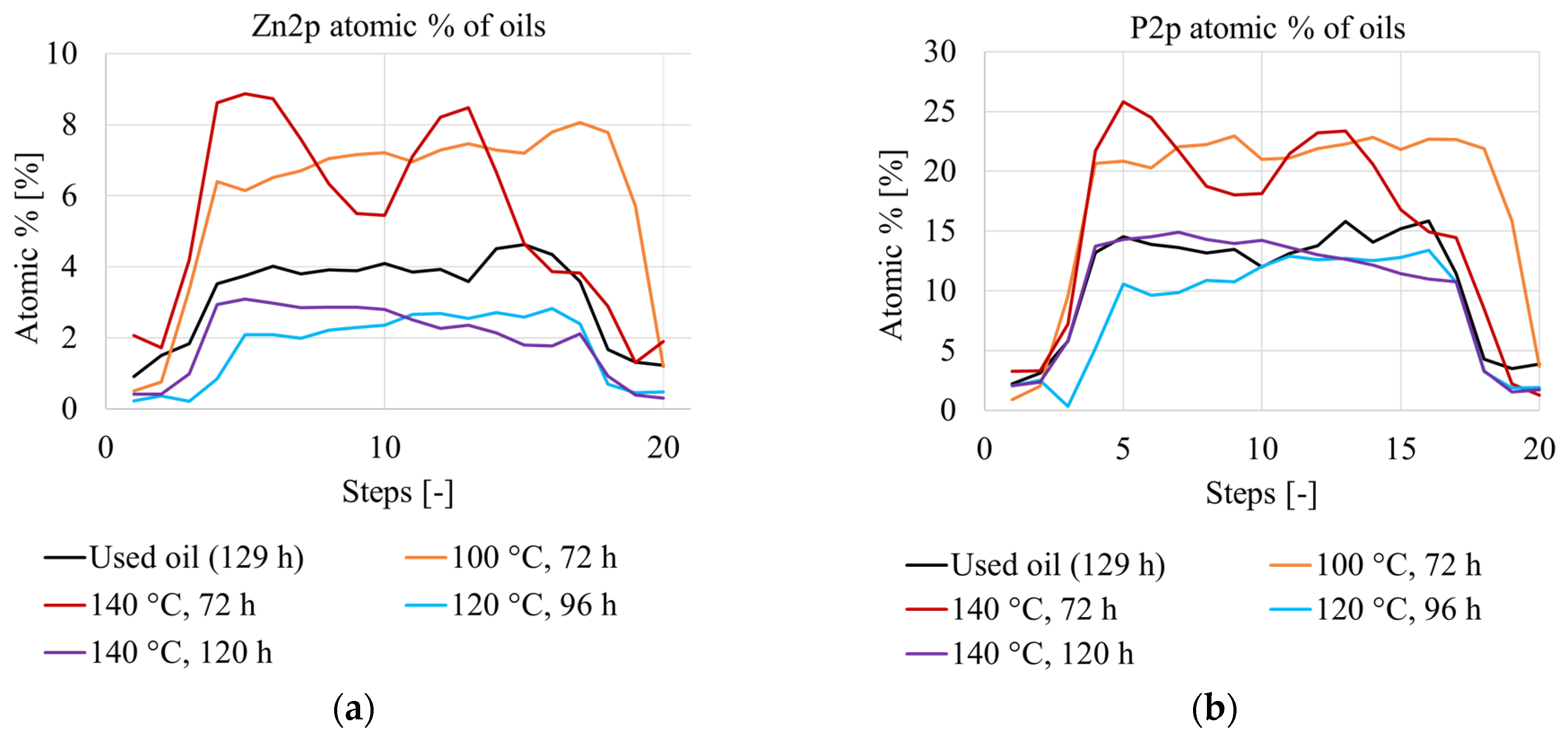

3. Results and Discussion

3.1. CoF Results

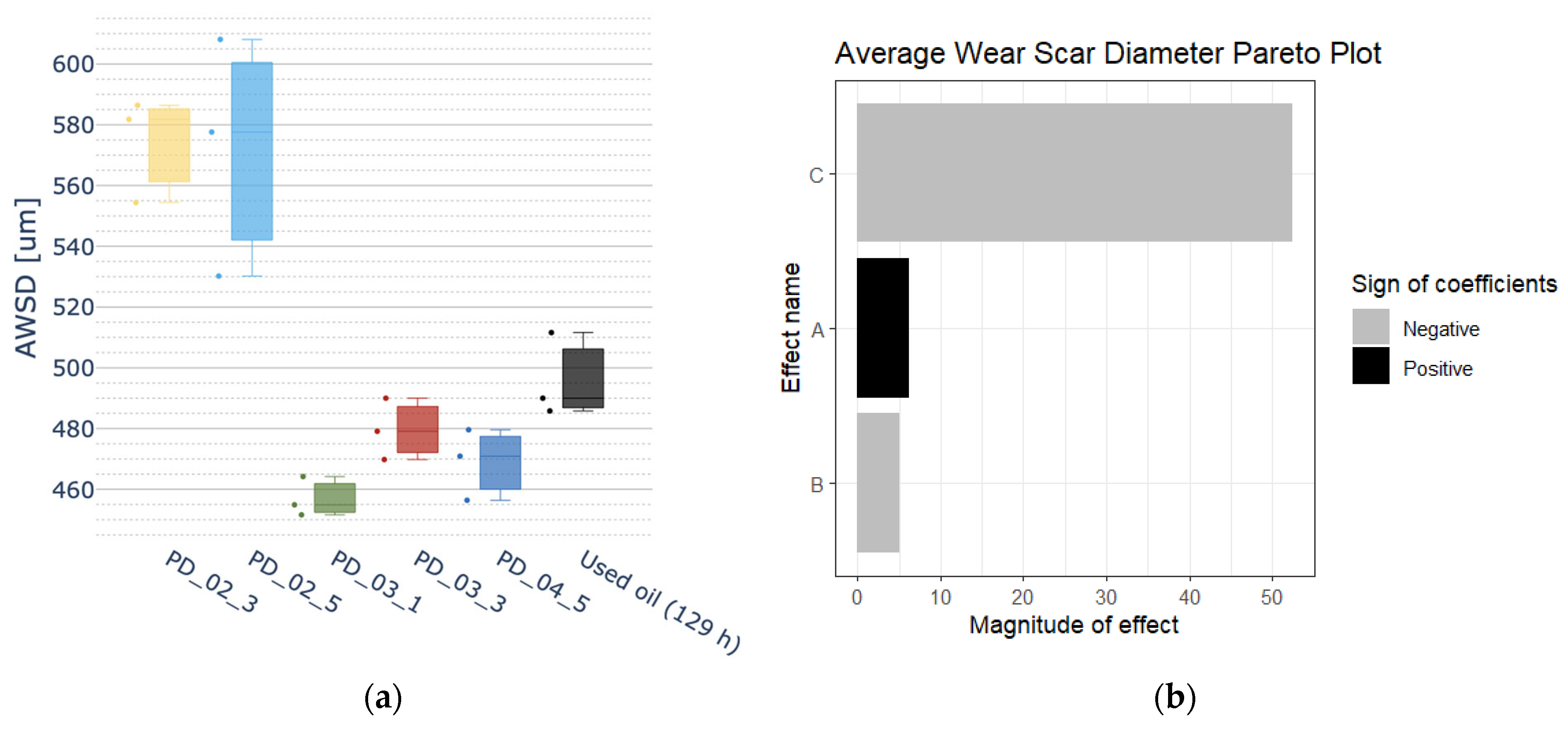

3.2. AWSD Results

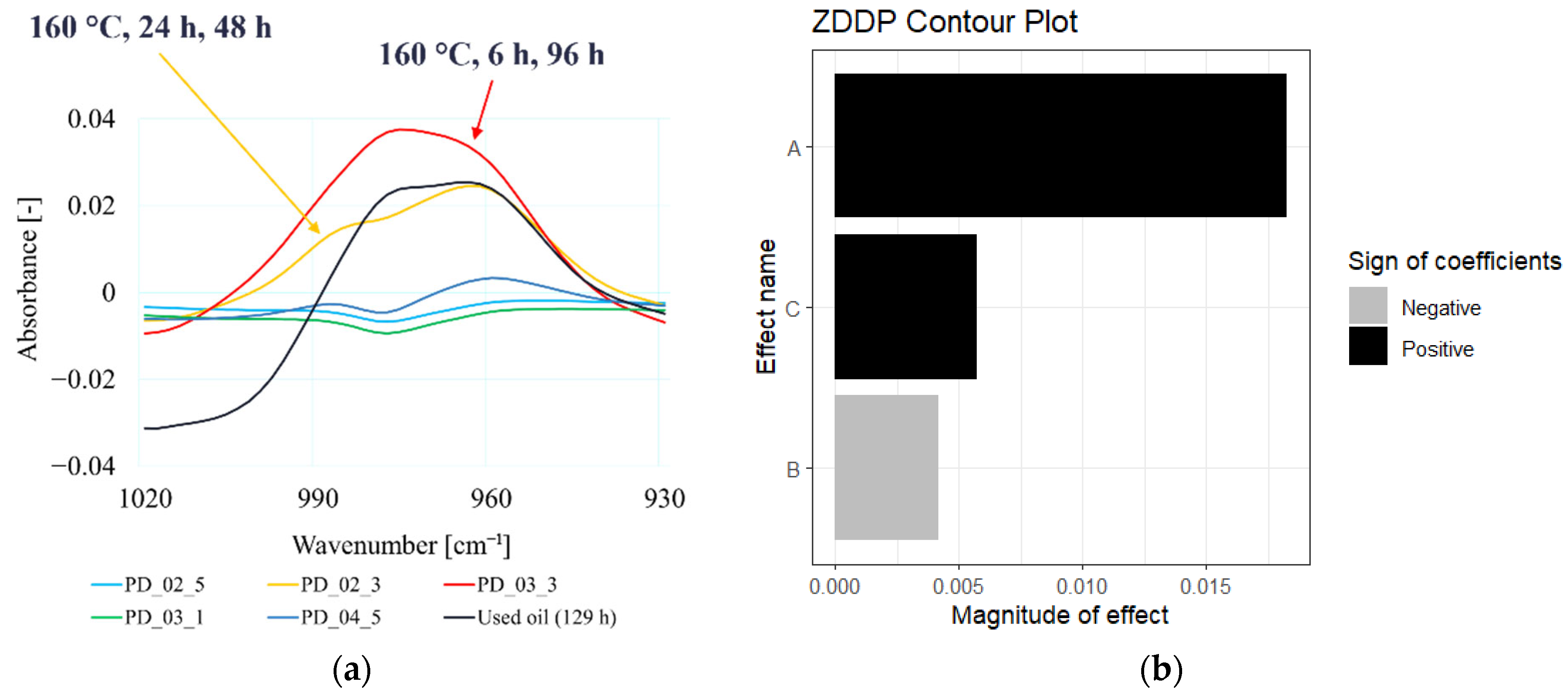

3.3. Oil Analysis Results

3.4. Gauss-Elimination Results

3.5. Surface Analysis

4. Conclusions

- A 120 °C aging temperature and 96 h aging time;

- A 140 °C aging temperature and 120 h aging time.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AWSD | Average wear scar diameter |

| CoF | Coefficient of friction |

| DoE | Design of experiment |

| E20 | 20% ethanol and 80% gasoline (petrol) |

| FT-IR | Fourier-transform infrared spectrometer |

| XPS | X-ray photoelectron spectrometer |

| ZDDP | Zinc dialkyldithiophosphate antiwear additive |

References

- Macharia, V.M.; Garg, V.K.; Kumar, D. A review of electric vehicle technology: Architectures, battery technology and its management system, relevant standards, application of artificial intelligence, cyber security, and interoperability challenges. IET Electr. Syst. Transp. 2023, 13, e12083. [Google Scholar] [CrossRef]

- Öörni, R. Barriers to Adoption of a Fully Electric Vehicle—A Study of Car Users in the Helsinki Region. In Transport Research Arena Conference; Springer Nature: Cham, Switzerland, 2024; pp. 633–639. [Google Scholar] [CrossRef]

- Shamsuddoha, M.; Nasir, T. The Road Ahead for Hybrid or Electric Vehicles in Developing Countries: Market Growth, Infrastructure, and Policy Needs. World Electr. Veh. J. 2025, 16, 180. [Google Scholar] [CrossRef]

- European Comission: Emissions in the Automotive Sector. Available online: https://single-market-economy.ec.europa.eu/sectors/automotive-industry/environmental-protection/emissions-automotive-sector_en (accessed on 20 July 2025).

- Namar, M.M.; Jahanian, O.; Shafaghat, R.; Nikzadfar, K. Engine Downsizing; Global Approach to Reduce Emissions: A World-Wide Review. HighTech Innov. J. 2021, 2, 384–399. [Google Scholar] [CrossRef]

- International Council on Clean Transportation (ICCT). European Vehicle Market Statistics: Pocketbook 2019/20. Available online: https://theicct.org/sites/default/files/publications/European_vehicle_market_statistics_20192020_20191216.pdf (accessed on 20 July 2025).

- Kumar, S.; Goga, G. Emission characteristics & performance analysis of a diesel engine fuelled with various alternative fuels—A review. Mat. Today Proc. 2023, in press. [Google Scholar] [CrossRef]

- Awogbemi, O.; Kallon, D.V.V.; Onuh, E.I.; Aigbodion, V.S. An Overview of the Classification, Production and Utilization of Biofuels for Internal Combustion Engine Applications. Energies 2021, 14, 5687. [Google Scholar] [CrossRef]

- Chybowski, L.; Wójcik, W.; Szczepanek, M. Evaluation of Rheological and Lubrication Properties of Selected Alcohol Fuels. Energies 2025, 18, 1038. [Google Scholar] [CrossRef]

- Aguilar-Rosas, O.A.; Farfan-Cabrera, L.I.; Erdemir, A.; Cao-Romero-Gallegos, J.A. Electrified four-ball testing–A potential alternative for assessing lubricants (E-fluids) for electric vehicles. Wear 2023, 522, 204676. [Google Scholar] [CrossRef]

- Xu, Y.; Zheng, Q.; Geng, J.; Dong, Y.; Tian, M.; Yao, L.; Dearn, K.D. Synergistic effects of electroless piston ring coatings and nano-additives in oil on the friction and wear of a piston ring/cylinder liner pair. Wear 2019, 422, 201–211. [Google Scholar] [CrossRef]

- Paulovics, L.; Kuti, R.; Rohde-Brandenburger, J.; Tóth-Nagy, C. Development of comparative investigation method for timing chain wear analysis using oscillating tribometer. Acta Tech. Jaurinensis 2021, 14, 406–423. [Google Scholar] [CrossRef]

- Dörr, N.; Agocs, A.; Besser, C.; Ristic, A.; Frauscher, M. Engine Oils in the Field: A Comprehensive Chemical Assessment of Engine Oil Degradation in a Passenger Car. Trib. Lett. 2019, 67, 68. [Google Scholar] [CrossRef]

- Agocs, A.; Nagy, A.L.; Tabakov, Z.; Perger, J.; Rohde-Brandenburger, J.; Schandl, M.; Besser, C.; Dörr, N. Comprehensive assessment of oil degradation patterns in petrol and diesel engines observed in a field test with passenger cars–Conventional oil analysis and fuel dilution. Tribol. Int. 2021, 161, 107079. [Google Scholar] [CrossRef]

- CEC L-48-A00; Oxidation Stability of Lubricating Oils Used in Automotive Transmissions by Artificial Ageing. Co-Ordinating European Council for the Development of Performance Tests for Fuels. Lubricants and other Fluids: Brussels, Belgium, 2014.

- ASTM D 6186; Standard Test Method for Oxidation Induction Time of Lubricating Oils by Pressure Differential Scanning Calorimetry (PDSC). ASTM International: West Conshohocken, PA, USA, 2013.

- ASTM D 943; Standard Test Method for Oxidation Characteristics of Inhibited Mineral Oils. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM D 2272; Standard Test Method for Oxidation Stability of Steam Turbine Oils by Rotating Pressure Vessel. ASTM International: West Conshohocken, PA, USA, 2014.

- Nagy, A.L.; Rohde-Brandenburger, J.; Zsoldos, I. Artificial Aging Experiments of Neat and Contaminated Engine Oil Samples. Lubricants 2021, 9, 63. [Google Scholar] [CrossRef]

- Steinschütz, K.; Geringer, B.; Jech, M.; Urbanek, M.; Wopelka, T.; Besser, C. Impact of Oil Aging on Wear of Piston Ring and Cylinder Liner System 2010-32-0124; SAE Technical Paper: Warrendale, PA, USA, 2010. [Google Scholar] [CrossRef]

- Motamen Salehi, F.; Morina, A.; Neville, A. The effect of soot and diesel contamination on wear and friction of engine oil pump. Tribol. Int. 2017, 115, 285–296. [Google Scholar] [CrossRef]

- Besser, C.; Agocs, A.; Ristic, A.; Frauscher, M. Implementation of Nitration Processes in Artificial Ageing for Closer-to-Reality Simulation of Engine Oil Degradation. Lubricants 2022, 10, 298. [Google Scholar] [CrossRef]

- Fuller, M.L.S.; Kasrai, M.; Bancroft, G.M.; Fyfe, K.; Tan, K.H. Solution decomposition of zinc dialkyl dithiophosphate and its effect on antiwear and thermal film formation studied by X-ray absorption spectroscopy. Tribol. Int. 1998, 31, 627–644. [Google Scholar] [CrossRef]

- Uy, D.; Simko, S.J.; Carter, R.O., III; Jensen, R.K.; Gangopadhyay, A.K. Characterization of anti-wear films formed from fresh and aged engine oils. Wear 2007, 263, 1165–1174. [Google Scholar] [CrossRef]

- Cen, H.; Morina, A.; Neville, A. Effect of lubricant ageing on lubricants’ physical and chemical properties and tribological performance; Part I: Effect of lubricant chemistry. Ind. Lubr. Tribol. 2018, 70, 385–392. [Google Scholar] [CrossRef]

- Besser, C.; Agocs, A.; Ronai, B.; Ristic, A.; Repka, M.; Jankes, E.; McAleese, C.; Dörr, N. Generation of engine oils with defined degree of degradation by means of a large scale artificial alteration method. Tribol. Int. 2019, 132, 39–49. [Google Scholar] [CrossRef]

- Spikes, H. Mechanisms of ZDDP—An update. Tribol. Lett. 2025, 73, 38. [Google Scholar] [CrossRef]

- Ueda, M.; Kadiric, A.; Spikes, H. On the crystallinity and durability of ZDDP tribofilm. Tribol. Lett. 2019, 67, 123. [Google Scholar] [CrossRef]

- Hsu, C.J.; Barrirero, J.; Merz, R.; Stratmann, A.; Aboulfadl, H.; Jacobs, G.; Gachot, C. Revealing the interface nature of ZDDP tribofilm by X-ray photoelectron spectroscopy and atom probe tomography. Ind. Lubr. Tribol. 2020, 72, 923–930. [Google Scholar] [CrossRef]

- Thornley, A. The Interactions of Surface-Active Engine Oil Additives in Low Viscosity Engine Oils and Their Effect on Tribological Performance. Doctoral Thesis, University of Leeds, Leeds, UK, 2023. [Google Scholar]

- Thersleff, T.; Jenei, I.Z.; Budnyk, S.; Dorr, N.; Slabon, A. Soot nanoparticles generated from tribofilm decomposition under real engine conditions for identifying lubricant hazards. ACS Appl. Nano Mater. 2020, 4, 220–228. [Google Scholar] [CrossRef]

- Agocs, A.; Frauscher, M.; Ristic, A.; Dörr, N. Impact of soot on internal combustion engine lubrication—Oil condition monitoring, tribological properties, and surface chemistry. Lubricants 2024, 12, 401. [Google Scholar] [CrossRef]

- Jech, M.; Hofer, A.; Tomastik, C.; Wopelka, T.; Gachot, C. Influence of artificially altered engine oil on tribofilm formation and wear behaviour of grey cast cylinder liners. Lubricants 2023, 11, 476. [Google Scholar] [CrossRef]

- Dörr, N.; Brenner, J.; Ristić, A.; Ronai, B.; Besser, C.; Pejaković, V.; Frauscher, M. Correlation between engine oil degradation, tribochemistry, and tribological behavior with focus on ZDDP deterioration. Tribol. Lett. 2019, 67, 62. [Google Scholar] [CrossRef]

- Dudás, A.; Laki, G.; Nagy, A.L.; Zsoldos, I.; Hanula, B.; Bartel, D. Wear behaviour of ceramic particle reinforced atmospheric plasma spray coatings on the cylinder running surface of internal combustion engines. Wear 2022, 502, 204373. [Google Scholar] [CrossRef]

- Nagy, A.L. Development of an artificial aging process for automotive lubricants. In Proceedings of the Spring Wind, Debrecen, Hungary, 3–5 May 2019; pp. 771–775. [Google Scholar]

- ISO 19291:2016(E); Lubricants—Determination of Tribological Quantities for Oils and Greases—Tribological Test in the Translator Oscillation Apparatus. International Organization for Standardization: Geneva, Switzerland, 2016.

- Hamrock, B.J.; Dowson, D. Isothermal Elastohydrodynamic Lubrication of Point Contacts, Part III—Fully Flooded Results. J. Lubr. Technol. 1977, 99, 264–276. [Google Scholar] [CrossRef]

- ASTM D7042-21; Standard Test Method for Dynamic Viscosity and Density of Liquids by Stabinger Viscometer (and the Calculation of Kinematic Viscosity). ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM E2412-10(2018); Standard Practice for Condition Monitoring of In-Service Lubricants by Trend Analysis Using Fourier Transform Infrared (FT-IR) Spectrometry. ASTM International: West Conshohocken, PA, USA, 2018.

- Agocs, A.; Besser, C.; Brenner, J.; Budnyk, S.; Frauscher, M.; Dörr, N. Engine oils in the field: A comprehensive tribological assessment of engine oil degradation in a passenger car. Tribol. Lett. 2022, 70, 28. [Google Scholar] [CrossRef]

| Average Wear Scar Diameter [μm] | Coefficient of Friction [-] | Kinematic Viscosity at 100 °C [mm/s2] | |

|---|---|---|---|

| PD_02_5 | 572 | 0.1496 | 8.029 |

| PD_03_5 | 570.8 | 0.1465 | 8.0162 |

| Variation | 0.21% | 2.16% | 0.16% |

| PD_02_3 | 30:00–30:05 | 30:00–35:00 | 55:00–55:05 | 55:00–60:00 | Variation |

|---|---|---|---|---|---|

| Measurement 1 | 0.137 | 0.139 | 0.14 | 0.138 | 0.12% |

| Measurement 2 | 0.144 | 0.144 | 0.142 | 0.144 | 0.1% |

| Measurement 3 | 0.139 | 0.139 | 0.14 | 0.141 | 0.07% |

| Variation | 2.42% | 1.78% | 0.76% | 2.0% | - |

| Sample ID | Type of Oils | Oil Aging Temperature [°C] | Oil Aging Heating Period [h] | Total Oil Aging Time [h] | Average Wear Scar Diameter [µm] | Surface Analytical Evaluation |

|---|---|---|---|---|---|---|

| PD_02_3 | Artificially aged oils | 160 | 24 | 48 | 574.2 | - |

| PD_02_5 | 120 | 6 | 48 | 572 | - | |

| PD_03_1 | 120 | 24 | 96 | 456.9 | X | |

| PD_03_3 | 160 | 6 | 96 | 479.6 | - | |

| PD_04_5 | 140 | 12 | 72 | 469 | X | |

| Used oil (129 h) | Used oil | ~132.8 * | - | ~103.1 * | 495.8 | X |

| PD_06_1 | Artificially aged oils | 140 | 12 | 120 | 495.1 | X |

| PD_06_3 | 180 | 12 | 72 | 637.5 | - | |

| PD_06_5 | 140 | 12 | 24 | 478.3 | - | |

| PD_07_5 | 100 | 12 | 72 | 504.2 | X |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pintér, D.; Nagy, A.L. Optimizing the Artificial Aging Process of Lubricating Oils Contaminated by Alternative Fuel Using Design of Experiments Methodology. Lubricants 2025, 13, 405. https://doi.org/10.3390/lubricants13090405

Pintér D, Nagy AL. Optimizing the Artificial Aging Process of Lubricating Oils Contaminated by Alternative Fuel Using Design of Experiments Methodology. Lubricants. 2025; 13(9):405. https://doi.org/10.3390/lubricants13090405

Chicago/Turabian StylePintér, Dominika, and András Lajos Nagy. 2025. "Optimizing the Artificial Aging Process of Lubricating Oils Contaminated by Alternative Fuel Using Design of Experiments Methodology" Lubricants 13, no. 9: 405. https://doi.org/10.3390/lubricants13090405

APA StylePintér, D., & Nagy, A. L. (2025). Optimizing the Artificial Aging Process of Lubricating Oils Contaminated by Alternative Fuel Using Design of Experiments Methodology. Lubricants, 13(9), 405. https://doi.org/10.3390/lubricants13090405