Levitation Performance of Radial Film Riding Seals for Gas Turbine Engines

Abstract

1. Introduction

Research Objectives

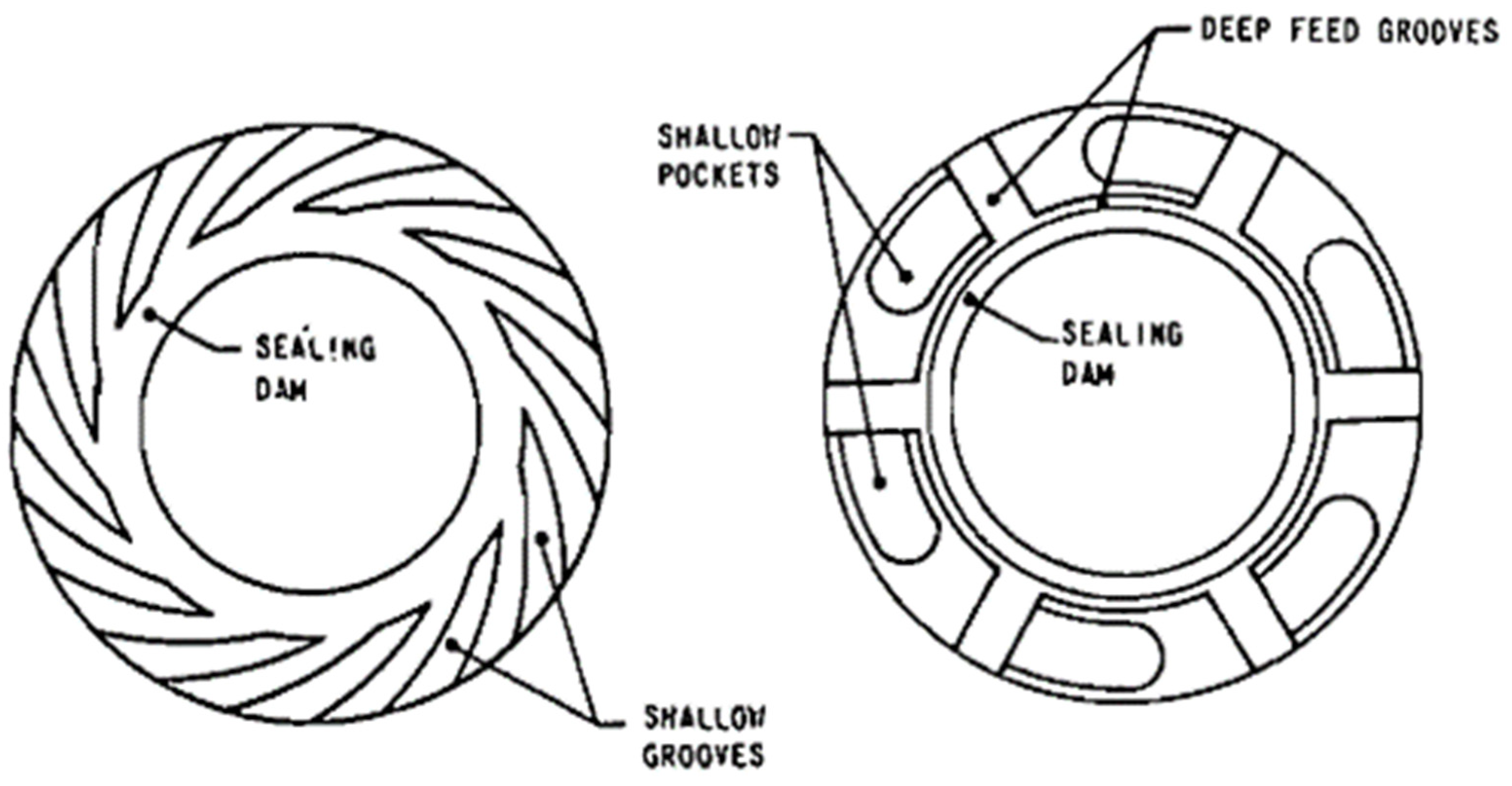

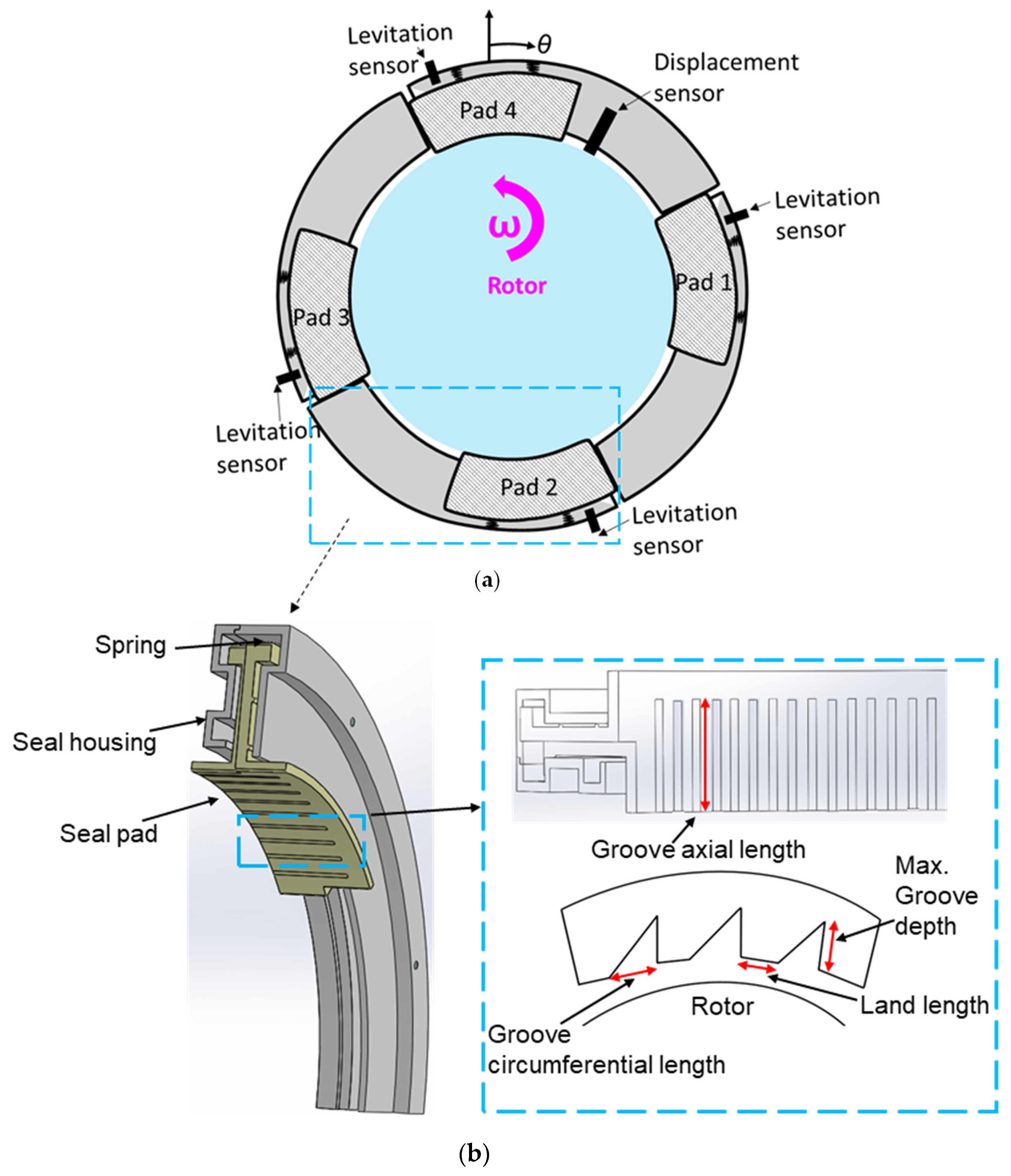

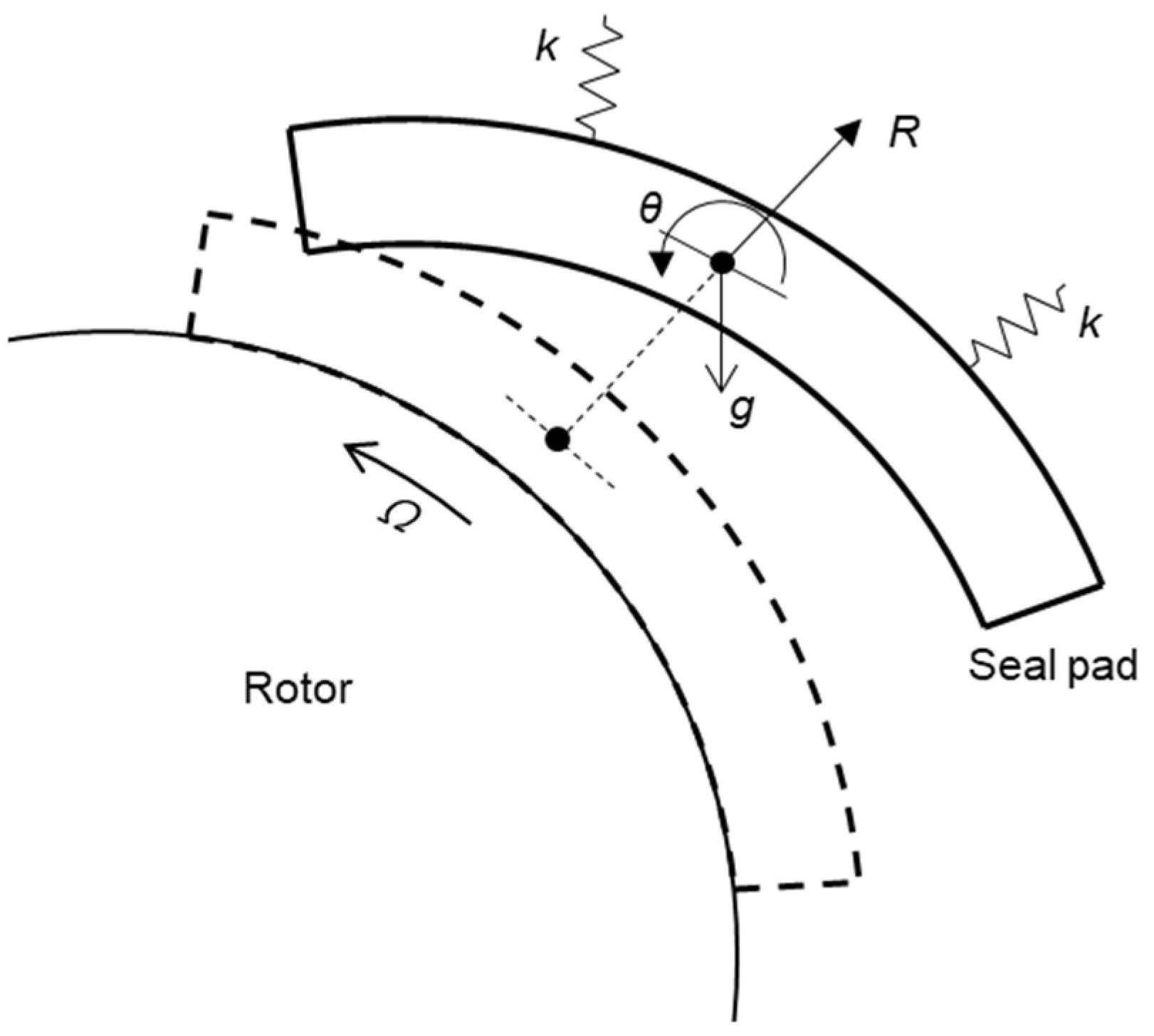

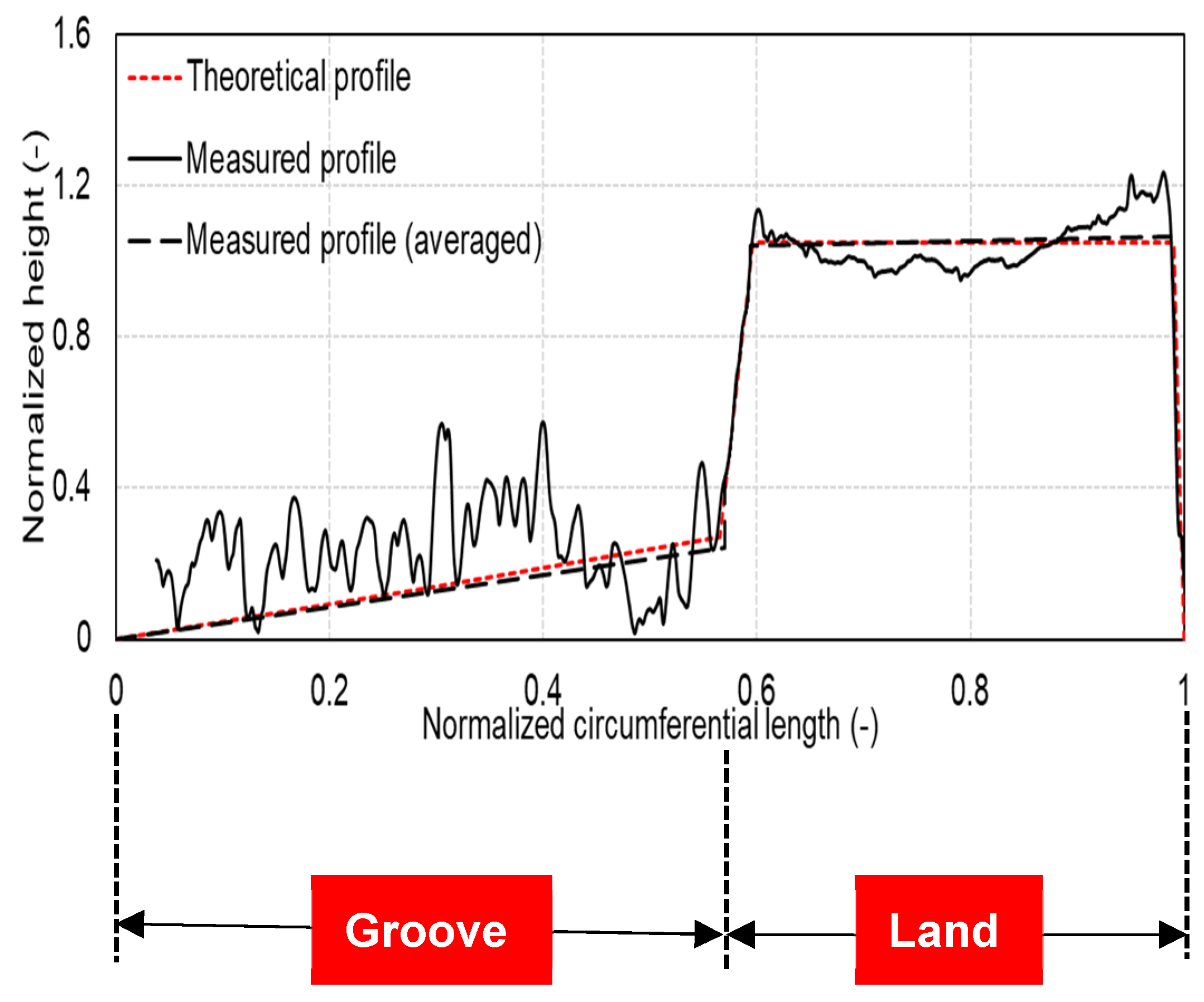

2. Description of FRS

3. Experimental Method for Estimation of FRS Pad Levitation

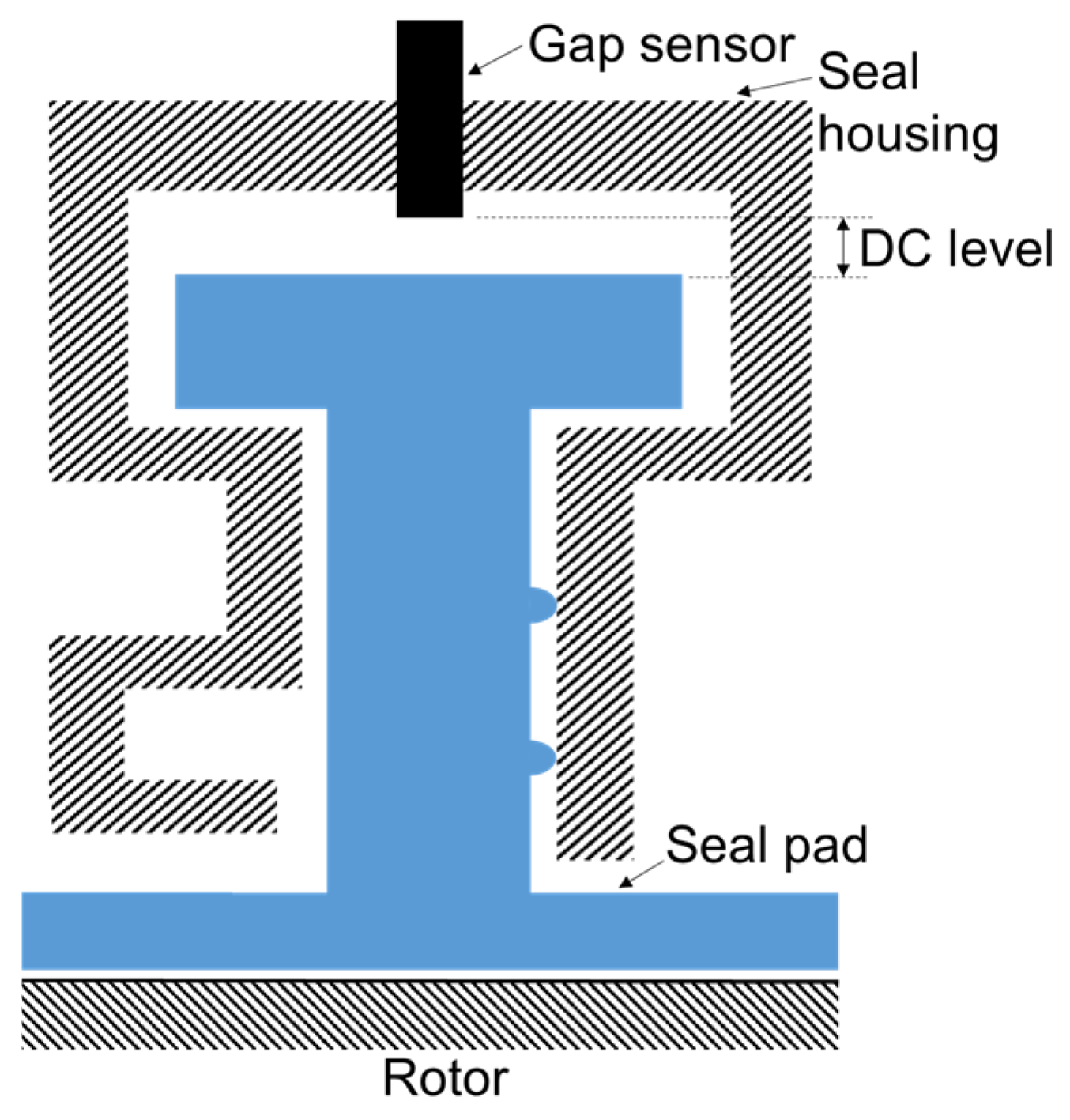

3.1. Description of the Test Rig

3.2. Measurements of Pad Levitation

4. Results

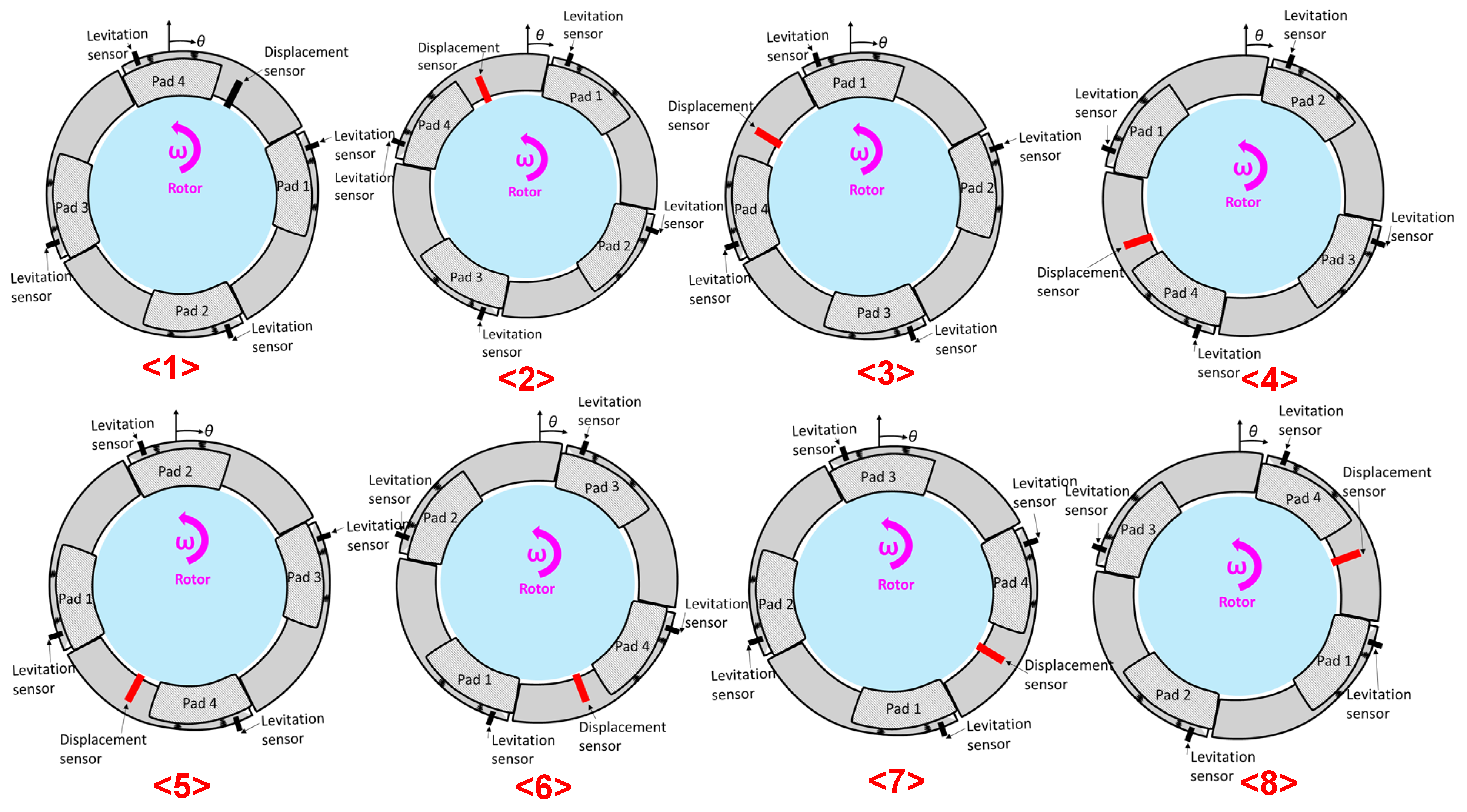

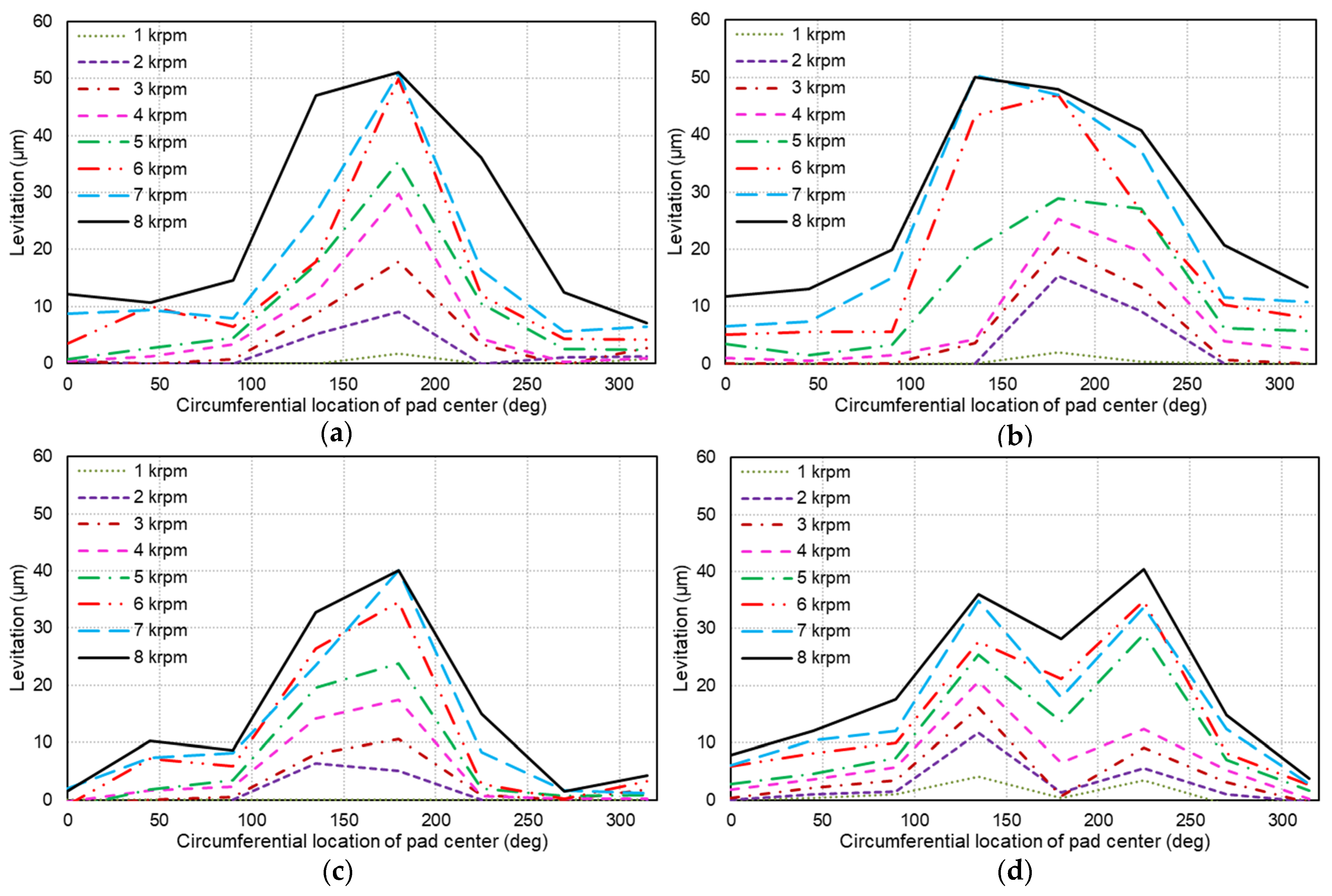

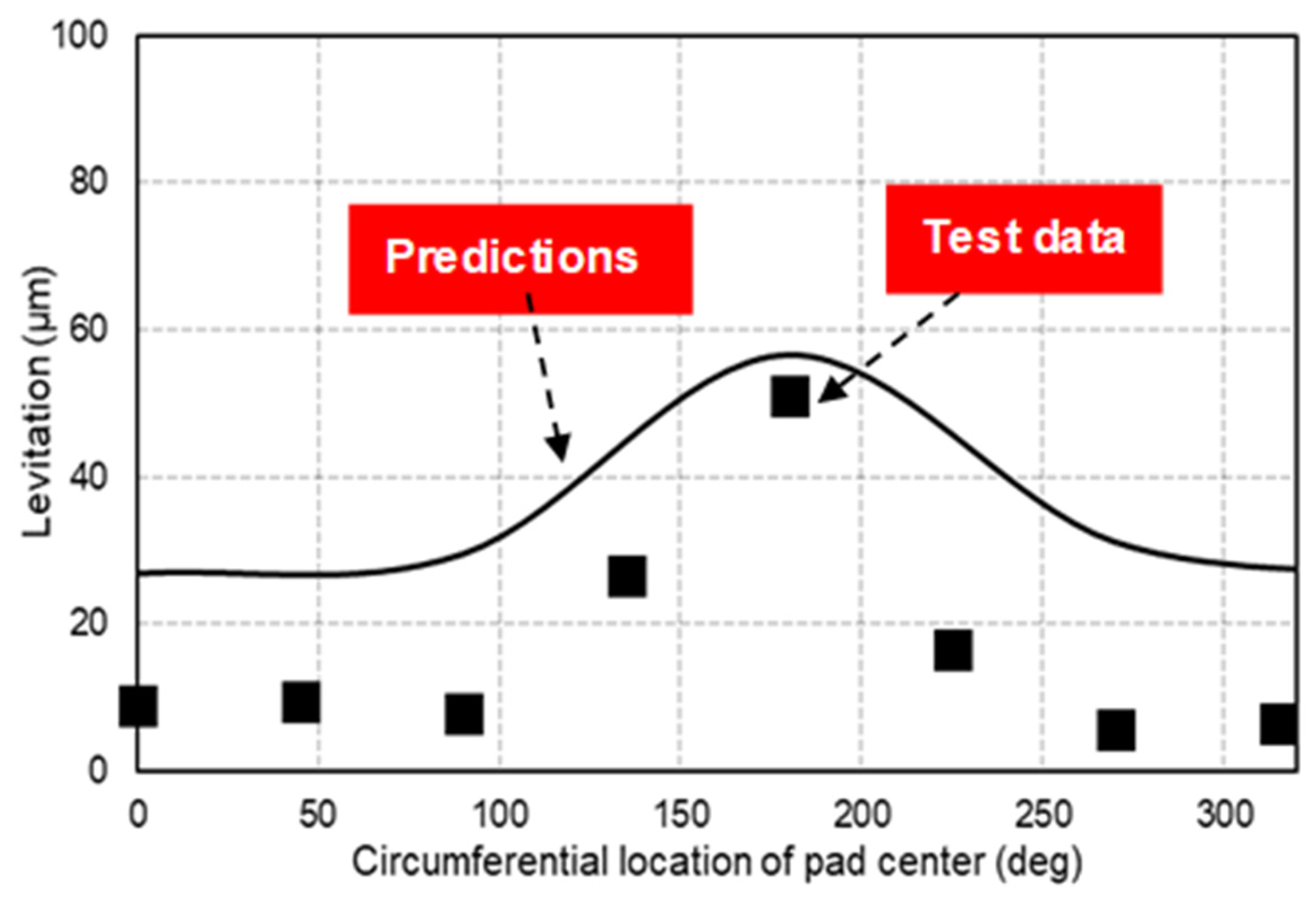

4.1. Pad Levitation vs. Circumferential Location

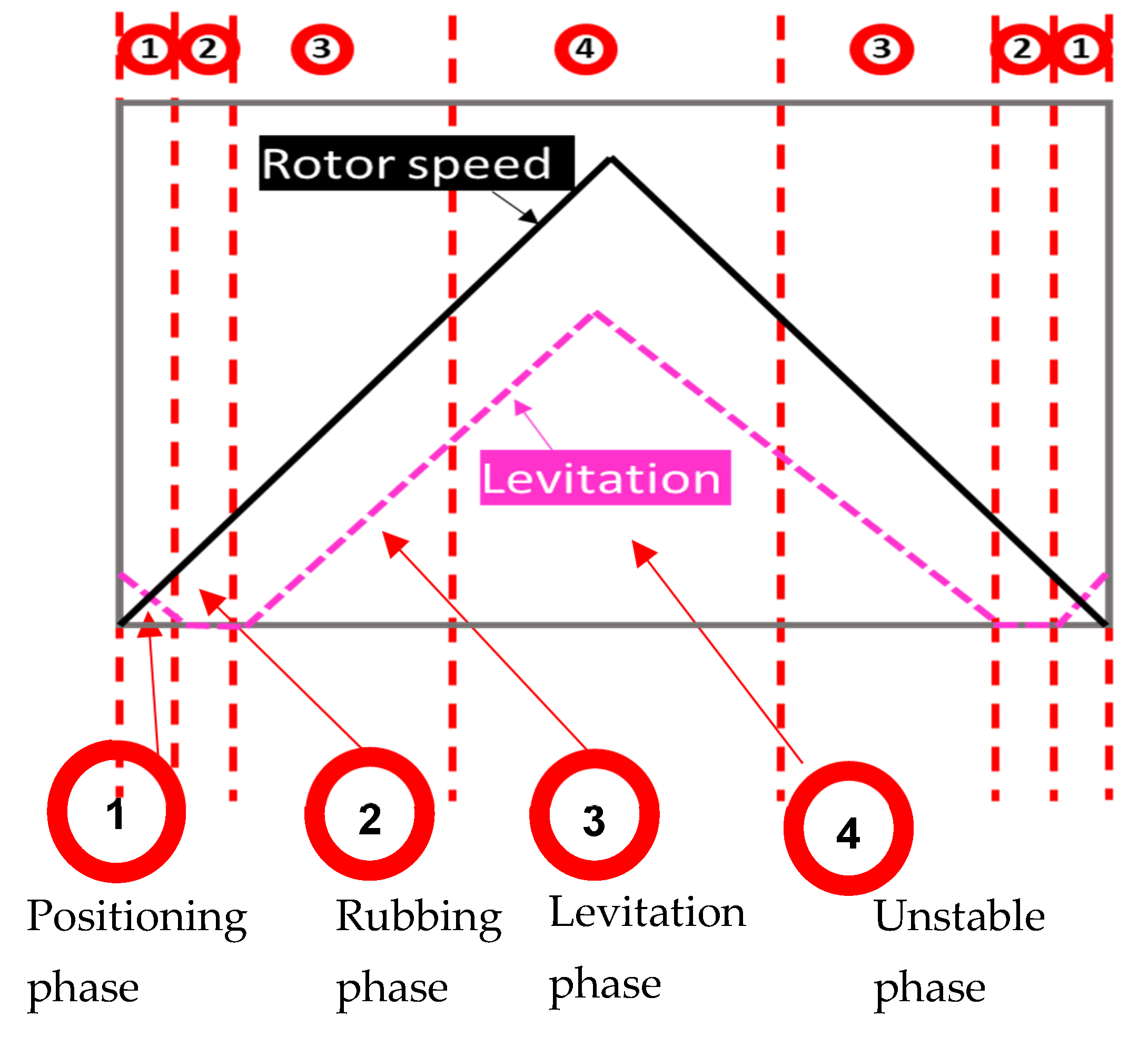

- (1)

- Positioning phase: A phase where the seal pad tries to find its position as, after assembling, the two springs at the back of the pad may become compressed or tensed or one of them may become compressed and the other tensed due to misalignment or any other reason. It thus takes time to adjust or find its original position where it should be in even contact with the rotor.

- (2)

- Rubbing phase: The seal pad’s displacement remains unchanged for a range of rotor speeds after it finds its real position, which is, in fact, even contact with the rotor disk. During this phase, the pad is in constant contact with the rotor as its displacement remains unchanged.

- (3)

- Levitation phase: FRS pads rub against the rotor disk until the pressure force becomes high enough to elevate the pad. True levitation starts at this point.

- (4)

- Unstable phase: With further increases in the rotor speed, a point comes where the time signal disrupts and noise can be observed, indicating the start of the unstable phase. The unstable phase lasts until the highest rotor speed. Although the time signal has noise, its DC level can still be observed, indicating pad levitation.

4.2. Test Data Compared with Theory

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Black, H.F. Effects of Hydraulic Forces in Annular Pressure Seals on the Vibrations of Centrifugal Pump Rotors. J. Mech. Eng. Sci. 1969, 11, 206–213. [Google Scholar] [CrossRef]

- Tibos, S.M.; Teixeira, J.A.; Georgakis, C. Investigation of Effective Groove Types for a Film Riding Seal. J. Eng. Gas Turbines Power 2017, 139, 072503. [Google Scholar] [CrossRef]

- Chupp, R.E.; Hendricks, R.C.; Lattime, S.B.; Steinetz, B.M. Sealing in Turbomachinery. J. Propuls. Power 2006, 22, 313–349. [Google Scholar] [CrossRef]

- Munson, J.; Pecht, G. Development of Film Riding Face Seals for a Gas Turbine Engine. Tribol. Trans. 1992, 35, 65–70. [Google Scholar] [CrossRef]

- Andres, L.S.; Ashton, Z. Comparison of Leakage Performance in Three Types of Gas Annular Seals Operating at a High Temperature (300 °C). Tribol. Trans. 2010, 53, 463–471. [Google Scholar] [CrossRef]

- Lynwander, P. Development of Helicopter Engine Seals; NASA Lewis Research Center: Cleveland, OH, USA, 1973. [Google Scholar]

- Lynwander, P. Development of Self-Acting Seals for Helicopter Engines; NASA Lewis Research Center: Cleveland, OH, USA, 1975. [Google Scholar]

- John, H.M. Testing of a High Performance Compressor Discharge Seal. In Proceedings of the AIAA/SAE/ASME/ASEE 29th Joint Propulsion Conference and Exhibit, Monterey, CA, USA, 28–30 June 1993. [Google Scholar]

- Steinetz, B.M.; Hendricks, R.C.; Munson, J. Advanced Seal Technology Role in Meeting Next Generation. In Proceedings of the RTO AVT Symposium on “Design Principles and Methods for Aircraft Gas Turbine Engines”, Toulouse, France, 11–15 May 1998; pp. 1–13. [Google Scholar]

- Sayma, A.I.; Bréard, C.; Vahdati, M.; Imregun, M. Aeroelasticity Analysis of Air-Riding Seals for Aero-Engine Applications. J. Tribol. 2002, 124, 607–616. [Google Scholar] [CrossRef]

- Sedy, J. Improved Performance of Film-Riding Gas Seals through Enhancement of Hydrodynamic Effects. ASLE Trans. 1980, 23, 35–44. [Google Scholar] [CrossRef]

- Jung, J.W.; Hwang, S.H.; Kim, T.H.; Kim, E.; Ha, J.W. Leakage Measurements of Labyrinth Seal, Brush Seal, and Radial Film Riding Face Seal. KSFM J. Fluid Mach. 2023, 26, 29–37. [Google Scholar] [CrossRef]

- Guardino, C.; Chew, J.W.; Hills, N.J. Calculation of Surface Roughness Effects on Air-Riding Seals. In Proceedings of the ASME Turbo Expo 2002, Amsterdam, The Netherlands, 3–6 June 2002; Volume 126, pp. 75–82. [Google Scholar]

- Trivedi, D.; Bidkar, R.A.; Wolfe, C.; Zheng, X. Film-Stiffness Characterization for Supercritical CO2 Film-Riding Seals. Proc. ASME Turbo Expo 2018, 5B-2018, 1–10. [Google Scholar] [CrossRef]

- Bidkar, R.A.; Sevincer, E.; Wang, J.; Thatte, A.M.; Mann, A.; Peter, M.; Musgrove, G.; Allison, T.; Moore, J. Low-Leakage Shaft-End Seals for Utility-Scale Supercritical CO2 Turboexpanders. J. Eng. Gas Turbines Power 2017, 139, 022503. [Google Scholar] [CrossRef]

- Bidkar, R.A.; Kumar, U.; Trivedi, D.; Zhang, X.; Rambacher, C.; Rimpel, A.; Kerr, T.; Johnson, J. Development of Large-Diameter Hybrid Film-Riding Seals for sCO2 Turbines. Proc. ASME Turbo Expo 2024, 8, 1–11. [Google Scholar] [CrossRef]

- Yang, S.H.; Kim, C.; Lee, Y.B. Experimental Study on the Characteristics of Pad Fluttering in a Tilting Pad Journal Bearing. Tribol. Int. 2006, 39, 686–694. [Google Scholar] [CrossRef]

| Rotor Disk Diameter (mm) | Seal Pad Diameter of Curvature (mm) | Seal Pad Axial Length (mm) | Groove Axial Length (mm) | Groove Arc Length (mm) | Rotor Material | Operating Conditions | Rotor Speed (krpm) |

|---|---|---|---|---|---|---|---|

| 140 | 140 | 13 | 10.4 | 1.22 | Steel | Room | 0–8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mehdi, S.M.; Kim, Y.C.; Kim, E. Levitation Performance of Radial Film Riding Seals for Gas Turbine Engines. Lubricants 2024, 12, 433. https://doi.org/10.3390/lubricants12120433

Mehdi SM, Kim YC, Kim E. Levitation Performance of Radial Film Riding Seals for Gas Turbine Engines. Lubricants. 2024; 12(12):433. https://doi.org/10.3390/lubricants12120433

Chicago/Turabian StyleMehdi, Syed Muntazir, Young Cheol Kim, and Eojin Kim. 2024. "Levitation Performance of Radial Film Riding Seals for Gas Turbine Engines" Lubricants 12, no. 12: 433. https://doi.org/10.3390/lubricants12120433

APA StyleMehdi, S. M., Kim, Y. C., & Kim, E. (2024). Levitation Performance of Radial Film Riding Seals for Gas Turbine Engines. Lubricants, 12(12), 433. https://doi.org/10.3390/lubricants12120433