Wear and Friction Characteristics of In Situ TiC-Reinforced Ti3SiC2-Ti5Si3 Composites Against 100Cr6 Steel Counterpart

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

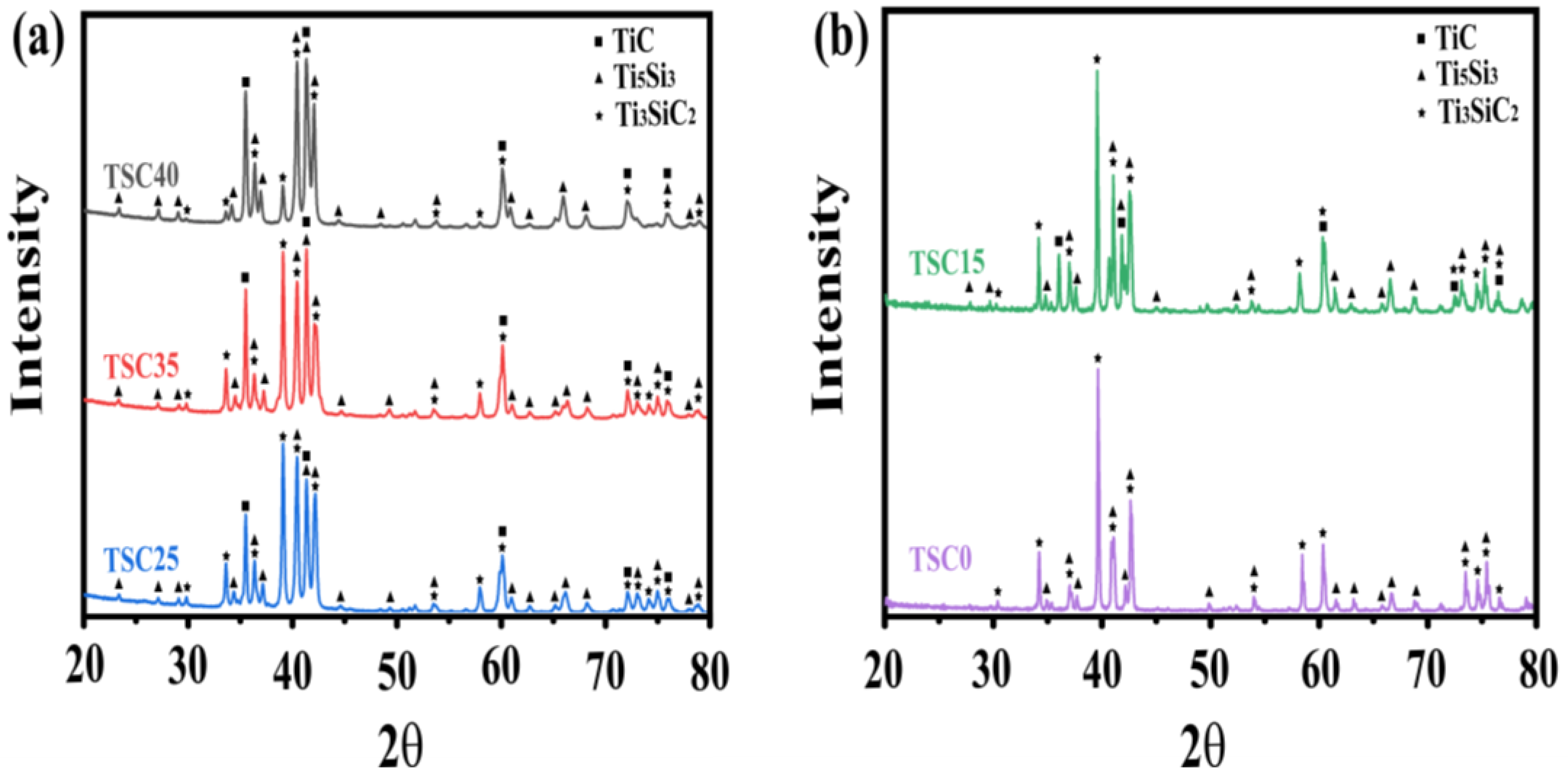

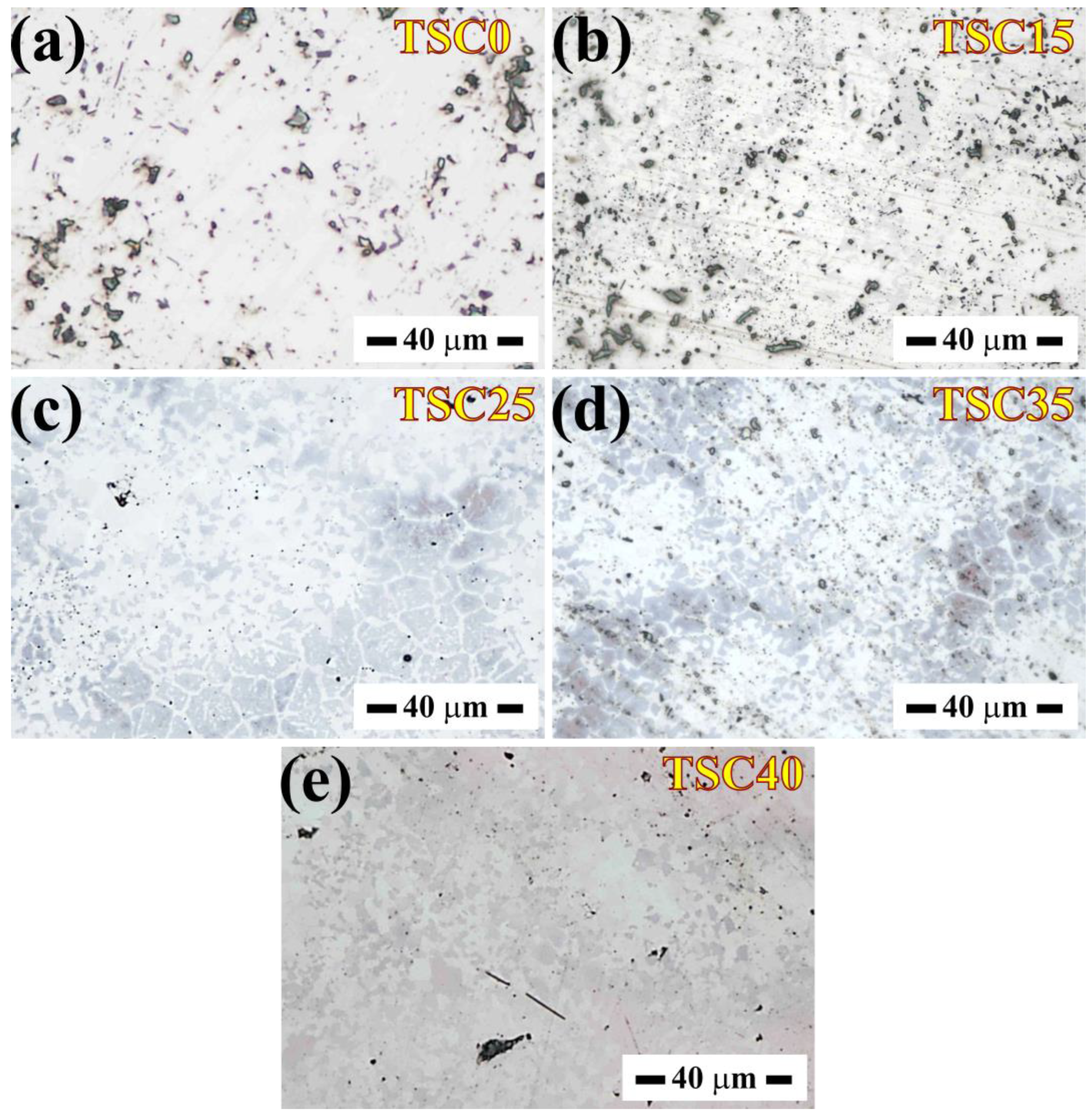

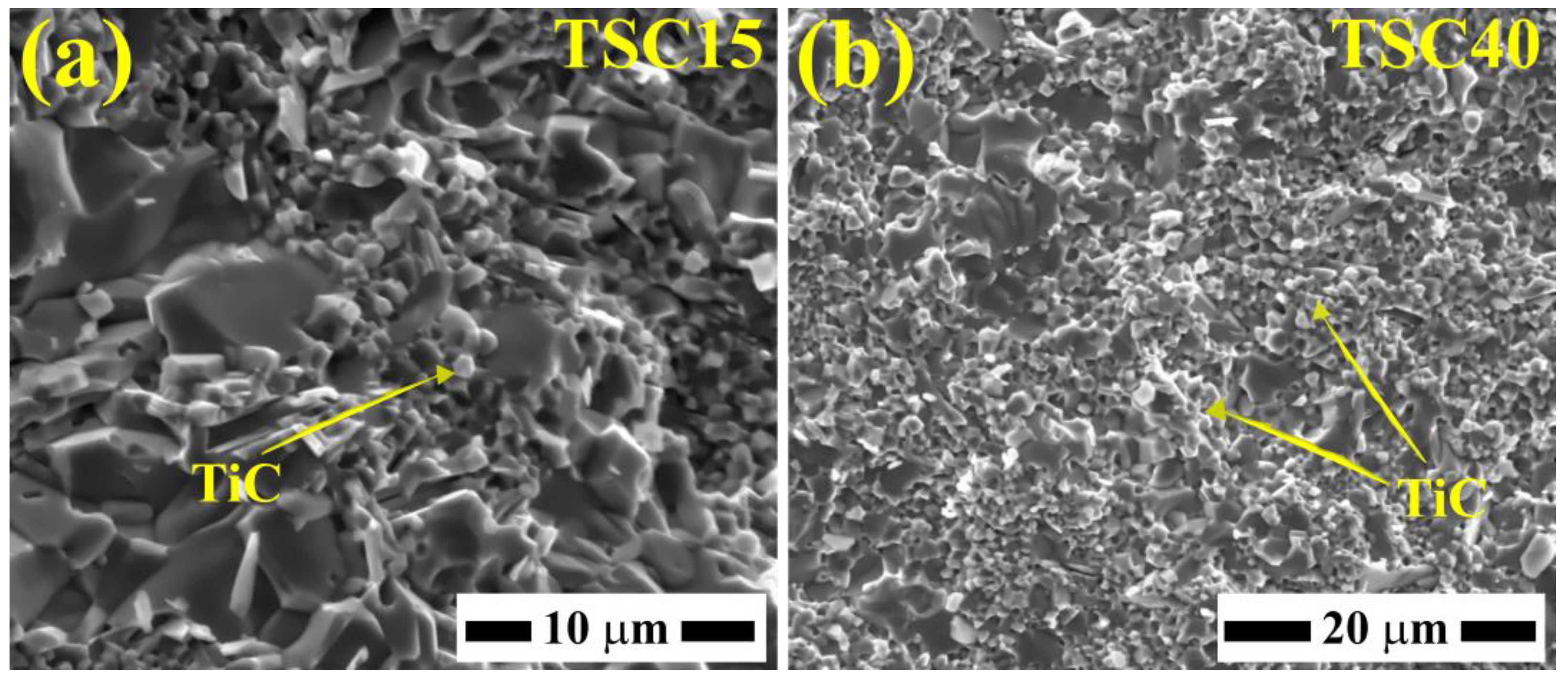

3.1. Microstructures and Phase Analysis of the TSC Composites

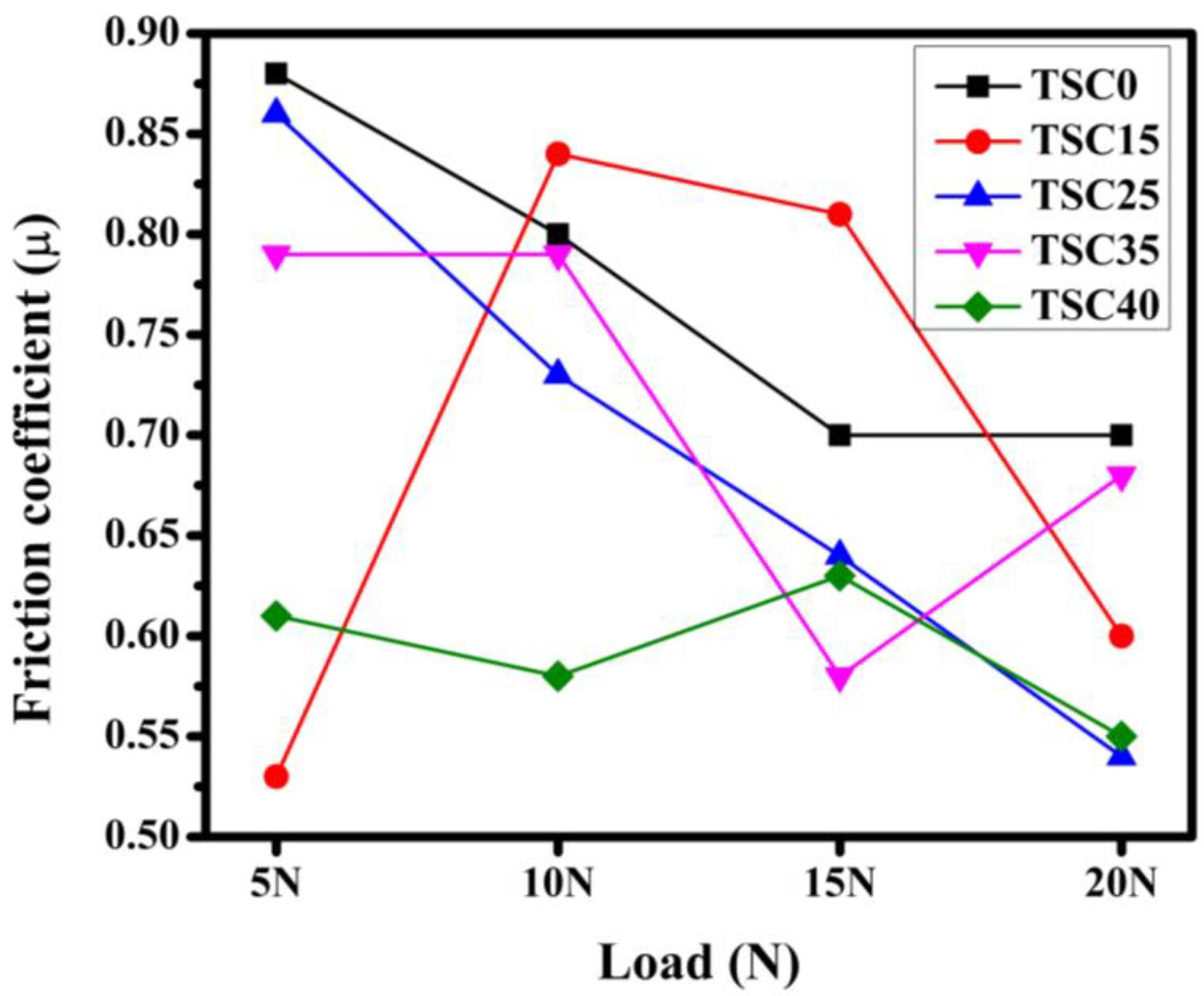

3.2. Wear and Friction Behavior of the TSC Composites

4. Conclusions

- Incorporation of the TiC phase provided increases in the hardness and wear resistance of the Ti3SiC2/Ti5Si3 matrix.

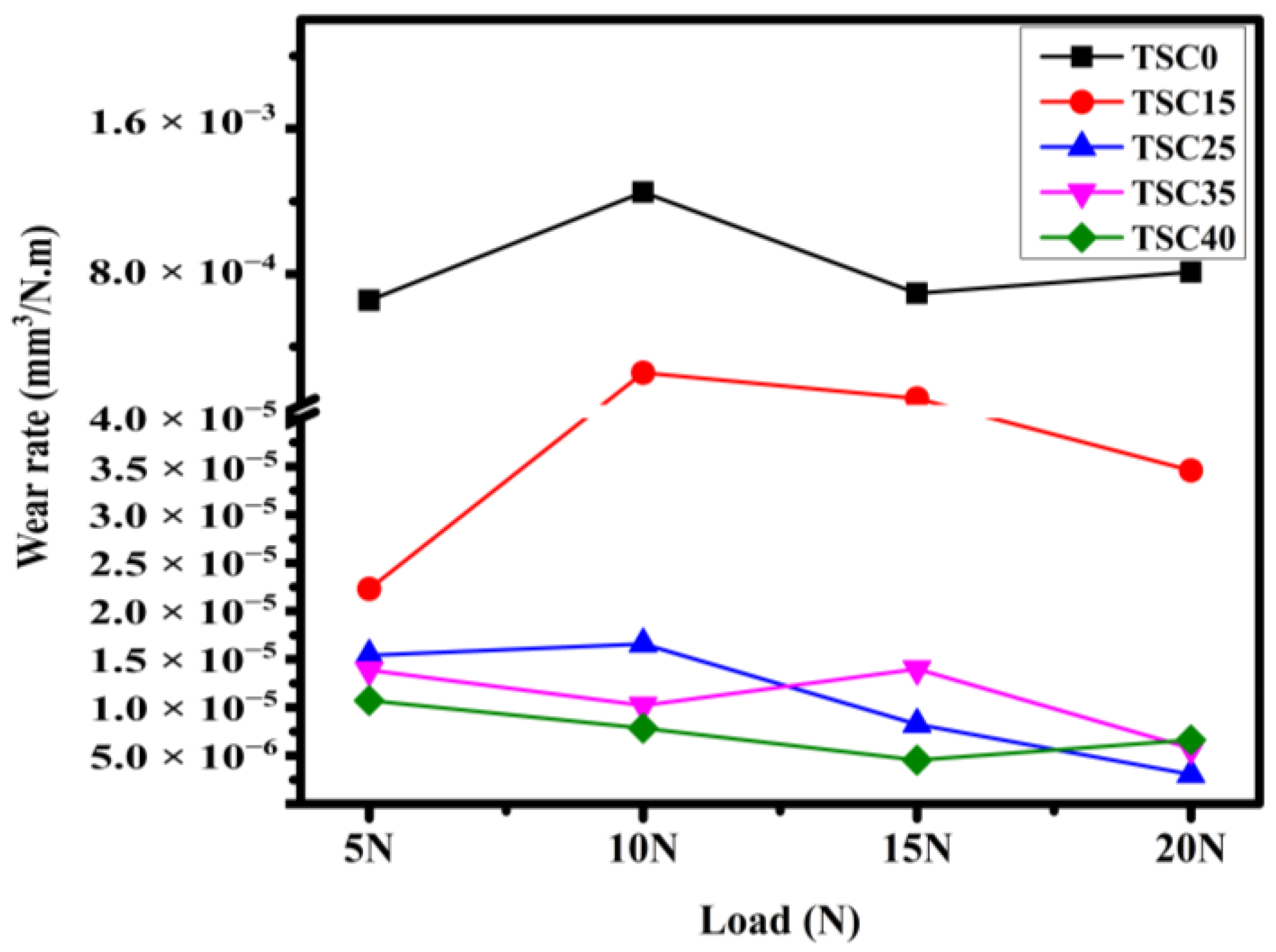

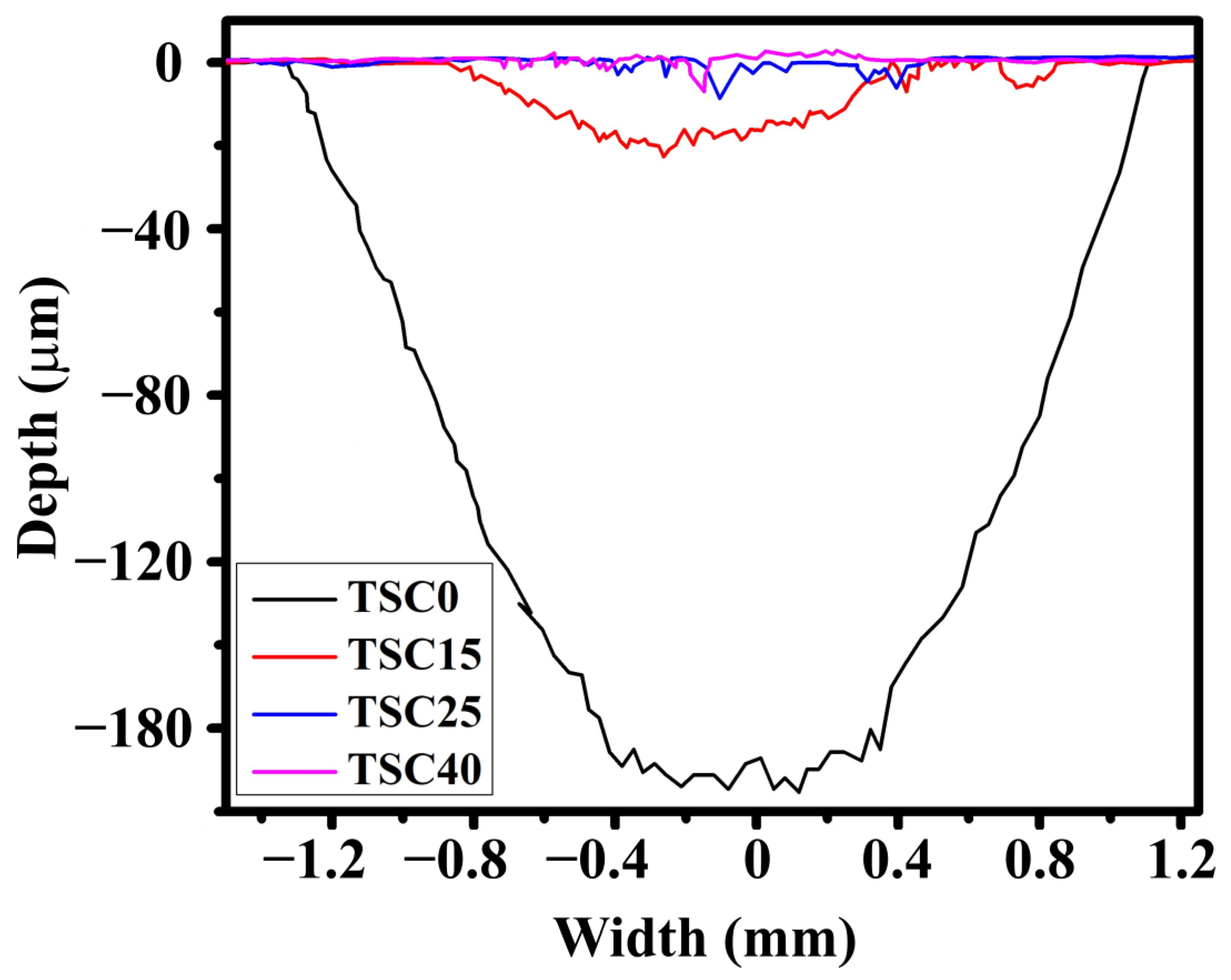

- Two wear regimes were observed in this study, namely, a severe-wear regime and a mild-wear regime:

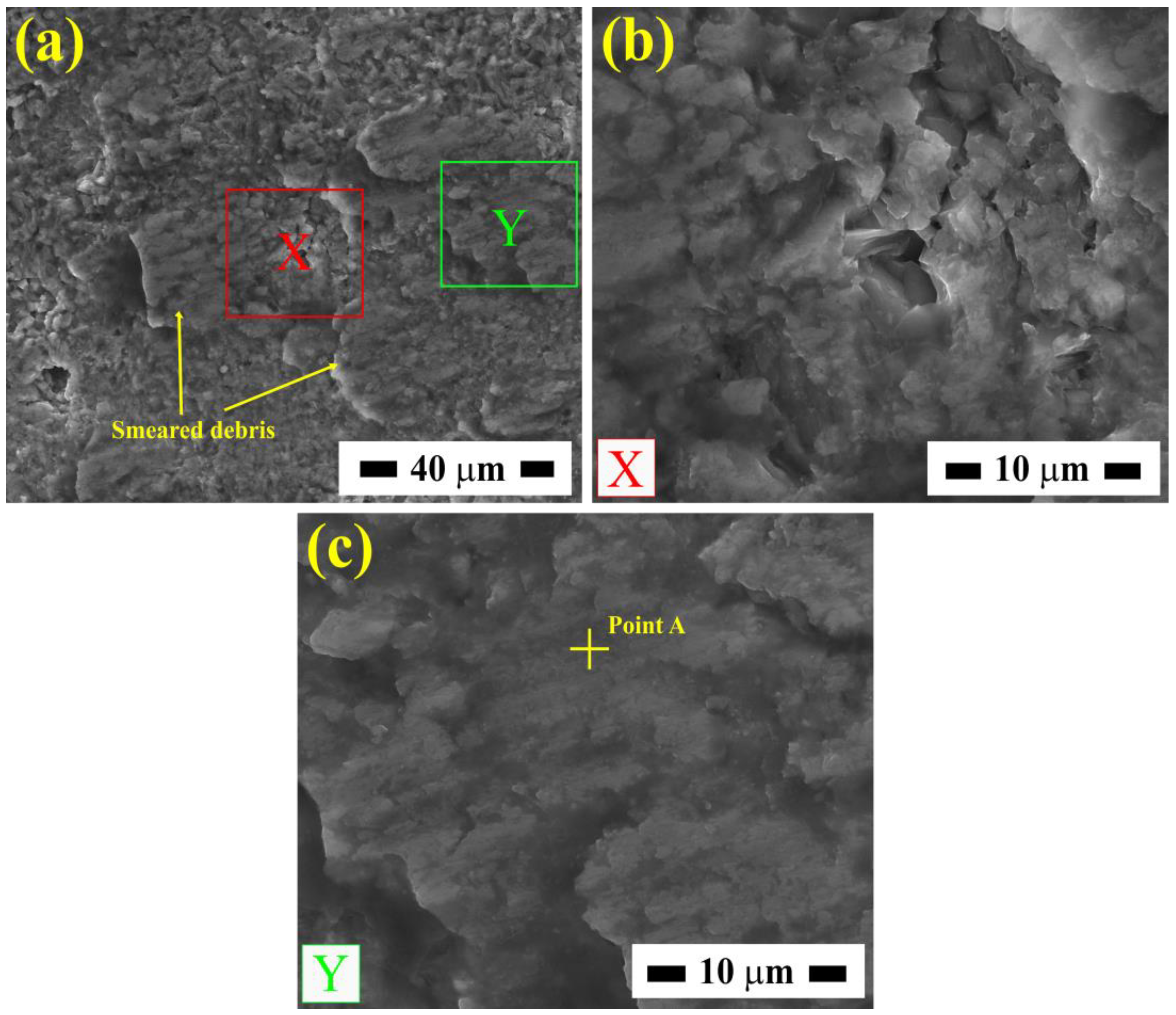

- The first was characterized by high adhesive wear behavior, tribo-oxidative wear, and minor abrasive wear. The 0wt% TiC composite was dominated by this wear regime under all tested loads.

- The second wear regime was characterized by the deposition of a ferrous layer composed of Ti, Si, Fe, and O. The tribolayers had an anti-wear behavior with a minor lubrication effect. Within this wear regime, the friction coefficient showed a downward trend with increasing applied load.

- The composite reinforced with 15 wt.% TiC showed a transition from mild wear under 5 N to severe wear at 10 N and higher.

- As the TiC content increased to 25 wt.% and higher, only the mild-wear regime was observed.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Munz, D.; Fett, T. Overview and Basic Properties BT. In Ceramics: Mechanical Properties, Failure Behaviour, Materials Selection; Munz, D., Fett, T., Eds.; Springer: Berlin/Heidelberg, Germany, 1999; pp. 1–7. ISBN 978-3-642-58407-7. [Google Scholar]

- Karadimas, G.; Salonitis, K. Ceramic Matrix Composites for Aero Engine Applications—A Review. Appl. Sci. 2023, 13, 3017. [Google Scholar] [CrossRef]

- Barsoum, M.W. MAX Phases: Properties of Machinable Ternary Carbides and Nitrides; John Wiley & Sons: Hoboken, NJ, USA, 2013; p. 421. [Google Scholar]

- Barsoum, M.W.; Radovic, M. Elastic and Mechanical Properties of the MAX Phases. Annu. Rev. Mater. Res. 2011, 41, 195–227. [Google Scholar] [CrossRef]

- Sokol, M.; Natu, V.; Kota, S.; Barsoum, M.W. On the Chemical Diversity of the MAX Phases. Trends Chem. 2019, 1, 210–223. [Google Scholar] [CrossRef]

- Luo, Y.; Pan, W.; Li, S.; Wang, R.; Li, J. Fabrication of Al2O3–Ti3SiC2 Composites and Mechanical Properties Evaluation. Mater. Lett. 2003, 57, 2509–2514. [Google Scholar] [CrossRef]

- Lou, Z.; Li, Y.; Zou, Q.; Luo, W.; Gu, H.; Li, Z.; Luo, Y. In-Situ Fabrication and Characterization of TiC Matrix Composite Reinforced by SiC and Ti3SiC2. Ceram. Int. 2023, 49, 20849–20859. [Google Scholar] [CrossRef]

- Fan, X.; Yin, X. Microstructure and Properties of Carbon Fiber Reinforced SiC Matrix Composites Containing Ti3SiC2. Adv. Eng. Mater. 2014, 16, 670–683. [Google Scholar] [CrossRef]

- Yan, H.; Liu, K.; Zhang, P.; Zhao, J.; Qin, Y.; Lu, Q.; Yu, Z. Fabrication and Tribological Behaviors of Ti3SiC2/Ti5Si3/TiC/Ni-Based Composite Coatings by Laser Cladding for Self-Lubricating Applications. Opt. Laser Technol. 2020, 126, 106077. [Google Scholar] [CrossRef]

- Dey, M.; Fuka, M.; AlAnazi, F.; Gupta, S. Synthesis and Characterization of Novel Ni-Ti3SiC2 Composites. In Proceedings of the 42nd International Conference on Advanced Ceramics and Composites: Ceramic Engineering and Science Proceedings; John Wiley & Sons: Hoboken, NJ, USA, 2019; pp. 105–116. ISBN 9781119543381. [Google Scholar]

- Chiker, N.; Benamor, A.; Hadji, Y.; Haddad, A.; Hakem, M.; Azzaz, M.; Sahraoui, T.; Hadji, M. Microstructure and Tribological Behavior of In Situ TiC-Ni(Si,Ti) Composites Elaborated from Ni and Ti3SiC2 Powders. J. Mater. Eng. Perform. 2020, 29, 1995–2005. [Google Scholar] [CrossRef]

- Zhang, F.; Zhao, L.; Yan, S.; He, J.; Yin, F. Microstructure and Mechanical Properties of Plasma Sprayed TiC/Ti5Si3/Ti3SiC2 Composite Coatings with Al Additions. Ceram. Int. 2020, 46, 16298–16309. [Google Scholar] [CrossRef]

- Zhang, F.; Zhao, L.; Yu, G.; Chen, J.; Yan, S.; He, J.; Yin, F. Effect of Annealing Temperature on Microstructure and Mechanical Properties of Plasma Sprayed TiC-Ti5Si3-Ti3SiC2 Composite Coatings. Surf. Coat. Technol. 2021, 422, 127581. [Google Scholar] [CrossRef]

- Li, C.; Zhou, Z.; Hu, L.; He, J.; Zheng, G.; Zhao, H.; Dong, Y.; Yang, Y.; Qin, Y.; Yin, F. Fabrication of Plasma-Sprayed TiC-Ti5Si3-Ti3SiC2 Composite Coatings from the Annealed Ti/SiC Powders. Surf. Coat. Technol. 2021, 417, 127227. [Google Scholar] [CrossRef]

- Li, Y.; Bi, Y.; Xing, Y.; Li, B.; He, J.; Qin, Y.; Zhao, H. Plasma Sprayed TiC–Ti5Si3–Ti3SiC2 Composite Coatings from Ti–SiC-Graphite Powders with Different SiC Particle Size. Ceram. Int. 2023, 49, 36763–36773. [Google Scholar] [CrossRef]

- Li, C.; Zhang, F.; He, J.; Yin, F. Preparation and Properties of Reactive Plasma Sprayed TiC–Ti5Si3–Ti3SiC2/Al Coatings from Ti–Si–C–Al Mixed Powders. Mater. Chem. Phys. 2021, 269, 124772. [Google Scholar] [CrossRef]

- Benamor, A.; Hadji, Y.; Chiker, N.; Haddad, A.; Bendiba, G.; Labaiz, M.; Hakem, M.; Tricoteaux, A.; Nivot, C.; Erauw, J.-P.; et al. Spark Plasma Sintering and Tribological Behavior of Ti3SiC2–Ti5Si3–TiC Composites. Ceram. Int. 2019, 45, 21781–21792. [Google Scholar] [CrossRef]

- Magnus, C.; Cooper, D.; Ma, L.; Rainforth, W.M. Microstructures and Intrinsic Lubricity of in Situ Ti3SiC2–TiSi2–TiC MAX Phase Composite Fabricated by Reactive Spark Plasma Sintering (SPS). Wear 2020, 448–449, 203169. [Google Scholar] [CrossRef]

- Magnus, C.; Sharp, J.; Rainforth, W.M. The Lubricating Properties of Spark Plasma Sintered (SPS) Ti3SiC2 MAX Phase Compound and Composite. Tribol. Trans. 2020, 63, 38–51. [Google Scholar] [CrossRef]

- Hadji, Y.; Benamor, A.; Chiker, N.; Haddad, A.; Tala-Ighil, N.; Erauw, J.; Dupont, V.; Tricoteaux, A.; Nivot, C.; Thuault, A.; et al. Tribological behavior of composites fabricated by reactive SPS sintering in Ti-Si-C system. Int. J. Appl. Ceram. Technol. 2019, 17, 695–706. [Google Scholar] [CrossRef]

- Ghosh, N.C.; Harimkar, S.P. Phase Analysis and Wear Behavior of In-Situ Spark Plasma Sintered Ti3SiC2. Ceram. Int. 2013, 39, 6777–6786. [Google Scholar] [CrossRef]

- Usha Kiran, N.; Das, P.; Chatterjee, S.; Besra, L. Effect of ‘Ti’ Particle Size in the Synthesis of Highly Pure Ti3SiC2 MAX Phase. Nano-Struct. Nano-Objects 2022, 30, 100849. [Google Scholar] [CrossRef]

- Tabares, E.; Jiménez-Morales, A.; Tsipas, S.A. Study of the Synthesis of MAX Phase Ti3SiC2 Powders by Pressureless Sintering. Boletín Soc. Española Cerámica Vidr. 2021, 60, 41–52. [Google Scholar] [CrossRef]

- Zhang, Z.F.; Sun, Z.M.; Hashimoto, H.; Abe, T. Effects of Sintering Temperature and Si Content on the Purity of Ti3SiC2 Synthesized from Ti/Si/TiC Powders. J. Alloys Compd. 2003, 352, 283–289. [Google Scholar] [CrossRef]

- Emmerlich, J.; Music, D.; Eklund, P.; Wilhelmsson, O.; Jansson, U.; Schneider, J.M.; Högberg, H.; Hultman, L. Thermal Stability of Ti3SiC2 Thin Films. Acta Mater. 2007, 55, 1479–1488. [Google Scholar] [CrossRef]

- Mitra, R. Microstructure and Mechanical Behavior of Reaction Hot-Pressed Titanium Silicide and Titanium Silicide-Based Alloys and Composites. Metall. Mater. Trans. A 1998, 29, 1629–1641. [Google Scholar] [CrossRef]

- Frommeyer, G.; Rosenkranz, R. Structures and Properties of the Refractory Silicides Ti5Si3 and TiSi2 and Ti-Si-(Al) Eutectic Alloys BT. In Metallic Materials with High Structural Efficiency; Senkov, O.N., Miracle, D.B., Firstov, S.A., Eds.; Springer: Dordrecht, The Netherlands, 2004; pp. 287–308. [Google Scholar]

- Wang, L.; Jiang, W.; Chen, L.; Bai, G. Microstructure of Ti5Si3–TiC–Ti3SiC2 and Ti5Si3–TiC Nanocomposites in Situ Synthesized by Spark Plasma Sintering. J. Mater. Res. 2004, 19, 3004–3008. [Google Scholar] [CrossRef]

- Guedouar, B.; Hadji, Y.; Benamor, A.; Chiker, N.; Haddad, A.; Tricoteaux, A.; Erauw, J.-P.; Dupont, V.; Hadj-Larbi, F.; Soualili, M.A.; et al. Oxidation Behavior of Al-Doped Ti3SiC2-20 Wt.%Ti5Si3 Composite. Ceram. Int. 2021, 47, 33622–33631. [Google Scholar] [CrossRef]

- Zhang, W.; Yamashita, S.; Kita, H. Effect of Counterbody on Tribological Properties of B4C–SiC Composite Ceramics. Wear 2020, 458–459, 203418. [Google Scholar] [CrossRef]

- Sharma, S.K.; Manoj Kumar, B.V.; Kim, Y.-W. Tribology of WC Reinforced SiC Ceramics: Influence of Counterbody. Friction 2019, 7, 129–142. [Google Scholar] [CrossRef]

- Gupta, Y.; Manoj Kumar, B.V. ZrB2–SiC Composites for Sliding Wear Contacts: Influence of SiC Content and Counterbody. Ceram. Int. 2022, 48, 14560–14567. [Google Scholar] [CrossRef]

- Zhang, Z.F.; Sun, Z.M. Shear Fracture Behavior of Ti3SiC2 Induced by Compression at Temperatures below 1000 °C. Mater. Sci. Eng. A 2005, 408, 64–71. [Google Scholar] [CrossRef]

- Zhang, L.; Wu, J. Ti5Si3 and Ti5Si3-Based Alloys: Alloyingbehavior, Microstructure and Mechanical Property Evaluation. Acta Mater. 1998, 46, 3535–3546. [Google Scholar] [CrossRef]

- Yang, J.; Pan, L.; Gu, W.; Qiu, T.; Zhang, Y.; Zhu, S. Microstructure and Mechanical Properties of in Situ Synthesized (TiB2+TiC)/Ti3SiC2 Composites. Ceram. Int. 2012, 38, 649–655. [Google Scholar] [CrossRef]

- Kumashiro, Y.; Itoh, A.; Kinoshita, T.; Sobajima, M. The Micro-Vickers Hardness of TiC Single Crystals up to 1500 °C. J. Mater. Sci. 1977, 12, 595–601. [Google Scholar] [CrossRef]

- Rosenkranz, R.; Frommeyer, G.; Smarsly, W. Microstructures and Properties of High Melting Point Intermetallic Ti5Si3 and Ti5i2 Compounds. In High Temperature Aluminides and Intermetallics; Whang, S.H., Pope, D.P., Liu, C.T., Eds.; Elsevier: Oxford, UK, 1992; pp. 288–294. ISBN 978-1-85166-822-9. [Google Scholar]

- El-Raghy, T.; Zavaliangos, A.; Barsoum, M.W.; Kalidindi, S.R. Damage Mechanisms around Hardness Indentations in Ti3SiC2. J. Am. Ceram. Soc. 1997, 80, 513–516. [Google Scholar] [CrossRef]

- Li, J.; Jiang, D.; Tan, S. Microstructure and Mechanical Properties of in Situ Produced Ti5Si3/TiC Nanocomposites. J. Eur. Ceram. Soc. 2002, 22, 551–558. [Google Scholar] [CrossRef]

- Chiker, N.; Benamor, A.; Haddad, A.; Hadji, Y.; Hakem, M.; Badji, R.; Labaiz, M.; Azzaz, M.; Hadji, M. Pressureless Sintering and Tribological Properties of In-Situ TiC-Ni3(Al,Ti)/Ni(Al,Ti) Composites. Int. J. Refract. Met. Hard Mater. 2021, 98, 105559. [Google Scholar] [CrossRef]

| Sample Designation | Powder Ratios | Phase Composition by Weight (%) | Hardness (GPa) | Sintering Time (min) | ||

|---|---|---|---|---|---|---|

| Ti3SiC2 | Ti5Si3 | TiC | ||||

| TSC40 | 3Ti:1SiC:1C | 13.30 | 47.79 | 39.18 | 9.76 ± 0.8 | 20 |

| TSC35 | 3Ti:1SiC:1C | 39.09 | 37.20 | 35.49 | 8.11 ± 0.7 | 40 |

| TSC25 | 3Ti:1.2SiC:0.8C | 50.82 | 25.62 | 23.56 | 7.88 ± 0.4 | 20 |

| TSC15 | 3Ti:1SiC:1C:0.2Al | 58.17 | 28.03 | 13.80 | 7.22 ± 0.1 | 20 |

| TSC0 | 3Ti:1.2SiC:0.8C:0.2Al | 80.26 | 19.74 | 0 | 5.24 ± 0.5 | 20 |

| Loads | |||||

|---|---|---|---|---|---|

| Sample | 5 N | 10 N | 15 N | 20 N | |

| TSC0 | Μ | 0.88 | 0.8 | 0.7 | 0.7 |

| SWR (mm3/N·m) × 10−4 | 6.5 | 12.5 | 6.9 | 8.1 | |

| Ball’s SWR (mm3/N·m) × 10−4 | 0.11 | 0.06 | 0.12 | 0.1 | |

| TSC15 | Μ | 0.53 | 0.84 | 0.81 | 0.6 |

| SWR (mm3/N·m) × 10−4 | 0.2 | 2.6 | 1.2 | 0.34 | |

| Ball’s SWR (mm3/N·m) × 10−4 | 0.09 | 0.26 | 0.23 | 0.17 | |

| TSC25 | Μ | 0.86 | 0.73 | 0.64 | 0.54 |

| SWR (mm3/N·m) × 10−4 | 0.15 | 0.16 | 0.08 | 0.03 | |

| Ball’s SWR (mm3/N·m) × 10−4 | 0.02 | 0.07 | 0.09 | 0.07 | |

| TSC35 | Μ | 0.79 | 0.79 | 0.58 | 0.68 |

| SWR (mm3/N·m) × 10−4 | 0.14 | 0.10 | 0.14 | 0.05 | |

| Ball’s SWR (mm3/N·m) ×10−4 | 0.01 | 0.014 | 0.04 | 0.05 | |

| TSC40 | Μ | 0.61 | 0.58 | 0.63 | 0.55 |

| SWR (mm3/N·m) × 10−4 | 0.10 | 0.07 | 0.04 | 0.06 | |

| Ball’s SWR (mm3/N·m) × 10−4 | 0.13 | 0.06 | 0.05 | 0.08 | |

| Point | Ti | Si | C | O | Fe | Nominal Elemental Comp. |

|---|---|---|---|---|---|---|

| A | 66 ± 0.1 | 9 ± 1 | 22 ± 0.9 | 3 ± 0.3 | 0.3 ± 0.2 | Ti66CxSi9O3Fe0.3 |

| B | 39 ± 0.4 | 6 ± 0.3 | 20 ± 1 | 23 ± 1.3 | 12 ± 0.5 | Ti39CxSi6O23Fe12 |

| C | 27 ± 0.05 | 4 ± 1.2 | 20 ± 0.8 | 23 ± 2 | 26 ± 2 | Ti27Fe26O23CxSi4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Benamor, A.; Benamor, H.; Hadji, Y.; Dey, M.; Chiker, N.; Haddad, A.; Badji, R.; Tricoteaux, A.; Erauw, J.-P.; Salhi, M.; et al. Wear and Friction Characteristics of In Situ TiC-Reinforced Ti3SiC2-Ti5Si3 Composites Against 100Cr6 Steel Counterpart. Lubricants 2024, 12, 368. https://doi.org/10.3390/lubricants12110368

Benamor A, Benamor H, Hadji Y, Dey M, Chiker N, Haddad A, Badji R, Tricoteaux A, Erauw J-P, Salhi M, et al. Wear and Friction Characteristics of In Situ TiC-Reinforced Ti3SiC2-Ti5Si3 Composites Against 100Cr6 Steel Counterpart. Lubricants. 2024; 12(11):368. https://doi.org/10.3390/lubricants12110368

Chicago/Turabian StyleBenamor, Abdessabour, Hiba Benamor, Youcef Hadji, Maharshi Dey, Nabil Chiker, Adel Haddad, Riad Badji, Arnaud Tricoteaux, Jean-Pierre Erauw, Merouane Salhi, and et al. 2024. "Wear and Friction Characteristics of In Situ TiC-Reinforced Ti3SiC2-Ti5Si3 Composites Against 100Cr6 Steel Counterpart" Lubricants 12, no. 11: 368. https://doi.org/10.3390/lubricants12110368

APA StyleBenamor, A., Benamor, H., Hadji, Y., Dey, M., Chiker, N., Haddad, A., Badji, R., Tricoteaux, A., Erauw, J.-P., Salhi, M., & Hadji, M. (2024). Wear and Friction Characteristics of In Situ TiC-Reinforced Ti3SiC2-Ti5Si3 Composites Against 100Cr6 Steel Counterpart. Lubricants, 12(11), 368. https://doi.org/10.3390/lubricants12110368