Comparative Cutting Fluid Study on Optimum Grinding Parameters of Ti-6Al-4V Alloy Using Flood, Minimum Quantity Lubrication (MQL), and Nanofluid MQL (NMQL)

Abstract

1. Introduction

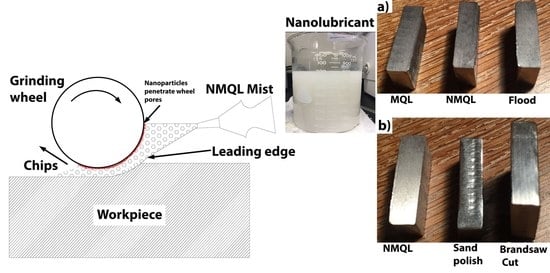

2. Material and Processes

2.1. Materials

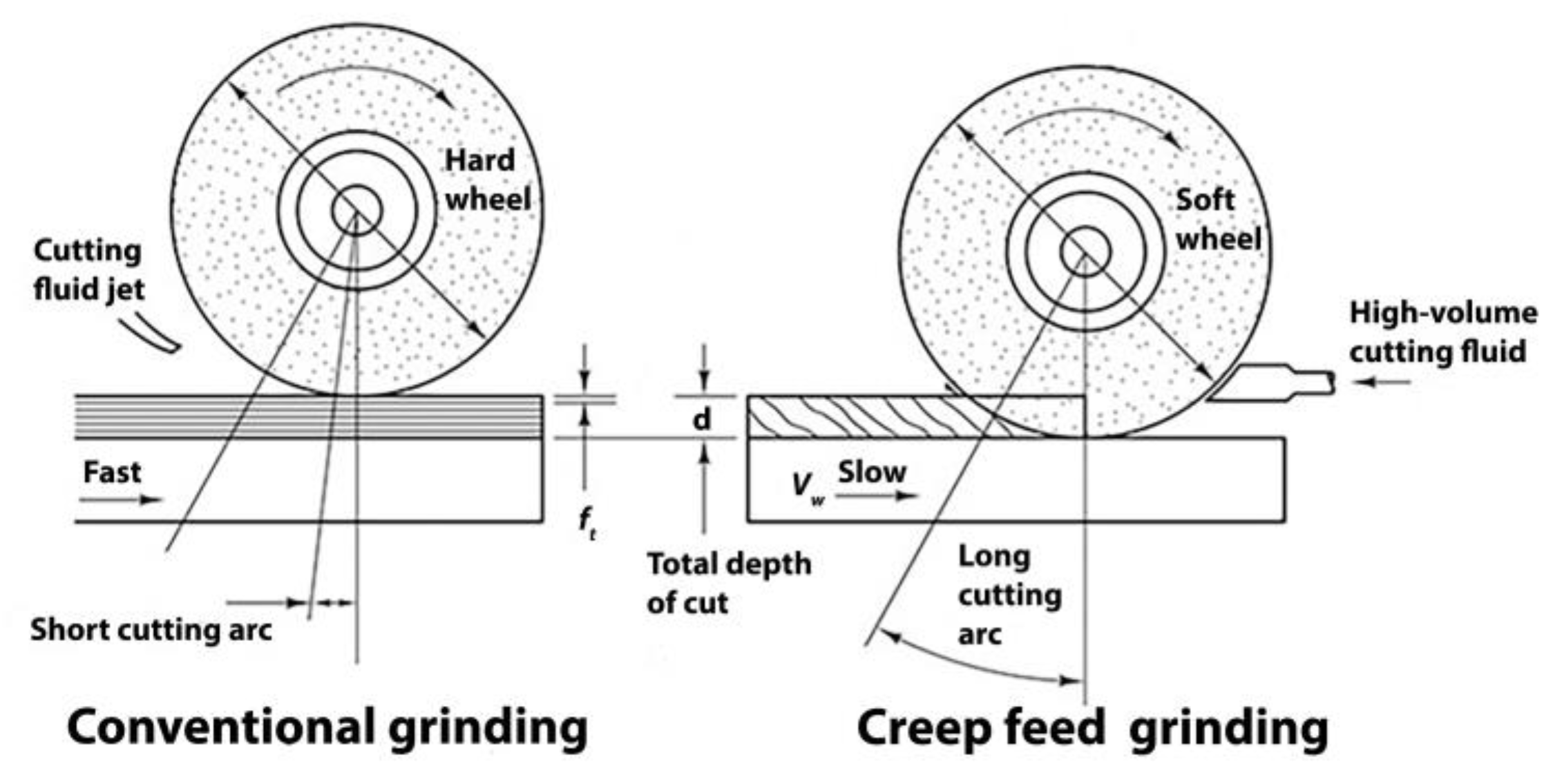

2.2. Grinding Operation

3. Experimentation

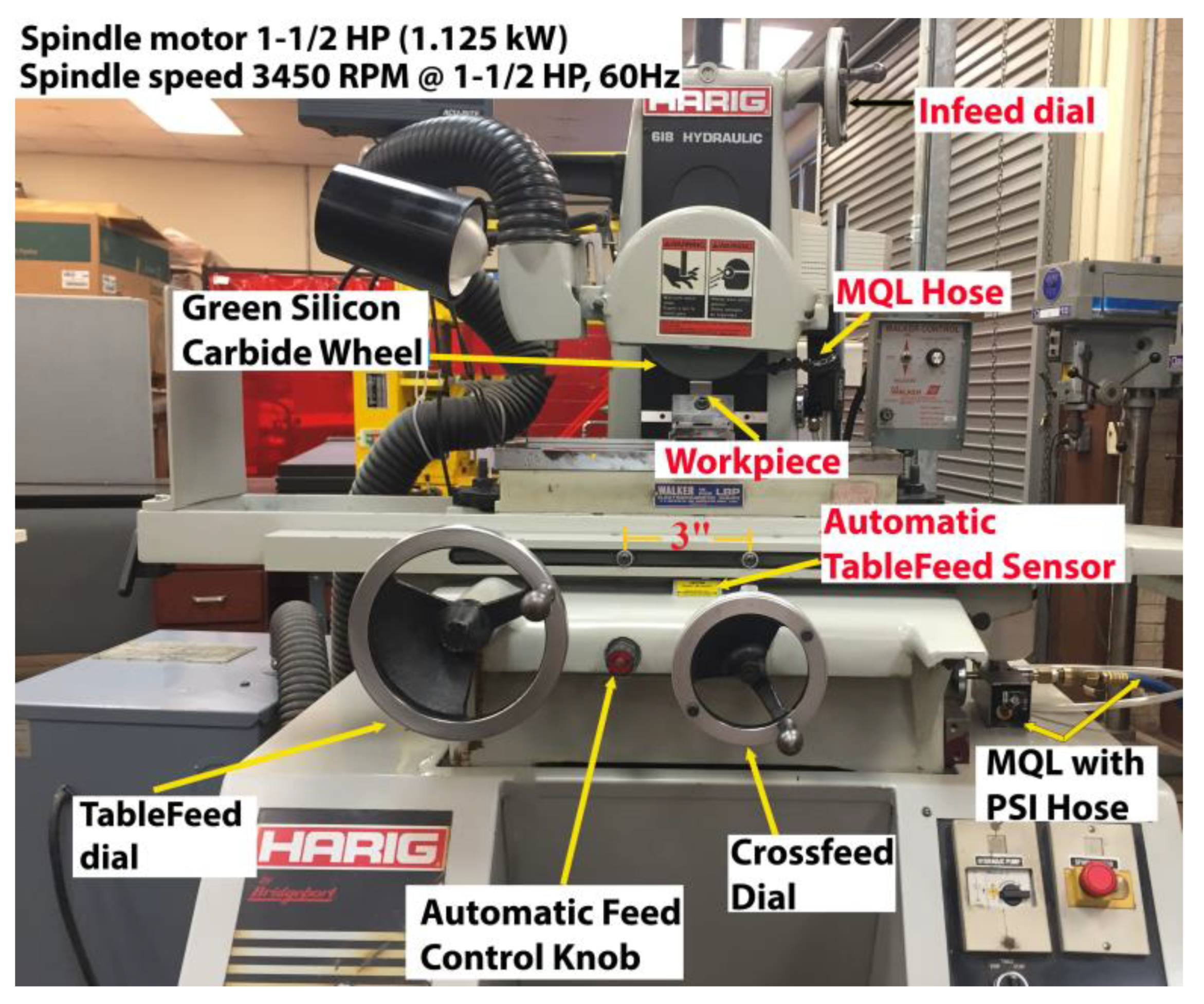

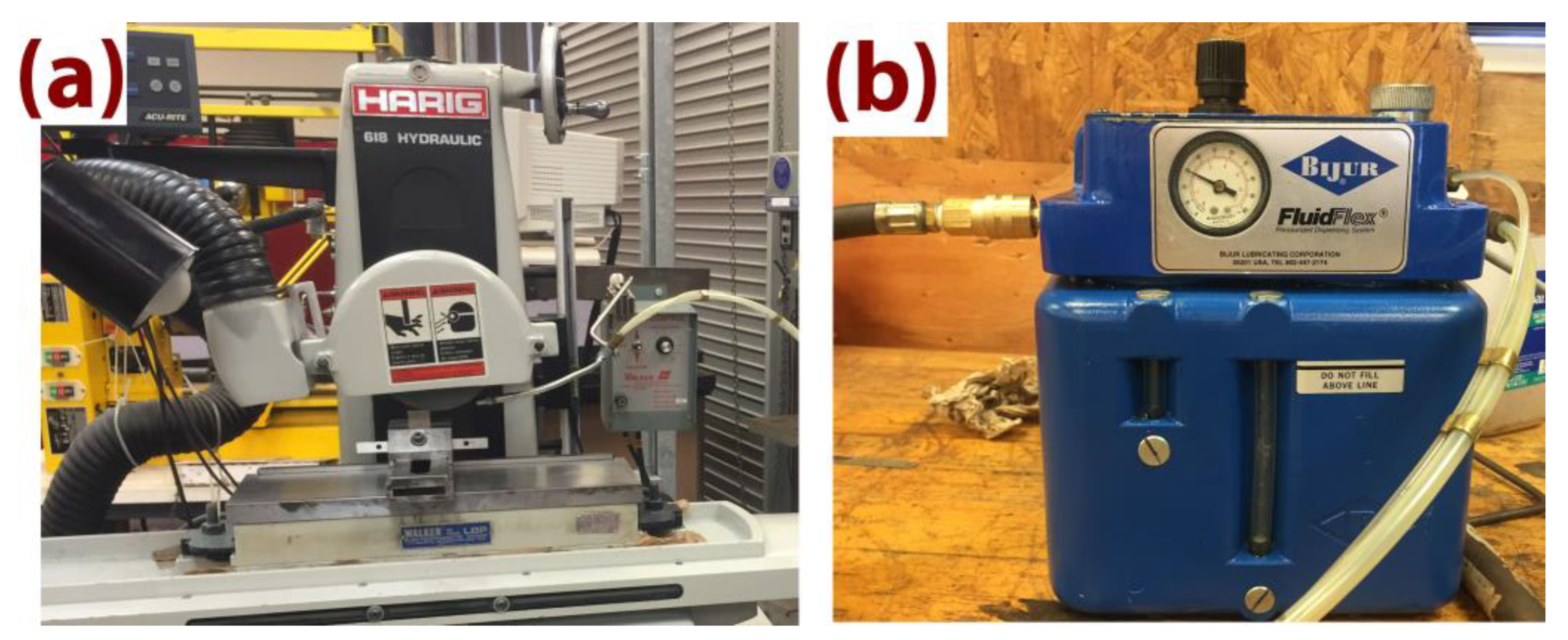

3.1. Hydraulic Surface Grinder

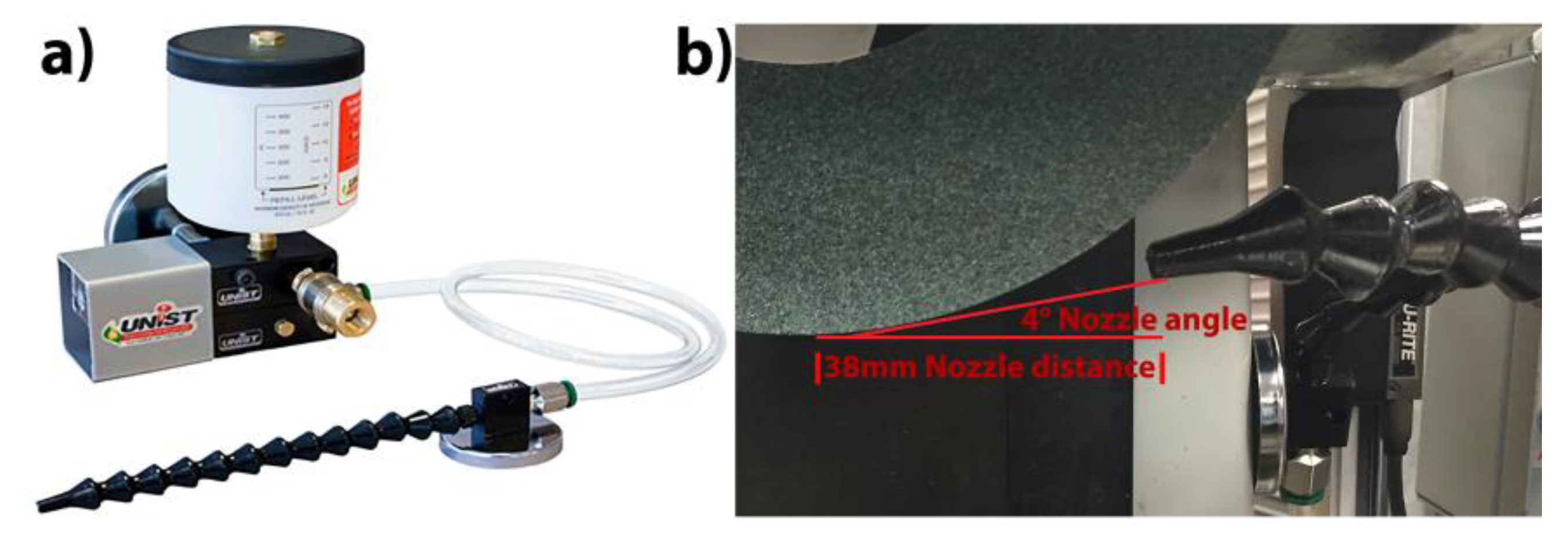

3.2. Minimum Quantity Lubrication (MQL)

3.3. Minimum Quantity Lubrication with Nanofluid

3.4. Flood Pressurized Lubrication

3.5. Preliminary Experiments

3.6. Flood Lubrication, MQL and NMQL Grinding Experiment

4. Results and Discussions

4.1. Experimental Results for Flood Lubrication, MQL, and NMQL

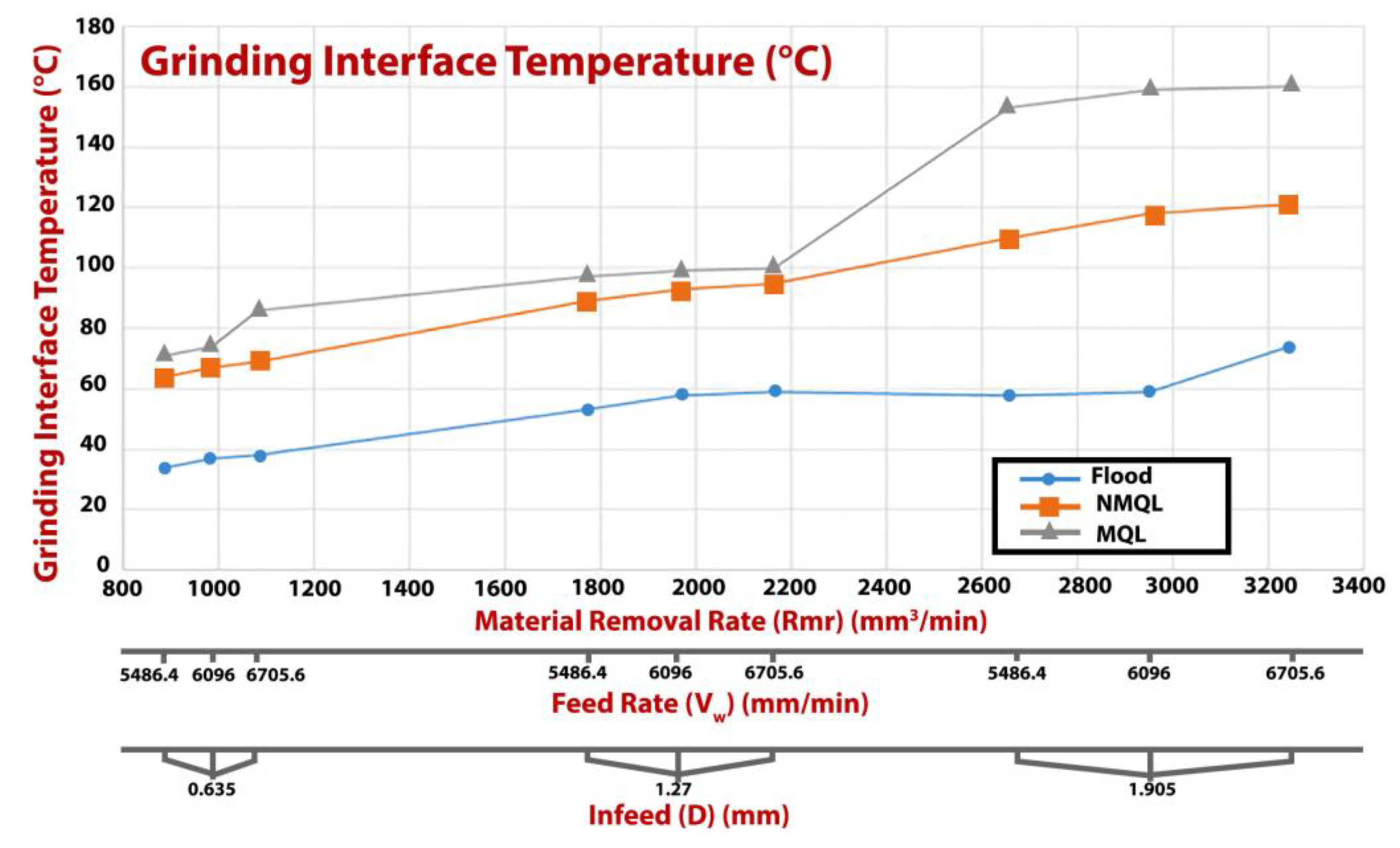

4.2. Grinding Interface Temperature Results

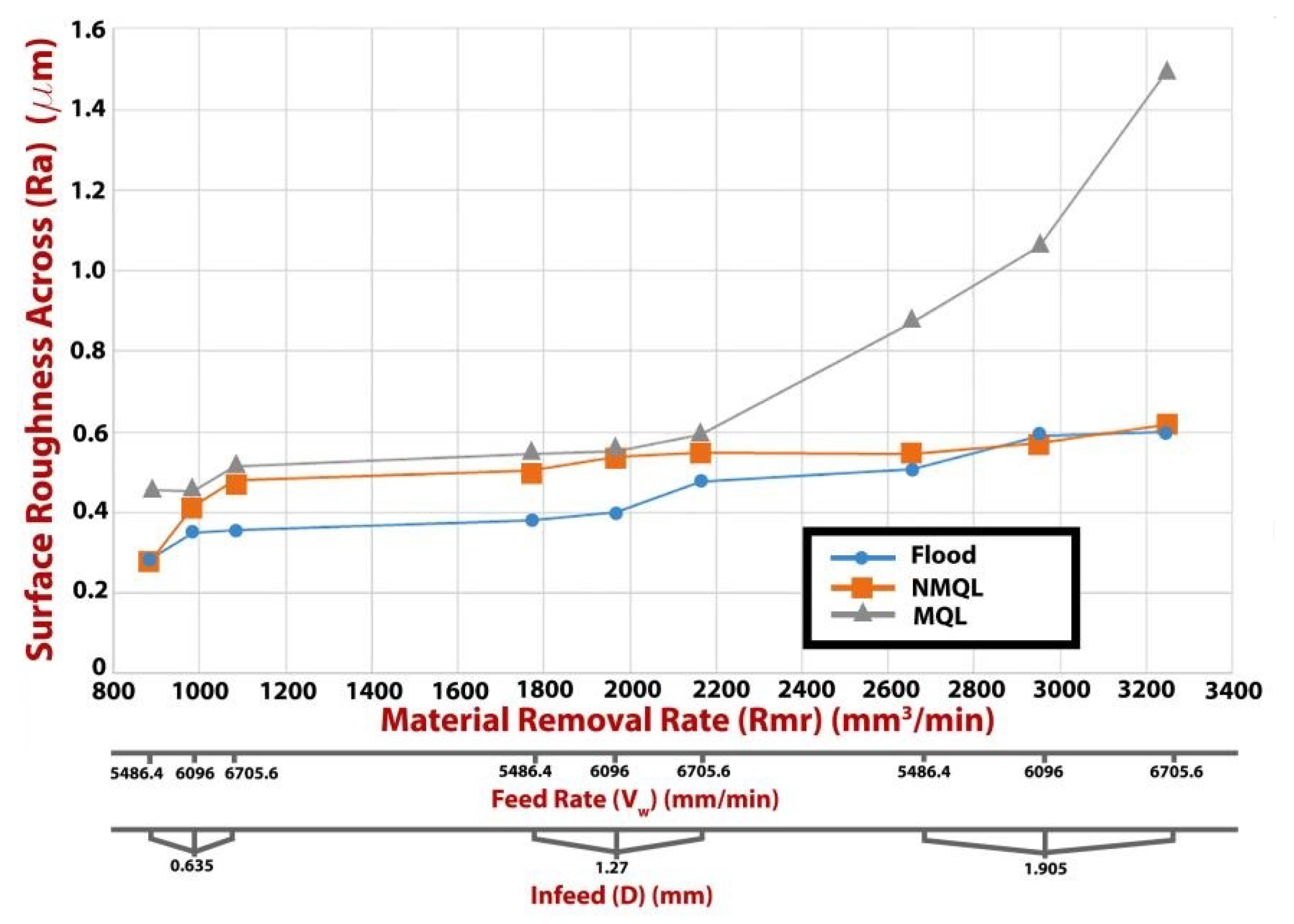

4.3. Surface Roughness (Ra) across of Ti-6Al-4V Samples

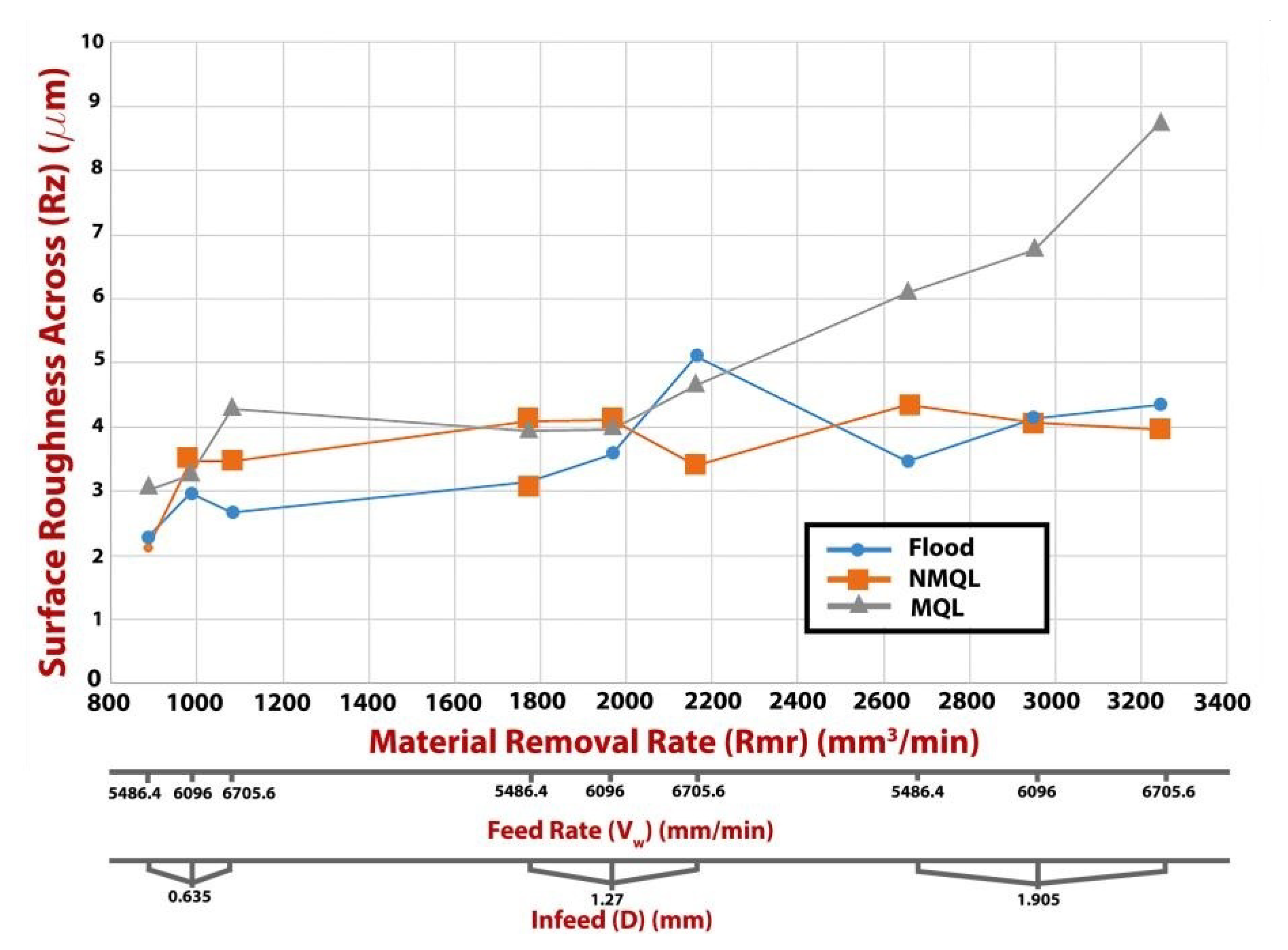

4.4. Surface Roughness (Rz) across of Ti-6Al-4V Samples

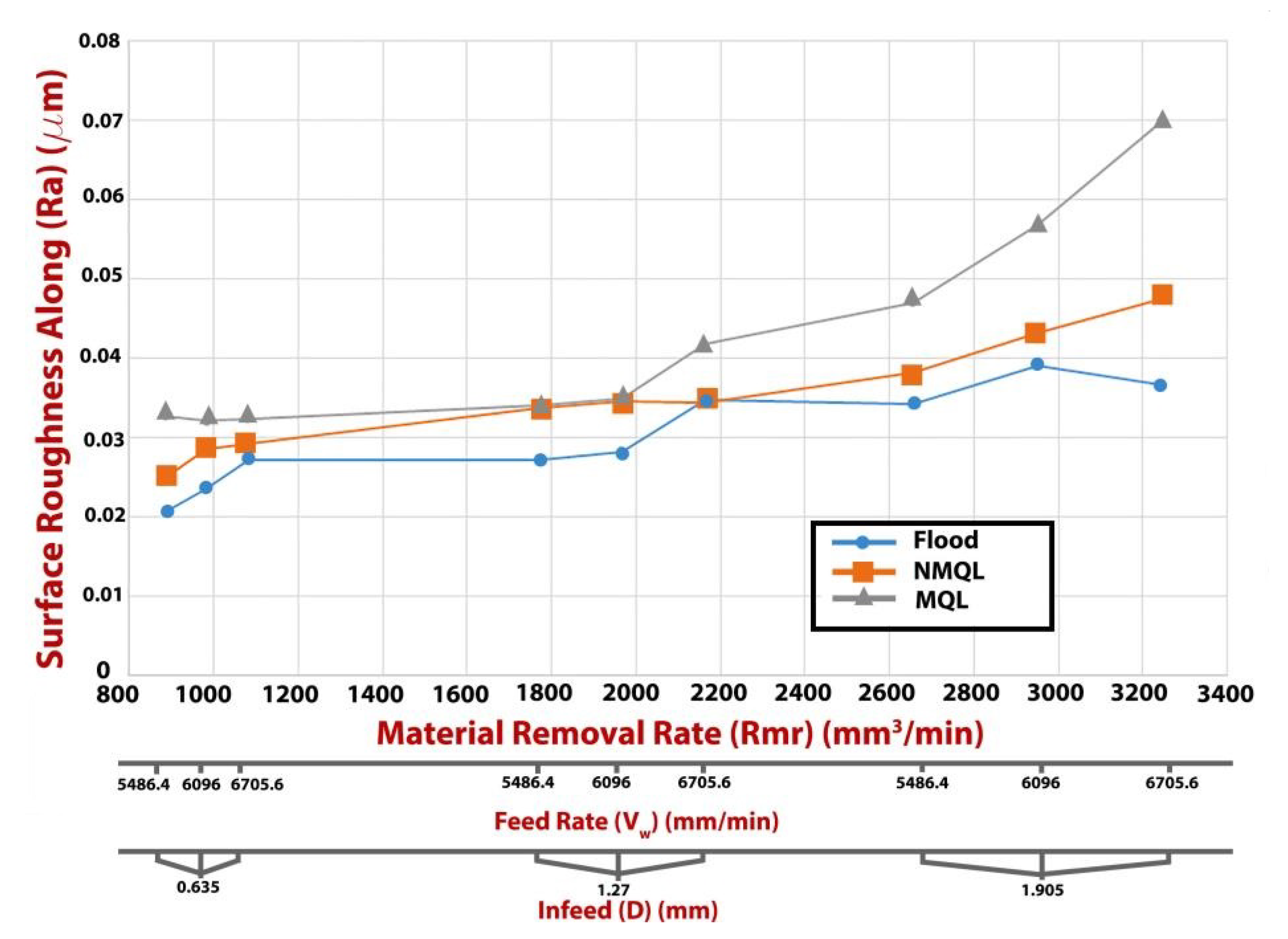

4.5. Surface Roughness (Ra) along of Ti-6Al-4V Samples

4.6. Surface Roughness (Rz) along of Ti-6Al-4V Samples

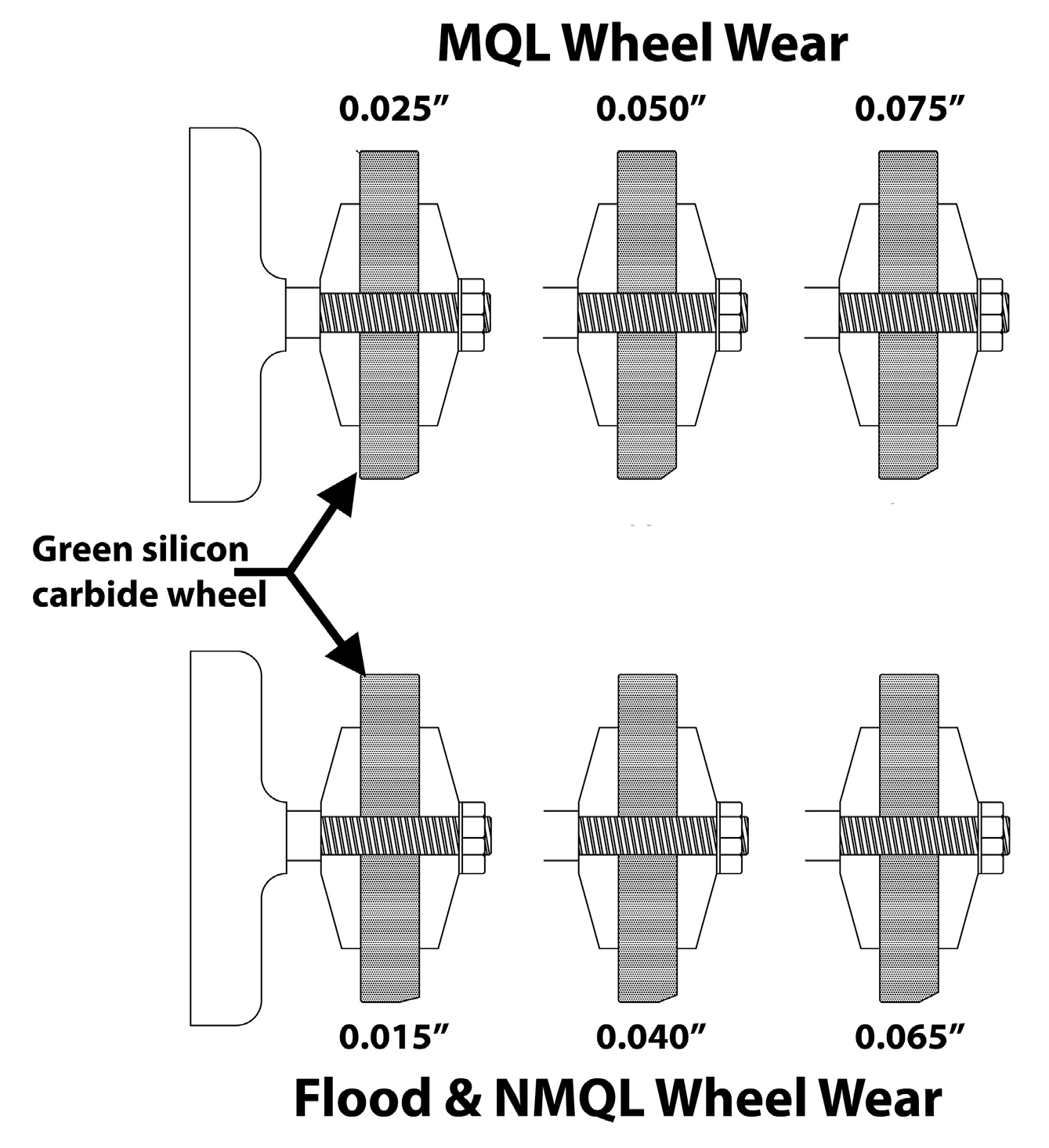

4.7. Lubrication Methods Wheel Wear

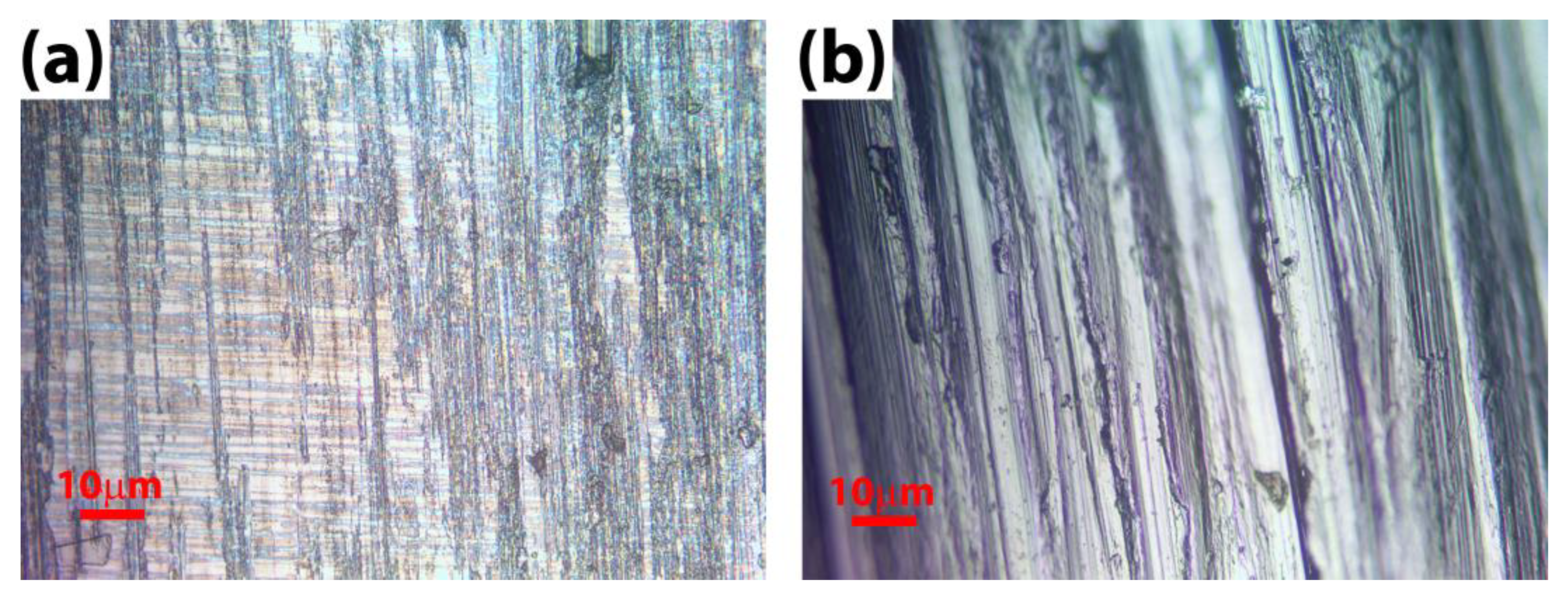

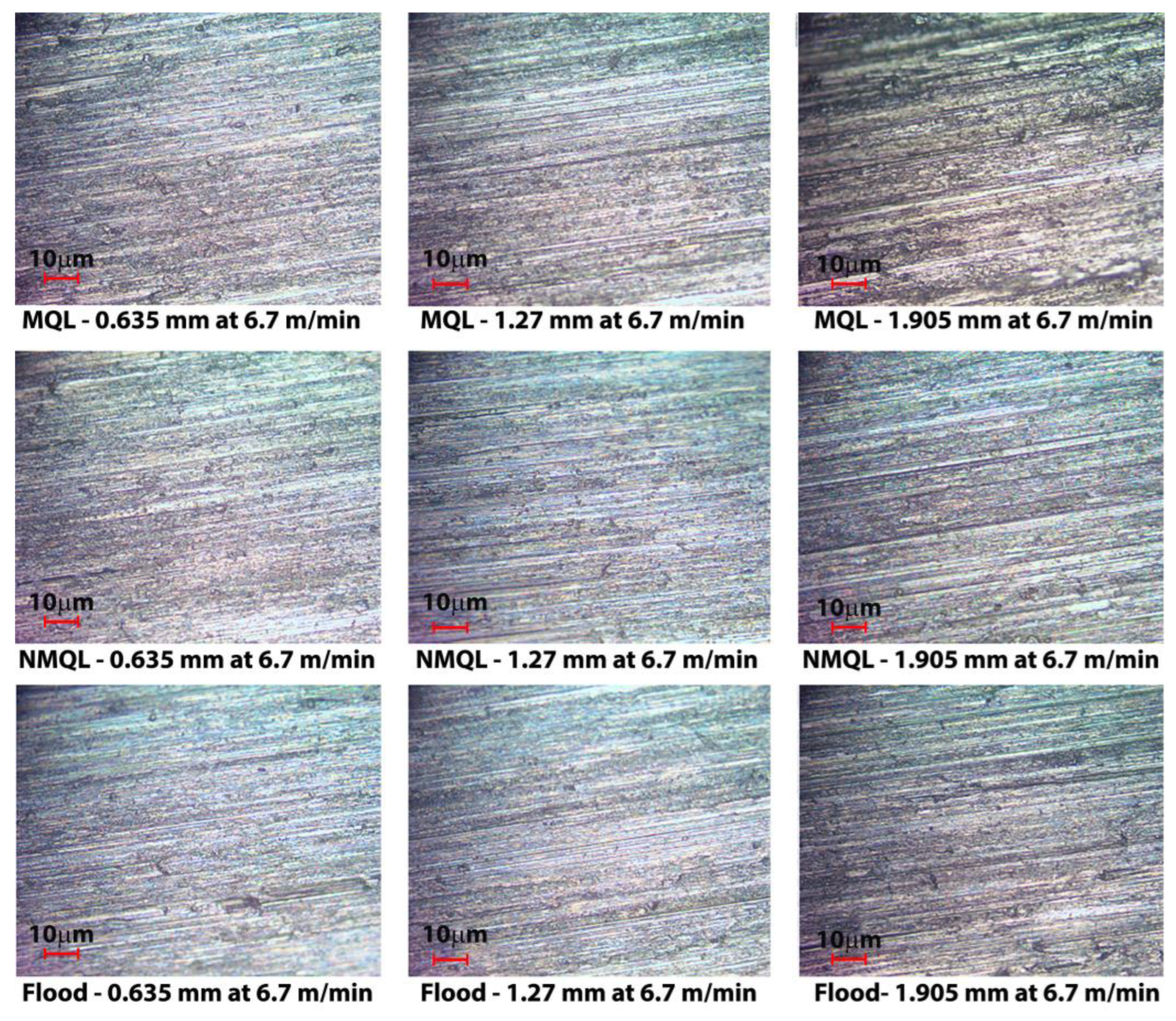

4.8. Comparative Microscopic Results

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Lee:, P.H.; Nam, J.S.; Li, C.; Lee, S.W. An experimental study on micro-grinding process with nanofluid minimum quantity lubrication (MQL). Int. J. Precis. Eng. Manuf. 2012, 13, 331–338. [Google Scholar] [CrossRef]

- Mallick, R.; Kumar, R.; Panda, A.; Sahoo, A.K. Current Status of Hard Turning in Manufacturing: Aspects of Cooling Strategy and Sustainability. Lubricants 2023, 11, 108. [Google Scholar] [CrossRef]

- Shah, R.; Shirvani, K.A.; Przyborowski, A.; Pai, N.; Mosleh, M. Role of Nanofluid Minimum Quantity Lubrication (NMQL) in Machining Application. Lubricants 2022, 10, 266. [Google Scholar] [CrossRef]

- Kumar, A.; Sharma, A.K.; Katiyar, J.K.; Kumar, A.; Sharma, A.K.; Katiyar, J.K. State-of-the-Art in Sustainable Machining of Different Materials Using Nano Minimum Quality Lubrication (NMQL). Lubricants 2023, 11, 64. [Google Scholar] [CrossRef]

- Duc, T.M.; Long, T.T.; Chien, T.Q. Performance Evaluation of MQL Parameters Using Al2O3 and MoS2 Nanofluids in Hard Turning 90CrSi Steel. Lubricants 2019, 7, 40. [Google Scholar] [CrossRef]

- Pereira, O.; Martín-Alfonso, J.E.; Rodríguez, A.; Calleja, A.; Fernández-Valdivielso, A.; López de Lacalle, L.N. Sustainability analysis of lubricant oils for minimum quantity lubrication based on their tribo-rheological performance. J. Clean. Prod. 2017, 164, 1419–1429. [Google Scholar] [CrossRef]

- Davim, J.P. (Ed.) Machining of Titanium Alloys; Springer: Berlin/Heidelberg, Germany, 2014; Volume 150. [Google Scholar]

- Gupta, M.K.; Etri, H.; Korkmaz, M.E.; Ross, N.S.; Krolczyk, G.M.; Gawlik, J.; Yaşar, N.; Pimenov, D.Y. Tribological and surface morphological characteristics of titanium alloys: A review. Arch. Civ. Mech. Eng. 2022, 22, 72. [Google Scholar] [CrossRef]

- Wood, P.; Boud, F.; Carter, W.; Varasteh, H.; Gunputh, U.; Pawlik, M.; Clementson, J.; Lu, Y.; Hossain, S.; Broderick, M.; et al. On the Lubricity and Comparative Life Cycle of Biobased Synthetic and Mineral Oil Emulsions in Machining Titanium Ti-6Al-4V at Low Cutting Speed. J. Manuf. Mater. Process 2022, 6, 154. [Google Scholar] [CrossRef]

- Setti, D.; Ghosh, S.; Rao, P.V. Application of Nano Cutting Fluid under Minimum Quantity Lubrication (MQL) Technique to Improve Grinding of Ti–6Al–4V Alloy. Int. J. Eng. Res. Technol. 2012, 6, 2107–2111. [Google Scholar]

- Kazeem, R.A.; Fadare, D.A.; Ikumapayi, O.M.; Adediran, A.A.; Aliyu, S.J.; Akinlabi, S.A.; Jen, T.C.; Akinlabi, E.T. Advances in the Application of Vegetable-Oil-Based Cutting Fluids to Sustainable Machining Operations: A Review. Lubricants 2022, 10, 69. [Google Scholar] [CrossRef]

- Taha-Tijerina, J.; Aviña, K.; Diabb, J.M. Tribological and thermal transport performance of SiO2-based natural lubricants. Lubricants 2019, 7, 71. [Google Scholar] [CrossRef]

- Taha-Tijerina, J.J.; Aviña, K.; Padilla-Gainza, V.; Akundi, A. Halloysite Reinforced Natural Esters for Energy Applications. Lubricants 2023, 11, 65. [Google Scholar] [CrossRef]

- Taha-Tijerina, J.; Aviña, K.; Martínez, J.M.; Arquieta-Guillén, P.Y.; González-Escobedo, M. Carbon Nanotori Structures for Thermal Transport Applications on Lubricants. Nanomaterials 2021, 11, 1158. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Yuan, F.; Tian, W.; Dai, C.; Yang, X.; Wang, D.; Du, J.; Yu, W.; Yuan, H. Heat Transfer Enhancement of Nanofluids with Non-Spherical Nanoparticles: A Review. Appl. Sci. 2022, 12, 4767. [Google Scholar] [CrossRef]

- Taha-Tijerina, J.; Narayanan, T.N.; Gao, G.; Rohde, M.; Tsentalovich, D.A.; Pasquali, M.; Ajayan, P.M. Electrically insulating thermal nano-oils using 2D fillers. ACS Nano 2012, 6, 1214–1220. [Google Scholar] [CrossRef] [PubMed]

- Mehrali, M.; Sadeghinezhad, E.; Akhiani, A.R.; Latibari, S.T.; Talebian, S.; Dolatshahi-Pirouz, A.; Metselaar, H.S.C. An ecofriendly graphene-based nanofluid for heat transfer applications. J. Clean. Prod. 2016, 137, 555–566. [Google Scholar] [CrossRef]

- Gupta, M.K.; Khan, A.M.; Song, Q.; Liu, Z.; Khalid, Q.S.; Jamil, M.; Kuntoğlu, M.; Usca, Ü.A.; Sarıkaya, M.; Pimenov, D.Y. A review on conventional and advanced minimum quantity lubrication approaches on performance measures of grinding process. Int. J. Adv. Manuf. Technol. 2021, 117, 729–750. [Google Scholar] [CrossRef]

- Singh, G.; Aggarwal, V.; Singh, S. Critical review on ecological, economical and technological aspects of minimum quantity lubrication towards sustainable machining. J. Clean. Prod. 2020, 271, 122185. [Google Scholar] [CrossRef]

- Villarrazo, N.; Caneda, S.; Pereira, O.; Rodríguez, A.; López de Lacalle, L.N. The Effects of Lubricooling Ecosustainable Techniques on Tool Wear in Carbon Steel Milling. Materials 2023, 16, 2936. [Google Scholar] [CrossRef]

- Balasuadhakar, A.; Kumaran, S.T.; Ahmed, F. A review on the role of nanoparticles in MQL machining. Mater. Today Proc. 2023, 72, 2828–2832. [Google Scholar] [CrossRef]

- Junankar, A.A.; Parate, S.R.; Dethe, P.K.; Dhote, N.R.; Gadkar, D.G.; Gadkar, D.D.; Gajbhiye, S.A. A Review: Enhancement of turning process performance by effective utilization of hybrid nanofluid and MQL. Mater. Today Proc. 2021, 38, 44–47. [Google Scholar] [CrossRef]

- Mane, P.A.; Kallol, A.N.; Doiphode, R.L.; Manjunath, G.A.; Saleh, B.; Abbas, M.; Saleel, C.A.; Alarifi, I. Inconel 718 Turning Process Parameters Optimization with MQL Nanofluid Based on CuO Nanoparticles. J. Nanomater. 2022, 2022, 1408529. [Google Scholar] [CrossRef]

- Khanafer, K.; Eltaggaz, A.; Deiab, I. Numerical study of flow and heat transfer of minimum quantity lubrication based nanofluid in a turning process using Inconel alloy. Int. J. Adv. Manuf. Technol. 2020, 108, 475–483. [Google Scholar] [CrossRef]

- Bai, X.; Jiang, J.; Li, C.; Dong, L.; Ali, H.M.; Sharma, S. Tribological Performance of Different Concentrations of Al2O3 Nanofluids on Minimum Quantity Lubrication Milling. Chin. J. Mech. Eng. 2023, 36, 11. [Google Scholar] [CrossRef]

- Sadeghi, M.H.; Haddad, M.J.; Tawakoli, T.; Emami, M. Minimal quantity lubrication-MQL in grinding of Ti-6Al-4V titanium alloy. Int. J. Adv. Manuf. Technol. 2009, 44, 487–500. [Google Scholar] [CrossRef]

- Zhang, D.; Li, C.; Jia, D.; Zhang, Y.; Zhang, X. Specific grinding energy and surface roughness of nanoparticle jet minimum quantity lubrication in grinding. Chin. J. Aeronaut. 2015, 28, 570–581. [Google Scholar] [CrossRef]

- Okokpujie, I.P.; Tartibu, L.K.; Sinebe, J.E.; Adeoye, A.O.M.; Akinlabi, E.T. Comparative Study of Rheological Effects of Vegetable Oil-Lubricant, TiO2, MWCNTs Nano-Lubricants, and Machining Parameters’ Influence on Cutting Force for Sustainable Metal Cutting Process. Lubricants 2022, 10, 54. [Google Scholar] [CrossRef]

- Lim, S.K.; Azmi, W.H.; Jamaludin, A.S.; Yusoff, A.R.; Lim, S.K.; Azmi, W.H.; Jamaludin, A.S.; Yusoff, A.R. Characteristics of Hybrid Nanolubricants for MQL Cooling Lubrication Machining Application. Lubricants 2022, 10, 350. [Google Scholar] [CrossRef]

- Singh, S.K.; Jha, A.K.; Ray, A.; Dewangan, S. Enhancing grinding parameters of TC4 titanium superalloy by using hybrid eco-friendly cooling system. Mater. Today Proc. 2022, 62, 1505–1509. [Google Scholar] [CrossRef]

- Jiang, G.; Zhao, Z.; Xiao, G.; Li, S.; Chen, B.; Zhuo, X.; Zhang, J.; Ruffino, F.; Jiang, G.; Zhao, Z.; et al. Study of Surface Integrity of Titanium Alloy (TC4) by Belt Grinding to Achieve the Same Surface Roughness Range. Micromachines 2022, 13, 1950. [Google Scholar] [CrossRef]

- Nosenko, V.A.; Nosenko, S.V.; Puzirkova, V.E. Grinding of Titanium Alloys. Key Eng. Mater. 2021, 887, 287–293. [Google Scholar] [CrossRef]

- Mahbubul, I.M.; Shahrul, I.M.; Khaleduzzaman, S.S.; Saidur, R.; Amalina, M.A.; Turgut, A. Experimental investigation on effect of ultrasonication duration on colloidal dispersion and thermophysical properties of alumina-water nanofluid. Int. J. Heat Mass Transf. 2015, 88, 73–81. [Google Scholar] [CrossRef]

| Experiment | Crossfeed (W) (mm) | Infeed (D) (mm) | Feed Rate (Vw) (mm/min) | Material Removal Rate (Rmr) (mm3/min) |

|---|---|---|---|---|

| 1 Flood | 0.254 | 0.635 | 5486.4 | 884.9 |

| 2 Flood | 0.254 | 0.635 | 6096.0 | 983.2 |

| 3 Flood | 0.254 | 0.635 | 6705.6 | 1081.5 |

| 4 Flood | 0.254 | 1.270 | 5486.4 | 1769.8 |

| 5 Flood | 0.254 | 1.270 | 6096.0 | 1966.4 |

| 6 Flood | 0.254 | 1.270 | 6705.6 | 2163.1 |

| 7 Flood | 0.254 | 1.905 | 5486.4 | 2654.7 |

| 8 Flood | 0.254 | 1.905 | 6096.0 | 2949.7 |

| 9 Flood | 0.254 | 1.905 | 6705.6 | 3244.6 |

| 10 NMQL | 0.254 | 0.635 | 5486.4 | 884.9 |

| 11 NMQL | 0.254 | 0.635 | 6096.0 | 983.2 |

| 12 NMQL | 0.254 | 0.635 | 6705.6 | 1081.5 |

| 13 NMQL | 0.254 | 1.270 | 5486.4 | 1769.8 |

| 14 NMQL | 0.254 | 1.270 | 6096.0 | 1966.4 |

| 15 NMQL | 0.254 | 1.270 | 6705.6 | 2163.1 |

| 16 NMQL | 0.254 | 1.905 | 5486.4 | 2654.7 |

| 17 NMQL | 0.254 | 1.905 | 6096.0 | 2949.7 |

| 18 NMQL | 0.254 | 1.905 | 6705.6 | 3244.6 |

| 19 MQL | 0.254 | 0.635 | 5486.4 | 884.9 |

| 20 MQL | 0.254 | 0.635 | 6096.0 | 983.2 |

| 21 MQL | 0.254 | 0.635 | 6705.6 | 1081.5 |

| 22 MQL | 0.254 | 1.270 | 5486.4 | 1769.8 |

| 23 MQL | 0.254 | 1.270 | 6096.0 | 1966.4 |

| 24 MQL | 0.254 | 1.270 | 6705.6 | 2163.1 |

| 25 MQL | 0.254 | 1.905 | 5486.4 | 2654.7 |

| 26 MQL | 0.254 | 1.905 | 6096.0 | 2949.7 |

| 27 MQL | 0.254 | 1.905 | 6705.6 | 3244.6 |

| Experiment | Material Removal Rate (Rmr) (mm3/min) | Surface Roughness across (Ra) (μm) | Surface Roughness across (Rz) (μm) | Surface Roughness along (Ra) (μm) | Surface Roughness along (Rz) (μm) | Grinding Interface Temp. (°C) |

|---|---|---|---|---|---|---|

| 1 Flood | 884.9 | 0.283 | 2.28 | 0.02060 | 0.133 | 34 |

| 2 Flood | 983.2 | 0.349 | 2.97 | 0.02360 | 0.150 | 37 |

| 3 Flood | 1081.5 | 0.356 | 2.66 | 0.02730 | 0.169 | 38 |

| 4 Flood | 1769.8 | 0.382 | 3.15 | 0.02730 | 0.174 | 53 |

| 5 Flood | 1966.4 | 0.400 | 3.58 | 0.02830 | 0.187 | 58 |

| 6 Flood | 2163.1 | 0.478 | 5.11 | 0.03480 | 0.215 | 59 |

| 7 Flood | 2654.7 | 0.506 | 3.47 | 0.03420 | 0.223 | 58 |

| 8 Flood | 2949.7 | 0.589 | 4.13 | 0.03920 | 0.245 | 39 |

| 9 Flood | 3244.6 | 0.599 | 4.35 | 0.03670 | 0.260 | 74 |

| 10 NMQL | 884.9 | 0.276 | 2.11 | 0.02490 | 0.167 | 64 |

| 11 NMQL | 983.2 | 0.416 | 3.47 | 0.02860 | 0.189 | 67 |

| 12 NMQL | 1081.5 | 0.481 | 3.46 | 0.02920 | 0.193 | 69 |

| 13 NMQL | 1769.8 | 0.505 | 4.09 | 0.03370 | 0.210 | 89 |

| 14 NMQL | 1966.4 | 0.540 | 4.11 | 0.03470 | 0.212 | 93 |

| 15 NMQL | 2163.1 | 0.550 | 3.41 | 0.03450 | 0.213 | 95 |

| 16 NMQL | 2654.7 | 0.545 | 4.35 | 0.03820 | 0.228 | 110 |

| 17 NMQL | 2949.7 | 0.572 | 4.07 | 0.04320 | 0.292 | 118 |

| 18 NMQL | 3244.6 | 0.616 | 3.97 | 0.04760 | 0.280 | 121 |

| 19 MQL | 884.9 | 0.456 | 3.02 | 0.03280 | 0.188 | 71 |

| 20 MQL | 983.2 | 0.452 | 3.26 | 0.03220 | 0.206 | 74 |

| 21 MQL | 1081.5 | 0.515 | 4.29 | 0.03240 | 0.230 | 86 |

| 22 MQL | 1769.8 | 0.546 | 3.94 | 0.03410 | 0.229 | 97 |

| 23 MQL | 1966.4 | 0.553 | 3.96 | 0.03490 | 0.222 | 99 |

| 24 MQL | 2163.1 | 0.592 | 4.66 | 0.04180 | 0.250 | 100 |

| 25 MQL | 2654.7 | 0.873 | 6.09 | 0.04710 | 0.297 | 153 |

| 26 MQL | 2949.7 | 1.060 | 6.77 | 0.05680 | 0.326 | 159 |

| 27 MQL | 3244.6 | 1.490 | 8.74 | 0.07000 | 0.391 | 160 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Taha-Tijerina, J.J.; Edinbarough, I.A. Comparative Cutting Fluid Study on Optimum Grinding Parameters of Ti-6Al-4V Alloy Using Flood, Minimum Quantity Lubrication (MQL), and Nanofluid MQL (NMQL). Lubricants 2023, 11, 250. https://doi.org/10.3390/lubricants11060250

Taha-Tijerina JJ, Edinbarough IA. Comparative Cutting Fluid Study on Optimum Grinding Parameters of Ti-6Al-4V Alloy Using Flood, Minimum Quantity Lubrication (MQL), and Nanofluid MQL (NMQL). Lubricants. 2023; 11(6):250. https://doi.org/10.3390/lubricants11060250

Chicago/Turabian StyleTaha-Tijerina, Jose Jaime, and Immanuel A. Edinbarough. 2023. "Comparative Cutting Fluid Study on Optimum Grinding Parameters of Ti-6Al-4V Alloy Using Flood, Minimum Quantity Lubrication (MQL), and Nanofluid MQL (NMQL)" Lubricants 11, no. 6: 250. https://doi.org/10.3390/lubricants11060250

APA StyleTaha-Tijerina, J. J., & Edinbarough, I. A. (2023). Comparative Cutting Fluid Study on Optimum Grinding Parameters of Ti-6Al-4V Alloy Using Flood, Minimum Quantity Lubrication (MQL), and Nanofluid MQL (NMQL). Lubricants, 11(6), 250. https://doi.org/10.3390/lubricants11060250