Microstructure and Wear Resistance of Ti5Si3/Ti3Al Composite Coatings Prepared by Laser Cladding on TA2 Titanium Alloy

Abstract

1. Introduction

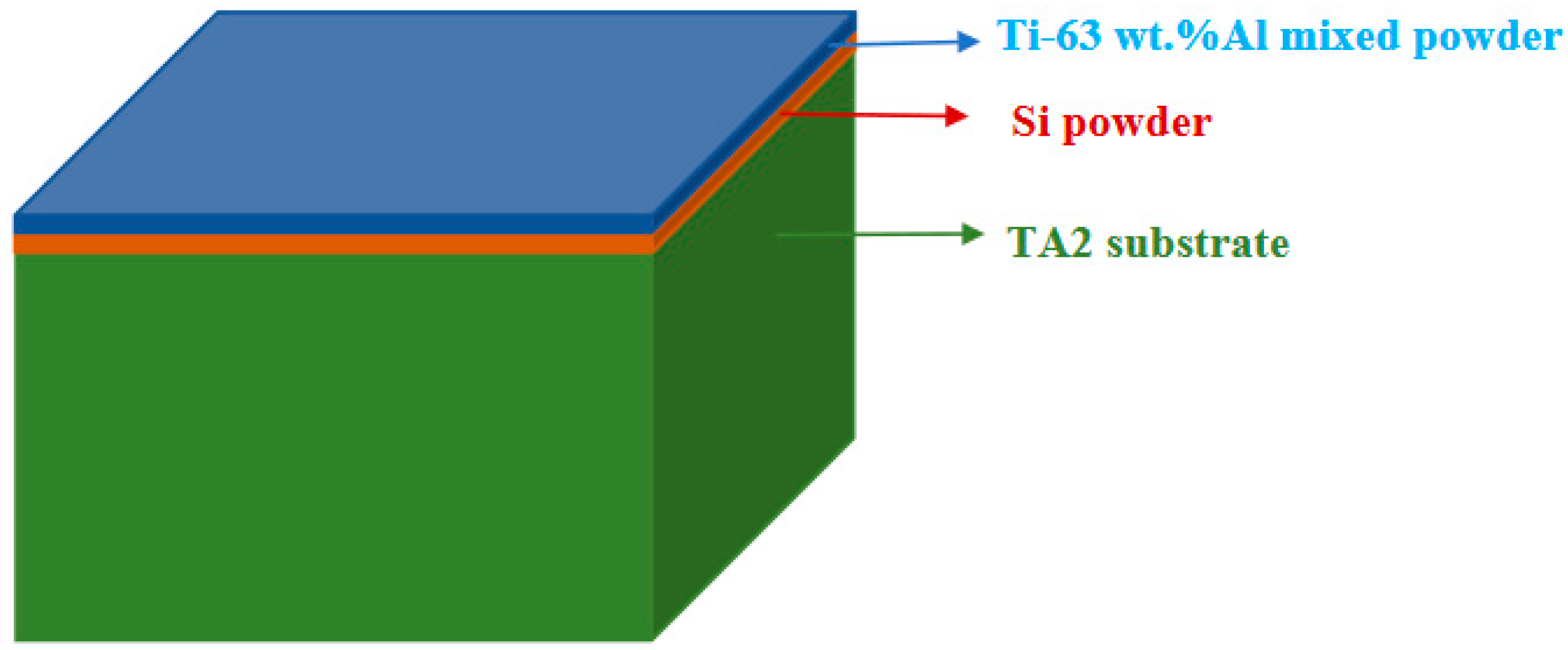

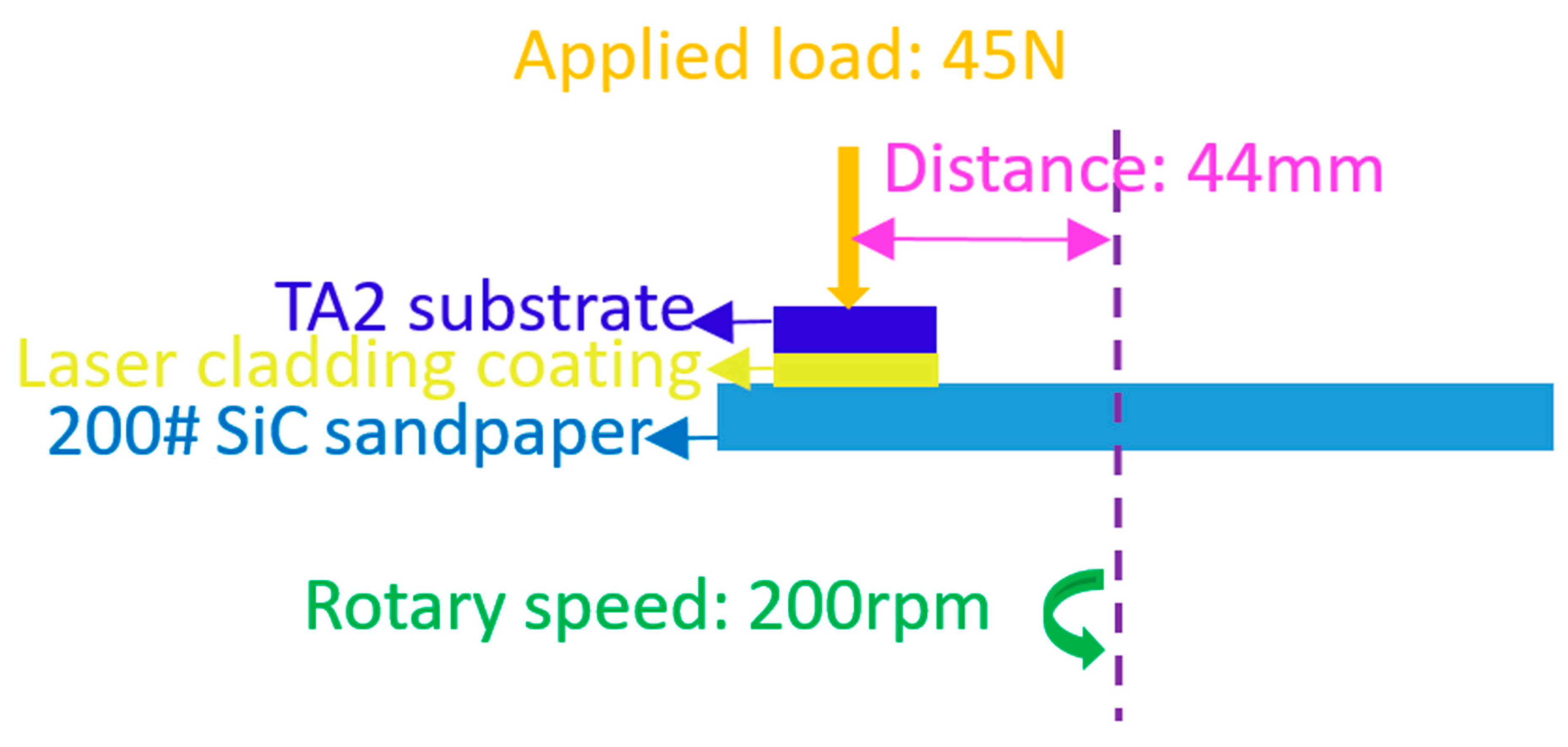

2. Materials and Methods

3. Results

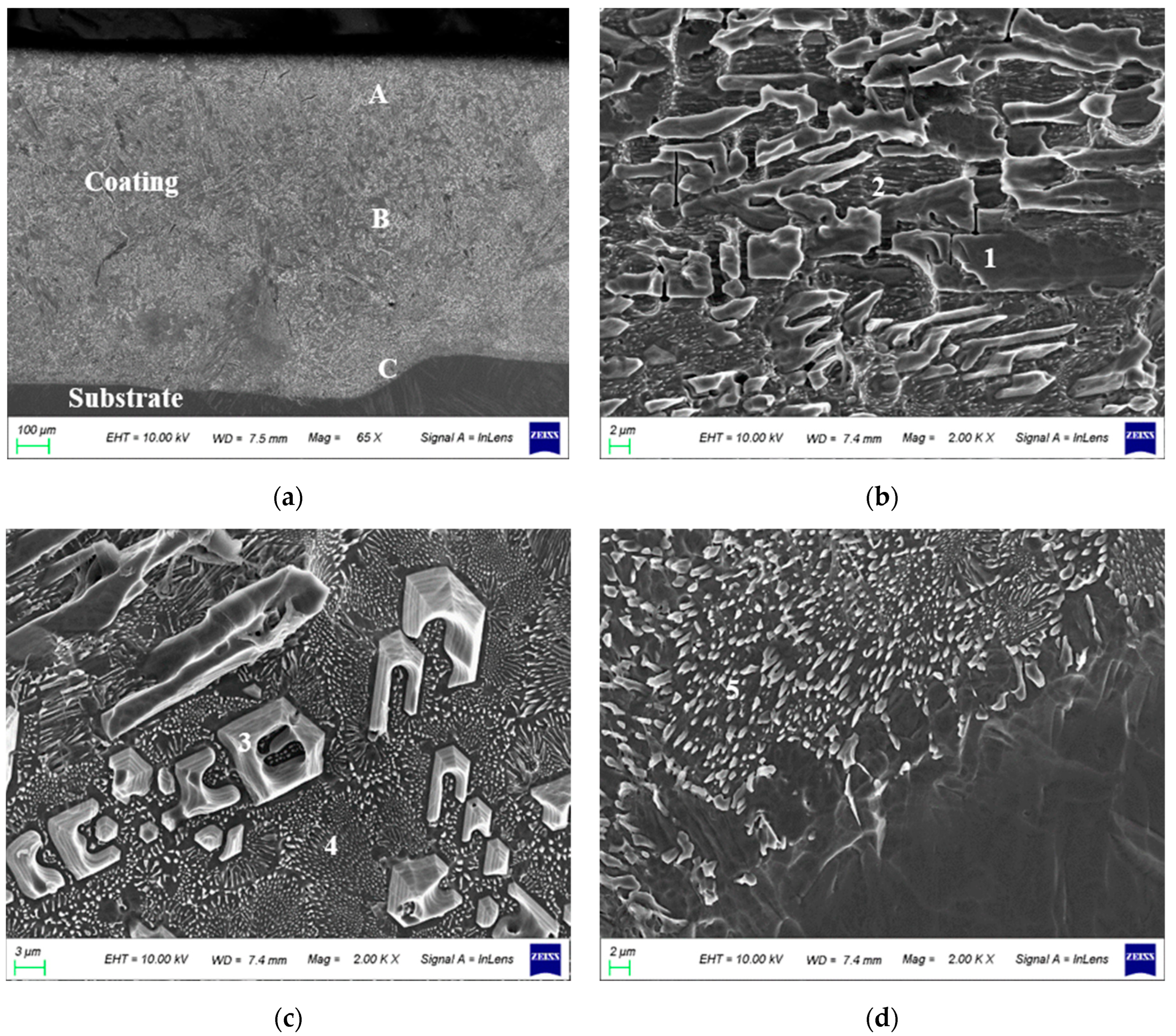

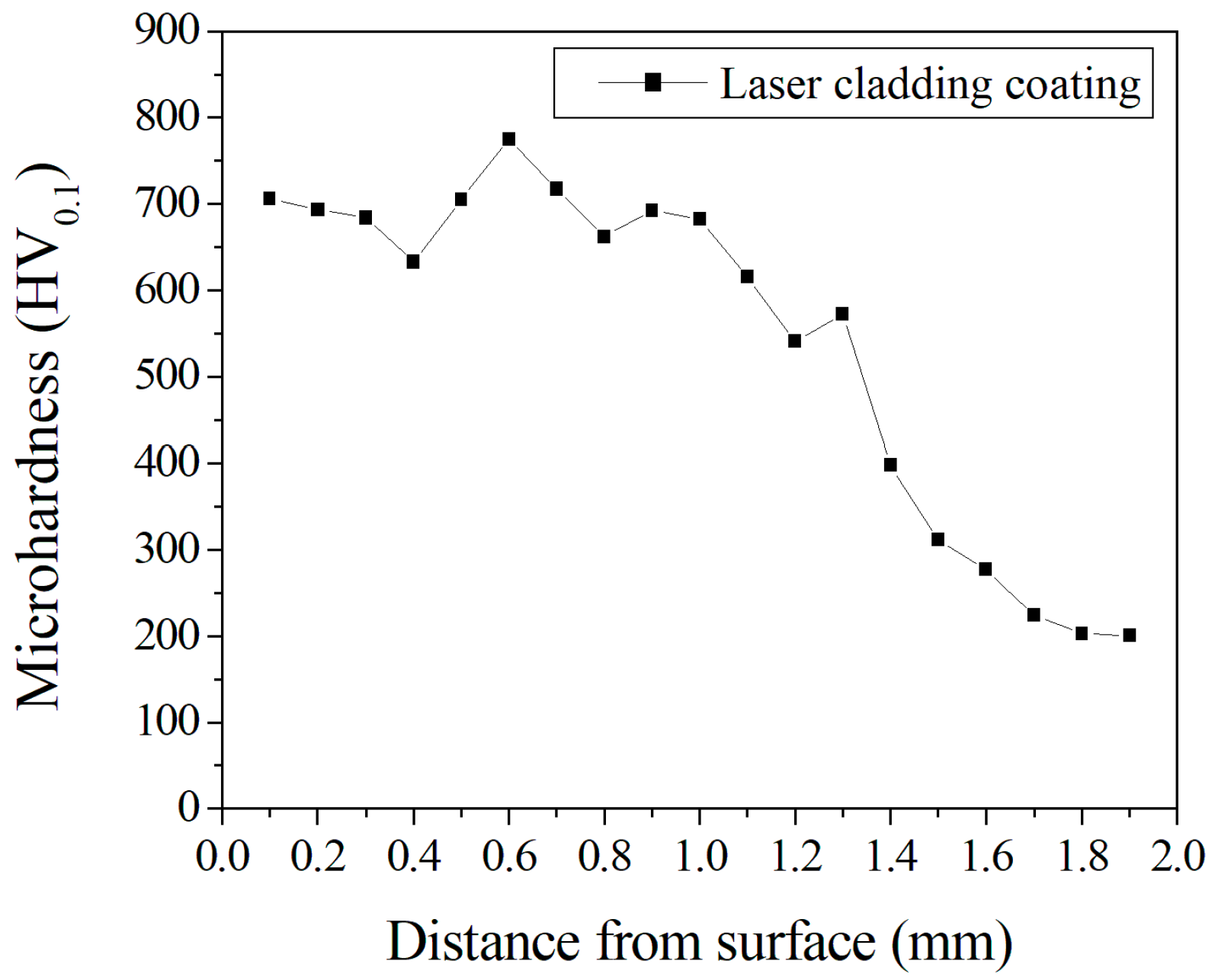

3.1. Microstructure of the Laser Cladding Coating

3.2. Wear Properties of the Laser Cladding Coating

4. Discussion

4.1. Formation and Flow Characteristics of the Laser Cladding Molten Pool with Double-Layer Preset Powder Layer

4.2. Formation Mechanism of Different Phases in the Coating

4.3. Wear Mechanism of the Coating and TA2 Matrix

5. Conclusions

- (1)

- The wear-resistant Ti5Si3/Ti3Al composite coatings were successfully prepared on TA2 titanium alloy by laser cladding using the double layer preset method of Ti-63 wt.% Al mixed powder layer/Si powder layer.

- (2)

- The coating is mainly composed of coarse primary Ti5Si3 phase and fine Ti5Si3/Ti3Al eutectic structure, with more Ti5Si3 on the top layer and in the middle of the coating and more Ti5Si3/Ti3Al eutectic on the bottom.

- (3)

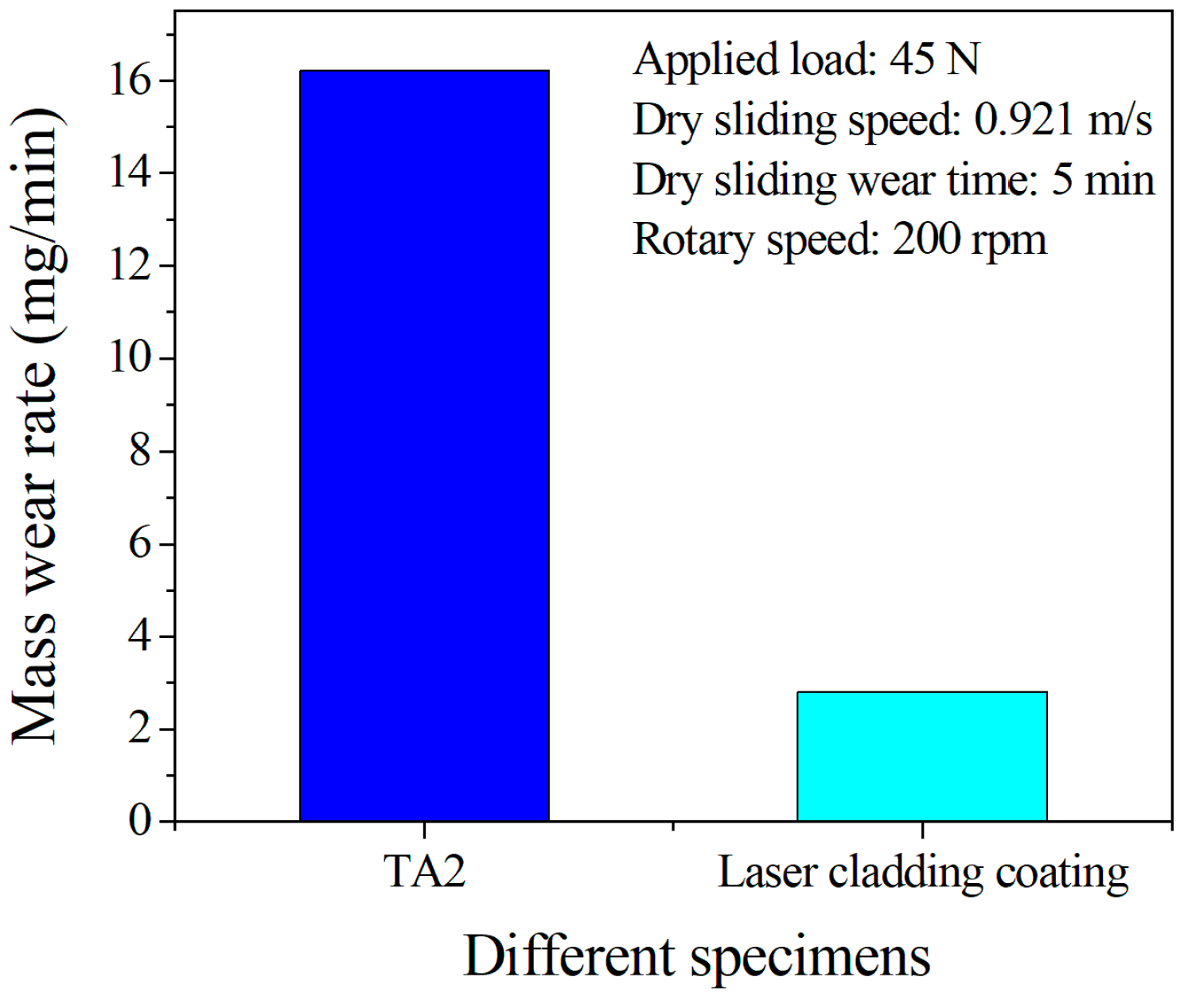

- The mass wear rate of the laser cladding coating is 1/5.79 of that of the TA2 matrix. The wear mechanisms of the coatings are mainly abrasive wear, adhesive wear and oxidative wear, whereas the wear mechanisms of the TA2 matrix are adhesive wear and oxidative wear.

- (4)

- The effect of laser cladding of the double preset powder layer is similar to that of the single preset powder layer because of the strong stirring effect of the Marongoni flow in the molten pool.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Budzynski, P.; Kaminski, M.; Surowiec, Z.; Turek, M.; Wiertel, M. Effect of carbon ion implantation and xenon ion irradiation on the tribological properties of titanium and Ti6Al4V Alloy. Acta Phy. Pol. A 2022, 142, 713–722. [Google Scholar] [CrossRef]

- Zhao, L.D.; Lugscheider, E. Reactive plasma spraying of TiAl6V4 alloy. Wear 2002, 253, 1214–1218. [Google Scholar] [CrossRef]

- Srinivasan, R.; Kamaraj, M.; Rajeev, D.; Ravi, S.; Senthilkumar, N. Plasma spray coating of aluminum-silicon-MWCNT blends on titanium grade 5 alloy substrate for enhanced wear and corrosion resistance. Silicon 2022, 14, 8629–8641. [Google Scholar] [CrossRef]

- Koshuro, V.; Fomina, M.; Zakharevich, A.; Fomin, A. Superhard Ta-O-N coatings produced on titanium using induction physical vapor deposition. Ceram. Int. 2022, 48, 19467–19483. [Google Scholar] [CrossRef]

- Hussein, M.A.; Adesina, A.Y.; Kumar, A.M.; Sorour, A.A.; Ankah, N.; Al-Aqeeli, N. Mechanical, in-vitro corrosion, and tribological characteristics of TiN coating produced by cathodic arc physical vapor deposition on Ti20Nb13Zr alloy for biomedical applications. Thin Solid Film. 2020, 709, 138183. [Google Scholar] [CrossRef]

- Chen, X.W.; Ren, P.; Zhang, D.F.; Hu, J.; Wu, C.; Liao, D.D. Corrosion and wear properties of h-BN-modified TC4 titanium alloy micro-arc oxide coatings. Surf. Innov. 2022, 11, 49–59. [Google Scholar] [CrossRef]

- Majumdar, J.D.; Weisheit, A.; Mordike, B.L.; Manna, I. Laser surface alloying of Ti with Si, Al and Si+Al for an improved oxidation resistance. Mater. Sci. Eng. A 1999, 266, 123–134. [Google Scholar] [CrossRef]

- Wang, Z.; Li, J.N.; Zhang, Z.; Li, J.M.; Su, M.L. Microstructure and wear resistance of Cu/La2O3 modified laser clad composites. Laser. Eng. 2019, 44, 33–39. [Google Scholar]

- Ali, S.R.A.S.; Hussein, A.H.A.; Nofal, A.; Elnaby, S.I.H.; Elgazzar, H. A contribution to laser cladding of Ti-6Al-4V titanium alloy. Metall. Res. Technol. 2019, 116, 634. [Google Scholar]

- Tian, Y.; Zhang, Z.; Li, J.N.; Huo, Y.S.; Su, M.L. Surface modification of TA7 titanium alloy with laser clad La2O3 amorphous coatings. Laser. Eng. 2019, 44, 331–339. [Google Scholar]

- Li, X.D.; Liu, S.S.; Wang, J.W.; Yu, M.X.; Tang, H.B. Effect of different ZrN addition on microstructure and wear properties of titanium based coatings by laser cladding technique. Coatings 2019, 9, 261. [Google Scholar] [CrossRef]

- Sui, X.M.; Lu, J.; Zhang, X.; Sun, L.; Zhang, W.P. Microstructure and properties of TiC-reinforced Ti2Ni/Ti5Si3 eutectic-based laser cladding composite coating. J. Therm. Spray Technol. 2020, 29, 1838–1846. [Google Scholar] [CrossRef]

- Chen, C.N.; Su, M. Study on microstructure and abrasive resistance of laser cladding TiN surface alloyed TC9. J. Beijing Univ. Aeronaut. Astronaut. 1998, 24, 253–255. [Google Scholar]

- Xiang, K.; Chen, L.Y.; Chai, L.J.; Guo, N.; Wang, H. Microstructural characteristics and properties of CoCrFeNiNbx high-entropy alloy coatings on pure titanium substrate by pulsed laser cladding. Appl. Surf. Sci. 2020, 517, 146214. [Google Scholar] [CrossRef]

- Wu, H.; Liang, L.X.; Lan, X.D.; Yin, Y.; Song, M.; Li, R.D.; Liu, Y.; Yang, H.O.; Liu, L.; Cai, A.H.; et al. Tribological and biological behaviors of laser cladded Ti-based metallic glass composite coatings. Appl. Surf. Sci. 2020, 507, 145104. [Google Scholar] [CrossRef]

- Chai, L.J.; Wang, C.; Xiang, K.; Wang, Y.Y.; Wang, T.; Ma, Y.L. Phase constitution, microstructure and properties of pulsed laser-clad ternary CrNiTi medium-entropy alloy coating on pure titanium. Surf. Coat. Technol. 2020, 402, 126503. [Google Scholar] [CrossRef]

- Ke, J.; Liu, X.B.; Liang, J.; Liang, L.; Luo, Y.S. Microstructure and fretting wear of laser cladding self-lubricating anti-wear composite coatings on TA2 alloy after aging treatment. Opt. Laser Technol. 2019, 119, 105599. [Google Scholar] [CrossRef]

- Guo, C.; Ma, M.L.; Chen, F.; Wei, B.L. Microstructure and space tribological properties of NiCrBSi/Ag composite coating prepared by laser cladding. Surf. Technol. 2019, 48, 177–184. [Google Scholar]

- Guo, C.; Zhou, J.S.; Zhao, J.R.; Wang, L.Q.; Yu, Y.J.; Chen, J.M.; Zhou, H.D. Improvement of the oxidation and wear resistance of pure Ti by laser-cladding Ti3Al coating at elevated temperature. Tribol. Lett. 2011, 42, 151–159. [Google Scholar] [CrossRef]

- Zhai, Y.J.; Liu, X.B.; Qiao, S.J.; Wang, M.D.; Lu, X.L.; Wang, Y.G.; Chen, Y.; Ying, L.X. Characteristics of laser clad α-Ti/TiC+(Ti,W)C1-x/Ti2SC+TiS composite coatings on TA2 titanium alloy. Opt. Laser Technol. 2017, 89, 97–107. [Google Scholar] [CrossRef]

- Liu, Y.N.; Yang, L.J.; Yang, X.J.; Zhang, T.G.; Sun, R.L. Optimization of microstructure and properties of composite coatings by laser cladding on titanium alloy. Ceram. Int. 2021, 47, 2230–2243. [Google Scholar] [CrossRef]

- An, Q.; Qi, W.J.; Zuo, X.G. Microstructure and wear resistance of in-situ TiC reinforced Ti-based coating by laser cladding on TA15 titanium alloy surface. J. Mater. Eng. 2022, 50, 139–146. [Google Scholar]

- Ye, Z.Y.; Li, J.N.; Liu, L.Q.; Ma, F.K.; Zhao, B.; Wang, X.L. Microstructure and wear performance enhancement of carbon nanotubes reinforced composite coatings fabricated by laser cladding on titanium alloy. Opt. Laser Technol. 2021, 139, 106957. [Google Scholar] [CrossRef]

- Maliutina, I.N.; Si-Mohand, H.; Sijobert, J.; Lazurenkoa, D.V.; Bataev, I.A. Structure and oxidation behavior of γ-TiAl coating produced by laser cladding on titanium alloy. Surf. Coat. Technol. 2017, 319, 136–144. [Google Scholar] [CrossRef]

- Weng, F.; Yu, H.J.; Liu, J.L.; Chen, C.Z.; Dai, J.J.; Zhao, Z.H. Microstructure and wear property of the Ti5Si3/TiC reinforced Co-based coatings fabricated by laser cladding on Ti-6Al-4V. Opt. Laser Technol. 2017, 92, 156–162. [Google Scholar] [CrossRef]

- Jiang, P.; Zhang, J.J.; Yu, L.G.; Wang, H.M. Wear-resistant Ti5Si3/TiC composite coatings made by laser surface alloying. Rare Metal Mater. Eng. 2000, 29, 269–272. [Google Scholar]

- Guo, C.; Zhou, J.S.; Chen, J.M.; Zhao, J.R.; Yu, Y.J.; Zhou, H.D. Improvement of the oxidation and wear resistance of pure Ti by laser cladding at elevated temperature. Surf. Coat. Technol. 2010, 205, 2142–2151. [Google Scholar] [CrossRef]

- Zhang, H.X. Investigation on Microstructure and Wear Resistance of Ti-Al-Si Ceramic Composite Coatings on Titanium Alloys by Laser Cladding. Ph.D. Thesis, Shandong University, Jinan, China, 2016. [Google Scholar]

- Vojtěch, D.; Novák, M.; Novák, P.; Lejček, P.; Kopeček, J. Unidirectional crystallization and high-temperature oxidation of in situ Ti3(Al,Si)-Ti5(Si,Al)3 composite. Mater. Sci. Eng. A 2008, 489, 1–10. [Google Scholar] [CrossRef]

- Wu, J.S.; Qiu, G.H.; Zhang, L.T. The β-Ti(Al,Si)+Ti5(Si,Al)3 eutectic line in the Ti-Al-Si ternary system. Mater. Sci. Technol. 1994, 2, 1–7. (In Chinese) [Google Scholar]

- Wu, J.S.; Beaven, P.A.; Wagner, R. The Ti3(Al,Si)+Ti5(Si,Al)3 eutectic reaction in the Ti-Al-Si system. Scr. Metall. Mater. 1990, 24, 207–212. [Google Scholar] [CrossRef]

- Wu, J.S.; Qiu, G.H.; Zhang, L.T. The β-Ti(Al,Si)+Ti5(Si,Al)3 eutectic line in the Ti-Al-Si ternary system. Scr. Metall. Mater. 1994, 30, 213–218. [Google Scholar] [CrossRef]

- Liu, J.L.; Zou, Z.R.; Su, B.R. High Energy Beam Heat Treatment; China Machine Press: Beijing, China, 1997; pp. 40–46. [Google Scholar]

- Jackson, M.J.; Robinson, G.M.; Gill, M.D.H.; Neill, W.O. The effect of nozzle design on laser micro-machining of M2 tool steels. J. Mater. Process. Technol. 2005, 160, 198–212. [Google Scholar] [CrossRef]

- Guo, C.; Chen, J.M.; Yao, R.G.; Zhou, J.S.; Zhang, S.T. Microstructure and tribological properties of Ti3Al intermetallic compound coating prepared by laser cladding. Tribol. Lett. 2013, 33, 14–21. [Google Scholar]

- Wang, Y.; Xiong, J.; Yan, J.; Fan, H.Y.; Wang, J. Oxidation resistance and corrosion behavior of hot-dip aluminized coatings on commercial-purity titanium. Surf. Coat. Technol. 2011, 206, 1277–1282. [Google Scholar] [CrossRef]

- Shi, G.N.; Wu, S.H.; Lu, X.L.; Liu, X.B. Microstructure and property of laser clad Ti2SC/TiS self-lubricating anti-wear composite coating on TA2 titanium alloy. Trans. Mater. Heat Treat. 2016, 37, 198–202. [Google Scholar]

- Okamoto, H. O-Ti (Oxygen-Titanium). J. Phase Equilibria Diffus. 2011, 32, 473–474. [Google Scholar] [CrossRef]

- Yu, P.C.; Liu, X.B.; Liu, X.L.; Zhu, G.X.; Chen, Y.; Wu, S.H. Study on tribology and high-temperature oxidation resistance of laser cladding composite coatings on Ti6Al4V alloy. Chin. J. Lasers 2015, 42, 81–88. [Google Scholar]

- Yu, J.J.; Zhang, X.Y.; Ma, L.L.; Li, H.; Zou, L.J.; Zhang, W.P. Microstructures and properties of laser cladding Ti/Ni+Si3N4/ZrO2 composite coatings on TA15 titanium alloys. Surf. Technol. 2016, 45, 105–109. [Google Scholar]

- Cui, Z.Y.; Fang, C.; Zhang, W.L. Effects of Marangoni flow on the thermal behavior and melt flow behavior in laser cladding. Appl. Laser 2018, 38, 409–416. [Google Scholar]

- Lee, Y.S.; Nordin, M.; Babu, S.S.; Farson, D.F. Influence of fluid convection on weld pool formation in laser cladding. Weld. J. 2014, 93, 292–300. [Google Scholar]

- Zhao, M.J.; Li, B.X.; Wu, T.; Zhao, L.Z.; Zeng, J.B.; Jiao, H.T.; Li, J.; Song, L.J. Study on the effect mechanism of laser cladding velocity field based on thermal-fluid coupling model. J. East China Jiaotong Univ. 2022, 39, 74–83. [Google Scholar]

- Mills, K.C.; Su, Y.C. Review of surface tension data for metallic elements and alloys: Part 1—Pure metals. Int. Mater. Rev. 2006, 51, 329–351. [Google Scholar] [CrossRef]

- Raghavan, V. Al-Si-Ti(Aluminum-Silicon-Titanium). J. Phase Equilibria Diffus. 2009, 30, 82–83. [Google Scholar] [CrossRef]

- ASM International. ASM Metals Handbook Volume 3-Alloy Phase Diagrams; The Materials Information Company: Houston, TX, USA, 1992; pp. 327, 1420. [Google Scholar]

- Zhu, Y.; Yang, Y.Q.; Ma, Z.J.; Chen, Y. Thermodynamic studies on interfacial reactions in SiC-fibre-reinforced Ti-matrix composites. Rare Met. Mater. Eng. 2002, 31, 279–282. [Google Scholar]

- Vojtěch, D.; Novák, M.; Novák, P.; Kopeček, J.; Guhlová, P. Properties of (Ti,Nb)Al–(Ti,Nb)Si eutectic composite. Compos. Struct. 2010, 92, 1440–1448. [Google Scholar] [CrossRef]

- Archard, J.F. Contact and rubbing of flat surfaces. J. Appl. Phys. 1953, 24, 981–988. [Google Scholar] [CrossRef]

| Element | Fe | Si | C | N | H | O | Ti |

|---|---|---|---|---|---|---|---|

| Content | 0.2 | 0.1 | 0.1 | 0.05 | 0.015 | 0.1 | Bal. |

| Different Points | Ti (at.%) | Al (at.%) | Si (at.%) | Possible Phases |

|---|---|---|---|---|

| 1 | 60.79 | 4.83 | 34.38 | Ti5Si3 |

| 2 | 70.00 | 19.82 | 10.18 | Ti5Si3/Ti3Al |

| 3 | 61.23 | 4.70 | 34.07 | Ti5Si3 |

| 4 | 78.83 | 12.18 | 8.99 | Ti5Si3/Ti3Al |

| 5 | 75.06 | 19.72 | 5.22 | Ti5Si3/Ti3Al |

| Different Points | Ti (at.%) | Al (at.%) | Si (at.%) | O (at.%) | Possible Phases |

|---|---|---|---|---|---|

| 1 | 91.80 | - | - | 8.20 | Ti + TiOx |

| 2 | 51.11 | - | - | 48.89 | TiO |

| 3 | 100.00 | - | - | - | Ti |

| 4 | 92.11 | - | - | 7.89 | Ti + TiOx |

| 5 | 87.00 | - | - | 13.00 | Ti + TiOx |

| 6 | 43.34 | 2.52 | 24.78 | 29.36 | Ti5Si3 + Al2O3 + TiO2 |

| 7 | 64.69 | 5.27 | 30.03 | - | Ti5Si3 + Ti3Al |

| 8 | 45.00 | 2.96 | 22.99 | 29.08 | Ti5Si3 + Al2O3 + TiO2 |

| 9 | 45.54 | 2.17 | 29.40 | 22.88 | Ti5Si3 + Al2O3 + TiO2 |

| 10 | 40.92 | 2.31 | 24.37 | 32.39 | Ti5Si3 + Al2O3 + TiO2 |

| 11 | 58.58 | 14.18 | 4.80 | 22.43 | Ti3Al + TiO2 + SiO2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, K.; Huang, W. Microstructure and Wear Resistance of Ti5Si3/Ti3Al Composite Coatings Prepared by Laser Cladding on TA2 Titanium Alloy. Lubricants 2023, 11, 213. https://doi.org/10.3390/lubricants11050213

Huang K, Huang W. Microstructure and Wear Resistance of Ti5Si3/Ti3Al Composite Coatings Prepared by Laser Cladding on TA2 Titanium Alloy. Lubricants. 2023; 11(5):213. https://doi.org/10.3390/lubricants11050213

Chicago/Turabian StyleHuang, Kaijin, and Wanxia Huang. 2023. "Microstructure and Wear Resistance of Ti5Si3/Ti3Al Composite Coatings Prepared by Laser Cladding on TA2 Titanium Alloy" Lubricants 11, no. 5: 213. https://doi.org/10.3390/lubricants11050213

APA StyleHuang, K., & Huang, W. (2023). Microstructure and Wear Resistance of Ti5Si3/Ti3Al Composite Coatings Prepared by Laser Cladding on TA2 Titanium Alloy. Lubricants, 11(5), 213. https://doi.org/10.3390/lubricants11050213