Abrasive Wear Behavior of Al–4Cu–1.5Mg–WC Composites Synthesized through Powder Metallurgy

Abstract

1. Introduction

2. Materials and Methods

3. Results

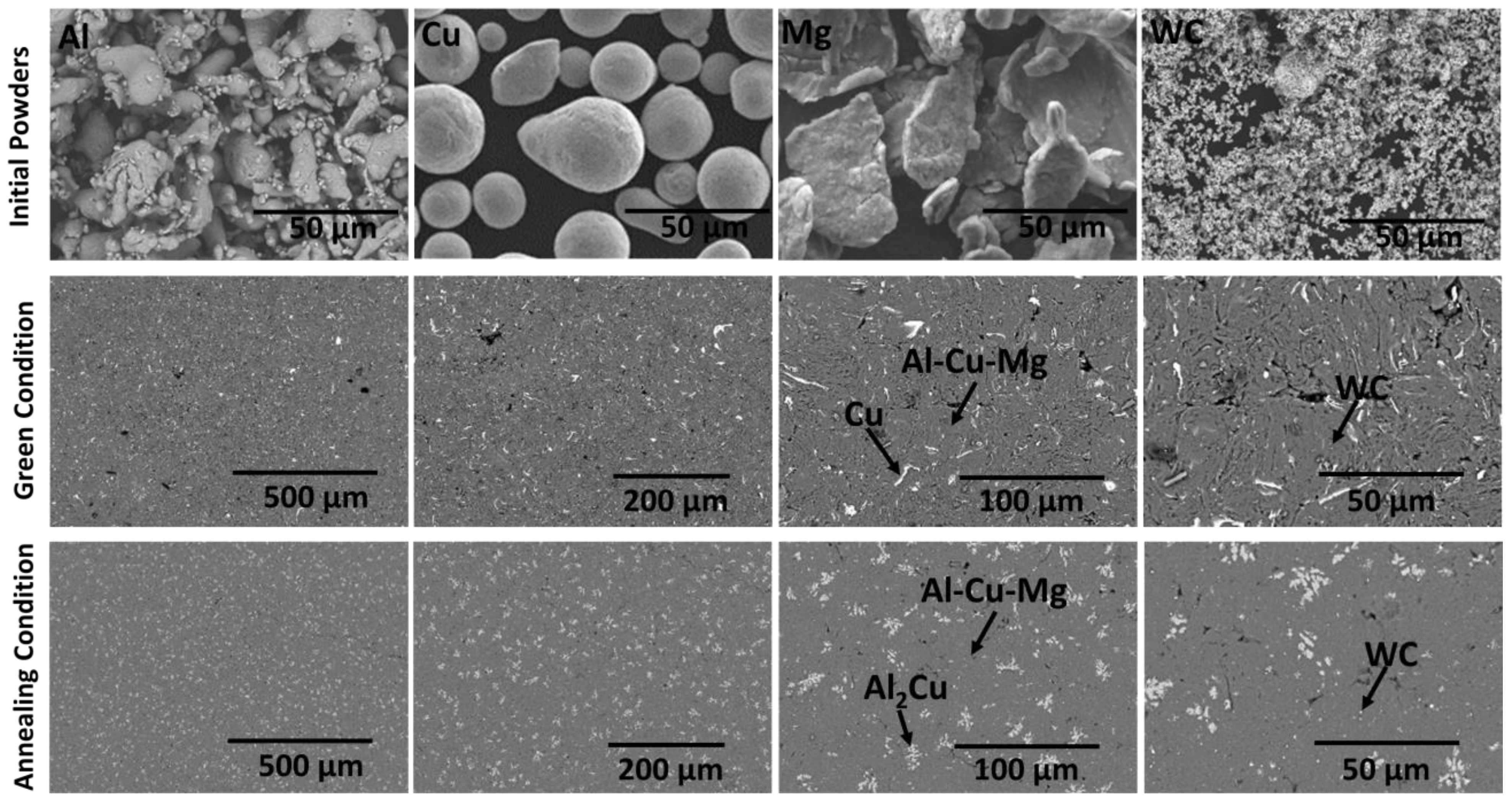

3.1. Characterization of the Initial Materials

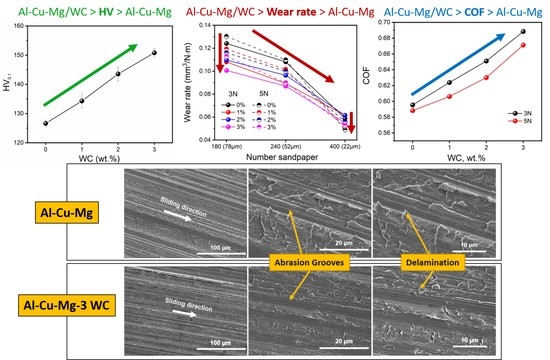

3.2. Mechanical and Wear Behavior

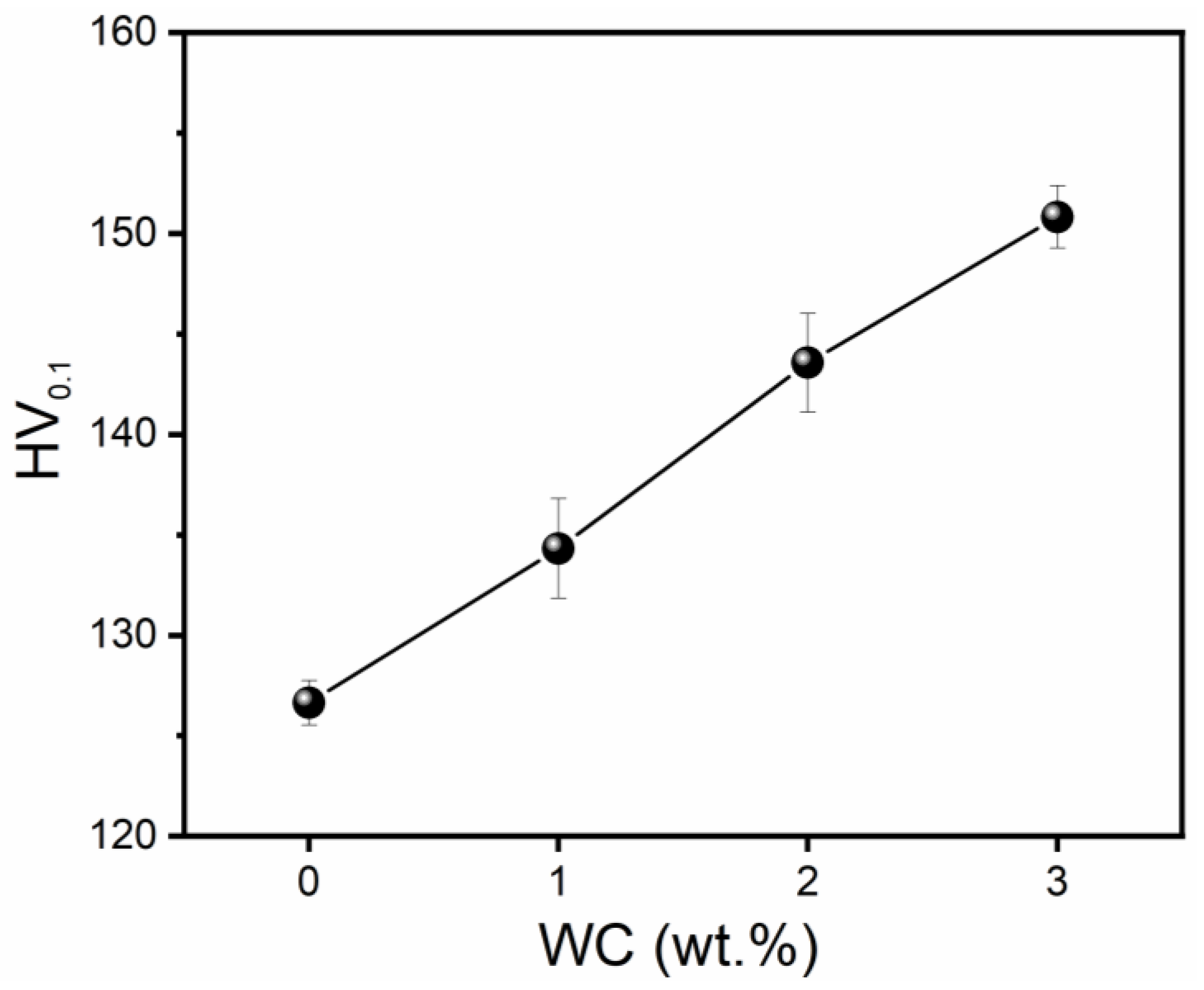

3.2.1. Vickers Hardness

3.2.2. Wear Rate (Pin-On-Disc Tests)

3.2.3. Coefficient of Friction (Linear Configuration Test)

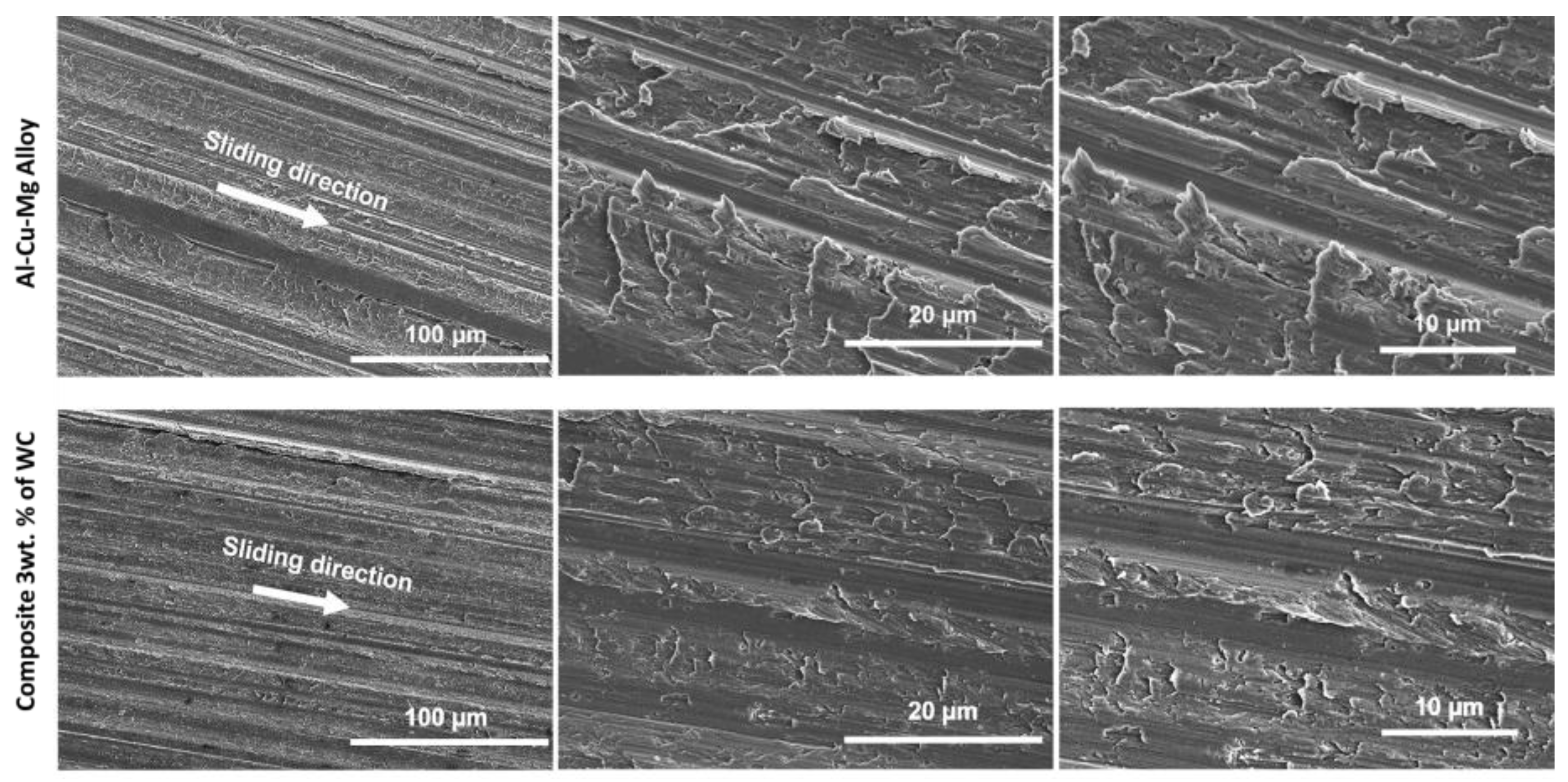

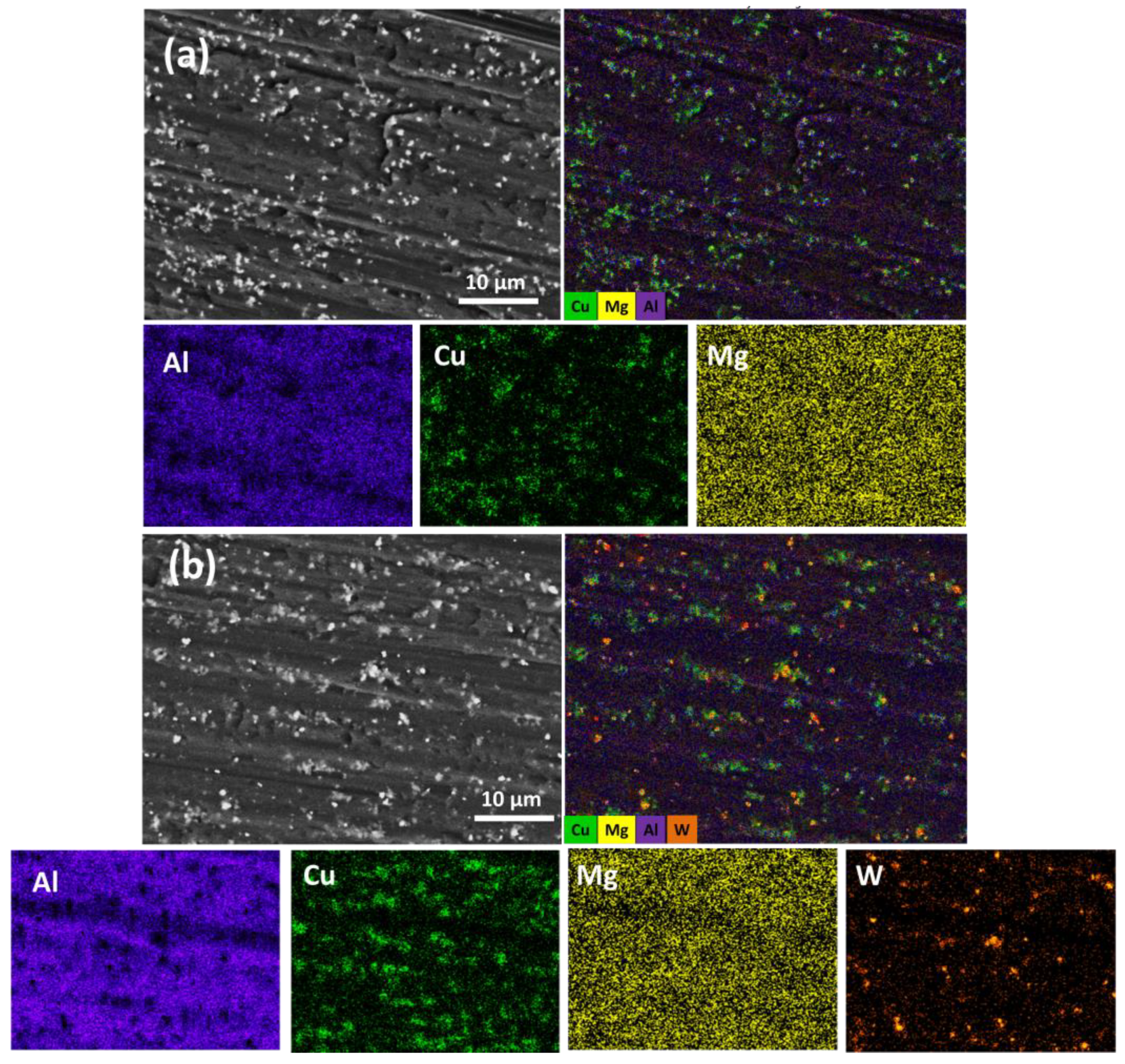

3.2.4. Worn Surfaces (Pin-On-Disc Tests)

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, J.; Song, B.; Wei, Q.; Bourell, D.; Shi, Y. A review of selective laser melting of aluminum alloys: Processing, microstructure, property and developing trends. J. Mater. Sci. Technol. 2019, 35, 270–284. [Google Scholar] [CrossRef]

- Xiong, H.; Su, L.; Kong, C.; Yu, H. Development of High Performance of Al Alloys via Cryo-Forming: A Review. Adv. Eng. Mater. 2021, 23, 2001533. [Google Scholar] [CrossRef]

- Barnwal, V.K.; Raghavan, R.; Tewari, A.; Narasimhan, K.; Mishra, S.K. Effect of microstructure and texture on forming behaviour of AA-6061 aluminium alloy sheet. Mater. Sci. Eng. A 2017, 679, 56–65. [Google Scholar] [CrossRef]

- Fernández-López, P.; Alves, S.A.; López-Ortega, A.; San José-Lombera, J.T.; Bayon, R. High performance tribological coatings on a secondary cast Al–Si alloy generated by Plasma Electrolytic Oxidation. Ceram. Int. 2021, 47, 31238–31250. [Google Scholar] [CrossRef]

- Kumar, H.P.; Xavior, M.A. Assessment of mechanical and tribological properties of Al 2024-SiC-graphene hybrid composites. Procedia Eng. 2017, 174, 992–999. [Google Scholar] [CrossRef]

- Lekatou, A.; Karantzalis, A.E.; Evangelou, A.; Gousia, V.; Kaptay, G.; Gácsi, Z.; Gácsi, Z.; Baumli, P.; Simon, A. Aluminium reinforced by WC and TiC nanoparticles (ex-situ) and aluminide particles (in-situ): Microstructure, wear and corrosion behaviour. Mater. Des. 2015, 65, 1121–1135. [Google Scholar] [CrossRef]

- Sathish, T.; Karthick, S. Wear behaviour analysis on aluminium alloy 7050 with reinforced SiC through taguchi approach. J. Mater. Res. Technol. 2020, 9, 3481–3487. [Google Scholar] [CrossRef]

- Fernández, R.; Cabeza, S.; Mishurova, T.; Fernández-Castrillo, P.; González-Doncel, G.; Bruno, G. Residual stress and yield strength evolution with annealing treatments in an age-hardenable aluminum alloy matrix composite. Mater. Sci. Eng. A 2018, 731, 344–350. [Google Scholar] [CrossRef]

- Mazahery, A.; Shabani, M.O. Influence of the hard coated B4C particulates on wear resistance of Al–Cu alloys. Compos. Part B: Eng. 2012, 43, 1302–1308. [Google Scholar] [CrossRef]

- Soltani, S.; Azari Khosroshahi, R.; Taherzadeh Mousavian, R.; Jiang, Z.Y.; Fadavi Boostani, A.; Brabazon, D. Stir casting process for manufacture of Al–SiC composites. Rare Met. 2017, 36, 581–590. [Google Scholar] [CrossRef]

- Rodríguez-Cabriales, G.; Lometo-Sánchez, A.M.; Guía-Tello, J.C.; Medrano-Prieto, H.M.; Gutiérrez-Castañeda, E.J.; Estrada-Guel, I.; Garay-Reyes, C.; Hernández-Rivera, J.; Cruz-Rivera, J.; Maldonado-Orozco, M.; et al. Synthesis and characterization of Al-Cu-Mg system reinforced with tungsten carbide through powder metallurgy. Mater. Today Commun. 2020, 22, 100758. [Google Scholar] [CrossRef]

- Simon, A.; Lipusz, D.; Baumli, P.; Balint, P.; Kaptay, G.; Gergely, G.; Sfikas, A.; Lekatou, A.; Karantzalis, A.; Gacsi, Z. Microstructure and mechanical properties of Al-WC composites. Arch. Metall. Mater. 2015, 60, 1517–1521. [Google Scholar] [CrossRef]

- Al-Mosawi, B.T.; Wexler, D.; Calka, A. Characterization and mechanical properties of α-Al2O3 particle reinforced aluminium matrix composites, synthesized via uniball magneto-milling and uniaxial hot pressing. Adv. Powder Technol. 2017, 28, 1054–1064. [Google Scholar] [CrossRef]

- Pandiyan, A.; Kumar, G.A.; Ranganthan, S.; Madhu, S. Optimization of wear performance on aluminium die cast A360-M1 master alloy using response surface method. Mater. Today Proc. 2020, 22, 551–557. [Google Scholar] [CrossRef]

- Krishna, U.B.; Vasudeva, B.; Auradi, V.; Nagaral, M. Effect of percentage variation on wear behaviour of tungsten carbide and cobalt reinforced Al7075 matrix composites synthesized by melt stirring method. J. Bio-Tribo-Corros. 2021, 7, 1–8. [Google Scholar] [CrossRef]

- Pal, A.; Poria, S.; Sutradhar, G.; Sahoo, P. Tribological behavior of Al-WC nano-composites fabricated by ultrasonic cavitation assisted stir-cast method. Mater. Res. Express 2018, 5, 036521. [Google Scholar] [CrossRef]

- Gowda, K.P.; Prakash, J.N.; Gowda, S.; Babu, B.S. Effect of particulate reinforcement on the mechanical properties of Al2024-WC MMCs. J. Miner. Mater. Charact. Eng. 2015, 3, 469–476. [Google Scholar] [CrossRef]

- Mosbah, A.Y.; Wexler, D.; Calka, A. Abrasive wear of WC–FeAl composites. Wear 2005, 258, 1337–1341. [Google Scholar] [CrossRef]

- Majzoobi, G.H.; Rahmani, K.; Atrian, A. Temperature effect on mechanical and tribological characterization of Mg–SiC nanocomposite fabricated by high rate compaction. Mater. Res. Express 2018, 5, 015046. [Google Scholar] [CrossRef]

- Rahmani, K.; Majzoobi, G.H. The effect of particle size on microstructure, relative density and indentation load of Mg-B4C composites fabricated at different loading rates. J. Compos. Mater. 2020, 54, 2297–2311. [Google Scholar] [CrossRef]

- Pérez-Bustamante, R.; Bueno-Escobedo, J.L.; Jiménez-Lobato, J.; Estrada-Guel, I.; Miki-Yoshida, M.; Licea-Jiménez, L.; Martínez-Sánchez, R. Wear behavior in Al2024–CNTs composites synthesized by mechanical alloying. Wear 2012, 292, 169–175. [Google Scholar] [CrossRef]

- ASTM G99-17; Standard Test Method for Wear Testing with A Pin-On-Disk Apparatus. ASTM International: West Conshohocken, PA, USA, 2017.

- Nemati, N.; Khosroshahi, R.; Emamy, M.; Zolriasatein, A. Investigation of microstructure, hardness and wear properties of Al–4.5 wt.% Cu–TiC nanocomposites produced by mechanical milling. Mater. Des. 2011, 32, 3718–3729. [Google Scholar] [CrossRef]

- Prakash, N.A.; Gnanamoorthy, R.; Kamaraj, M. Friction and wear behavior of surface nanocrystallized aluminium alloy under dry sliding condition. Mater. Sci. Eng. B 2010, 168, 176–181. [Google Scholar] [CrossRef]

- Huang, Y.; Fan, H.; Wang, D.; Sun, Y.; Liu, F.; Shen, J.; Sun, J.; Mi, J. The effect of cooling rate on the wear performance of a ZrCuAlAg bulk metallic glass. Mater. Des. 2014, 58, 284–289. [Google Scholar] [CrossRef]

- Elhefnawey, M.; Shuai, G.L.; Li, Z.; Nemat-Alla, M.; Zhang, D.T.; Li, L. On dry sliding wear of ECAPed Al-Mg-Zn alloy: Wear rate and coefficient of friction relationship. Alex. Eng. J. 2021, 60, 927–939. [Google Scholar] [CrossRef]

- Moheimani, S.K.; Keshtgar, A.; Khademzadeh, S.; Tayebi, M.; Rajaee, A.; Saboori, A. Tribological behaviour of AZ31 magnesium alloy reinforced by bimodal size B4C after precipitation hardening. J. Magnes. Alloy. 2021, 10, 3267–3280. [Google Scholar] [CrossRef]

- Rahimian, M.; Parvin, N.; Ehsani, N. Investigation of particle size and amount of alumina on microstructure and mechanical properties of Al matrix composite made by powder metallurgy. Mater. Sci. Eng. A 2010, 527, 1031–1038. [Google Scholar] [CrossRef]

- Abarghouie, S.M.; Reihani, S.S. Investigation of friction and wear behaviors of 2024 Al and 2024 Al/SiCp composite at elevated temperatures. J. Alloys Compd. 2010, 501, 326–332. [Google Scholar] [CrossRef]

- Li, C.; Li, S.; Liu, C.; Zhang, Y.; Deng, P.; Guo, Y.; Wang, J.; Wang, Y. Effect of WC addition on microstructure and tribological properties of bimodal aluminum composite coatings fabricated by laser surface alloying. Mater. Chem. Phys. 2019, 234, 9–15. [Google Scholar] [CrossRef]

- Weng, Z.; Wang, A.; Wu, X.; Wang, Y.; Yang, Z. Wear resistance of diode laser-clad Ni/WC composite coatings at different temperatures. Surf. Coat. Technol. 2016, 304, 283–292. [Google Scholar] [CrossRef]

- Kaushik, N.; Sri Chaitanya, C.; Rao, R.N. Abrasive grit size effect on wear depth of stir cast hybrid Al–Mg–Si composites at high stress condition. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2018, 232, 672–684. [Google Scholar] [CrossRef]

- Kök, M. Abrasive wear of Al2O3 particle reinforced 2024 aluminium alloy composites fabricated by vortex method. Compos. Part A Appl. Sci. Manuf. 2006, 37, 457–464. [Google Scholar] [CrossRef]

- Kök, M.; Özdin, K. Wear resistance of aluminium alloy and its composites reinforced by Al2O3 particles. J. Mater. Process. Technol. 2007, 183, 301–309. [Google Scholar] [CrossRef]

- Suryanarayana, C. Mechanical alloying and milling. Prog. Mater. Sci. 2001, 46, 1–184. [Google Scholar] [CrossRef]

- Ergül, E.; Kurt, H.İ.; Oduncuoğlu, M.; Can, Ç.İ.V.İ. Wear Properties of Al-Cu-Mg Composites Reinforced with MGO and MWCNT under Different Loads. Int. J. Mater. Eng. Technol. 2020, 2, 70–75. [Google Scholar]

- Rao, R.N.; Devi, S.T. Wear regimes of Al-Cu-Mg matrix composites. Composites 2013, 5, 6. [Google Scholar] [CrossRef]

- Hidalgo-Hernandez, R.G.; Plaza, N.; Suárez, O.M. A study on tribological characterization of Al-Cu-Mg-B composites subjected to mechanical wear. Sci. Eng. Compos. Mater. 2014, 21, 333–339. [Google Scholar] [CrossRef]

| Element Powder | Purity (%) | Particle Size (µm) |

|---|---|---|

| Al | 99.5 | <32 |

| Cu | 99.5 | <32 |

| Mg | 99.8 | <32 |

| WC | 99.9 | <1 |

| Sample Name (wt. %) | Theoretical Density (g/cm3) | Archimedes Density (g/cm3) | Relative Density | Porosity (%) |

|---|---|---|---|---|

| Al–4.5Cu–1.5Mg | 2.764 | 2.736 ± 0.010 | 0.99 | 1 |

| Al–4.5Cu–1.5Mg + 1%WC | 2.787 | 2.703 ± 0.013 | 0.97 | 3 |

| Al–4.5Cu–1.5Mg + 2%WC | 2.811 | 2.642 ± 0.008 | 0.94 | 6 |

| Al–4.5Cu–1.5Mg + 3%WC | 2.836 | 2.581 ± 0.0115 | 0.91 | 9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rodríguez-Cabriales, G.; Garay-Reyes, C.G.; Guía-Tello, J.C.; Medrano-Prieto, H.M.; Estrada-Guel, I.; García-Hernández, L.J.; Ruiz-Esparza-Rodríguez, M.A.; Mendoza-Duarte, J.M.; García-Aguirre, K.A.; Gonzáles-Sánchez, S.; et al. Abrasive Wear Behavior of Al–4Cu–1.5Mg–WC Composites Synthesized through Powder Metallurgy. Lubricants 2023, 11, 103. https://doi.org/10.3390/lubricants11030103

Rodríguez-Cabriales G, Garay-Reyes CG, Guía-Tello JC, Medrano-Prieto HM, Estrada-Guel I, García-Hernández LJ, Ruiz-Esparza-Rodríguez MA, Mendoza-Duarte JM, García-Aguirre KA, Gonzáles-Sánchez S, et al. Abrasive Wear Behavior of Al–4Cu–1.5Mg–WC Composites Synthesized through Powder Metallurgy. Lubricants. 2023; 11(3):103. https://doi.org/10.3390/lubricants11030103

Chicago/Turabian StyleRodríguez-Cabriales, Gustavo, Carlos G. Garay-Reyes, Juan C. Guía-Tello, Hansel M. Medrano-Prieto, Ivanovich Estrada-Guel, Lilia J. García-Hernández, Marco A. Ruiz-Esparza-Rodríguez, José M. Mendoza-Duarte, Karen A. García-Aguirre, Sergio Gonzáles-Sánchez, and et al. 2023. "Abrasive Wear Behavior of Al–4Cu–1.5Mg–WC Composites Synthesized through Powder Metallurgy" Lubricants 11, no. 3: 103. https://doi.org/10.3390/lubricants11030103

APA StyleRodríguez-Cabriales, G., Garay-Reyes, C. G., Guía-Tello, J. C., Medrano-Prieto, H. M., Estrada-Guel, I., García-Hernández, L. J., Ruiz-Esparza-Rodríguez, M. A., Mendoza-Duarte, J. M., García-Aguirre, K. A., Gonzáles-Sánchez, S., & Martínez-Sánchez, R. (2023). Abrasive Wear Behavior of Al–4Cu–1.5Mg–WC Composites Synthesized through Powder Metallurgy. Lubricants, 11(3), 103. https://doi.org/10.3390/lubricants11030103