Mass and Energy Balance of a Three-Body Tribosystem

Abstract

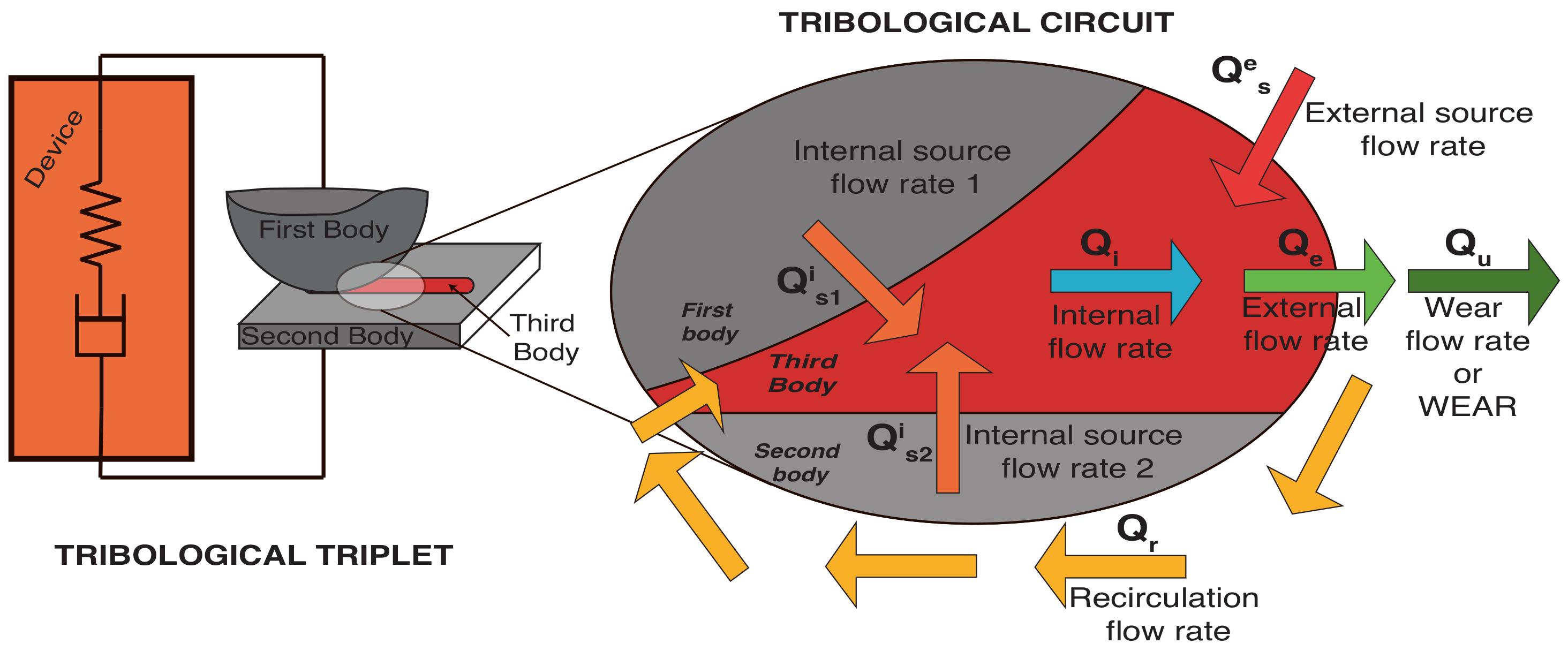

:1. Introduction

- the contact formation;

- the formation of a junction;

- the contact separation.

- the production of debris by the first bodies;

- the circulation of the debris in the interface;

- the ejection of the debris from the contact.

- There is no expression of the mass balance determined from a thermodynamic approach of open systems;

- No energy balance follows from this.

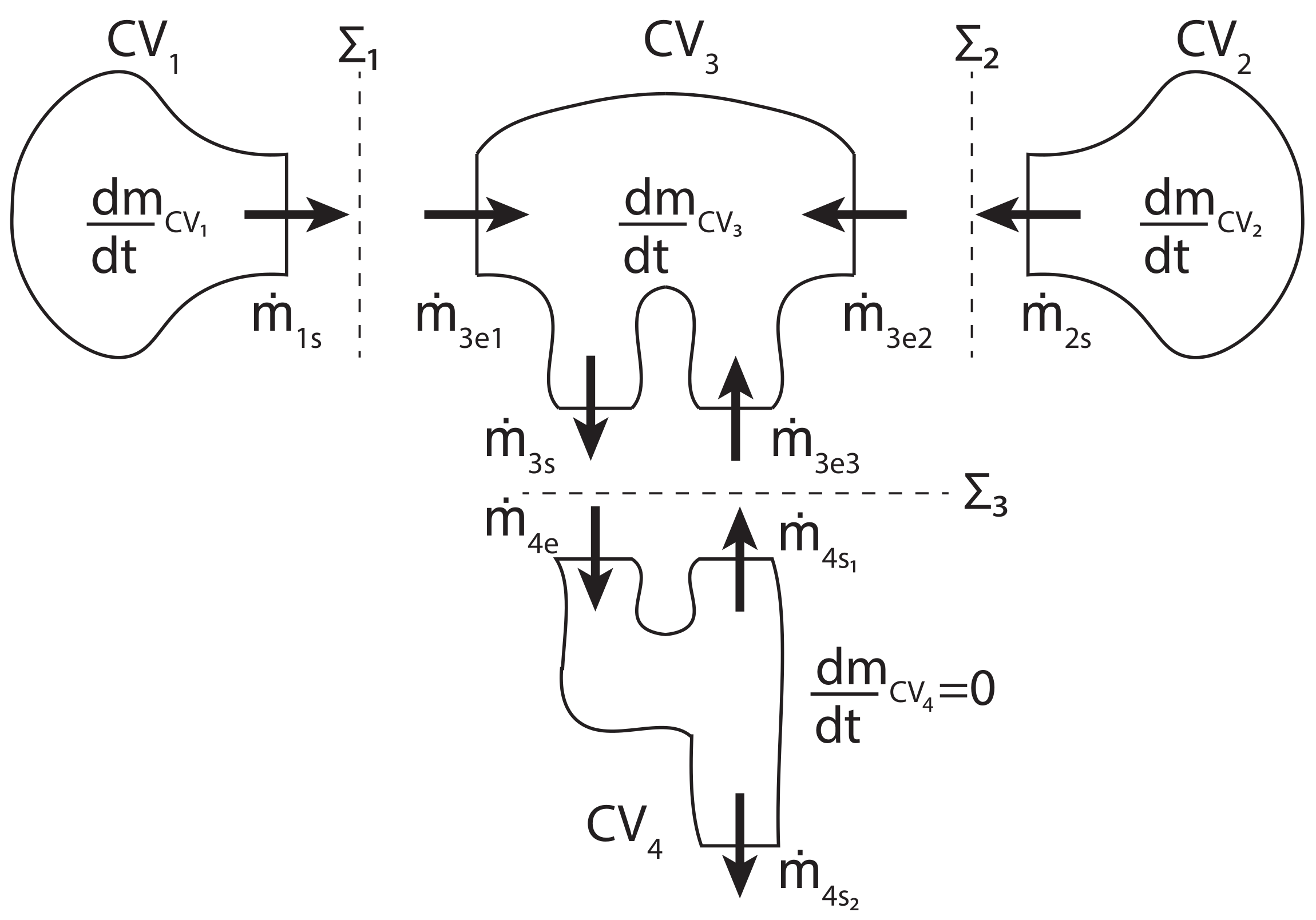

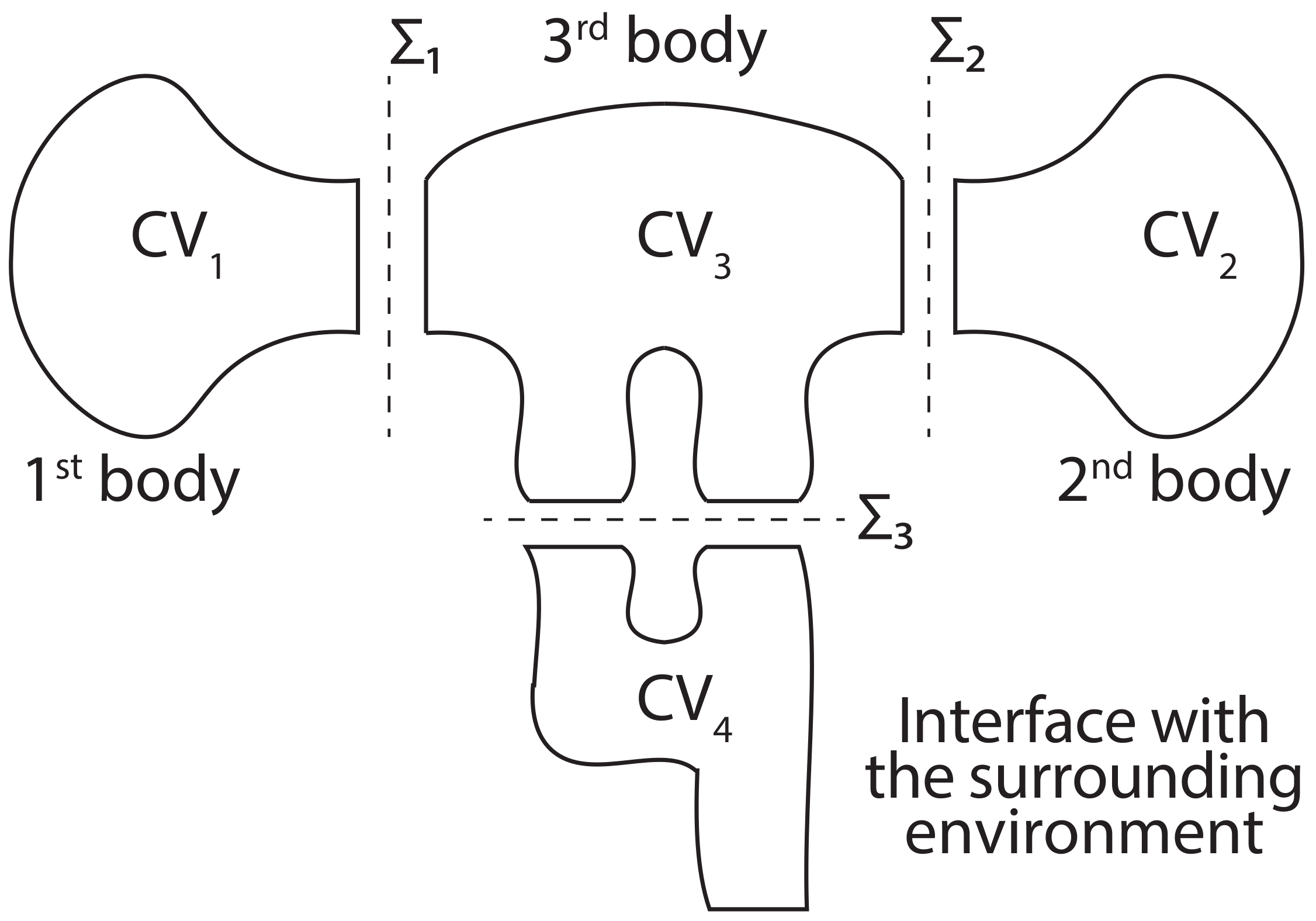

2. Mass Balance

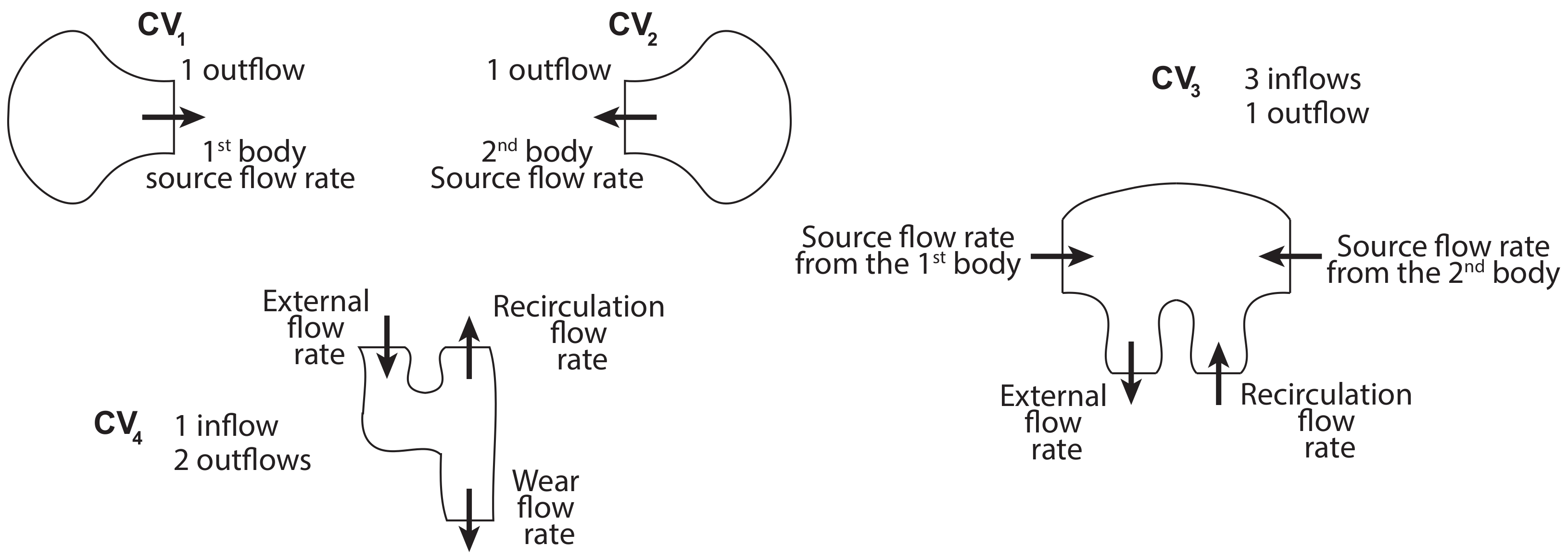

- CV1, the first body;

- CV2, the second body;

- CV3, the third body;

- CV4, the fourth body, or the interface with the environment which models the external flow rate.

- , between the first body and the third body;

- , the second body and the third body;

- , the third body and the wear;

- CV1, one outflow, noted s;

- CV2, one outflow, noted s;

- CV3, three inflows and one outflow, noted , , and s respectively;

- CV4, one inflow and two outflow, noted e, and .

- , the mass flow rate leaving the first body, it is the first source flow rate;

- , the mass flow rate leaving the second body, it is the second source flow rate;

- , the first flow entering the third body and coming from the first body;

- , the second flow entering the third body from the second body;

- , this third mass flow enters the third body. The matter arrives from the fourth control volume. This is the recirculation flow;

- , the mass flow out of the third body into the fourth body is the external flow;

- , the mass flow entering the fourth body and coming from the third body;

- , the mass flow rate leaving the fourth body and recirculating to the third body;

- , the mass flow leaving the fourth control volume and which is evacuated definitively to the outside. This is the wear.

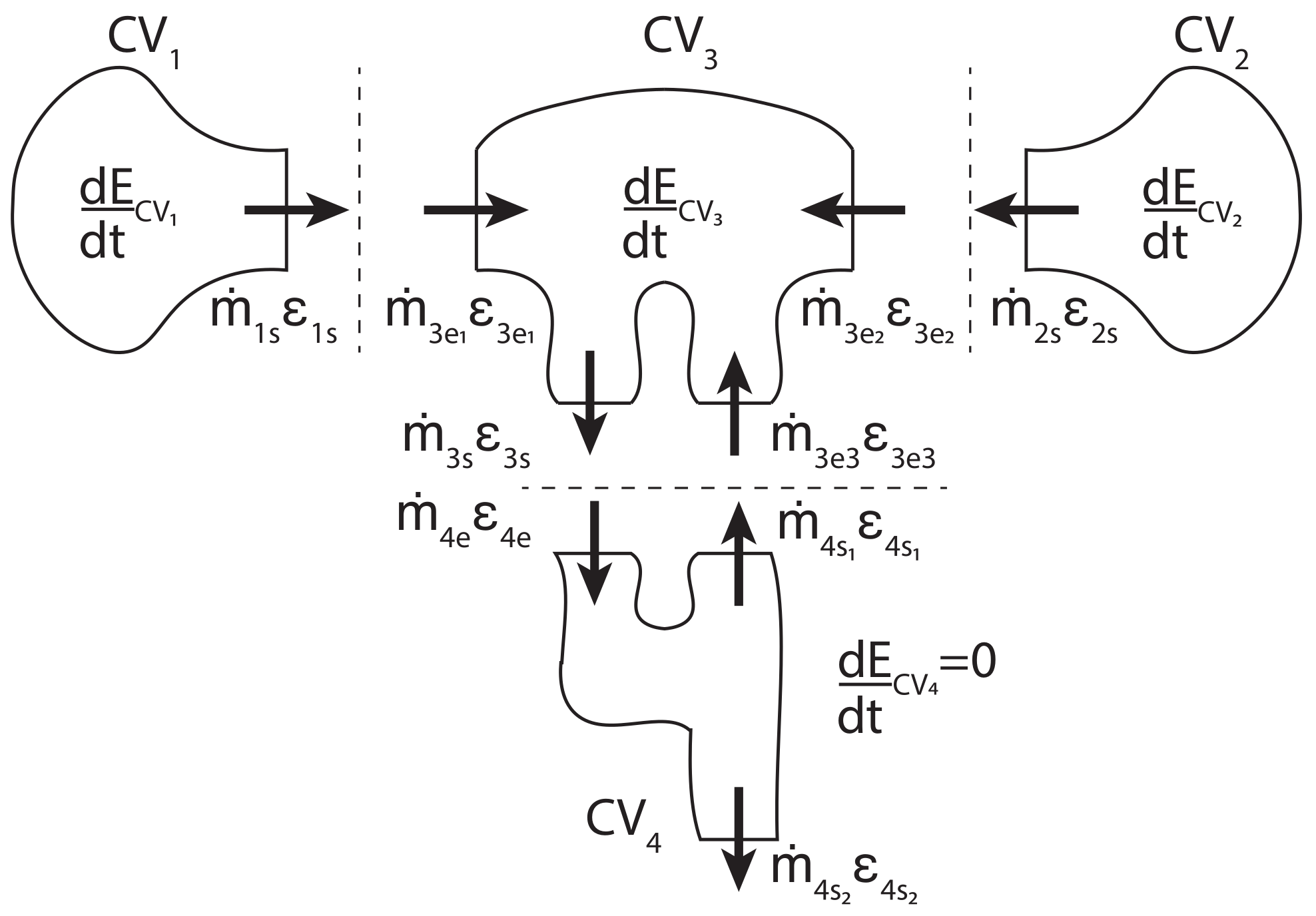

3. Energy Balance

- : the total energy in the i-th control volume CVi;

- : the total net power balance, which contains the total power entering in the i-th control volume and that leaving it.

- : the total energy per unit of mass entering the i-th control volume CVi;

- : the total energy per unit of mass leaving the i-th control volume CVi;

- : the non-thermal power exchanged by the i-th control volume CVi;

- : the thermal power exchanged by the i-th control volume CVi.

- For the first bodies:

- For the third body:

- For the control volume, which models the interface with the external environment:The non-thermal powers express the elastic deformation and the plastic deformation, the shear, the breakage or the rolling, i.e., all accommodation modes presented in Section 1. The index i is associated with accommodation sites, so the i-th control volume. From this we can deduce that:where represents the non-thermal power of a given accommodation mechanism. The index j varies from 0 to 4, according to the Denapes’ notation for the accommodation mechanisms (Table 2). Those mechanisms are identified in all control volumes, except in the fourth. Indeed, the fourth control volume schematises the external flow rate but is not considered as an accommodation site in the tribosystem.Then, Equation (24) therefore becomes:

- Between the two first bodies and the third body, it is established that:In other words, the flow of total energy transported by the matter from the first bodies enters the third body;

- Not forgetting the flow of material that can return from the external environment to the third body through the recirculation flow:

- It is also necessary to take into account the flow of total energy transported by the material lost by the third body and which is received by the external environment:

4. Discussion

5. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dowson, D. History of Tribology; Professional Engineering Publishing: London, UK, 1998. [Google Scholar]

- Dowson, D. Elastohydrodynamic and micro-elastohydrodynamic lubrication. Wear 1995, 190, 125–138. [Google Scholar] [CrossRef]

- Frêne, J.; Arghir, M.; Constantinescu, V. Combined thin-film and Navier–Stokes analysis in high Reynolds number lubrication. Tribol. Int. 2006, 39, 734–747. [Google Scholar] [CrossRef]

- Medwell, J.O.; Gethin, D.T.; Taylor, C. A finite element analysis of the Navier-Stokes equations applied to high speed thin film lubrication. J. Tribol. 1987, 109, 71–76. [Google Scholar] [CrossRef]

- Patel, R.; Khan, Z.A.; Saeed, A.; Bakolas, V. A Review of Mixed Lubrication Modelling and Simulation. Tribol. Ind. 2022, 44, 150. [Google Scholar] [CrossRef]

- Holey, H.; Codrignani, A.; Gumbsch, P.; Pastewka, L. Height-Averaged Navier–Stokes Solver for Hydrodynamic Lubrication. Tribol. Lett. 2022, 70, 36. [Google Scholar] [CrossRef]

- Deshmukh, K.; Warudkar, V. Thermohydrodynamic Analysis of Journal Bearing Using Non-newtonian Lubricants. In Advances in Mechanical Engineering and Technology; Springer: Singapore, 2022; pp. 97–106. [Google Scholar]

- Doumeng, M.; Ferry, F.; Delbé, K.; Mérian, T.; Chabert, F.; Berthet, F.; Marsan, O.; Nassiet, V.; Denape, J. Evolution of crystallinity of PEEK and glass-fibre reinforced PEEK under tribological conditions using Raman spectroscopy. Wear 2019, 426, 1040–1046. [Google Scholar] [CrossRef] [Green Version]

- Doumeng, M. Étude des Propriétés Intrinsèques et Tribologiques des Composites à Matrice PEEK Chargés de Renforts Micro/Nanométriques. Ph.D. Thesis, INPT, Toulouse, France, 2021. [Google Scholar]

- Zhang, X.; Zhang, Y.; Jin, Z. A review of the bio-tribology of medical devices. Friction 2021, 10, 4–30. [Google Scholar] [CrossRef]

- Wagner, R.M.; Maiti, R.; Carré, M.J.; Perrault, C.M.; Evans, P.C.; Lewis, R. Bio-tribology of vascular devices: A review of tissue/device friction research. Biotribology 2021, 25, 100169. [Google Scholar] [CrossRef]

- Zheng, Y.; Bashandeh, K.; Shakil, A.; Jha, S.; Polycarpou, A.A. Review of dental tribology: Current status and challenges. Tribol. Int. 2022, 166, 107354. [Google Scholar] [CrossRef]

- Jones, W.R.; Jansen, M.J. Tribology for space applications. Proc. Inst. Mech. Eng. Part J. Eng. Tribol. 2008, 222, 997–1004. [Google Scholar] [CrossRef]

- Bashandeh, K.; Tsigkis, V.; Lan, P.; Polycarpou, A.A. Extreme environment tribological study of advanced bearing polymers for space applications. Tribol. Int. 2021, 153, 106634. [Google Scholar] [CrossRef]

- Orozco Gomez, S.; Delbé, K.; Benitez, A.; Paris, J.Y.; Denape, J. High temperature tribological behaviour of metal matrix composites produced by SPS. Key Eng. Mater. 2021, 482, 89–100. [Google Scholar] [CrossRef] [Green Version]

- Delbé, K.; Orozco Gomez, S.; Carrillo Mancuso, J.M.; Paris, J.Y.; Denape, J. Tribological behaviour of stellite matrix composites for high temperatures applications. Key Eng. Mater. 2012, 498, 89–101. [Google Scholar] [CrossRef] [Green Version]

- Lafon-Placette, S.; Delbé, K.; Denape, J.; Ferrato, M. Tribological characterization of silicon carbide and carbon materials. J. Eur. Ceram. Soc. 2015, 35, 1147–1159. [Google Scholar] [CrossRef] [Green Version]

- Zeng, Q.; Ning, Z. High-temperature tribological properties of diamond-like carbon films: A review. Rev. Adv. Mater. Sci. 2021, 60, 276–292. [Google Scholar] [CrossRef]

- Gopinath, V.M.; Arulvel, S. A review on the steels, alloys/high entropy alloys, composites and coatings used in high temperature wear applications. Mater. Today Proc. 2021, 43, 817–823. [Google Scholar] [CrossRef]

- Nyberg, E.; Llopart i Cervelló, D.; Minami, I. Tribology in space robotic actuators: Experimental method for evaluation and analysis of gearboxes. Aerospace 2021, 8, 75. [Google Scholar] [CrossRef]

- Bowden, F.P.; Tabor, D. The Friction and Lubrication of Solids; Oxford University Press: New York, NY, USA, 2001. [Google Scholar]

- Godet, M. The third-body approach: A mechanical view of wear. Wear 1984, 100, 437–452. [Google Scholar] [CrossRef]

- Berthier, Y. Mécanismes et Tribologie. Ph.D. Thesis, INSA, Lyon, France, 1988. [Google Scholar]

- Berthier, Y.; Vincent, L.; Godet, M. Velocity accommodation sites and modes in tribology. Eur. J. Mech. A/Solids 1992, 11, 35–47. [Google Scholar]

- Denape, J.; Berthier, Y.; Vincent, L. Wear Particle Life in a Sliding Contact Under Dry Conditions: Third Body Approach Fundamentals of Tribology and Bridging the Gap Between Macro and Micro-Nanoscale. NATO Sci. Ser. II 2001, 10, 393–411. [Google Scholar]

- Denape, J. Third Body Concept and Wear Particle Behaviour in Dry Sliding Friction. Key Eng. Mater. 2015, 640, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Fillot, N. Étude Mécanique de L’usure: Modélisation par Éléments Discrets des Débits de Troisième Corps Solide. Ph.D. Thesis, INSA, Lyon, France, 2004. [Google Scholar]

- Fillot, N.; Iordanoff, I.; Berthier, Y. Simulation of wear through mass balance in a dry contact. J. Tribol. 2005, 127, 230–237. [Google Scholar] [CrossRef]

- Fillot, N.; Iordanoff, I.; Berthier, Y. Wear modeling and the third body concept. Wear 2007, 262, 949–957. [Google Scholar] [CrossRef]

- Dragon-Louiset, M. Modèles micromécaniques de l’interface d’un système tribologique dans une approche thermodynamique de l’usure continue. Méc. Ind. 2000, 1, 37–42. [Google Scholar] [CrossRef]

- Dragon-Louiset, M. On a predictive macroscopic contact-sliding wear model based on micromechanical considerations. Int. J. Solids Struct. 2001, 38, 1625–1639. [Google Scholar] [CrossRef]

- Czichos, H. Tribology: A Systems Approach to the Science and Technology of Friction, Lubrication, and Wear; Elsevier: Amsterdam, The Netherlands, 2009; Volume 1. [Google Scholar]

- Lyashenko, I.A.; Khomenko, A.V.; Metlov, L.S. Thermodynamics and kinetics of boundary friction. Tribol. Int. 2011, 44, 476–482. [Google Scholar] [CrossRef] [Green Version]

- Maciąg, M. Thermodynamic model of the metallic friction process. J. Tribol. 2010, 132, 031603. [Google Scholar] [CrossRef]

- Maciąg, M. Specific Heat of Tribological Wear Debris Material. J. Tribol. 2015, 137, 031601. [Google Scholar] [CrossRef]

- Banjac, M.; Vencl, A.; Otović, S. Friction and Wear Processes—Thermodynamic Approach. Tribol. Ind. 2014, 36, 341–347. [Google Scholar]

- Fedorov, S.V. Energy Balance of Friction and Friction Coefficient in Energetical Interpretation. Tribol. Ind. 2015, 37, 380–389. [Google Scholar]

- Fedorov, S.V. Structural-Energy Interpretation of a Tribosystem. J. Frict. Wear 2021, 42, 117–123. [Google Scholar] [CrossRef]

- Fedorov, S.V. Analysis of the Energy Balance of Friction on the Rolling Contact. Tribol. Ind. 2021, 43, 283–297. [Google Scholar] [CrossRef]

- Bejan, A. Evolution in thermodynamics. Appl. Phys. Rev. 2017, 4, 011305. [Google Scholar] [CrossRef]

- Lafon-Placette, S. Performances Tribologiques d’un Carbure de Silicium Pour Paliers D’étanchéité Dynamique Fonctionnant en Conditions Sévères. Ph.D. Thesis, INPT, Toulouse, France, 2015. [Google Scholar]

- Delbé, K.; Lafon-Placette, S.; Ferrato, M.; Welemane, H.; Denape, J. Influence des imprégnations du carbone-graphite sur les performances tribologiques d’un couple de frottement C/SiC. In Proceedings of the 24th Congrès Français de la Mécanique, Nantes, France, 26–30 August 2019. [Google Scholar]

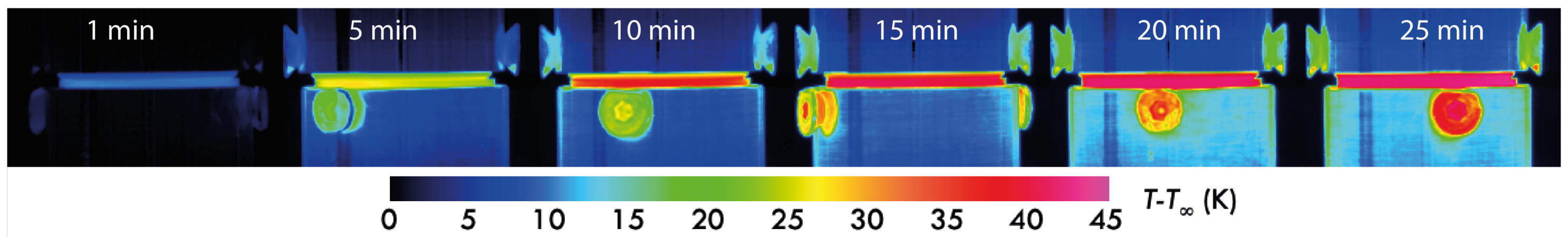

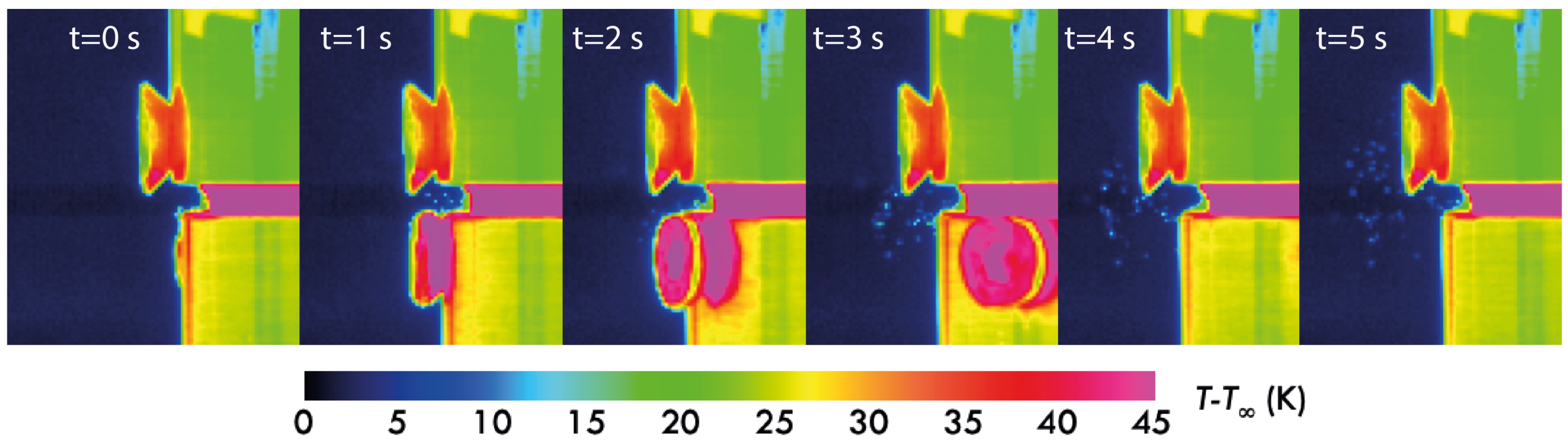

- Kasem, H.; Brunel, J.F.; Dufrenoy, P.; Desplanques, Y.; Desmet, B. Monitoring of temperature and emissivity during successive disc revolutions in braking. Proc. Inst. Mech. Engin. Part J. Eng. Tribol. 2012, 226, 748–759. [Google Scholar] [CrossRef]

- Nosko, O.; Tsybrii, Y. Inverse determination of sliding surface temperature based on measurements by thermocouples with account of their thermal inertia. Tribol. Int. 2021, 164, 107200. [Google Scholar] [CrossRef]

- Nassef, M.G.A.; Soliman, M.; Nassef, B.G.; Daha, M.A.; Nassef, G.A. Impact of Graphene Nano-Additives to Lithium Grease on the Dynamic and Tribological Behavior of Rolling Bearings. Lubricants 2022, 10, 29. [Google Scholar] [CrossRef]

- Lai, V.V.; Paszkiewicz, I.; Brunel, J.F.; Dufrénoy, P. Squeal occurrence related to the tracking of the bearing surfaces on a pin-on-disc system. Mech. Syst. Signal Process. 2022, 165, 108364. [Google Scholar] [CrossRef]

- Jlaiel, K.; Yahiaoui, M.; Paris, J.Y.; Denape, J. Acoustic signature identification of damage and wear mechanisms in a steel/glass sliding contact. Proc. Inst. Mech. Engin. Part J. Eng. Tribol. 2021, 13506501211040599. [Google Scholar] [CrossRef]

- Jlaiel, K.; Yahiaoui, M.; Paris, J.Y.; Denape, J. Tribolumen: A Tribometer for A Correlation Between AE Signals and Observation of Tribological Process in real-time—Application to a dry steel/glass reciprocating sliding contact. Lubricants 2020, 8, 47. [Google Scholar] [CrossRef] [Green Version]

- Yahiaoui, M.; Marconnet, M.; Jlaiel, K.; Paris, J.Y.; Denape, J. Acoustic Emission Characterization of Transgranular Cracks in WC–Co Cemented Carbides During a One-way Scratch. Tribol. Lett. 2021, 69, 1–8. [Google Scholar] [CrossRef]

- Fouvry, S. Fretting wear analysis through a mechanical friction energy approach: Impact of contact loadings and ambient conditions. In European Federation of Corrosion (EFC) Series, Mechanical and Electro-Chemical Interactions Under Tribocorrosion; Ponthiaux, P., Celis, J.-P., Eds.; Woodhead Publishing: Sawston, Cambridge, UK, 2021; pp. 131–167. [Google Scholar]

- Prigogine, I. Introduction à la Thermodynamique des Processus Irréversibles: Introduction to Thermodynamics of Irreversible Processes; Dunod: Paris, France, 1968; pp. 1–13. [Google Scholar]

| Site | Notation | Mode | Notation |

|---|---|---|---|

| Mechanical device | S0 | Elastic deformation | M1 |

| First body | S1 | Rupture | M2 |

| Screen 1 | S2 | Shear | M3 |

| Third body | S3 | Rolling | M4 |

| Screen 2 | S4 | ||

| Second Body | S5 |

| Site | Notation | Mode | Notation |

|---|---|---|---|

| Mechanical device | S0 | Elastic deformation | M0 |

| First body | S1 | Plastic deformation | M1 |

| Second Body | S2 | Rupture | M2 |

| Third body | S3 | Shear | M3 |

| Screen 1 | S4 | Rolling | M4 |

| Screen 2 | S5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Delbé, K. Mass and Energy Balance of a Three-Body Tribosystem. Lubricants 2022, 10, 95. https://doi.org/10.3390/lubricants10050095

Delbé K. Mass and Energy Balance of a Three-Body Tribosystem. Lubricants. 2022; 10(5):95. https://doi.org/10.3390/lubricants10050095

Chicago/Turabian StyleDelbé, Karl. 2022. "Mass and Energy Balance of a Three-Body Tribosystem" Lubricants 10, no. 5: 95. https://doi.org/10.3390/lubricants10050095

APA StyleDelbé, K. (2022). Mass and Energy Balance of a Three-Body Tribosystem. Lubricants, 10(5), 95. https://doi.org/10.3390/lubricants10050095