1. Introduction

Hydrodynamic bearings are used in a wide range of applications in rotating machinery. The wear-free operation under full lubrication and the easy mounting are the main advantages. In turbomachinery, tilting pad journal bearings (TPJB) play an important role as they show good stiffness and damping characteristics and do not tend to cause self-excited vibrations. With an increasing demand for better efficiency of high-speed machinery, the aim is to keep the power loss of the bearings as low as possible.

In hydrodynamic bearings, the power loss is equivalent to the heat resulting from friction. The heat is dissipated as an unavoidable consequence of the shearing of the oil, which is vital for the pressure build-up in the lubrication gap between shaft and bearing. Besides the lubrication gap, notable friction power occurs in other areas of the bearing that do not contribute to pressure build-up. In TPJB, the friction in the intermediates space between two pads account for a significant proportion of the power loss. Depending on the mixture of oil and air, the amount of friction power in these pad intermediate spaces can be up to 50% of the total bearing power loss [

1]. For a fixed-pad bearing, Hagemann and Schwarze [

2] find that up to 35% of the power loss relates to dissipation in the interpad spaces.

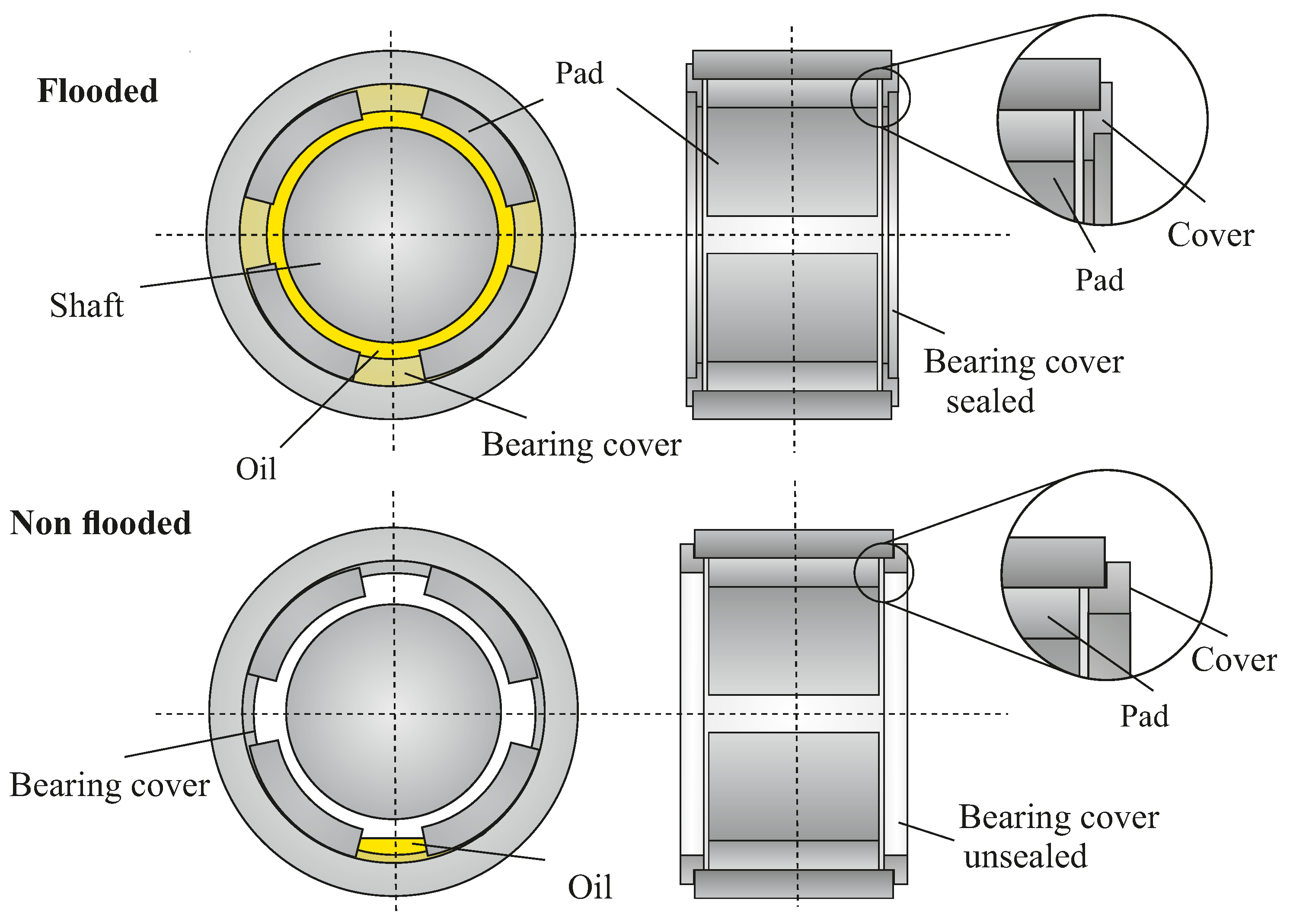

Regarding the lubrication concept of TPJB, an oil-flooded and non-flooded design can be assumed as two limiting cases. While in a flooded bearing design the intermediate spaces between the pads are fully filled with oil, in a non-flooded design these spaces are theoretically oil-free. In both cases the intermediate spaces do not contribute to the hydrodynamic load carrying capacity of the bearing, but have an effect on the converted frictional power.

Regardless of the bearing design, a relatively simple approach to reduce friction power loss is to adjust oil supply. Simmons and Dixon [

3] investigate experimentally a considerable reduction of lubricant supply for a 200

five-pad TPJB in conventional design without compromising the reliability of the bearing. By reducing the lubricant flow rate to half, they lower power loss by 20% at a circumferential speed of 105

/

. Studies of San Andres et al. [

4,

5] show similar results for two 102

TPJB with flooded seal ends. For a five-pad TPJB [

4], a 15% decrease in power loss at shaft speed 74

/

is realized by a flow reduction of 50%. With the same flow reduction for a four-pad TPJB [

5], power loss is reduced by 19% at 64

/

.

However, the oil supply cannot be reduced at arbitrary rates, since starvation in the lubrication gap and rising temperatures are limiting factors [

6]. Therefore, alternative lubrication methods have been developed to supply oil directed towards the leading edge region of the pad or directly into the lubrication gap [

7,

8]. Harangozo et al. [

9] compare the effects of a directed lubrication, where oil is fed in via spray-bars with several inlet holes, a direct lubrication via leading-edge-grooves (LEG) and a conventional flooded lubrication on the performance of a 127

four-pad TPJB. With the directed and direct lubrication, the bearing is designed without axial seals, so that bearing is not flooded with oil. In the experimental results, the flooded bearing shows the greatest power loss, while for the directed lubricated bearing the lowest power loss is observed. The authors attribute the differences in the spray-bar and LEG lubricated bearing to the generally lower temperatures and thus, the higher viscosity with the LEG lubricated bearing as well as to the higher shear stress losses within the LEG. Experimental analyses of a 120

four-pad TPJB in a spray-bar and direct LEG lubricated configuration at a broad range of rotational speed show similar results [

10]. A comparison of both lubrication methods shows a considerably lower frictional power for spray-bar lubrication than for the LEG lubrication at higher speeds. Hagemann and Schwarze relate these findings to the fact, that with the LEG nearly the entire oil is supplied to the lubrication gap, while with the spray-bars a bypass flow emerges.

A proven method for an evacuation of the intermediate spaces between the pads to reduce maximum bearing temperatures is a TPJB design with open end seals and large drain channels [

7,

11]. Nicholas [

12] investigates a 102

five-pad TPJB in a flooded pressurized housing design in comparison with an evacuated housing design featuring directed lubrication on the temperatures without considering power loss. Dmochowski and Blair [

13] examine a 99

five-pad TPJB in an evacuated housing design, realized by enlarging the clearance of the end seals. Compared to a flooded bearing, oil evacuation leads to a reduction in power loss of 25% at highest shaft speeds

/

. With an additional reduction in oil flow by approximately 30%, a decrease in power loss of 12% is observed. Bang et al. [

14] evaluate a 301

six-pad TPJB with conventional and LEG lubrication method, each with and without end seals. Detecting a reduction of power loss in the bearings without end seals, they find the lowest power loss for the conventional lubricated bearing without seals (39.2% lower than for the conventional bearing with seals). As in other works, a decrease in power loss is achieved by reducing oil flow rate. Sano et al. [

15] obtain comparable results for a large-scale TPJB with nominal diameter 890

. By leaving out the upper two pads of a four-pad TPJB in a non-flooded design with spray-bar lubrication, power loss is decreased to less than half.

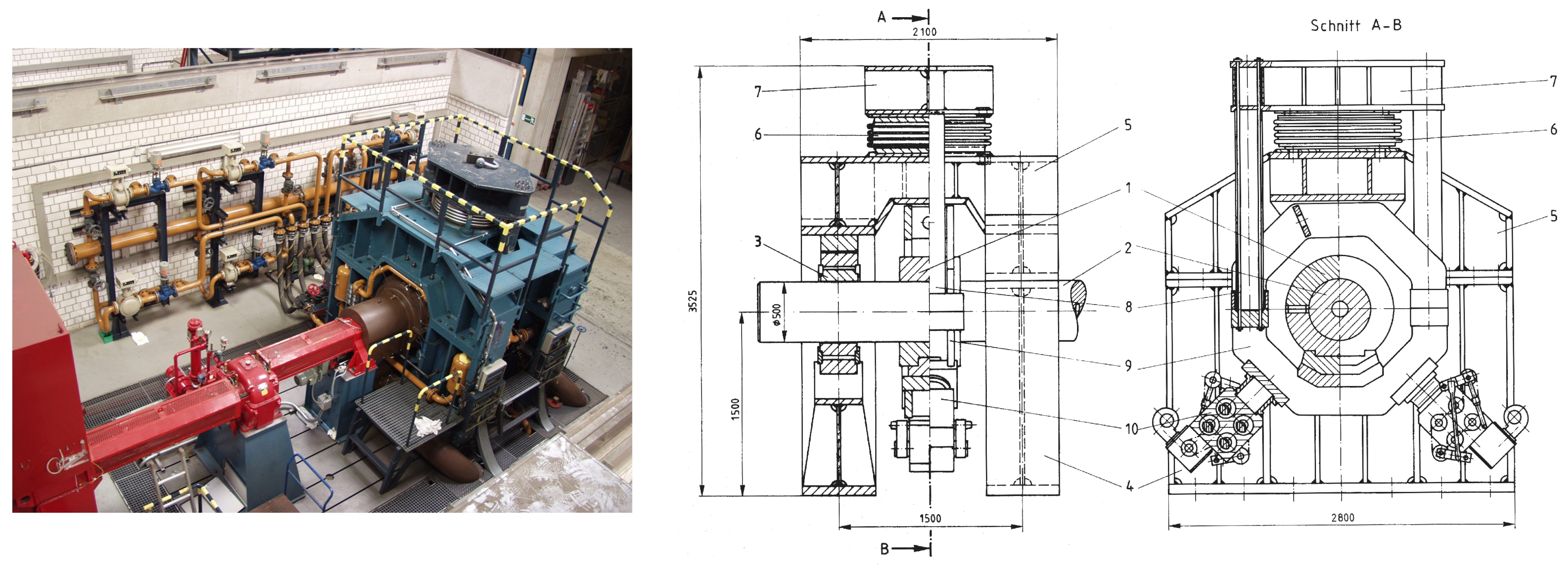

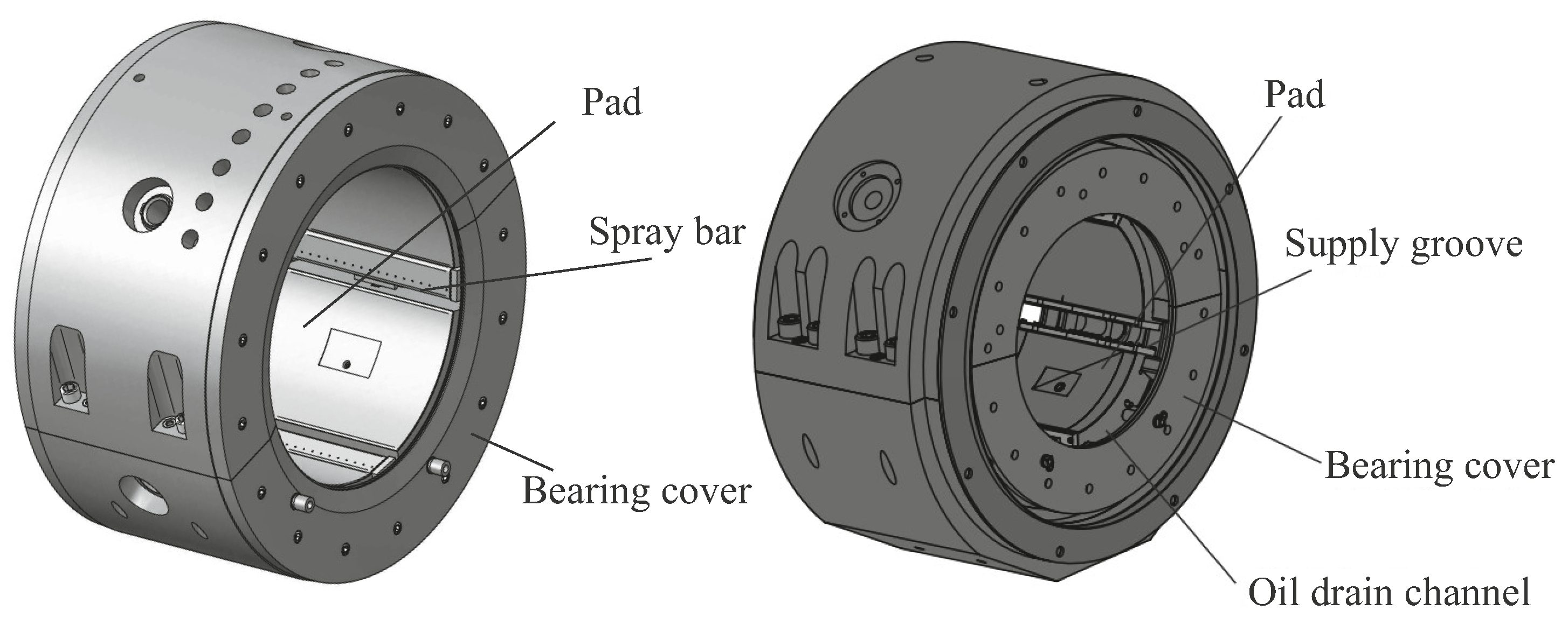

In this paper, we experimentally investigate a five-pad TPJB with nominal diameter 500 in a flooded and non-flooded design. In the flooded design, the bearing is axially sealed and assumed to be fully filled with oil. By leaving out the axial seals in the non-flooded design, intermediate spaces between pads are only partially filled with oil. The aim of our research is to analyse how the bearing design and lubrication method influence the load carrying capacity and efficiency of the bearing. The experimental testing takes place at the Bochum test rig for large journal bearings. We measure the main operating parameters oil film thickness, oil film pressure and pad temperatures as well as the friction power. We compare the measurement data of both bearing designs and identify the impact of the lubrication method on the bearing characteristics. The approach presented in this paper allows for a direct comparison of different lubrication concepts for a large-scale TPJB. In industrial applications, bearings are frequently operated at reduced oil supply rates without modifying the bearing design. Therefore, oil accumulation may occur despite the non-full flooding. The test bearing in the non-flooded design in our research is designed in such a way that no oil accumulates in the pad intermediate spaces and non-flooding can be explicitly investigated.

3. Experimental Results

In the following section, the operating characteristics of the non-flooded bearing design are compared with those of the flooded one [

20]. For both bearing designs, flooded and non-flooded, the nominal oil flow rate is

/

.

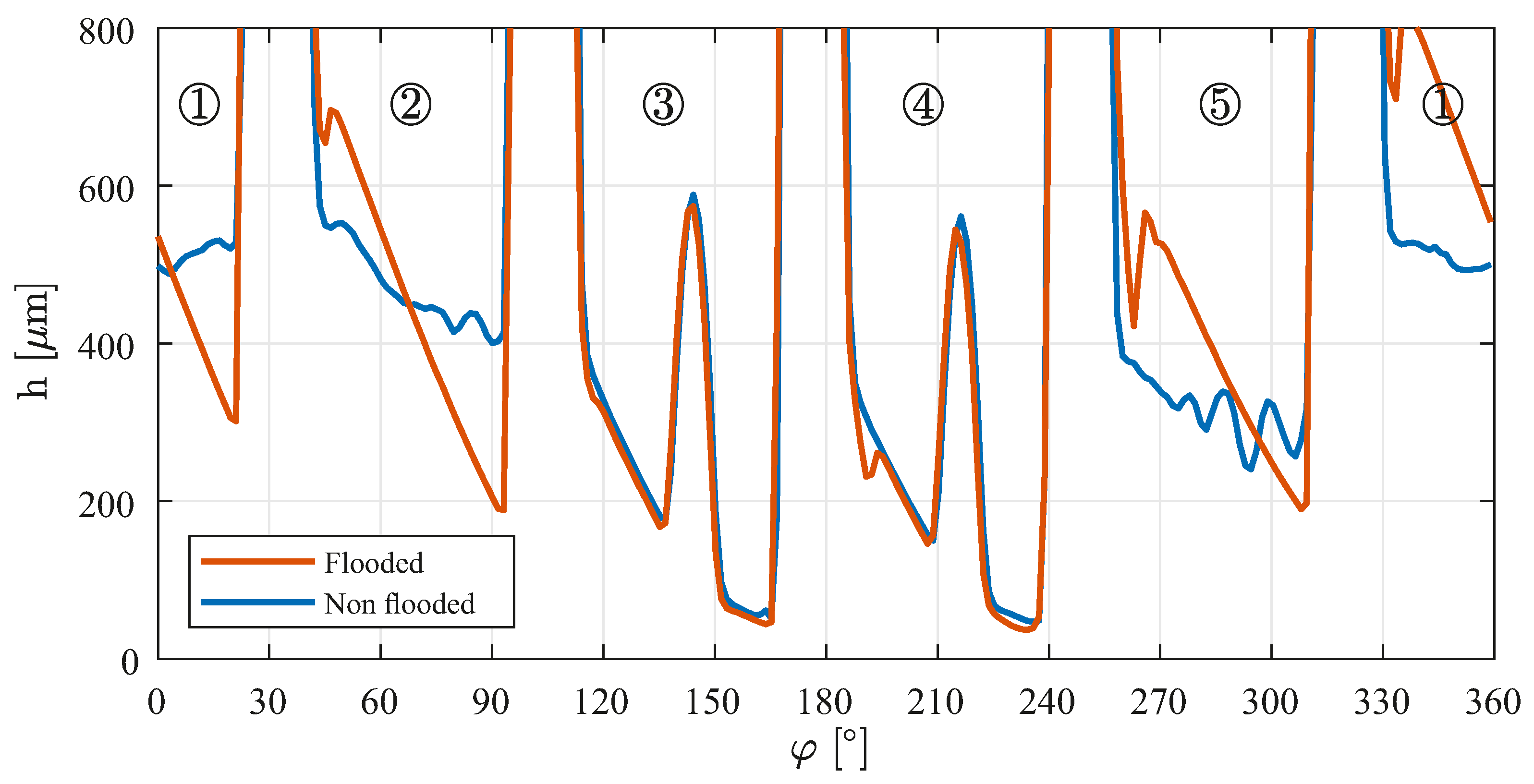

As an example,

Figure 4 shows the lubricant film thickness and

Figure 5 the lubricant film pressure of both bearing designs plotted against the bearing circumference in the bearing center. The peaks in lubricant film thickness for pads 3 and 4 (≈135°–150° and 207°–222°) and the corresponding disruption in pressure are due to the hydrostatic jacking grooves. In the flooded version, all five pads show complete gap filling, while in the non-flooded version only the lower loaded pads 3 and 4 are fully filled. Here, a significant difference between the two designs becomes apparent. Due to the sealed bearing configuration on the sides, in the flooded design the complete bearing is almost completely filled with oil. Each pad is provided with a sufficient amount of lubricant and a hydrodynamic pressure build-up is generated. By redesigning the spaces between the pads (elimination of the spray-bars) and increasing the axial distance between the pads and the bearing cover in the non-flooded design, pressure build-up of the lubricant is not possible. Only the oil provided at the leading edge is supplied to each pad. To completely fill the gaps of the non-loaded pads, the total volume flow supplied would have to be significantly increased.

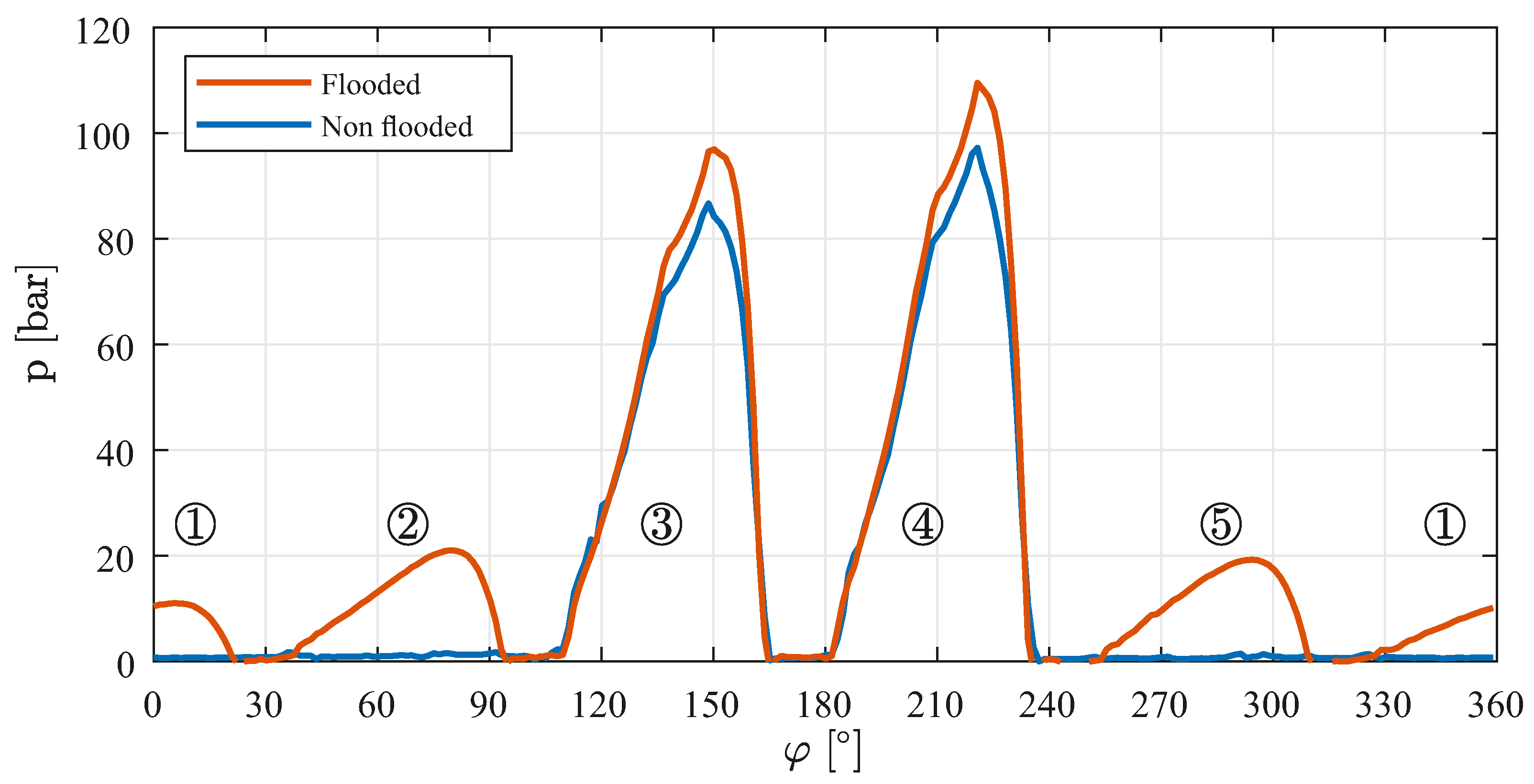

The differences described can also be found in the measured pressure distribution. While in the non-flooded bearing design only the loaded pads generate a hydrodynamic pressure build-up, in the flooded design a pressure build-up is observed for all five pads, as shown in

Figure 5. As a result, the lower pads 3 and 4 are subject to additional loads from upper pads 1, 2 and 5 in addition to the external load, resulting in higher maximum pressure and smaller film thickness.

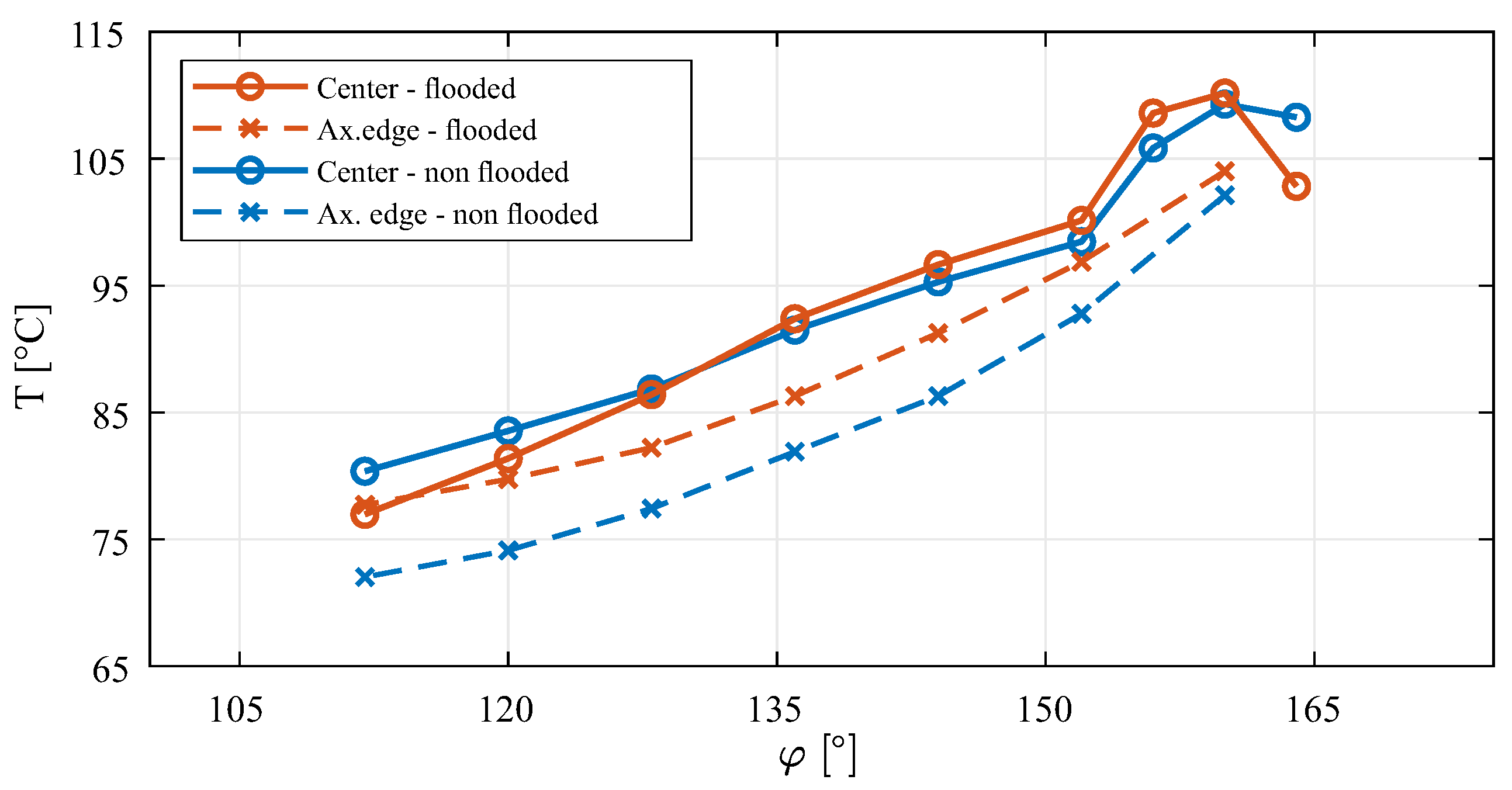

The temperature curves of a pad of the respective bearing designs are in qualitative agreement, see

Figure 6. A comparison of the measured temperatures at the leading edge of the pad shows differences in the gap entry temperatures between the flooded and non-flooded versions of the bearing. For the flooded design, no particular difference across the bearing width can be detected at the pad beginning. A clear difference in the initial temperatures can be seen across the pad width for the non-flooded bearing configuration (ax. edge–center). The temperatures measured laterally are approx. 10 K below the temperature in the center of the pad. The reason for the temperature differences at the beginning of the pad is the different lubricant supply systems of the two bearing designs. In the flooded version, the fresh oil is supplied via spray-bars in the inter-pad spaces, resulting in a more homogeneous mixing temperature across the bearing width. In the non-flooded design, the lubricant is supplied via a groove at the leading edge of the pad. Due to the groove design, the temperature of the fresh oil supplied dominates in the peripheral areas. In the center of the bearing, the lubricant is mixed with the hot oil carried over from the previous pad, so that the temperatures in this area are higher than those in the peripheral areas and the axial temperature gradient is ultimately established at leading edge.

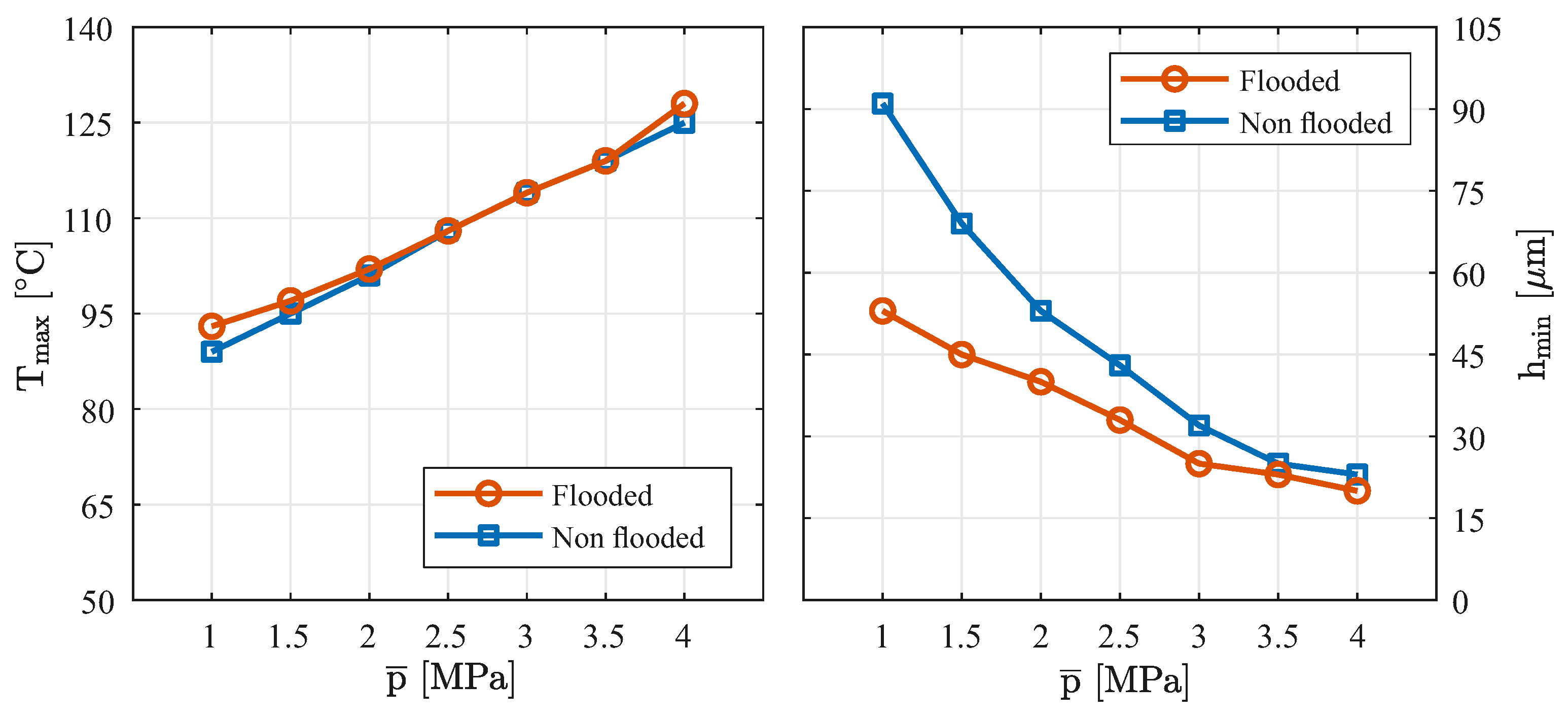

Figure 7 shows the experimentally determined maximum bearing temperatures (left) and the minimum lubricant film thicknesses (right) of the different bearing designs above the specific bearing load at speed of 3000 rpm. It can be seen that the curves of the maximum bearing temperatures of the flooded and non-flooded variants are consistent between

MPa and

MPa. Only in the lower bearing load range and at

MPa, the non-flooded bearing operates at a lower maximum temperature. The direct comparison of the measured minimum film thickness shows that the bearing in the flooded design has a significantly lower film thickness over the complete load range than in the non-flooded design.

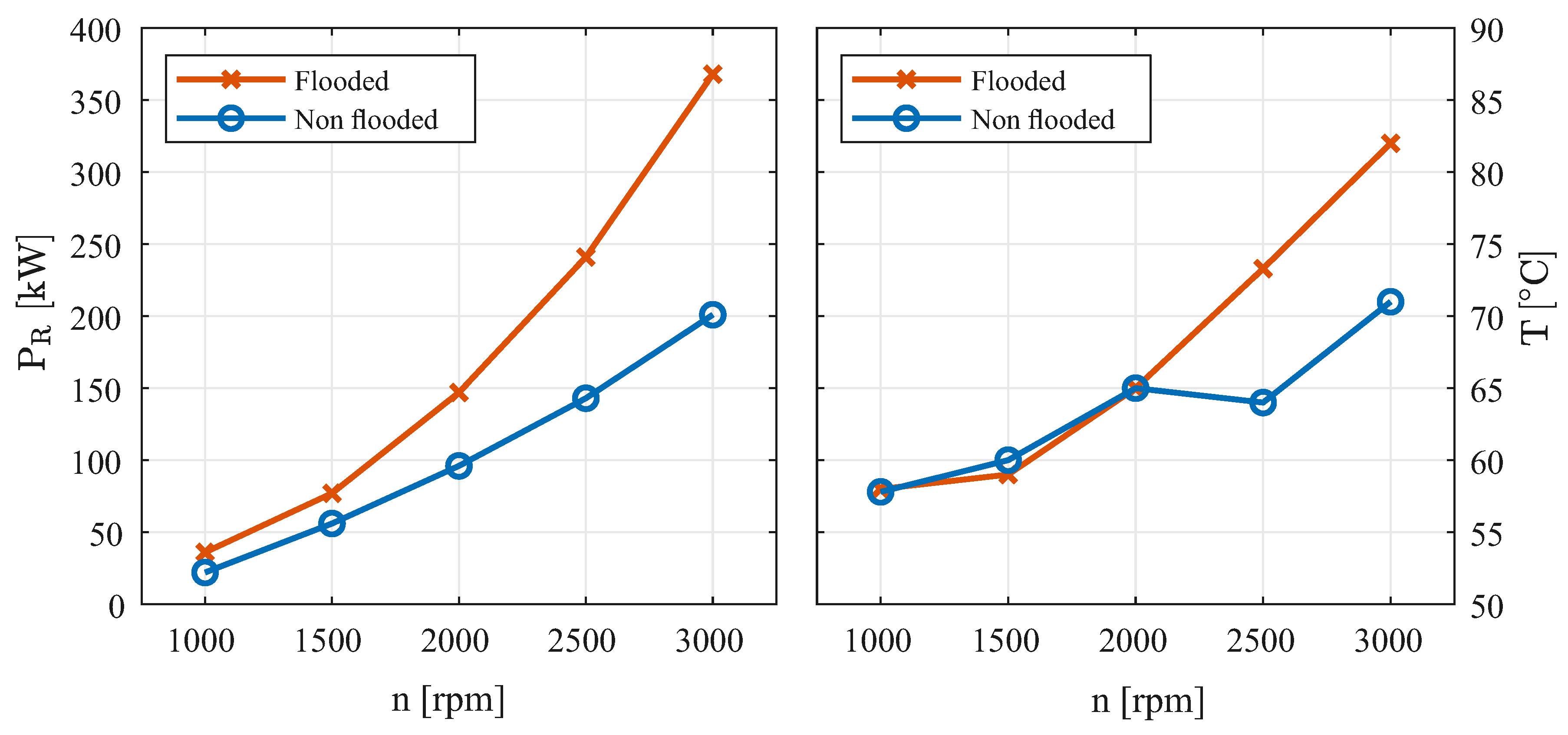

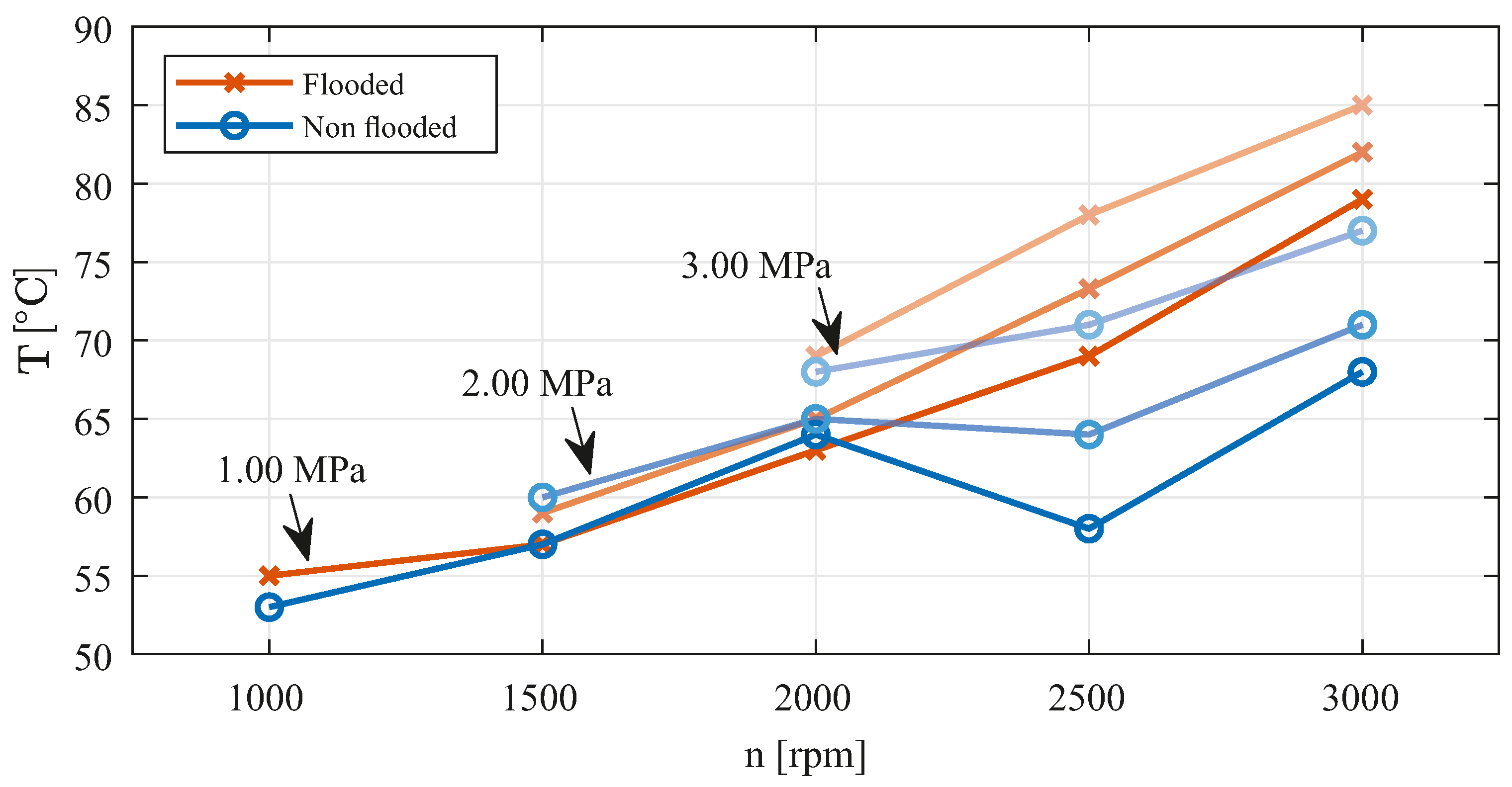

A comparison of the experimentally determined power losses of the flooded and non-flooded bearing configurations shows that the non-flooded design allows for a significant reduction of the power loss. For this purpose, the left part of the

Figure 8 plots the measured power losses of both variants at a specific bearing load of

MPa as a function of speed. The corresponding measured shaft temperatures are plotted in the right part of the Figure.

On the one hand, the reduction in frictional power is due to the non-flooded gaps and, on the other hand, to the incipient deficient lubrication of the unloaded pads. The oil-free gaps and the oil-air mixture in the incompletely filled gaps result in a lower shear stress between the surfaces compared with a fully filled bearing. When looking at the associated measured shaft temperatures (

Figure 8 on the right), the occurring deficient lubrication of the unloaded pads in the non-flooded bearing design becomes apparent. While in the flooded lubrication the shaft temperature rises steadily above speed, indicating complete gap filling of all pads above speed, the course of the non-flooded design shows a slight drop in shaft temperature between speeds 2000 rpm and 2500 rpm. This temperature drop is due to the onset of insufficient lubrication of the unloaded pads. In these areas, the shaft is cooled or, in direct comparison with flooded lubrication, the heat input is reduced by the energy dissipated in the lubrication gap. This effect can be observed particularly at comparatively low loads, while at high loads partial filling of the unloaded pads can be observed over the entire speed spectrum (no drop in the measured shaft temperature over the speed). For this purpose,

Figure 9 shows the measured shaft temperatures of both bearing variants versus speed for different bearing loads.

4. Discussion and Conclusions

In our investigations, we have experimentally examined a bearing design in two different configurations. The two bearings differ only in the oil feed and the axial sealing. All other parameters are identical.

By comparing the experimentally determined operating characteristics of the flooded and non-flooded design, it can be shown that the non-flooded design has a positive influence on the load carrying capacity (higher minimum lubricant film thickness at the same load level). Mainly this can be related to the non-existing hydrodynamic pressure build-up of the unloaded pads. Due to the pressure build-up in the upper pads in the flooded version, there is an additional load on the lower loaded pads. The measured pad temperatures are at an identical level, but differ at the pad edges due to the different oil regimes in the intermediate spaces.

However, the major difference between the two configurations is evident in the measured frictional powers. The power loss at a speed of 3000 rpm can be reduced by almost half by designing the bearing in a non-flooded configuration. This reduction in power loss is attributed to the unloaded pads and the spaces between them not being filled with oil. In these areas, there is less shear stress on the shaft surface and the frictional power converted in the bearing is reduced.

In conclusion, we demonstrate that the concept of lubrication can positively influence the frictional performance of a TPJB without reducing or increasing the operational safety parameters such as minimum lubricant film thickness or maximum bearing temperature.