Air Kerma Calculation in Diagnostic Medical Imaging Devices Using Group Method of Data Handling Network

Abstract

1. Introduction

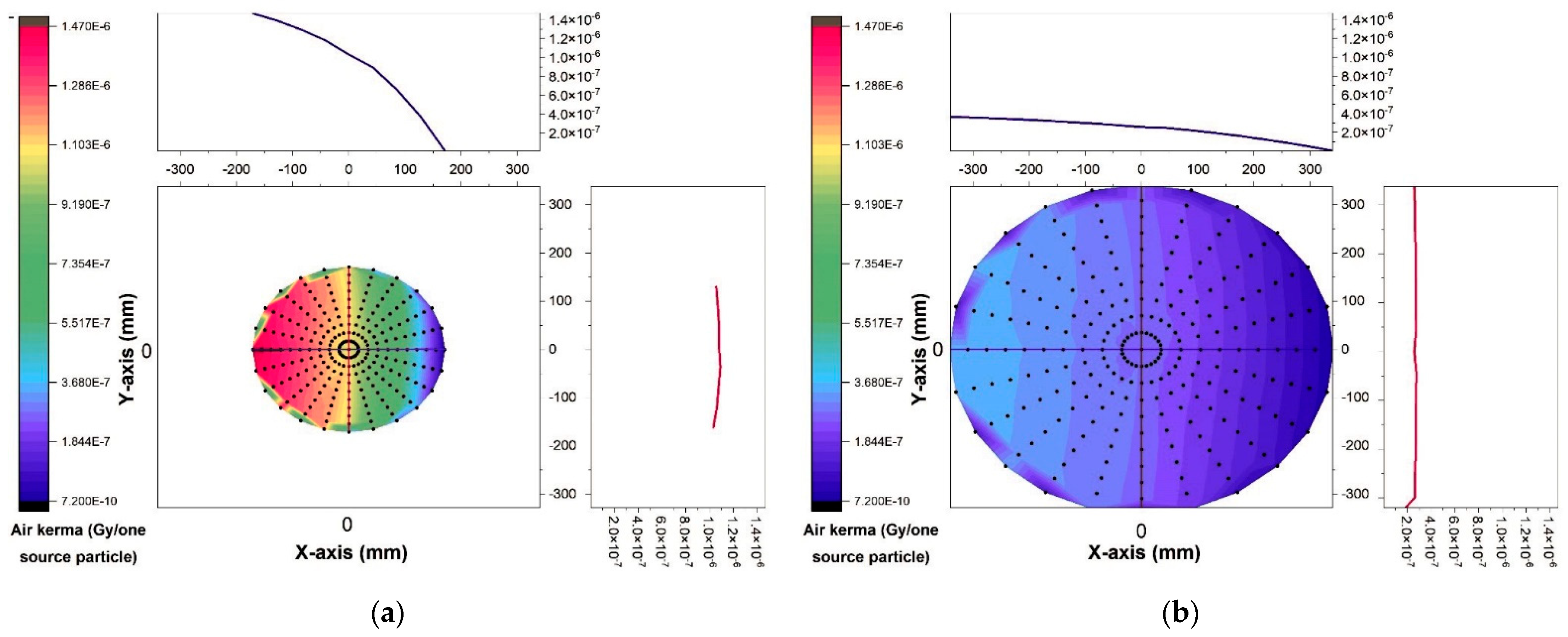

- The heel effect is taken into account while calculating air kerma.

- Calculating the air kerma by employing an artificial neural network and training it with a limited amount of data in varying angles, distances, and voltages of tubes.

- Using an artificial neural network, the calculation of air kerma was executed extremely quickly and accurately compared to earlier efforts.

- Calculating the air kerma for medical tubes’ operating voltage.

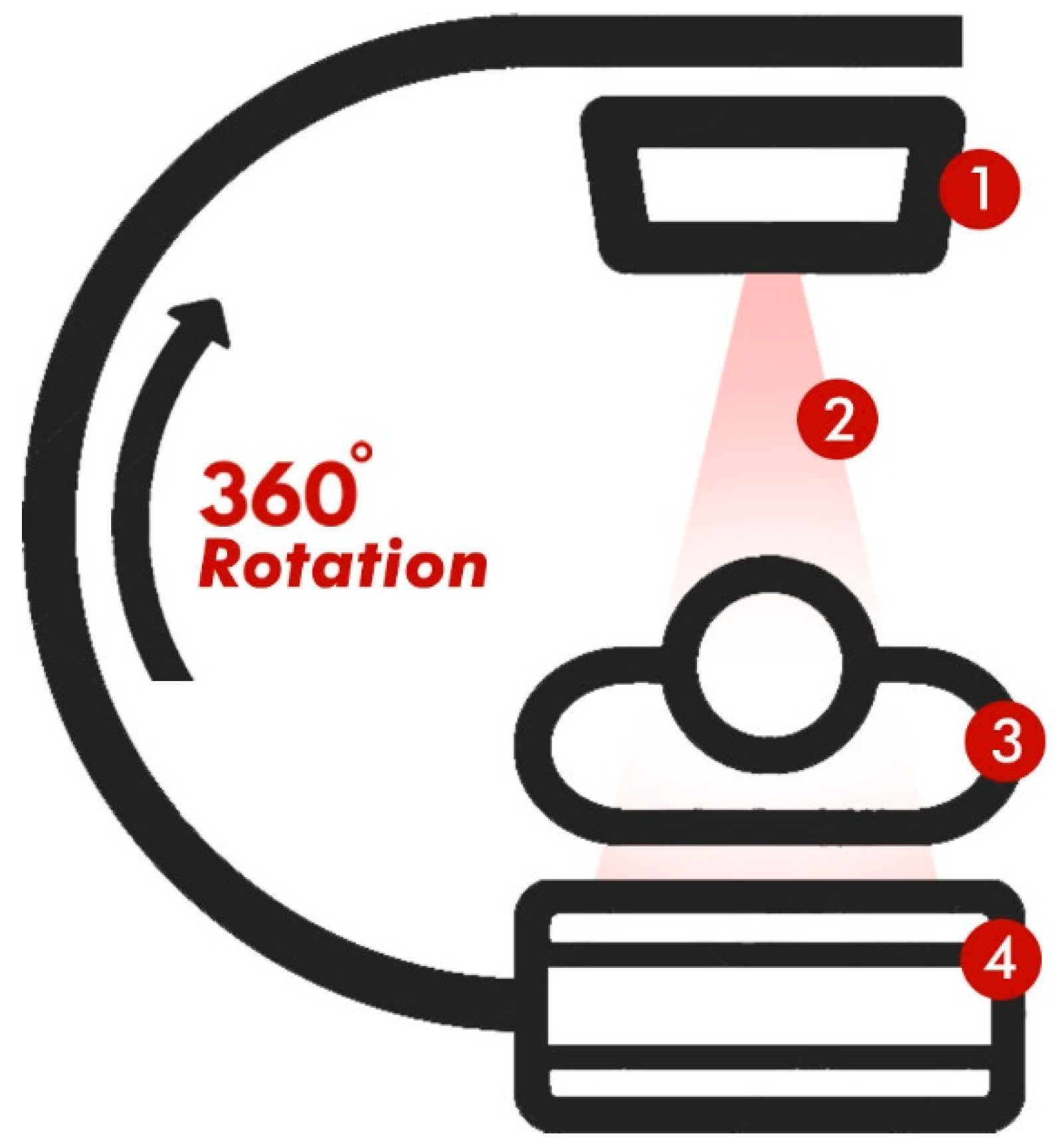

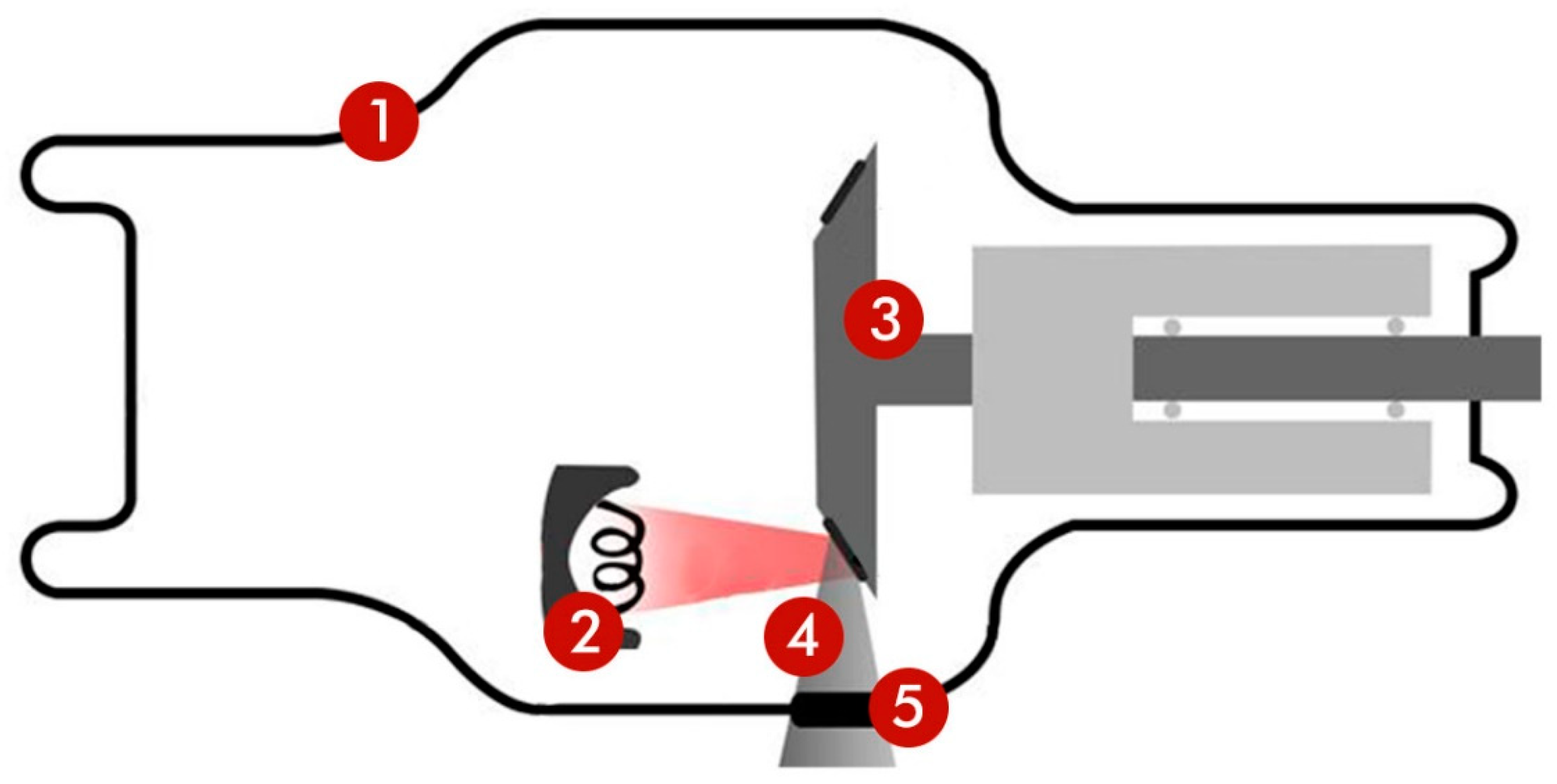

2. Methodology

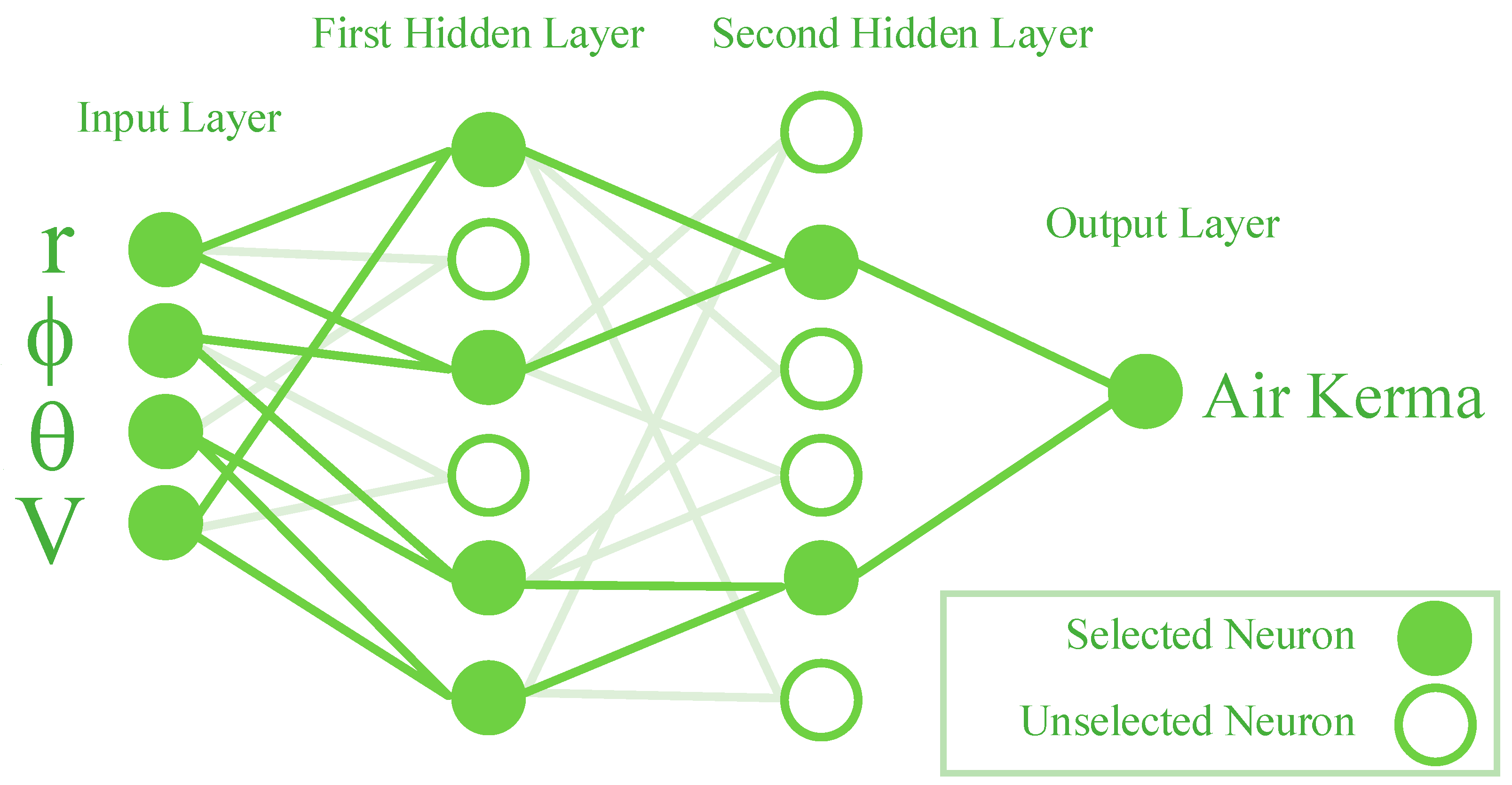

GMDH Neural Network

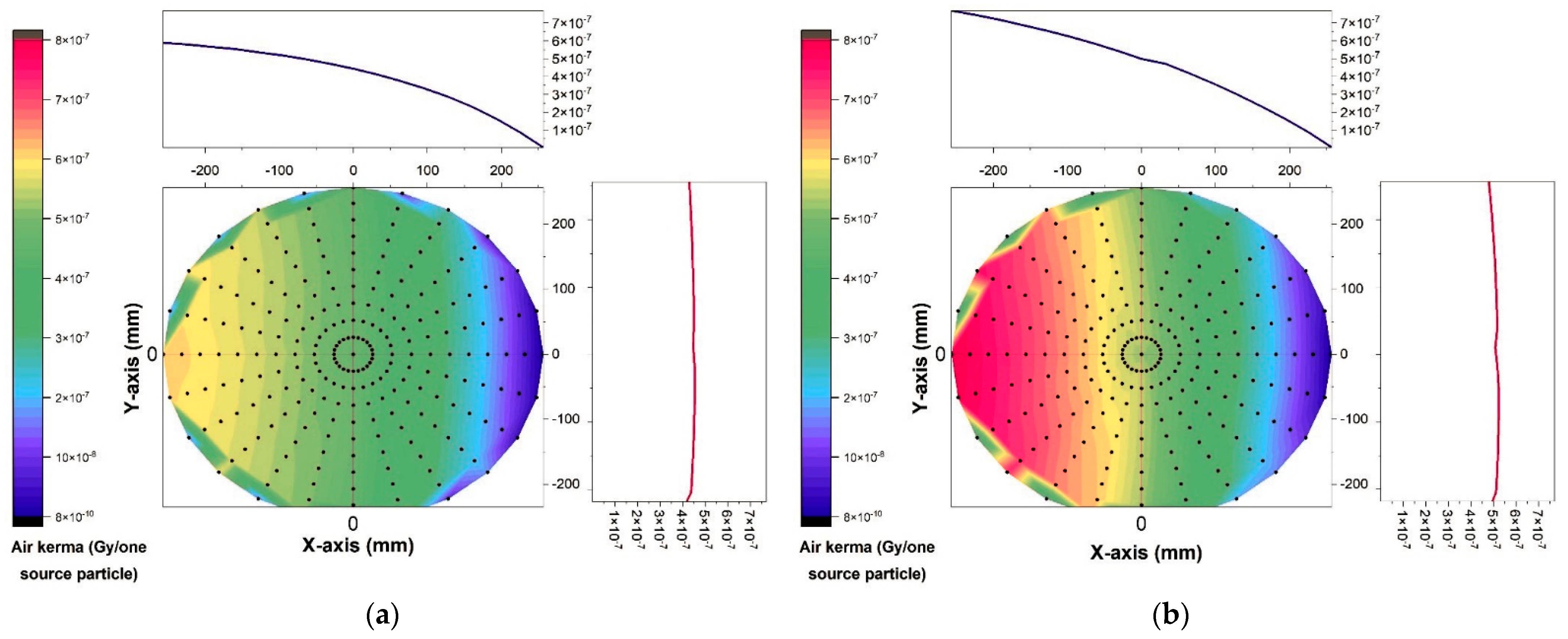

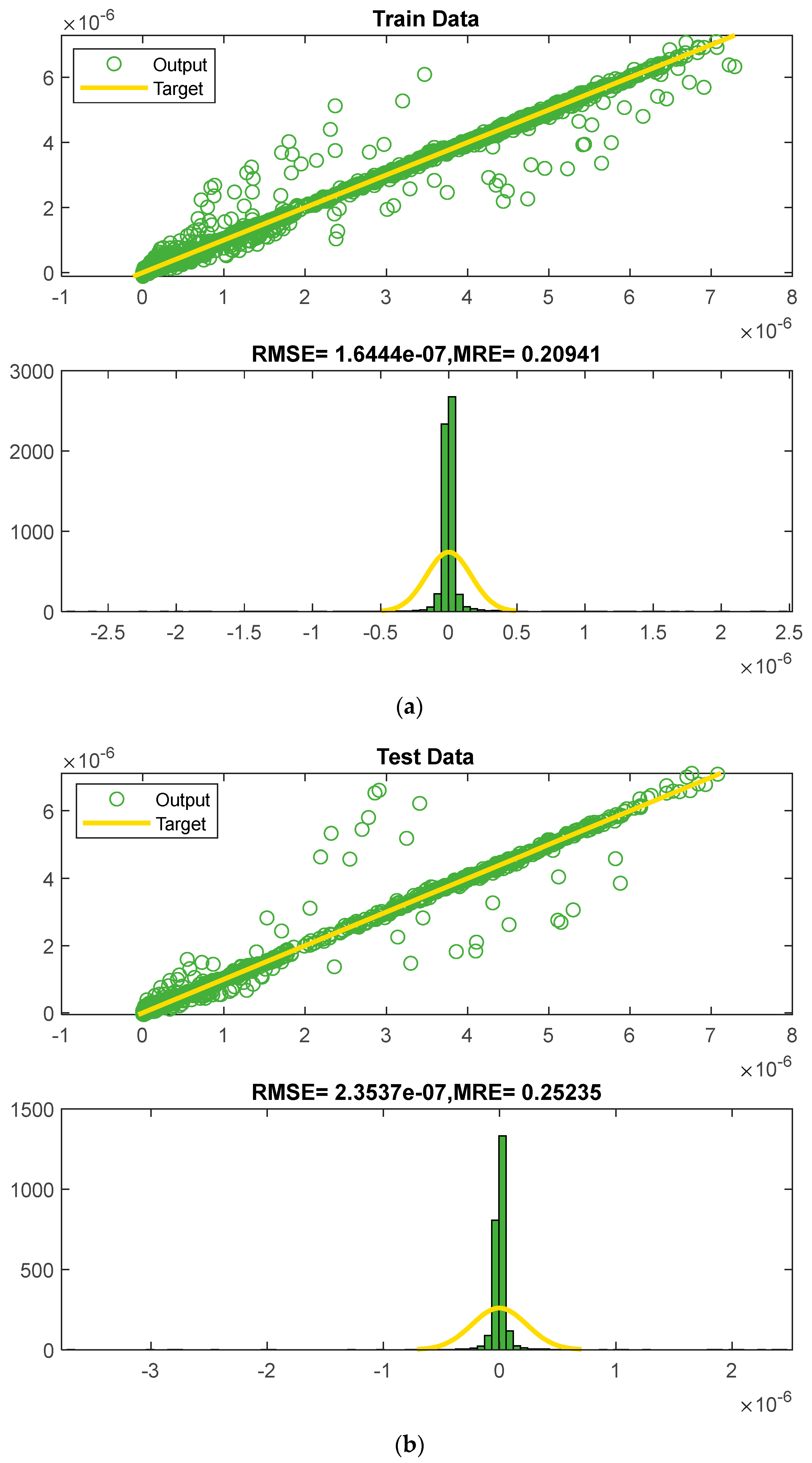

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cember, H.; Johnson, T.E. Introduction to Health Physics; McGraw-Hill Inc.: New York, NY, USA, 2009. [Google Scholar]

- Calibration of Radiation Protection. Monitoring Instruments; IAEA Safety Report No. 16; IAEA: Vienna, Austria, 2000. [Google Scholar]

- Miller, D.L.; Balter, S.; Schueler, B.A.; Wagner, L.K.; Strauss, K.J.; Vano, E. Clinical Radiation Management for Fluoroscopically Guided Interventional Procedures. Radiology 2010, 257, 321–332. [Google Scholar] [CrossRef] [PubMed]

- Katoh, Y.; Mita, S.; Fukushi, M.; Nyui, Y.; Abe, S.; Kimura, J. Calculation of air-kerma rate of diagnostic X-ray generators. Radiol. Phys. Technol. 2011, 4, 1–6. [Google Scholar] [CrossRef] [PubMed]

- Oliveira, L.S.R.; Conti, C.C.; Amorim, A.S.; Balthar, M.C.V. NaI (Tl) scintillator detectors stripping procedure for air kerma measurements of diagnostic X-ray beams. Nucl. Instrum. Methods Phys. Res. 2013, 705, 106–110. [Google Scholar] [CrossRef]

- Porto, L.; Lunelli, N.; Paschuk, S.; Oliveira, A.; Ferreira, J.; Schelin, H.; Miguel, C.; Denyak, V.; Kmiecik, C.; Tilly, J.; et al. Evaluation of entrance surface air kerma in pediatric chest radiography. Radiat. Phys. Chem. 2014, 104, 252–259. [Google Scholar] [CrossRef]

- Alonso, T.C.; Mourão Filho, A.P.; Da Silva, T.A. Measurements of air kerma index in computed tomography: A comparison among methodologies. Appl. Radiat. Isot. 2018, 138, 10–13. [Google Scholar] [CrossRef]

- Haba, T.; Koyama, S.; Aoyama, T.; Kinomura, Y.; Ida, Y.; Kobayashi, M.; Kameyama, H.; Tsutsumi, Y. Pin-photodiode array for the measurement of fan-beam energy and air kerma distributions of X-ray CT scanners. Phys. Medica 2016, 32, 905–913. [Google Scholar] [CrossRef]

- Kwon, D.; Little, M.P.; Miller, D.L. Reference air kerma and kerma-area product as estimators of peak skin dose for fluoroscopically guided interventions. Med. Phys. 2011, 38, 4196–4204. [Google Scholar] [CrossRef]

- Bushberg, J.T.; Seibert, J.A.; Leidholdt, E.M., Jr.; Boone, J.M. The Essential Physics of Medical Imaging, 3rd ed.; Lippincott Williams & Wilkins: Philadelphia, PA, USA, 2012. [Google Scholar]

- Perera, H.; Williamson, J.F.; Li, Z.; Mishra, V.; Meigooni, A.S. Dosimetric Characteristics, Air-Kerma Strength Calibration and Verification of Monte Carlo Simulation for a New Ytterbium-169 Brachytherapy Source. Int. J. Radiat. Oncol. Biol. Phys. 1994, 28, 953–970. [Google Scholar] [CrossRef]

- Oliveira, C.; Salgado, J.; de Carvalho, A.F. Dose rate determinations in the Portuguese Gamma Irradiation Facility: Monte Carlo simulations and measurements. Radiat. Phys. Chem. 2000, 58, 279–285. [Google Scholar] [CrossRef]

- Liu, Y.; Wei, B.; Zhuoa, R.; Wena, D.; Ding, D.; Xu, Y.; Mao, B. Determination of the Conventional True Value of Gamma-Ray Air Kerma in a Mini-type Reference Radiation. Appl. Radiat. Isot. 2016, 118, 238–245. [Google Scholar] [CrossRef]

- Ounoughi, N.; Mavon, C.; Belafrites, A.; Fromm, M. Spatial distribution of air kerma rate and impact of accelerating voltage on the quality of an ultra soft X-ray beam generated by a cold cathode tube in air. Radiat. Meas. 2015, 80, 23–28. [Google Scholar] [CrossRef]

- Mettivier, G.; Sarno, A.; Lai, Y.; Golosio, B.; Fanti, V.; Italiano, M.E.; Jia, X.; Russo, P. Virtual Clinical Trials in 2D and 3D X-ray Breast Imaging and Dosimetry: Comparison of CPU-Based and GPU-Based Monte Carlo Codes. Cancers 2022, 14, 1027. [Google Scholar] [CrossRef]

- Nazemi, E.; Rokrok, B.; Movafeghi, A.; Dinca, M.; Kabir, M. Calculation of air kerma inside the radiation field of X-ray tube. Radiat. Meas. 2019, 124, 79–84. [Google Scholar] [CrossRef]

- Lu, Y.; Zheng, N.; Ye, M.; Zhu, Y.; Zhang, G.; Nazemi, E.; He, J. Proposing Intelligent Approach to Predicting Air Kerma within Radiation Beams of Medical X-ray Imaging Systems. Diagnostics 2023, 13, 190. [Google Scholar] [CrossRef]

- International Commission on Radiological Protection. Data for Use in Protection against External Radiation; ICRP Publication 51; Pergamon Press: Oxford, UK, 1987. [Google Scholar]

- Nazemi, E.; Movafeghi, A.; Rokrok, B.; Dastjerdi, M.H.C. A novel method for predicting pixel value distribution non-uniformity due to heel effect of X-ray tube in industrial digital radiography using artificial neural network. J. Nondestruct. Eval. 2018, 38, 3. [Google Scholar] [CrossRef]

- Sattari, M.A.; Roshani, G.H.; Hanus, R.; Nazemi, E. Applicability of time-domain feature extraction methods and artificial intelligence in two-phase flow meters based on gamma-ray absorption technique. Measurement 2021, 168, 108474. [Google Scholar] [CrossRef]

- Sattari, M.A.; Roshani, G.H.; Hanus, R. Improving the structure of two-phase flow meter using feature extraction and GMDH neural network. Radiat. Phys. Chem. 2020, 171, 108725. [Google Scholar] [CrossRef]

- Nazemi, E.; Feghhi, S.A.H.; Roshani, G.H. Void fraction prediction in two-phase flows independent of the liquid phase density changes. Radiat. Meas. 2014, 68, 49–54. [Google Scholar] [CrossRef]

- Roshani, G.H.; Hanus, R.; Khazaei, A.; Zych, M.; Nazemi, E.; Mosorov, V. Density and velocity determination for single-phase flow based on radiotracer technique and neural networks. Flow Meas. Instrum. 2018, 61, 9–14. [Google Scholar] [CrossRef]

- Roshani, G.H.; Nazemi, E.; Feghhi, S.A.H.; Setayeshi, S. Flow regime identification and void fraction prediction in two-phase flows based on gamma ray attenuation. Measurement 2015, 62, 25–32. [Google Scholar] [CrossRef]

- Roshani, G.H.; Karami, A.; Nazemi, E. An intelligent integrated approach of Jaya optimization algorithm and neuro-fuzzy network to model the stratified three-phase flow of gas–oil–water. Comput. Appl. Math. 2019, 38, 5. [Google Scholar] [CrossRef]

- Roshani, M.; Sattari, M.A.; Ali, P.J.M.; Roshani, G.H.; Nazemi, B.; Corniani, E.; Nazemi, E. Application of GMDH neural network technique to improve measuring precision of a simplified photon attenuation based two-phase flowmeter. Flow Meas. Instrum. 2020, 75, 101804. [Google Scholar] [CrossRef]

- Nazemi, E.; Roshani, G.H.; Feghhi, S.A.H.; Setayeshi, S.; Zadeh, E.E.; Fatehi, A. Optimization of a method for identifying the flow regime and measuring void fraction in a broad beam gamma-ray attenuation technique. Int. J. Hydrogen Energy 2016, 41, 7438–7444. [Google Scholar] [CrossRef]

- Roshani, G.H.; Feghhi, S.A.H.; Mahmoudi-Aznaveh, A.; Nazemi, E.; Adineh-Vand, A. Precise volume fraction prediction in oil–water–gas multiphase flows by means of gamma-ray attenuation and artificial neural networks using one detector. Measurement 2014, 51, 34–41. [Google Scholar] [CrossRef]

- Nazemi, E.; Feghhi, S.A.H.; Roshani, G.H.; Peyvandi, R.G.; Setayeshi, S. Precise Void Fraction Measurement in Two-Phase Flows Independent of the Flow Regime using gamma-ray attenuation. Nucl. Eng. Technol. 2016, 48, 64–71. [Google Scholar] [CrossRef]

- Balubaid, M.; Sattari, M.A.; Taylan, O.; Bakhsh, A.A.; Nazemi, E. Applications of discrete wavelet transform for feature extraction to increase the accuracy of monitoring systems of liquid petroleum products. Mathematics 2021, 9, 3215. [Google Scholar] [CrossRef]

- Hartman, E.J.; Keeler, J.D.; Kowalski, J.M. Layered neural networks with Gaussian hidden units as universal approxima-tors. Neural Comput. 1990, 2, 210–215. [Google Scholar] [CrossRef]

- Lalbakhsh, A.; Mohamadpour, G.; Roshani, S.; Ami, M.; Roshani, S.; Sayem, A.S.M.; Alibakhshikenari, M.; Koziel, S. Design of a compact planar transmission line for miniaturized rat-race coupler with harmonics suppression. IEEE Access 2021, 9, 129207–129217. [Google Scholar] [CrossRef]

- Hookari, M.; Roshani, S.; Roshani, S. High-efficiency balanced power amplifier using miniaturized harmonics suppressed coupler. Int. J. RF Microw. Comput.-Aided Eng. 2020, 30, e22252. [Google Scholar] [CrossRef]

- Lotfi, S.; Roshani, S.; Roshani, S.; Gilan, M.S. Wilkinson power divider with band-pass filtering response and harmonics suppression using open and short stubs. Frequenz 2020, 74, 169–176. [Google Scholar] [CrossRef]

- Jamshidi, M.; Siahkamari, H.; Roshani, S.; Roshani, S. A compact Gysel power divider design using U-shaped and T-shaped resonators with harmonics suppression. Electromagnetics 2019, 39, 491–504. [Google Scholar] [CrossRef]

- Khan, A.A.; Shaikh, Z.A.; Baitenova, L.; Mutaliyeva, L.; Moiseev, N.; Mikhaylov, A.; Laghari, A.A.; Idris, S.A.; Alshazly, H. QoS-ledger: Smart contracts and metaheuristic for secure quality-of-service and cost-efficient scheduling of medical-data processing. Electronics 2021, 10, 3083. [Google Scholar] [CrossRef]

- Yumashev, A.; Mikhaylov, A. Development of polymer film coatings with high adhesion to steel alloys and high wear resistance. Polym. Compos. 2020, 41, 2875–2880. [Google Scholar] [CrossRef]

- Alwaely, S.A.; Yousif, N.B.A.; Mikhaylov, A. Emotional development in preschoolers and socialization. Early Child Dev. Care 2020, 191, 2484–2493. [Google Scholar] [CrossRef]

- Roshani, S.; Jamshidi, M.B.; Mohebi, F.; Roshani, S. Design and modeling of a compact power divider with squared resonators using artificial intelligence. Wirel. Pers. Commun. 2021, 117, 2085–2096. [Google Scholar] [CrossRef]

- Roshani, S.; Azizian, J.; Roshani, S.; Jamshidi, M.B.; Parandin, F. Design of a miniaturized branch line microstrip coupler with a simple structure using artificial neural network. Frequenz 2022, 76, 255–263. [Google Scholar] [CrossRef]

- Khaleghi, M.; Salimi, J.; Farhangi, V.; Moradi, M.J.; Karakouzian, M. Application of Artificial Neural Network to Predict Load Bearing Capacity and Stiffness of Perforated Masonry Walls. CivilEng 2021, 2, 48–67. [Google Scholar] [CrossRef]

- Dabiri, H.; Farhangi, V.; Moradi, M.J.; Zadehmohamad, M.; Karakouzian, M. Applications of Decision Tree and Random Forest as Tree-Based Machine Learning Techniques for Analyzing the Ultimate Strain of Spliced and Non-Spliced Reinforcement Bars. Appl. Sci. 2022, 12, 4851. [Google Scholar] [CrossRef]

- Hernandez, A.M.; Boone, J.M. Tungsten anode spectral model using interpolating cubic splines: Unfiltered X-ray spectra from 20 kV to 640 kV. Med. Phys. 2014, 41, 042101. [Google Scholar] [CrossRef]

- Zhang, G.; Liu, R.; Ge, Y.; Mayet, A.M.; Chan, S.; Li, G.; Nazemi, E. Investigation on the Wilson Neuronal Model: Optimized Approximation and Digital Multiplierless Implementation. IEEE Trans. Biomed. Circuits Syst. 2022, 16, 1181–1190. [Google Scholar] [CrossRef]

- Ivakhnenko, A.G. Polynomial Theory of Complex Systems. IEEE Trans. Syst. Man Cybern. 1971, SMC-1, 364e378. [Google Scholar] [CrossRef]

| ϕ (deg) | θ (deg) | R (mm) | V (kV) | Simulated Air Kerma (1 × e−5) | Predicted Air Kerma (1 × e−5) |

|---|---|---|---|---|---|

| 0 | 0 | 250 | 40 | 0.3730 | 0.3699 |

| 2 | 0 | 250 | 40 | 0.3190 | 0.3272 |

| 4 | 0 | 250 | 40 | 0.3040 | 0.2977 |

| 6 | 0 | 250 | 40 | 0.2850 | 0.2757 |

| 8 | 0 | 250 | 40 | 0.2630 | 0.2593 |

| 10 | 0 | 250 | 40 | 0.2370 | 0.2414 |

| 12 | 0 | 250 | 40 | 0.2060 | 0.2111 |

| 14 | 0 | 250 | 40 | 0.1680 | 0.1650 |

| 16 | 0 | 250 | 40 | 0.1220 | 0.1148 |

| 18 | 0 | 250 | 40 | 0.0648 | 0.0718 |

| 0 | 15 | 500 | 40 | 0.0932 | 0.0934 |

| 2 | 15 | 500 | 40 | 0.0799 | 0.0788 |

| 4 | 15 | 500 | 40 | 0.0761 | 0.0749 |

| 6 | 15 | 500 | 40 | 0.0717 | 0.0698 |

| 8 | 15 | 500 | 40 | 0.0667 | 0.0640 |

| 10 | 15 | 500 | 40 | 0.0605 | 0.0598 |

| 12 | 15 | 500 | 40 | 0.0530 | 0.0540 |

| 14 | 15 | 500 | 40 | 0.0443 | 0.0426 |

| 16 | 15 | 500 | 40 | 0.0335 | 0.0289 |

| 18 | 15 | 500 | 40 | 0.0204 | 0.0194 |

| 20 | 15 | 500 | 40 | 0.0019 | 0.0031 |

| 0 | 30 | 750 | 40 | 0.0414 | 0.0408 |

| 2 | 30 | 750 | 40 | 0.0350 | 0.0361 |

| 4 | 30 | 750 | 40 | 0.0335 | 0.0370 |

| 6 | 30 | 750 | 40 | 0.0318 | 0.0344 |

| 8 | 30 | 750 | 40 | 0.0298 | 0.0289 |

| 10 | 30 | 750 | 40 | 0.0276 | 0.0253 |

| 12 | 30 | 750 | 40 | 0.0248 | 0.0249 |

| 14 | 30 | 750 | 40 | 0.0216 | 0.0244 |

| 16 | 30 | 750 | 40 | 0.0179 | 0.0214 |

| 18 | 30 | 750 | 40 | 0.0135 | 0.0165 |

| 20 | 30 | 750 | 40 | 0.0085 | 0.0066 |

| 0 | 45 | 1000 | 40 | 0.0233 | 0.0204 |

| 2 | 45 | 1000 | 40 | 0.0198 | 0.0181 |

| 4 | 45 | 1000 | 40 | 0.0191 | 0.0189 |

| 6 | 45 | 1000 | 40 | 0.0184 | 0.0198 |

| 8 | 45 | 1000 | 40 | 0.0175 | 0.0189 |

| 10 | 45 | 1000 | 40 | 0.0166 | 0.0171 |

| 12 | 45 | 1000 | 40 | 0.0154 | 0.0160 |

| 14 | 45 | 1000 | 40 | 0.0142 | 0.0160 |

| 16 | 45 | 1000 | 40 | 0.0128 | 0.0161 |

| 18 | 45 | 1000 | 40 | 0.0111 | 0.0150 |

| 20 | 45 | 1000 | 40 | 0.0026 | 0.0104 |

| 0 | 60 | 1250 | 40 | 0.0149 | 0.0135 |

| 2 | 60 | 1250 | 40 | 0.0139 | 0.0116 |

| 4 | 60 | 1250 | 40 | 0.0136 | 0.0111 |

| 6 | 60 | 1250 | 40 | 0.0132 | 0.0122 |

| 8 | 60 | 1250 | 40 | 0.0128 | 0.0129 |

| 10 | 60 | 1250 | 40 | 0.0124 | 0.0121 |

| 12 | 60 | 1250 | 40 | 0.0119 | 0.0105 |

| 14 | 60 | 1250 | 40 | 0.0114 | 0.0096 |

| 16 | 60 | 1250 | 40 | 0.0109 | 0.0096 |

| 18 | 60 | 1250 | 40 | 0.0102 | 0.0084 |

| 20 | 60 | 1250 | 40 | 0.0095 | 0.0028 |

| 0 | 0 | 250 | 60 | 0.3990 | 0.3975 |

| 2 | 0 | 250 | 60 | 0.3780 | 0.3801 |

| 4 | 0 | 250 | 60 | 0.3530 | 0.3544 |

| 6 | 0 | 250 | 60 | 0.3240 | 0.3247 |

| 8 | 0 | 250 | 60 | 0.2930 | 0.2961 |

| 10 | 0 | 250 | 60 | 0.2580 | 0.2651 |

| 12 | 0 | 250 | 60 | 0.2180 | 0.2218 |

| 14 | 0 | 250 | 60 | 0.1730 | 0.1636 |

| 16 | 0 | 250 | 60 | 0.1220 | 0.1034 |

| 18 | 0 | 250 | 60 | 0.0654 | 0.0562 |

| 0 | 15 | 500 | 60 | 0.0998 | 0.0974 |

| 2 | 15 | 500 | 60 | 0.0948 | 0.0920 |

| 4 | 15 | 500 | 60 | 0.0885 | 0.0889 |

| 6 | 15 | 500 | 60 | 0.0818 | 0.0821 |

| 8 | 15 | 500 | 60 | 0.0743 | 0.0742 |

| 10 | 15 | 500 | 60 | 0.0659 | 0.0673 |

| 12 | 15 | 500 | 60 | 0.0564 | 0.0577 |

| 14 | 15 | 500 | 60 | 0.0459 | 0.0415 |

| 16 | 15 | 500 | 60 | 0.0339 | 0.0239 |

| 18 | 15 | 500 | 60 | 0.0205 | 0.0141 |

| 20 | 15 | 500 | 60 | 0.0042 | 0.0030 |

| 0 | 30 | 750 | 60 | 0.0444 | 0.0457 |

| 2 | 30 | 750 | 60 | 0.0427 | 0.0408 |

| 4 | 30 | 750 | 60 | 0.0402 | 0.0399 |

| 6 | 30 | 750 | 60 | 0.0375 | 0.0375 |

| 8 | 30 | 750 | 60 | 0.0345 | 0.0338 |

| 10 | 30 | 750 | 60 | 0.0311 | 0.0312 |

| 12 | 30 | 750 | 60 | 0.0274 | 0.0293 |

| 14 | 30 | 750 | 60 | 0.0233 | 0.0250 |

| 16 | 30 | 750 | 60 | 0.0188 | 0.0182 |

| 18 | 30 | 750 | 60 | 0.0138 | 0.0122 |

| 20 | 30 | 750 | 60 | 0.0084 | 0.0047 |

| 0 | 45 | 1000 | 60 | 0.0250 | 0.0285 |

| 2 | 45 | 1000 | 60 | 0.0243 | 0.0247 |

| 4 | 45 | 1000 | 60 | 0.0231 | 0.0215 |

| 6 | 45 | 1000 | 60 | 0.0219 | 0.0205 |

| 8 | 45 | 1000 | 60 | 0.0206 | 0.0206 |

| 10 | 45 | 1000 | 60 | 0.0191 | 0.0208 |

| 12 | 45 | 1000 | 60 | 0.0176 | 0.0201 |

| 14 | 45 | 1000 | 60 | 0.0158 | 0.0182 |

| 16 | 45 | 1000 | 60 | 0.0139 | 0.0152 |

| 18 | 45 | 1000 | 60 | 0.0119 | 0.0121 |

| 20 | 45 | 1000 | 60 | 0.0040 | 0.0079 |

| 0 | 60 | 1250 | 60 | 0.0160 | 0.0154 |

| 2 | 60 | 1250 | 60 | 0.0158 | 0.0177 |

| 4 | 60 | 1250 | 60 | 0.0153 | 0.0163 |

| 6 | 60 | 1250 | 60 | 0.0147 | 0.0149 |

| 8 | 60 | 1250 | 60 | 0.0142 | 0.0143 |

| 10 | 60 | 1250 | 60 | 0.0135 | 0.0136 |

| 12 | 60 | 1250 | 60 | 0.0129 | 0.0124 |

| 14 | 60 | 1250 | 60 | 0.0121 | 0.0112 |

| 16 | 60 | 1250 | 60 | 0.0114 | 0.0106 |

| 18 | 60 | 1250 | 60 | 0.0105 | 0.0100 |

| 20 | 60 | 1250 | 60 | 0.0096 | 0.0077 |

| 0 | 0 | 250 | 80 | 0.4130 | 0.4087 |

| 2 | 0 | 250 | 80 | 0.4070 | 0.4051 |

| 4 | 0 | 250 | 80 | 0.3750 | 0.3739 |

| 6 | 0 | 250 | 80 | 0.3410 | 0.3326 |

| 8 | 0 | 250 | 80 | 0.3040 | 0.2938 |

| 10 | 0 | 250 | 80 | 0.2630 | 0.2587 |

| 12 | 0 | 250 | 80 | 0.2190 | 0.2180 |

| 14 | 0 | 250 | 80 | 0.1710 | 0.1641 |

| 16 | 0 | 250 | 80 | 0.1200 | 0.1029 |

| 18 | 0 | 250 | 80 | 0.0645 | 0.0490 |

| 0 | 15 | 500 | 80 | 0.1030 | 0.1027 |

| 2 | 15 | 500 | 80 | 0.1020 | 0.1040 |

| 4 | 15 | 500 | 80 | 0.0942 | 0.0983 |

| 6 | 15 | 500 | 80 | 0.0861 | 0.0862 |

| 8 | 15 | 500 | 80 | 0.0772 | 0.0732 |

| 10 | 15 | 500 | 80 | 0.0675 | 0.0633 |

| 12 | 15 | 500 | 80 | 0.0570 | 0.0546 |

| 14 | 15 | 500 | 80 | 0.0456 | 0.0423 |

| 16 | 15 | 500 | 80 | 0.0333 | 0.0278 |

| 18 | 15 | 500 | 80 | 0.0202 | 0.0183 |

| 20 | 15 | 500 | 80 | 0.0061 | 0.0082 |

| 0 | 30 | 750 | 80 | 0.0459 | 0.0453 |

| 2 | 30 | 750 | 80 | 0.0462 | 0.0443 |

| 4 | 30 | 750 | 80 | 0.0431 | 0.0445 |

| 6 | 30 | 750 | 80 | 0.0398 | 0.0423 |

| 8 | 30 | 750 | 80 | 0.0362 | 0.0372 |

| 10 | 30 | 750 | 80 | 0.0323 | 0.0315 |

| 12 | 30 | 750 | 80 | 0.0281 | 0.0266 |

| 14 | 30 | 750 | 80 | 0.0236 | 0.0217 |

| 16 | 30 | 750 | 80 | 0.0187 | 0.0170 |

| 18 | 30 | 750 | 80 | 0.0136 | 0.0144 |

| 20 | 30 | 750 | 80 | 0.0082 | 0.0094 |

| 0 | 45 | 1000 | 80 | 0.0258 | 0.0274 |

| 2 | 45 | 1000 | 80 | 0.0263 | 0.0254 |

| 4 | 45 | 1000 | 80 | 0.0249 | 0.0232 |

| 6 | 45 | 1000 | 80 | 0.0234 | 0.0229 |

| 8 | 45 | 1000 | 80 | 0.0218 | 0.0231 |

| 10 | 45 | 1000 | 80 | 0.0201 | 0.0219 |

| 12 | 45 | 1000 | 80 | 0.0183 | 0.0191 |

| 14 | 45 | 1000 | 80 | 0.0162 | 0.0155 |

| 16 | 45 | 1000 | 80 | 0.0141 | 0.0129 |

| 18 | 45 | 1000 | 80 | 0.0119 | 0.0119 |

| 20 | 45 | 1000 | 80 | 0.0054 | 0.0090 |

| 0 | 60 | 1250 | 80 | 0.0165 | 0.0154 |

| 2 | 60 | 1250 | 80 | 0.0167 | 0.0183 |

| 4 | 60 | 1250 | 80 | 0.0161 | 0.0173 |

| 6 | 60 | 1250 | 80 | 0.0154 | 0.0160 |

| 8 | 60 | 1250 | 80 | 0.0147 | 0.0151 |

| 10 | 60 | 1250 | 80 | 0.0140 | 0.0141 |

| 12 | 60 | 1250 | 80 | 0.0132 | 0.0124 |

| 14 | 60 | 1250 | 80 | 0.0123 | 0.0109 |

| 16 | 60 | 1250 | 80 | 0.0114 | 0.0106 |

| 18 | 60 | 1250 | 80 | 0.0105 | 0.0109 |

| 20 | 60 | 1250 | 80 | 0.0094 | 0.0094 |

| 0 | 0 | 250 | 100 | 0.4320 | 0.4285 |

| 2 | 0 | 250 | 100 | 0.4260 | 0.4248 |

| 4 | 0 | 250 | 100 | 0.3910 | 0.3876 |

| 6 | 0 | 250 | 100 | 0.3530 | 0.3424 |

| 8 | 0 | 250 | 100 | 0.3120 | 0.3028 |

| 10 | 0 | 250 | 100 | 0.2680 | 0.2694 |

| 12 | 0 | 250 | 100 | 0.2220 | 0.2328 |

| 14 | 0 | 250 | 100 | 0.1720 | 0.1816 |

| 16 | 0 | 250 | 100 | 0.1200 | 0.1156 |

| 18 | 0 | 250 | 100 | 0.0657 | 0.0503 |

| 0 | 15 | 500 | 100 | 0.1080 | 0.1099 |

| 2 | 15 | 500 | 100 | 0.1070 | 0.1105 |

| 4 | 15 | 500 | 100 | 0.0982 | 0.1016 |

| 6 | 15 | 500 | 100 | 0.0891 | 0.0888 |

| 8 | 15 | 500 | 100 | 0.0793 | 0.0762 |

| 10 | 15 | 500 | 100 | 0.0688 | 0.0668 |

| 12 | 15 | 500 | 100 | 0.0577 | 0.0593 |

| 14 | 15 | 500 | 100 | 0.0459 | 0.0487 |

| 16 | 15 | 500 | 100 | 0.0334 | 0.0332 |

| 18 | 15 | 500 | 100 | 0.0203 | 0.0186 |

| 20 | 15 | 500 | 100 | 0.0075 | 0.0073 |

| 0 | 30 | 750 | 100 | 0.0480 | 0.0437 |

| 2 | 30 | 750 | 100 | 0.0482 | 0.0445 |

| 4 | 30 | 750 | 100 | 0.0447 | 0.0450 |

| 6 | 30 | 750 | 100 | 0.0410 | 0.0437 |

| 8 | 30 | 750 | 100 | 0.0371 | 0.0388 |

| 10 | 30 | 750 | 100 | 0.0328 | 0.0320 |

| 12 | 30 | 750 | 100 | 0.0284 | 0.0258 |

| 14 | 30 | 750 | 100 | 0.0237 | 0.0209 |

| 16 | 30 | 750 | 100 | 0.0187 | 0.0173 |

| 18 | 30 | 750 | 100 | 0.0135 | 0.0153 |

| 20 | 30 | 750 | 100 | 0.0081 | 0.0100 |

| 0 | 45 | 1000 | 100 | 0.0270 | 0.0264 |

| 2 | 45 | 1000 | 100 | 0.0275 | 0.0262 |

| 4 | 45 | 1000 | 100 | 0.0259 | 0.0247 |

| 6 | 45 | 1000 | 100 | 0.0242 | 0.0243 |

| 8 | 45 | 1000 | 100 | 0.0224 | 0.0237 |

| 10 | 45 | 1000 | 100 | 0.0205 | 0.0214 |

| 12 | 45 | 1000 | 100 | 0.0185 | 0.0176 |

| 14 | 45 | 1000 | 100 | 0.0164 | 0.0140 |

| 16 | 45 | 1000 | 100 | 0.0142 | 0.0126 |

| 18 | 45 | 1000 | 100 | 0.0119 | 0.0129 |

| 20 | 45 | 1000 | 100 | 0.0069 | 0.0094 |

| 0 | 60 | 1250 | 100 | 0.0173 | 0.0179 |

| 2 | 60 | 1250 | 100 | 0.0175 | 0.0195 |

| 4 | 60 | 1250 | 100 | 0.0168 | 0.0192 |

| 6 | 60 | 1250 | 100 | 0.0160 | 0.0181 |

| 8 | 60 | 1250 | 100 | 0.0152 | 0.0166 |

| 10 | 60 | 1250 | 100 | 0.0144 | 0.0147 |

| 12 | 60 | 1250 | 100 | 0.0135 | 0.0127 |

| 14 | 60 | 1250 | 100 | 0.0125 | 0.0115 |

| 16 | 60 | 1250 | 100 | 0.0115 | 0.0116 |

| 18 | 60 | 1250 | 100 | 0.0105 | 0.0119 |

| 20 | 60 | 1250 | 100 | 0.0095 | 0.0083 |

| 0 | 0 | 250 | 120 | 0.4490 | 0.4500 |

| 2 | 0 | 250 | 120 | 0.4350 | 0.4375 |

| 4 | 0 | 250 | 120 | 0.3970 | 0.3968 |

| 6 | 0 | 250 | 120 | 0.3580 | 0.3535 |

| 8 | 0 | 250 | 120 | 0.3150 | 0.3137 |

| 10 | 0 | 250 | 120 | 0.2700 | 0.2756 |

| 12 | 0 | 250 | 120 | 0.2230 | 0.2338 |

| 14 | 0 | 250 | 120 | 0.1730 | 0.1809 |

| 16 | 0 | 250 | 120 | 0.1220 | 0.1145 |

| 18 | 0 | 250 | 120 | 0.0674 | 0.0488 |

| 0 | 15 | 500 | 120 | 0.1120 | 0.1165 |

| 2 | 15 | 500 | 120 | 0.1090 | 0.1112 |

| 4 | 15 | 500 | 120 | 0.1000 | 0.1001 |

| 6 | 15 | 500 | 120 | 0.0904 | 0.0903 |

| 8 | 15 | 500 | 120 | 0.0802 | 0.0805 |

| 10 | 15 | 500 | 120 | 0.0694 | 0.0700 |

| 12 | 15 | 500 | 120 | 0.0580 | 0.0589 |

| 14 | 15 | 500 | 120 | 0.0462 | 0.0453 |

| 16 | 15 | 500 | 120 | 0.0337 | 0.0277 |

| 18 | 15 | 500 | 120 | 0.0207 | 0.0108 |

| 20 | 15 | 500 | 120 | 0.0088 | 0.0034 |

| 0 | 30 | 750 | 120 | 0.0499 | 0.0468 |

| 2 | 30 | 750 | 120 | 0.0487 | 0.0462 |

| 4 | 30 | 750 | 120 | 0.0451 | 0.0447 |

| 6 | 30 | 750 | 120 | 0.0412 | 0.0440 |

| 8 | 30 | 750 | 120 | 0.0371 | 0.0414 |

| 10 | 30 | 750 | 120 | 0.0328 | 0.0360 |

| 12 | 30 | 750 | 120 | 0.0283 | 0.0295 |

| 14 | 30 | 750 | 120 | 0.0236 | 0.0231 |

| 16 | 30 | 750 | 120 | 0.0186 | 0.0175 |

| 18 | 30 | 750 | 120 | 0.0135 | 0.0133 |

| 20 | 30 | 750 | 120 | 0.0082 | 0.0080 |

| 0 | 45 | 1000 | 120 | 0.0280 | 0.0285 |

| 2 | 45 | 1000 | 120 | 0.0278 | 0.0285 |

| 4 | 45 | 1000 | 120 | 0.0261 | 0.0254 |

| 6 | 45 | 1000 | 120 | 0.0243 | 0.0234 |

| 8 | 45 | 1000 | 120 | 0.0224 | 0.0228 |

| 10 | 45 | 1000 | 120 | 0.0205 | 0.0222 |

| 12 | 45 | 1000 | 120 | 0.0185 | 0.0204 |

| 14 | 45 | 1000 | 120 | 0.0163 | 0.0174 |

| 16 | 45 | 1000 | 120 | 0.0141 | 0.0146 |

| 18 | 45 | 1000 | 120 | 0.0118 | 0.0126 |

| 20 | 45 | 1000 | 120 | 0.0085 | 0.0071 |

| 0 | 60 | 1250 | 120 | 0.0179 | 0.0190 |

| 2 | 60 | 1250 | 120 | 0.0180 | 0.0180 |

| 4 | 60 | 1250 | 120 | 0.0172 | 0.0178 |

| 6 | 60 | 1250 | 120 | 0.0163 | 0.0168 |

| 8 | 60 | 1250 | 120 | 0.0155 | 0.0153 |

| 10 | 60 | 1250 | 120 | 0.0146 | 0.0139 |

| 12 | 60 | 1250 | 120 | 0.0136 | 0.0130 |

| 14 | 60 | 1250 | 120 | 0.0127 | 0.0125 |

| 16 | 60 | 1250 | 120 | 0.0117 | 0.0122 |

| 18 | 60 | 1250 | 120 | 0.0106 | 0.0110 |

| 20 | 60 | 1250 | 120 | 0.0095 | 0.0057 |

| 0 | 0 | 250 | 140 | 0.4610 | 0.4537 |

| 2 | 0 | 250 | 140 | 0.4390 | 0.4354 |

| 4 | 0 | 250 | 140 | 0.4000 | 0.3975 |

| 6 | 0 | 250 | 140 | 0.3590 | 0.3586 |

| 8 | 0 | 250 | 140 | 0.3160 | 0.3161 |

| 10 | 0 | 250 | 140 | 0.2710 | 0.2689 |

| 12 | 0 | 250 | 140 | 0.2240 | 0.2218 |

| 14 | 0 | 250 | 140 | 0.1750 | 0.1763 |

| 16 | 0 | 250 | 140 | 0.1240 | 0.1262 |

| 18 | 0 | 250 | 140 | 0.0697 | 0.0725 |

| 0 | 15 | 500 | 140 | 0.1150 | 0.1178 |

| 2 | 15 | 500 | 140 | 0.1100 | 0.1099 |

| 4 | 15 | 500 | 140 | 0.1010 | 0.0996 |

| 6 | 15 | 500 | 140 | 0.0907 | 0.0931 |

| 8 | 15 | 500 | 140 | 0.0805 | 0.0840 |

| 10 | 15 | 500 | 140 | 0.0697 | 0.0697 |

| 12 | 15 | 500 | 140 | 0.0583 | 0.0548 |

| 14 | 15 | 500 | 140 | 0.0467 | 0.0430 |

| 16 | 15 | 500 | 140 | 0.0343 | 0.0321 |

| 18 | 15 | 500 | 140 | 0.0213 | 0.0201 |

| 20 | 15 | 500 | 140 | 0.0099 | 0.0121 |

| 0 | 30 | 750 | 140 | 0.0513 | 0.0496 |

| 2 | 30 | 750 | 140 | 0.0486 | 0.0492 |

| 4 | 30 | 750 | 140 | 0.0449 | 0.0455 |

| 6 | 30 | 750 | 140 | 0.0410 | 0.0439 |

| 8 | 30 | 750 | 140 | 0.0368 | 0.0420 |

| 10 | 30 | 750 | 140 | 0.0325 | 0.0376 |

| 12 | 30 | 750 | 140 | 0.0280 | 0.0312 |

| 14 | 30 | 750 | 140 | 0.0234 | 0.0249 |

| 16 | 30 | 750 | 140 | 0.0186 | 0.0197 |

| 18 | 30 | 750 | 140 | 0.0137 | 0.0165 |

| 20 | 30 | 750 | 140 | 0.0085 | 0.0130 |

| 0 | 45 | 1000 | 140 | 0.0288 | 0.0273 |

| 2 | 45 | 1000 | 140 | 0.0277 | 0.0282 |

| 4 | 45 | 1000 | 140 | 0.0260 | 0.0231 |

| 6 | 45 | 1000 | 140 | 0.0242 | 0.0191 |

| 8 | 45 | 1000 | 140 | 0.0222 | 0.0188 |

| 10 | 45 | 1000 | 140 | 0.0203 | 0.0208 |

| 12 | 45 | 1000 | 140 | 0.0183 | 0.0214 |

| 14 | 45 | 1000 | 140 | 0.0162 | 0.0184 |

| 16 | 45 | 1000 | 140 | 0.0140 | 0.0133 |

| 18 | 45 | 1000 | 140 | 0.0118 | 0.0098 |

| 20 | 45 | 1000 | 140 | 0.0100 | 0.0072 |

| 0 | 60 | 1250 | 140 | 0.0185 | 0.0190 |

| 2 | 60 | 1250 | 140 | 0.0183 | 0.0162 |

| 4 | 60 | 1250 | 140 | 0.0174 | 0.0165 |

| 6 | 60 | 1250 | 140 | 0.0166 | 0.0161 |

| 8 | 60 | 1250 | 140 | 0.0157 | 0.0151 |

| 10 | 60 | 1250 | 140 | 0.0147 | 0.0148 |

| 12 | 60 | 1250 | 140 | 0.0138 | 0.0147 |

| 14 | 60 | 1250 | 140 | 0.0128 | 0.0137 |

| 16 | 60 | 1250 | 140 | 0.0118 | 0.0120 |

| 18 | 60 | 1250 | 140 | 0.0107 | 0.0111 |

| 20 | 60 | 1250 | 140 | 0.0097 | 0.0109 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, L.; Xu, F.; Wang, L.; Chen, Y.; Nazemi, E.; Zhang, G.; Zhang, X. Air Kerma Calculation in Diagnostic Medical Imaging Devices Using Group Method of Data Handling Network. Diagnostics 2023, 13, 1418. https://doi.org/10.3390/diagnostics13081418

Zhang L, Xu F, Wang L, Chen Y, Nazemi E, Zhang G, Zhang X. Air Kerma Calculation in Diagnostic Medical Imaging Devices Using Group Method of Data Handling Network. Diagnostics. 2023; 13(8):1418. https://doi.org/10.3390/diagnostics13081418

Chicago/Turabian StyleZhang, Licheng, Fengzhe Xu, Lubing Wang, Yunkui Chen, Ehsan Nazemi, Guohua Zhang, and Xicai Zhang. 2023. "Air Kerma Calculation in Diagnostic Medical Imaging Devices Using Group Method of Data Handling Network" Diagnostics 13, no. 8: 1418. https://doi.org/10.3390/diagnostics13081418

APA StyleZhang, L., Xu, F., Wang, L., Chen, Y., Nazemi, E., Zhang, G., & Zhang, X. (2023). Air Kerma Calculation in Diagnostic Medical Imaging Devices Using Group Method of Data Handling Network. Diagnostics, 13(8), 1418. https://doi.org/10.3390/diagnostics13081418