Performance Verification of a Flexible Vibration Monitoring System

Abstract

1. Introduction

2. System Overview

2.1. Software

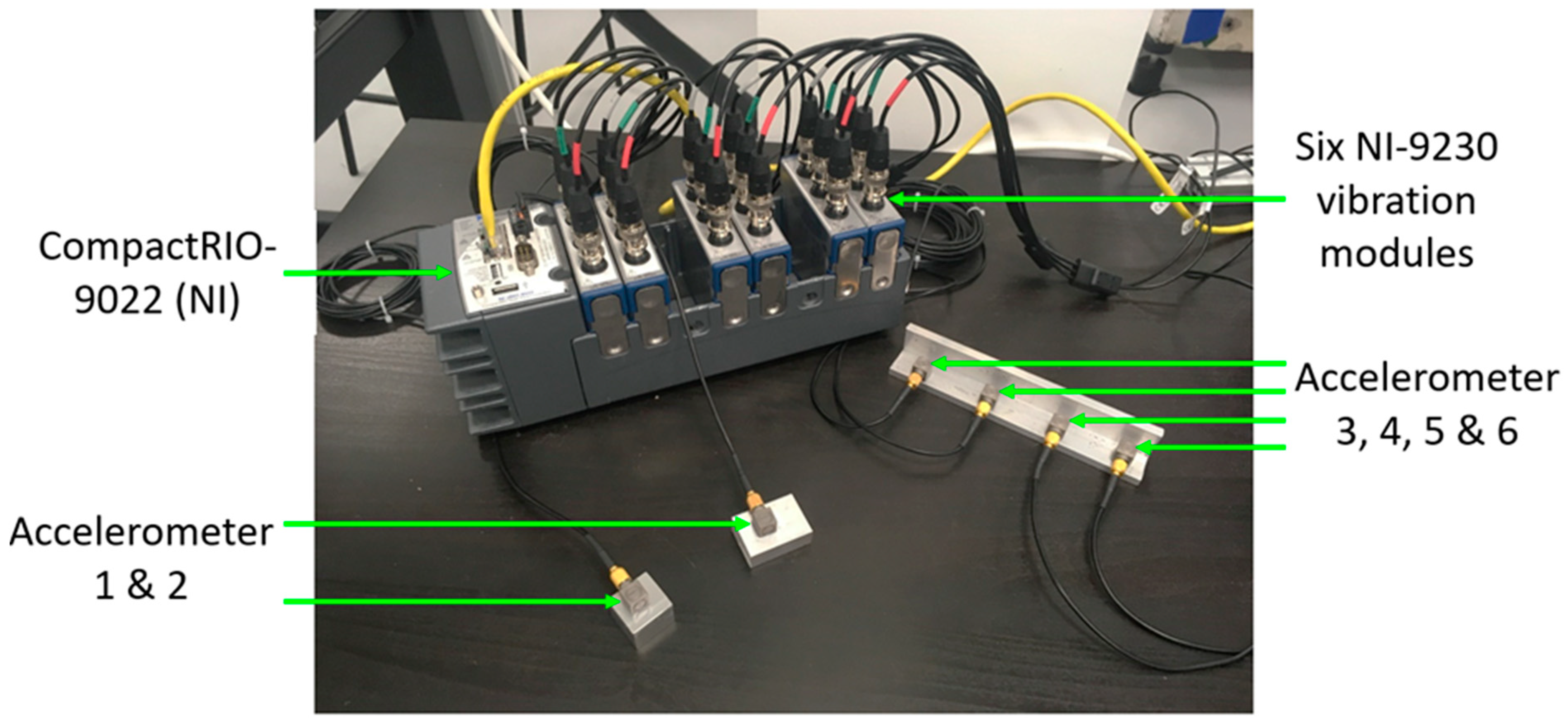

2.2. Hardware

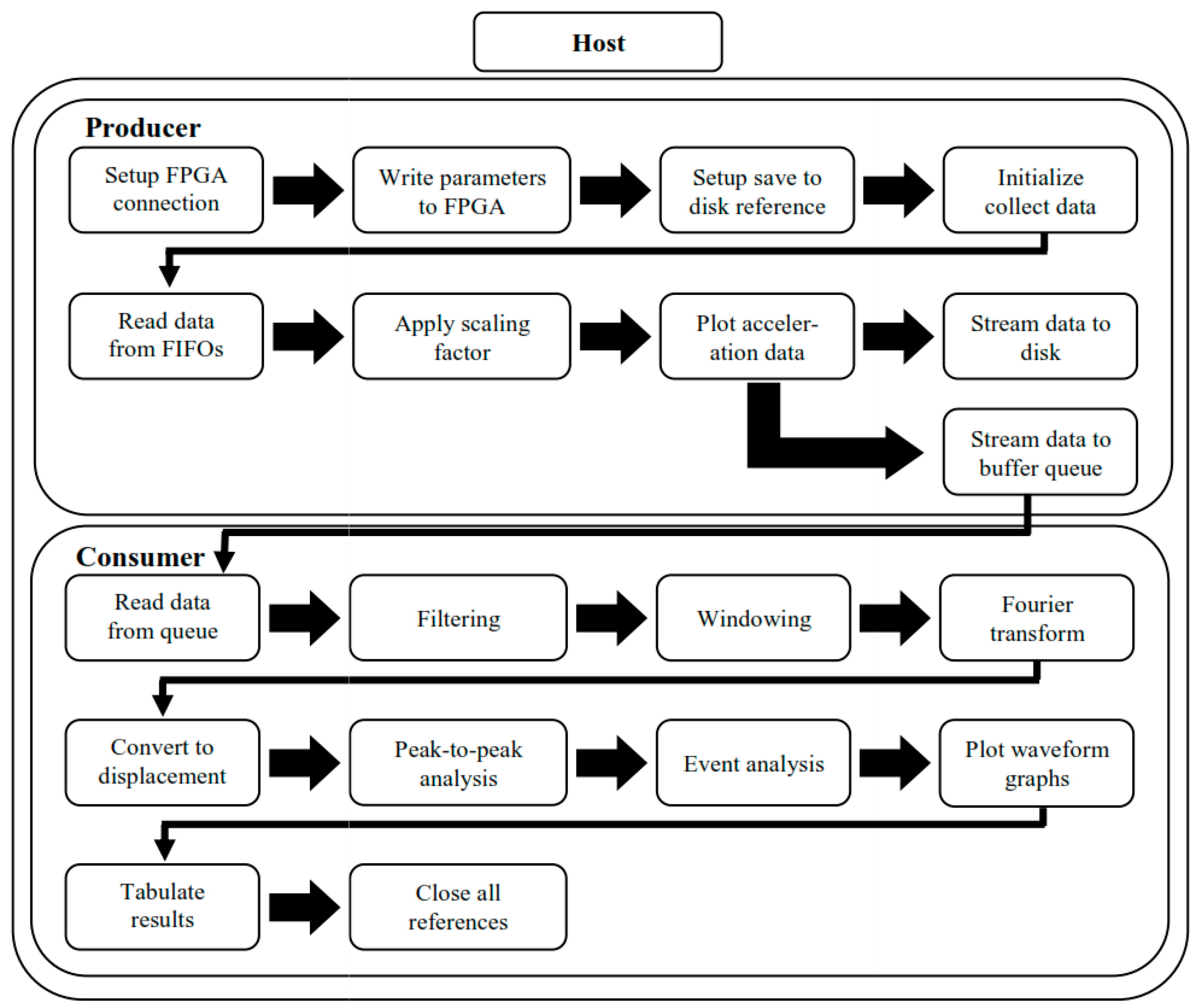

3. Software Framework

3.1. Establishing Parameter Set

3.2. Filtering

3.3. Windowing Options

3.4. Signal Conversion

3.5. Analysis Type

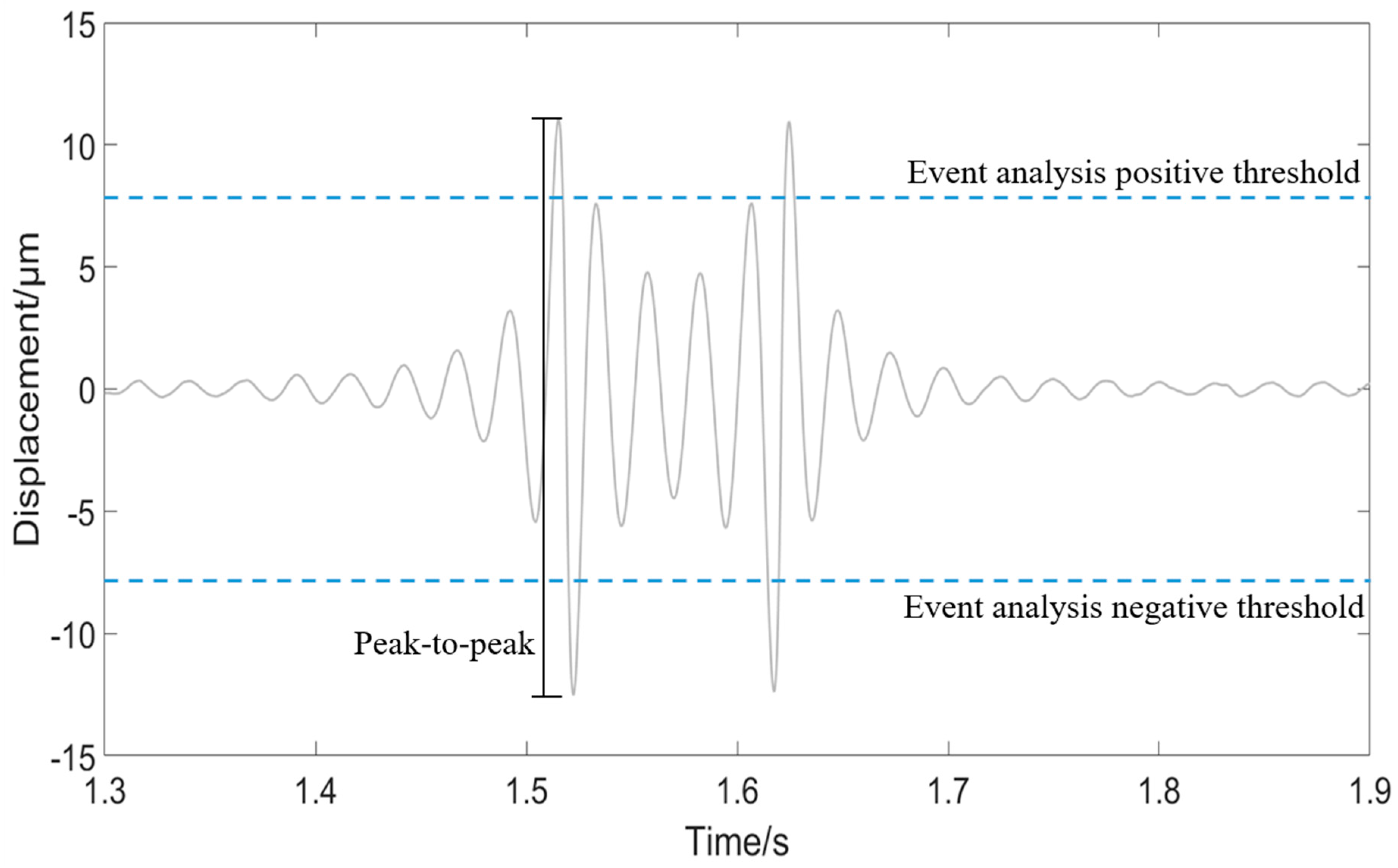

3.5.1. Peak-to-Peak

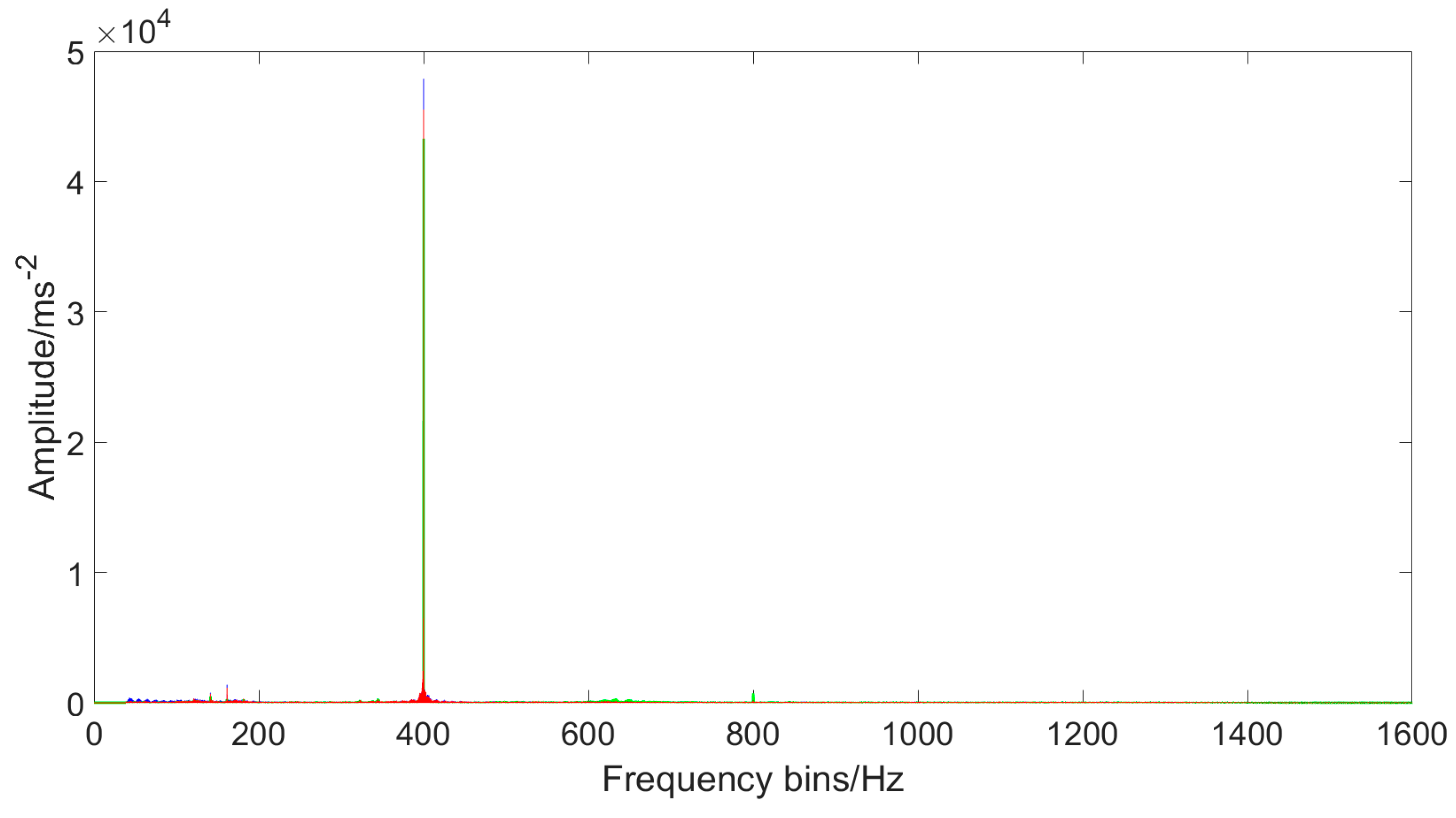

3.5.2. Frequency Spectrum Analysis

3.5.3. Power Spectral Density

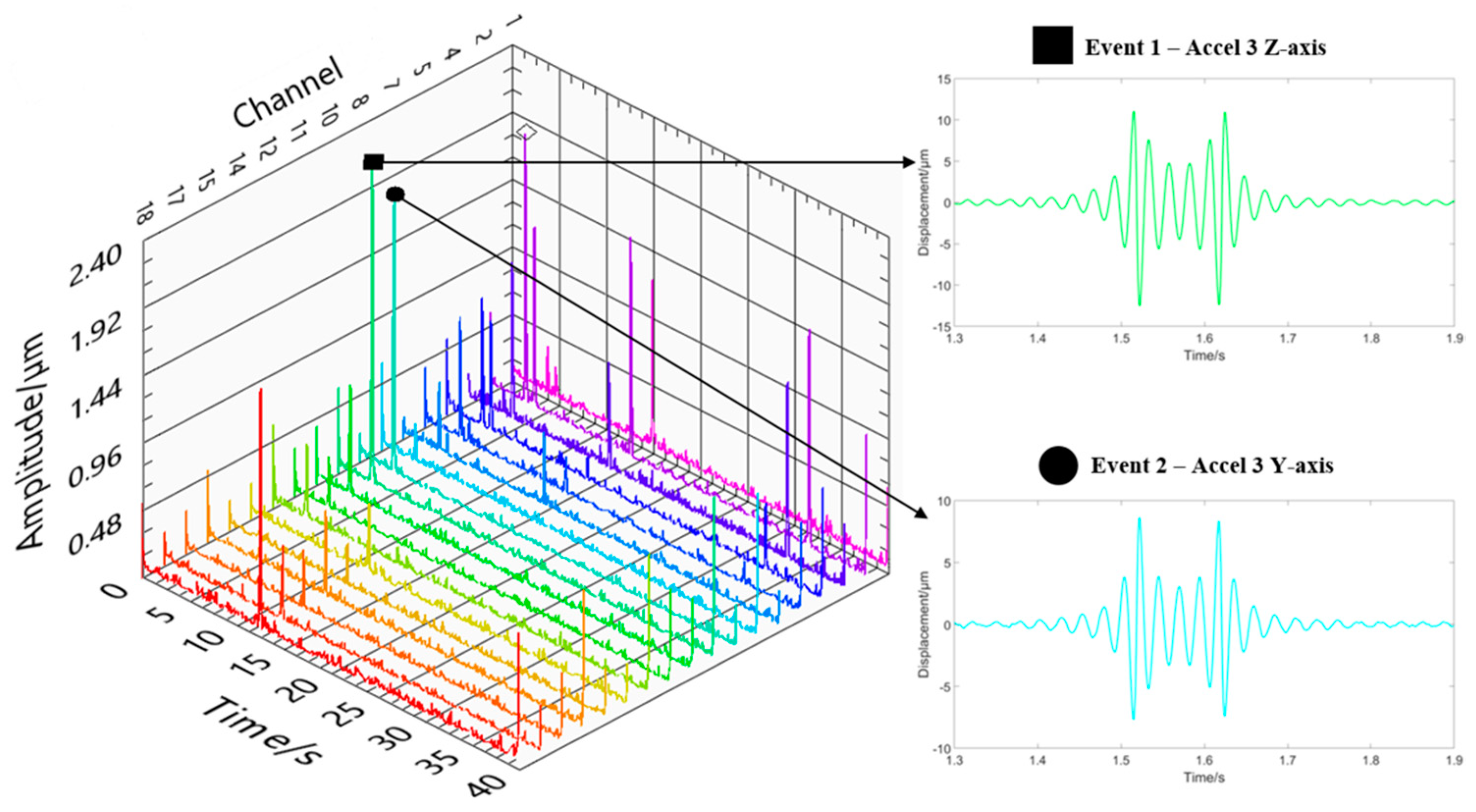

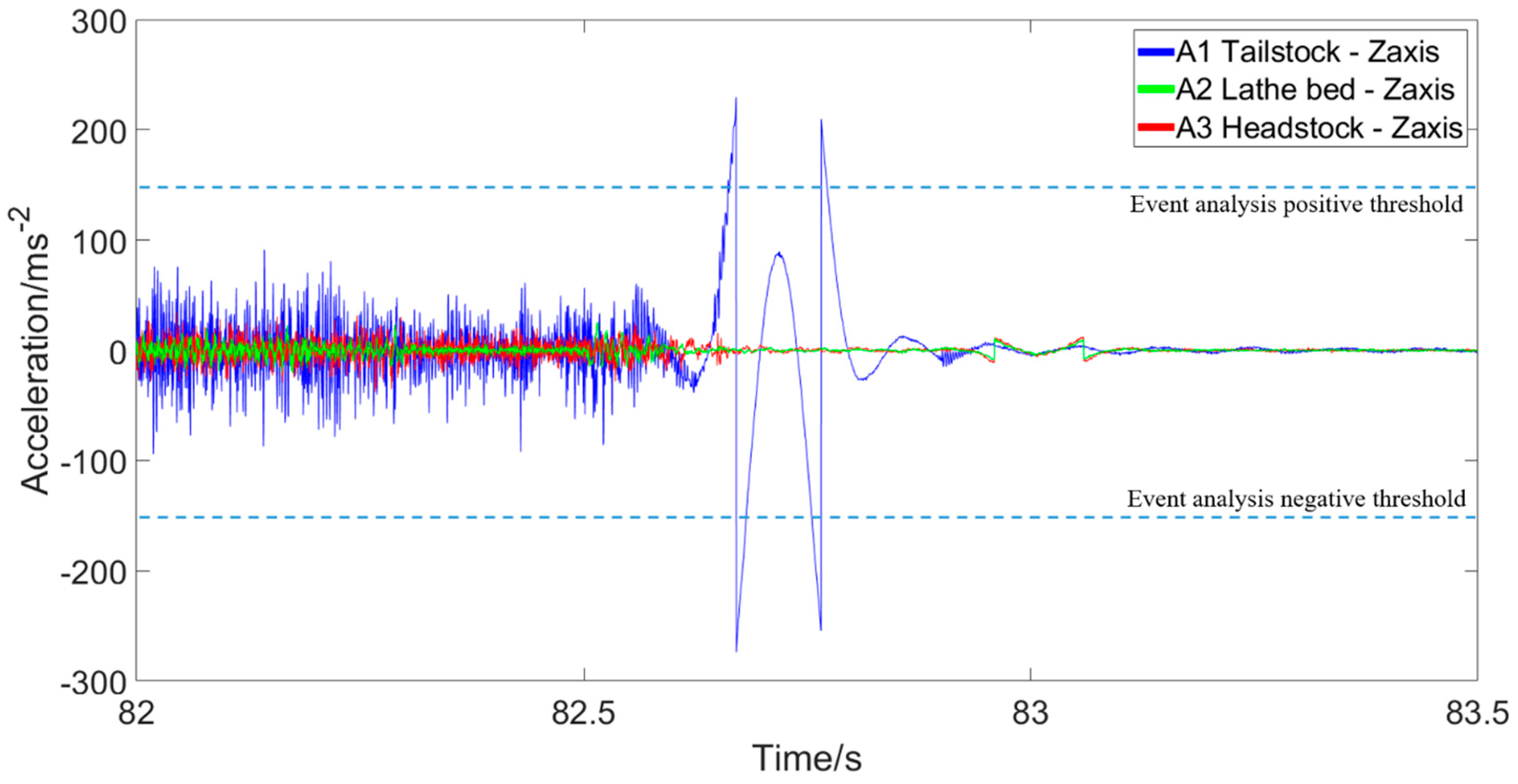

3.5.4. Event Analysis

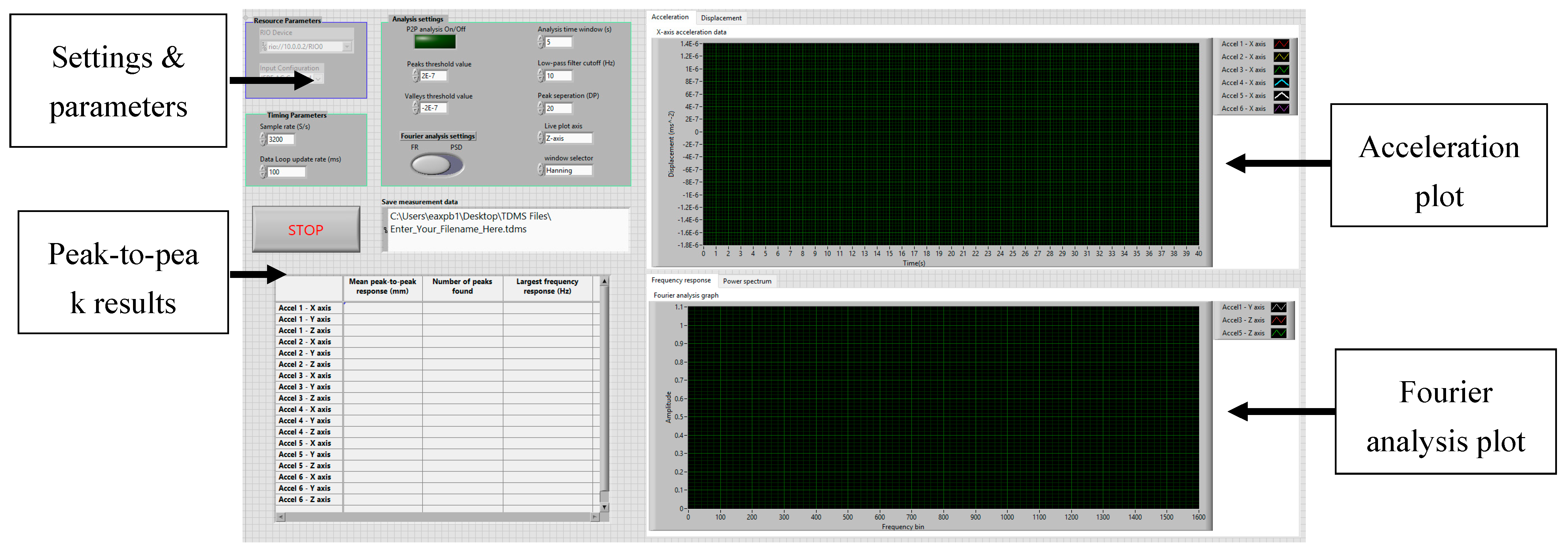

4. User Interface

4.1. Results—Live Data VI

4.2. Results—Post-Measurement Analysis VI

4.3. System Properties and Errors Section

4.4. Data Handling

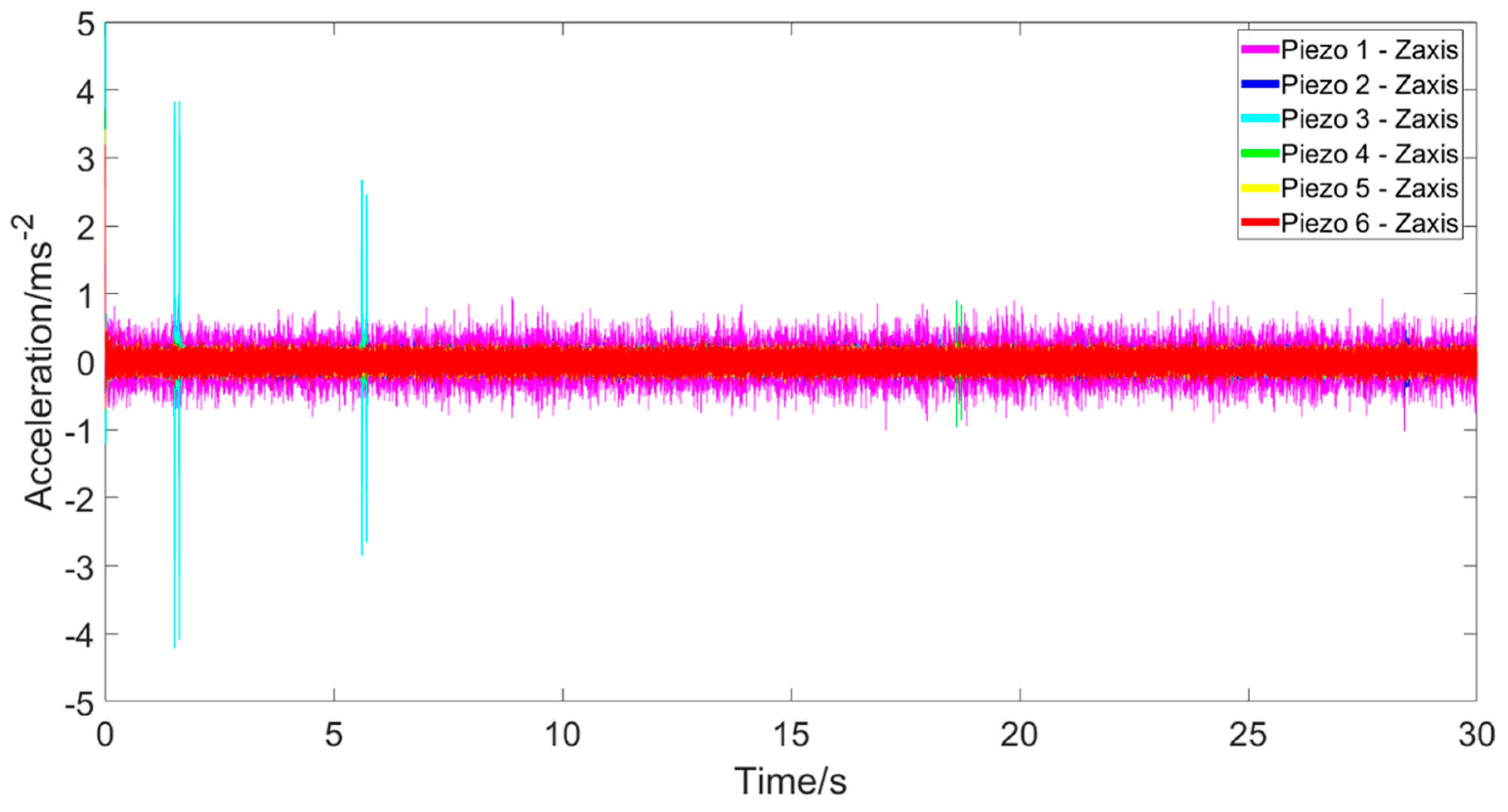

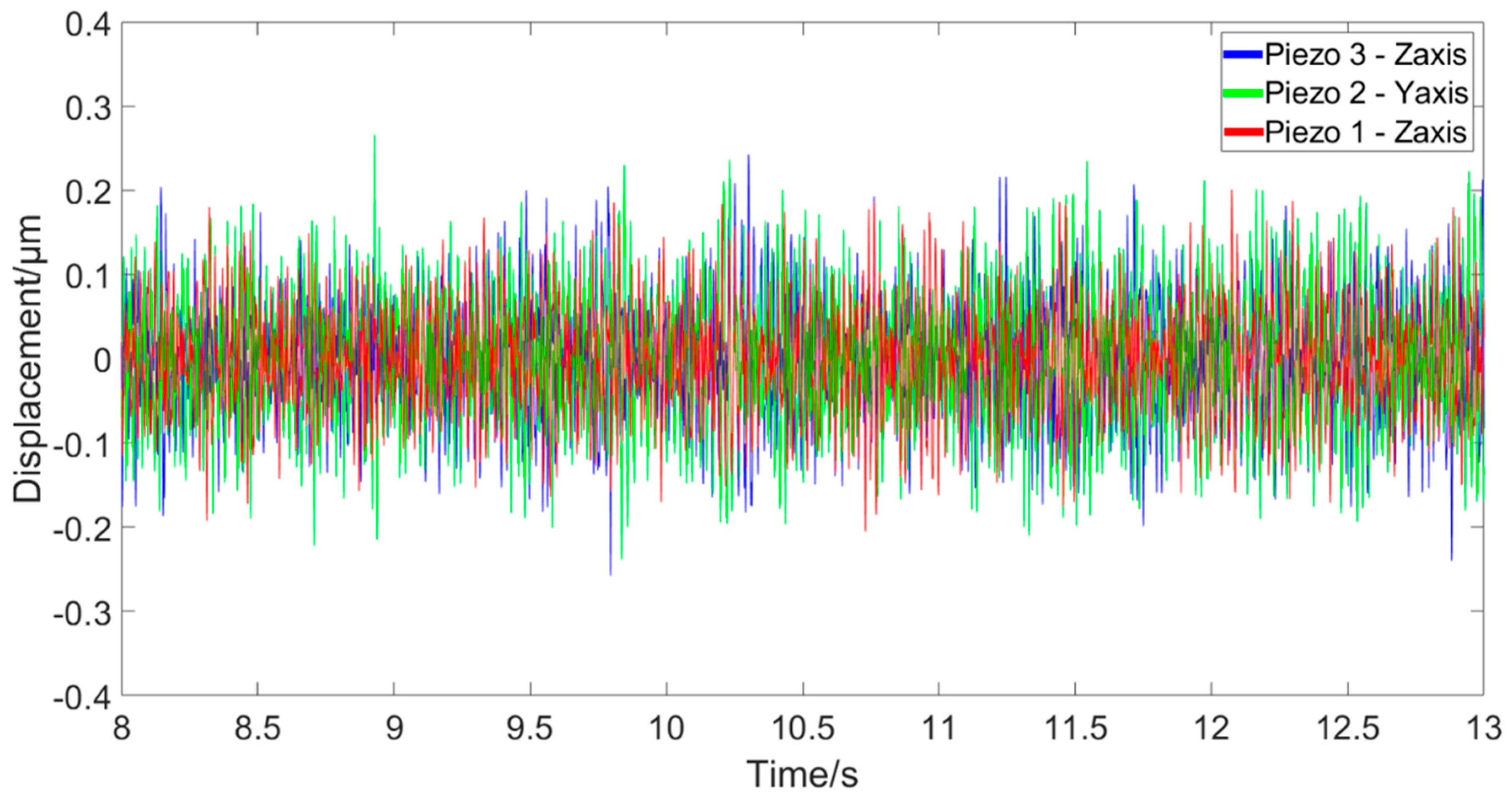

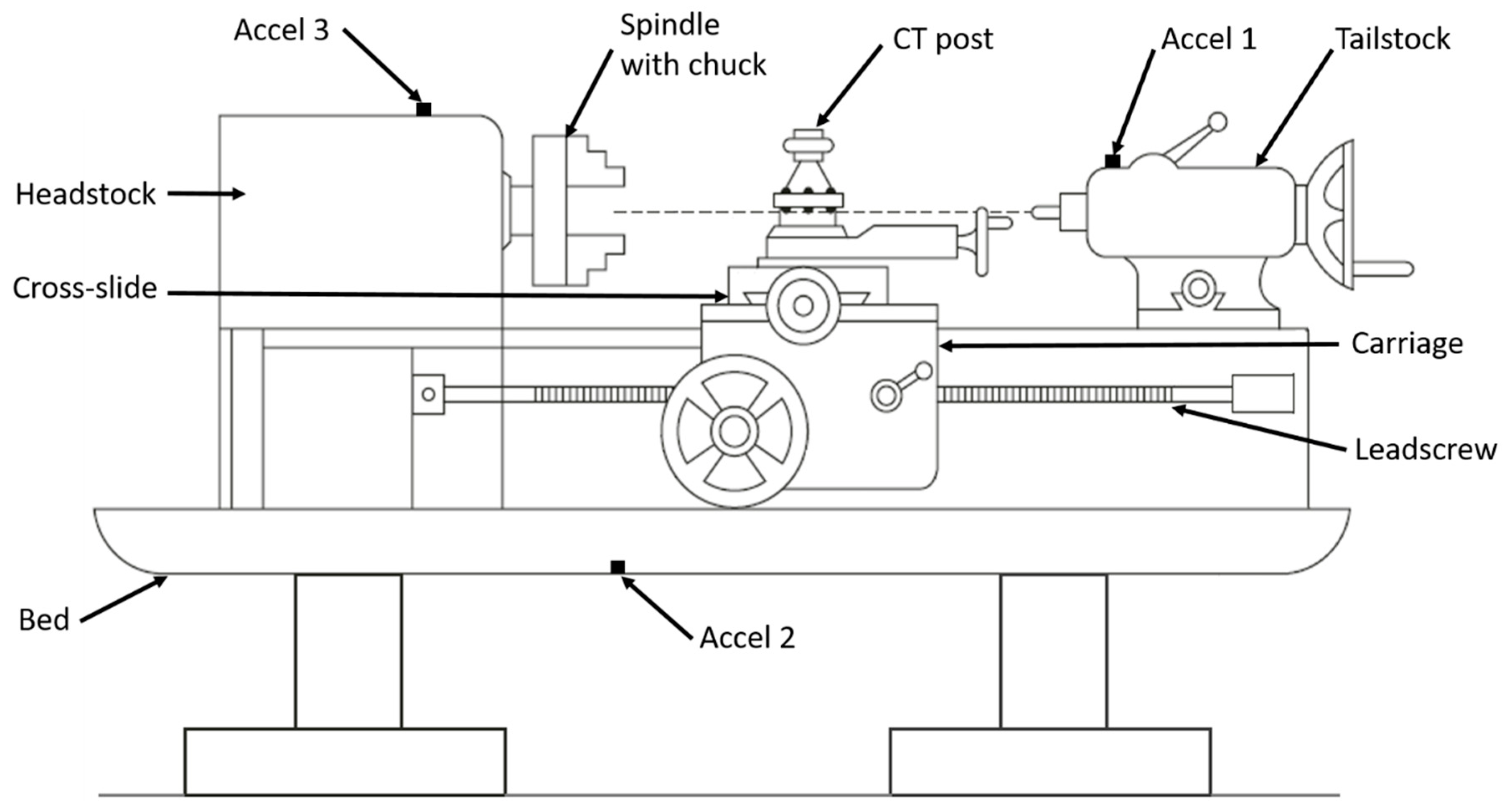

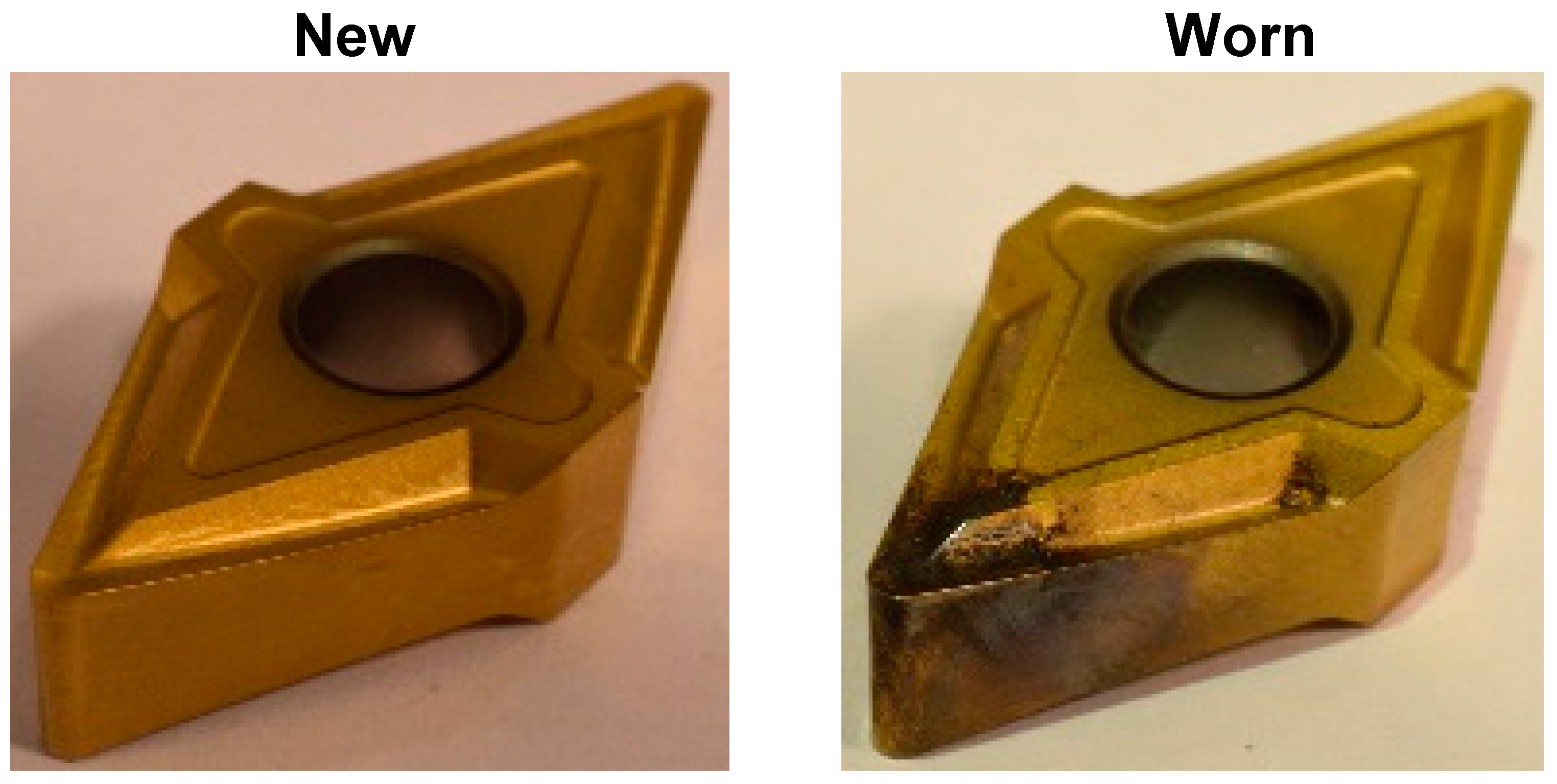

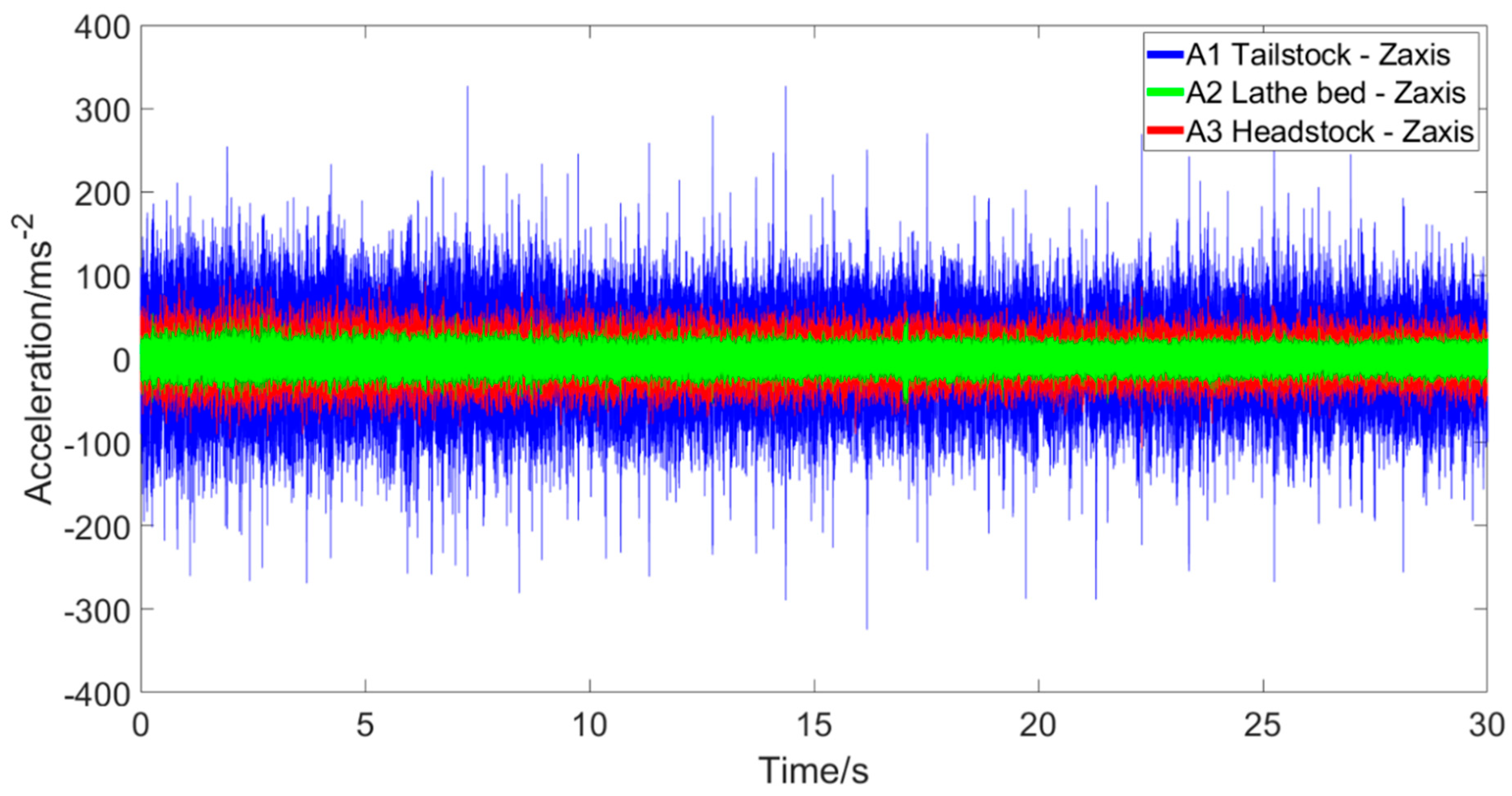

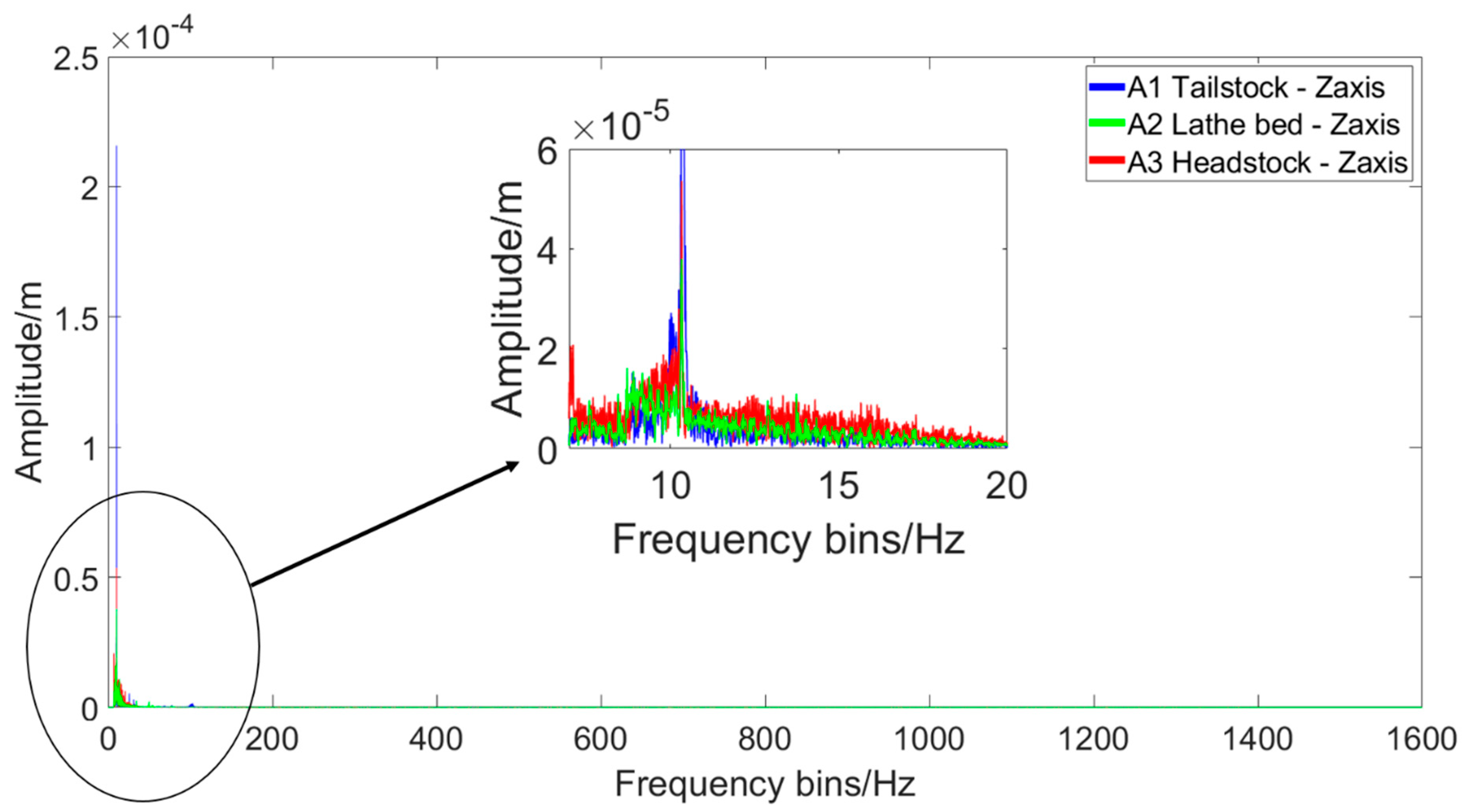

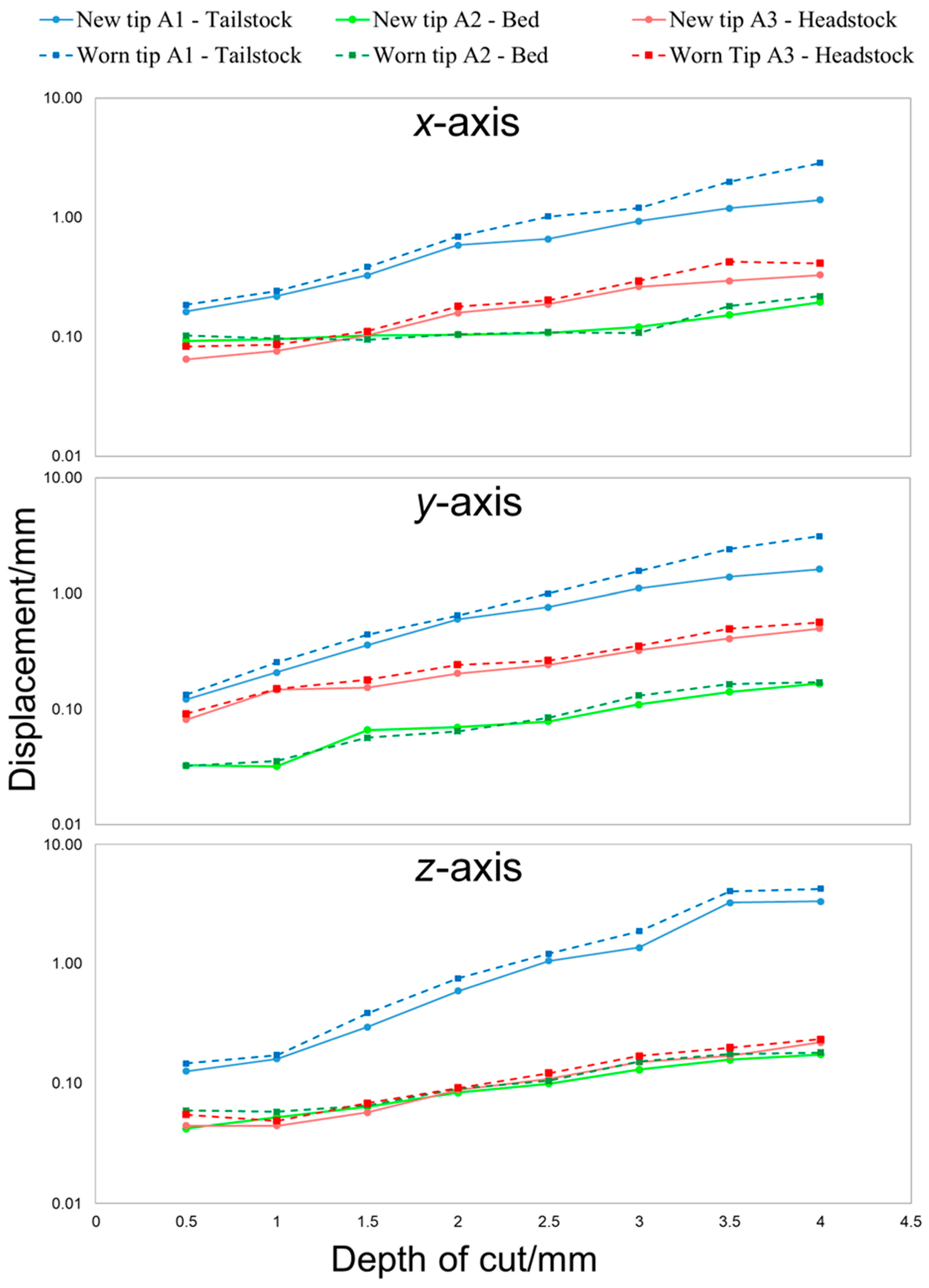

5. Lathe Condition Monitoring Investigation

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Leach, R.K. Fundamental Principles of Engineering Nanometrology; Elsevier: London, UK, 2014. [Google Scholar]

- Savio, E.; De Chiffre, L.; Carmignato, S.; Meinertz, J. Economic benefits of metrology in manufacturing. CIRP Ann. 2016, 65, 495–498. [Google Scholar] [CrossRef]

- Leach, R.K.; Bourell, D.; Carmignato, S.; Donmez, A.; Senin, N.; Dewulf, W. Geometrical metrology for metal additive manufacturing. CIRP Ann. 2019, 68, 677–700. [Google Scholar] [CrossRef]

- Nie, M.; Wang, L. Review of condition monitoring and fault diagnosis technologies for wind turbine gearbox. Proc. CIRP 2013, 11, 287–290. [Google Scholar] [CrossRef]

- Ahirrao, N.S.; Bhosle, S.P.; Nehete, D.V. Dynamics and vibration measurements in engines. Proc. Manuf. 2018, 20, 434–439. [Google Scholar] [CrossRef]

- Lei, Y.; Lin, J.; Zuo, M.J.; He, Z. Condition monitoring and fault diagnosis of planetary gearboxes: A review. Measurement 2014, 48, 292–305. [Google Scholar] [CrossRef]

- Randall, R.B. Vibration-Based Condition Monitoring: Industrial, Aerospace and Automotive Applications; John Wiley & Sons: London, UK, 2011. [Google Scholar]

- Ambhore, N.; Kamble, D.; Chinchanikar, S.; Wayal, V. Tool condition monitoring system: A review. Mater. Today Proc. 2015, 2, 3419–3428. [Google Scholar] [CrossRef]

- Cawley, P. Structural health monitoring: Closing the gap between research and industrial deployment. Struct. Health Monit. 2018, 17, 1225–1244. [Google Scholar] [CrossRef]

- Carlucci, A.P.; Chiara, F.F.; Laforgia, D. Analysis of the relation between injection parameter variation and block vibration of an internal combustion diesel engine. J. Sound Vib. 2006, 295, 141–164. [Google Scholar] [CrossRef]

- Albizuri, J.; Fernandes, M.H.; Garitaonandia, I.; Sabalza, X.; Uribe-Etxeberria, R.; Hernández, J.M. An active system of reduction of vibrations in a centerless grinding machine using piezoelectric actuators. Int. J. Mach. Tools Manuf. 2007, 47, 1607–1614. [Google Scholar] [CrossRef]

- Taghizadeh-Alisaraei, A.; Ghobadian, B.; Tavakoli-Hashjin, T.; Mohtasebi, S.S. Vibration analysis of a diesel engine using biodiesel and petrodiesel fuel blends. Fuel 2012, 102, 414–422. [Google Scholar] [CrossRef]

- Tatar, K.; Gren, P. Measurement of milling tool vibrations during cutting using laser vibrometry. Int. J. Mach. Tools Manuf. 2008, 48, 380–387. [Google Scholar] [CrossRef]

- Miyaguchi, T.; Masuda, M.; Takeoka, E.; Iwabe, H. Effect of tool stiffness upon tool wear in high spindle speed milling using small ball end mill. Precis. Eng. 2001, 25, 145–154. [Google Scholar] [CrossRef]

- Wojciechowski, S. Machined surface roughness including cutter displacements in milling of hardened steel. Metrol. Meas. Syst. 2011, 18, 429–440. [Google Scholar] [CrossRef]

- Wojciechowski, S.; Twardowski, P.; Pelic, M.; Maruda, R.W.; Barrans, S.; Krolczyk, G.M. Precision surface characterization for finish cylindrical milling with dynamic tool displacements model. Precis. Eng. 2016, 46, 158–165. [Google Scholar] [CrossRef]

- El-Basheer, T.M.; Shawky, H.A. Measurement and limits of vibration affecting the sensitive equipments of some metrological laboratories. Euronoise 2018, 11, 2637–2644. [Google Scholar]

- ISO 23165:2006: Geometrical Product Specification (GPS)-Guidelines for the Evaluation of Coordinate Measuring Machine (CMM) Test Uncertainty; International Organisation for Standardisation: Geneva, Switzerland, 2006.

- Zygo New View TM8300 Specifications. 2014. Available online: http://www.lambdaphoto.co.uk/pdfs/Zygo/Lambda_NewView8300_Specs_SS0100_3_14.pdf (accessed on 10 July 2019).

- Feese, T.; Hill, C.L. Prevention of torsional vibration problems in reciprocating machinery. In The 38th Turbomachinery Symposium; Texas A&M University: College Station, TX, USA, 2009; pp. 213–238. [Google Scholar]

- ISA-RP-372. Guide for Specifications and Tests for Piezoelectric Acceleration Transducers for Aerospace Testing; International Society of Automation (ISA): Pittsburgh, NC, USA, 1995. [Google Scholar]

- Link, A.; Täubner, A.; Wabinski, W.; Bruns, T.; Elster, C. Calibration of accelerometers: Determination of amplitude and phase response upon shock excitation. Meas. Sci. Technol. 2006, 17, 1888. [Google Scholar] [CrossRef]

- Brandt, A. Noise and Vibration Analysis: Signal Analysis and Experimental Procedures; John Wiley & Sons: London, UK, 2011. [Google Scholar]

- Prabhu, K.M. Window Functions and Their Applications in Signal Processing; CRC Press: Boca Raton, FL, USA, 2013; Chapter 3. [Google Scholar]

- Mercer, C. Acceleration, velocity and displacement spectra-omega arithmetic. Prosig Signal Process. Tutor. 2006, 1, 1–8. [Google Scholar]

| Feature/Attribute | Specification |

|---|---|

| Model | 65L-100 |

| Sensitivity | 102.5 mV/ms−2 |

| Number of axes | 3 |

| Mass | 5 g |

| Dimensions | (10 × 10 ×10) mm |

| Dynamic range | ±50 g |

| Measurement uncertainty | ±5% |

| Temperature range | −53 °C to +125 °C |

| Mounting | Adhesive or M2.5 thread |

| Frequency response | 1 Hz to 6000 Hz |

| Attribute | Setting |

|---|---|

| Spindle speed | 600 RPM |

| Feed rate | 0.15 mm/rev |

| Cut length | 100 mm |

| Material | EN 24 steel |

| Diameter | 38 mm |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bointon, P.; Todhunter, L.; Clare, A.; Leach, R. Performance Verification of a Flexible Vibration Monitoring System. Machines 2020, 8, 3. https://doi.org/10.3390/machines8010003

Bointon P, Todhunter L, Clare A, Leach R. Performance Verification of a Flexible Vibration Monitoring System. Machines. 2020; 8(1):3. https://doi.org/10.3390/machines8010003

Chicago/Turabian StyleBointon, Patrick, Luke Todhunter, Adam Clare, and Richard Leach. 2020. "Performance Verification of a Flexible Vibration Monitoring System" Machines 8, no. 1: 3. https://doi.org/10.3390/machines8010003

APA StyleBointon, P., Todhunter, L., Clare, A., & Leach, R. (2020). Performance Verification of a Flexible Vibration Monitoring System. Machines, 8(1), 3. https://doi.org/10.3390/machines8010003