Double Lighting Machine Vision System to Monitor Harvested Paddy Grain Quality during Head-Feeding Combine Harvester Operation

Abstract

:1. Introduction

| Type of Conditions | Harvesting Grain Condition | Necessary Adjustment of Combine Harvester Setting |

|---|---|---|

| Unwanted material | Many long rachis branches | Increased travelling speed |

| Stronger wind blower | ||

| Narrower opening sieve | ||

| Narrower dust ejection | ||

| Large amount of grass and leaves | Stronger wind blower | |

| Narrower opening sieve | ||

| Shallower threshing depth | ||

| Many stem | Narrower opening sieve | |

| Damage Grain | Large amount of brown and cracked rice | Decreased travelling speed |

| Weaker wind blower | ||

| Wider opening sieve |

2. The Proposed Machine Vision System for Monitoring Harvested Grain Quality

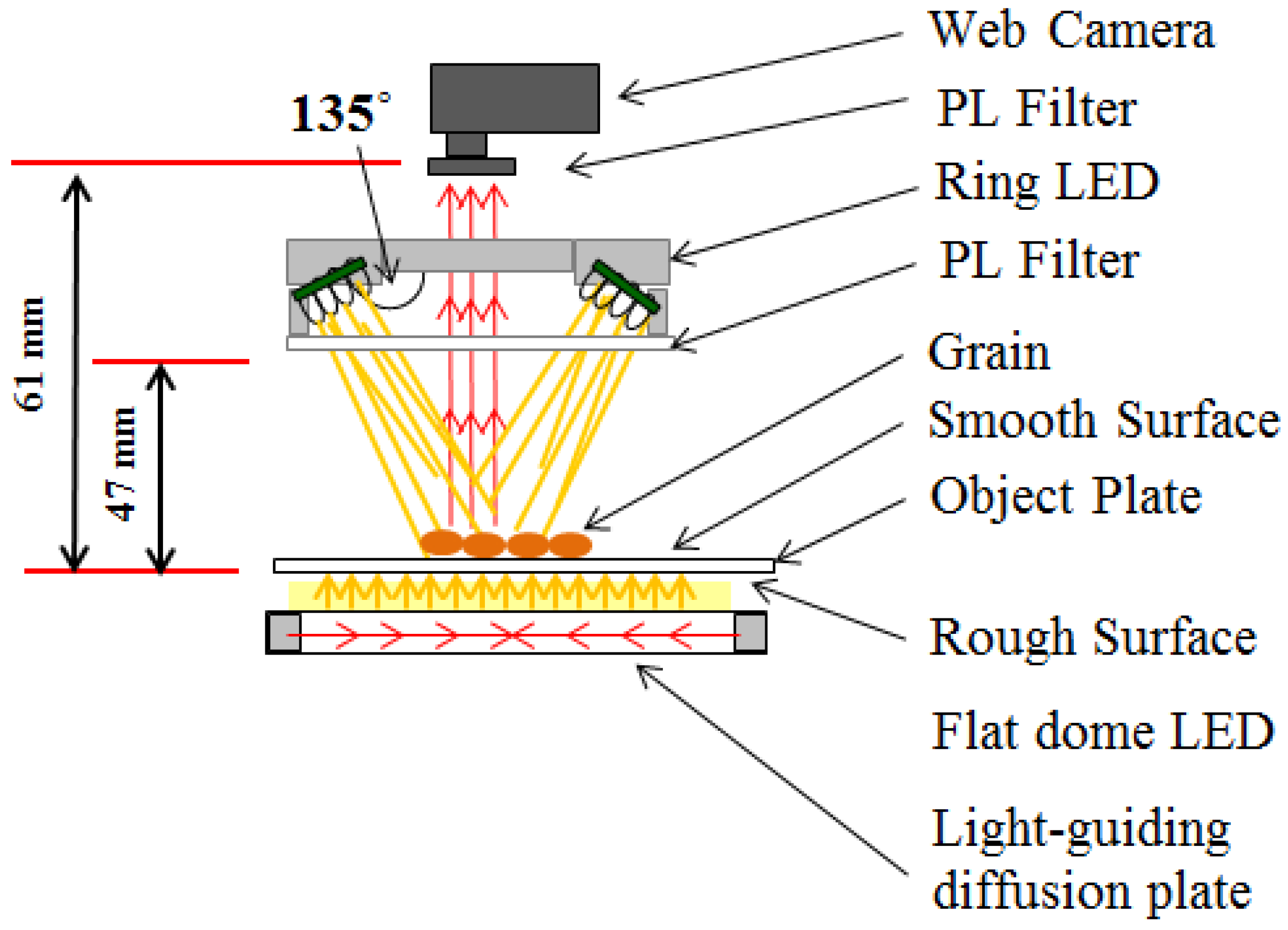

2.1. Design of Double Lighting System

2.1.1. Frontlight System

2.1.2. Backlight System

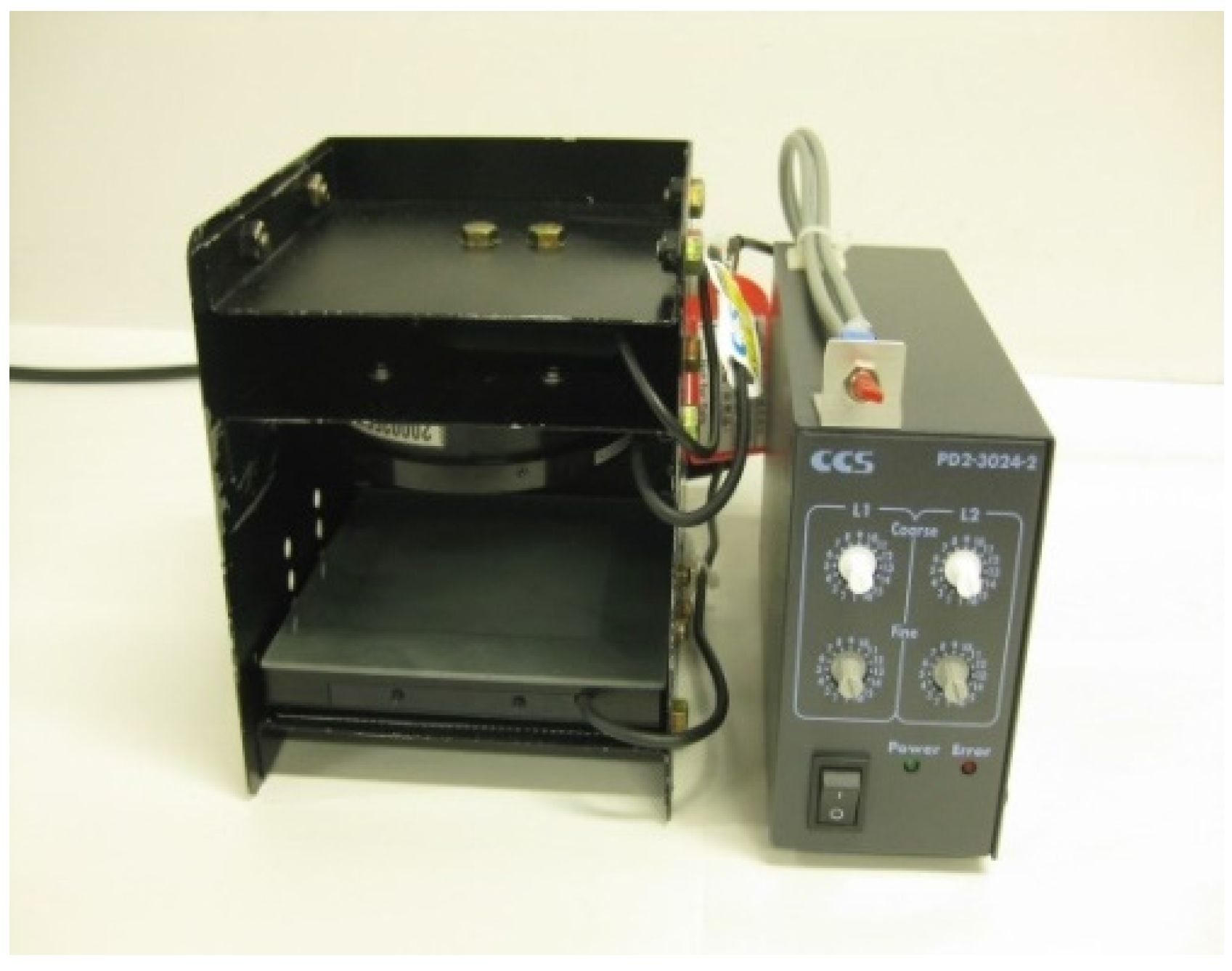

2.2. Overall Setup of Double Lighting System

2.2.1. Design of Whole System

2.2.2. Object Plate

2.2.3. Camera

3. Materials and Method

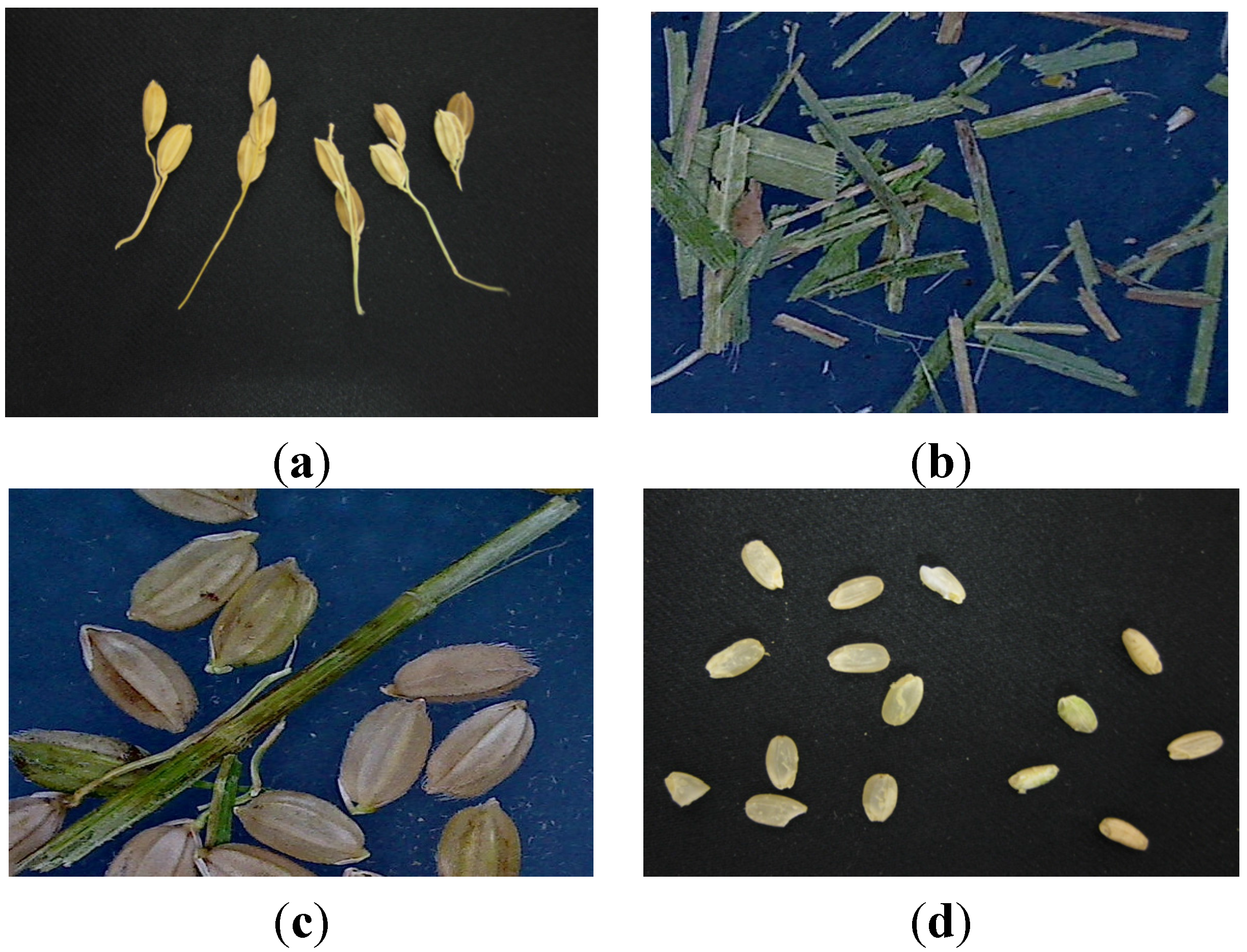

3.1. Target Materials

3.2. Image Acquisition Method

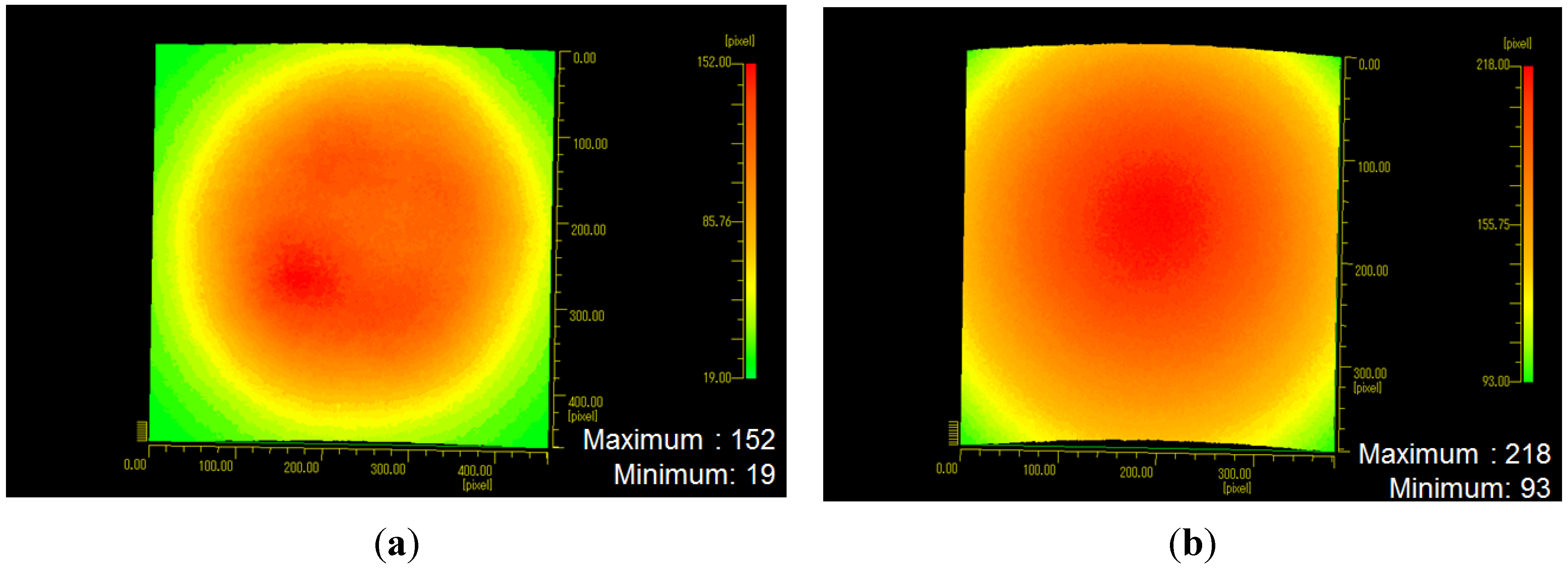

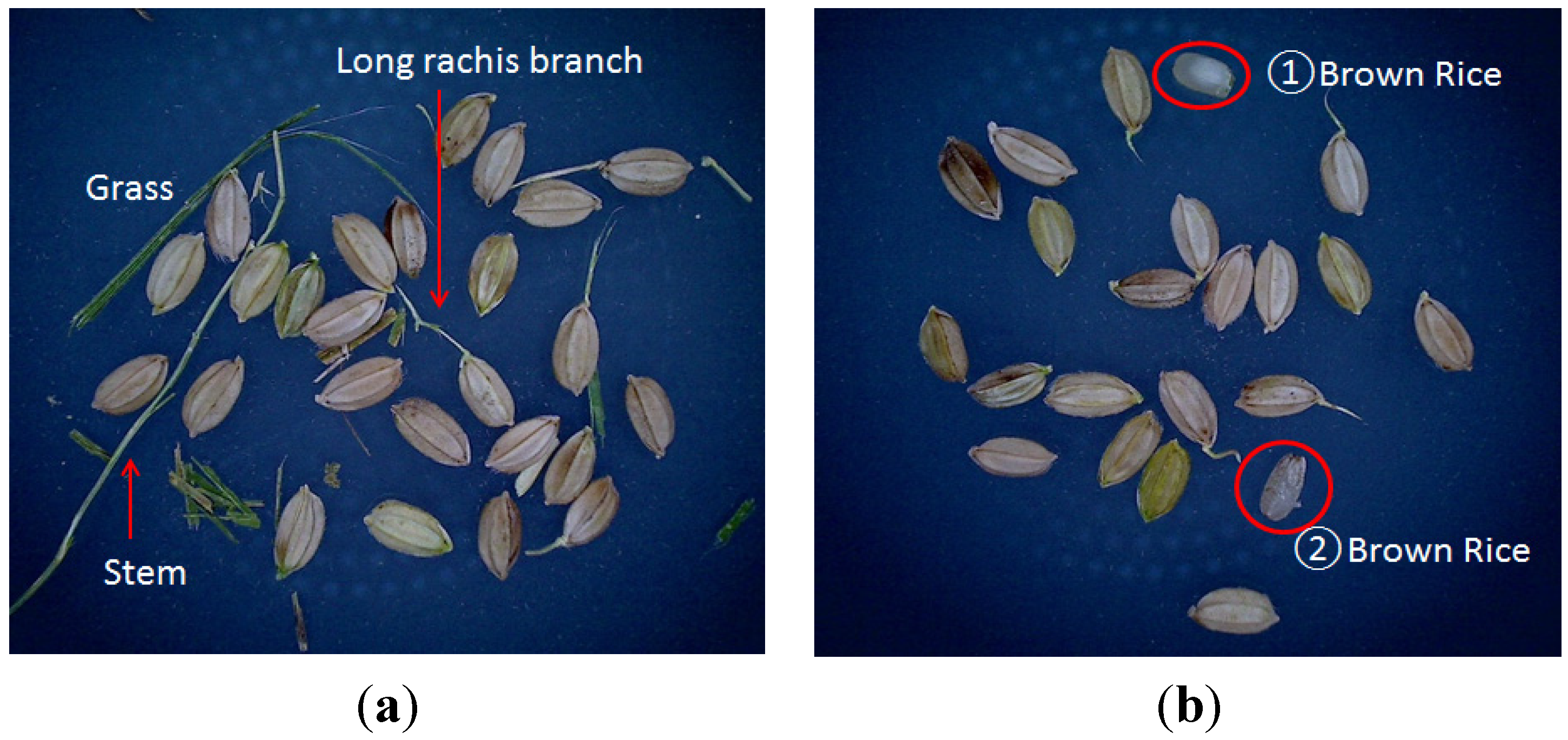

3.2.1. Frontlight System Performance

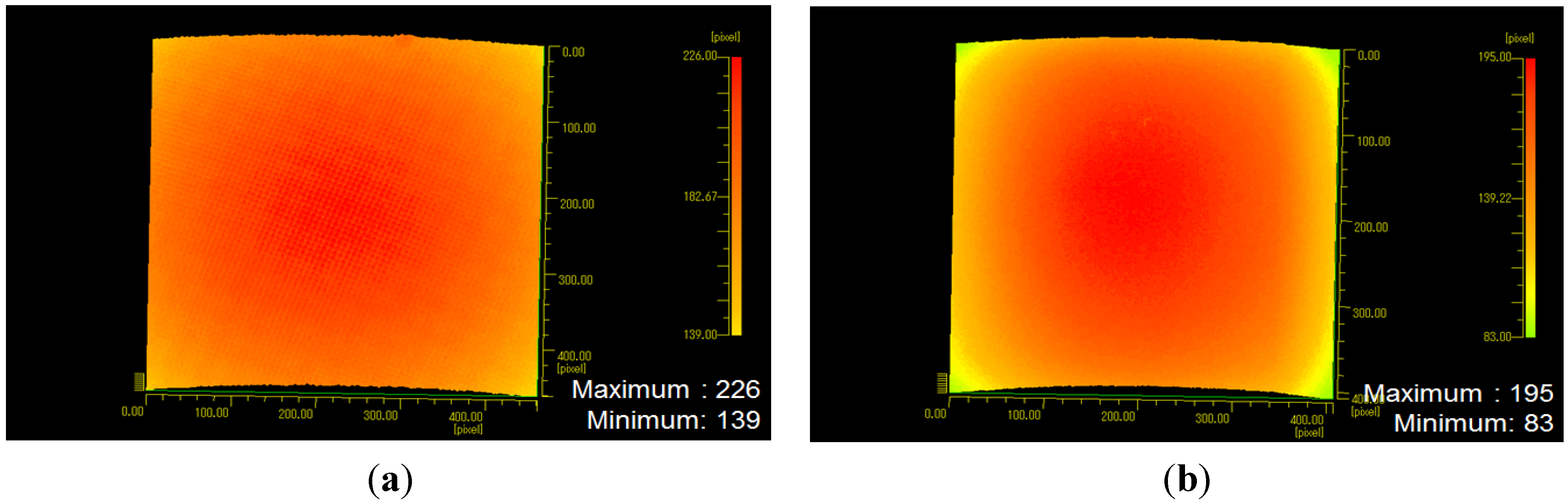

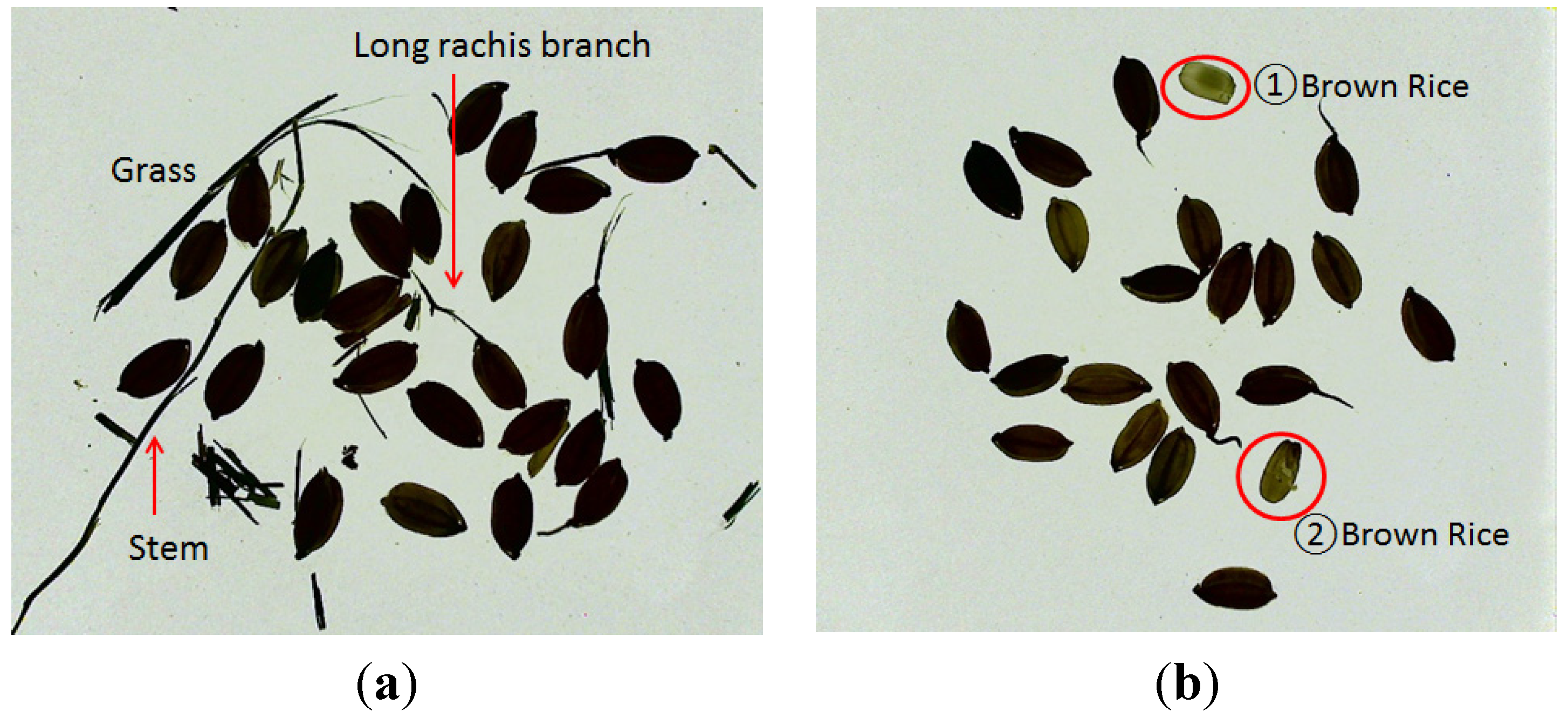

3.2.2. Comparison of Frontlight and Backlight Image Performance

4. Results and Discussion

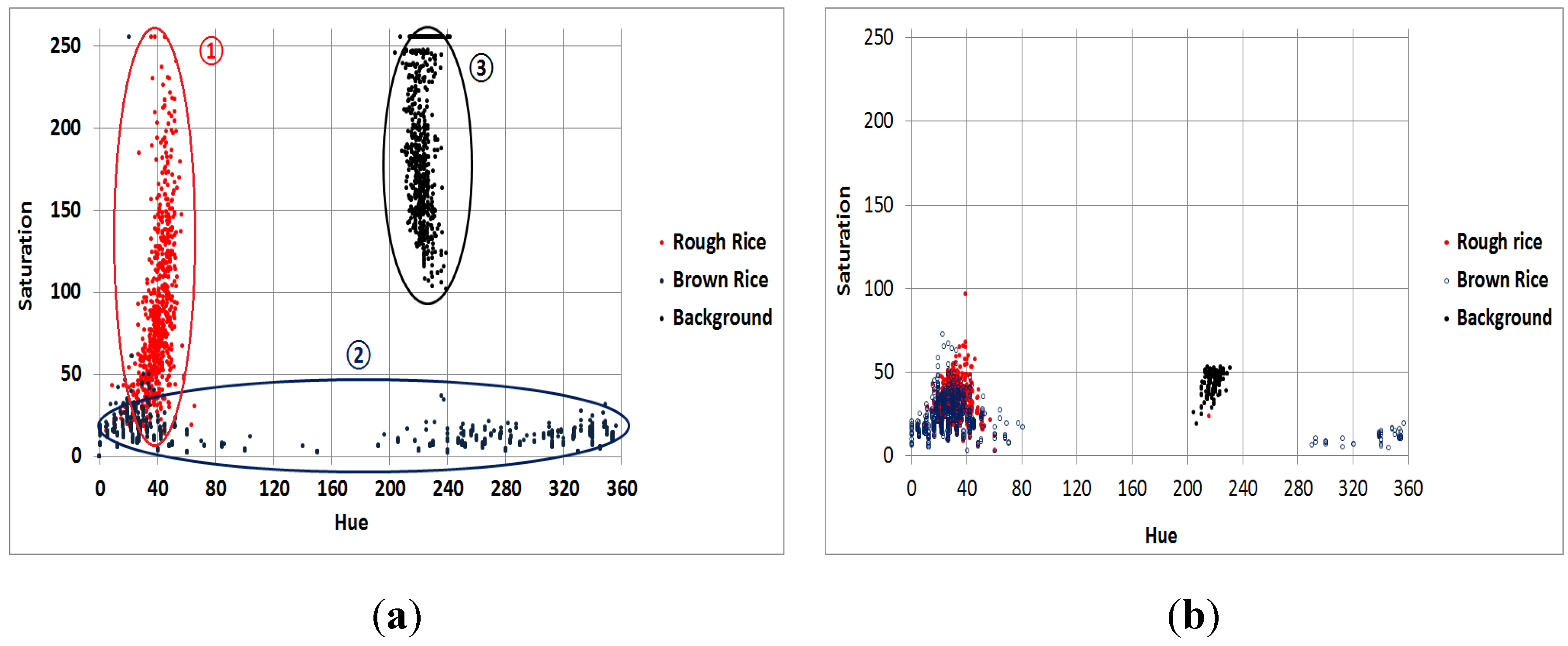

4.1. Result of Frontlight System Performance

4.2. Comparison of Frontlight and Backlight Image Performance

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Reyns, P.; Spaepen, P.; de Baerdemaeker, J. Site-specific Relationship between Grain Quality and Yield. Precis. Agric. 2000, 2, 231–246. [Google Scholar] [CrossRef]

- Bramble, T.; Herrman, T.J.; Loughin, T.; Dowell, F. Single Kernel Protein Variance Structure in Commercial Wheat Fields in Western Kansas. Crop Sci. 2002, 42, 1488–1492. [Google Scholar] [CrossRef]

- Maertens, K.; Reyns, P.; de Baerdemaeker, J. On-line Measurement of Grain Quality with NIR Technology. Trans. ASAE 2004, 47, 1135–1140. [Google Scholar] [CrossRef]

- Paliwal, J.; Visen, N.S.; Jayas, D.S.; White, N.D.G. Cereal Grain and Dockage Identification Using Machine Vision. Biosyst. Eng. 2003, 85, 51–57. [Google Scholar] [CrossRef]

- Hobson, D.M.; Carter, R.M.; Yan, Y. Characterisation and Identification of Rice Grains through Digital Image Analysis. In Proceedings of the IEEE Instrumentation and Measurement Technology Conference, Warsaw, Poland, 1–3 May 2007; pp. 1–5.

- Liu, W.; Tao, Y.; Siebenmorgen, T.J.; Chen, H. Digital Image Analysis Method for Rapid Measurement of Rice Degree of Milling. In 1997 ASAE Annual International Meeting Technical Papers; Paper No. 973028; ASAE: St. Joseph, MI, USA, 1997. [Google Scholar]

- Lloyd, B.J.; Cnossen, A.G.; Siebenmorgen, T.J. Evaluation of Two Methods for Separating Head Rice from Brokensfor Head Rice Yield Determination. In 2000 ASAE Annual International Meeting Technical Papers; Paper No. 006074; ASAE: St. Joseph, MI, USA, 2000. [Google Scholar]

- Matsui, M. Threshing Unit of Head Feeding Type Combine. J. Jpn. Soc. Agric. Mach. 1999, 61, 45–46. [Google Scholar]

- Takahara, K.; Hayashi, S. Cleaner Control System for Head-feeding Combine Harvesters. J. Jpn. Soc. Agric. Mach. 1996, 58, 125–126. [Google Scholar]

- Bebis, G.; Egbert, D.; Sham, M. Review of Computer Vision Education. IEEE Trans. Educ. 2003, 46, 2–21. [Google Scholar] [CrossRef]

- Brosnan, T.; Sun, D.W. Improving Quality Inspection of Food Products by Computer Vision—A Review. J. Food Eng. 2004, 61, 3–16. [Google Scholar] [CrossRef]

- Shantaiya, S.; Ansari, U. Identification of Food Grains and Its Quality Using Pattern Classification. In Proceedings of the 12th IEEE International Conference (ICCT-2010), Bhubaneswar, India, 3–5 December 2010; Volume 2.

- Verma, B. Image Processing Techniques for Grading & Classification of Rice. In Proceedings of the 2010 International Conference on Computer & Communication Technology (ICCCT ’10), Allahabad, India, 17–19 September 2010; pp. 220–223.

- Yao, M.; Liu, M.; Zhen, H. Exterior Quality Inspection of Rice Based on Computer Vision. In Proceedings of the IEEE 2010 World Automation Congress (WAC), Kobe, Japan, 19–23 September 2010; pp. 369–374.

- Novini, A. Fundamentals of Machine Vision Component Selection. In Food Processing Automation II—Proceedings of the 1990 Conference Hyatt Regency; ASAE: Lexington, KY, USA, 1990; p. 60. [Google Scholar]

- Gunasekaran, S. Computer Vision Technology for Food Quality Assurance. Trends Food Sci. Technol. 1996, 7, 245–256. [Google Scholar] [CrossRef]

- CCS Inc. Flat-Dome Lights LFXS2 Series Manual; CCS Inc.: Kyoto, Japan, 2015; pp. 77–80. [Google Scholar]

- CCS Inc. Ring Lights LDR2 Series Manual; CCS Inc.: Kyoto, Japan, 2015; pp. 9–12. [Google Scholar]

- Miyamoto, M.; Kondo, N.; Ogawa, Y.; Yamamoto, K. Combine Harvester. Yanmar Co., Ltd; Kyoto University. Japan Patent No. 5,780,642, 24 July 2015. [Google Scholar]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jahari, M.; Yamamoto, K.; Miyamoto, M.; Kondo, N.; Ogawa, Y.; Suzuki, T.; Habaragamuwa, H.; Ahmad, U. Double Lighting Machine Vision System to Monitor Harvested Paddy Grain Quality during Head-Feeding Combine Harvester Operation. Machines 2015, 3, 352-363. https://doi.org/10.3390/machines3040352

Jahari M, Yamamoto K, Miyamoto M, Kondo N, Ogawa Y, Suzuki T, Habaragamuwa H, Ahmad U. Double Lighting Machine Vision System to Monitor Harvested Paddy Grain Quality during Head-Feeding Combine Harvester Operation. Machines. 2015; 3(4):352-363. https://doi.org/10.3390/machines3040352

Chicago/Turabian StyleJahari, Mahirah, Kazuya Yamamoto, Munenori Miyamoto, Naoshi Kondo, Yuichi Ogawa, Tetsuhito Suzuki, Harshana Habaragamuwa, and Usman Ahmad. 2015. "Double Lighting Machine Vision System to Monitor Harvested Paddy Grain Quality during Head-Feeding Combine Harvester Operation" Machines 3, no. 4: 352-363. https://doi.org/10.3390/machines3040352

APA StyleJahari, M., Yamamoto, K., Miyamoto, M., Kondo, N., Ogawa, Y., Suzuki, T., Habaragamuwa, H., & Ahmad, U. (2015). Double Lighting Machine Vision System to Monitor Harvested Paddy Grain Quality during Head-Feeding Combine Harvester Operation. Machines, 3(4), 352-363. https://doi.org/10.3390/machines3040352