Robotized Surface Mounting of Permanent Magnets

Abstract

:1. Introduction

2. Experimental Section

2.1. Method

2.1.1. PM Assembly Force Experimental Setup

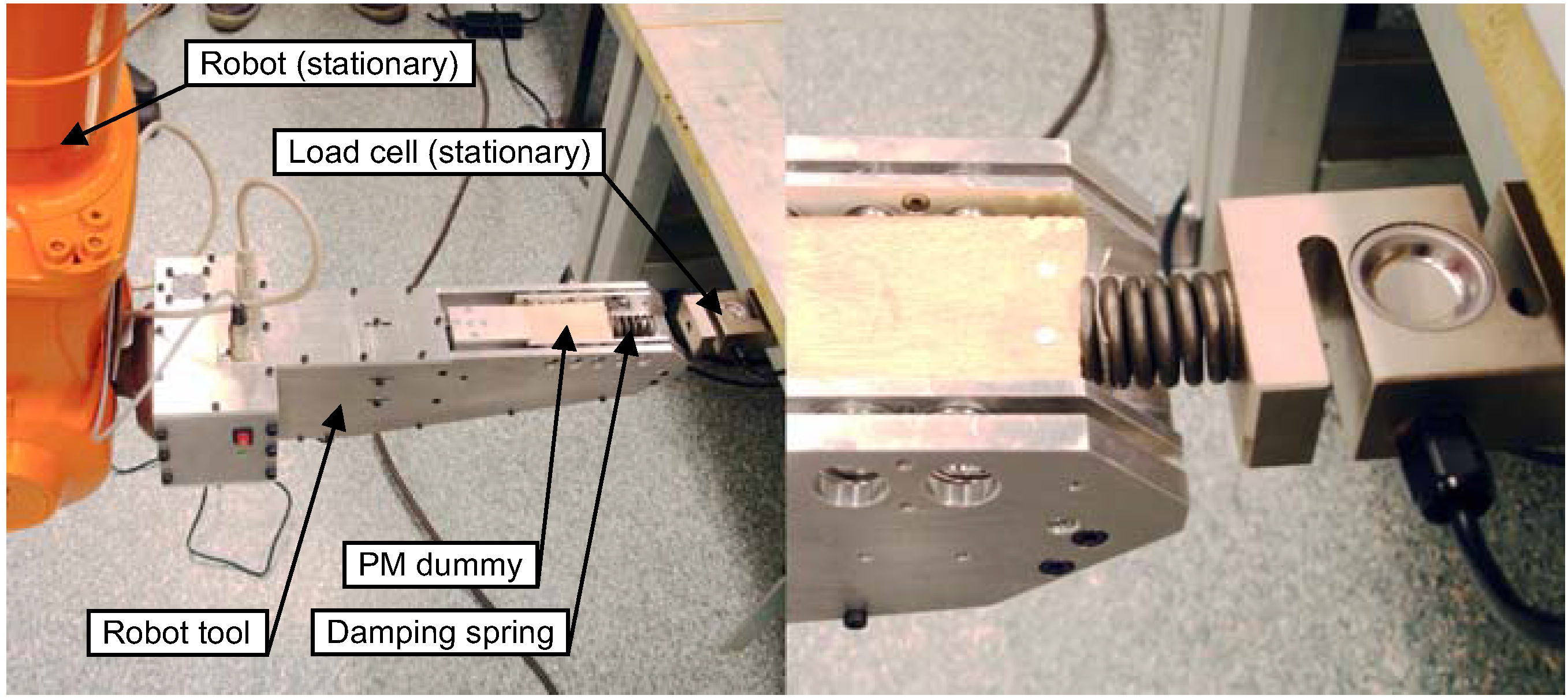

2.1.2. Robot Tool Assembly Force Experimental Setup

2.1.3. Economic Calculations

2.2. Requirements on the Automation

- In total, 848 PMs should be mounted on the eight sides of the translator, with a shifted PM polarization direction for every PM row.

- The required force for sliding one PM into the translator frame was determined to be about 100 N.

- Mechanical collateral fixation of the PMs on the translator sides is required.

- Damaging the PMs during the assembly must be avoided.

- Strong magnetic forces between the PMs, between the PMs and the translator and between the PMs and other equipment must be handled.

- Separation of individual PMs from delivered stacks, with PMs separated by wood plates, is required.

- Simple, robust and not unnecessarily expensive equipment is desired.

- A flexible automation method that can be adapted for other rotor designs is desired.

2.3. Robot Cell and Equipment Design

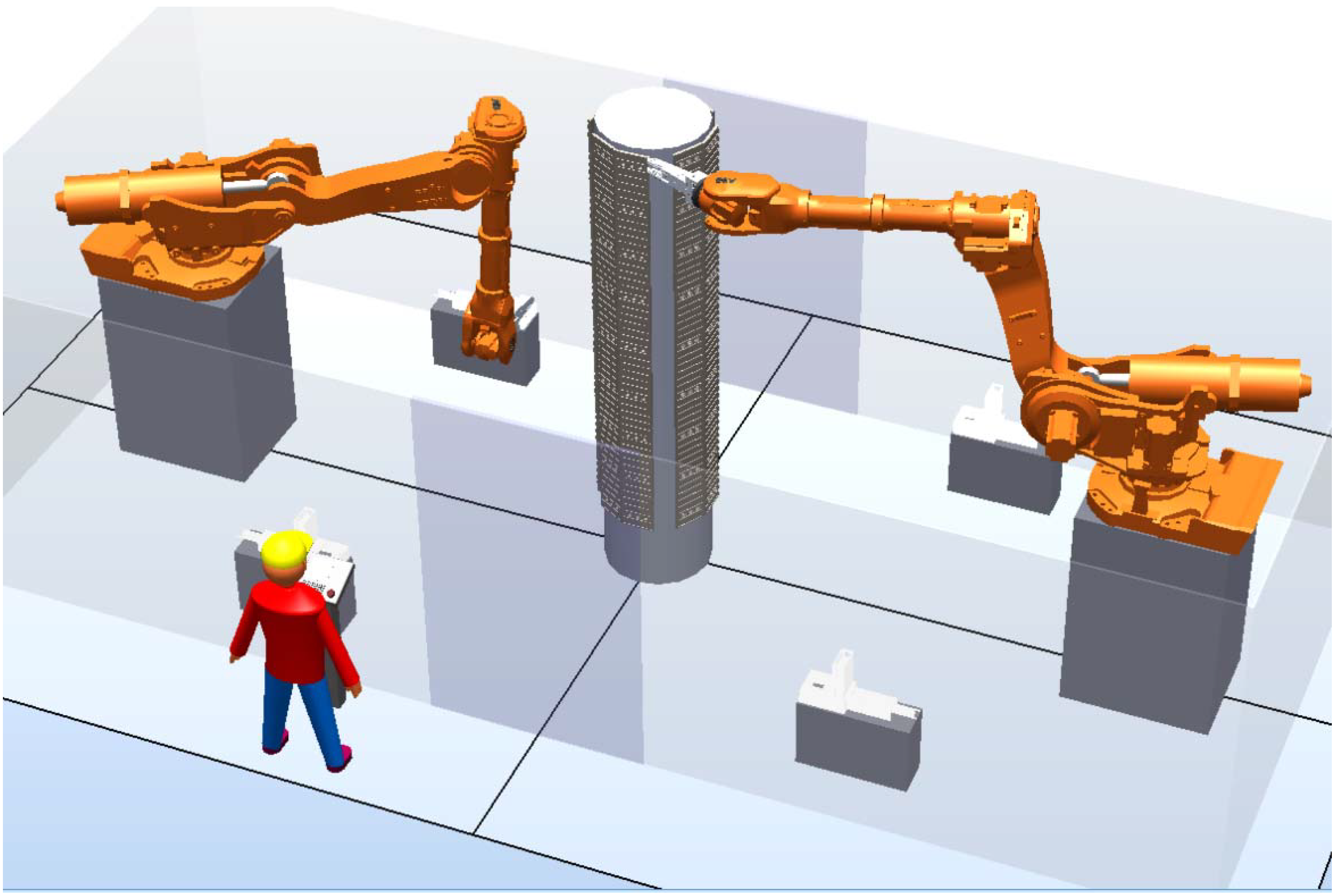

2.3.1. Robot Cell Layout

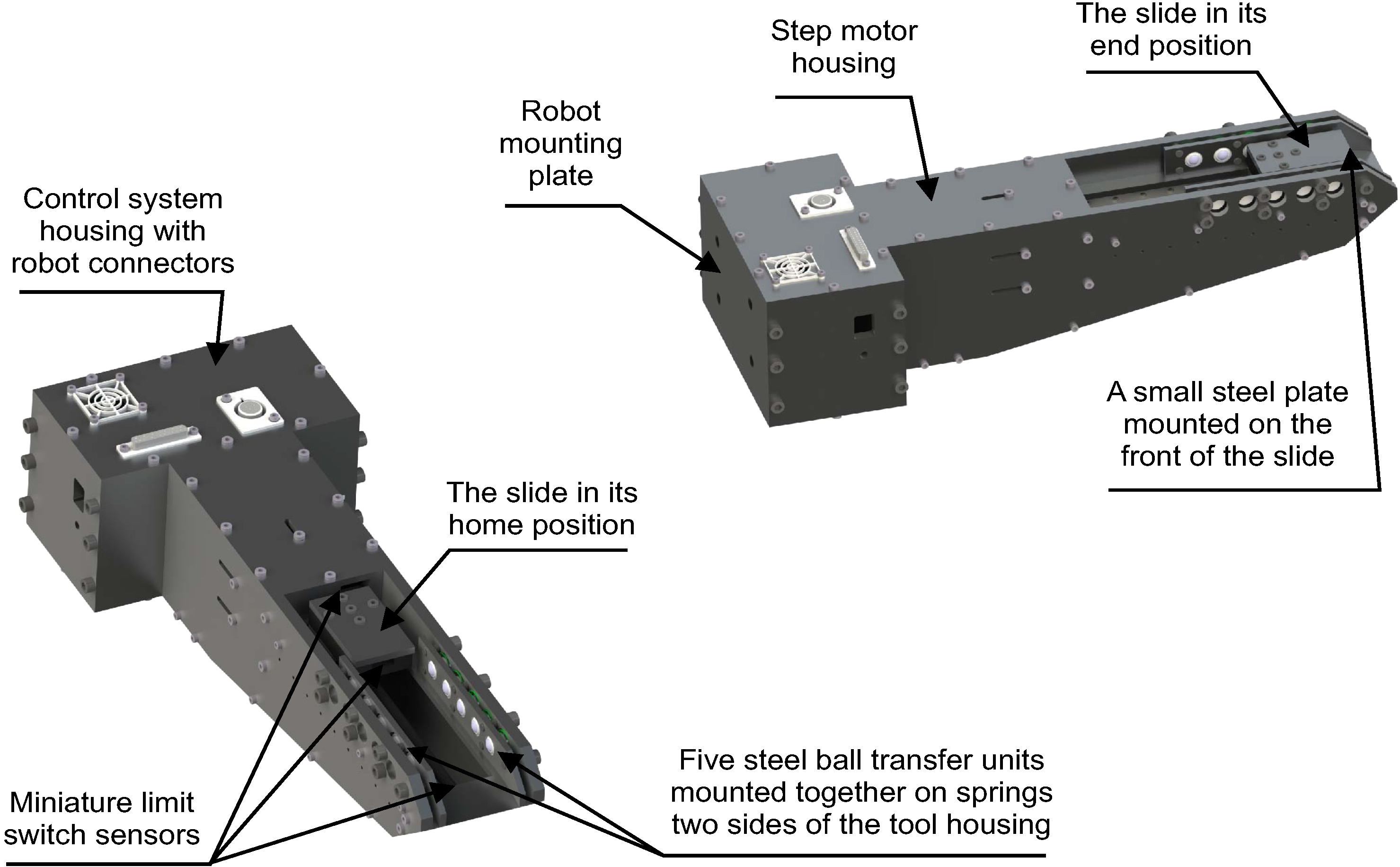

2.3.2. PM Mounting Robot Tool Design

2.3.3. PM Delivery Station Design

2.3.4. PM Mounting Frame Design

3. Results and Discussion

3.1. Experimental Results

3.2. Economic Analysis

| Parameter | Value |

|---|---|

| Robotized assembly investment cost units per cell | |

| Industrial robots including pedestals | 150,000 EUR |

| PM mounting robot tools | 20,000 EUR |

| PM delivery stations | 20,000 EUR |

| Cell enclosure, safety, control and installation | 10,000 EUR |

| Robotized assembly running cost parameters per cell | |

| Number of personnel | 1 |

| Personnel cost | 30 EUR/h |

| Factory floor space required | 36 m2 |

| Power consumption | 20 kW |

| Yearly maintenance | 10,000 EUR |

| Investment economical lifetime | 5 years |

| Investment discount rate | 4% |

| Investment rest value | 40,000 EUR |

| Manual assembly running cost parameters per station | |

| Number of personnel | 4 |

| Personnel cost | 20 EUR/h |

| Factory floor space required | 16 m2 |

| Shared running cost parameters | |

| Factory floor space cost | 0.1 EUR/m2/h |

| Electricity cost | 0.1 EUR/kWh |

| Yearly production time | 4000 h |

3.3. Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Haring, T.; Forsman, K.; Huhtanen, T.; Zawadzki, M. Direct drive – opening a new era in many applications. In Conference Record of the 2003 Annual Pulp and Paper Industry Technical Conference, Charleston, USA, 16–20 June 2003; pp. 171–179.

- Hsieh, M.F.; Hsu, Y.C.; Dorrell, D.G. Design of large-power surface-mounted permanent-magnet motors using postassembly magnetization. IEEE Trans. Ind. Electron. 2010, 57, 3376–3384. [Google Scholar]

- Itagaki, T.; Hiwasa, H.; Haga, K. Design and manufacturing technology of Fuji Electric’s large-capacity, air-cooled turbine generator. Chall. Power Eng. Environ. 2007, 1–2, 395–399. [Google Scholar]

- Uchida, H.; Amemiya, Y. FANUC—The planning and development of a highly advanced robotized production system for servo motors. Assem. Autom. 1998, 18, 270–274. [Google Scholar]

- Franke, J.; Tremel, J.; Kühl, A. Innovative developments for automated magnet handling and bonding of rare earth magnets. In Proceedings of the 2011 IEEE International Symposium on Assembly and Manufacturing ISAM, Tampere, Finland, 25–27 May 2011; pp. 1–5.

- Joseph, E.; Tremel, J.; Hofmann, B.; Meyer, A.; Franke, J.; Eschrich, S. Automated magnet assembly for large PM synchronous machines with integrated permanent magnets. In Proceedings of the 3rd International Electric Drives Production Conference, Nuremberg, German, 29–30 October 2013; pp. 1–6.

- Tremel, J.; Hofmann, B.; Risch, F. Handling and fixation of permanent magnets. Adv. Mater. Res. 2013, 769, 3–10. [Google Scholar]

- Sugimori, Y.; Kusunoki, K.; Cho, F.; Uchikawa, S. Toyota production system and Kanban system materialization of just-in-time and respect-for-human system. Int. J. Prod. Res. 1977, 15, 553–564. [Google Scholar]

- Hong, Y.; Hultman, E.; Castellucci, V.; Ekergård, B.; Sjökvist, L.; Soman, D.E.; Krishna, R.; Haikonen, K.; Baudoin, A.; Lindblad, L.; et al. Status update of the wave energy research at Uppsala University. In Presented at the 10th European Wave and Tidal Energy Conference (EWTEC), Aalborg, Denmark, 2–5 September 2013.

- Egaña, I.; Elosegui, I.; Rico, A.G.; Echeverrfa, J.M.; Martinez-Iturralde, M. Flat magnets in surface-mounted permanent magnet machines: Influence and design. In Proceedings of the International Symposium on Power Electronics, Electrical Drives, Automation and Motion (SPEEDAM), Ischia, Italy, 11–13 June 2008; pp. 697–701.

- Hultman, E.; Leijon, M. Utilizing cable winding and industrial robots to facilitate the manufacturing of electric machines. Robot. Comput. Integr. Manuf. 2013, 29, 246–256. [Google Scholar]

- Hultman, E.; Ekergård, B.; Leijon, M. Electromagnetic, mechanical and manufacturing properties for cable wound direct-drive PM linear generators for offshore environments. In Presented at the 31st International Conference on Ocean, Offshore and Arctic Engineering, Rio de Janeiro, Brazil, 1–6 July 2012.

- Aleksashkin, A.; Mikkola, A. Literature Review on Permanent Magnet Generators Design and Dynamic Behaviour; Research Report 77; Lappeenranta University of Technology: Lappeenranta, Finland, 2008. [Google Scholar]

- Binder, A.; Schneider, T.; Klohr, M. Fixation of buried and surface-mounted magnets in high-speed permanent-magnet synchronous machines. IEEE Trans. Ind. Appl. 2006, 42, 1031–1037. [Google Scholar]

- Hultman, E.; Leijon, M. Six-degrees-of-freedom (6-DOF) work object positional calibration using a robot-held proximity sensor. Machines 2013, 1, 63–80. [Google Scholar]

- Chen, S.; Li, Y.; Ming Kwok, N. Active vision in robotic systems: A survey of recent developments. Int. J. Robot. Res. 2012, 30, 1343–1377. [Google Scholar]

- Okumura, S.; Take, N.; Okino, N. Error prevention in robotic assembly tasks by a machine vision and statistical pattern recognition method. Int. J. Prod. Res. 2005, 43, 1397–1410. [Google Scholar]

© 2014 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hultman, E.; Salar, D.; Leijon, M. Robotized Surface Mounting of Permanent Magnets. Machines 2014, 2, 219-232. https://doi.org/10.3390/machines2040219

Hultman E, Salar D, Leijon M. Robotized Surface Mounting of Permanent Magnets. Machines. 2014; 2(4):219-232. https://doi.org/10.3390/machines2040219

Chicago/Turabian StyleHultman, Erik, Dana Salar, and Mats Leijon. 2014. "Robotized Surface Mounting of Permanent Magnets" Machines 2, no. 4: 219-232. https://doi.org/10.3390/machines2040219

APA StyleHultman, E., Salar, D., & Leijon, M. (2014). Robotized Surface Mounting of Permanent Magnets. Machines, 2(4), 219-232. https://doi.org/10.3390/machines2040219