Tool Wear Detection in Milling Using Convolutional Neural Networks and Audible Sound Signals

Abstract

1. Introduction

1.1. Background Research

1.2. Related Work and Novelty

- -

- Introduction and problem context.

- -

- Methodology and experimental setup.

- -

- Results and discussion.

- -

- Conclusions and future research directions.

2. Methodology

- -

- Condition 1_Idle: Machine running without any cutting operations.

- -

- Condition 2_Fresh tool: Cutting operation performed using a fresh cutting tool with 0 flank wear.

- -

- Condition 3_Moderate tool: Cutting operation performed using a moderately worn tool (VB = 0.1–0.2 mm).

- -

- Condition 4_Worn tool: Cutting operation performed using a worn tool (VB > 0.3 mm).

| Condition | 520 rpm | 635 rpm | Total | Duration (s) |

|---|---|---|---|---|

| Idle | 175 | 172 | 347 | 10 |

| Fresh tool | 200 | 181 | 381 | 10 |

| Moderate tool | 188 | 188 | 376 | 10 |

| Worn tool | 181 | 203 | 384 | 10 |

| Total | 744 | 744 | 1488 | 4.13 h |

2.1. Preprocessing and Feature Extraction

2.2. Convolutional Neural Network (CNN)

3. Results and Discussion

4. Conclusions and Future Work

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, G.; Shang, X.; Sun, L.; Fu, B.; Yang, L.; Zhou, H. Application of audible sound signals in tool wear monitoring: A review. Adv. Manuf. Sci. Technol. 2025, 5, 2025003. [Google Scholar] [CrossRef]

- Mamedov, A.; Dinc, A.; Guler, M.A.; Demiral, M.; Otkur, M. Tool wear in micromilling: A review. Int. J. Adv. Manuf. Technol. 2025, 137, 47–65. [Google Scholar] [CrossRef]

- Pimenov, D.Y.; Kumar Gupta, M.; da Silva, L.R.; Kiran, M.; Khanna, N.; Krolczyk, G.M. Application of measurement systems in tool condition monitoring of Milling: A review of measurement science approach. Measurement 2022, 199, 111503. [Google Scholar] [CrossRef]

- Gururaja, S.; Singh, K.K. Development of smart manufacturing framework for micromilling of thin-walled Ti6Al4V. Mach. Sci. Technol. 2024, 28, 459–488. [Google Scholar] [CrossRef]

- Abhilash, P.M.; Chakradhar, D. Performance monitoring and failure prediction system for wire electric discharge machining process through multiple sensor signals. Mach. Sci. Technol. 2022, 26, 245–275. [Google Scholar] [CrossRef]

- Wegener, K.; Bleicher, F.; Heisel, U.; Hoffmeister, H.-W.; Möhring, H.-C. Noise and vibrations in machine tools. CIRP Ann. 2021, 70, 611–633. [Google Scholar] [CrossRef]

- Unal, P.; Deveci, B.U.; Ozbayoğlu, A.M. A Review: Sensors Used in Tool Wear Monitoring and Prediction. In Lecture Notes in Computer Science; Springer: Cham, Switzerland, 2022; Volume 13475. [Google Scholar] [CrossRef]

- Li, Z.; Liu, R.; Wu, D. Data-driven smart manufacturing: Tool wear monitoring with audio signals and machine learning. J. Manuf. Process. 2019, 48, 66–76. [Google Scholar] [CrossRef]

- Zafar, T.; Kamal, K.; Mathavan, S.; Hussain, G.; Alkahtani, M.; Alqahtani, F.M.; Aboudaif, M.K. A Hybrid Approach for Noise Reduction in Acoustic Signal of Machining Process Using Neural Networks and ARMA Model. Sensors 2021, 21, 8023. [Google Scholar] [CrossRef]

- Ai, C.S.; Sun, Y.J.; He, G.W.; Ze, X.B.; Li, W.; Mao, K. The milling tool wear monitoring using the acoustic spectrum. Int. J. Adv. Manuf. Technol. 2012, 61, 457–463. [Google Scholar] [CrossRef]

- Kanakasuntharam, J.; Wijethunge, A. CNN and ANN Based Tool Condition Monitoring in Gear Machining Using Audio and Vibration Signals Via Cost Effective Sensors. In Proceedings of the International Conference on Emerging Smart Computing and Informatics (ESCI), Pune, India, 5–7 March 2024; pp. 1–6. [Google Scholar] [CrossRef]

- Liu, M.K.; Tseng, Y.H.; Tran, M.Q. Tool wear monitoring and prediction based on sound signal. Int. J. Adv. Manuf. Technol. 2019, 103, 3361–3373. [Google Scholar] [CrossRef]

- Peng, C.-Y.; Raihany, U.; Kuo, S.-W.; Chen, Y.-Z. Sound Detection Monitoring Tool in CNC Milling Sounds by K-Means Clustering Algorithm. Sensors 2021, 21, 4288. [Google Scholar] [CrossRef]

- Han, S.; Mannan, N.; Stein, D.C.; Pattipati, K.R.; Bollas, G.M. Classification and regression models of audio and vibration signals for machine state monitoring in precision machining systems. J. Manuf. Syst. 2021, 61, 45–53. [Google Scholar] [CrossRef]

- Ntalampiras, S. One-shot learning for acoustic diagnosis of industrial machines. Expert Syst. Appl. 2021, 178, 114984. [Google Scholar] [CrossRef]

- Zhou, Y.; Sun, B.; Sun, W.; Lei, Z. Tool wear condition monitoring based on a two-layer angle kernel extreme learning machine using sound sensor for milling process. J. Intell. Manuf. 2022, 33, 247–258. [Google Scholar] [CrossRef]

- Liu, T.H.; Chi, J.Z.; Wu, B.L.; Chen, Y.S.; Huang, C.H.; Chu, Y.S. Design and Implementation of Machine Tool Life Inspection System Based on Sound Sensing. Sensors 2023, 23, 284. [Google Scholar] [CrossRef] [PubMed]

- Wu, M.; Yao, Z.; Verbeke, M.; Karsmakers, P.; Gorissen, B.; Reynaerts, B. Data-driven models with physical interpretability for real-time cavity profile prediction in electrochemical machining processes. Eng. Appl. Artif. Intell. 2025, 160, 111807. [Google Scholar] [CrossRef]

- Yao, Z.; Wu, M.; Qian, J.; Reynaerts, D. Intelligent discharge state detection in micro-EDM process with cost-effective radio frequency (RF) radiation: Integrating machine learning and interpretable AI. Expert Syst. Appl. 2025, 291, 128607. [Google Scholar] [CrossRef]

- Soni, N.; Kumar, A.; Patel, H. Acoustic Analysis of Cutting Tool Vibrations of Machines for Anomaly Detection and Predictive Maintenance. In Proceedings of the IEEE 11th Region 10 Humanitarian Technology Conference (R10-HTC), Rajkot, India, 16–18 October 2023; pp. 43–46. [Google Scholar] [CrossRef]

- Kumar, A.; Yadav, J. Machine learning for audio processing: From feature extraction to model selection. Mach. Learn. Models Archit. Biomed. Signal Process. 2025, 97–123. [Google Scholar] [CrossRef]

- Liang, B.; Iwnicki, S.D.; Zhao, Y. Application of power spectrum, cepstrum, higher order spectrum and neural network analyses for induction motor fault diagnosis. Mech. Syst. Signal Process. 2013, 39, 342–360. [Google Scholar] [CrossRef]

- Abdul, Z.K.; Al-Talabani, A.K. Mel Frequency Cepstral Coefficient and its Applications: A Review. IEEE Access 2022, 10, 122136–122158. [Google Scholar] [CrossRef]

- Feldman, H.A.; Kaiser, N.; Peacock, J.A. Power-spectrum analysis of three-dimensional redshift surveys. Astrophys. J. 1994, 426, 23. [Google Scholar] [CrossRef]

- Strang, G. The discrete cosine transform. SIAM Rev. 1999, 41, 135–147. [Google Scholar] [CrossRef]

- Yang, X.; Yu, H.; Jia, L. Speech Recognition of Command Words Based on Convolutional Neural Network. In Proceedings of the International Conference on Computer Information and Big Data Applications, Guiyang, China, 17–19 April 2020; pp. 465–469. [Google Scholar] [CrossRef]

- Wahyuni, E.S. Arabic speech recognition using MFCC feature extraction and ANN classification. In Proceedings of the 2nd International Conferences on Information Technology, Information Systems and Electrical Engineering, Yogyakarta, Indonesia, 1–3 November 2017; pp. 22–25. [Google Scholar] [CrossRef]

- Hasan, R.; Hasan, M.; Hossein, Z. How many Mel-frequency cepstral coefficients to be utilized in speech recognition? A study with the Bengali language. J. Eng. 2021, 12, 817–827. [Google Scholar] [CrossRef]

- O’Shaugynessy, D. Speech Communications: Human and Machine; Wiley-IEEE Press: Hoboken, NJ, USA, 2000; ISBN 978-0-780-33449-6. [Google Scholar]

- Rawat, W.; Wang, Z. Deep Convolutional Neural Networks for Image Classification: A Comprehensive Review. Neural Comput. 2017, 29, 2352–2449. [Google Scholar] [CrossRef]

- Krizhevsky, A.; Sutskever, I.; Hinton, G.E. ImageNet classification with deep convolutional neural networks. Adv. Neural Inf. Process. Syst. 2012, 25, 1097–1105. [Google Scholar] [CrossRef]

- Abdel-Hamid, O.; Mohamed, A.R.; Jiang, H.; Deng, L.; Penn, G.; Yu, D. Convolutional neural networks for speech recognition. IEEE/ACM Trans. Audio Speech Lang. Process. 2014, 22, 1533–1545. [Google Scholar] [CrossRef]

- Piczak, K.J. Environmental sound classification with convolutional neural networks. In Proceedings of the IEEE 25th International Workshop on Machine Learning for Signal Processing, Boston, MA, USA, 17–20 September 2015; pp. 1–6. [Google Scholar] [CrossRef]

- Sokolova, M.; Lapalme, G. A systematic analysis of performance measures for classification tasks. Inf. Process. Manag. 2009, 45, 427–437. [Google Scholar] [CrossRef]

| Hyper Parameter | Value |

|---|---|

| Optimizer | Adam |

| Learning rate | 0.0001 |

| Loss function | Categorical cross-entropy |

| Epoch | 30 |

| Batch Size | 16 |

| Early Stopping patience | 5 |

| Train/Val/Test Split | 80%/10%/10% |

| Scaler | Standard Scaler |

| Evaluation metric | Accuracy |

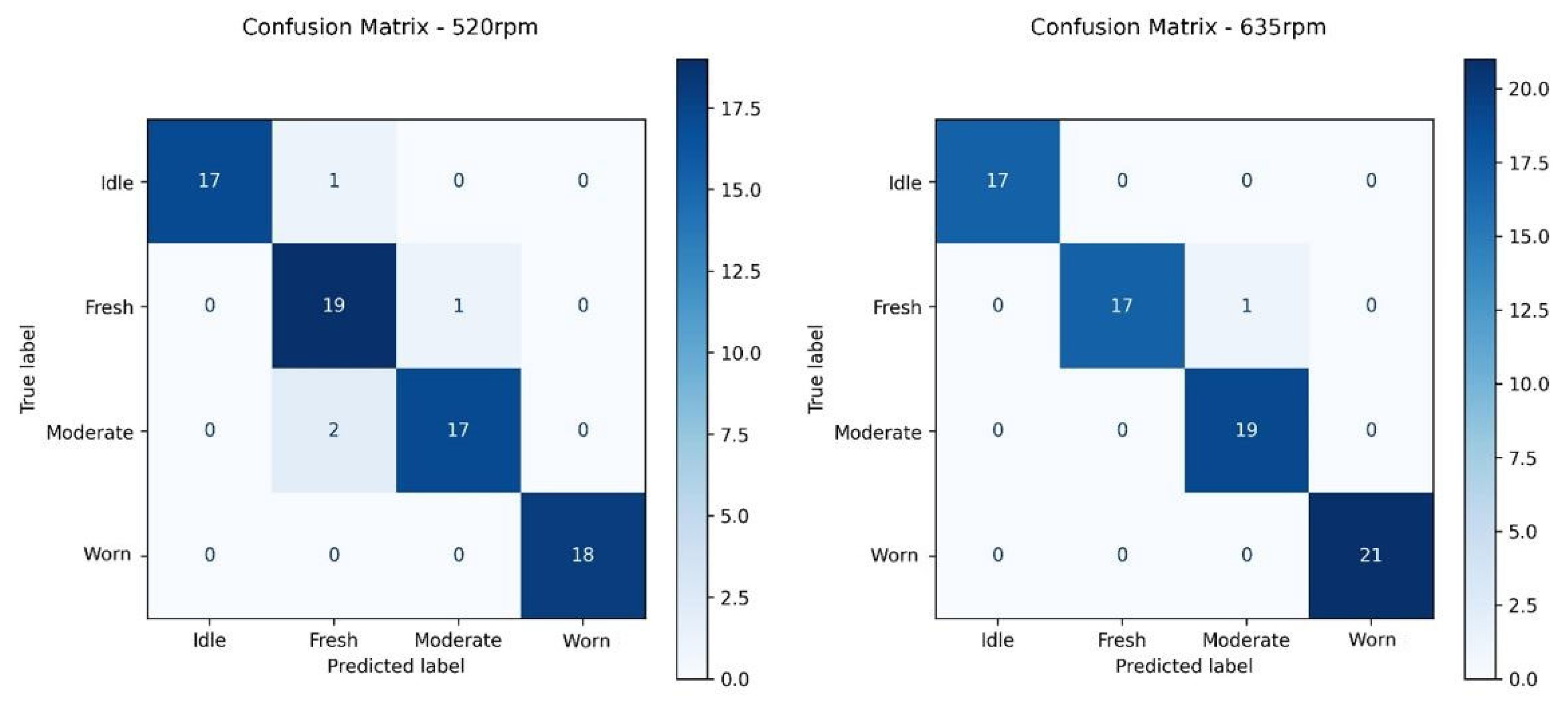

| 520 rpm | 635 rpm | |||||

|---|---|---|---|---|---|---|

| Precision | Recall | F1-Score | Precision | Recall | F1-Score | |

| Idle | 1.00 | 0.94 | 0.97 | 1.00 | 1.00 | 1.00 |

| Fresh | 0.86 | 0.95 | 0.90 | 1.00 | 0.94 | 0.97 |

| Moderate | 0.94 | 0.89 | 0.92 | 0.95 | 1.00 | 0.97 |

| Worn | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2026 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.

Share and Cite

Turan, H.I.; Mamedov, A. Tool Wear Detection in Milling Using Convolutional Neural Networks and Audible Sound Signals. Machines 2026, 14, 59. https://doi.org/10.3390/machines14010059

Turan HI, Mamedov A. Tool Wear Detection in Milling Using Convolutional Neural Networks and Audible Sound Signals. Machines. 2026; 14(1):59. https://doi.org/10.3390/machines14010059

Chicago/Turabian StyleTuran, Halil Ibrahim, and Ali Mamedov. 2026. "Tool Wear Detection in Milling Using Convolutional Neural Networks and Audible Sound Signals" Machines 14, no. 1: 59. https://doi.org/10.3390/machines14010059

APA StyleTuran, H. I., & Mamedov, A. (2026). Tool Wear Detection in Milling Using Convolutional Neural Networks and Audible Sound Signals. Machines, 14(1), 59. https://doi.org/10.3390/machines14010059