1. Introduction

The thermal management of high-power density electric machines is an important aspect of enhancing their operating life and efficiency [

1]. Conventionally adopted thermal management strategies include indirect liquid cooling techniques, which lead to increased thermal resistance and a reduced heat dissipation rate between the targeted component and the coolant. Therefore, commercially adopted indirect liquid cooling techniques fail to achieve efficient thermal management in high-energy-density electric machines [

2]. To overcome the limitations of conventional cooling methods, direct liquid cooling is emerging as an advanced thermal management strategy for high-flux-density components. There are several approaches for direct liquid cooling, such as liquid impingement cooling, liquid spray cooling, liquid jet cooling, liquid pool cooling, and microchannel cooling [

3,

4,

5,

6]. Spray cooling is a promising thermal management technique that provides the benefits of low thermal resistance and enhanced heat transfer efficiency compared to other direct liquid cooling techniques [

7]. In recent times, spray cooling has been researched widely as a potential emerging cooling technique for the thermal management of next-generation electric machines [

8].

Zhao et al. have investigated the effects of spray height, nozzle type, surface area, and inlet pressure on the heat transfer performance of heating plates using spray cooling [

9]. Yakut et al. have investigated the thermal performance of heating elements with electrospray under variations in flow rate, voltage, and nozzle length and diameter [

10]. Tao et al. have analyzed the heat transfer characteristics of water-based spray cooling based on various spray heights, temperatures, and flow rates for the thermal management of high-power devices [

11]. Su et al. have concluded that the spray angle of 55° and coolant flow rate of 9.44 kg/s depict the enhanced performance for spray cooling [

12]. Jiang et al. have developed a spray cooling module that maintains the maximum temperature difference of the heat source within 6.5 °C [

13]. Zhao et al. have achieved a heat transfer coefficient of 168.4 kW/m

2-K for an electronic chip with a spray cooling system [

14]. Bao et al. have investigated the thermal and flow performances of nozzle spray cooling for thermal management of data center chips [

15]. Kansy et al. have evaluated the effect of spray height, nozzle inclination, and pressure on heat dissipation rate for nozzle types of flat jet, full cone, and hollow cone [

16]. Bulut et al. have numerically investigated the thermal performance of surface temperature, heat transfer rate, and heat transfer area for spray cooling based on single and multi-nozzles under various factors of spray height, flow rate, and spray angle [

17]. Tan et al. have studied the thermal behavior of a copper plate heat source based on spray cooling using six swirl-jet nozzles [

18]. Bandaru et al. have designed the multi-nozzle configuration in a 2 × 3 matrix for cooling of heat sources at various angles [

19].

The next generation of electric vehicles are incorporated with advanced traction motors with high power density to improve the efficiency of electric drive trains [

20]. These high-power-density traction motors dissipate the heat in magnitude up to kilowatts depending on operating conditions [

21,

22,

23]. Therefore, these advanced traction motors demand an effective thermal management strategy to enable safe driving and enhanced efficiency. The spray cooling is a potential solution for thermal management of such high-power density traction motors [

24]. Gioia et al. have achieved the maximum power density of 7.19 kW/L for an electric motor enabled with ATF oil spray through holes in an annular ring [

25]. Sharma et al. have optimized the geometrical factors, rotational speed, and flow rate to enhance the oil flow circulation through holes in the shaft for thermal management of the electric motor [

26]. Han et al. have investigated the effect of rotational speed, flow rate, and temperature on the thermal performance of an electric motor cooled by oil splashed from a cooling pipe [

27]. Liu et al. have compared the heat transfer performance of multi-nozzle oil spray cooling and oil jet cooling for thermal management of electric motors [

28]. Lim and Kim have proposed oil spray cooling to attain the maximum temperature of windings within 137.8 °C [

29]. Ha and Kim have studied the effect of nozzle diameter and number of nozzles on oil flow distribution of end windings and achieved maximum oil coverage of 83% [

30].

The open literature reveals that the limitations of conventional cooling have imposed motivation on developing advanced cooling strategies for thermal management of electric machines with continuously increasing energy density. Spray cooling as an emerging direct liquid cooling method has the potential to replace conventional cooling for effective thermal management of high flux density electric machines. To commercialize the oil spray cooling as a replacement to the conventional thermal management strategies for electric machines, the research database incorporating the relationship between key performance indicators and corresponding influential factors needs to be established. This database will offer guidelines to design effective oil spray cooling systems for next-generation electric machines. The thermal management of electric machines using oil spray cooling based on various factors such as the effective arrangement of the best nozzle type and operating conditions is not explored in the existing open literature. In addition, the neural network modeling with an aim to reduce the experimental efforts has been proposed in the present work, which was missing in the case of electric machine thermal management based on oil spray cooling. The present study fills the gaps in the open literature by adding the findings from the present experimental parametric investigations supported with neural network modeling in the area of oil spray cooling-based thermal management of high energy density cylindrical-shaped electromechanical devices, specifically traction motors.

The objective of the present study is to experimentally investigate the oil spray cooling based on a multi-nozzle configuration for high-power-density electric machines. The cylindrical heat source with heat generation equivalent to heat loss of a commercial traction motor (as a presentation of electric machines) is developed. Flat jet and two full cone nozzles are studied under different numbers of nozzles, heights, and oil flow rates to evaluate the stator and winding temperatures, heat transfer coefficient, injection pressure, and power consumption. Furthermore, the objective of the study is extended to develop a neural network model for predicting the thermal performances of a high-power density traction motor with oil spray cooling. Two algorithms of ANN-LM-Tan and ANN-LM-Log are developed using MATLAB R2018a commercial software to predict the stator and winding temperatures, heat transfer coefficient, and injection pressure.

2. Experimental Method

2.1. Experimental Set-Up

The traction motor is considered the high-power density electric machine in the present work. The heat generation of a commercial traction motor of 100 kW is replicated by developing a cylindrical heat source made up of a steel stator. A total of 12 holes are drilled in the cylindrical heat source to integrate hollow copper as windings. The extended parts of hollow copper outside the steel stator act as end windings. It should be noted that the simplified configuration of the traction motor is replicated in the present experimental study with an aim to investigate the thermal performances of the motor equivalent heat source with an oil spray cooling system. The steel stator is developed without any laminations; windings are replicated as hollow cylinders, and there is no insulation material between the stator and windings. The cylindrical heat source has dimensions of 20 cm diameter and 15 cm length. The cartridge heaters are inserted within the hollow copper windings to enable the heat generation for the cylindrical heat source. The cartridge heater is customized with a heating capacity of 0.65 kW and a 1.9 cm diameter. Thus, the cylindrical heat source is provided with maximum heat generation of 7.8 kW (assuming 92% efficiency for a commercial electric vehicle motor with conventional cooling [

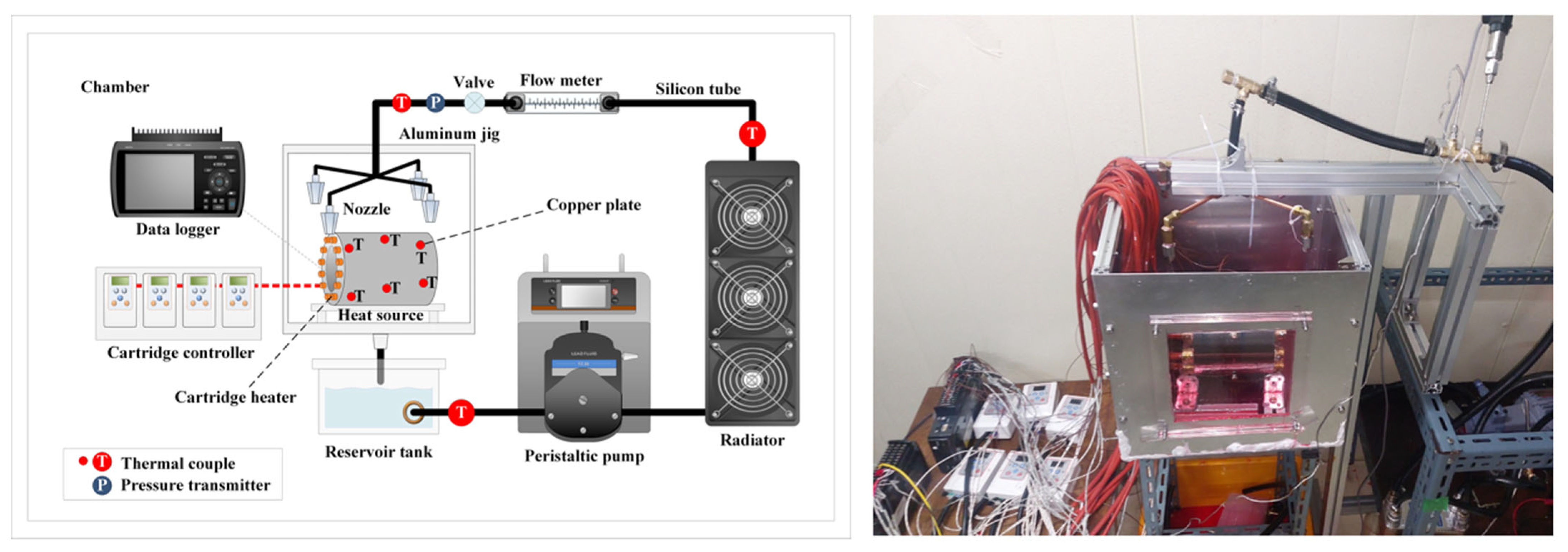

31]), combining the heating capacities of all cartridge heaters. The cartridge heaters are connected to a controller with a temperature limit of 350 °C. The oil spray cooling is developed with a multi-nozzle configuration, considering nozzle types of flat jet and two full cones. The cylindrical heat source is surrounded by a multi-nozzle configuration comprising different numbers of nozzles of each type to enable the oil spray for cooling. The distance between the multi-nozzle configuration and the cylindrical heat source is adjusted to achieve the uniform oil distribution. The experimental setup comprises a cylindrical heat source, a multi-nozzle configuration and an oil flow circuit, as shown in

Figure 1. The cylindrical heat source and multi-nozzle configuration are housed within an aluminum spray chamber. The oil circuit is made up of rubber, which connects the pump, inverter, radiator, and sensors. The commercially used automotive transmission oil is circulated in a spray cooling system. The TOP-212HB oil pump (Nippon Oil Pump Co., Ltd., Saitama, Japan) with a capacity of 400 W is used to circulate the oil in the spray cooling system. The flow rate of oil is adjusted as required using the pump inverter. The radiator is used to cool the heated oil from the cylindrical heat source. To monitor the temperature of the cylindrical heat source, it is attached with T-type thermocouples enabling a maximum measurement of 400 °C. To measure the injection temperature and pressure of sprayed oil, a Pt-100 temperature sensor and an EDS.305 pressure sensor (Daho Tronic Ltd., Seoul, Republic of Korea) enabling maximum measurements of 650 °C and 50 bar are installed at the inlet of the spray chamber. The thermocouples and sensors are connected to the GL840 datalogger (GRAPHTEC Corporation, Yokohama, Japan) to record the measurement data (with a sampling interval of 2 s). The experimental setup is built inside a chamber that maintains the constant surrounding temperature (25 °C).

2.2. Data Reduction

The experiments are conducted on a spray cooling system to achieve the effective thermal management of a cylindrical heat source by changing the nozzle type, number of nozzles, height of the multi-nozzle configuration from the cylindrical heat source, and oil flow rate. The nozzle types are selected as a flat jet with a diameter of 2.9 mm and a maximum spray angle of 50°, a first full cone with a diameter of 2.3 mm and a maximum spray angle of 90° and a second full cone with a diameter of 2.8 mm and a maximum spray angle of 120°. The number of nozzles is varied as 2, 4, and 6; the height (vertical distance between the center of the multi-nozzle configuration and the cylindrical heat source) is varied as 3 cm and 5 cm, referring to low height and high height; and the oil flow rate is varied in the range of 12 LPM to 20 LPM. The stator temperature, winding temperature, and injection pressure are measured during the experimentation, whereas the heat transfer coefficient and power consumption are evaluated based on measured parameters.

The heat flux generated on the cylindrical heat source through conduction is given by [

32],

It should be noted that the heat flux (W/m2) is calculated assuming the cylindrical heat source is a combination of multiple slabs, each with an individual hollow copper cylinder in combination of a cartridge heater and a corresponding area of steel stator.

The temperature difference between the heater and the cylindrical surface is evaluated as [

33],

The heat transfer coefficient for the proposed cooling is calculated as [

34],

The power consumption is expressed as [

35],

Here, is the thermal conductivity of the heat source, is the distance between the heater and the heat source surface, is the heater temperature, is the average temperature of the heat source, is the oil inlet temperature, is the injection pressure, and is the volume flow rate of oil.

The inaccuracy in measured and calculated parameters during the experimentation is presented through uncertainty in each parameter. The uncertainties in measured and calculated parameters are obtained through a linearized fractional approach based on Equation (5) [

36,

37]. The accuracy of experimental devices and uncertainties in measured and calculated parameters are presented in

Table 1.

Here, stands for the dependent parameter and the uncertainty in the relevant parameter is presented by , whereas , , … present the independent parameters and the uncertainties in relevant parameters are presented by , , … .

3. Results and Discussion

In this section, the effect of nozzle types, number of nozzles, nozzle heights, and oil flow rates on stator and winding temperatures, heat transfer coefficient, injection pressure, and power consumption are discussed for a cylindrical heat source with oil spray cooling. In addition, the elaboration on the development of a neural network model comprising two algorithms is presented for predicting the thermal performances of a cylindrical heat source with oil spray cooling.

3.1. Effect of Nozzle Types

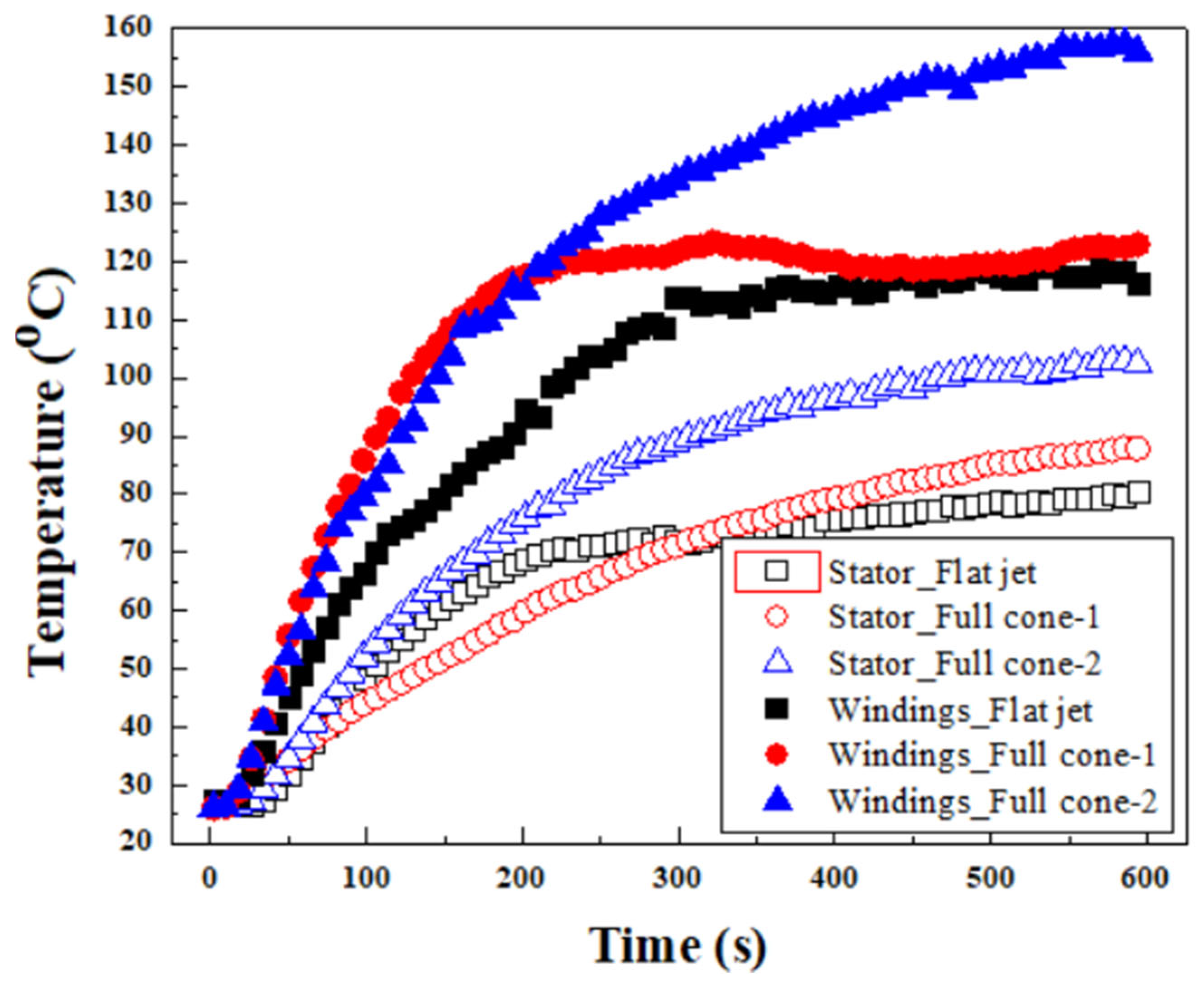

The comparisons of stator and winding temperatures for flat jet and two full cone nozzles are shown in

Figure 2. The flat jet nozzle covers the maximum portion of the cylindrical heat source compared to both full cone nozzles owing to the diagonal arrangement and spray angle specification of the flat jet nozzle. Therefore, the spray cooling performance is improved for the flat jet nozzle compared to the full cone-1 and full cone-2 nozzles. In addition, the portion of oil sprayed on the cylindrical heat source is improved in the case full cone-1 nozzle, which results in lower stator and winding temperatures compared to the full cone-2 nozzle. The flat jet, full cone-1, and full cone-2 nozzles show maximum stator temperatures of 80.4 °C, 88.26 °C and 103.4 °C, respectively, and they show maximum winding temperatures of 120.2 °C, 123.8 °C and 157.7 °C, respectively. The developed oil spray cooling restricts the maximum winding temperature below the threshold limit for H-class insulation. Hence, it assures the safe and efficient operations for the corresponding traction motor [

38].

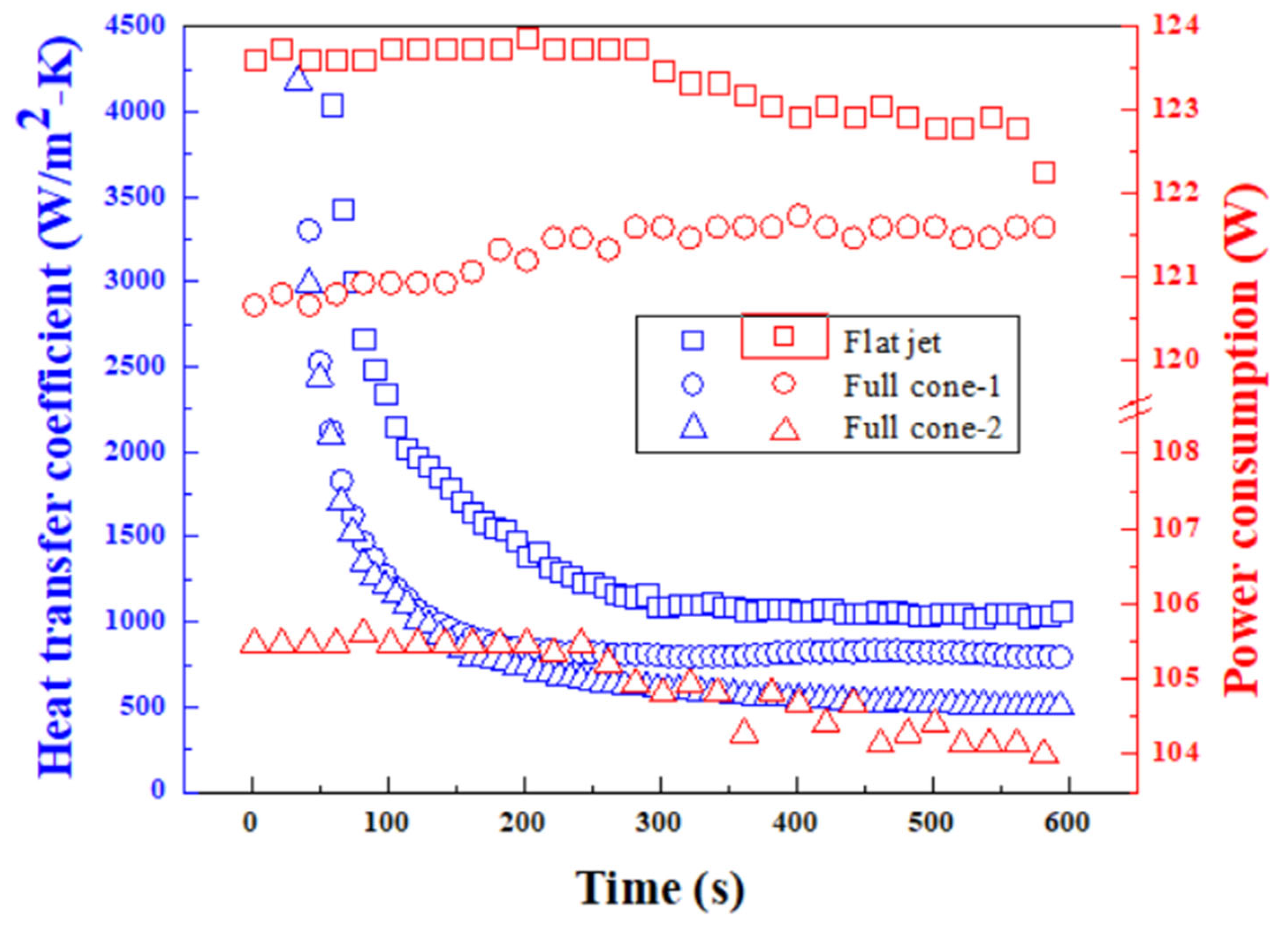

The variations in heat transfer coefficient and power consumption for different nozzle types are depicted in

Figure 3. The heat transfer coefficient depends on the amount of heat removed by the coolant from the heating source. In the case of nozzle type, the arrangement of nozzles (diagonal arrangement with relevant distance) offers a significant advantage in addition to its geometrical specifications (spray angle and spray hole diameter) for achieving the improved coolant flow distribution over the cylindrical-shaped heat source and thus results in enhanced cooling performance in terms of surface temperature and heat transfer coefficient. It is observed that the maximum portion of the cylindrical heat source is covered through sprayed oil by the configuration of flat jet nozzles, which results in a higher heat removal rate and thus a lower temperature of the heat source compared to other nozzle configurations. Therefore, the superior heat transfer coefficient is extracted in the case of the flat jet nozzle, followed by the full cone-1 and full cone-2 nozzles in decremental order. The flat jet nozzle shows a maximum heat transfer coefficient of 3028.6 W/m

2-K which is restricted to 2771.7 W/m

2-K and 2234.5 W/m

2-K in the case of full cone-1 and full cone-2 nozzles, respectively. In contrast to the heat transfer coefficient, the power consumption, which depends on the injection pressure, is superior for the flat jet nozzle compared to other nozzle types. However, the differences in power consumption for different nozzle types are not sufficiently large. The flat jet, full cone-1, and full cone-2 nozzles show power consumptions of 123.9 W, 121.7 W, and 105.7 W, respectively. The optimum balance between the cooling performance and energy consumption needs to be established to suggest the best nozzle type. The flat jet nozzle shows maximum power consumption, which is not significantly larger than other nozzle types. However, the cooling performance in terms of heat transfer coefficient in the case of the flat jet nozzle is significantly superior to both full cone nozzles. The percentage difference in heat transfer coefficient and power consumption between the flat jet nozzle and both full cone nozzles is presented in

Table 2. Therefore, based on the trade-off relation between heat transfer coefficient and power consumption (

Table 2), a flat jet nozzle is recommended for the oil spray cooling system to achieve the desired thermal management of the cylindrical heat source.

3.2. Effect of Number of Nozzles

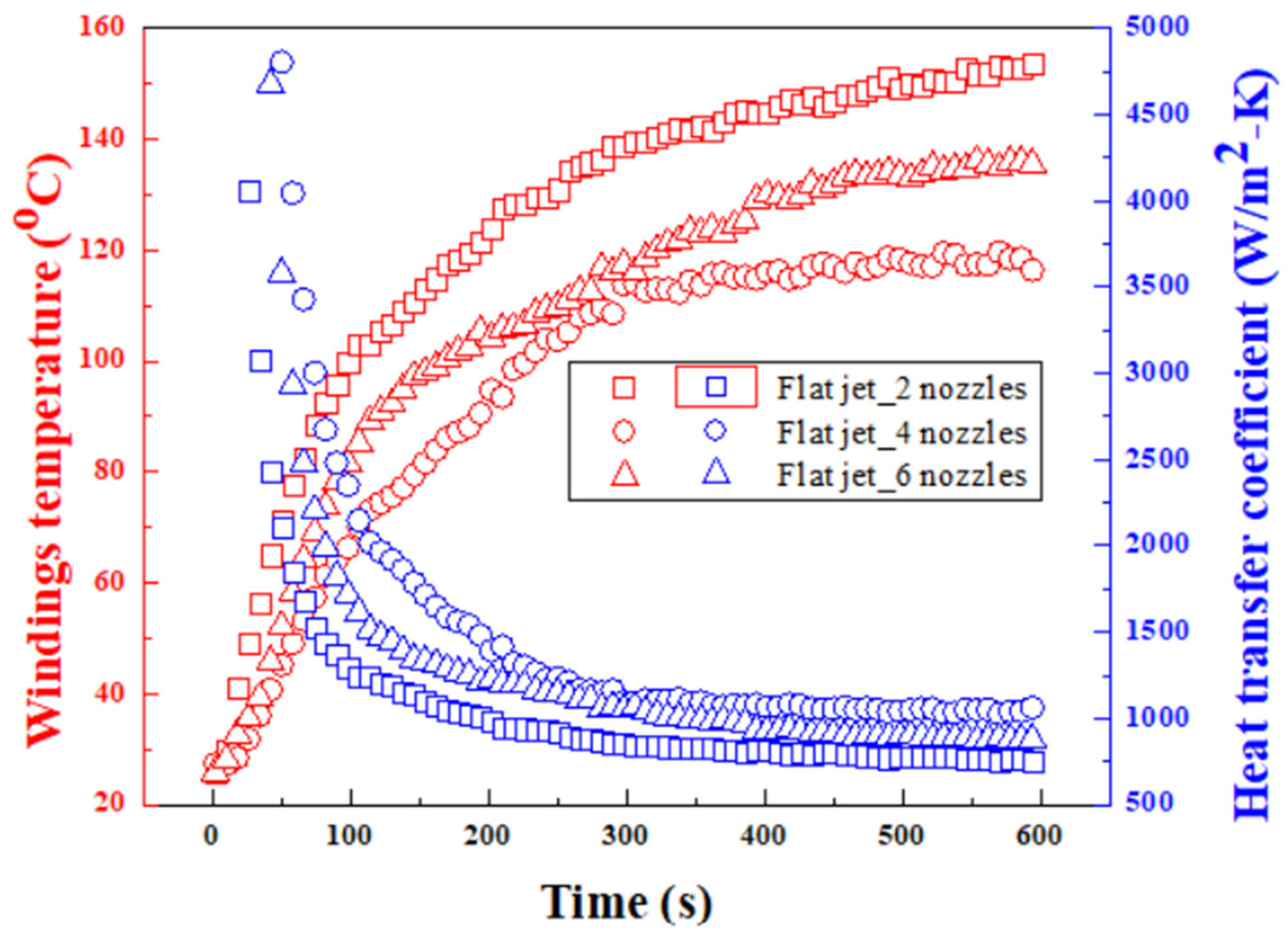

The variation in winding temperature for the oil spray cooling system with different numbers of flat jet nozzles is presented in

Figure 4. It can be noted that the cooling performance is superior for that number of nozzles, which shows uniformity of coolant distribution around the targeted heating device. Therefore, the combination of four flat jet nozzles arranged diagonally around the cylindrical heat source has presented a lower temperature of windings compared to the combination of two and six flat jet nozzles. In addition, the two flat jet nozzles present poor oil spray coverage area over the cylindrical surface compared to six flat jet nozzles. The increase in the number of nozzles creates excessive loss of coolant distribution over the targeted surface. Hence, the cooling performance improved in the order of two, six, and four flat jet nozzles. The oil spray cooling system with two, four, and six numbers of flat jet nozzles shows winding temperatures of 154.9 °C, 120.2 °C and 136.6 °C, respectively.

The variation in heat transfer coefficient for change in number of flat jet nozzles is also depicted in

Figure 4. Four flat jet nozzles arranged diagonally have shown the lowest temperature of the cylindrical heat source, which indicates higher heat dissipation from the cylindrical heat source to the sprayed oil in the case of four flat jet nozzles compared to other numbers of flat jet nozzles. Hence, the oil spray cooling system with four flat jet nozzles shows a superior heat transfer coefficient compared to that with two and six flat jet nozzles. The heat transfer coefficients of 1995.06 W/m

2-K, 3028.6 W/m

2-K, and 2945.08 W/m

2-K are evaluated for an oil spray cooling system with two, four, and six flat jet nozzles, respectively.

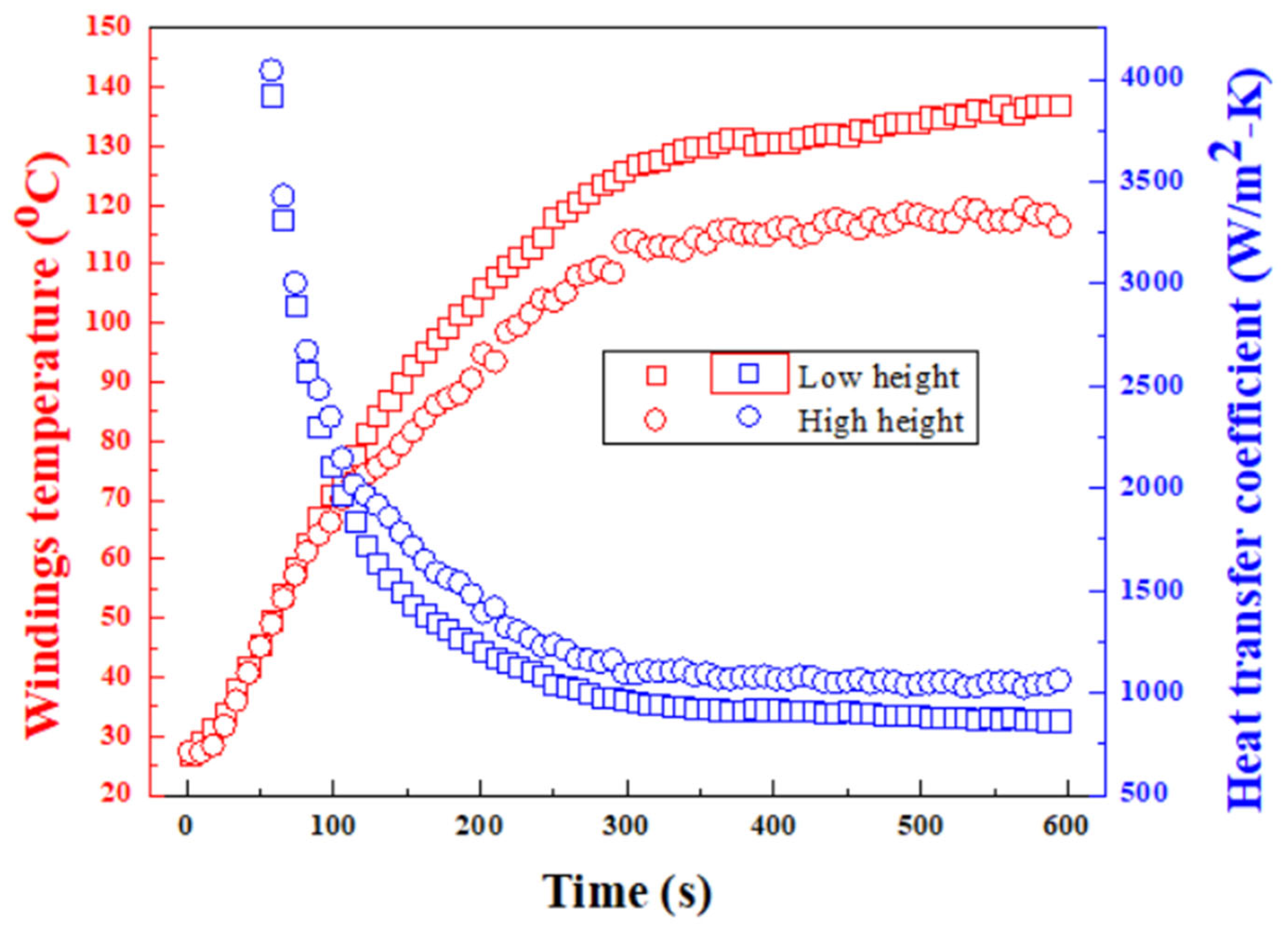

3.3. Effect of Nozzle Height

The criteria for adjusting the height of the multi-nozzle configuration from the cylindrical heat source are based on achieving maximum possible oil flow distribution over the cylindrical heat source and minimizing the complexity of fabricating the actual motor housing with such a nozzle configuration. There is a critical height at which the coolant flow distribution is superior, and thus the spray cooling performance is enhanced for that optimum height, as concluded by Zhou et al. and Salman et al. [

39,

40]. Therefore, based on this criterion, two vertical heights of 3 cm and 5 cm for the combination of four flat jet nozzles are decided to evaluate the thermal performances. The variation of winding temperatures and heat transfer coefficient with change in height of nozzle configuration is depicted in

Figure 5. The increase in the height of nozzle configuration from the cylindrical heat source improves the cooling because of the enhanced oil spray coverage area at a higher height. The combination of four flat jet nozzles at high height shows winding temperature lower by 17.8 °C than that at low height from a cylindrical heat source. The improvement in cooling of a cylindrical heat source with a rise in height has shown a higher heat dissipation rate to sprayed oil and thus an enhancement in the evaluated heat transfer coefficient. The heat transfer coefficient for cylindrical heat source with four flat jet nozzles-based oil spray cooling improved by 24.2% at high height compared to low height.

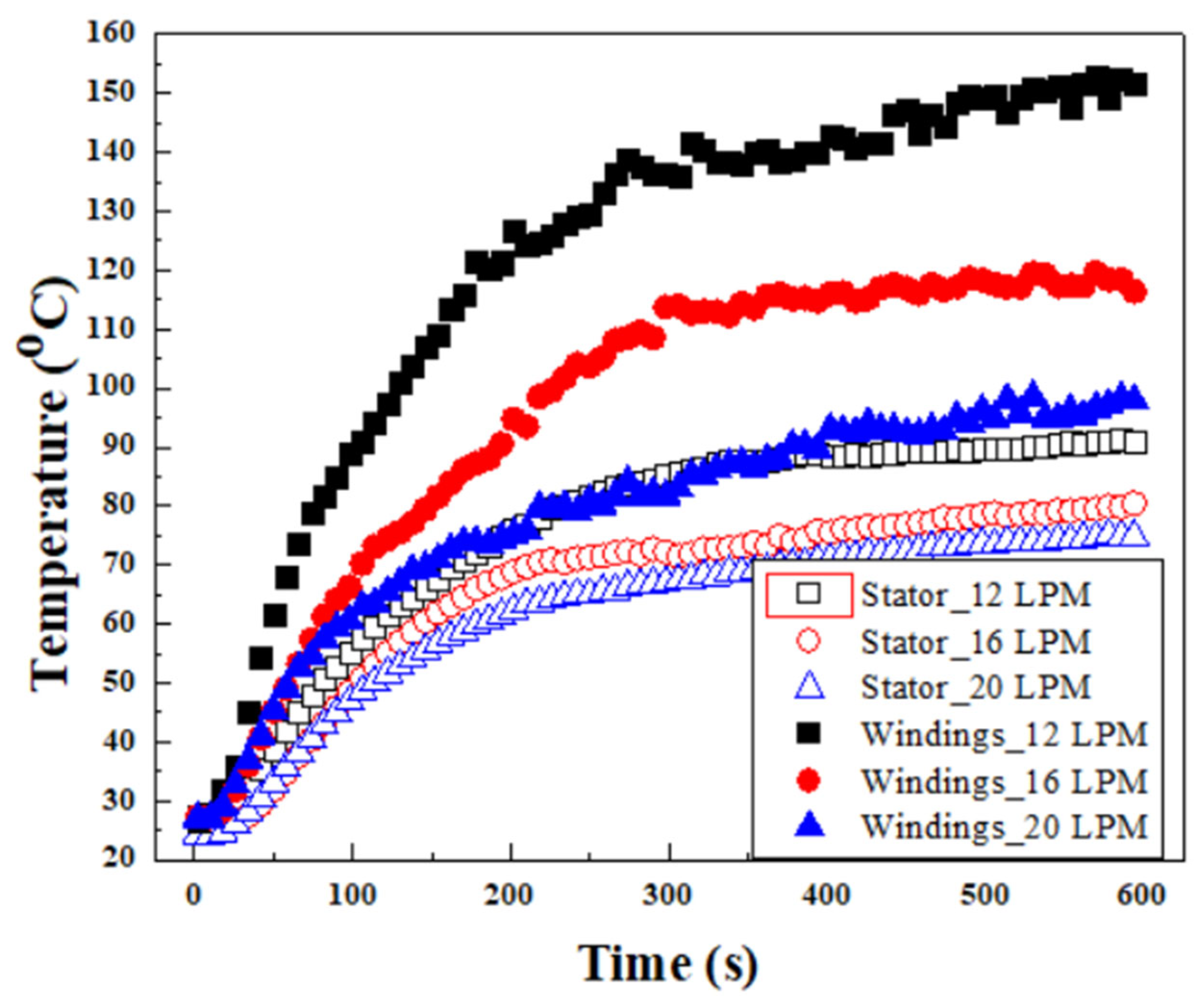

3.4. Effect of Oil Flow Rate

The cooling performance of the flat jet nozzle configuration is further improved by increasing the flow rate of oil. The variations in stator and winding temperatures with change in oil flow rate are depicted in

Figure 6. The increase in oil flow rate enhances the convective heat transfer rate from the cylindrical heat source to the sprayed oil, which improves the cooling performance. Therefore, the stator and winding temperatures show decremental trends with an increase in oil flow rate. The stator temperature reduces from 91.5 °C to 74.9 °C, and the winding temperature reduces from 153.1 °C to 98.9 °C as the oil flow rate increases from 12 LPM to 20 LPM.

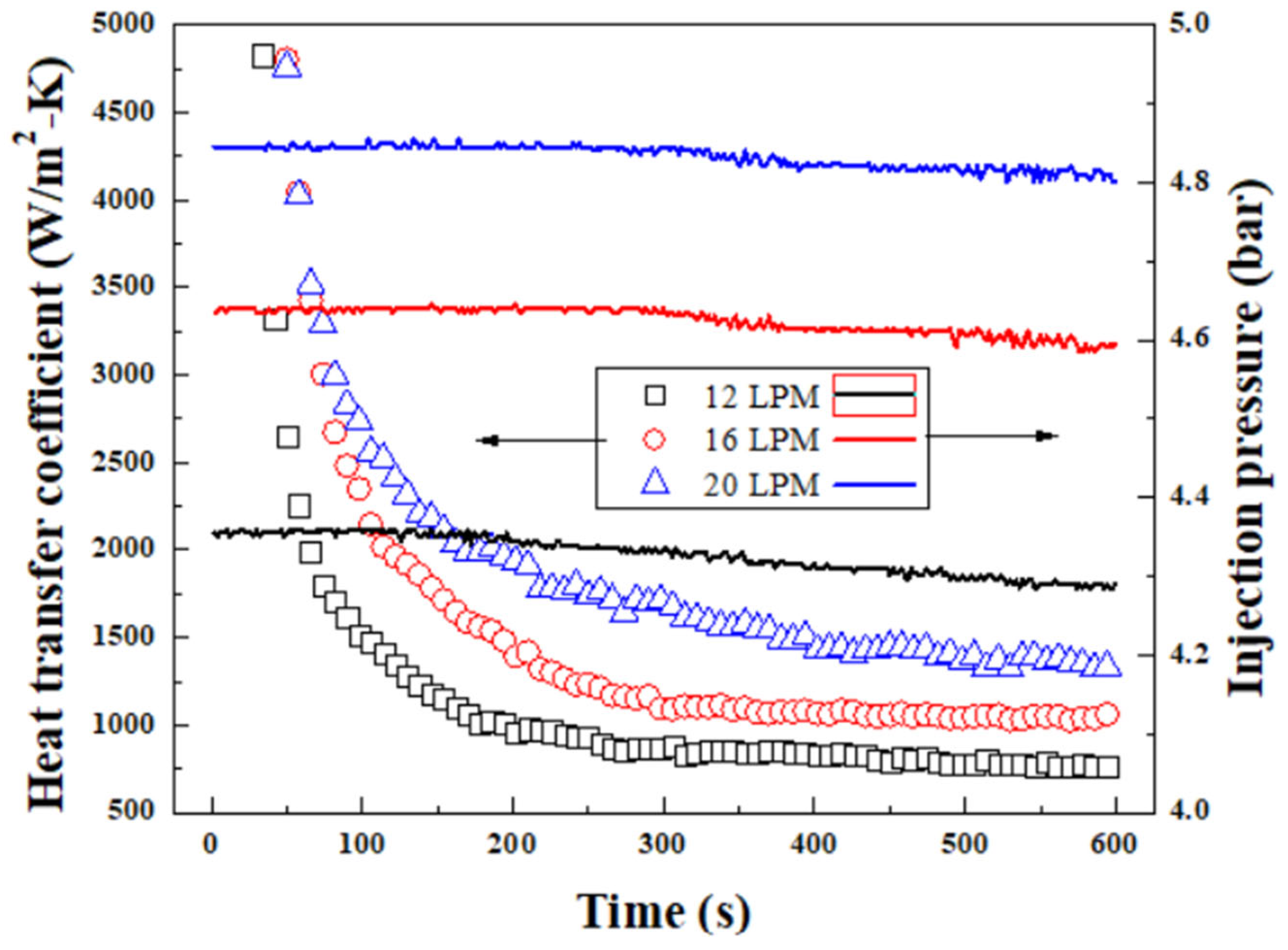

The effect of change in oil flow rate on heat transfer coefficient and injection pressure is presented in

Figure 7. The increase in flow rate expands the heat removal capacity of the sprayed oil from the cylindrical heat source. Hence, the heat transfer coefficient enhances from 2347.02 W/m

2-K to 3408.6 W/m

2-K for oil spray cooling with a flat jet nozzle as the flow rate increases from 12 LPM to 20 LPM. In addition, the increment in the oil flow rate creates increased turbulence and hence higher injection pressure at the higher flow rate of oil. With an increase in the oil flow rate from 12 LPM to 20 LPM, the injection pressure increases from 4.35 bar to 4.85 bar. The increase in the injection pressure indicates an increase in the power consumption. Hence, the oil flow rate should be increased up to the point where desired cooling for the cylindrical heat source is achieved. The increasing trend of injection pressure with a rise in oil flow rate is also presented by Tao et al. [

11]. The higher injection pressure indicates a decrease in surface temperature and thus an improvement in the heat transfer coefficient of spray cooling as proposed by Cai et al. [

41].

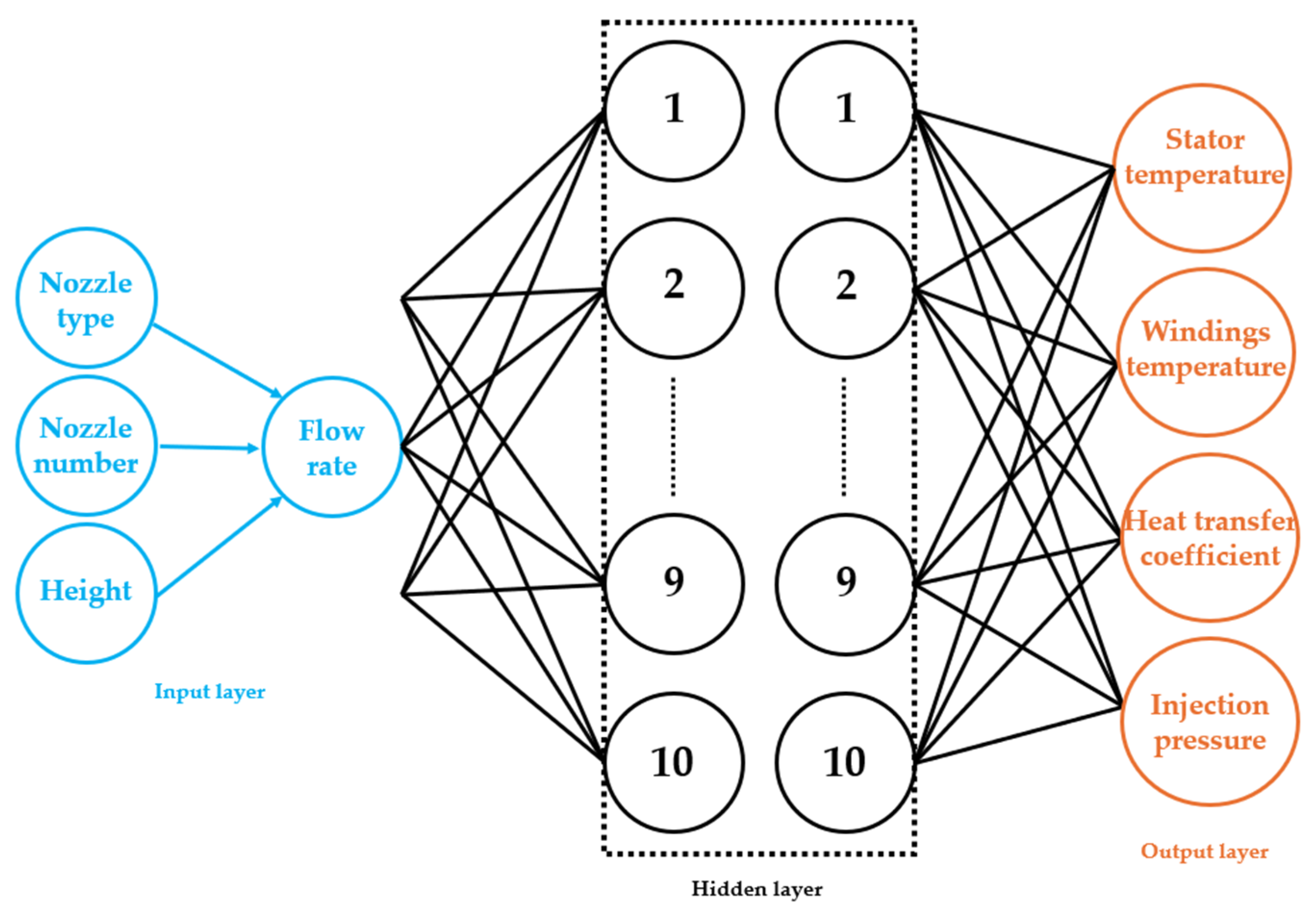

3.5. Neural Network Modeling for Thermal Performances

The combination of four flat jet nozzles installed at the high height has shown enhanced thermal performances of the cylindrical heat source with oil spray cooling. The increment in flow rate improves the performance of oil spray cooling to dissipate the heat from high power density components. The proposition of the artificial neural network (ANN) model enables a reduction in efforts on expensive and time-consuming experiments. Therefore, the neural network model is developed to predict the thermal performances of oil spray cooling with the best combination under various flow rates. The structure of the neural network model developed in the present work is depicted in

Figure 8. The present neural network model is developed based on experimental data for a cylindrical heat source with oil spray cooling. The experimental data (a total 900 data points based on three flow rates) is divided into three parts as training, testing, and validation with corresponding proportions of 70%, 15%, and 15%. The proposed neural network is modeled with a feedforward back-propagation algorithm comprising the Levenberg–Marquardt (LM) training variant and tangential-sigmoidal (Tan) and logarithmic-sigmoidal (Log) transfer functions. The neural network model with two combinations of algorithms is developed in MATLAB 2018 software. The mathematical formulation for the proposed algorithm is presented in Equations (6)–(8), reflecting output prediction and Tan and Log functions, respectively [

42].

Here, indicates output, corresponds to the neural layer, is the transfer function, is the connection matrix, and is the matrix for the bias weights.

The statistical accuracy of the developed neural network model is evaluated in terms of coefficient of determination (

) and coefficient of variance (

) as presented in Equations (9) and (10) [

42].

Here, and are the predicted and experimental values, is the average of experimental values and presented the total data points.

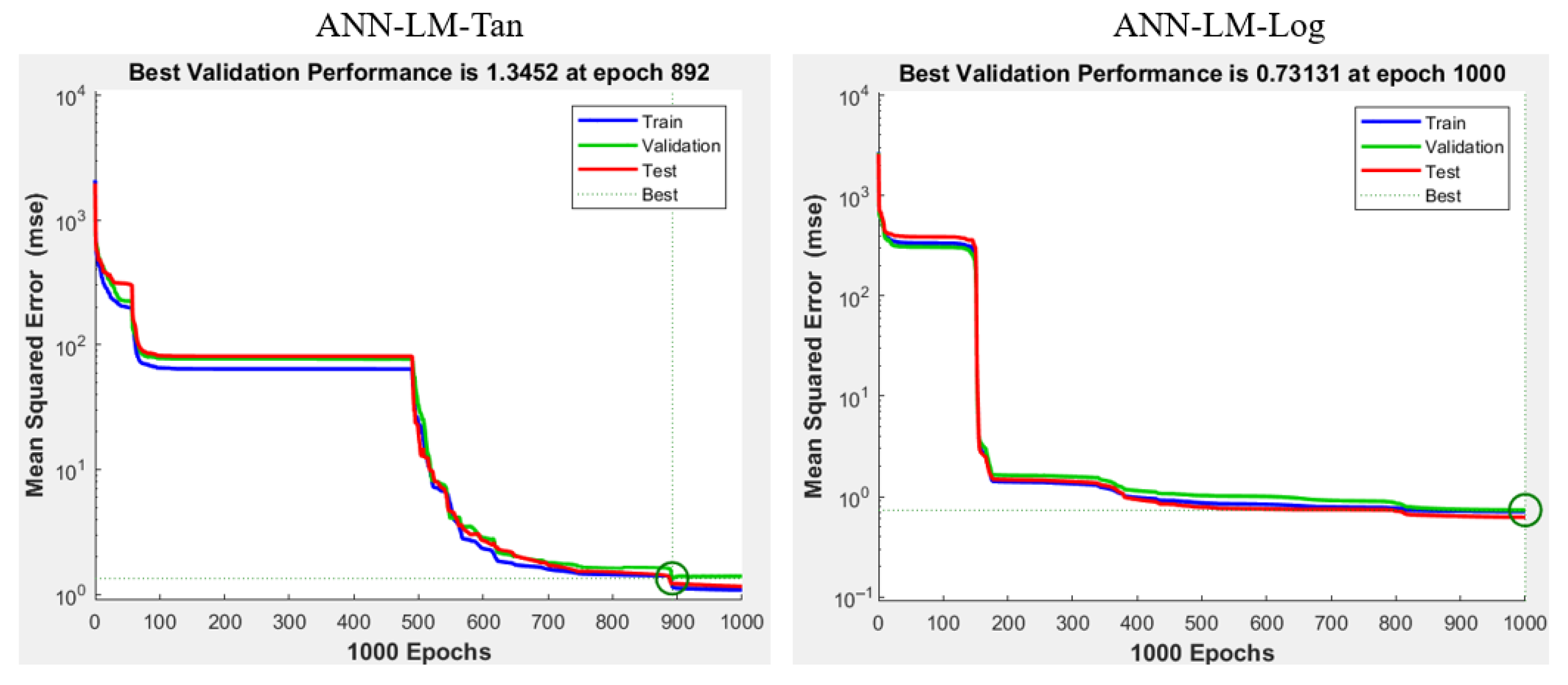

The neural network model is trained based on part of the experimental data using two algorithms, ANN-LM-Tan and ANN-LM-Log. The mean squared error (MSE) for two considered algorithms based on training data is shown in

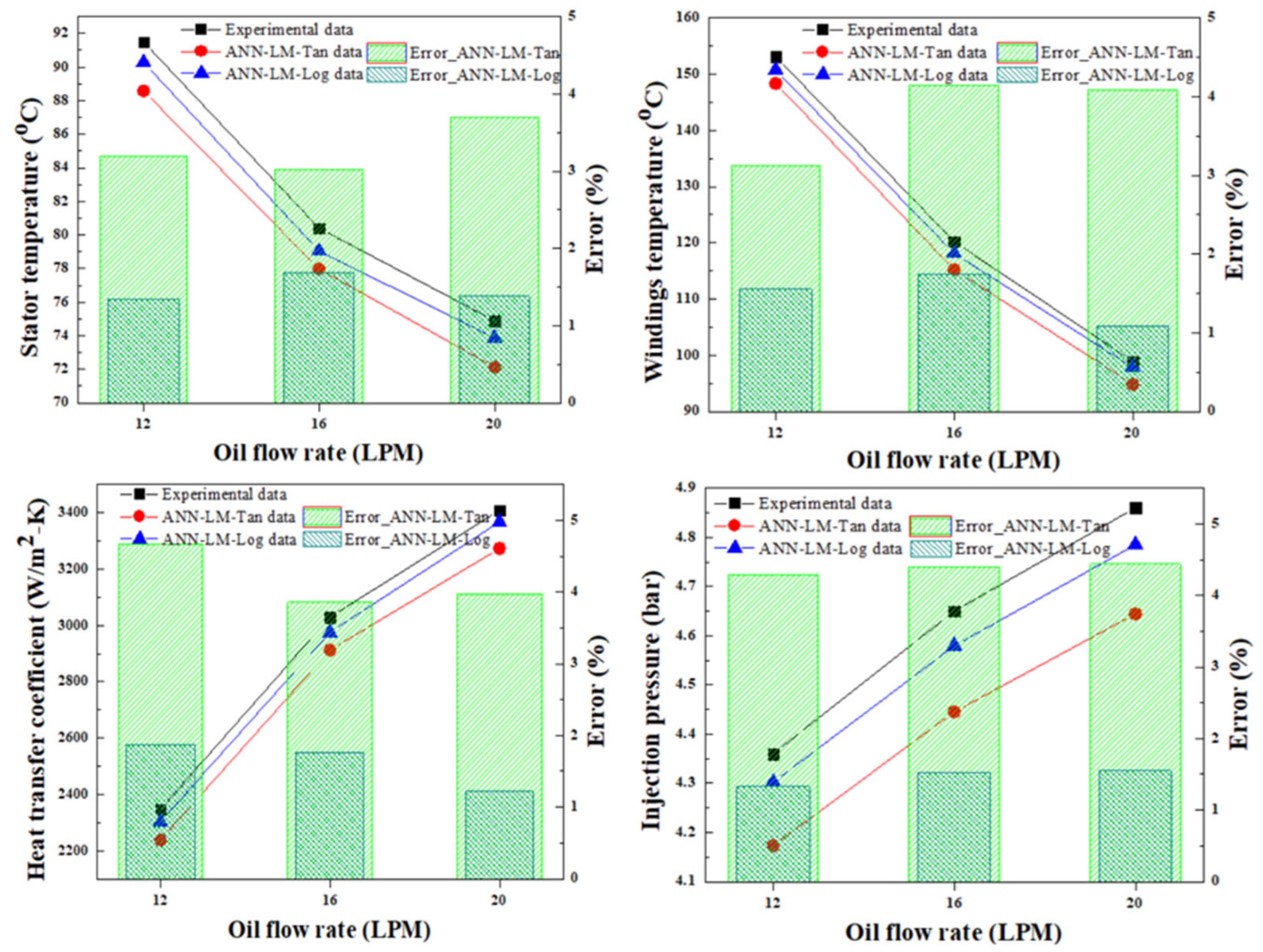

Figure 9. The ANN-LM-Log algorithm depicts a lower MSE of 0.73 compared to the ANN-LM-Tan algorithm with a corresponding MSE of 1.35. The predicted results of thermal performances and errors for two algorithms compared to experimental data are presented in

Figure 10. The ANN-LM-Log algorithm predicts closer results with experimental results for all thermal performances compared to the ANN-LM-Tan algorithm owing to lower MSE. The ANN-LM-Log algorithm shows R

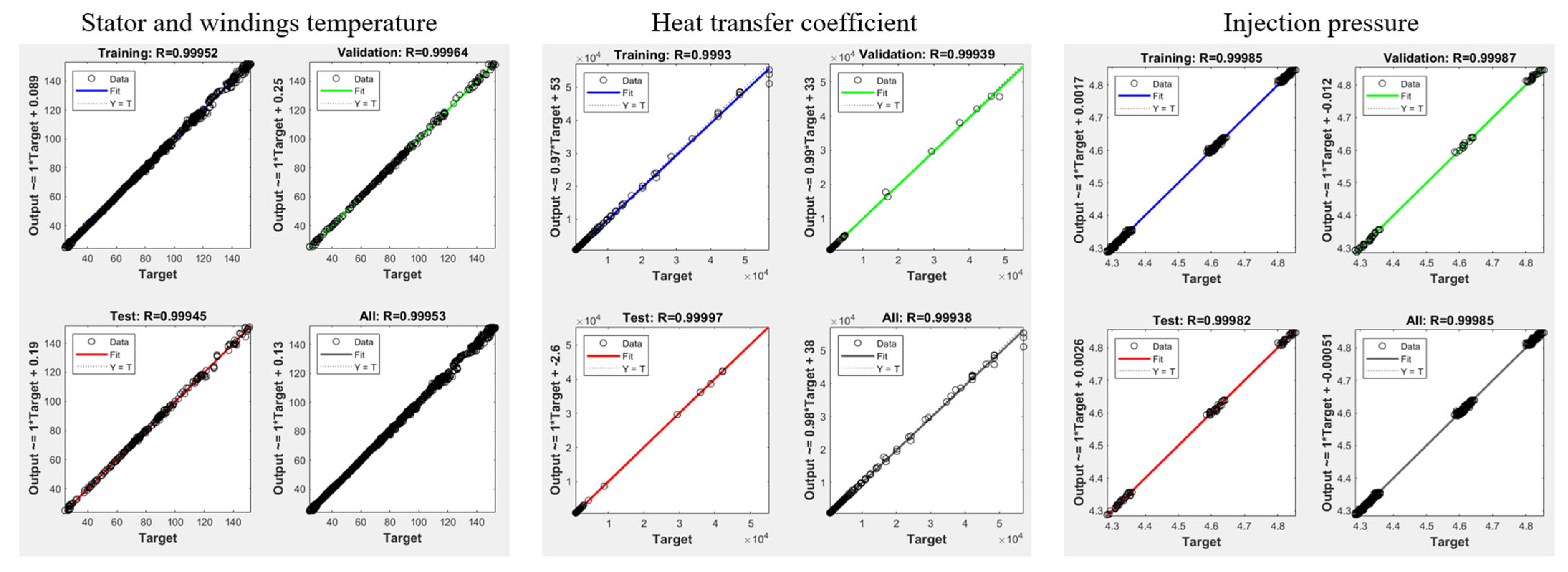

2 and COV of 0.992 and 2.144, which are deviated to 0.977 and 5.481 in the case of the ANN-LM-Tan algorithm. The maximum prediction errors for stator temperature, winding temperature, heat transfer coefficient, and injection pressure are 3.70%, 4.15%, 4.66%, and 4.40%, respectively, in the case of the ANN-LM-Tan algorithm, whereas they are 1.68%, 1.74%, 1.87%, and 1.55%, respectively, in the case of the ANN-LM-Log algorithm. In addition, the overall performance of the ANN-LM-Log algorithm including the accuracies for training, testing, and validation, is presented in

Figure 11. The agreement between predicted output results from the ANN-LM-Log algorithm with target data (experimental results) shows an overall accuracy of 0.99. Therefore, a neural network with the LM-Log algorithm is adopted to predict the accurate results of thermal performances for a cylindrical heat source with oil spray cooling under various flow rates.

4. Conclusions

The oil spray cooling based on three multi-nozzle combinations (flat jet and two full cone nozzle types) is proposed for thermal management of traction motors as high-power-density electric machines. The stator and winding temperatures, injection pressure, heat transfer coefficient, and power consumption are analyzed for various nozzle types, numbers of nozzles, heights, and oil flow rates. To reduce the experimental time and cost, a neural network model with two algorithms (ANN-LM-Tan and ANN-LM-Log) is developed in the present work to predict the thermal performances of a traction motor with oil spray cooling. The flat jet nozzle presents 3.5 °C and 37.4 °C lower winding temperatures compared to the full cone-1 and full cone-2 nozzles, respectively. The heat transfer coefficient is improved by 35.5%, and power consumption increases by 17.2% for the flat jet nozzle compared to both full cone nozzles. A flat jet nozzle is recommended for oil spray cooling to achieve enhanced thermal management of the traction motor based on the trade-off between heat transfer coefficient and power consumption. The combination of four flat jet nozzles shows 34.1% and 2.76% improved heat transfer coefficient compared to combinations of two and six flat jet nozzles, respectively. The heat transfer coefficient is enhanced by 24.2% for a combination of four flat jet nozzles at a high height compared to that at a low height. With an increase in oil flow rate from 12 LPM to 20 LPM, the winding temperature decreases by 54.2 °C, whereas the heat transfer coefficient and injection pressure increase by 45.2% and 11.5%, respectively. The ANN-LM-Log algorithm proposes the lowest prediction errors of 1.74%, 1.87%, and 1.55% for winding temperature, heat transfer coefficient, and injection pressure compared to corresponding experimental data. The present work proposes an effective thermal management strategy using oil spray cooling for electric machines with capacity targeting over 100 kW.