Influence of Previous Turning on the Surface Integrity Stability of Diamond-Burnished Medium-Carbon Steel

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials Used

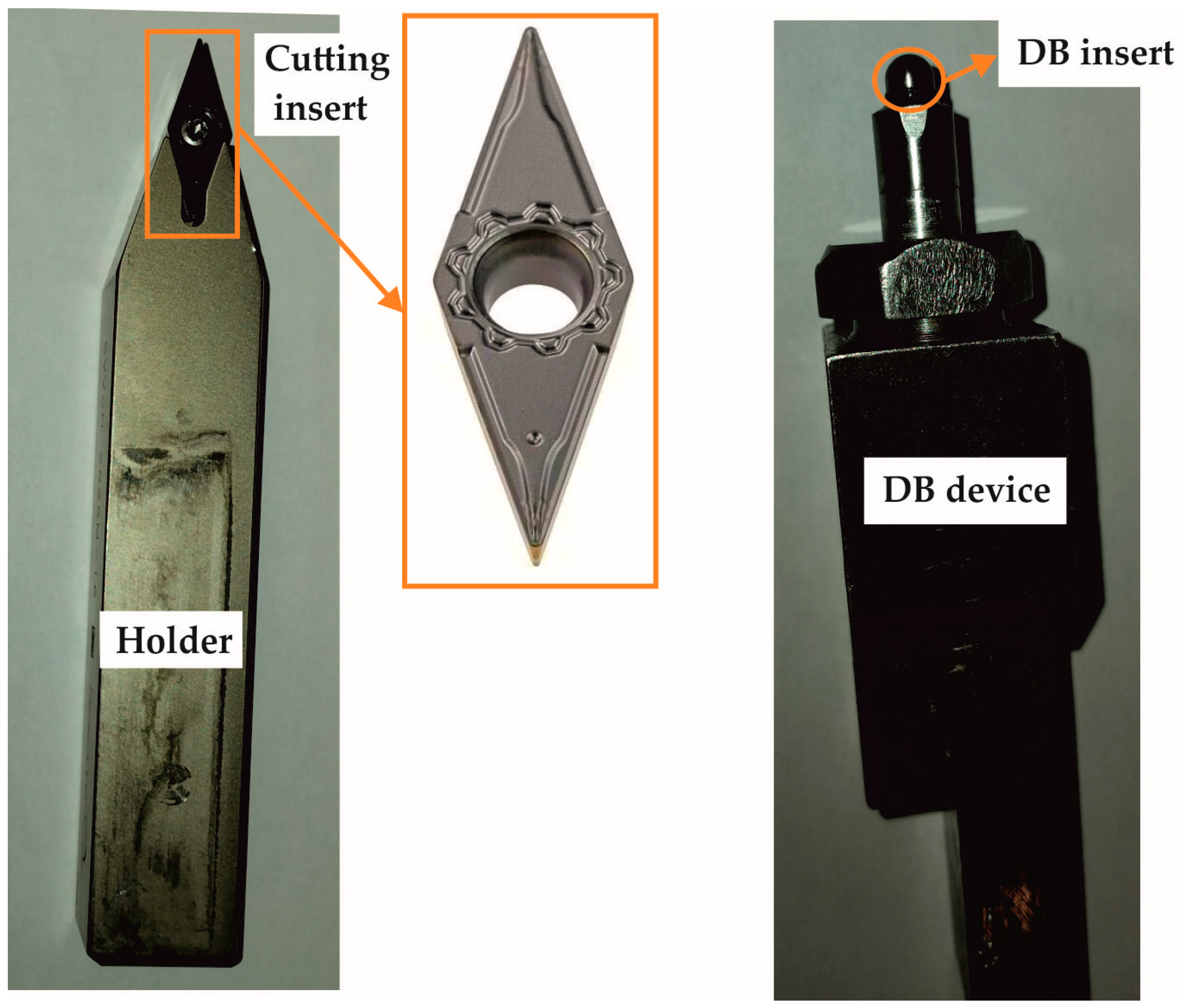

2.2. Turning and DB Implementation

2.3. Measurement of SI Characteristics

3. Experimental Results

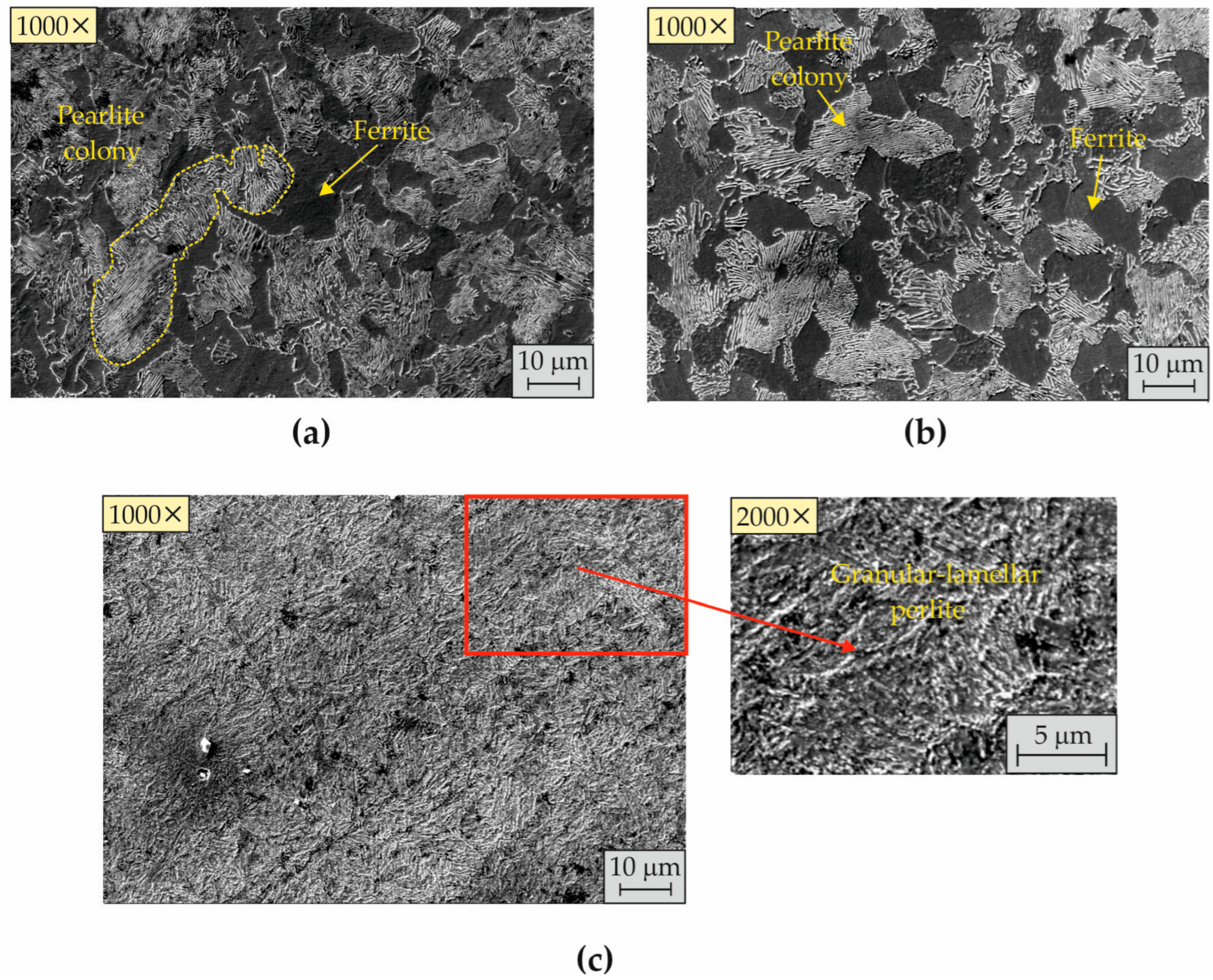

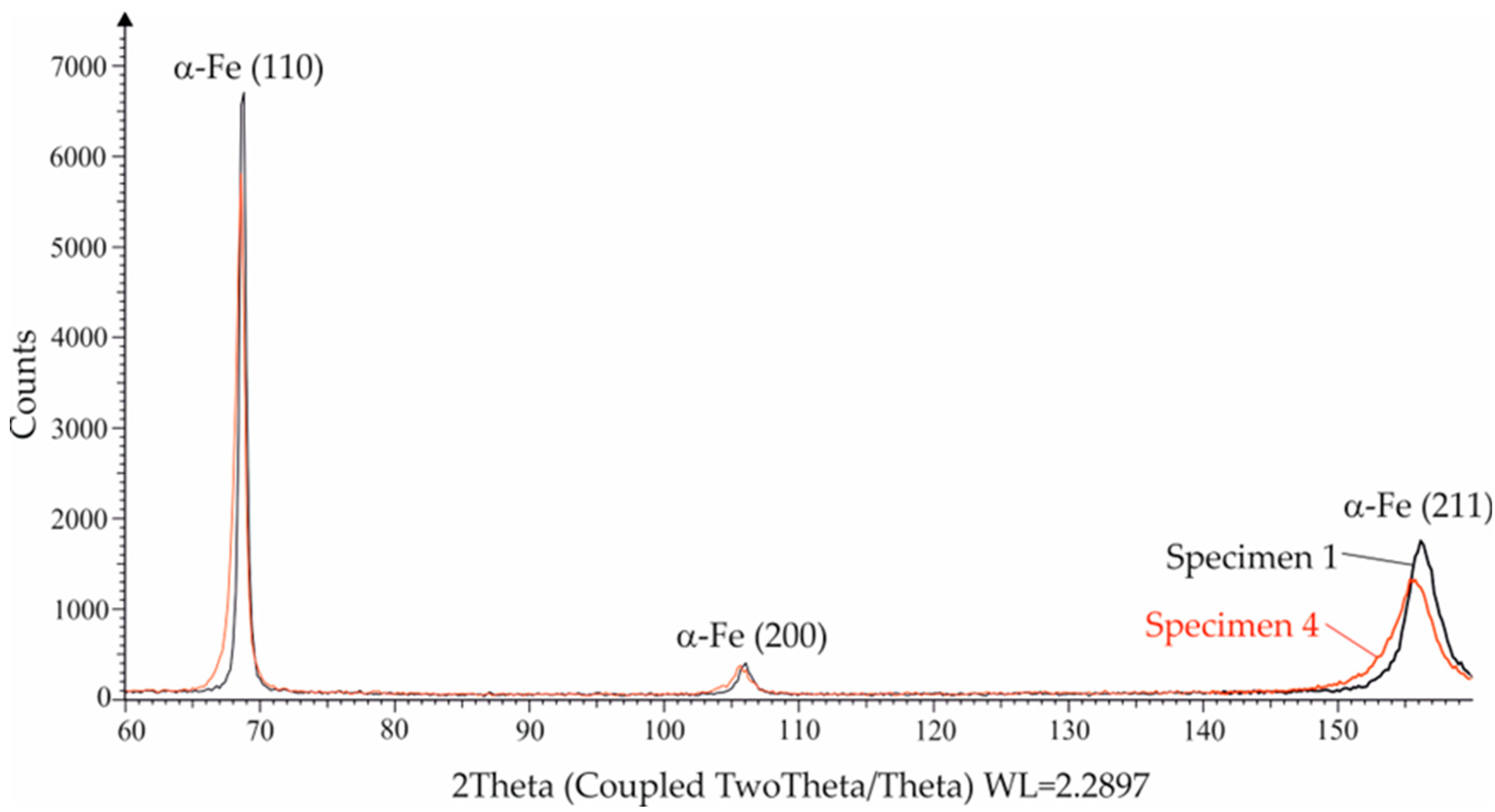

3.1. Material Identification

3.2. Investigation of the Previous Turning

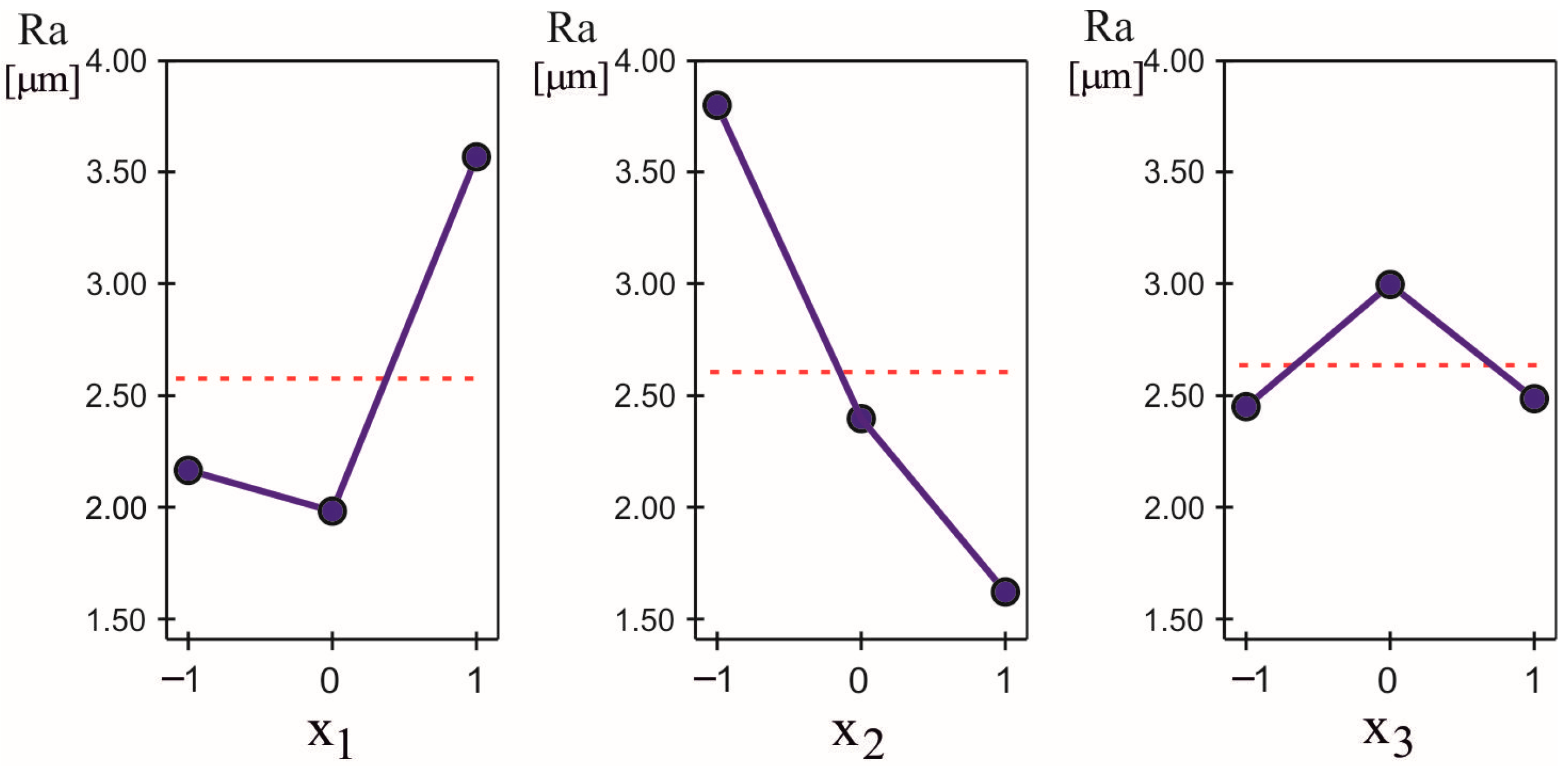

3.2.1. Governing Factors, Levels and Objective Functions

3.2.2. Analysis of Variance Outcomes

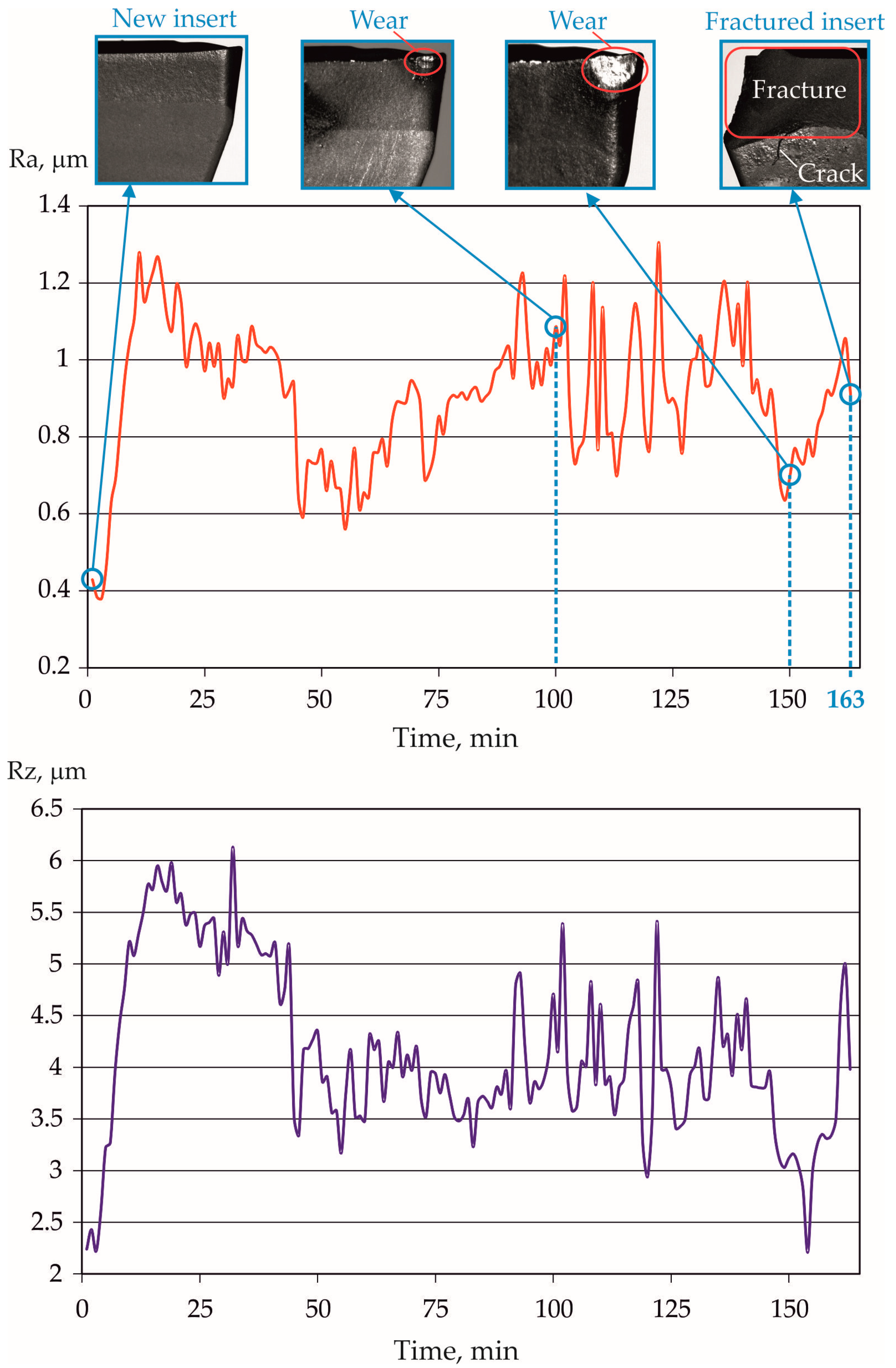

3.2.3. Dependence of the Ra on the Wear of the Cutting Insert

3.3. DB Process Optimisation

3.3.1. Selection of Rainit Value

3.3.2. Factors and Levels of the DB Process

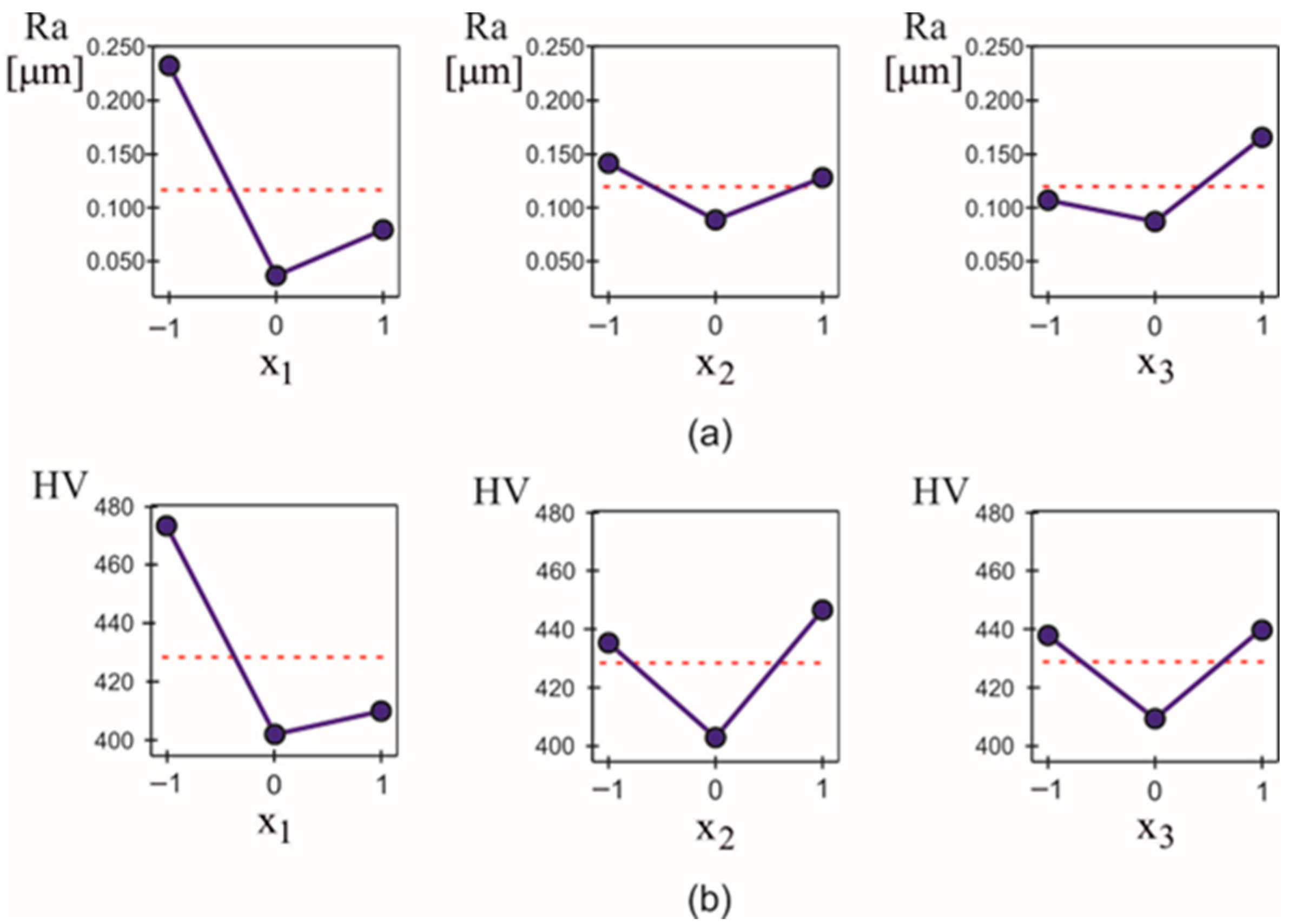

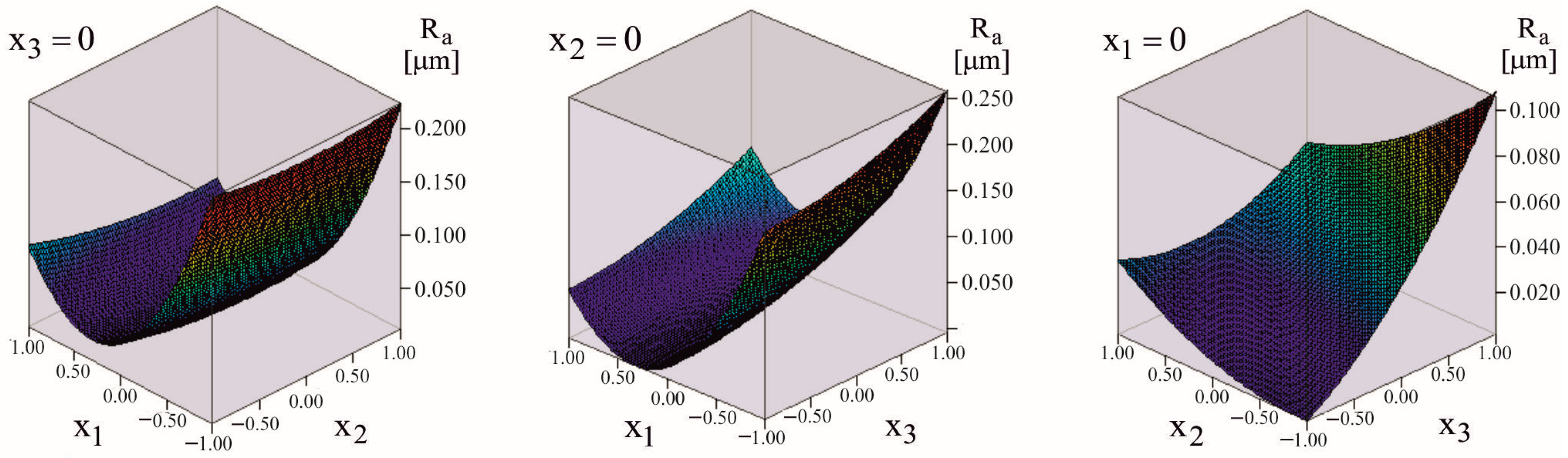

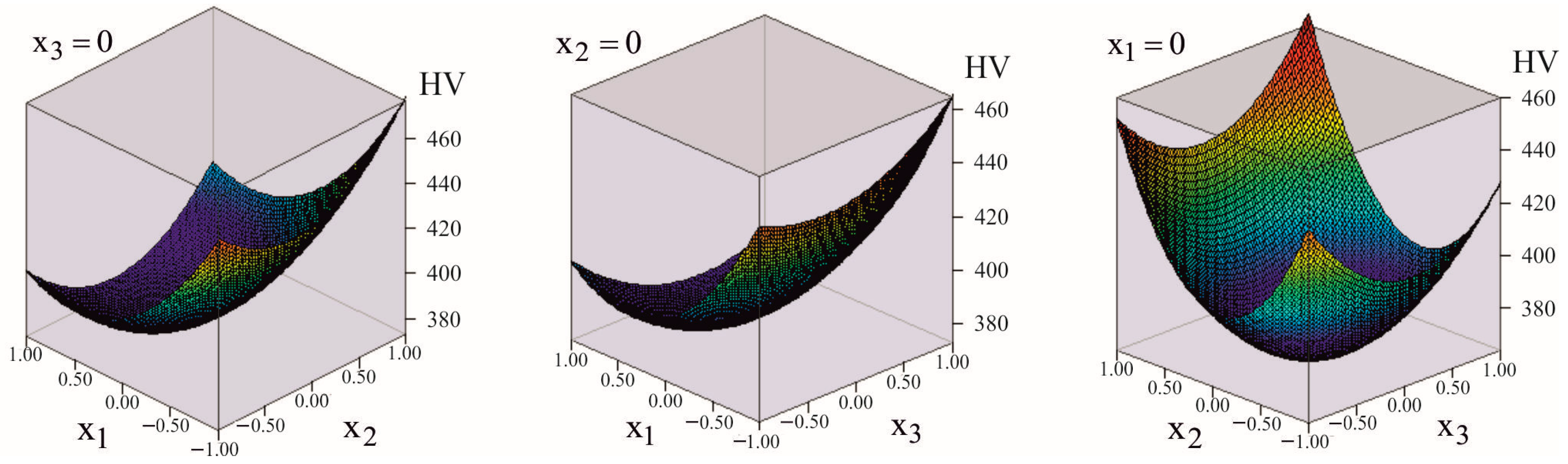

3.3.3. Study of Objective Functions and

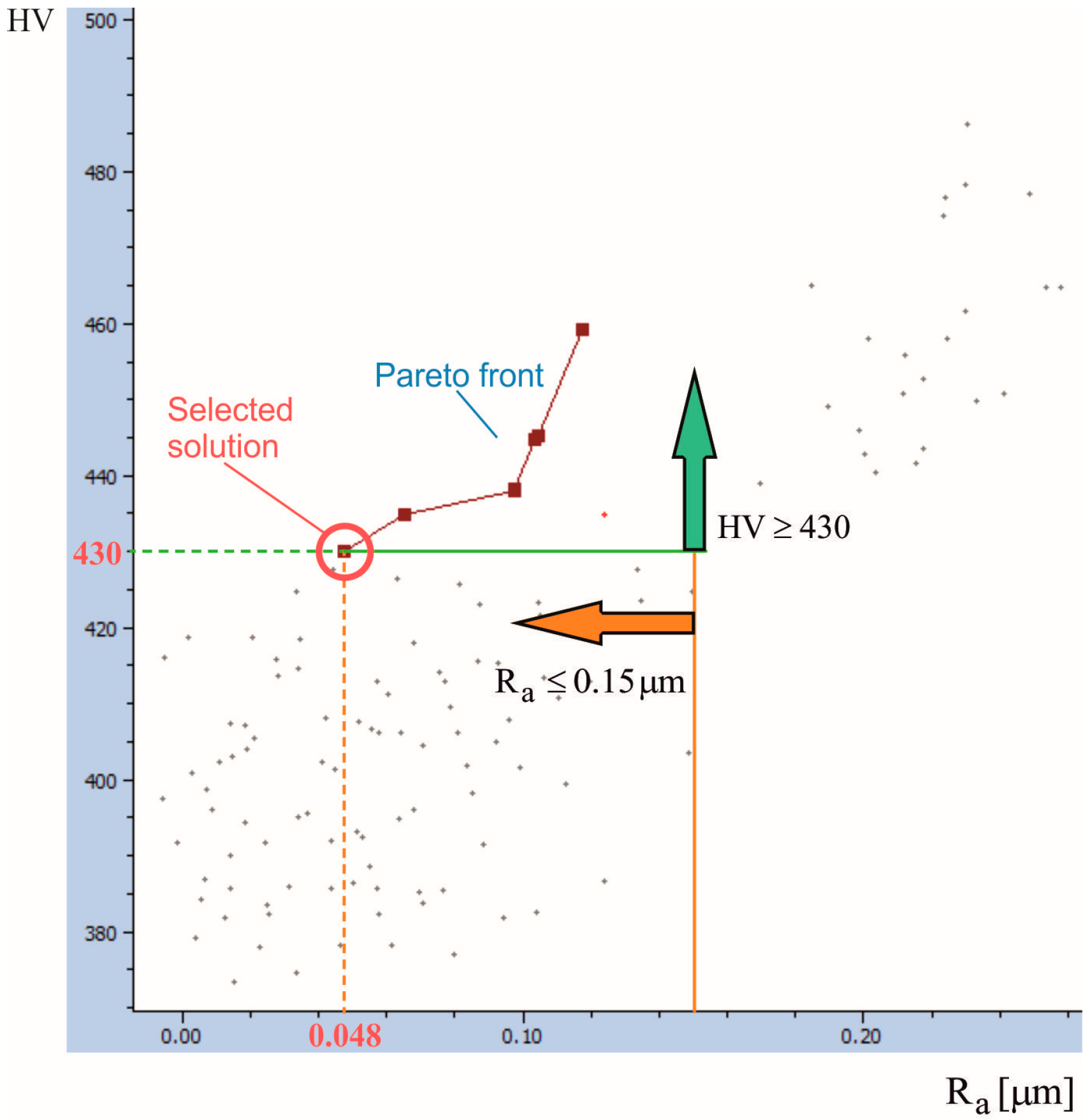

3.3.4. DB Optimisation

3.4. Influence of the Rainit on the SI Characteristics After DB

3.4.1. Providing a Different Rainit

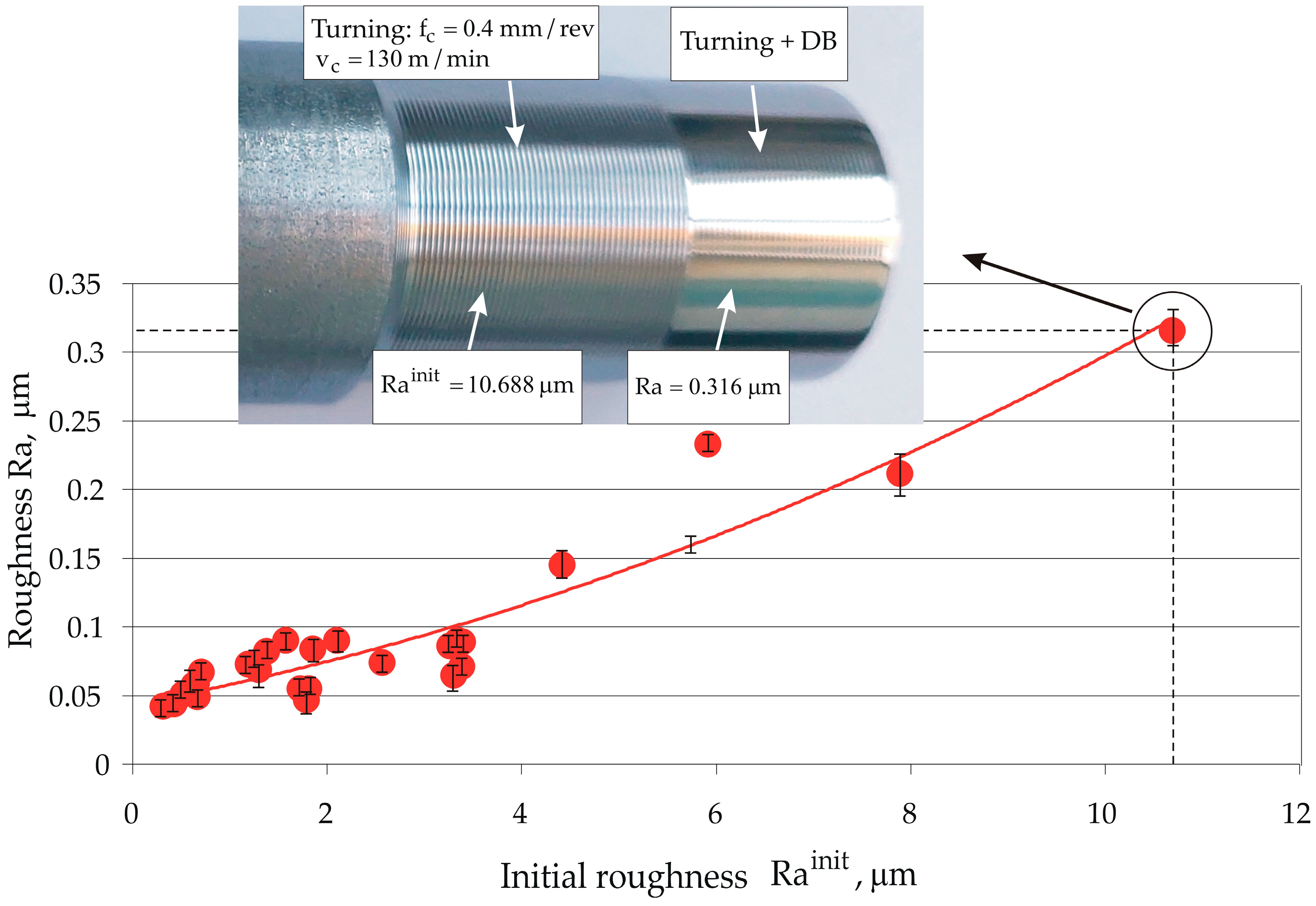

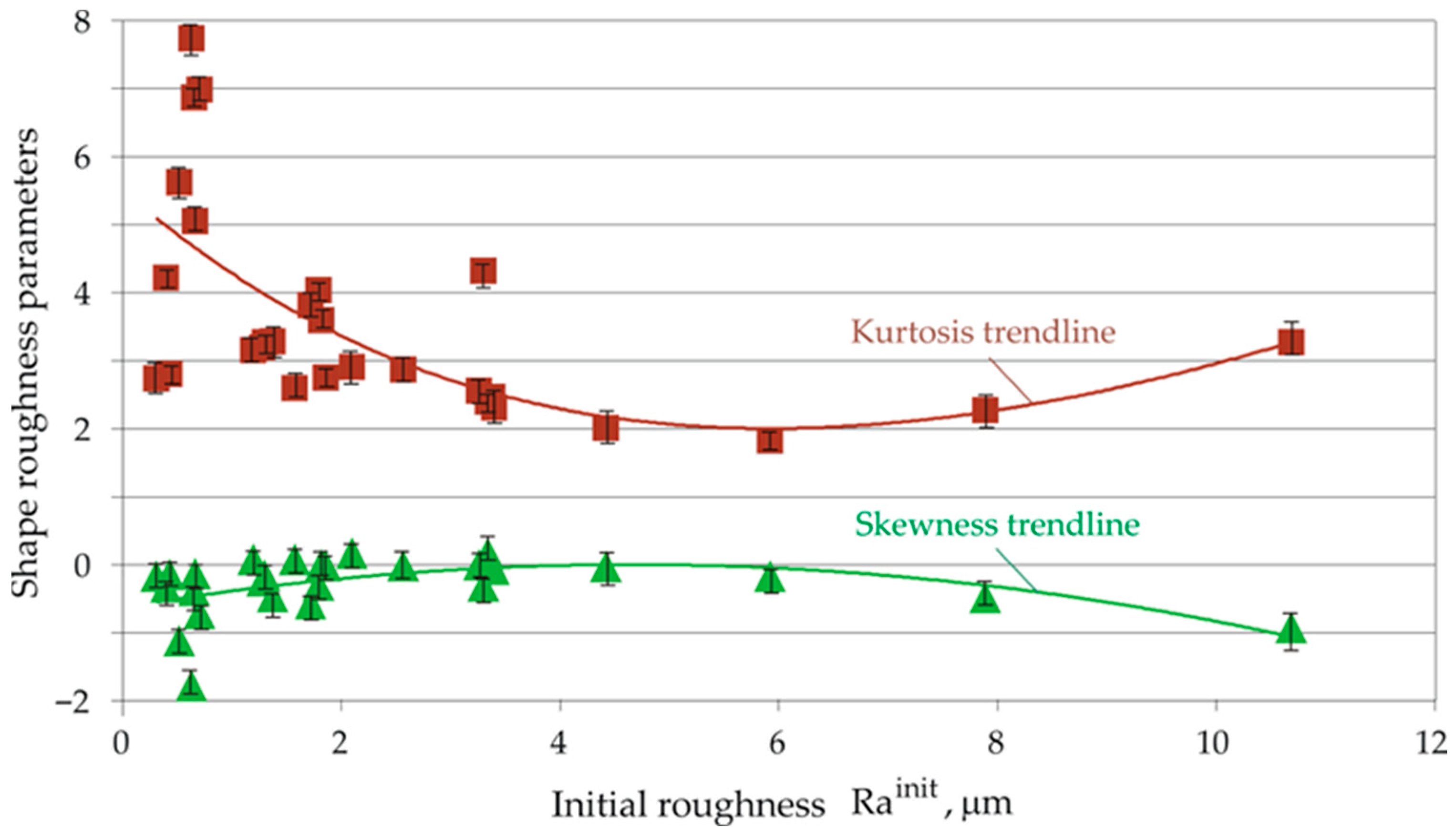

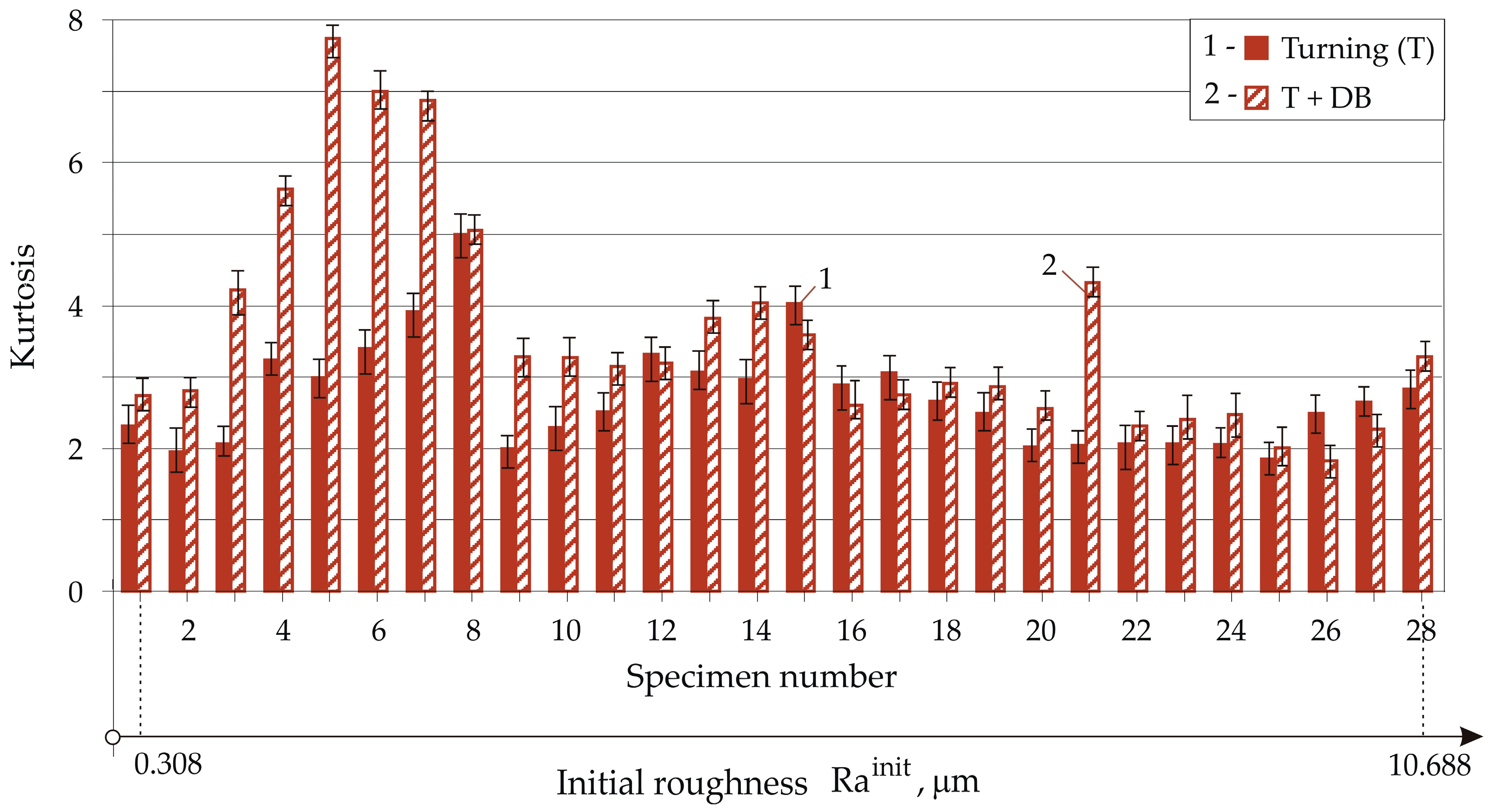

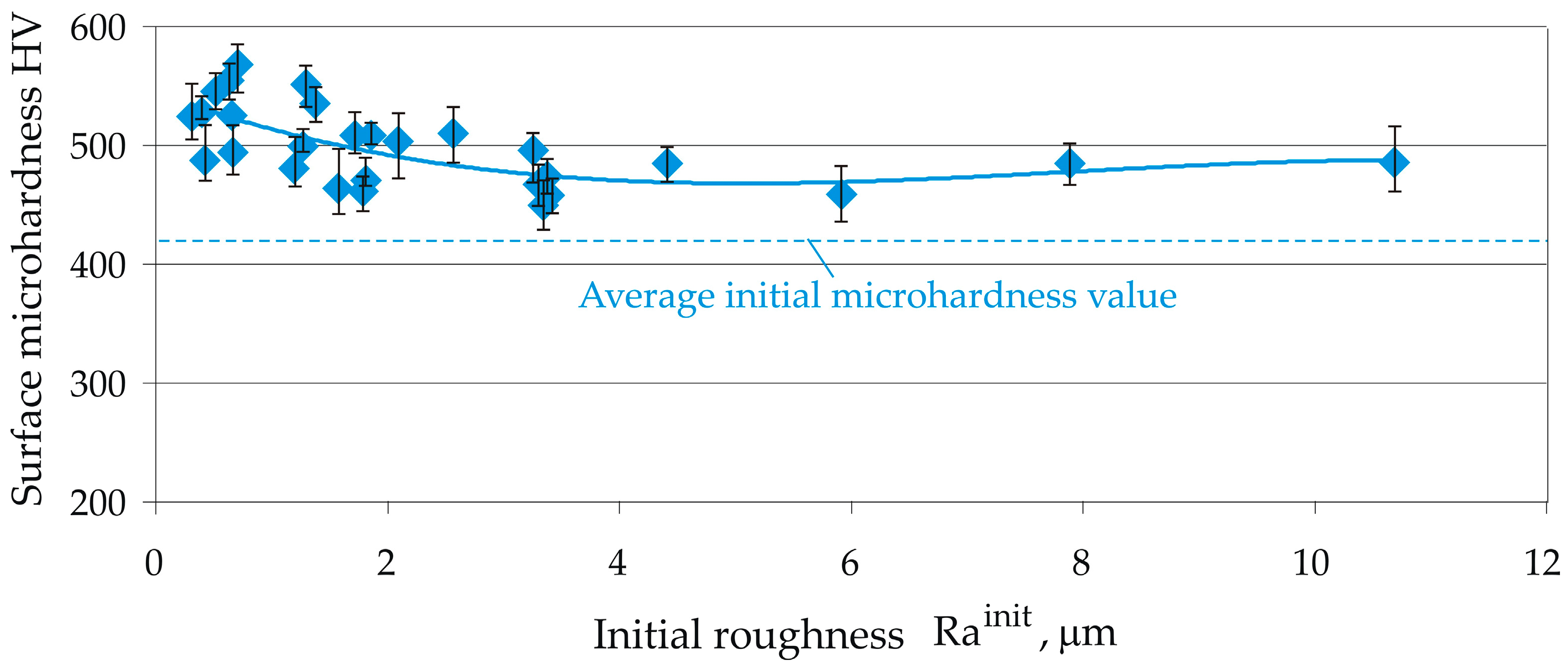

3.4.2. Influence of Rainit on Surface Roughness and Microhardness

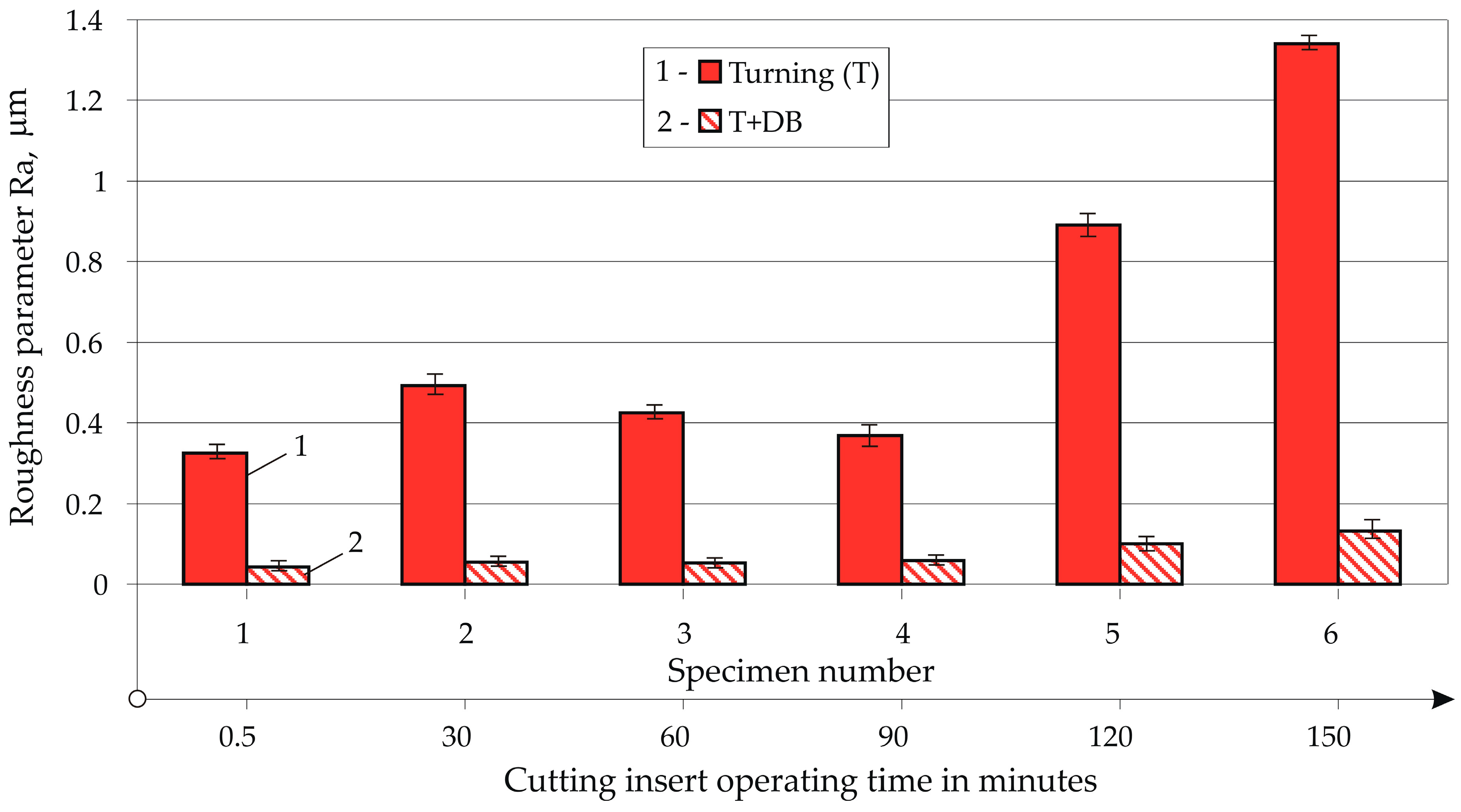

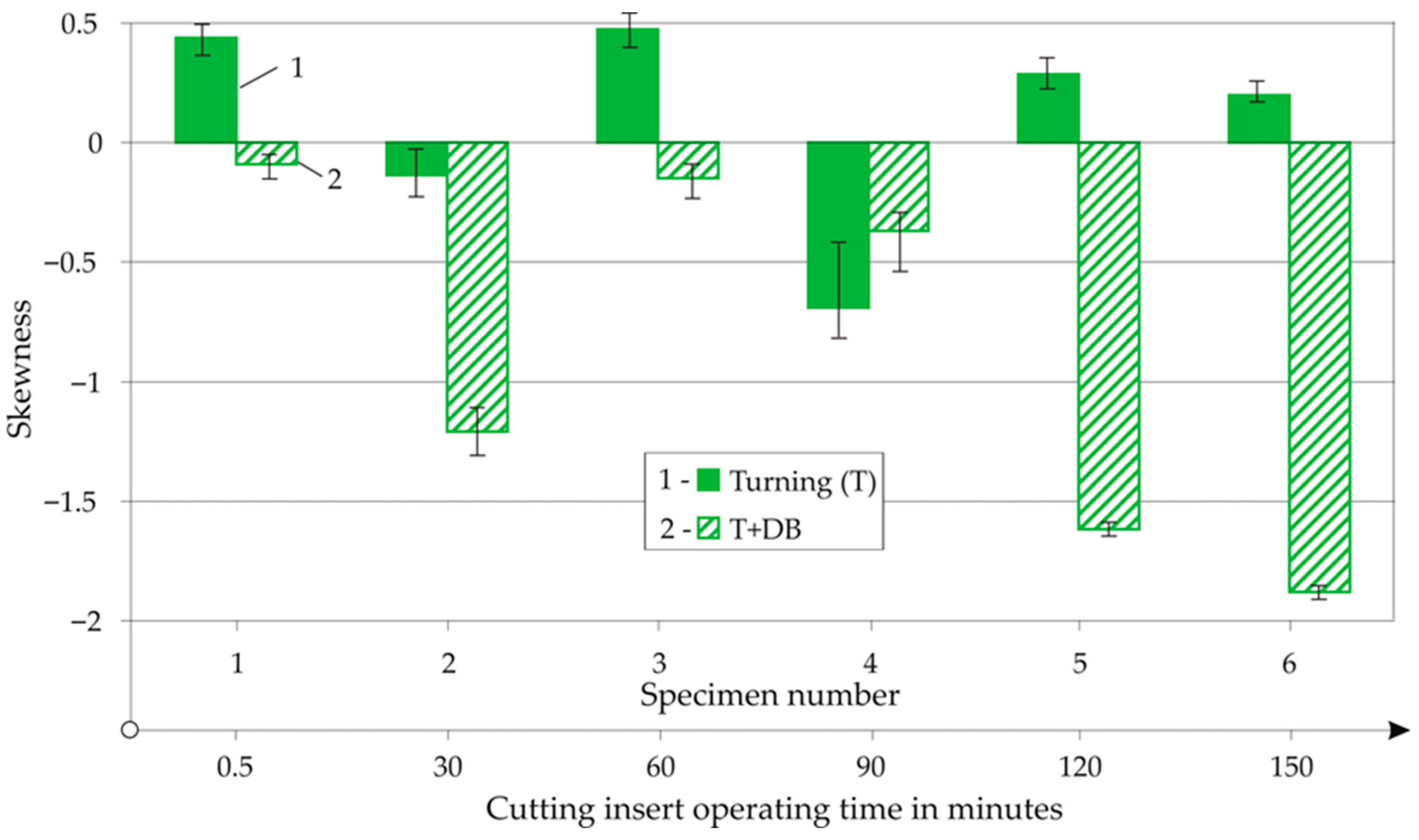

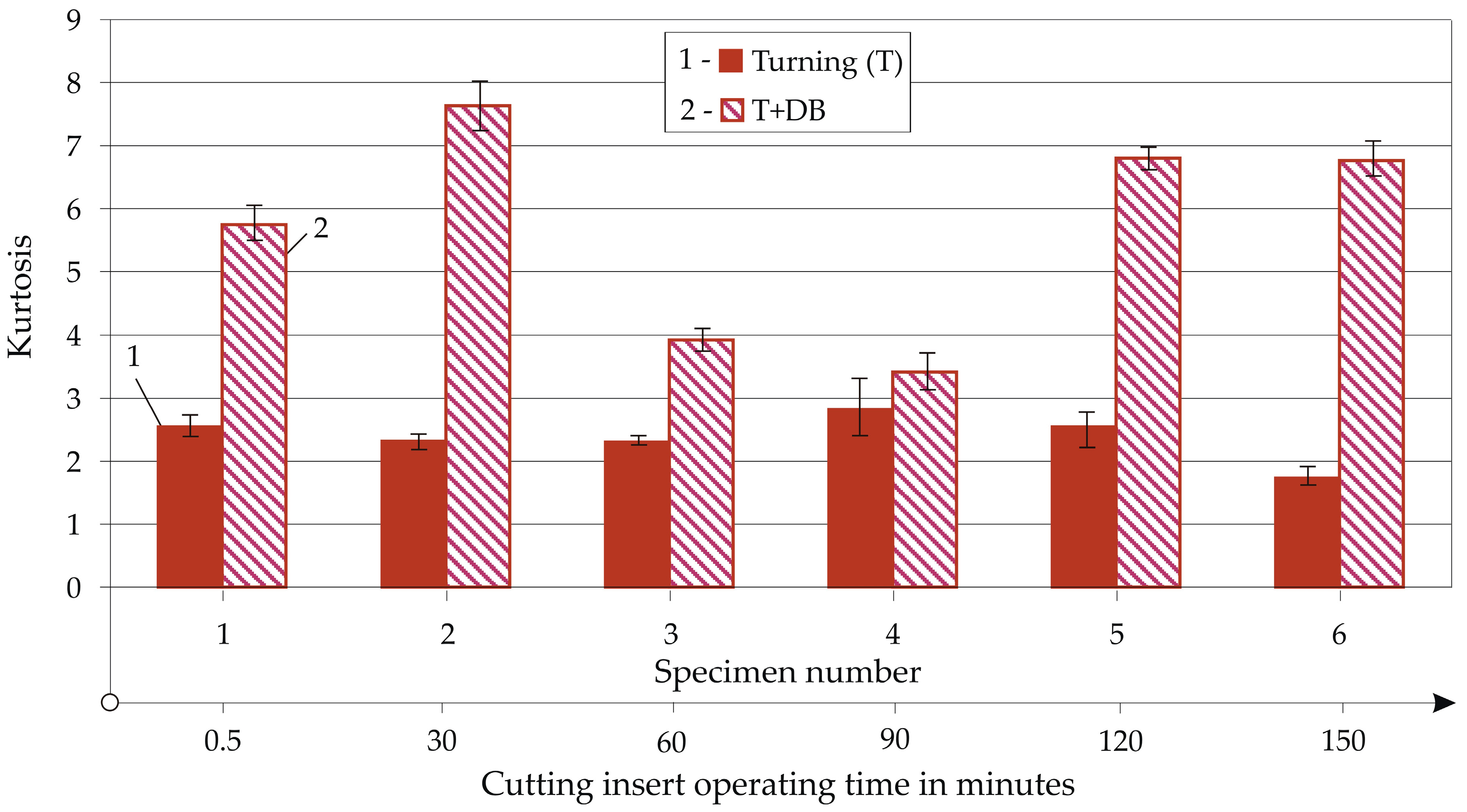

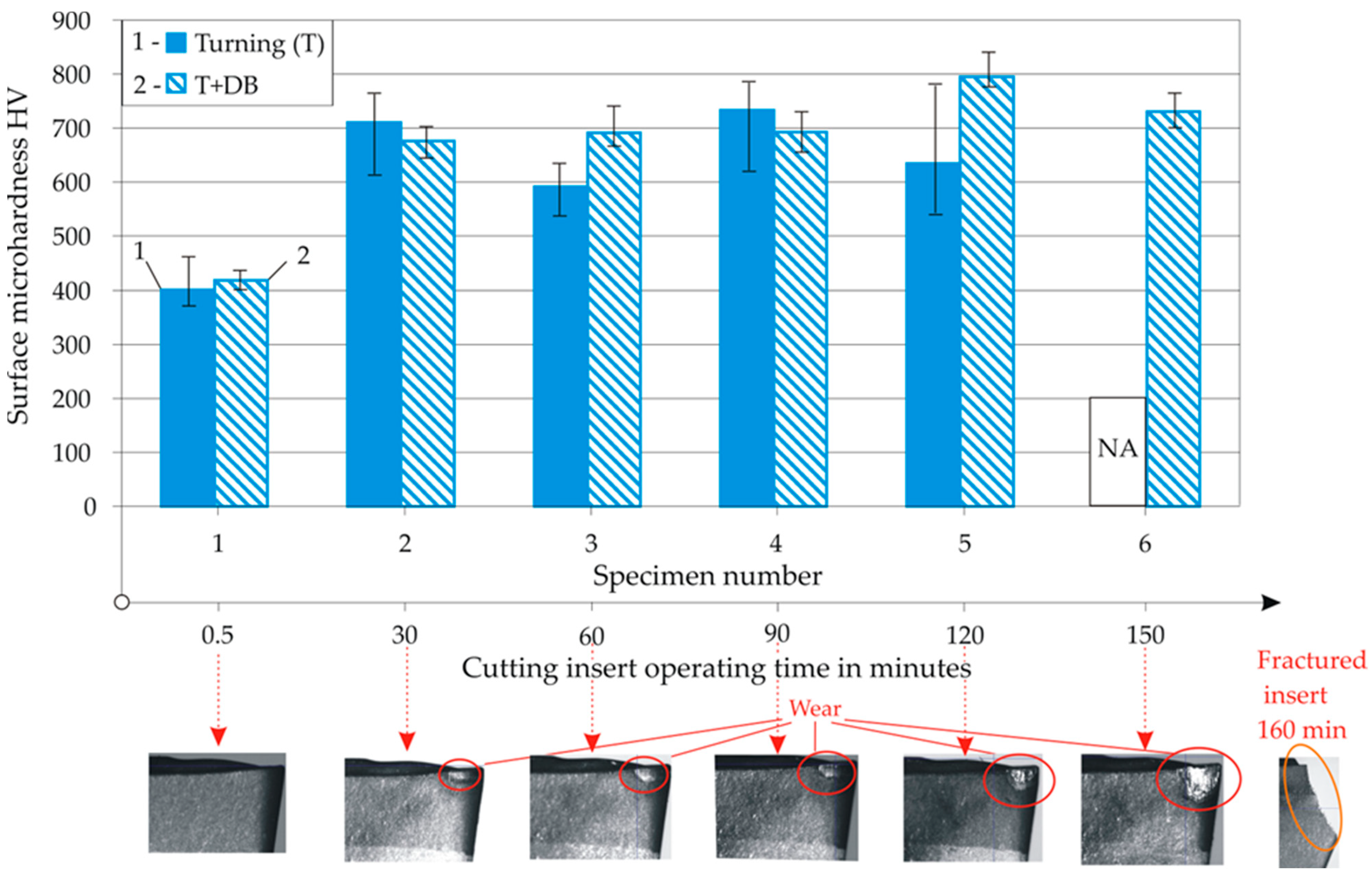

3.5. Verification of the SI Stability Under Production Conditions

4. Conclusions

- The service life of the cutting insert to complete wear, when operating using optimal parameters in the turning process, is 163 min, during which time the Ra changed unevenly from 0.38 to 1.31 μm and the Rz from 2.21 to 6.13 μm.

- Under conditions of artificially created Rainit values of 0.308 to 10.688 μm, DB provided stable Ra values from 0.042 to 0.089 μm when the Rainit increased to 3.379 μm. The skewness and kurtosis were weakly affected by Rainit. Whereas turning led to positive skewness and a kurtosis below three, DB provided sustained negative skewness and kurtosis values above three. This combination of skewness and kurtosis values, together with the low Ra (mirror-like surface), favoured the tribological behaviour of the diamond-burnished surface under boundary friction conditions. The surface microhardness varied from 461 to 568 HV.

- Under production conditions, with the previous turning performed using optimal parameters, DB provided a stable Ra of ≤0.059 µm of the resulting mirror-like surface during the first 90 min of operation of a new (unused) cutting insert, after which the Ra values increased linearly, from 0.059 to 0.133 μm. After 30 min of operation up to the cutting insert being completely worn, the microhardness after DB varied in a range of 676 to 795 HV. The high surface microhardness was due to a complex process of surface thermo-mechanical strengthening (including strain and transformation hardening) in the previous turning caused by wear on the cutting insert.

- The in-depth study of the process of thermo-mechanical strengthening due to cutting insert wear requires numerous additional studies, which will be conducted by the authors, and the results will be the subject of a subsequent publication.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| ANOVA | Analysis of variance |

| DB | Diamond burnishing |

| SI | Surface integrity |

| SPD | Surface plastic deformation |

| XRD | X-ray diffraction |

References

- Korzynski, M. (Ed.) Slide diamond burnishing. In Nonconventional Finishing Technologies; Polish Scientific Publisher: Warsaw, Poland, 2013; pp. 9–34. [Google Scholar]

- Hull, E.H.; Nerad, A.J. Irregular Diamond Burnishing Tool. United States Patent 2966722, 3 January 1961. [Google Scholar]

- Korzynski, M. Modeling and experimental validation of the force-surface roughness relation for smoothing burnishing with a spherical tool. Int. J. Mach. Tools Manuf. 2007, 47, 1956–1964. [Google Scholar] [CrossRef]

- Korzynski, M. A model of smoothing slide ball-burnishing and an analysis of the parameter interaction. J. Mater. Process. Technol 2009, 209, 625–633. [Google Scholar] [CrossRef]

- Felho, C.; Varga, G. CAD and FEM modelling of theoretical roughness in diamond burnishing. Int. J. Precis. Eng. Manuf. 2022, 23, 375–384. [Google Scholar] [CrossRef]

- Felho, C.; Varga, G. 2D FEM investigation of residual stress in diamond burnishing. J. Manuf. Mater. Process. 2022, 6, 123. [Google Scholar] [CrossRef]

- Chodor, J.; Kukielka, L.; Chomka, G.; Bohdal, L.; Patyk, R.; Kowalik, M.; Trzepiecinski, T.; Radchenko, A.M. Using the FEM method in the prediction of stress and deformation in the processing zone of an elastic/visco-plastic material during diamond sliding burnishing. Appl. Sci. 2023, 13, 1963. [Google Scholar] [CrossRef]

- Borysenko, D.; Welzel, F.; Karpuschewski, B.; Kundrák, J.; Voropai, V. Simulation of the burnishing process on real surface structures. Precis. Eng. 2021, 68, 166–173. [Google Scholar] [CrossRef]

- Bembenek, M.; Kopei, V.; Ropyak, L.; Levchuk, K. Stressed state of chrome parts during diamond burnishing. Met. Adv. Technol. 2023, 45, 239–250. [Google Scholar] [CrossRef]

- Jimenez-Garcia, J.I.; Gapilla, G.C.; Balvantin-Garciq, A.J.; Travieso-Rodriguez, J.A.; Ruiz-Lopez, I.; Saldana-Robles, A. A numerical investigation into the influence of the slide burnishing process on the real surface roughness and residual stress profiles of AHSS. J. Mater. Res. Techol 2024, 33, 1406–1419. [Google Scholar] [CrossRef]

- Saldana-Robles, A.; Plascencia-Mora, H.; Aguilera-Gomez, E.; Saldana-Robles, A.; Marquez-Herrera, A.; Diosdado-De la Pena, J.A. Influence of ball-burnishing on roughness, hardness and corrosion resistance of AISI 1045 steel. Surf. Coat. Technol. 2018, 339, 191–198. [Google Scholar] [CrossRef]

- Skoczylas, A.; Zaleski, K. Study on the surface layer properties and fatigue life of a workpiece machined by centrifugal shot peening and burnishing. Materials 2022, 15, 6677. [Google Scholar] [CrossRef]

- Bourebia, M.; Bouri, A.; Hamadache, H.; Achouri, S.; Laouar, L.; Gharbi, A.; Ghelloudj, O.; Bouhamla, K. Study of the effect burnishing on superficial hardness and hardening of S355JR steel using experimental planning. Energy Procedia 2019, 157, 568–577. [Google Scholar] [CrossRef]

- Koszela, W.; Balon, P.; Rejman, S.E.; Kielbasa, B.; Smusz, R.; Bembenek, M. The influence of structuring surfaces and slide burnishing on tribological properties. Met. Adv. Technol. 2023, 45, 403–421. [Google Scholar] [CrossRef]

- Hamadache, H.; Zemouri, Z.; Laouar, L.; Dominiak, S. Improvement of surface conditions of 36CrNiMo6 steel by ball burnishing process. J. Mech. Sci. Technol. 2014, 28, 1491–1498. [Google Scholar] [CrossRef]

- Kuznetsov, V.P.; Tarasov, S.Y.; Dmitriev, A.I. Nanostructuring burnishing and subsurface shear instability. J. Mater. Process Technol. 2015, 217, 327–335. [Google Scholar] [CrossRef]

- Zielecki, W.; Bucior, M.; Trzepiecinski, T.; Ochał, K. Effect of slide burnishing of shoulder fillets on the fatigue strength of X19NiCrMo4 steel shafts. Int. J. Adv. Manuf. Technol. 2020, 106, 2583–2593. [Google Scholar] [CrossRef]

- Kluz, R.; Antosz, K.; Trzepieciński, T.; Bucior, M. Modelling the Influence of Slide Burnishing Parameters on the Surface Roughness of Shafts Made of 42CrMo4 Heat-Treatable Steel. Materials 2021, 14, 1175. [Google Scholar] [CrossRef]

- Dunchev, V.P. Comprehensive model of the micro-hardness of diamond burnished 41Cr4 steel specimens. J. Tech. Univ. Gabrovo 2020, 60, 25–33. [Google Scholar]

- Taamllah, O.; Hamadache, H.; Mokas, N.; Amirat, A.; Hamadi, B. Investigation of the effect of slide diamond burnishing process on the mechanical performance of GCr15 steel. J. Fail. Anal. Prev. 2023, 23, 1101–1113. [Google Scholar] [CrossRef]

- Labanowski, J.; Ossowska, A. Influence of burnishing on stress corrosion cracking susceptibility of duplex steel. J. Achiev. Mater. Manuf. Eng. 2006, 19, 46–52. [Google Scholar]

- Kuznetsov, V.P.; Kosareva, A.V. Increase of wear and heat resistance of the AISI 304 steel surface layer by multi-pass nanostructuring burnishing. J. Mater. Eng. 2023, 1, 55–61. [Google Scholar] [CrossRef]

- Aliev, K.T.; Aslanov, T.I. The influence of diamond burnishing on the fatigue strength and wear resistance of the shafts of petroleum chains. Chem. Pet. Eng. 1979, 15, 459–461. [Google Scholar] [CrossRef]

- Argirov, Y.B.; Maximov, J.T.; Duncheva, G.V.; Anchev, A.P.; Dunchev, V.P.; Mechkarova, T.M. Evolution of surface integrity characteristics and mechanical behavior of diamond burnished and turned AISI 304 steel specimens after prolonged exposure to natural seawater. Coatings 2025, 15, 31. [Google Scholar] [CrossRef]

- Maximov, J.; Duncheva, G.; Anchev, A.; Dunchev, V.; Anastasov, K.; Argirov, Y. Sustainable Diamond Burnishing of Chromium–Nickel Austenitic Stainless Steels: Effects on Surface Integrity and Fatigue Limit. Appl Sci 2024, 14, 9031. [Google Scholar] [CrossRef]

- Maximov, J.T.; Duncheva, G.V.; Dunchev, V.P.; Anchev, A.P. Different strategies for finite element simulations of static mechanical surface treatment processes—A comparative analysis. J. Braz. Soc. Mech. Sci. Eng. 2021, 43, 371. [Google Scholar] [CrossRef]

- Kato, H.; Hirokawa, W.; Todaka, Y.; Yasunaga, K. Improvement in surface roughness and hardness for carbon steel by slide burnishing process. Mater. Sci. Appl. 2021, 12, 171–181. [Google Scholar] [CrossRef]

- Abdallah, A.; Abdelsalam, M.; Ibrahim, A.A.; Hassan, H.A.; Youssef, W.F. The effect of initial surface profile on the surface roughness and roundness in ball burnishing process. J. Eng. Sci. 2025, 53, 140–156. [Google Scholar] [CrossRef]

- Magnabosco, I.; Ferro, P.; Tiziani, A.; Bonollo, F. Induction heat treatment of a ISO C45 steel bar: Experimental and numerical analysis. Comput. Mater. Sci. 2006, 35, 98–106. [Google Scholar] [CrossRef]

- Blaoui, M.M.; Zemri, M.; Brahami, A. Effect of heat treatment parameters on mechanical properties of medium carbon steel. Mech. Mech. Eng. 2018, 22, 909–918. [Google Scholar] [CrossRef]

- Wozniak, W.; Sasiadek, M.; Jachowicz, T.; Edl, M.; Zajac, P. Studies on the mechanical properties of C45 steel with martensitic structure after a high tempering process. Adv. Sci. Technol. Res. J. 2022, 16, 306–315. [Google Scholar] [CrossRef]

- Bubphachot, B.; Premanond, V.; Keawtatip, P. Optimum heat treatment conditions for C45 steel in fine blanking process. Eng. Appl. Sci. Res. 2005, 32, 551–562. [Google Scholar]

- Laouissi, A.; Blaoui, M.M.; Abderazek, H.; Nouioua, M.; Bouchoucha, A. Heat treatment process study and ANN-GA based multi-response optimization of C45 steel mechanical properties: A. Laouissi et al. Met. Mater. Int. 2022, 28, 3087–3105. [Google Scholar] [CrossRef]

- Al-Qawabah, S.M.A.; Alshabatat, N.; Al-Qawabeha, U.F. Effect of annealing temperature on the microstructure, microhardness, mechanical behavior and impact toughness of low carbon steel grade 45. Int. J. Eng. Res. Appl. 2012, 2, 1550–1553. [Google Scholar]

- Omar, A.A.; El-Shennawy, M.; Elhabib, O.A. Effect of cyclic heat treatment on microstructure and mechanical properties of C45 steel. Int. J. Mech. Eng. 2014, 3, 69–76. [Google Scholar]

- Moravčíková, J.; Moravčík, R.; Palcut, M. Effect of heat treatment on the resulting dimensional characteristics of the C45 carbon steel after turning. Metals 2022, 12, 1899. [Google Scholar] [CrossRef]

- Ghiban, B.; Rucai, V.; Navodariu, N.; Saceleanu, V.; Bran, D.-T. The influence of the heat treatment over the mechanical behavior of steels used for alternator shafts. UPB Sci. Bull. Ser. B 2019, 81, 219–231. [Google Scholar]

- Kulawik, A.; Wrobel, J.; Sobiepanski, M. Experimental and simulation of C45 steel bar heat treatment with the GTAW method application. Heat Mass Transf. 2021, 57, 595–604. [Google Scholar] [CrossRef]

- ISO 6892-1:2019; Metallic Materials—Tensile Testing—Part1: Method of Test at Room Temperature. ISO: Geneva, Switzerland, 2019.

- ISO 26843:2015; Metallic Materials. Measurement of Fracture Toughness at Impact Loading Rates Using Precracked Charpy-Type Test Pieces. ISO: Geneva, Switzerland, 2015.

- Vuchkov, I.N.; Vuchkov, I.I. QStatLab Professional, version 6.1.1.3; Statistical Quality Control Software, User’s Manual; QStatLab: Sofia, Bulgaria, 2009. [Google Scholar]

- Ferencsik, V.; Varga, G. Examination of 3D surface topography of diamond burnished C45 workpieces. Cut. Tools Technol. Syst. 2019, 90, 158–167. [Google Scholar] [CrossRef]

- Skoczylas, A.; Klonica, M. Selected properties of the surface layer of C45 steel samples after slide burnishing. Materials 2023, 16, 6513. [Google Scholar] [CrossRef]

- Zaghal, J.; Molnar, V.; Benke, M. Improving surface integrity by optimizing slide diamond burnishing parameters after hard turning of 42CrMo4 steel. Int. J. Adv. Manuf. Technol. 2023, 128, 2087–2103. [Google Scholar] [CrossRef]

- Vuchkov, I.N.; Stoyanov, S.K. Mathematical Modeling and Optimization of Technological Objects; Technika: Sofia, Bulgaria, 1986. (In Bulgarian) [Google Scholar]

- Chang, L.; Jeng, Y.R. Effects of negative skewness of surface roughness on the contact and lubrication of nominally flat metallic surfaces. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2012, 227, 559–569. [Google Scholar] [CrossRef]

- Sedlacek, M.; Podgornik, B.; Vizintin, J. Correlation between standard roughness parameters skewness and kurtosis and tribological behaviour of contact surface. Tribol. Int. 2012, 48, 102–112. [Google Scholar] [CrossRef]

- Korzynski, M.; Dudek, K.; Kruczek, B.; Kocurek, P. Equilibrium surface texture of valve stems and burnishing method to obtain it. Tribol. Int. 2018, 124, 195–199. [Google Scholar] [CrossRef]

| Fe | C | Si | Mn | P | S | Cr | Ni | Mo | Cu | Al | Nb | Sn | Other |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 98.34 | 0.420 | 0.203 | 0.671 | 0.012 | 0.004 | 0.070 | 0.069 | 0.009 | 0.114 | 0.018 | 0.013 | 0.034 | balance |

| State | Rm, MPa | R02, MPa | Elongation, % | Hardness, HB | |

|---|---|---|---|---|---|

| AR | 745 | 503 | 20.7 | 208 | 37 |

| N | 690 | 449 | 20.9 | 208 | 44 |

| N + Q + T | 1055 | 890 | 13.1 | 320 | 80 |

| Governing Factors | Levels | |||||||

|---|---|---|---|---|---|---|---|---|

| Feed rate | 0.050 | 0.125 | 0.200 | −1 | 0 | 1 | ||

| Cutting velocity | 130 | 155 | 180 | −1 | 0 | 1 | ||

| Cutting depth | 0.10 | 0.55 | 1.00 | −1 | 0 | 1 | ||

| No | Governing Factors | Ra, μm | ||

|---|---|---|---|---|

| 1 | −1 | −1 | −1 | 2.957 |

| 2 | 1 | −1 | −1 | 4.169 |

| 3 | −1 | 1 | −1 | 0.614 |

| 4 | 1 | 1 | −1 | 3.032 |

| 5 | −1 | −1 | 1 | 3.190 |

| 6 | 1 | −1 | 1 | 4.707 |

| 7 | −1 | 1 | 1 | 0.370 |

| 8 | 1 | 1 | 1 | 2.857 |

| 9 | −1 | 0 | 0 | 3.717 |

| 10 | 1 | 0 | 0 | 3.089 |

| 11 | 0 | −1 | 0 | 3.944 |

| 12 | 0 | 1 | 0 | 1.232 |

| 13 | 0 | 0 | −1 | 1.460 |

| 14 | 0 | 0 | 1 | 1.287 |

| Governing Factors | Levels | |||||||

|---|---|---|---|---|---|---|---|---|

| Diamond radius r [mm] | 2 | 3 | 4 | −1 | 0 | 1 | ||

| Burnishing force | 100 | 150 | 200 | −1 | 0 | 1 | ||

| Feed rate | 0.02 | 0.05 | 0.08 | −1 | 0 | 1 | ||

| No | Governing Factors | Ra, μm | HV | ||

|---|---|---|---|---|---|

| 1 | −1 | −1 | −1 | 0.188 | 470 |

| 2 | 1 | −1 | −1 | 0.034 | 420 |

| 3 | −1 | 1 | −1 | 0.221 | 476 |

| 4 | 1 | 1 | −1 | 0.062 | 430 |

| 5 | −1 | −1 | 1 | 0.286 | 475 |

| 6 | 1 | −1 | 1 | 0.162 | 406 |

| 7 | −1 | 1 | 1 | 0.249 | 510 |

| 8 | 1 | 1 | 1 | 0.079 | 408 |

| 9 | −1 | 0 | 0 | 0.219 | 435 |

| 10 | 1 | 0 | 0 | 0.058 | 385 |

| 11 | 0 | −1 | 0 | 0.038 | 406 |

| 12 | 0 | 1 | 0 | 0.031 | 410 |

| 13 | 0 | 0 | −1 | 0.026 | 393 |

| 14 | 0 | 0 | 1 | 0.051 | 399 |

| 0.02569 | −0.0768 | −0.0066 | 0.0296 | 0.11281 | 0.00881 | 0.01281 | −0.00637 | −0.02262 | 0 | |

| 382.312 | −31.7 | 5.7 | 0 | 27.6875 | 25.6875 | 13.6875 | −3.625 | 2.625 | −9.375 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maximov, J.; Duncheva, G.; Anastasov, K.; Ichkova, M.; Daskalova, P. Influence of Previous Turning on the Surface Integrity Stability of Diamond-Burnished Medium-Carbon Steel. Machines 2025, 13, 864. https://doi.org/10.3390/machines13090864

Maximov J, Duncheva G, Anastasov K, Ichkova M, Daskalova P. Influence of Previous Turning on the Surface Integrity Stability of Diamond-Burnished Medium-Carbon Steel. Machines. 2025; 13(9):864. https://doi.org/10.3390/machines13090864

Chicago/Turabian StyleMaximov, Jordan, Galya Duncheva, Kalin Anastasov, Mariana Ichkova, and Petya Daskalova. 2025. "Influence of Previous Turning on the Surface Integrity Stability of Diamond-Burnished Medium-Carbon Steel" Machines 13, no. 9: 864. https://doi.org/10.3390/machines13090864

APA StyleMaximov, J., Duncheva, G., Anastasov, K., Ichkova, M., & Daskalova, P. (2025). Influence of Previous Turning on the Surface Integrity Stability of Diamond-Burnished Medium-Carbon Steel. Machines, 13(9), 864. https://doi.org/10.3390/machines13090864