Microstructure Characterization and Mechanical Properties of Dissimilar Al/Al-Li Alloy T-Joints Welded by Friction Stir Welding

Abstract

1. Introduction

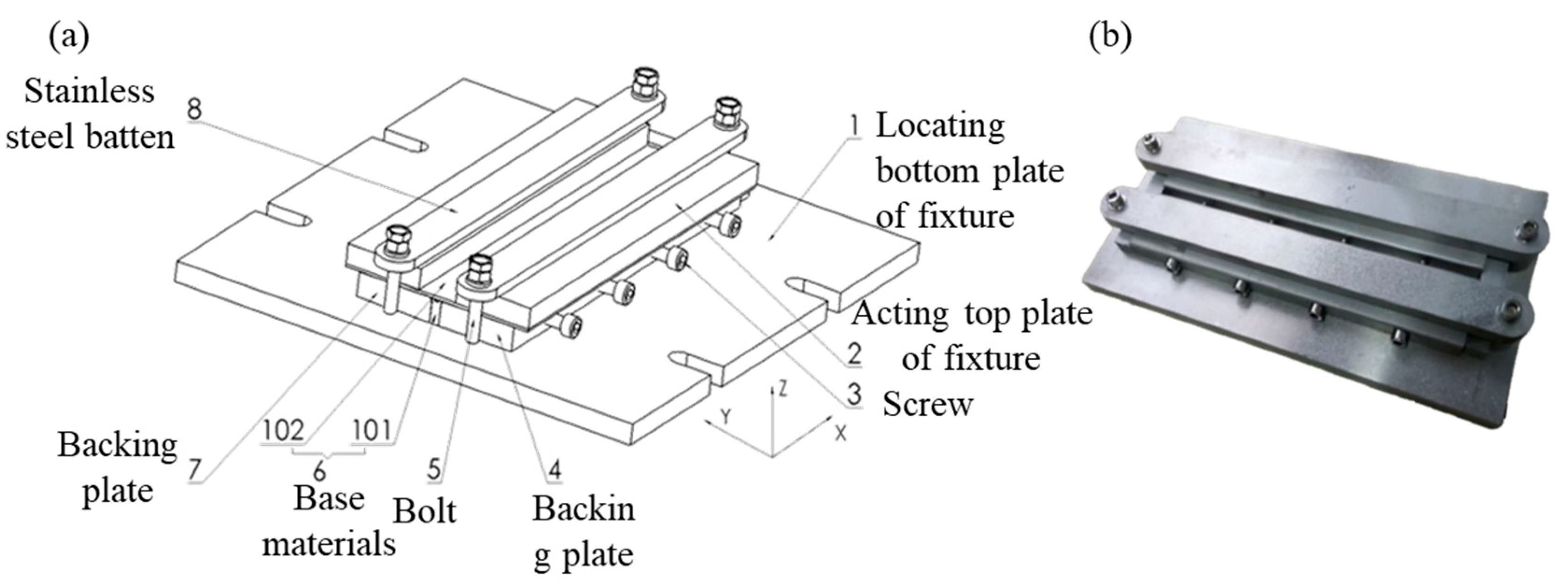

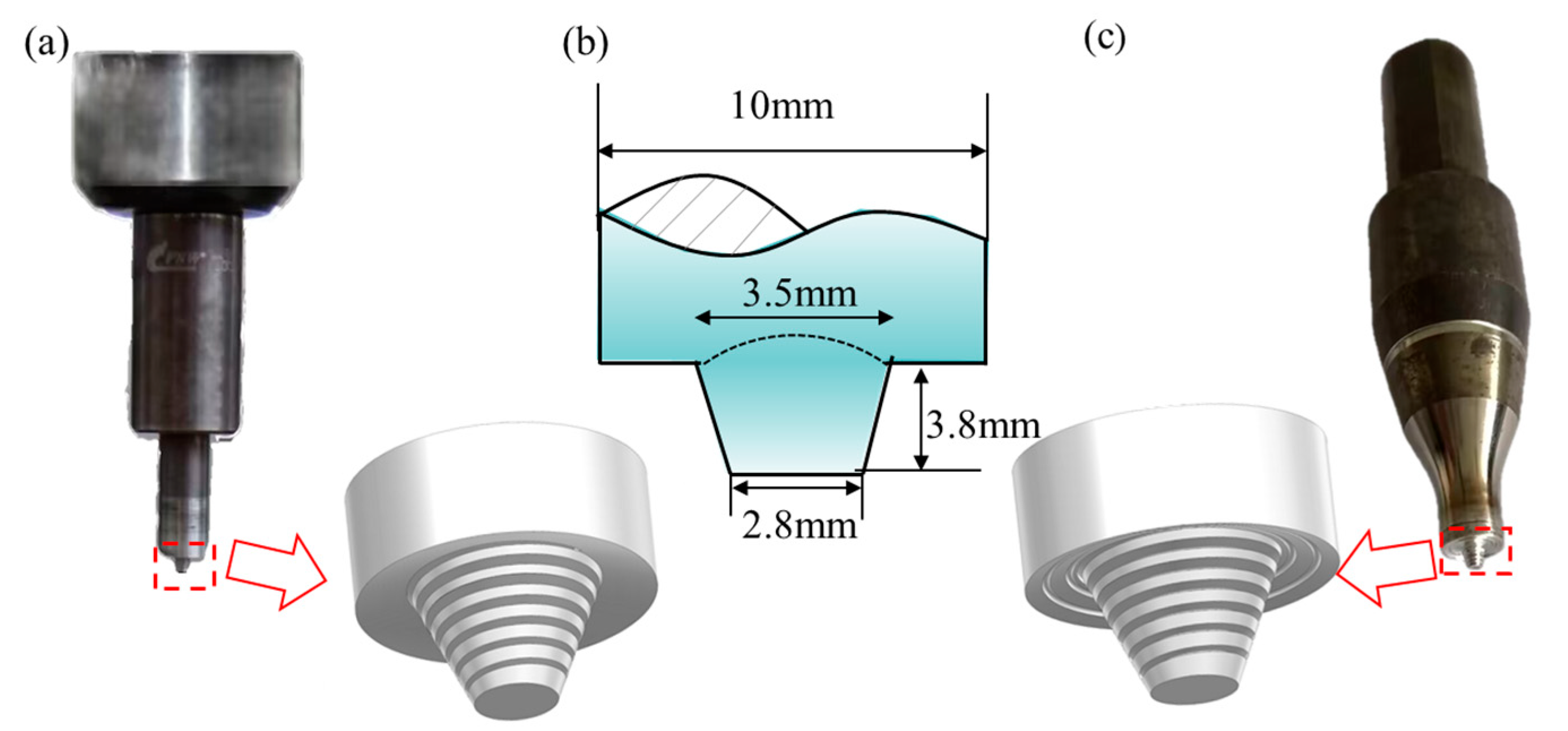

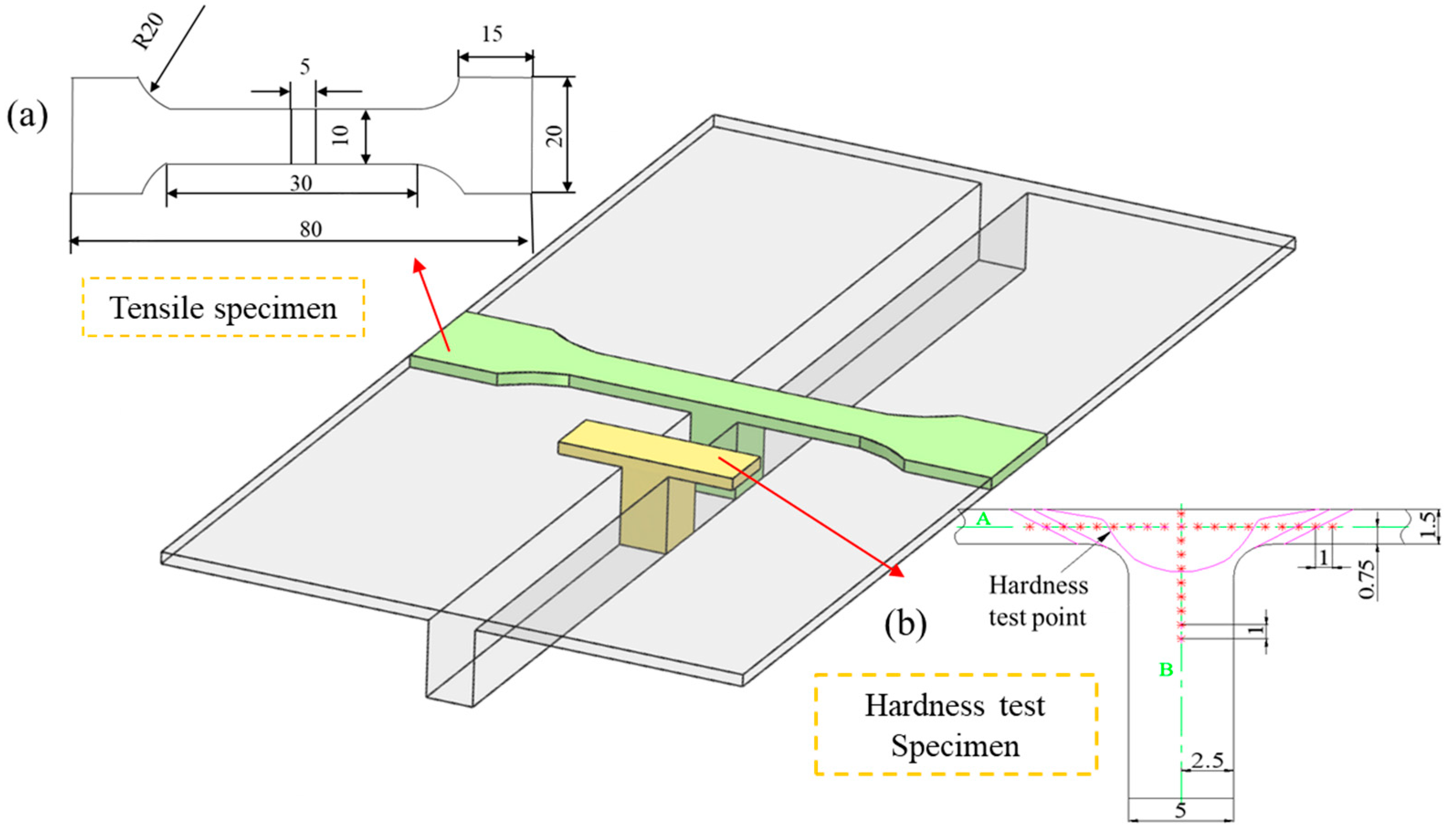

2. Experimental Procedure

3. Results and Discussion

3.1. Forming Characteristics of T-Joint Welds

3.1.1. Weld Surface Morphology

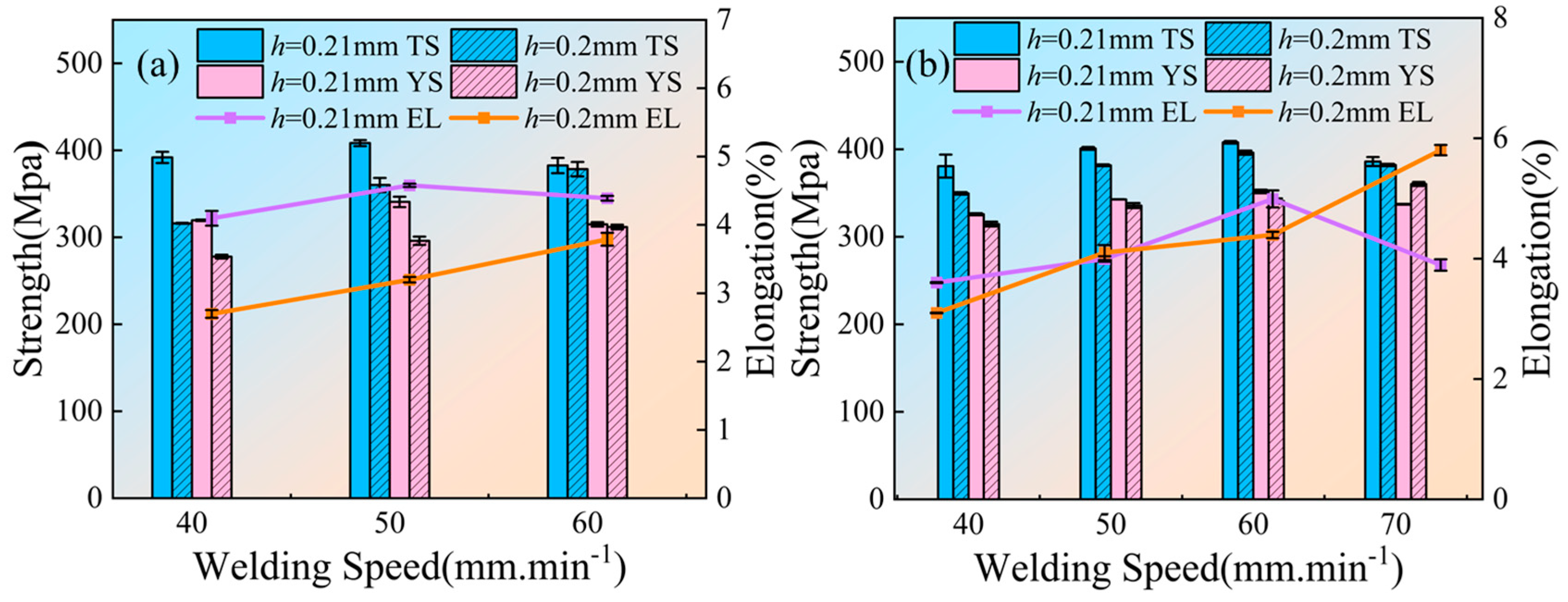

3.1.2. Tensile Test

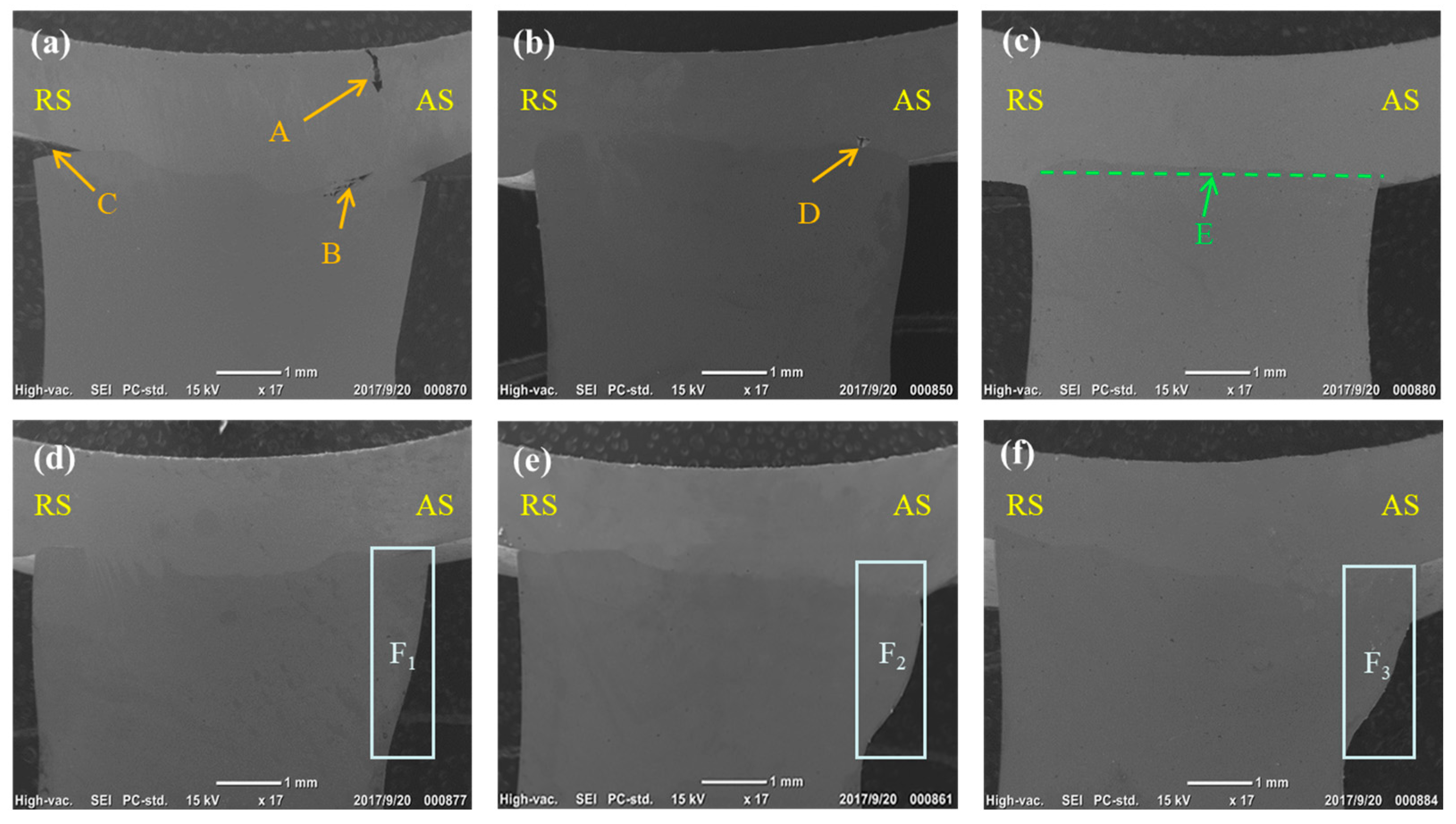

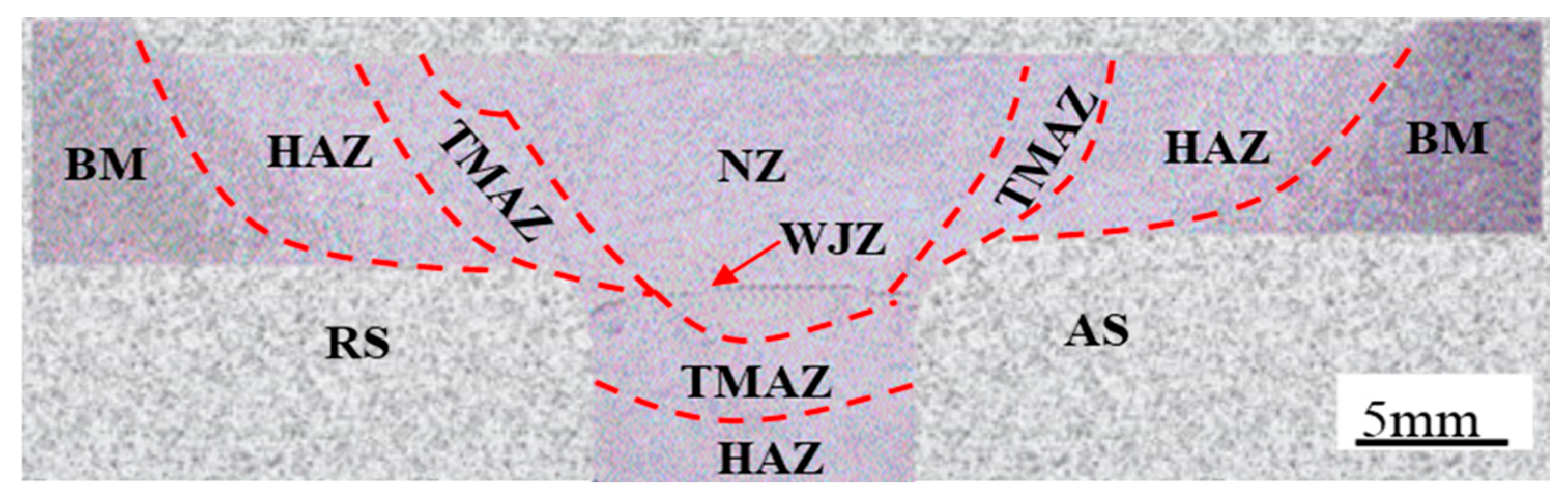

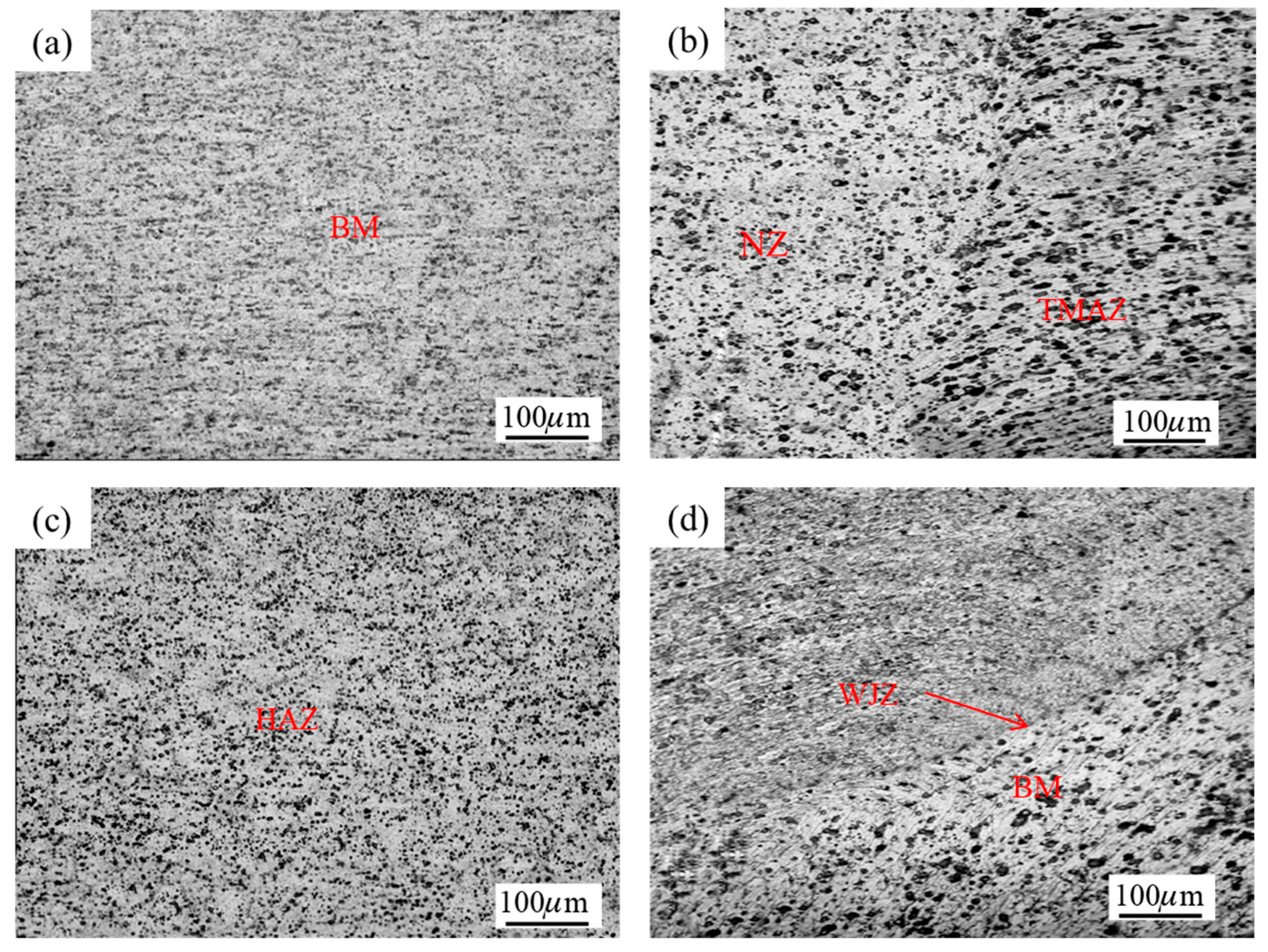

3.2. Microstructural Features

3.2.1. Microstructural Evolution

3.2.2. Tensile Fracture Morphology

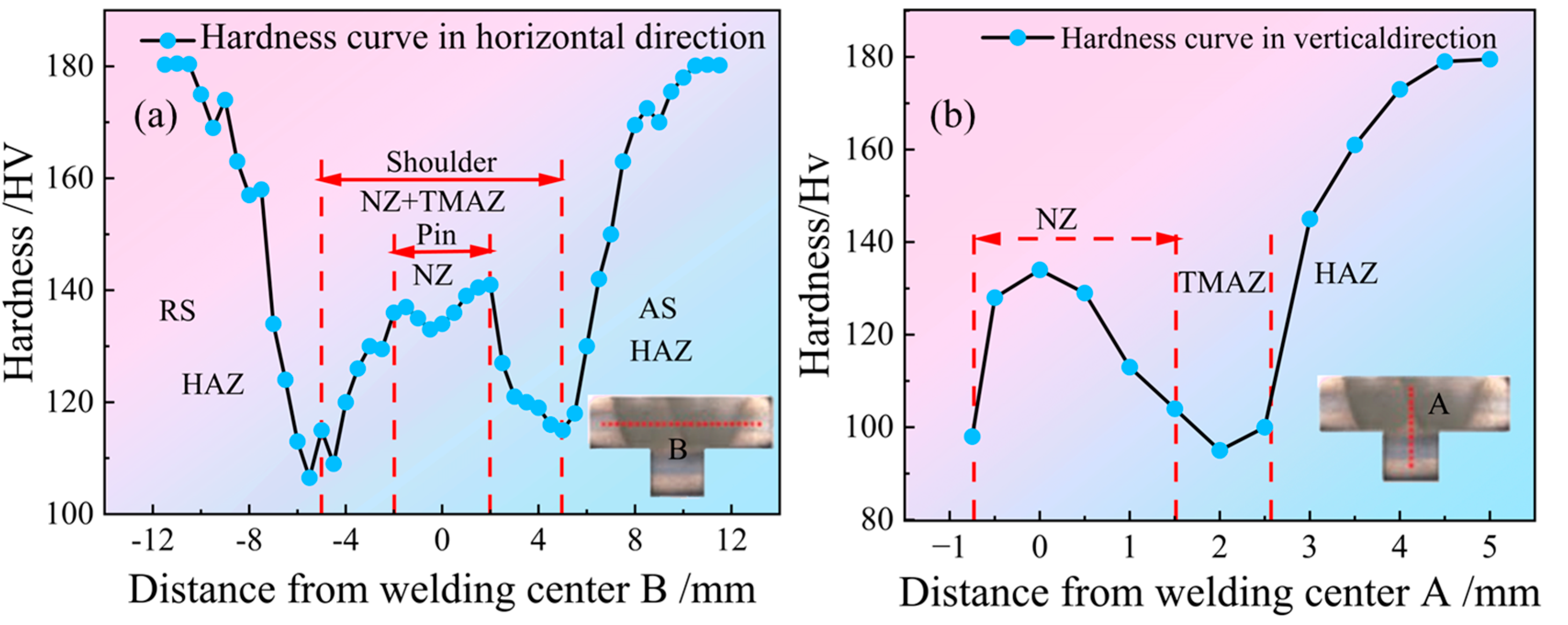

3.3. Microhardness Test

4. Conclusions

- (1)

- The ICSWS shoulder structure produces superior T-joint morphology with fewer weld defects compared to ICSWOS. Its spiral design reduces the actual contact area, leading to increased normal pressure and concentrates strain under identical axial downward force, thereby generating greater frictional and plastic deformation heat input.

- (2)

- Defect-free T-joints are achieved at w = 350 rpm, v = 60 mm/min, h = 0.21 mm, with simultaneous peak values of YS (352 MPa), TS (408 MPa), and EL (5%). The TS reaches 68.0% and 71.6% of base materials 7055-T61 and 2197-T8, respectively. Tensile specimens exhibit ductile fracture characterized by abundant deep dimples and elongated tear ridges on fracture surfaces—consistent with macroscopic tensile property trends.

- (3)

- According to the heat source distribution in the T-joint based on the distance from the centerline of the plate thickness, it can be divided into NZ, TMAZ, HAZ, and BM, with a WJZ between TMAZ and HAZ. Further research on the microstructure changes in NZ indicates the precipitation of θ′, T1, η′, and η phases. Simultaneously, newly formed fine precipitates emerge along grain boundaries, characterized by their significantly reduced size and more dispersed, discontinuous distribution. These finely dispersed precipitates effectively inhibit grain coarsening, thereby further enhancing the mechanical strength of the joint.

- (4)

- The microhardness in the NZ correlate with precipitated phases. And along the centerline B of the weld, the T-joints exhibit a “W” distribution pattern, with the HAZ beneath the axis shoulder having the lowest hardness (106.5 Hv). Along the centerline A of the weld, the T-joints exhibit a “Z” distribution pattern, with the lowest hardness near the TMAZ.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, L.; Meng, X.; Huang, S.; Wang, H.; Li, P.; Zhou, J. Investigating the effect of the scanning speed on the characteristics of Al-Li alloy fabricated by selective laser melting. J. Manuf. Process. 2022, 75, 719–728. [Google Scholar] [CrossRef]

- Wu, G.; Sun, J.; Zhang, L.; Ding, W. Current status and prospects of research and application of aluminum-lithium alloy. Nonferr Met. Sci. Eng. 2019, 10, 31–46. [Google Scholar]

- Tian, S.; Shang, J.; Gai, P.T. Numerical simulation and deformation prediction of stress peen forming for integrally stiffened panels. Acta Aeronaut. Astronaut. Sin. 2019, 40, 279–291. [Google Scholar]

- Jesus, J.; Costa, J.; Loureiro, A.; Ferreira, J. Fatigue Strength Improvement of GMAW T-welds in AA 5083 by Friction-Stir Processing. Int. J. Fatigue 2017, 97, 124–134. [Google Scholar] [CrossRef]

- Rhodes, C.G.; Mahoney, M.W.; Bingel, W.H.; Spurling, R.A.; Bampton, C.C. Effects of friction stir welding on microstructure of 7075 aluminum. Scr. Mater. 1997, 36, 69–75. [Google Scholar] [CrossRef]

- Zuo, D.Q.; Cao, Z.Q.; Cao, Y.J.; Huo, L.B.; Li, W.Y. Thermal fields in dissimilar 7055 Al and 2197 Al-Li alloy FSW T-joints: Numerical simulation and experimental verification. Int. J. Adv. Manuf. Technol. 2019, 103, 3495–3512. [Google Scholar] [CrossRef]

- Li, J.; Shen, Y.; Hou, W.; Qi, Y. Friction stir welding of Ti-6Al-4V alloy: Friction tool, microstructure, and mechanical properties. J. Manuf. Process 2020, 58, 344–354. [Google Scholar] [CrossRef]

- Yuvaraj, K.; Varthanan, P.A.; Haribabu, L.; Madhubalan, R.; Boopathiraja, K. Optimization of FSW tool parameters for joining dissimilar AA7075-T651 and AA6061 aluminium alloys using Taguchi Technique. Mater. Today Proc. 2021, 45, 919–925. [Google Scholar] [CrossRef]

- Kaushik, P.; Dwivedi, D.K. Effect of tool geometry in dissimilar Al-Steel Friction Stir Welding. J. Manuf. Process. 2021, 68 Pt B, 198–208. [Google Scholar] [CrossRef]

- Goel, P.; Siddiquee, A.N.; Khan, N.Z.; Hussain, M.A.; Khan, Z.A.; Abidi, M.H.; Al-Ahmari, A. Investigation on the Effect of Tool Pin Profiles on Mechanical and Microstructural Properties of Friction Stir Butt and Scarf Welded Aluminium Alloy 6063. Metals 2018, 8, 74. [Google Scholar] [CrossRef]

- Burek, R.; Wydrzyński, D.; Sęp, J.; Więckowski, W. The effect of tool wear on the quality of lap joints between 7075 T6 aluminum alloy sheet metal created with the FSW method. Eksploat. Niezawodn. 2018, 20, 100–106. [Google Scholar] [CrossRef]

- Regensburg, A.; Schürer, R.; Weigl, M.; Bergmann, J.P. Influence of Pin Length and Electrochemical Platings on the Mechanical Strength and Macroscopic Defect Formation in Stationary Shoulder Friction Stir Welding of Aluminium to Copper. Metals 2018, 8, 85. [Google Scholar] [CrossRef]

- Li, D.; Zhang, B.; Zhang, J.; Liu, S.; Jiang, K.; Yang, X. Microstructure characteristics, static and fatigue properties of additive FSW T-joint of 6061 alloy. Trans. China Weld. Inst. 2021, 42, 62–68+91+100. [Google Scholar]

- Ajri, A.; Rohatgi, N.; Shin, Y.C. Analysis of defect formation mechanisms and their effects on weld strength during friction stir welding of Al 6061-T6 via experiments and finite element modeling. Int. J. Adv. Manuf. Technol. 2020, 107, 4621–4635. [Google Scholar] [CrossRef]

- Frigaard, Ø.; Grong, Ø.; Midling, O.T. process model for friction stir welding of age harding aluminum alloy. Met. Mater. Trans. A 2001, 32, 1189–1200. [Google Scholar] [CrossRef]

- Zareie, O.; Mousavizade, S.M.; Ezatpour, H.R.; Zareie, H.; Farmanbar, N. Effect of plunging depth and dwelling time on microstructure and mechanical properties of 6061 aluminum alloy welded by protrusion friction stir spot welding. Weld. World 2020, 64, 785–805. [Google Scholar] [CrossRef]

- Gao, S.; Zhou, L.; Zhang, X.; Zhang, J.; Li, G.; Zhao, H. Microstructure and properties of friction stir welded joints for 6061-T6/7075-T6 dissimilar aluminum alloy. Trans. China Weld. Inst. 2022, 43, 35–42. [Google Scholar]

- Shi, L.; Wu, C.; Jiang, Y.; Gao, S.; Fu, L. Microstructure and mechanical properties of 2195-T6 Al–Li alloy joint prepared by friction stir welding. Trans. China Weld. Inst. 2022, 43, 25–34. [Google Scholar]

- Vidakis, N.; Petousis, M.; David, C.; Sagris, D.; Mountakis, N.; Moutsopoulou, A. The impact of process parameters and pin-to-shoulder ratio in FSW of polycarbonate: Welding forces and critical quality indicators. Int. J. Adv. Manuf. Technol. 2024, 130, 5457–5477. [Google Scholar] [CrossRef]

- Liu, H.; Gao, Y.; Zhang, Q.; Zhao, H. Microstructure and mechanical properties of friction stir welded joint of 2A14-T4 aluminum alloy thick plate. Trans. China Weld. Inst. 2022, 43, 20–24. [Google Scholar]

- Yang, H.; Zhao, H.; Xu, X.; Zhou, L.; Zhao, H.; Liu, H. Effect of Stirring Pin Rotational speed on Microstructure and Mechanical Properties of 2A14-T4 Alloy T-Joints Produced by Stationary Shoulder Friction Stir Welding. Materials 2021, 14, 1938. [Google Scholar] [CrossRef] [PubMed]

- Thomae, M.; Gester, A.; Wagner, G. Comparison of process behavior, microstructure and mechanical properties of ultrasound enhanced friction stir welded titanium/titanium joints. Weld. World 2022, 66, 1131–1140. [Google Scholar] [CrossRef]

- Su, Y.; Li, W.; Liu, X.; Gao, F.; Yu, Y.; Vairis, A. Evolution of microstructure, texture and mechanical properties of special friction stir welded T-joints for an alpha titanium alloy. Mater. Charact. 2021, 177, 111152. [Google Scholar] [CrossRef]

- Raj, S.; Biswas, P. Experimental investigation of the effect of induction preheating on the microstructure evolution and corrosion behaviour of dissimilar FSW (IN718 and SS316L) joints. J. Manuf. Process 2023, 95, 143–159. [Google Scholar] [CrossRef]

- Jesus, J.; Costa, J.; Loureiro, A.; Ferreira, J. Assessment of Friction Stir Welding Aluminium T-Joints. J. Mater. Process Technol. 2018, 255, 387–399. [Google Scholar] [CrossRef]

- Zuo, D.; Cao, Z.; Cao, Y.; Zheng, G. Effect of pre-stretching on microstructures and mechanical behaviors of creep-aged 7055 Al alloy and its constitutive modeling. Metals 2019, 9, 584. [Google Scholar] [CrossRef]

- Zuo, D.; Cao, Z.; Cao, Y.; Zheng, G. Research on theoretical modeling and numerical simulation of viscoelastic-plastic bending neutral layer in T-welding stiffened panels-based aged stress relaxation forming. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2020, 234, 2881–2894. [Google Scholar] [CrossRef]

- Lu, L.; Xue, W.B.; Jin, X.Y.; Du, J.C.; Li, Y. Surface protection of friction stir welding joint of 5083 aluminum alloy by micro-arc oxidation. Trans. Mater. Heat Treat. 2011, 32, 140–144. [Google Scholar]

- Manuel, N.; Costa, J.M.; Loureiro, A. Effect of Material Properties and Process Parameters on Morphology and Strength of Friction-Stir-Welded Dissimilar T-Joints. J. Mater. Eng. Perform. 2019, 28, 5233–5244. [Google Scholar] [CrossRef]

- Kasirajan, T.; Ravindran, R.; Ramkumar, T.; Selvakumar, M. Investigation of the microstructural, mechanical, and thermal evolution of dissimilar aluminium alloys during friction stir welding. Trans. Can. Soc. Mech. Eng. 2020, 44, 38–48. [Google Scholar] [CrossRef]

- Ghangas, G.; Singhal, S. Influence of Process Parameters on Mechanical and Microstructural Property of Dissimilar Friction Stir Welded Joints of Armor Aluminium Alloys AA7039 and AA5083. Indian J. Eng. Mater. Sci. (IJEMS) 2022, 29, 686–695. [Google Scholar]

- GB/T2651—2008; General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China, Standardization Administration of China. Tensile Test Method of Welded Joints; Standards Press of China: Beijing, China, 2008; p. 8.

- Burek, R.; Wydrzyński, D.; Kubit, A.; Łogin, W. The influence of the shoulder depth on the properties of the thin sheet joint made by FSW technology. Aircr. Eng. Aerosp. Technol. 2020, 93, 120–126. [Google Scholar] [CrossRef]

- Du, S.; Liu, H.; Jiang, M.; Hu, Y.; Zhou, L. Eliminating the cavity defect and improving mechanical properties of TA5 alloy joint by titanium alloy supporting friction stir welding. J. Manuf. Process 2021, 69, 215–222. [Google Scholar] [CrossRef]

- Gangwar, K.; Ramulu, M. Friction stir welding of titanium alloys: A review. Mater. Des. 2018, 141, 230–255. [Google Scholar] [CrossRef]

- Abbasi, M.; Bagheri, B.; Sharifi, F. Simulation and experimental study of dynamic recrystallization process during friction stir vibration welding of magnesium alloys. Trans. Nonferrous Met. Soc. China 2021, 31, 2626–2650. [Google Scholar] [CrossRef]

- Hou, W.; Shen, Z.; Huda, N.; Oheil, M.; Shen, Y.; Jahed, H.; Gerlich, A.P. Enhancing metallurgical and mechanical properties of friction stir Butt welded joints of Al–Cu via cold sprayed Ni interlayer. Mater. Sci. Eng. A 2021, 809, 140992. [Google Scholar] [CrossRef]

- Zuo, J.; Hou, L.; Shi, J.; Cui, H.; Zhuang, L.; Zhang, J. Effect of deformation induced precipitation on grain refinement and improvement of mechanical properties AA 7055 aluminum alloy. Mater. Charact. 2017, 130, 123–134. [Google Scholar] [CrossRef]

- Yuk, S.; Shim, S.H.; Jeong, M.; Lee, D.; Lee, K.; Kim, S.H.; Lee, S.Y.; Han, J.H. Micro/nanostructure evolution and deformation mechanisms in friction-stir-welded 7075 Al alloy: A comparative analysis of weld zones. J. Mater. Res. Technol. 2025, 36, 5193–5210. [Google Scholar] [CrossRef]

| 7055-T61 alloy | Zn | Mg | Cu | Zr | Fe | Mn | Si | Ti | Cr | Al |

| 7.9 | 2.1 | 2.3 | 0.05 | 0.15 | 0.05 | 0.1 | 0.06 | 0.001 | Bal. | |

| 2197-T8 alloy | Li | Cu | Ag | Mn | Mg | Zr | Fe | Si | Zn | Al |

| 1.5 | 2.88 | 0.36 | 0.35 | 0.24 | 0.09 | 0.05 | 0.04 | 0.006 | Bal. |

| Materials | Transverse Tensile Strength/MPa | Longitudinal Tensile Strength/MPa | Elongation/% | Melting Point/°C |

|---|---|---|---|---|

| 7055-T61 | 600 | 540 | 13 | 590 |

| 2197-T8 | 570 | 530 | 6 | 560 |

| Experimental Group | Rotational Speed w (rpm) | Welding Speed v (mm/min) | Insertion Depth h (mm) | Shoulder Structure |

|---|---|---|---|---|

| 1 | 250 | 50 | 0.21 | ICSWS |

| 2 | 250 | 60 | 0.21 | ICSWS |

| 3 | 300 | 40 | 0.21 | ICSWOS |

| 4 | 300 | 40 | 0.21 | ICSWS |

| 5 | 300 | 50 | 0.21 | ICSWOS |

| 6 | 300 | 50 | 0.21 | ICSWS |

| 7 | 300 | 60 | 0.21 | ICSWOS |

| 8 | 300 | 60 | 0.21 | ICSWS |

| 9 | 300 | 70 | 0.21 | ICSWOS |

| 10 | 300 | 70 | 0.21 | ICSWS |

| 11 | 300 | 80 | 0.21 | ICSWOS |

| 12 | 300 | 80 | 0.21 | ICSWS |

| 13 | 350 | 40 | 0.21 | ICSWOS |

| 14 | 350 | 40 | 0.21 | ICSWS |

| 15 | 350 | 50 | 0.21 | ICSWOS |

| 16 | 350 | 50 | 0.21 | ICSWS |

| 17 | 350 | 60 | 0.21 | ICSWOS |

| 18 | 350 | 60 | 0.21 | ICSWS |

| 19 | 350 | 70 | 0.21 | ICSWOS |

| 20 | 350 | 70 | 0.21 | ICSWS |

| 21 | 350 | 80 | 0.21 | ICSWOS |

| 22 | 350 | 80 | 0.21 | ICSWS |

| 23 | 400 | 50 | 0.21 | ICSWS |

| 24 | 400 | 60 | 0.21 | ICSWS |

| 25 | 350 | 60 | 0.18 | ICSWS |

| 26 | 350 | 60 | 0.19 | ICSWS |

| 27 | 350 | 60 | 0.20 | ICSWS |

| 28 | 350 | 60 | 0.22 | ICSWS |

| 29 | 350 | 60 | 0.23 | ICSWS |

| Sample No. | K | M | Y | N |

|---|---|---|---|---|

| Defect | roughness | groove | channel | flash |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, Y.; Zuo, D.; Xu, T.; Ma, G.; Feng, S.; Fu, H.; Cao, Z.; Li, W. Microstructure Characterization and Mechanical Properties of Dissimilar Al/Al-Li Alloy T-Joints Welded by Friction Stir Welding. Machines 2025, 13, 852. https://doi.org/10.3390/machines13090852

Han Y, Zuo D, Xu T, Ma G, Feng S, Fu H, Cao Z, Li W. Microstructure Characterization and Mechanical Properties of Dissimilar Al/Al-Li Alloy T-Joints Welded by Friction Stir Welding. Machines. 2025; 13(9):852. https://doi.org/10.3390/machines13090852

Chicago/Turabian StyleHan, Yanjie, Duquan Zuo, Tianyu Xu, Guoling Ma, Shilin Feng, Haoran Fu, Zengqiang Cao, and Wenya Li. 2025. "Microstructure Characterization and Mechanical Properties of Dissimilar Al/Al-Li Alloy T-Joints Welded by Friction Stir Welding" Machines 13, no. 9: 852. https://doi.org/10.3390/machines13090852

APA StyleHan, Y., Zuo, D., Xu, T., Ma, G., Feng, S., Fu, H., Cao, Z., & Li, W. (2025). Microstructure Characterization and Mechanical Properties of Dissimilar Al/Al-Li Alloy T-Joints Welded by Friction Stir Welding. Machines, 13(9), 852. https://doi.org/10.3390/machines13090852