Training for Industry 5.0: Evaluating Effectiveness and Mapping Emerging Competences

Abstract

1. Introduction

1.1. State of the Art

1.2. Research Questions

1.3. The Structure of the Paper

2. Background

- The use of self-report surveys to capture perceived gains and engagement;

- The statistical treatment of upskilling outcomes, enabling cross-case comparison.

3. Methodology

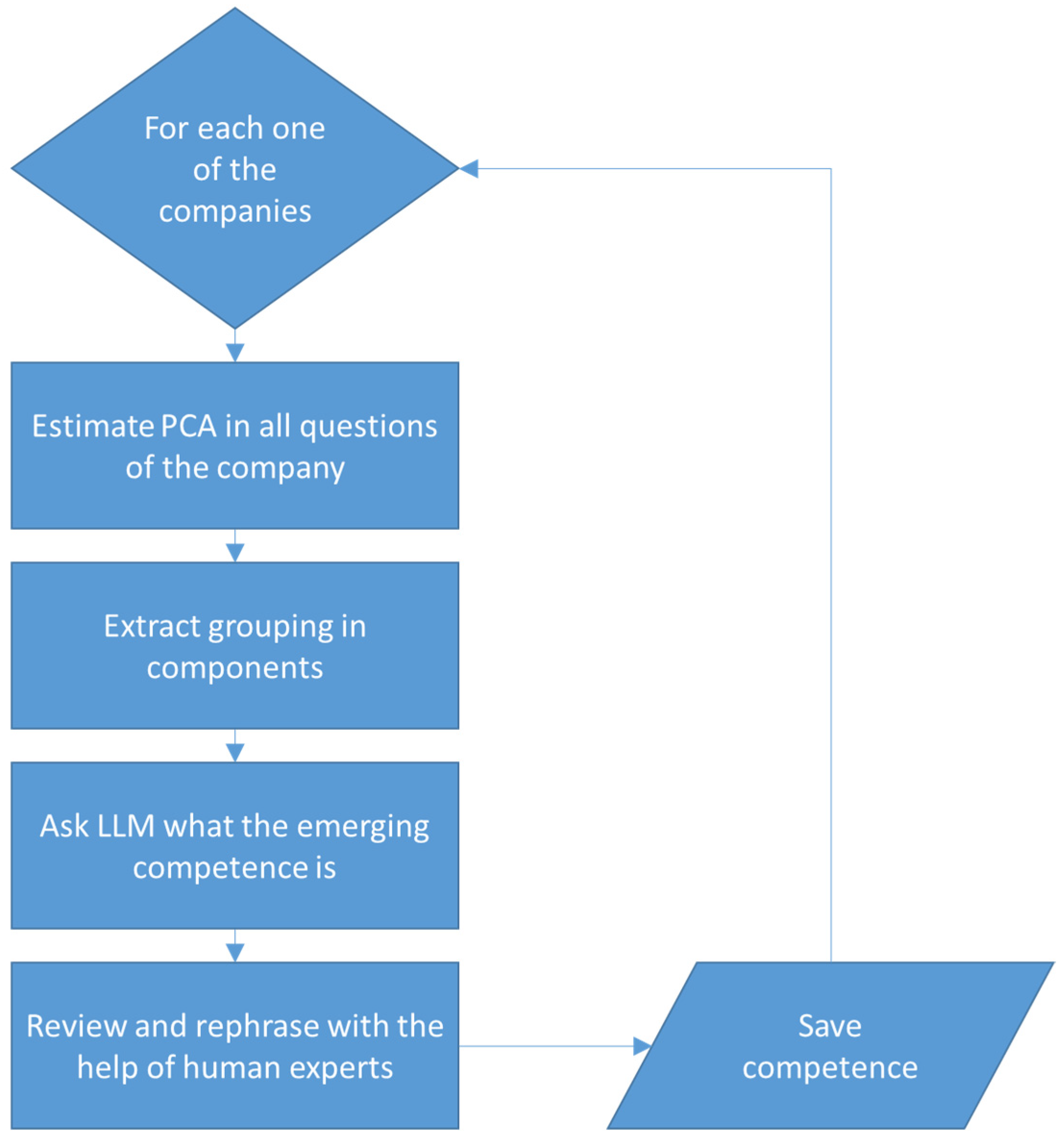

- The loadings and the questions per se were given as input to ChatGPT;

- ChatGPT suggested the naming;

- Three different experts that were involved in the corresponding training were called to confirm the naming of the emerging competence. Their background was mixed, meaning that there were two from academia and one from the company.

4. Results and Discussion on Upskilling Effectiveness (RQ1 and RQ2)

4.1. Raw Data per Industry 5.0 Pillar

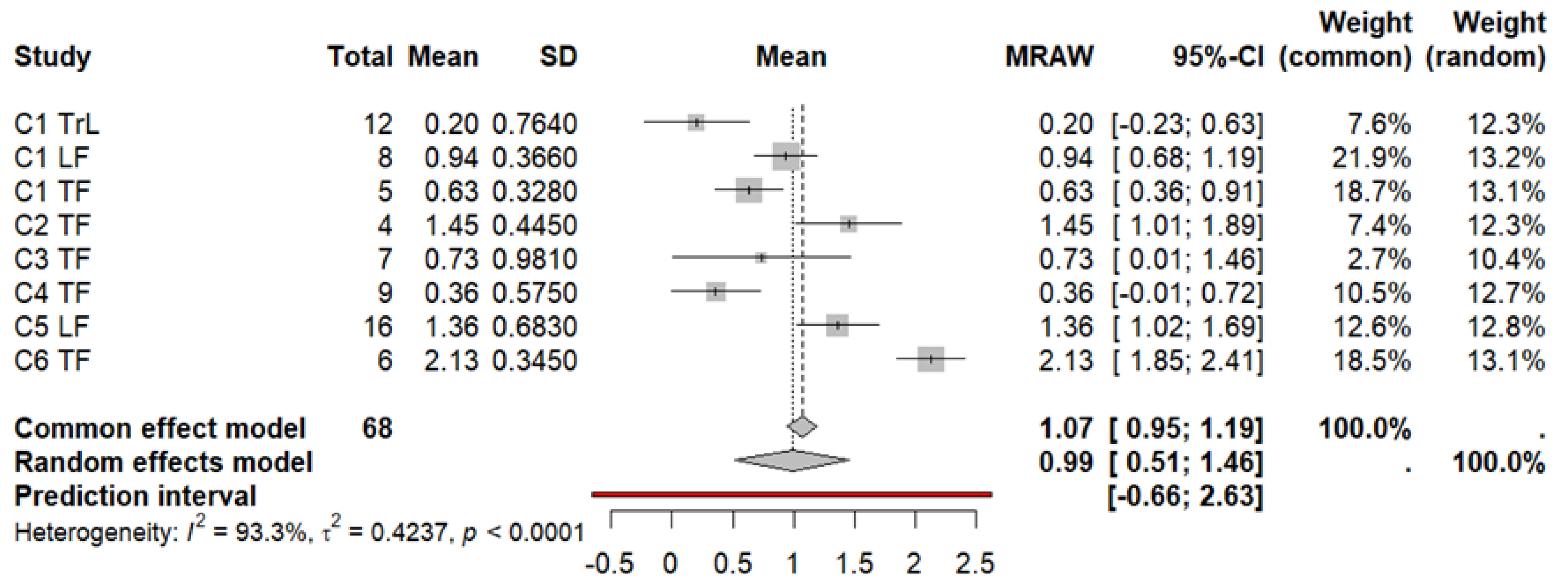

4.2. Results on Overall Industry 5.0 Metric (RQ1)

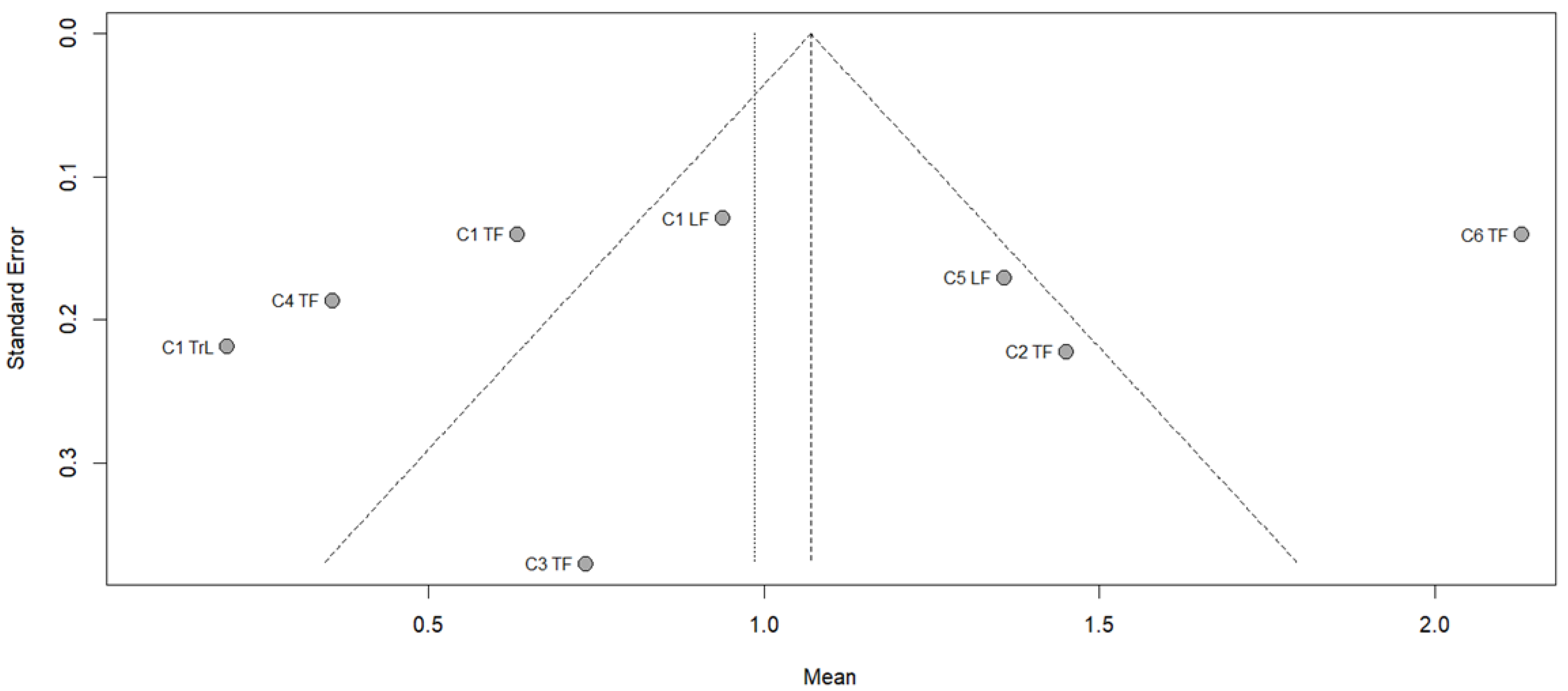

4.3. Results as a Function of Training Method (RQ2)

- TF (Teaching Factory): coded as 1 when the intervention was implemented in a teaching factory context—typically characterized by collaboration between academia and industry, with a focus on real-world production scenarios.

- LF (Learning Factory): coded as 1 when the intervention took place in a learning factory environment—usually emphasizing hands-on experiential learning in simulated or semi-real production setups.

- psych: coded as 1 when the intervention included behavioral or psychological components, such as reflective learning, motivational aspects, or mindset development.

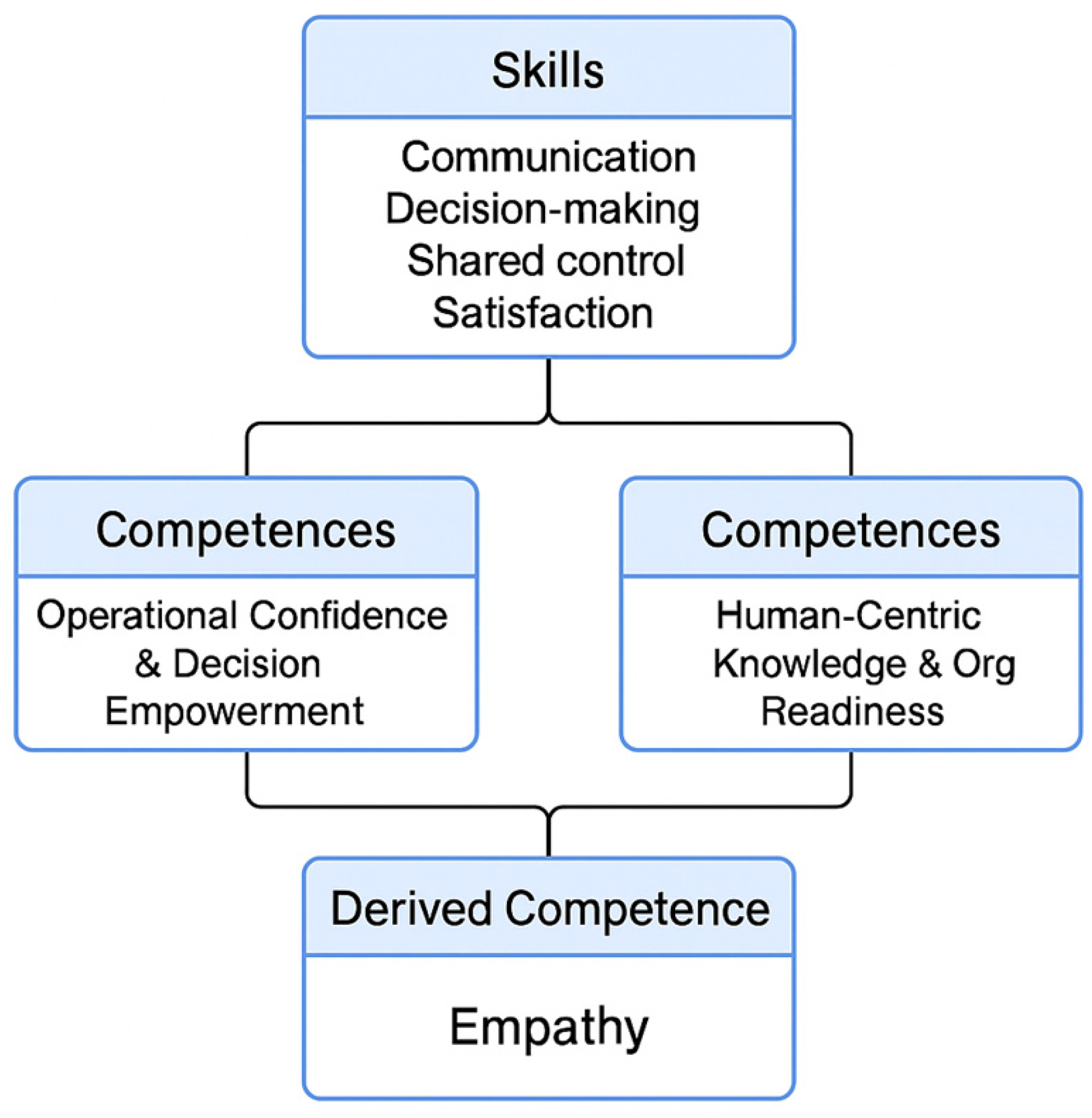

5. Results and Discussion on the Competences (RQ3)

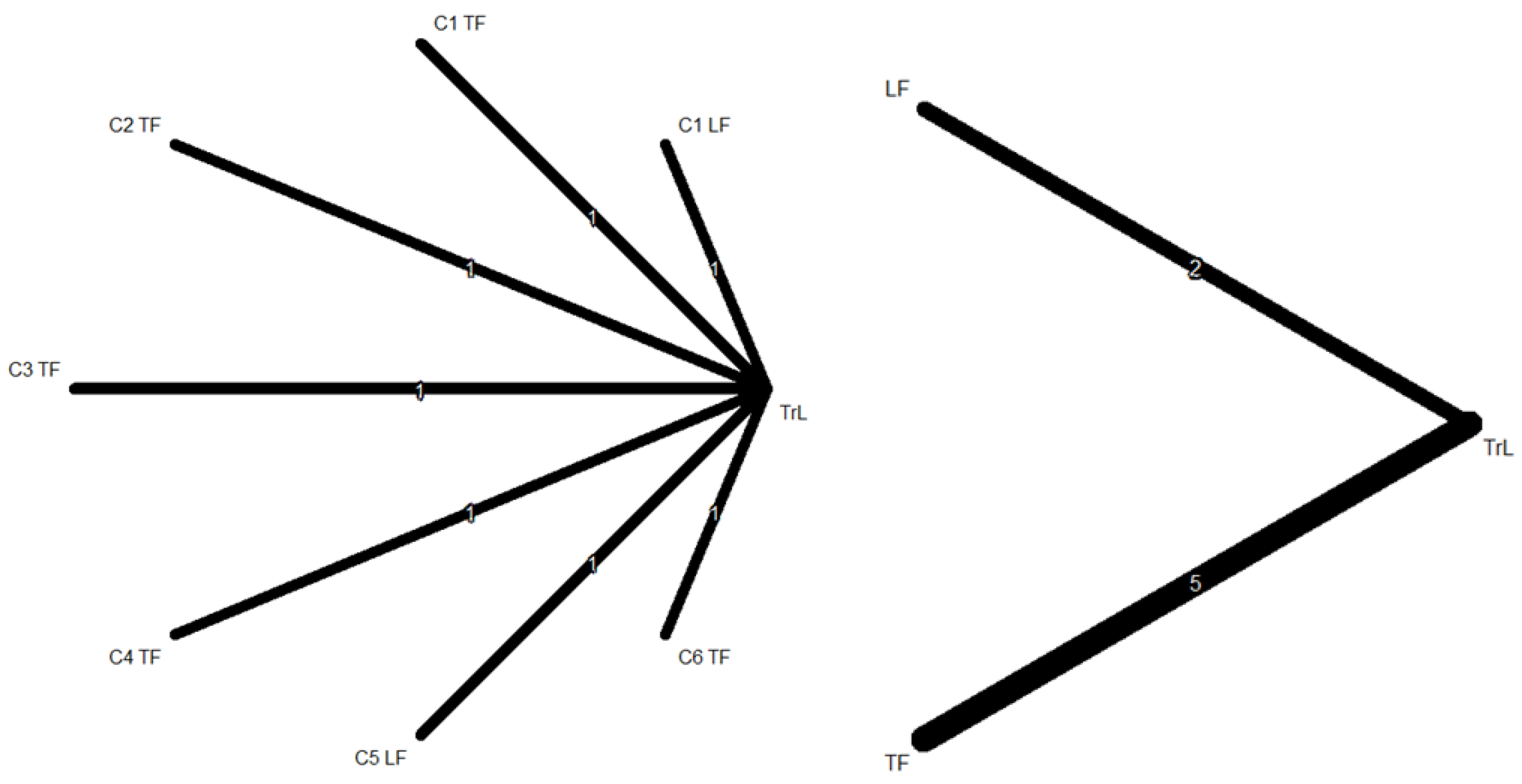

5.1. Identifying Capabilities

5.1.1. The Competences in the Company C1

5.1.2. The Competences in the Companies C2–C6

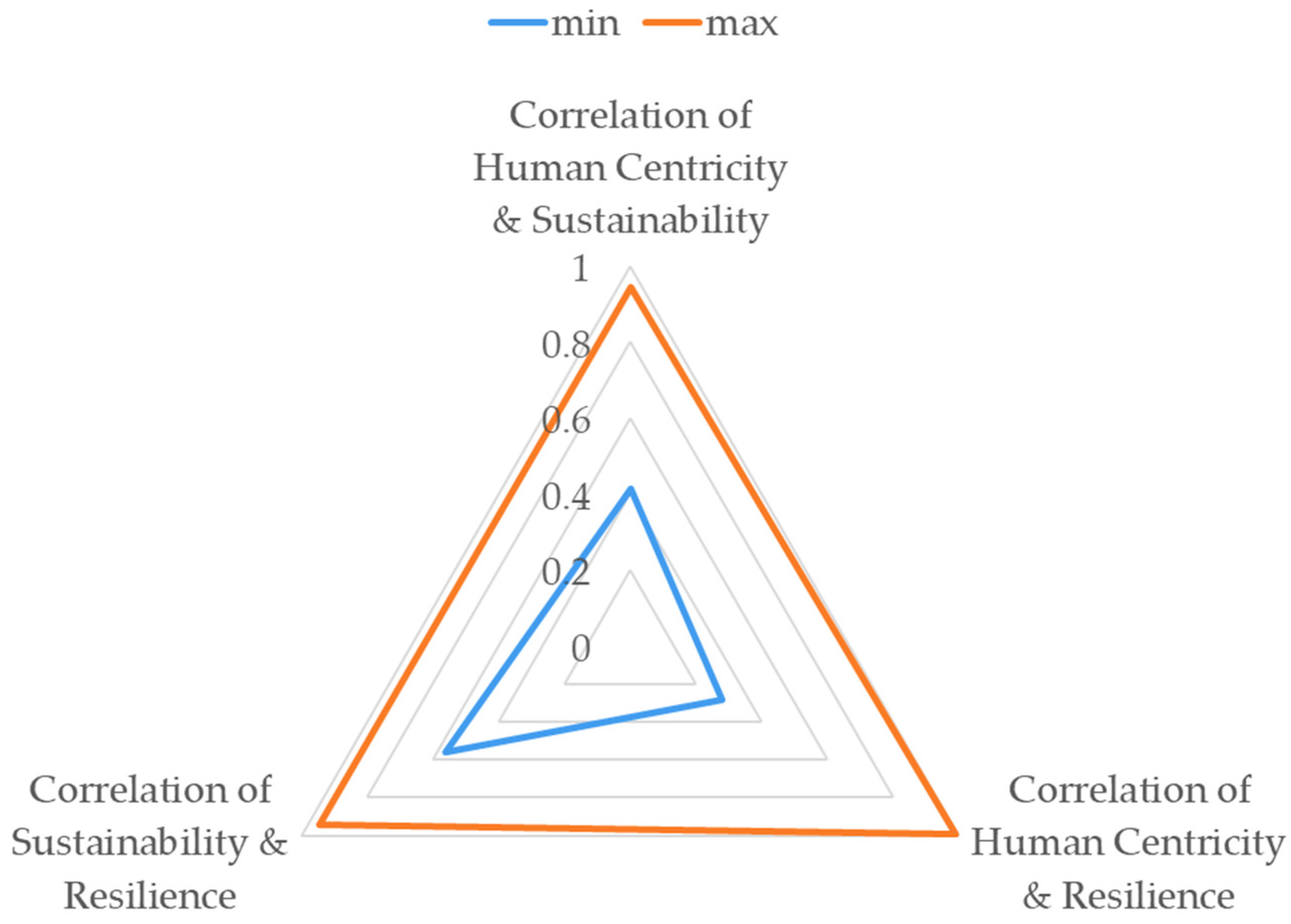

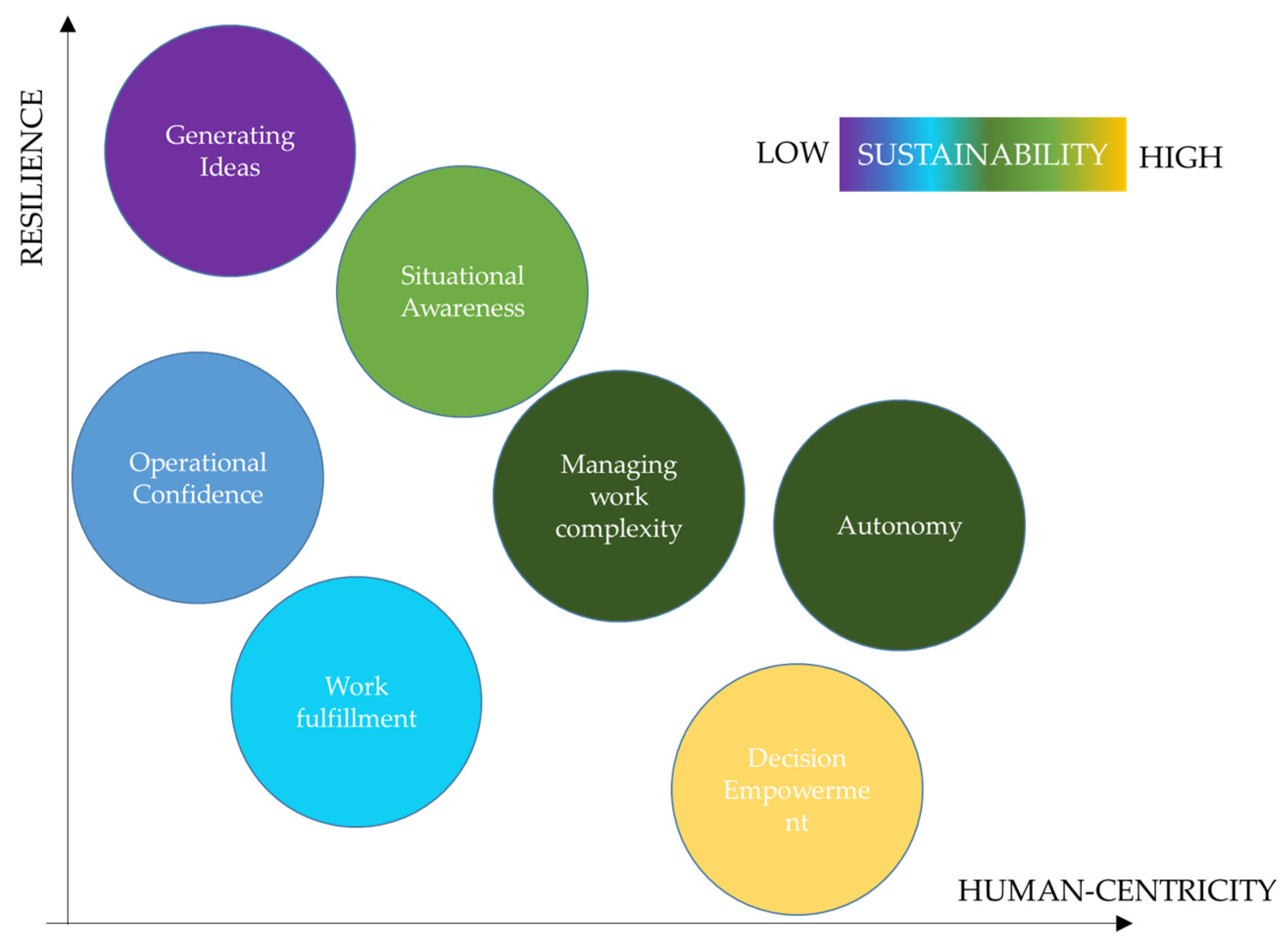

5.2. Characterization of Emerging Competences

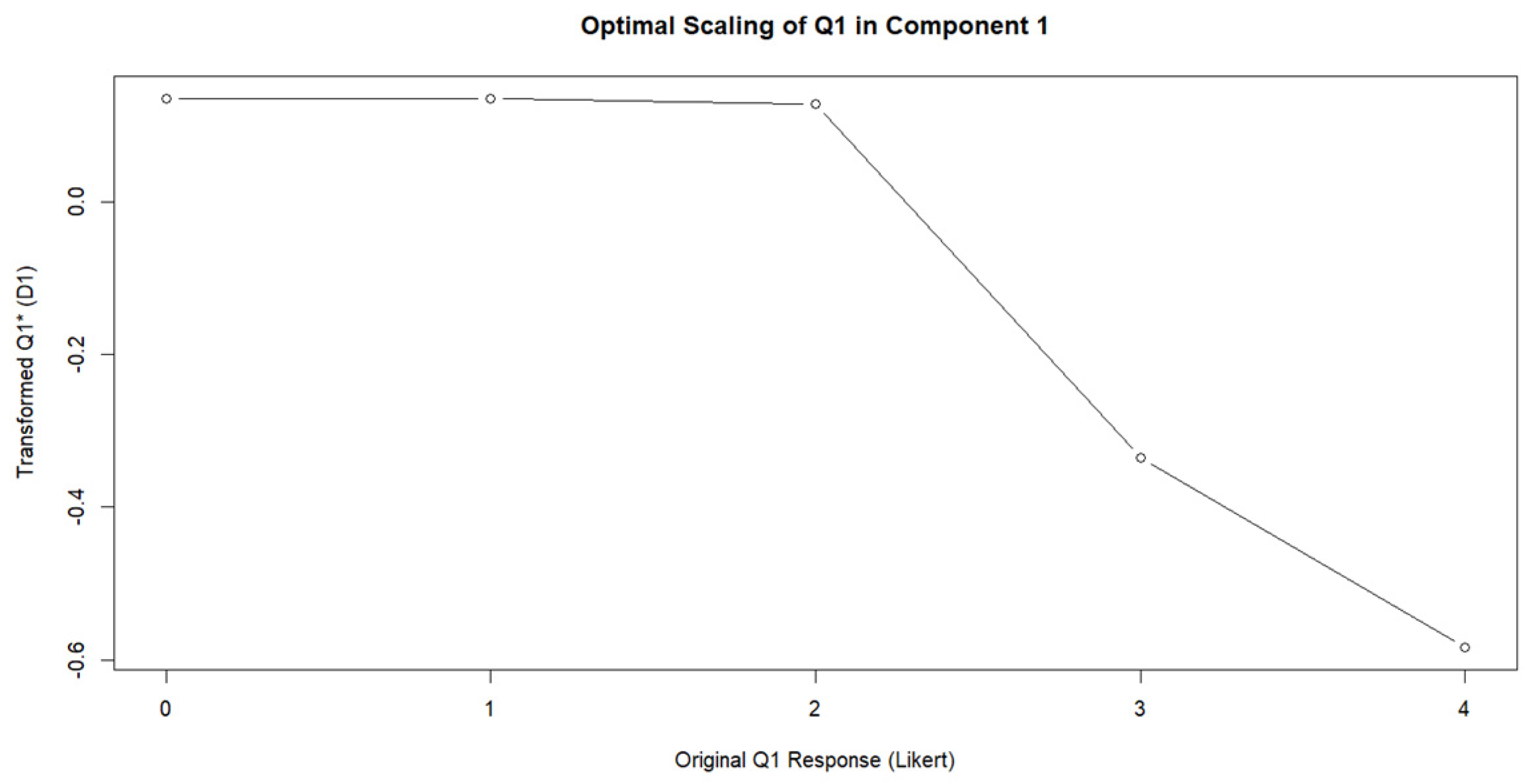

5.3. Non-Linear Approach

6. Conclusions and Future Outlook

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A. Trainee Questionnaires per Company

| Case | Question | Characterization |

|---|---|---|

| C1 | How informed are you about the technology subject of the course? How much do you think that the use of a robotic welding solution will have on your role as an operator, considering that the machine will do physical work? How much do you think that the implementation of this technology can improve the quality of the welding operations? | General |

| C1 | How much do you feel prepared to deal with the introduction of this new, bombastic welding technology in your role as an operator? How much do you expect that your role as an operator will change with the introduction of modern technology for robotic welding? How important is it for you to have adequate training to manage and supervise the activity of the technological solution? How much do you think you have the skills necessary to adapt to the new role that the use of this modern technology for welding involves? How much do you think that collaboration with this modern technology will make your job more satisfying? | Human Centricity |

| C1 | How important is it to you that the welding technology is efficient from an energy perspective? How much do you think the use of a technological solution can help reduce material waste during welding, considering a change in the working process? How important is it for you that the robotic welding technology contributes to creating a safer work environment? | Sustainability |

| C1 | How much do you think that the introduction of a technology for robotic welding can make the production process more robust in the face of unexpected events (e.g. lack of qualified personnel, ergonomic problems, …)? How important is it to you that the technological solution is designed to be easy to use, maintain, and repairable in case of problems? How much do you think this technology can improve the continuity of welding operations? | Resilience |

| C2 and C3 | Do you have an idea about why people disengage in the company? Do you have an idea of what criteria to use as a guide for implementing human-centric initiatives? Do you know the organisational practices that can help develop a more human-centric organisation? Do you feel you have more knowledge about HOW to digitise/implement a modern technology? | Human Centricity |

| C2 and C3 | Do you know how to improve organisational flexibility (performance) while achieving a more human-centric organisation? | Resilience |

| C2 and C3 | Once digitised, do you feel confident using production optimisation to improve environmental sustainability? Do you feel confident using production optimisation to improve waste reduction? | Sustainability |

| C4 | Do you feel confident in solving problems during the manufacturing process? Do you feel confident in using shared control between human and machine? | Human Centricity |

| C4 | Do you feel confident in working on multiple projects simultaneously? Do you feel confident in working in different areas of the company? | Resilience |

| C4 | Do you rate the new organisation setup more fulfilling than before? Do you feel that the organisation setup helps you in making your decision-making process better (communication interface, hardware/software tools, empowerment? | Sustainability |

| C5 | I am familiar with 3 main values of the Company I know what is “Y” information system and how to use it in practice | General |

| C5 | I know how to behave in the workplace in compliance with ESD safety I understand how to identify the direction of an electronic component I feel confident when working in different working areas (operations) in the company I feel confident when communicating problems to other team members/supervisors | Human Centricity |

| C5 | I understand the principles of lean methodology (5S principles) I know how to sort hazardous production waste I feel confident and I know how to sort waste in my daily routine | Sustainability |

| C5 | I know what is “X” information system and how to use it in practice I know “IT security standards” in the company and understand their importance I understand the meaning and importance of production documentation (product assembly instruction) | Resilience |

| C6 | Do you feel confident in solving problems during the manufacturing process? | Sustainability, Human Centricity |

| C6 | Do you feel confident in using shared control between human and machine? | Resilience, Human Centricity |

| C6 | Do you feel confident in working in different project at the same time? | Resilience, Human Centricity |

| C6 | Do you feel confident in working in different working areas in the company? | Resilience, Human Centricity |

Appendix B. Network Meta-Analysis

References

- Kaswan, M.S.; Chaudhary, R.; Garza-Reyes, J.A.; Singh, A. A review of Industry 5.0: From key facets to a conceptual implementation framework. Int. J. Qual. Reliab. Manag. 2025, 42, 1196–1223. [Google Scholar] [CrossRef]

- European Commission—What is Industry 5.0. Available online: https://research-and-innovation.ec.europa.eu/research-area/industrial-research-and-innovation/industry-50_en (accessed on 8 June 2025).

- Dacre, N.; Yan, J.; Frei, R.; Al-Mhdawi, M.K.S.; Dong, H. Advancing sustainable manufacturing: A systematic exploration of industry 5.0 supply chains for sustainability, human-centricity, and resilience. Prod. Plan. Control. 2024, 36, 1–30. [Google Scholar] [CrossRef]

- Tusquellas, N.; Santiago, R.; Palau, R. Professional Development Analytics: A Smart Model for Industry 5.0. Appl. Sci. 2025, 15, 2057. [Google Scholar] [CrossRef]

- Shabur, M.A.; Shahriar, A.; Ara, M. From automation to collaboration: Exploring the impact of industry 5.0 on sustainable manufacturing. Discov. Sustain. 2025, 6, 341. [Google Scholar] [CrossRef]

- Valtonen, A.; Holopainen, M. Mitigating employee resistance and achieving well-being in digital transformation. Inf. Technol. People 2025, 38, 42–72. [Google Scholar] [CrossRef]

- European Commission—COP-5 Final Report. Directorate-General for Research and Innovation. Available online: https://research-and-innovation.ec.europa.eu/document/download/8aea695d-2b97-4366-812f-971b7ebbfda8_en?filename=cop-5-final-report.pdf&prefLang=nl (accessed on 8 June 2025).

- Piecuch-Jodłowiec, J. Adapting HRM Practices for Generation Z with a Human-centric Management Approach to Mental Health and Employee Development. In Human at the Center of the Organization: Visions, Realities, Challenges; Stor, M., Ed.; Publishing House of Wroclaw University of Economics and Business: Wrocław, Poland, 2024; pp. 103–115. [Google Scholar]

- Bakator, M.; Nikolić, M.; Ćoćkalo, D.; Stanisavljev, S. Transition to industry 5.0 with AI and digilitalization of production systems. J. Eng. Manag. 2024, 2, 8–12. [Google Scholar] [CrossRef]

- Papacharalampopoulos, A.; Stavropoulos, P.; Ziarsolo, U.; Karagianni, O.M. Teaching Learning Factories 5.0: Shaping Training, Skilling and Reskilling for the Future. In Proceedings of the International Association for the Management of Technology Conference, Porto, Portugal, 8–11 July 2024; Springer Nature Switzerland: Cham, Switzerland; pp. 159–167. [Google Scholar]

- Acemoglu, D.; Autor, D. Skills, tasks and technologies: Implications for employment and earnings. In Handbook of Labor Economics; Elsevier: Amsterdam, The Netherlands, 2011; Volume 4, pp. 1043–1171. [Google Scholar]

- Sony, M.; Naik, S. Industry 4.0 integration with socio-technical systems theory: A systematic review and proposed theoretical model. Technol. Soc. 2020, 61, 101248. [Google Scholar] [CrossRef]

- Papacharalampopoulos, A.; Stavropoulos, P.; Karagianni, O.M.; Ziarsolo, U.; Sotil, A.; Elorza, U.; Fedeli, M.; Timo, F.; Ippolito, M.; Gumuliauskas, A.; et al. Developing the Teaching Factory 5.0. Phases 1, 2 and 3 (BRIDGES 5.0 deliverable D5.1). 2025. Available online: https://cordis.europa.eu/project/id/101069651 (accessed on 26 August 2025).

- Papacharalampopoulos, A.; Elorza, U.; Schröder, A.J.; Karagianni, O.M.; Stavropoulos, P. Industry 5.0 interventions: Towards an approach for behavioral Teaching Factories. In Proceedings of the Conference Advancing Industry 5.0 Conference, Leuven, Belgium, 16–17 June 2025. [Google Scholar]

- Papacharalampopoulos, A.; Stavropoulos, P.; Karagianni, O.M.; Ippolito, M. Integrating successfully Industry 5.0 in industry: Technological perspective and experiential training at process level. In Proceedings of the 19th CIRP Conference on Intelligent Computation in Manufacturing Engineering, Gulf of Naples, Italy, 16 July 2025. [Google Scholar]

- Zanoli, T.; Kolesnikov, M.; Gonçalves, G.; Žilka, M.; Pinto, R. Enabling Professionals for Industry 5.0: The Self-Made Programme. Procedia Comput. Sci. 2024, 232, 2911–2920. [Google Scholar] [CrossRef]

- Pluchino, P.; Gamberini, L. Industry 5.0: A comprehensive insight into the future of work, social sustainability, sustainable development, and career. Aust. J. Career Dev. 2024, 33, 5–14. [Google Scholar] [CrossRef]

- Fraile, F.; Alarcón, F.; Joan, J.; Psarommatis, F. A Methodological Framework for Designing Personalised Training Programs to Support Personnel Upskilling in Industry 5.0. Computers 2023, 12, 224. [Google Scholar] [CrossRef]

- Kumar, D.; Shivhare, M.; Pathak, A. Smart Educational Ecosystems: Tailoring Employee Training With Ai and Iot in the Industry 5.0 Landscape. In Proceedings of the 4th International Conference on Technological Advancements in Computational Sciences (ICTACS), Tashkent, Uzbekistan, 13–15 November 2024; pp. 1862–1868. [Google Scholar]

- Vyas, P.; Sumathy, S.; Koppu, S.; Bhulakshmi, D.; Bhattacharya, S.; Mahmud, M.; Supriya, Y.; Gadekallu, T.; Brown, D.; Kaluri, R. Industry 5.0 in Smart Education: Concepts, Applications, Challenges, Opportunities, and Future Directions. IEEE Access 2024, 12, 81938–81967. [Google Scholar] [CrossRef]

- Ruppert, T.; Romero, D.; Gładysz, B.; Tran, T.; Abonyi, J.; Van Erp, T. Current development on the Operator 4.0 and transition towards the Operator 5.0: A systematic literature review in light of Industry 5.0. J. Manuf. Syst. 2023, 70, 160–185. [Google Scholar] [CrossRef]

- Hartmann, D.; Köhler, C.; Schwinn, A.; Petry, M. How to train Industry 5.0 skills in a learning factory using existing technologies? In Proceedings of the 13th Conference on Learning Factories (CLF 2023), Saarbrücken, Germany, 9–11 May 2023. [Google Scholar]

- World Economic Forum—EU Falling Short of Digital Transformation Goals, New Report Finds. Available online: https://www.weforum.org/stories/2024/07/eu-digital-transformation-lagging/ (accessed on 31 July 2025).

- Balduzzi, S.; Rücker, G.; Schwarzer, G. How to perform a meta-analysis with R: A practical tutorial. Evid.-Based Ment. Health 2019, 22, 153–160. [Google Scholar] [CrossRef]

- Viechtbauer, W. Conducting meta-analyses in R with the metafor package. J. Stat. Softw. 2010, 36, 1–48. [Google Scholar]

- ESCO—Green Skills. Available online: https://esco.ec.europa.eu/en/about-esco/publications/publication/green-skills-and-knowledge-concepts-labelling-esco (accessed on 8 June 2025).

- JRC—The European Sustainability Competence Framework. Available online: https://publications.jrc.ec.europa.eu/repository/handle/JRC128040 (accessed on 8 June 2025).

- Kotsios, P. Business resilience skills for SMEs. J. Innov. Entrep. 2023, 12, 37. [Google Scholar] [CrossRef]

- González García, A.; Pinto-Carral, A.; Pérez González, S.; Marqués-Sánchez, P. A competency model for nurse executives. Int. J. Nurs. Pract. 2022, 28, e13058. [Google Scholar] [CrossRef]

- Omoraka, A.E. A principal component analysis of supply chain management skills for the Nigerian construction industry. Int. J. Constr. Manag. 2022, 22, 2413–2421. [Google Scholar] [CrossRef]

- Celume, M.P.; Maoulida, H. Psychometric Properties of the Competencies Compound Inventory for the Twenty-First Century. In Frontiers in Education; Frontiers Media SA 7: Lausanne, Switzerland, 2022; p. 877129. [Google Scholar]

- Todhunter, F. Using principal components analysis to explore competence and confidence in student nurses as users of information and communication technologies. Nurs. Open 2015, 2, 72–84. [Google Scholar] [CrossRef] [PubMed]

- Prime, K.; Sundaram, S.; Kingston, M. Future-proofing training: Plans for the next generation of GUM doctors. Sex. Transm. Infect. 2020, 96, 555. [Google Scholar] [CrossRef] [PubMed]

- Koppenol-Gonzalez, G.; Coetzee, A.; Jordans, M.; Schafer, A.; Steen, F.; Itani, M.; Chammay, E.; Pedersen, G.; Chamate, S.; Masri, E.; et al. Evaluation of competency-driven training for facilitators delivering a psychological intervention for children in Lebanon: A proof-of-concept study. Epidemiol. Psychiatr. Sci. 2022, 31, e48. [Google Scholar]

- Vealey, R. Future Directions in Psychological Skills Training. IEEE Trans. Signal Process. 1988, 2, 318–336. [Google Scholar] [CrossRef]

- Becker, J.; Feltes, M.; McCall, N.; Mbanjumucyo, G.; Wang, N.; Sivasankar, S. Teaching How to Teach in a Train-the-Trainer Program. J. Grad. Med. Educ. 2019, 11 (Suppl. S4), 202–204. [Google Scholar]

- Van Hoek, R.; Brockhaus, S.; DeNunzio, S. Future-Proofing Supply Chain Education. Transp. J. 2023, 62, 355–368. [Google Scholar] [CrossRef]

- Christensen, H.; Zbukvic, I.; Huckvale, K.; Boydell, K.; Batterham, P.; Lingam, R.; Torok, M.; Beames, J.; Werner-Seidler, A.; Calear, A.; et al. Protocol for the process evaluation of a complex intervention delivered in schools to prevent adolescent depression: The Future Proofing Study. BMJ Open 2020, 11, e042133. [Google Scholar]

- EU Project BRIDGES Website. Available online: https://bridges5-0.eu/ (accessed on 31 July 2025).

- Abele, E.; Metternich, J.; Tisch, M.; Chryssolouris, G.; Sihn, W.; ElMaraghy, H.; Hummel, V.; Ranz, F. Learning factories for research, education, and training. Procedia CIRP 2015, 32, 1–6. [Google Scholar] [CrossRef]

- Mavrikios, D.; Georgoulias, K.; Chryssolouris, G. The teaching factory paradigm: Developments and outlook. Procedia Manuf. 2018, 23, 1–6. [Google Scholar] [CrossRef]

- Rodgers, R. The Control Group and Meta-Analysis. J. Methods Meas. Soc. Sci. 2014, 5, 3–21. [Google Scholar] [CrossRef][Green Version]

- Hadi, P. The influence of self-efficacy on employee performance mediated by work motivation and work engagement. Int. J. Res. Bus. Soc. Sci. 2023, 12, 653–661. [Google Scholar] [CrossRef]

- Landrum, B. Examining Students’ Confidence to Learn Online, Self-Regulation Skills and Perceptions of Satisfaction and Usefulness of Onlines Classes. Online Learn. 2020, 24, 128–146. [Google Scholar] [CrossRef]

- Cuijpers, P.; Weitz, E.; Cristea, I.A.; Twisk, J. Pre-post effect sizes should be avoided in meta-analyses. Epidemiol. Psychiatr. Sci. 2017, 26, 364–368. [Google Scholar] [CrossRef]

- Tanujaya, B.; Prahmana, R.C.I.; Mumu, J. Likert scale in social sciences research: Problems and difficulties. FWU J. Soc. Sci. 2022, 16, 89–101. [Google Scholar] [CrossRef]

- McGrath, S.; Zhao, X.; Ozturk, O.; Katzenschlager, S.; Steele, R.; Benedetti, A. metamedian: An R package for meta-analyzing studies reporting medians. Res. Synth. Methods 2024, 15, 332–346. [Google Scholar] [CrossRef] [PubMed]

- Heissel, A.; Heinen, D.; Brokmeier, L.L.; Skarabis, N.; Kangas, M.; Vancampfort, D.; Stubbs, B.; Firth, J.; Ward, P.B.; Rosenbaum, S.; et al. Exercise as medicine for depressive symptoms? A systematic review and meta-analysis with meta-regression. Br. J. Sports Med. 2023, 57, 1049–1057. [Google Scholar] [CrossRef] [PubMed]

- The jamovi project. Jamovi Version 2.3 Computer Software; 2022. Available online: https://www.jamovi.org (accessed on 15 May 2025).

- R Core Team. R: A Language and Environment for Statistical Computing Version 4.1 Computer Software. 2021. Available online: https://cran.r-project.org (accessed on 1 January 2022).

- Fox, J.; Weisberg, S. Car: Companion Appl. Regres.—R Package. 2020. Available online: https://cran.r-project.org/package=car (accessed on 26 August 2025).

- Revelle, W. Psych: Procedures for Psychological, Psychometric, and Personality Research—R Package. 2019. Available online: https://cran.r-project.org/package=psych (accessed on 26 August 2025).

- OpenAI—ChatGPT Large Language Model. Available online: https://chat.openai.com/ (accessed on 8 June 2025).

- Norman, G.R.; Sloan, J.A.; Wyrwich, K.W. Interpretation of Changes in Health-related Quality of Life: The Remarkable Universality of Half a Standard Deviation. Med. Care 2003, 41, 582–592. [Google Scholar] [CrossRef]

- Madsen, A.; Sayre, E.; McKagan, S. Effect Size: What Is It and When and How Should I Use It? Available online: https://www.physport.org/recommendations/Entry.cfm?ID=93385 (accessed on 31 July 2025).

- Lakens, D. Calculating and reporting effect sizes to facilitate cumulative science: A practical primer for t-tests and ANOVAs. Front. Psychol. 2013, 4, 863. [Google Scholar]

- Institute of Medicine. Small Clinical Trials: Issues and Challenges; National Academies Press: Washington, DC, USA, 2001. [Google Scholar] [CrossRef]

- Richmond, H.; Copsey, B.; Hall, A.M.; Davies, D.; Lamb, S.E. A systematic review and meta-analysis of online versus alternative methods for training licensed health care professionals to deliver clinical interventions. BMC Med. Educ. 2017, 17, 227. [Google Scholar] [CrossRef] [PubMed]

- Balduzzi, S.; Rücker, G.; Nikolakopoulou, A.; Papakonstantinou, T.; Salanti, G.; Efthimiou, O.; Schwarzer, G. netmeta: An R Package for Network Meta-Analysis Using Frequentist Methods. J. Stat. Softw. 2023, 106, 1–40. [Google Scholar] [CrossRef]

- Shrestha, N. Factor analysis as a tool for survey analysis. Am. J. Appl. Math. Stat. 2021, 9, 4–11. [Google Scholar] [CrossRef]

- Parker, S.K.; Ballard, T.; Billinghurst, M.; Collins, C.; Dollard, M.; Griffin, M.A.; Johal, W.; Jorritsma, K.; Kowalkiewicz, M.; Kyndt, E.; et al. Quality work in the future: New directions via a co-evolving sociotechnical systems perspective. Aust. J. Manag. 2025, 2025, 03128962251331813. [Google Scholar] [CrossRef]

- Mair, P.; De Leeuw, J. Gifi: Multivariate Analysis with Optimal Scaling—R Package, Version 0.4-0. 2022. Available online: https://CRAN.R-project.org/package=Gifi (accessed on 15 May 2025).

| Case | Sector | Starting Point | Purpose/Focus Area | Achieved Final Result |

|---|---|---|---|---|

| C1 | Automotive Robotics | Awareness of digital gaps | Explore and test different training methods for human-centric digital transformation | Identified skill gaps, validated co-design practices, and fostered mindset shift toward digital adoption |

| C2 | Consumer Goods | Digitalization phase | Promote adoption of digital tools for flexible work | Improved digital mindset and willingness to adopt structured technologies |

| C3 | Industrial Equipment | Process variability | Enhance transparency and improve internal coordination | Defined standardized workflows and boosted communication |

| C4 | Semiconductors | Departmental restructuring | Align organizational units under a digital production strategy | Fostered collaboration and initiated roadmap development |

| C5 | Electronics | Low automation | Investigate MES integration and operator-machine collaboration | Identified upskilling needs and initiated digital transition planning |

| C6 | Industrial Engineering | Partial smart systems | Improve adaptability and responsiveness through real-time data | Implemented feedback loops and enhanced situational awareness |

| Company | Training Type | Target Group | Incentive | Objective |

|---|---|---|---|---|

| C1 | Traditional learning (TrL) and partially hands-on | Engineers | Semi-automation | Belief |

| C1 | LF | Operators | Semi-automation | Technology adoption |

| C1 | TF | Engineers/Managers | Semi-automation | Technology redesign |

| C2 | TF | Operators/Managers | Digitalization | Behavior |

| C3 | TF | Operators/Managers | Digitalization | Behavior |

| C4 | TF | Engineers/Managers | Knowledge transfer | Problem solving |

| C5 | LF | Operators | Reduction in turnover | Full workflow |

| C6 | TF | Operators/Managers | Digitalization and Green transformation | Behavior |

| Company | Sustainability | Resilience | Human Centricity |

|---|---|---|---|

| C1 TrL | 0.207 | 0.27 | 0.22 |

| C1 LF | 1.397 | 1.375 | 0.816 |

| C1 TF | 0.533 | 0.467 | 0.433 |

| C2 | 0.95 | 1.75 | 1.625 |

| C3 | 0.571 | 0.851 | 0.786 |

| C4 | 0.567 | 0.1 | 0.268 |

| C5 | 1.21 | 1.45 | 1.23 |

| C6 | 1.83 | 1.4 | 1.67 |

| Company | Industry 5.0 Overall Metric | Verbal Characterization of Upskilling Impact Based on Cohen’s d of the Overall Metric |

|---|---|---|

| C1 TrL | Small (0.207) | Small (0.27) |

| C1 LF | Medium (0.938) | Large (2.56) |

| C1 TF | Medium (0.633) | Large (1.93) |

| C2 | Large (1.45) | Extremely Large (3.26) |

| C3 | Medium (0.735) | Large (0.75) |

| C4 | Marginal (0.357) | Medium (0.6) |

| C5 | Medium (1.359) | Large (1.99) |

| C6 | Large (2.13) | Extremely Large (6.17) |

| Company | TF Variable | LF Variable | Psych (Psychological/Behavioral Component) |

|---|---|---|---|

| C1 TrL | 0 | 0 | 0 |

| C1 LF | 0 | 1 | 0 |

| C1 TF | 1 | 0 | 0 |

| C2 | 1 | 0 | 1 |

| C3 | 1 | 0 | 1 |

| C4 | 1 | 0 | 0 |

| C5 | 0 | 1 | 0 |

| C6 | 1 | 0 | 1 |

| Factor | Estimate | Confidence Interval Lower Limit |

|---|---|---|

| intercept | 0.2 | <0 |

| TF | 0.3652 | <0 |

| LF | 0.8319 | <0 |

| psych | 0.9214 | >0 (marginally) |

| Factor | Barlett Success | KMO Success |

|---|---|---|

| C1 LF | Yes | |

| C2 | Yes | |

| C3 | Yes | |

| C4 | ||

| C4 excluding last question from the questionnaire | Yes, but marginally | |

| C5 | Yes | |

| C6 | Yes |

| Original Question | PC 1 Engagement | PC 2 Engagement | PC 3 Engagement |

|---|---|---|---|

| Awareness | Low | ||

| Impact on physical work | High | ||

| Perceived quality improvement | High | ||

| Feeling prepared for change | Medium | Low | |

| Anticipated role change | High | ||

| Training importance | |||

| Perceived adaptability | Medium | Low | |

| Job satisfaction through tech | Medium | ||

| Energy efficiency | High | ||

| Material waste | High | ||

| Safety | Low | ||

| Maintainability | High | ||

| Continuity | High | ||

| Competence name | Self-efficacy and openness to technological change | positive perceptions and value attribution | Sustainability and efficiency awareness |

| Case | Engaged Skills (Through Principal Components’ Loadings) | Name of the Emerging Competence |

|---|---|---|

| C2 | Strategic understanding, operational capability, understanding of disengagement (negative loading) | Human-Centric Transformation Readiness |

| C3 | Disengagement causes, human-centric criteria and practices, tech implementation knowledge, integration of human-centricity with performance | Human-Centric Knowledge and Organizational Readiness |

| C3 | Reducing waste, environmental sustainability via optimization | Confidence in Sustainable Optimization |

| C4 | Problem solving, shared control, project multitasking | Operational Confidence |

| C4 | Solving problems, project multitasking | Decision Empowerment |

| C5 | Company principles, Lean methodology, security standards, production documentation, ERP use, communication | Company Standards and Procedures |

| C5 | ESD safety, hazardous waste sorting, component orientation, manufacturing execution system (MES) use | Core Operational Competence |

| C5 | General waste sorting, working across different areas, communication | Adaptability and Practical Skills |

| C6 | Problem solving, human–machine collaboration, multitasking/project switching | Adaptive Operational Readiness |

| C6 | Problem solving, human–machine collaboration, Multitasking/project switching, spatial/functional adaptability across work areas | Cross-Functional Readiness |

| Competence | Work System | Technology | Social |

|---|---|---|---|

| Company Standards and Procedures | X | X | |

| Process and Safety Control | X | X | |

| Self-efficacy and Openness to Technological Change | X | X | |

| Positive Perceptions and Value Attribution | X | ||

| Sustainability and Efficiency Awareness | X | X | X |

| Human-Centric Transformation Readiness | X | X | X |

| Human-Centric Knowledge and Organizational Readiness | X | X | X |

| Confidence in Sustainable Optimization | X | ||

| Adaptive Operational Readiness | X | X | |

| Cross-Functional Readiness | X | X | |

| Operational Confidence | X | X | |

| Decision Empowerment | X | X | |

| Organizational Systems Fluency | X | X | |

| Operational Safety and Agility | X | X |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Papacharalampopoulos, A.; Karagianni, O.M.; Fedeli, M.; Lackner, P.; Aleksandraviciene, G.; Ippolito, M.; Elorza, U.; Schröder, A.J.; Stavropoulos, P. Training for Industry 5.0: Evaluating Effectiveness and Mapping Emerging Competences. Machines 2025, 13, 825. https://doi.org/10.3390/machines13090825

Papacharalampopoulos A, Karagianni OM, Fedeli M, Lackner P, Aleksandraviciene G, Ippolito M, Elorza U, Schröder AJ, Stavropoulos P. Training for Industry 5.0: Evaluating Effectiveness and Mapping Emerging Competences. Machines. 2025; 13(9):825. https://doi.org/10.3390/machines13090825

Chicago/Turabian StylePapacharalampopoulos, Alexios, Olga Maria Karagianni, Matteo Fedeli, Philipp Lackner, Gintare Aleksandraviciene, Massimo Ippolito, Unai Elorza, Antonius Johannes Schröder, and Panagiotis Stavropoulos. 2025. "Training for Industry 5.0: Evaluating Effectiveness and Mapping Emerging Competences" Machines 13, no. 9: 825. https://doi.org/10.3390/machines13090825

APA StylePapacharalampopoulos, A., Karagianni, O. M., Fedeli, M., Lackner, P., Aleksandraviciene, G., Ippolito, M., Elorza, U., Schröder, A. J., & Stavropoulos, P. (2025). Training for Industry 5.0: Evaluating Effectiveness and Mapping Emerging Competences. Machines, 13(9), 825. https://doi.org/10.3390/machines13090825