1. Introduction

The performance and control of electrical drives rely on electrical steel sheets, valued for their low core losses and high magnetic permeability. Each manufacturing stage gradually degrades these magnetic properties. In the preliminary stage of the production process, cutting the laminations exerts a deleterious influence on the magnetic properties [

1,

2,

3]. The two most commonly used cutting methods in industrial manufacturing and prototype construction are punching and laser cutting. Punching changes the microstructure in the area of the cut edge by introducing local mechanical stresses [

1,

4,

5]. Laser cutting changes the microstructure of the edge zone mainly through heat input, which also leads to local mechanical stresses [

5,

6].

Axial stacking further reduces magnetic performance. In addition to packaging methods such as interlocking [

7,

8] and back-lack bonding [

9,

10], welding is a frequently used method for producing stator stacks. The choice of welding process, along with the number of weld seams, can cause the substantial degradation of the magnetic properties [

11,

12,

13,

14,

15].

The final manufacturing step for a laminated core typically involves pressing it into a casing for mechanical fastening and torque transmission. This press fit introduces additional mechanical stresses to the stator core, further degrading its magnetic properties [

16,

17,

18,

19,

20]. Studies in [

21] have also shown that ferromagnetic conductive casings can cause additional losses, especially in highly saturated machines. An investigation in [

19] found that shrink fitting a permanent magnet motor increased core losses by 30% and reduced maximum permeability by 50%. Preliminary tests in [

22] on laser-cut stator laminations pressed into test casings—without axial connection—showed magnetization demand rising by up to 270% at 50

, with specific core losses increasing by up to 42%. Despite these findings, the impact of such manufacturing effects on overall machine performance and controllability remains largely underexplored.

This study demonstrates how magnetic measurements from a manufactured stator core can improve the design and calculation of an electrical machine. Many control concepts rely on flux linkage maps [

23,

24], yet most data for electrical steel sheets come from manufacturer specifications that ignore manufacturing effects. To address this gap, we perform magnetic measurements on a strip sample, a stator core, and a pressed-in stator core. The test machine is a 4-pole reluctance synchronous machine (RSM) from [

25] designed with various magnetic material definitions.

The primary objectives are to calculate flux linkage in the d- and q-axes and air gap torque, and to compare these results with prototype measurements. We also compare calculated and measured core losses at the rated operating point.

2. Experiment Description

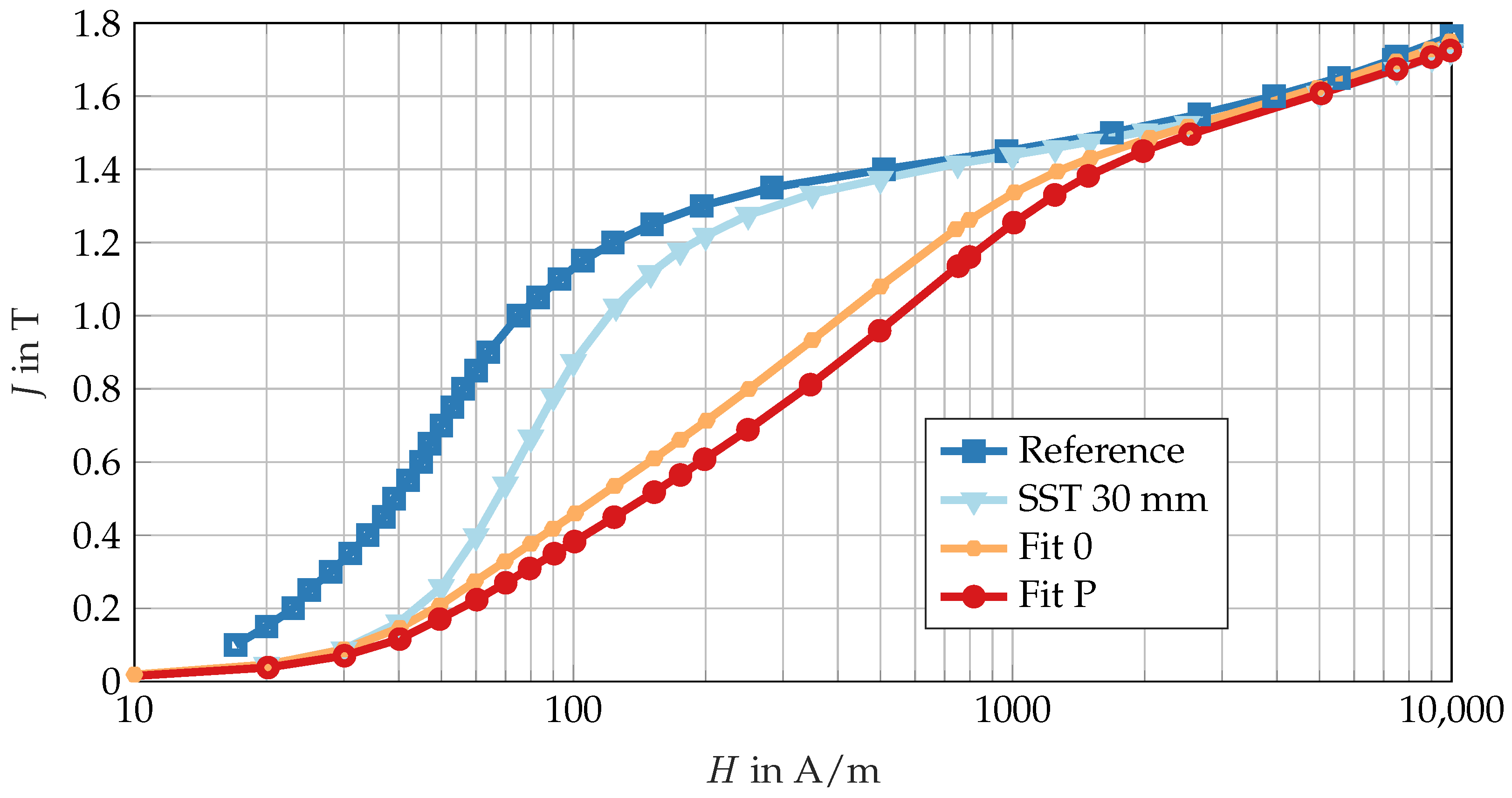

The test requires magnetic data from unaffected electrical steel sheets as well as magnetic data after various manufacturing steps. The grade M270-50A is used in the stator of the RSM under investigation. An overview of the electrical steel sheets investigated, categorized by their manufacturing state, is provided in

Table 1.

A freely available manufacturer’s data set is used as a reference method and is referred to below as ‘Reference’. As a starting point for the actual electrical steel sheet used, 30

wide test strips are laser-cut from M270-50A. Strips that are cut both lengthwise and transversely to the rolling direction are considered in this study. These strips are measured in a test coil built as a 30

single strip tester (SST 30

) as described in [

26]. This measurement can be equated with the measurement in an Epstein frame [

27]. Due to the strip width of 30 mm, a slight but noticeable influence of the cutting process on the magnetic properties must already be expected here [

5,

26,

28,

29]. Given the availability of samples of these dimensions from the supplier, which are derived from the material batch used prior to design, and the capacity to measure these samples using standardized measuring coils, this material is selected as the fundamental basis for the design of the stator under investigation. In order to create samples of the stator in

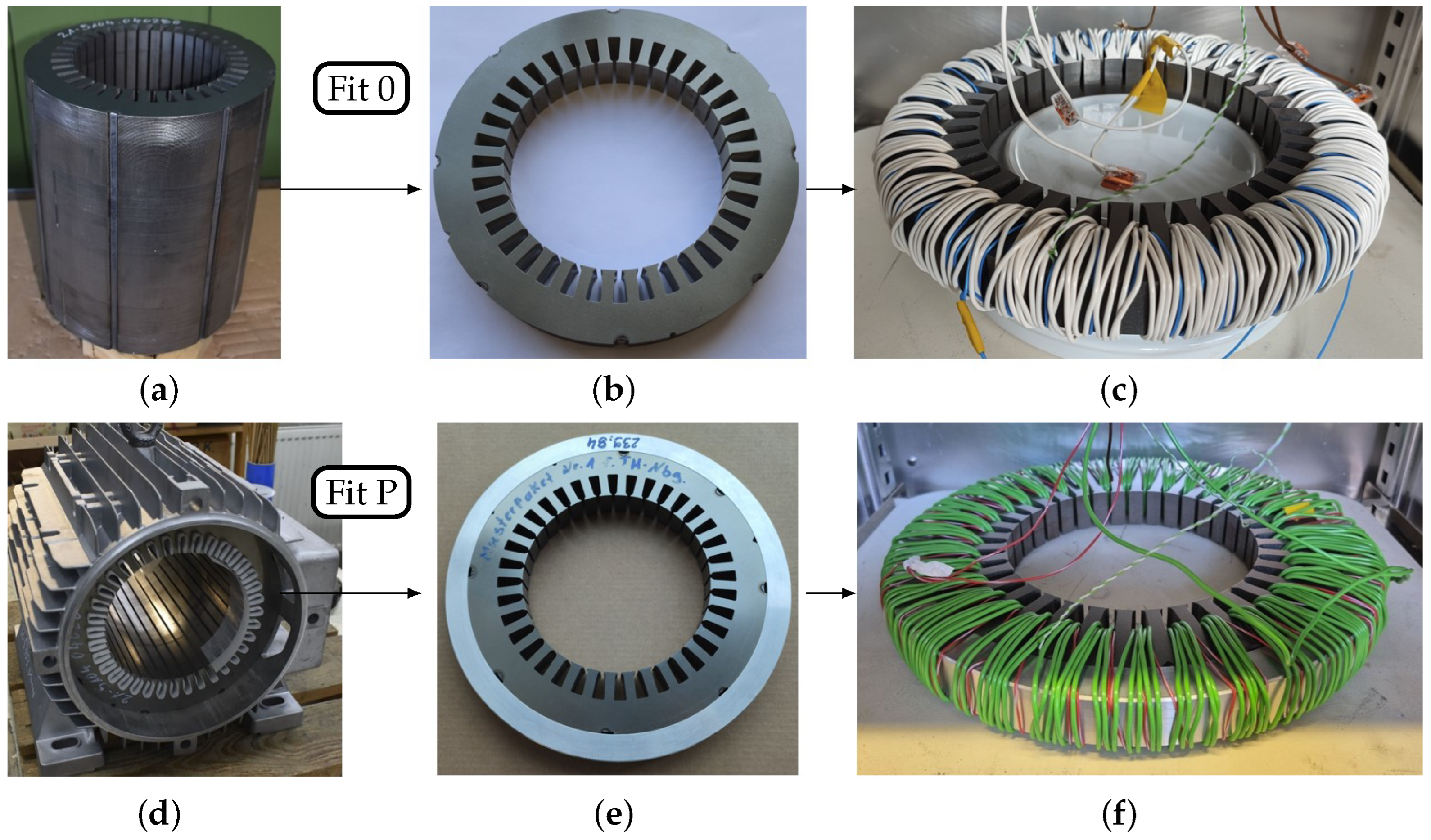

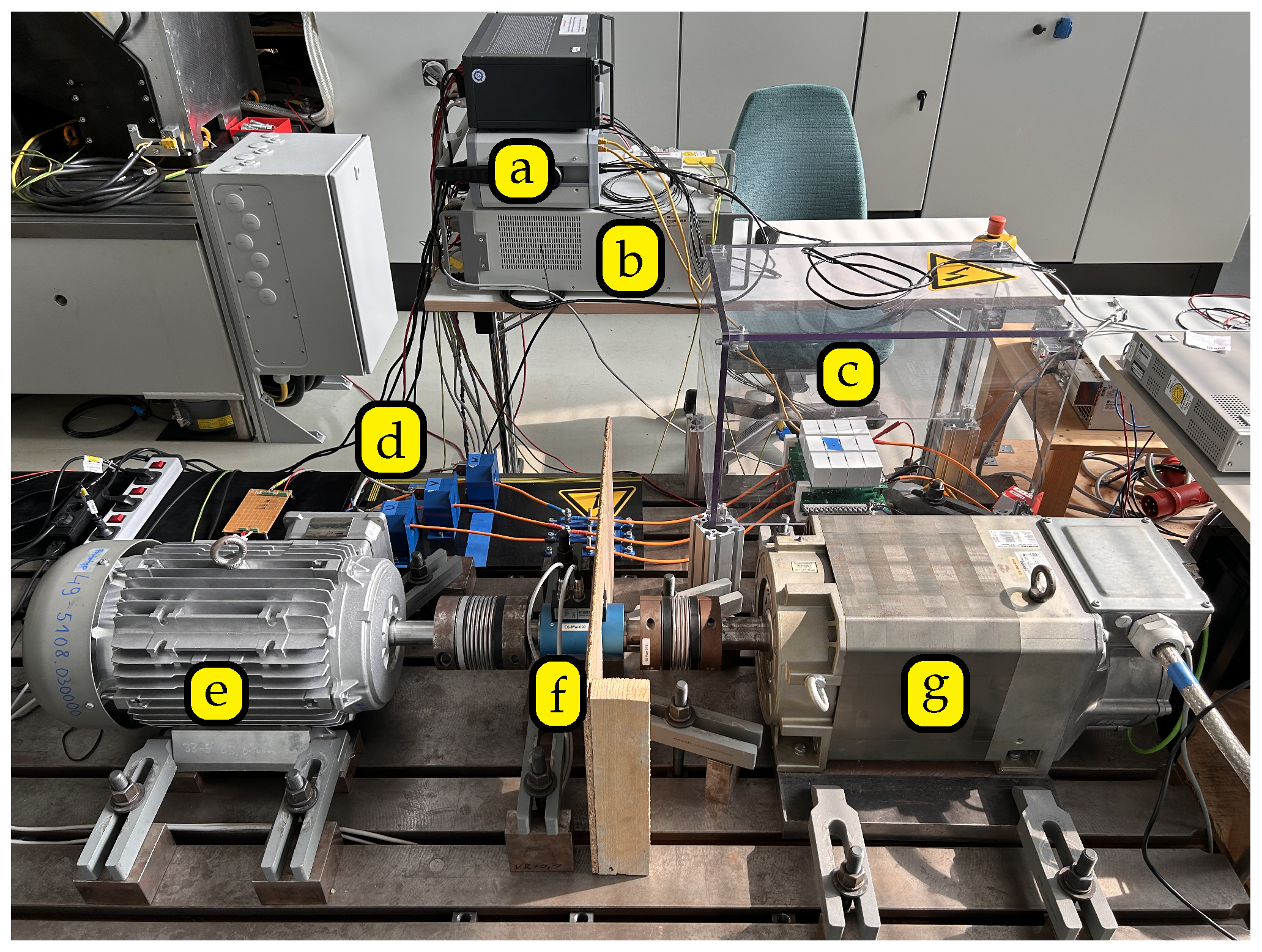

Figure 1a that can be handled for magnetic measurement and meet the specifications of IEC 60404 [

30,

31], 25

high stator core stacks (

Figure 1b) are produced. The stator laminations have been punched, and the axial packaging is created by welding. The resulting measurement sample is designated Fit 0 and, apart from the axial length, has the same geometric dimensions as the real stator of the prototype machine. Conducting magnetic measurements with the given stator outer and slot base diameters is only possible if the axial stator length is reduced to 25

. The stator of the real machine is not suitable for measurement due to its electrical steel sheet mass and the resulting voltage induced per measurement winding. Fit P represents the final measurement sample and consists of the stator ring core (Fit 0) pressed into an aluminum ring with a defined press fit, as illustrated in

Figure 1e. The press fit corresponds to the press fit of the prototype machine (

Figure 1d).

The following method is used to determine the mechanical stresses in the stator yoke of the pressed-in sample Fit P. Initially, the outer stator radius

of the sample designated as Fit 0 and the inner radius

of the machine casing at 20

are measured. The machine casing is reproduced in a reduced length of 25

using aluminum EN AW-6082 press sleeves that are manufactured by turning. The press sleeves have the same inner diameter as the casing of the prototype machine, and, therefore, also the same interference fit. By heating the press sleeve to 120

in an oven, its inner diameter expands to such an extent that the cold stator ring core sample can be inserted. After cooling, this creates a secure interference fit with the same mechanical properties as the prototype machine (

Figure 1d).

Table 2 shows the analytically calculated geometric properties as well as the maximum mechanical stress occurring in the stator yoke for the operating point of the machine with a steady-state operating temperature of 60

in the casing and stator yoke. The operating temperature was determined from the actual machine measurement on the test bench.

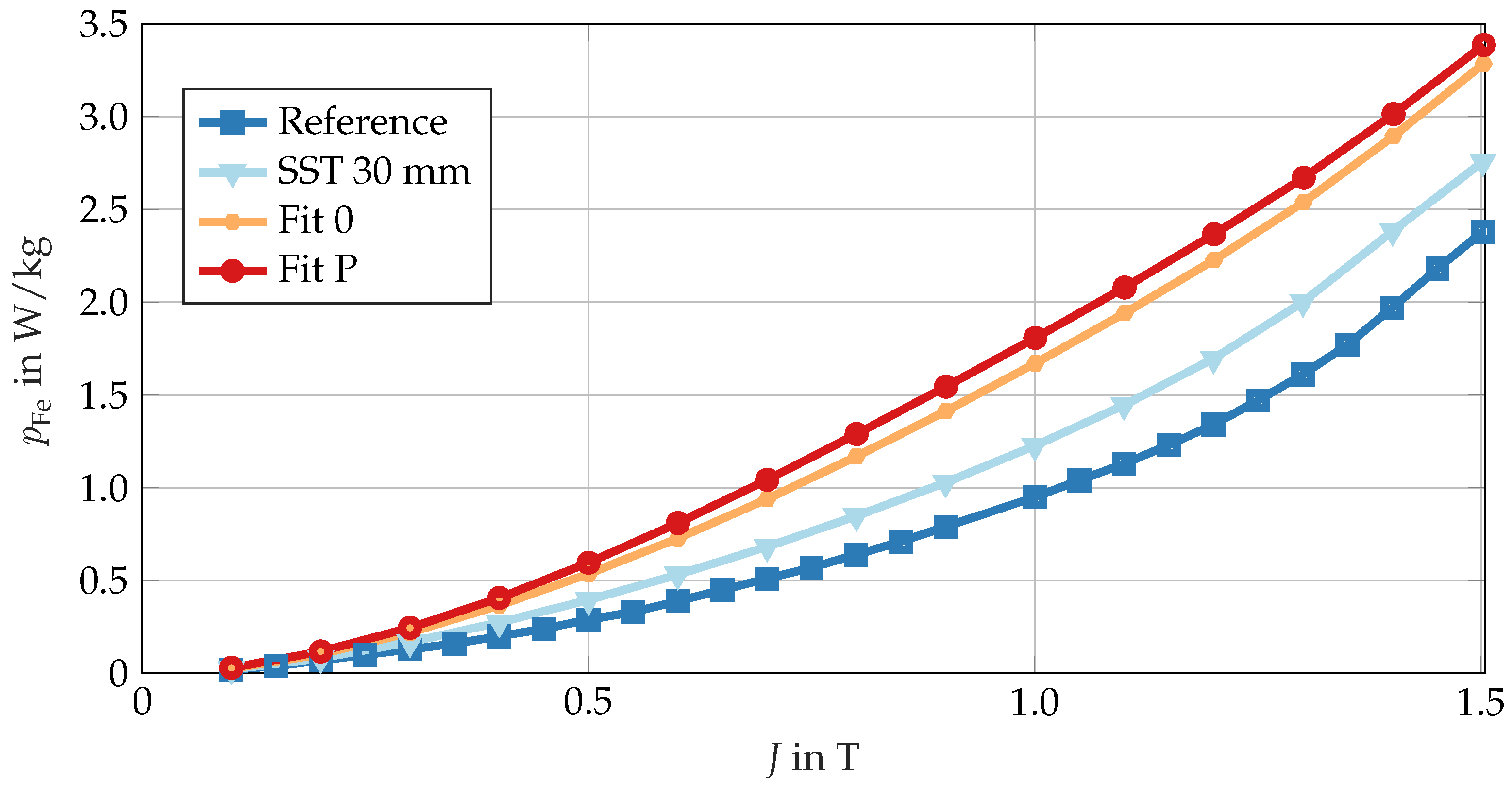

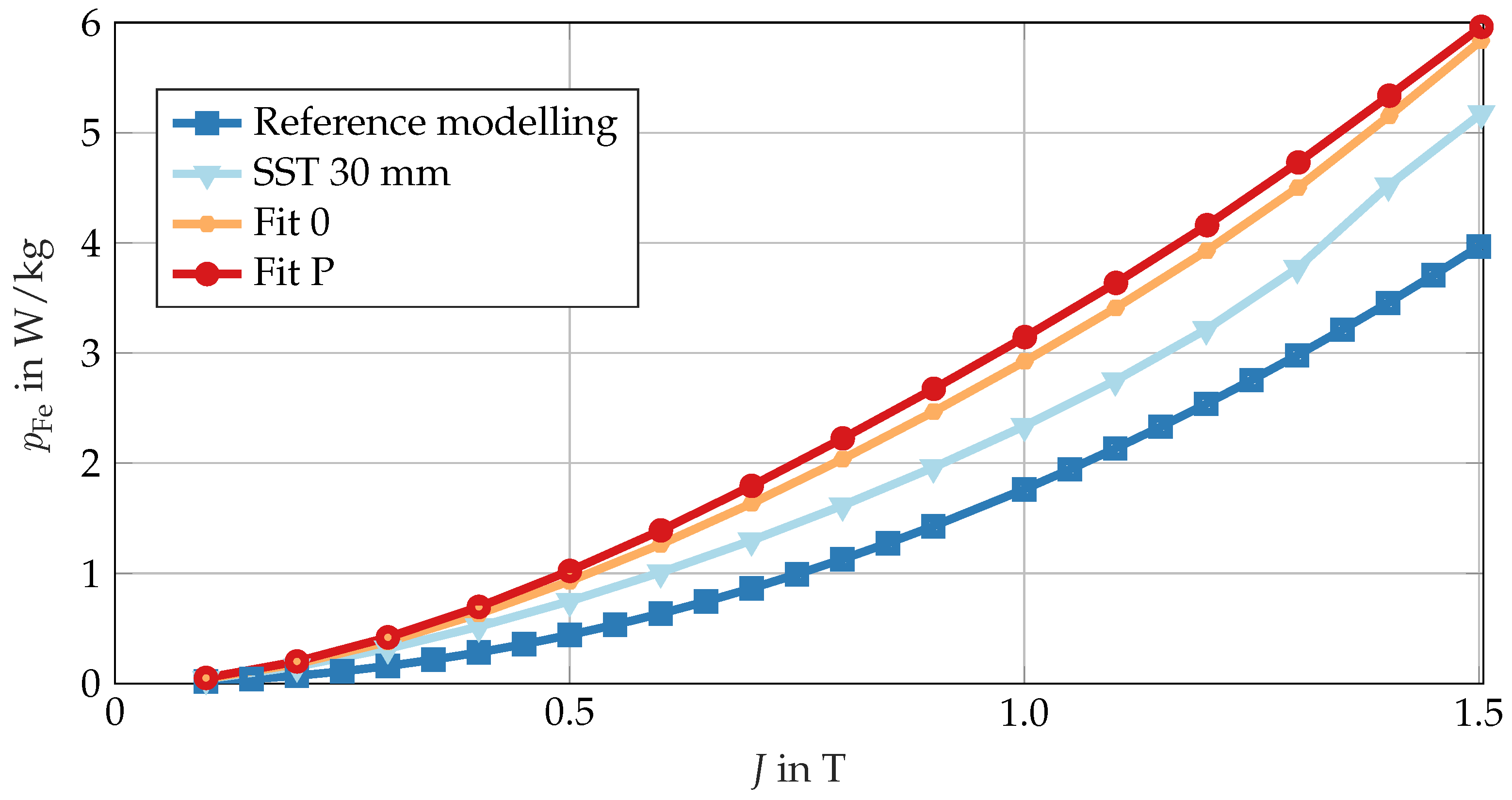

4. Core Loss Separation

The Bertotti approach [

36] is utilized in order to carry out the separation and description of the specific core losses (

4).

The Bertotti approach is part of many pieces of electromagnetic finite element analysis (FEA) software for the integration of core losses. The specific core losses denoted by

are further subdivided into three parts: specific hysteresis losses

, specific eddy current losses

and specific excess losses

. All three loss parts are dependent on magnetic polarization and frequency. The specific core loss coefficients

,

and

are determined through the analysis of the respective loss measurements of the electrical steel sheets.

As indicated in the literature [

36], the specific eddy current coefficient

(

5) is determined by using the physical parameters thickness

d, physical density

, and specific electrical resistivity

. Consequently, it is viable to utilize the coefficient parameter set that has been determined at 50

for simulations at higher frequencies. In order to ascertain the eddy current coefficient of sample Fit P, it is necessary to adjust the underlying electrical resistivity to 60

in accordance with the findings reported in [

37]. Subsequent to determining

, the coefficients

and

are subsequently derived mathematically, according to the methodology outlined in [

26]. The separation with resulting specific core loss parts is shown in

Table 3 for the investigated electrical steel sheet specimens at 50

and in

Table 4 for the extraction from the

measurement. The parameters previously mentioned serve as the foundation for the calculation of core losses in the finite element analysis

Section 6.

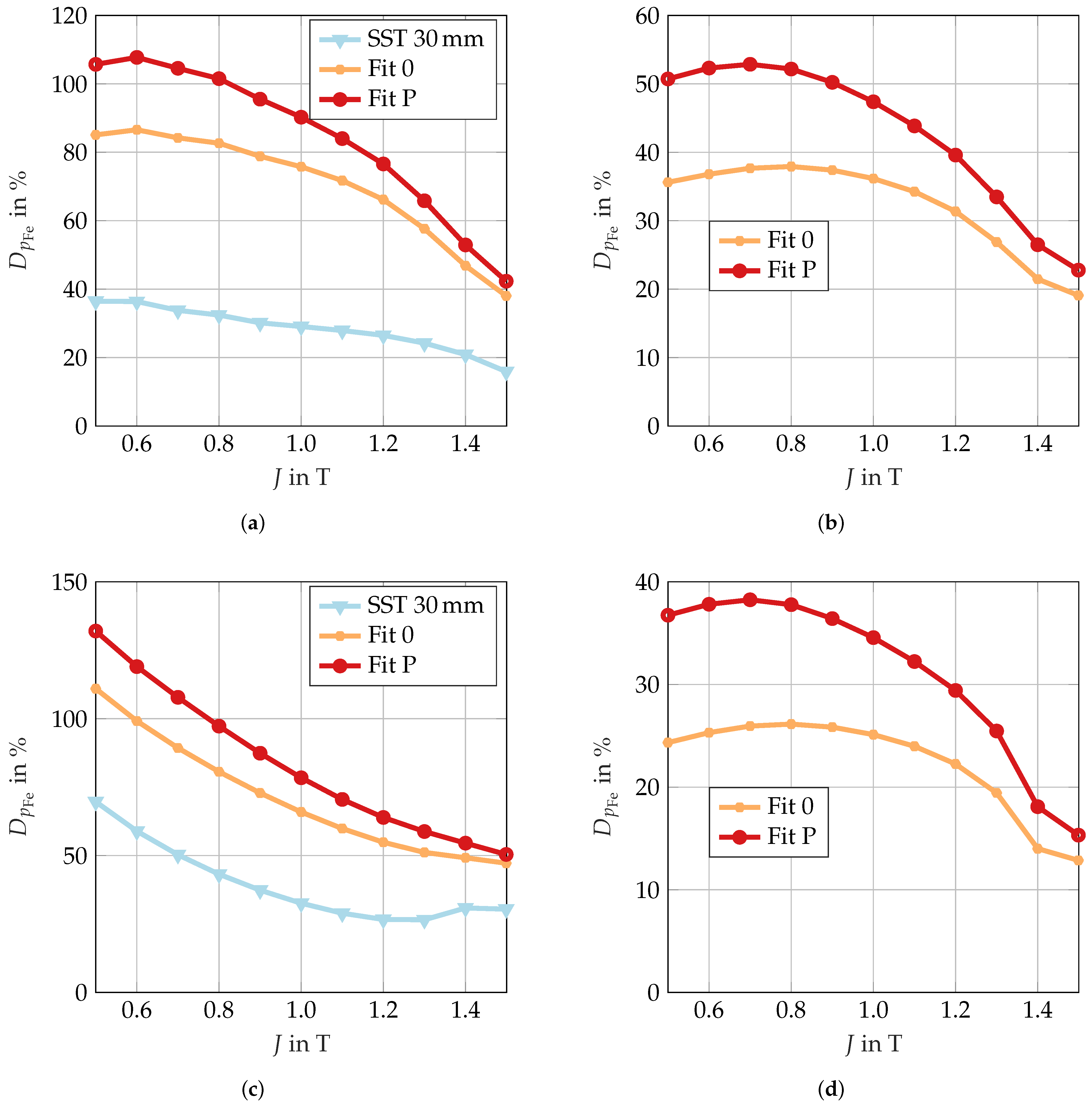

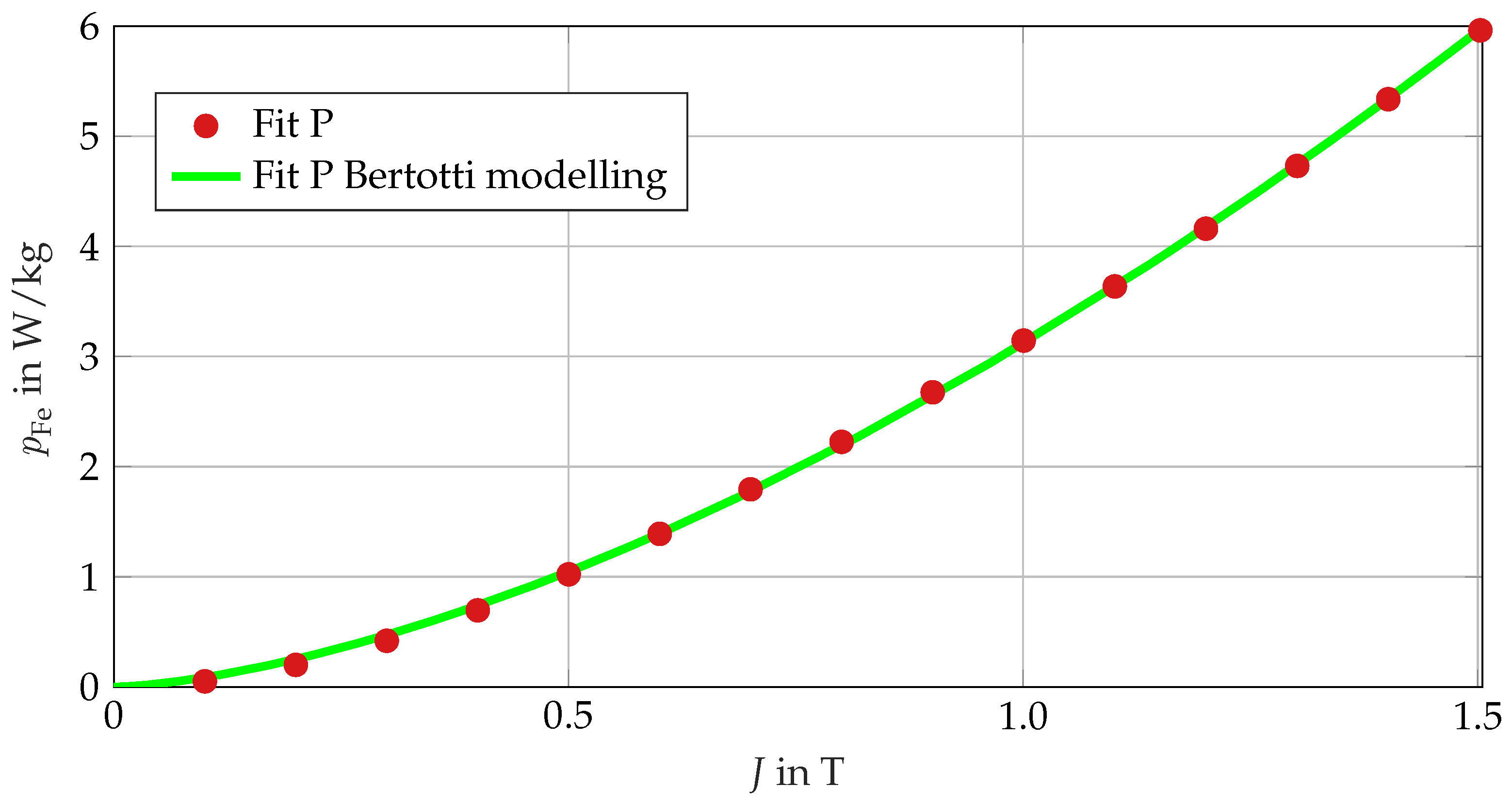

The substantial reduction in the hysteresis component and the pronounced increase in the excess component at Fit 0 and Fit P are particularly notable. This phenomenon can be attributed to the lower gradient of the specific loss curves when mathematically fitting the coefficients. As demonstrated in

Figure 7, the utilization of the Bertotti model still enables a very good replication of the specific core loss characteristic curve of Fit P. However, it should be noted that the hysteresis loss and excess loss components determined therein have become devoid of any physical reference. A notable benefit of this approach is its compatibility with a range of pieces of finite element analysis software that support the Bertotti methodology.

6. Finite Element Analysis

In order to design and calculate the operating point-dependent air gap torque and the core losses , it is necessary to consider the flux linkage maps of the d- and q-axis of the RSM. These are calculated in a 2D FEA.

For the purposes of this study, the machine model from

Figure 8 has been converted into two 2D FE models. As illustrated in

Figure 9a, the model under consideration features a single stator region, which incorporates both the stator yoke and stator teeth. This model is employed in simulations devoid of manufacturing influences. Conversely, the stator is modeled as a two-region system, as depicted in

Figure 9b delineates the distinction between the stator yoke region and the stator teeth region. This provides the opportunity to assign different material parameters to the stator to take into account the investigated manufacturing influences.

The following cases, enumerated in

Table 7, are to be investigated and presented in order to ascertain their respective influences on the calculation results.

In all cases, an M530-50A electrical steel from a manufacturer’s specification is utilized as rotor material. The rotor does not contribute to core losses at the fundamental frequency, and higher harmonics are outside the scope of this study. In the q-axis, manufacturing influences on magnetization in the rotor’s electrical steel sheet are negligible because the air proportion in the flux barriers and the typically saturated radial webs dominate the path. In the d-axis, an influence due to cut edges may occur. However, no cutting edge-influenced material data for the rotor electrical steel sheet are available for the machine under investigation. Based on these considerations, a uniform electrical steel sheet was selected, removing the rotor as a possible influencing factor. The simulation cases examined are, therefore, only valid for considering the influence of manufacturing on the stator. Case 1 represents the standard approach, which involves defining the one-region model in the stator (

Figure 9a) using the manufacturer’s material data. Case 2 delineates the one-region model with the self-measured characteristic curves from the SST measurement of the 30 mm strip specimen. This case demonstrates the availability of electrical steel sheet measurement data for samples that have been magnetically measured without any manufacturing influence. In Case 3, the pressed-in test sample (Fit P) is used in the two-region model (

Figure 9b) as the definition of the stator yoke material. Therefore, the real geometry is considered in conjunction with the impact of the actual punching process, axial welding, and the influence of the interference fit at an operating temperature of 60

. The material of the stator teeth is characterized by its definition, as determined by the SST 30

measurement, with no additional manufacturing influences. Finally, Case 4 extends the investigation to include the manufacturing influence in the stator teeth through the adaptive use of the Fit 0 characteristic curves in the teeth. This analysis encompasses the impact of the cutting process and the axial packaging. The teeth of the machine had an average width of

. The findings reported in [

26] demonstrate the influence of the cut edges in this particular domain on various electrical steel sheets. This observation aligns with the relative deviations observed between Fit 0 and the SST 30

strip measurement depicted in

Figure 6b. This finding serves to substantiate the utilization of Fit 0 in the stator teeth of Case 4 in this study.

The FEA is conducted in the time domain using a transient solver. Machine symmetry allows quarter-model simulations (

Figure 9) with matching symmetry conditions. In the current-fed model, two periods with a step size of

are simulated. This enables a resolution of up to approx.

at a supply frequency of

. The supply currents are ideally sinusoidal, and the stator windings are in a Y-connection. Only the second period is evaluated for magnetic flux linkage, torque, and core losses. The 2D-FE model excludes the winding overhang, and the outer region of the stator is neglected due to the zero vector potential boundary condition at the stator’s outer diameter. In order to calculate the core losses

, it is necessary to determine the time course of the magnetic flux density

for each finite element, based on the electrical period. In the second electrical period, the core losses for each time step can be determined according to Bertotti’s core loss model according to (

4).

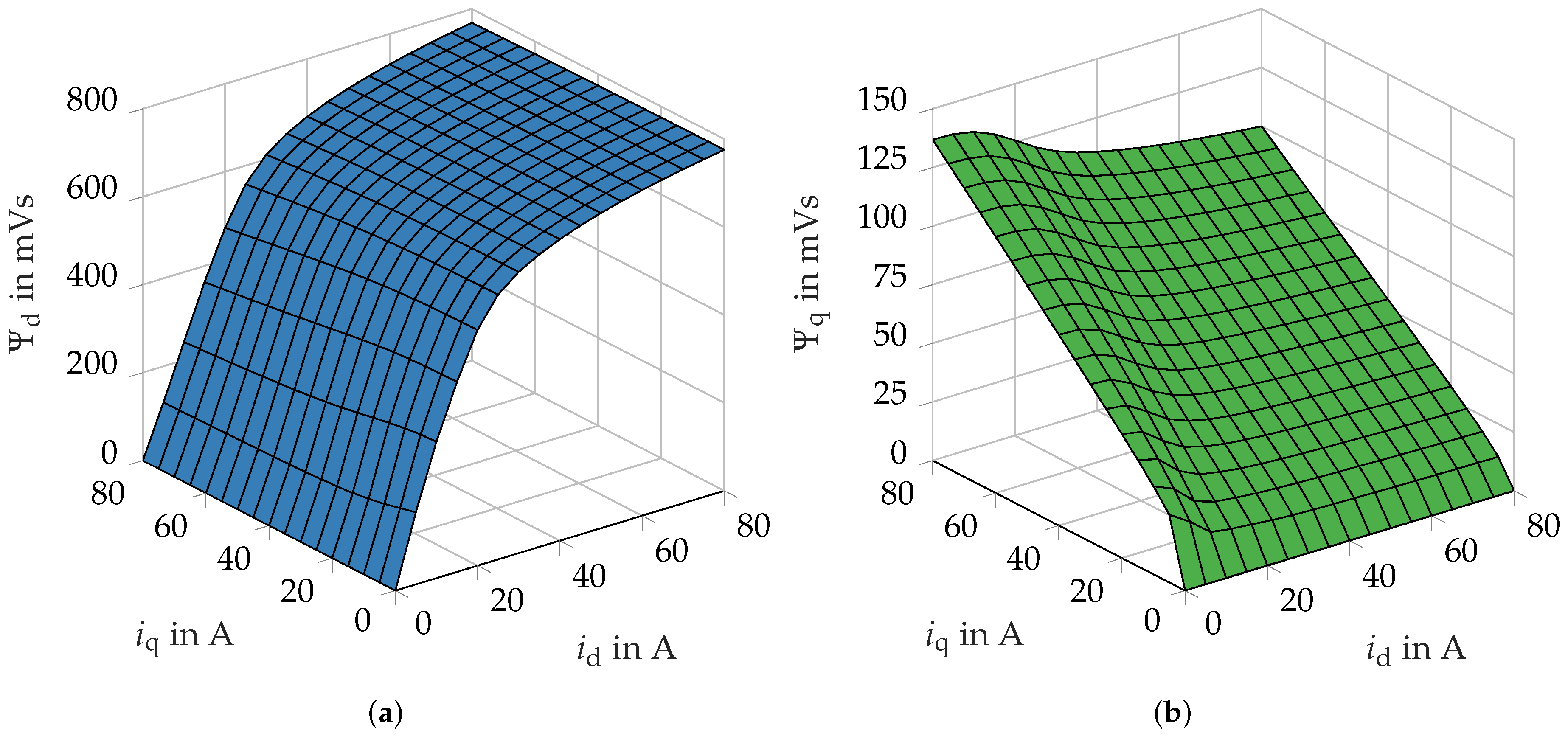

The calculation of the magnetic flux linkages, denoted by and , is imperative for the determination of the magnetic field. In the given context, it is evident that the d- and q-currents are set at specific value, namely, to . The model is simulated with a constant step size of . It is imperative to acknowledge at this juncture that the currents referenced in the FEA are equivalent to the magnetization currents and .

Initially, the Case 1 simulation is executed as a reference point. This case represents a standard scenario in the design and calculation of an electrical machine. The simulation results of the magnetic flux linkage

and

for the simulated current range are shown in

Figure 10.

The calculation of the average torque of the RSM is possible through the use of the determined flux linkage maps

and

as a function of the number of pole pairs

p, the number of strands

m, and the magnetization currents

and

. This calculation is outlined in (

6).

Rather than utilizing magnetization currents

and

, it is more appropriate to employ the effective current

I and the current angle

in this context. The following relationships must be considered: (

7) and (

8).

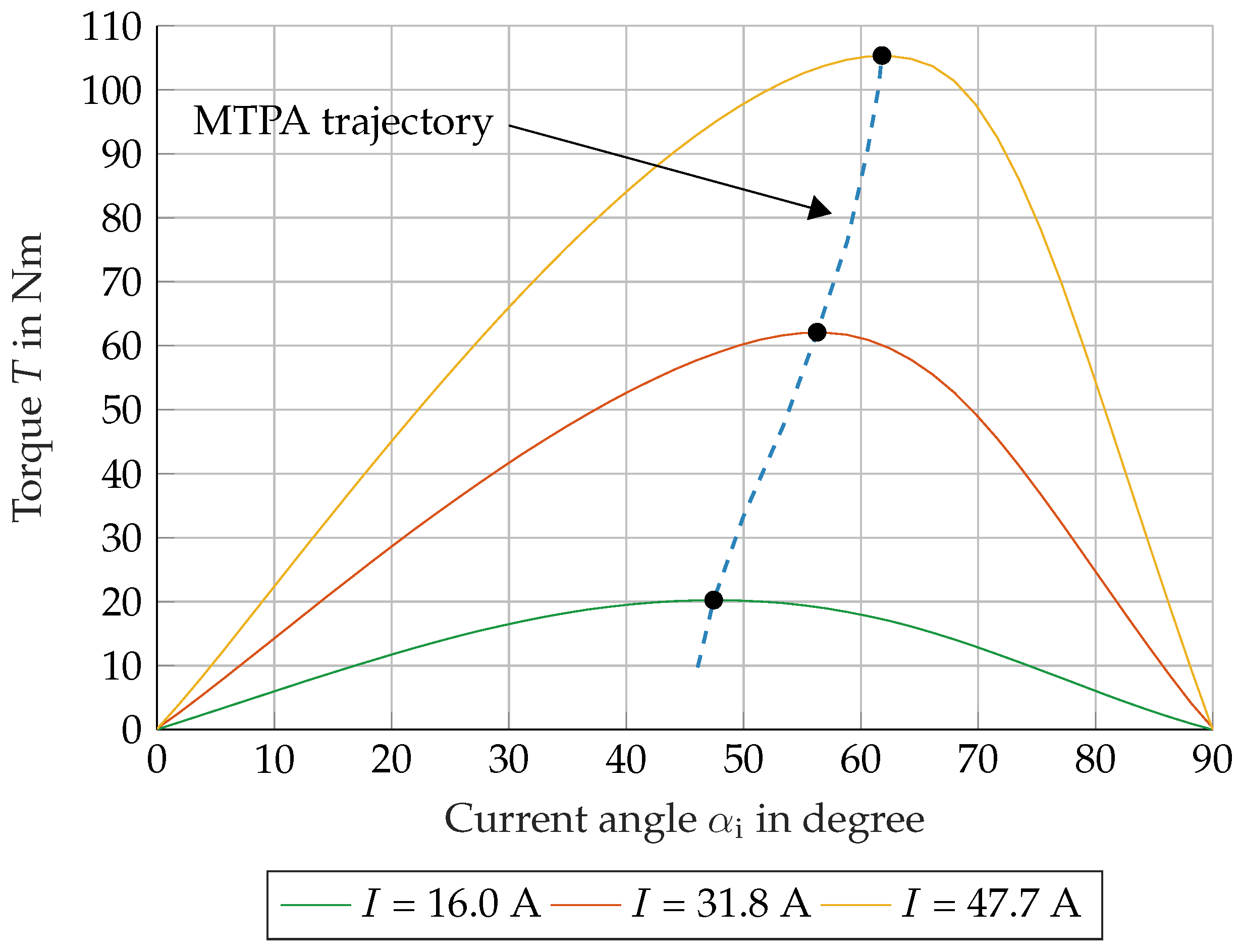

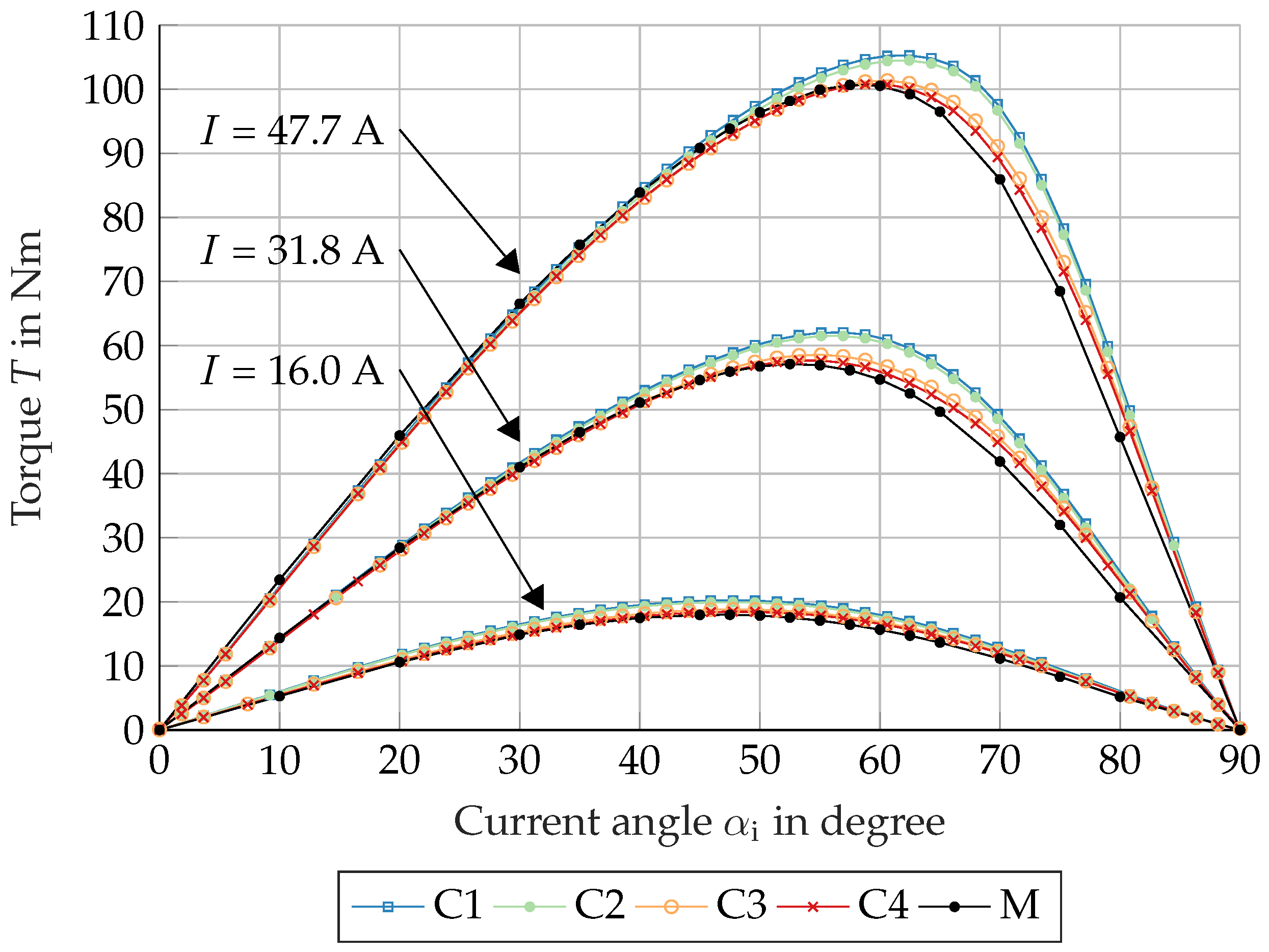

In

Figure 11, the calculated air gap torque

is illustrated over the current angle

as a function of the set effective phase current

I for the exemplary currents

,

, and

.

As illustrated in

Figure 11, with an increase in the effective current

I, the current angle

of the maximum torque also increases. This phenomenon can be attributed to the saturation of the magnetizing rotor axis (d-axis). It has been demonstrated that when the d-axis saturates, the torque can be further increased by a higher q current

. The maximum is necessary to determine the trajectory for the maximum torque per ampere (MTPA) control method. The torque and the associated current angle depend on the material parameters and, consequently, exert an influence on the calculation result.

The present study will examine Case 1 (C1) to Case 4 (C4) to investigate the manufacturing influences on machine behavior. For this purpose, the various material parameters listed in

Table 7 are assigned to the respective regions in the FE model. The flux linkage maps

,

and the average air gap torque

are calculated. The results of the calculation of the four simulation cases are shown in

Figure 12 for comparison.

As illustrated in

Figure 12 it can be seen that the manufacturing influence and the pressing of the stator core into the machine casing have a significant influence on the maximum torque (−4.2% at

) and the corresponding current angle

(−3.4% at

). The manufacturing process has a negative impact on the magnetization characteristics of the electrical steel sheet. Due to the shift of the commutation curve to higher magnetic polarizations (see

Figure 2), a higher phase current is required for the same magnetomotive force

. Additionally, a comparison of the results presented in

Figure 12 reveals that the existing mechanical stresses in the stator yoke, resulting from the press-fit process in Case 3 and Case 4, exert a more substantial influence.

The influence of mechanical stresses on the behavior of the simulated machine can be described and compared as follows. The entire magnetic flux linkage of a magnetic pole is spread out across the stator yoke. For a comparison and a physically explanation, the flux linkage of the machine is transformed into the rotor coordinate system

. The magnetic path of the d-axis mainly consists of electrical steel. The q-axis, however, consists mainly of air due to the flux barriers in the rotor. It should be noted that the influence of manufacturing on the rotor is not considered in this work and, therefore, the material of the rotor was not changed. The focus lies in the investigation of the manufacturing influences in the stator core and their influences on the machine performance. For that, the presented simulation results from Case 1 to Case 4 are used for the explanation. To illustrate this, the operating point at maximum torque with a set current of

is considered as an example. In

Table 8 the flux linkages

and the associated absolute inductance

are listed for a comparison.

When the same current is applied to the machine, the magnetization characteristic shifts from Case 1 to Case 4, towards higher magnetic field strengths (

Figure 2). This has an effect on the flux linkage

and, thus, on the flux linkages

in the rotor coordinate system. From this, it can be deduced that the d-axis is more dependent on manufacturing influences than the q-axis.

Table 8 shows that the flux linkage

in the d-axis decreases due to the various manufacturing influences taken into account. The poorer magnetization is evident here. Simultaneously, the current angle must be reduced in order to achieve the maximum possible magnetization of the d-axis, due to the increasing demand for magnetic field strengths (

Figure 2). Furthermore, the comparison shows that, due to the smaller required current angle, the flux linkage in the q-axis decreases to almost the same extent as the q-current. This means that the q-axis is less susceptible to manufacturing influences because of the dominant linear behavior of air in the flux barriers.

This becomes clear by a comparison of the absolute inductance

at the operating point.

remains constant across the cases under consideration, whereas

decreases by 7.5%, comparing Case 4 to Case 1. The average air gap torque

also decreases due to the need of reducing the current angle

for the best possible magnetization of the machine. From (

6), it can be seen that poorer magnetization and a simultaneous reduction in the current angle results in a decreasing difference of the term

. Finally, this effect decreases the generated air gap torque of the RSM by 4.2%, comparing Case 4 to Case 1.

In order to verify the simulated torque values and the magnetic flux linkages and , the RSM is measured on a motor test bench. The results of this measurement are then compared with those calculated here.

7. Measurements on the Machine Test Bench

In order to validate the simulation results presented in

Section 6, the previously designed RSM is measured on a machine test bench. The machine test bench is illustrated in

Figure 13.

As illustrated in

Figure 13, the motor test bench is equipped with a prototype of a RSM (e) that is coupled to a load machine (g) via a torque measuring shaft (f). The load machine has a rated power of

. The RSM is connected to a frequency inverter (c). The current control and the control of the inverter are both regulated via the UltraZohm (a) [

38]. A power analyzer (b) is used for precise power measurement. It measures the three phase voltages

,

, and

as well as the three phase currents

,

, and

in the time domain via current transformers (d). The torque measuring shaft (f) is connected to the power meter to measure the mechanical power (

) simultaneously.

The load machine has been configured to operate at a speed of . This speed corresponds to an electrical frequency of .

Due to the low frequency, the core losses can be neglected when measuring the flux linkage maps. The current angle is set from to for different current amplitudes, ranging from to via the current control. The electrical and mechanical measured variables are recorded in the time domain.

A comparison of the corresponding measurements has been conducted for the example currents

,

, and

used in

Section 6. As illustrated in

Figure 14, the average torque is plotted against the current angle and the corresponding currents.

As illustrated in

Figure 14, the measurement results demonstrate a strong correlation with the FEA results. When manufacturing influences are taken into account, a significant improvement in the calculation results compared to the measurement results can be achieved. The slight deviations observed in the torque values and the current angle of the descending branch can be ascribed to the fact that the air gap torque is determined in the FEA. In the context of experimental analysis, the shaft torque will be lower than that calculated in the FEA due to friction and ventilation losses.

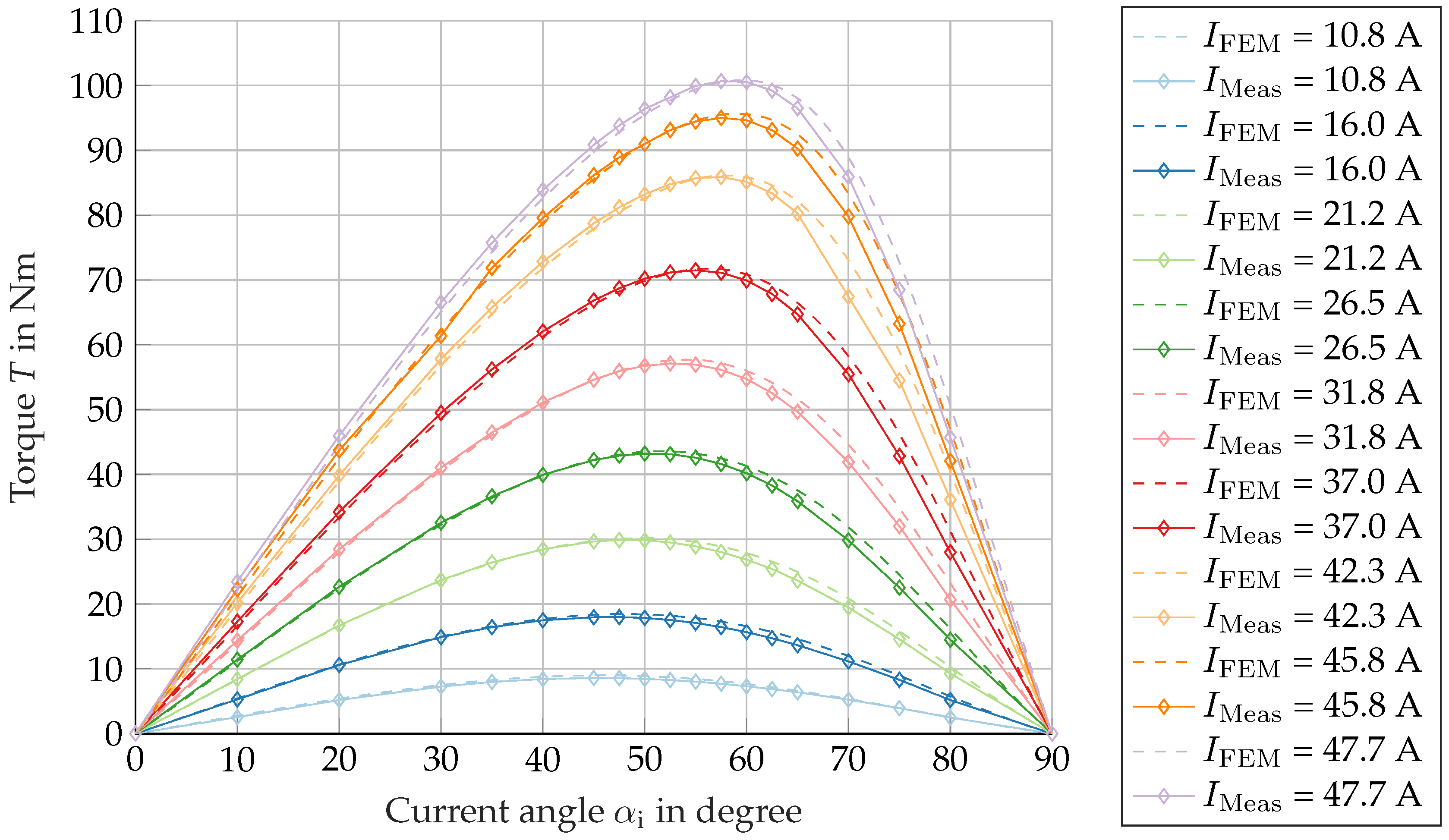

Case 4 demonstrated the most favorable outcome in comparison to the established measurement. Consequently, this case is employed for the purpose of determining additional current values, which are then used for the validation process. As illustrated in

Figure 15, the torque characterization for different current amplitudes is plotted over the current angle in comparison to the FE calculation Case 4.

The torque characteristics of the measured RSM in

Figure 15 demonstrate a high degree of consistency across the range of effective currents set.

The influence of production on the calculated torque can be explained in more detail using the flux linkage maps of the d- and q-axis in

Figure 16. The slope of the flux linkage in the d-axis (a) is reduced due to the weaker magnetization characteristic from Case 1 to Case 4. The aforementioned phenomenon culminates in a diminution of the flux linkage in the d-axis, particularly within the normally magnetized range. Consequently, this results (according to (

8)) in a reduction in the average torque. As illustrated in

Figure 16, the simulated flux linkage maps of the d- and q-axes of Cases 1 and 4 are presented in a comparative manner. The following

Figure 16c,d offer a visual representation of the percentage deviation between Case 1 and Case 4. The areas of greatest deviation in the d-axis are attributable to the locations of the deviations in

Figure 2, in conjunction with the specifications outlined in

Table 7. A close examination reveals that the q-axis exhibits minimal variation. This can be explained by the fact that the enclosed air represents the dominant (magnetically linear) component in the q-axis. Due to the flux barriers, the manufacturing process has no significant influence on the magnetization characteristics.

In order to facilitate the analysis of core losses, the rated operating point of the machine according to

Table 6 is selected at a speed of 2300

(

) and a rated power of 23

. As illustrated in

Table 9, the associated currents

and

are displayed, in addition to the results of the core losses for the simulation cases and the test bench measurement.

The discrepancy between the manufacturer’s data (Case 1) and the measured data of the machine is represented by a percentage of −33% for the core losses. As demonstrated in the following cases, the FEA results in deviations of −22%, −19%, and −15%, respectively. This finding suggests that by incorporating the manufacturing-related characteristic material curves, the discrepancy between the simulated core losses and the measured value on the test bench can be mitigated by more than half. A non-negligible portion of the core losses in the machine under investigation is located in the rotor, caused by higher air gap harmonics resulting from stator slots. With regard to these results, it should be noted that manufacturing influences have not yet been taken into account for this part of the core losses from the rotor and are the focus of further work.