Study on Friction and Wear Performance of Bionic Function Surface in High-Speed Ball Milling

Abstract

1. Introduction

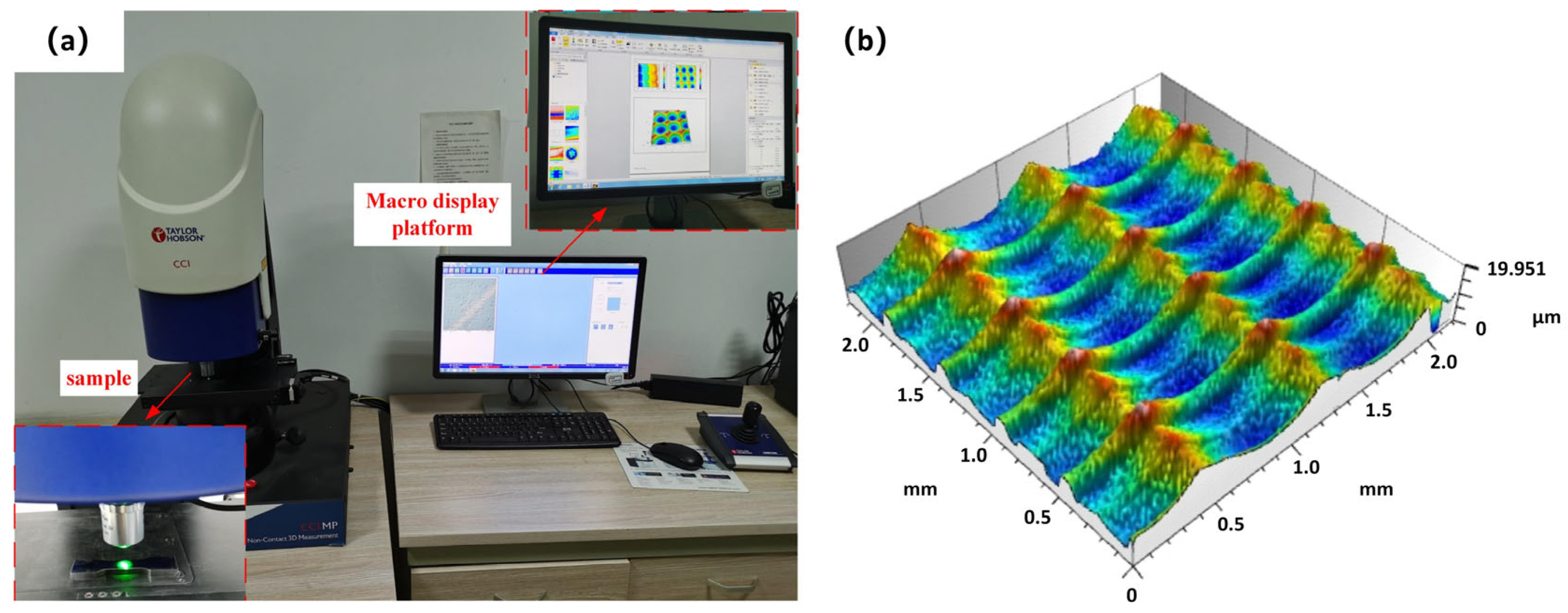

2. Materials and Methods

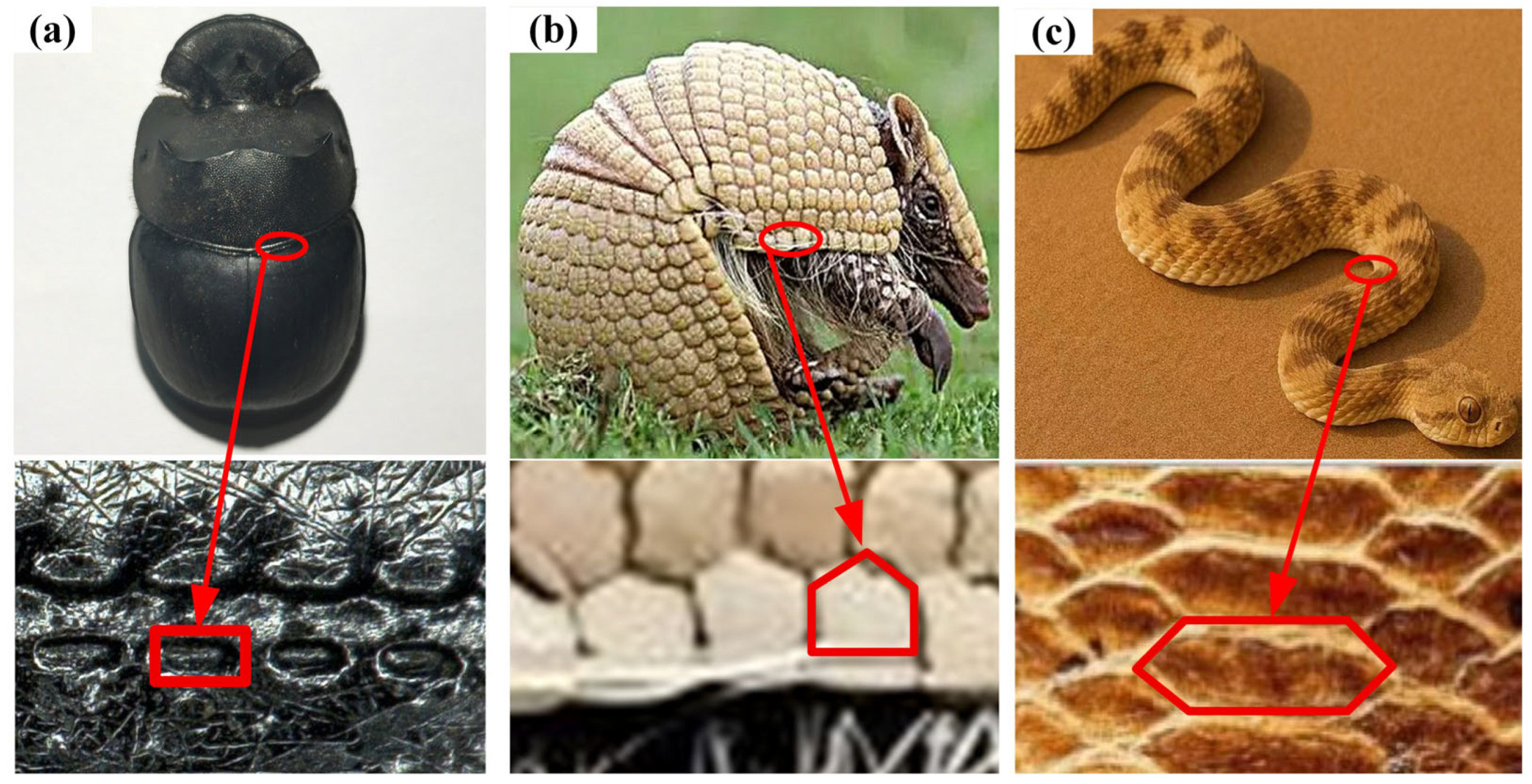

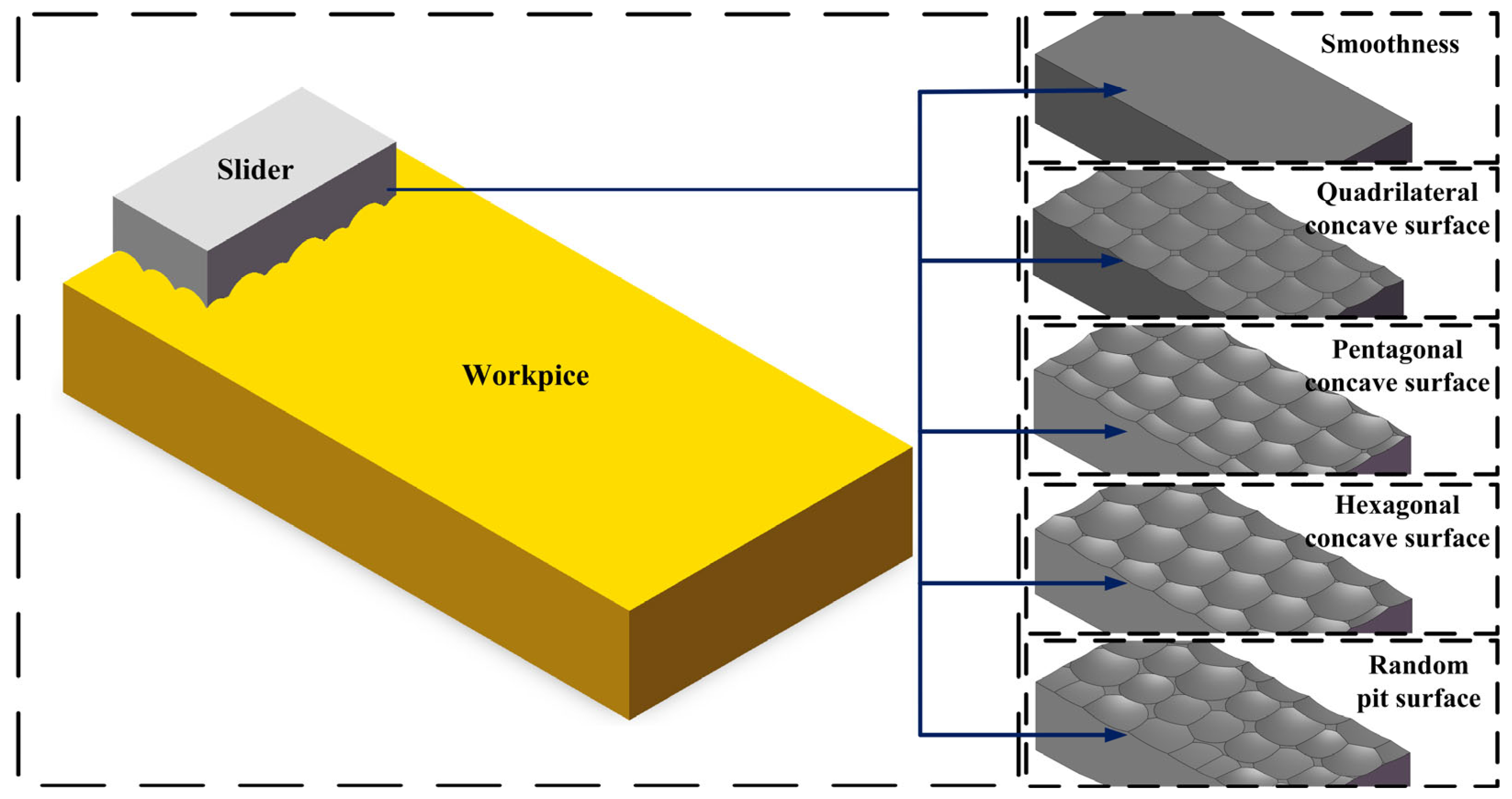

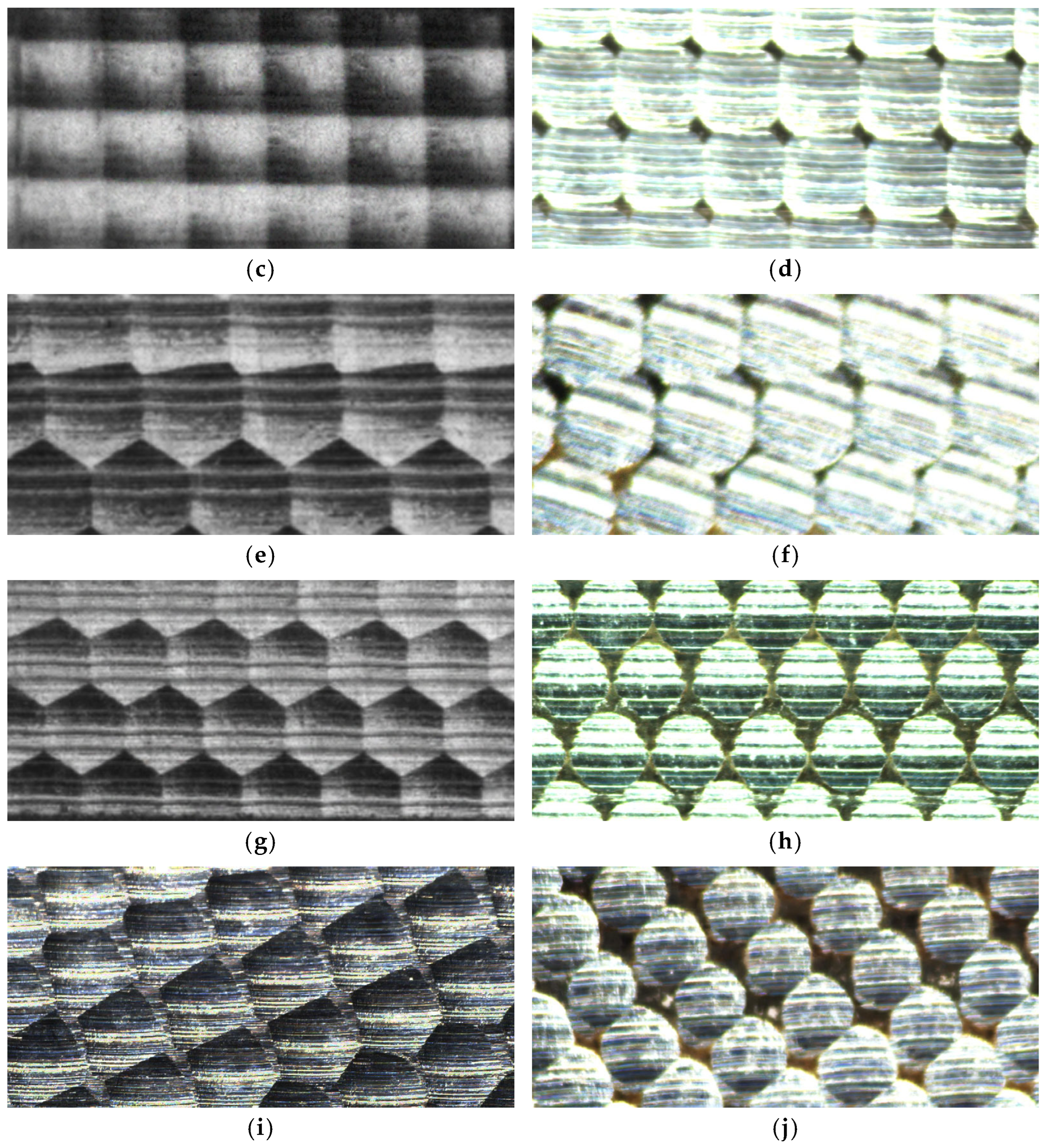

2.1. Selection of Biomimetic Prototypes and Establishment of Models

2.2. Friction and Wear Theory

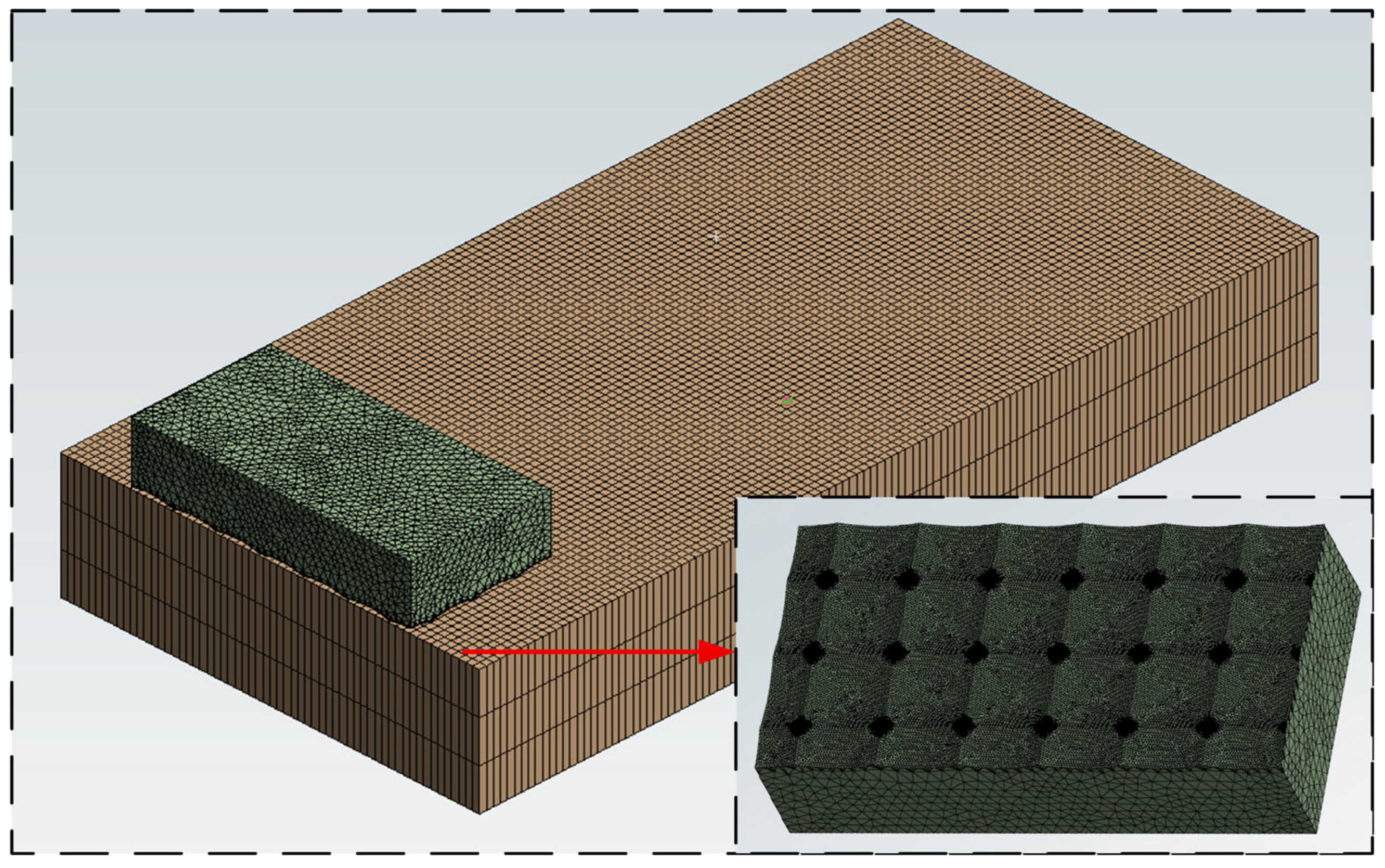

2.3. Preprocessing of Finite Element Simulation

| Element | C | Cr | Mo | V | Mn |

| Content | 1.45–1.70 | 11.00–12.50 | 0.4–0.6 | 0.15~0.30 | ≤0.40 |

| Element | Si | Ni | Cu | S | P |

| Content | ≤0.40 | ≤0.25 | ≤0.30 | ≤0.030 | ≤0.030 |

| Density (kg/m3) | Young’s Modulus (GPa) | Poisson’s Ratio | Thermal Conductivity (W·m−1·K−1) | Specific Heat Capacity (J·kg−1·K−1) |

|---|---|---|---|---|

| 7.7 | 218 | 0.28 | 24 | 460 |

2.4. Design of Experiments

2.5. Optimization Design of Milling Parameters

3. Simulation Analysis of Different Bionic Functional Surfaces

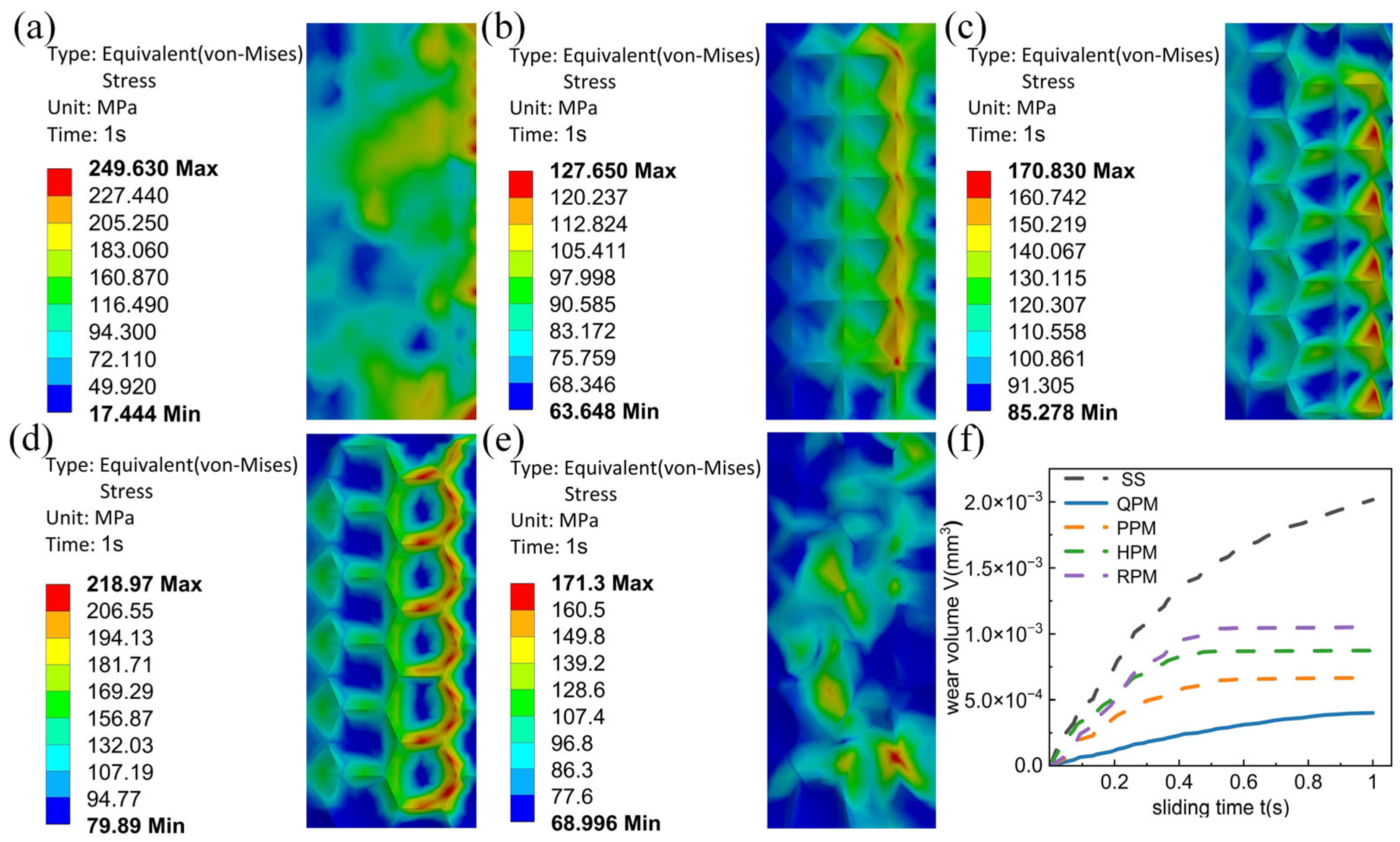

3.1. Simulation Analysis of Wear Volume for Different Bionic Functional Surfaces

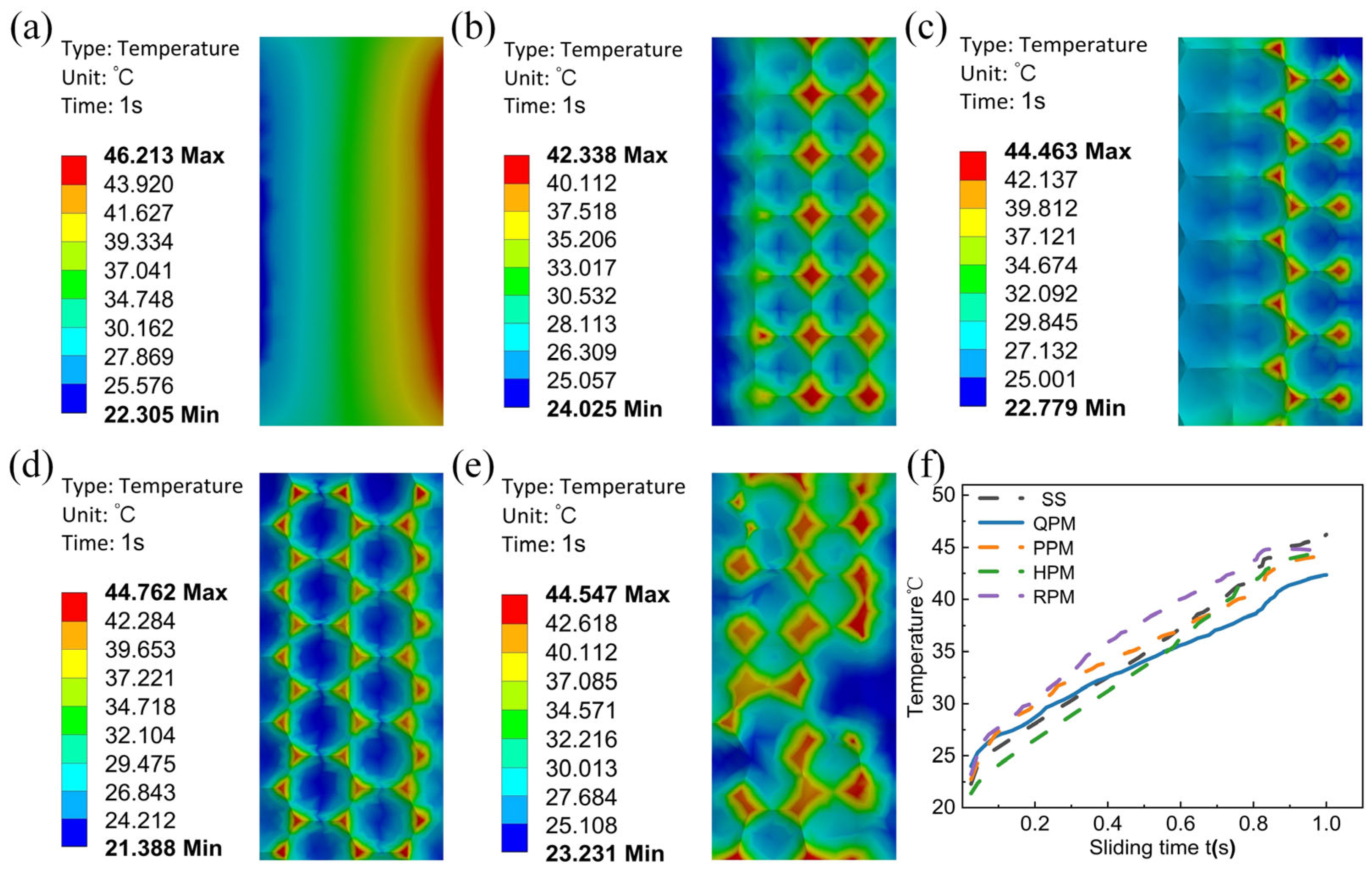

3.2. Simulation Analysis of Wear-Induced Temperature for Different Bionic Functional Surfaces

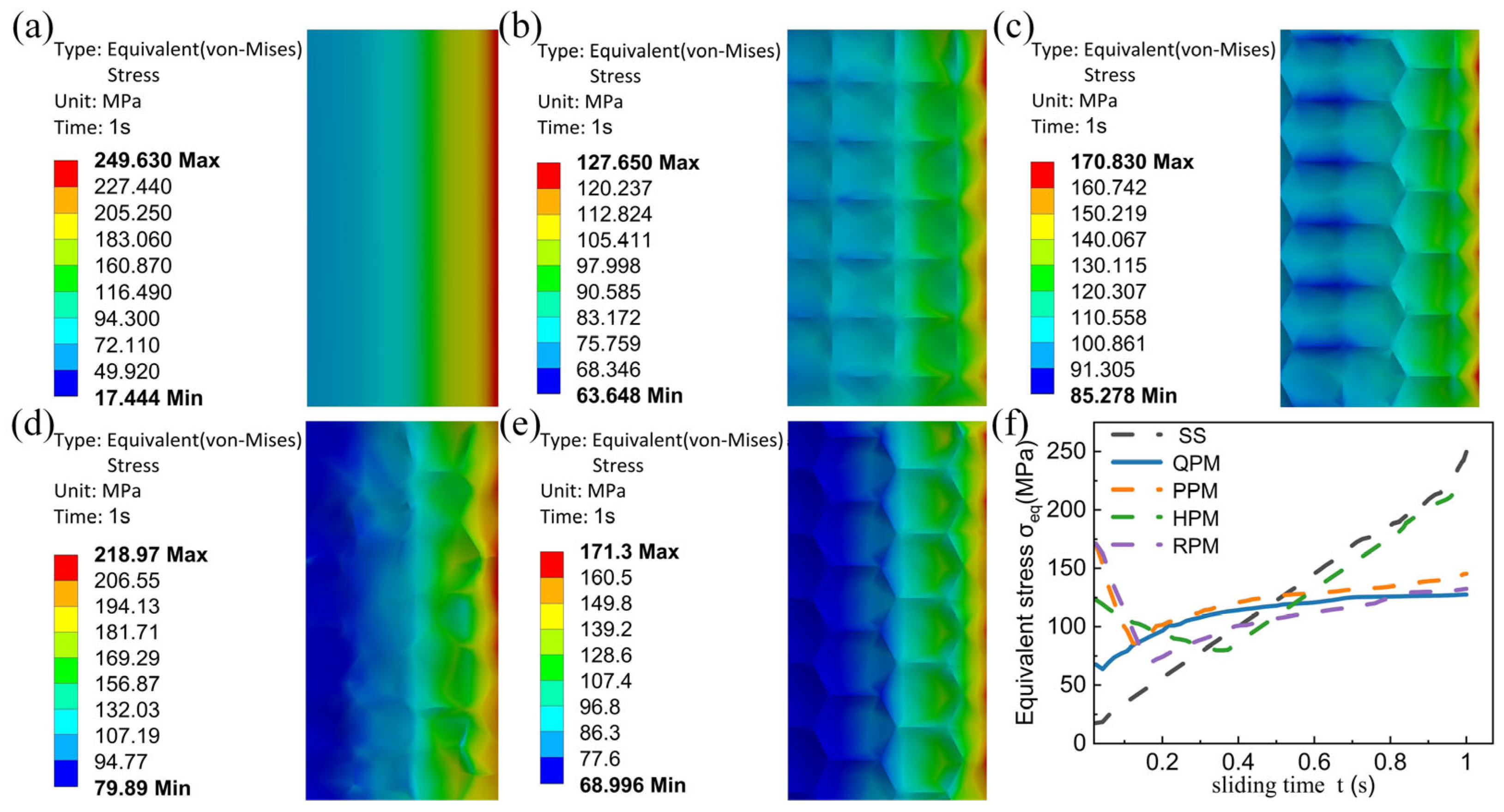

3.3. Simulation Analysis of Equivalent Stress Distribution for Different Bionic Functional Surfaces

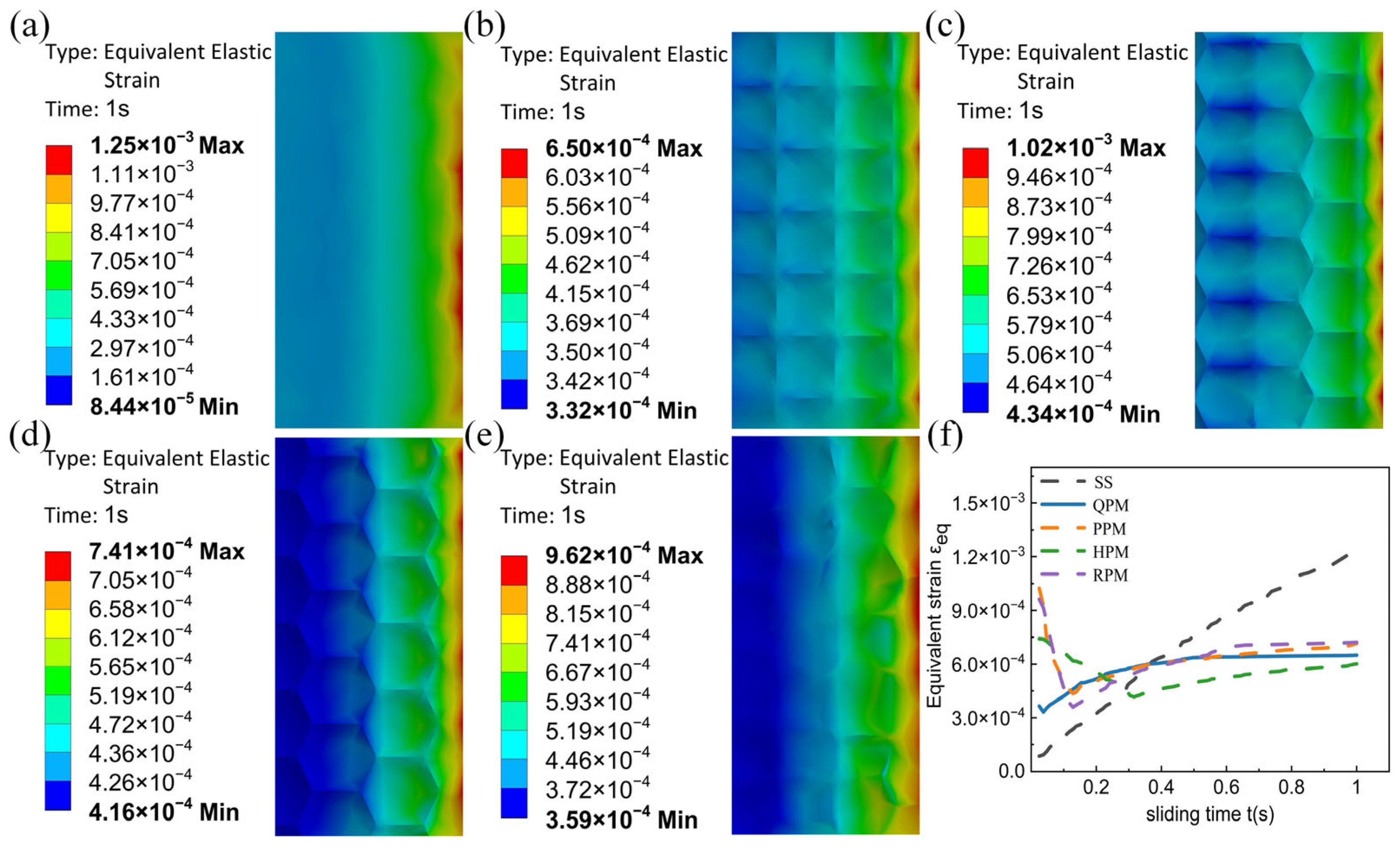

3.4. Simulation Analysis of Equivalent Elastic Strain for Different Bionic Functional Surfaces

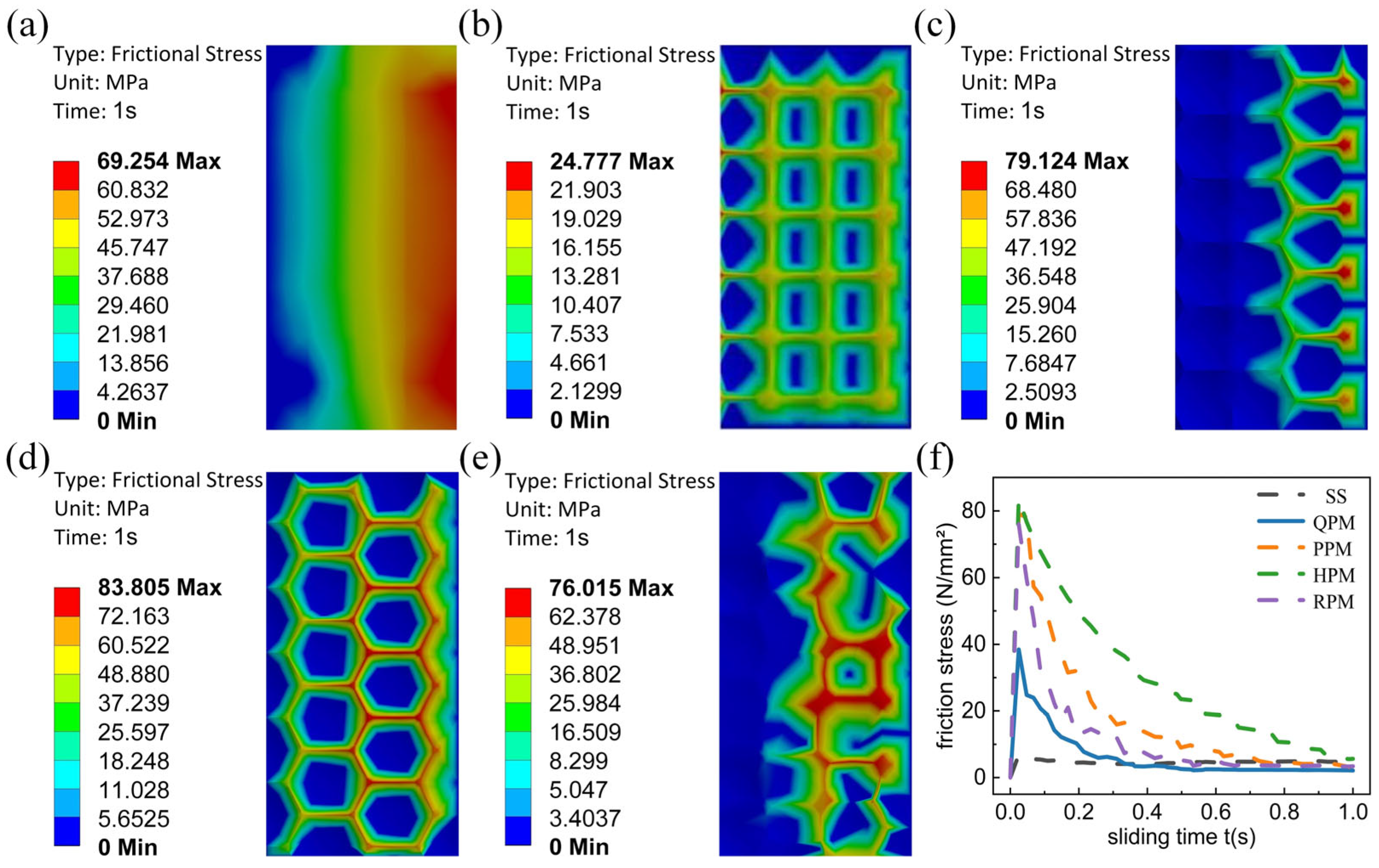

3.5. Simulation Analysis of Frictional Stress on Different Bionic Functional Surfaces

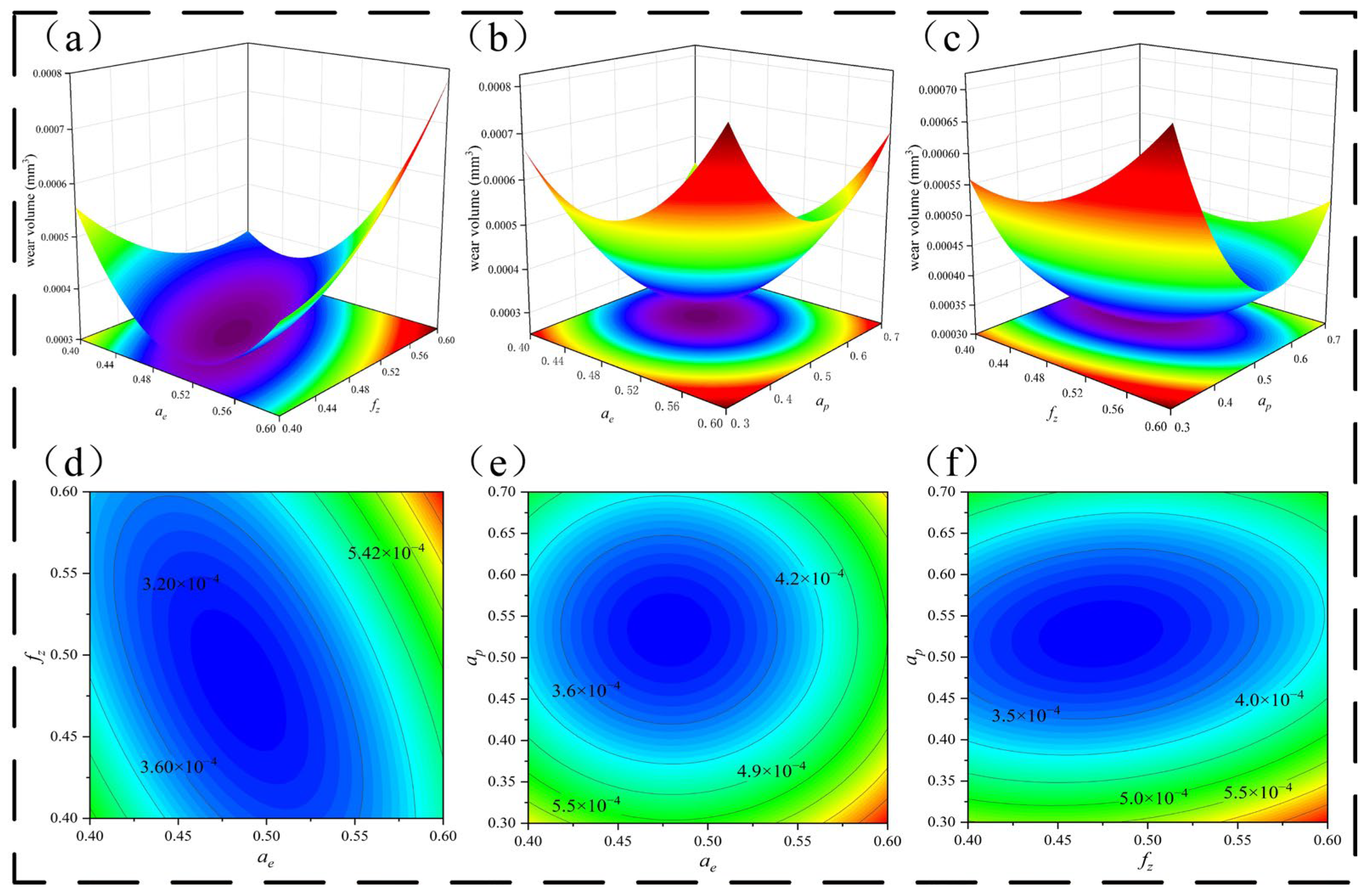

4. Optimization Design of Machining Parameters

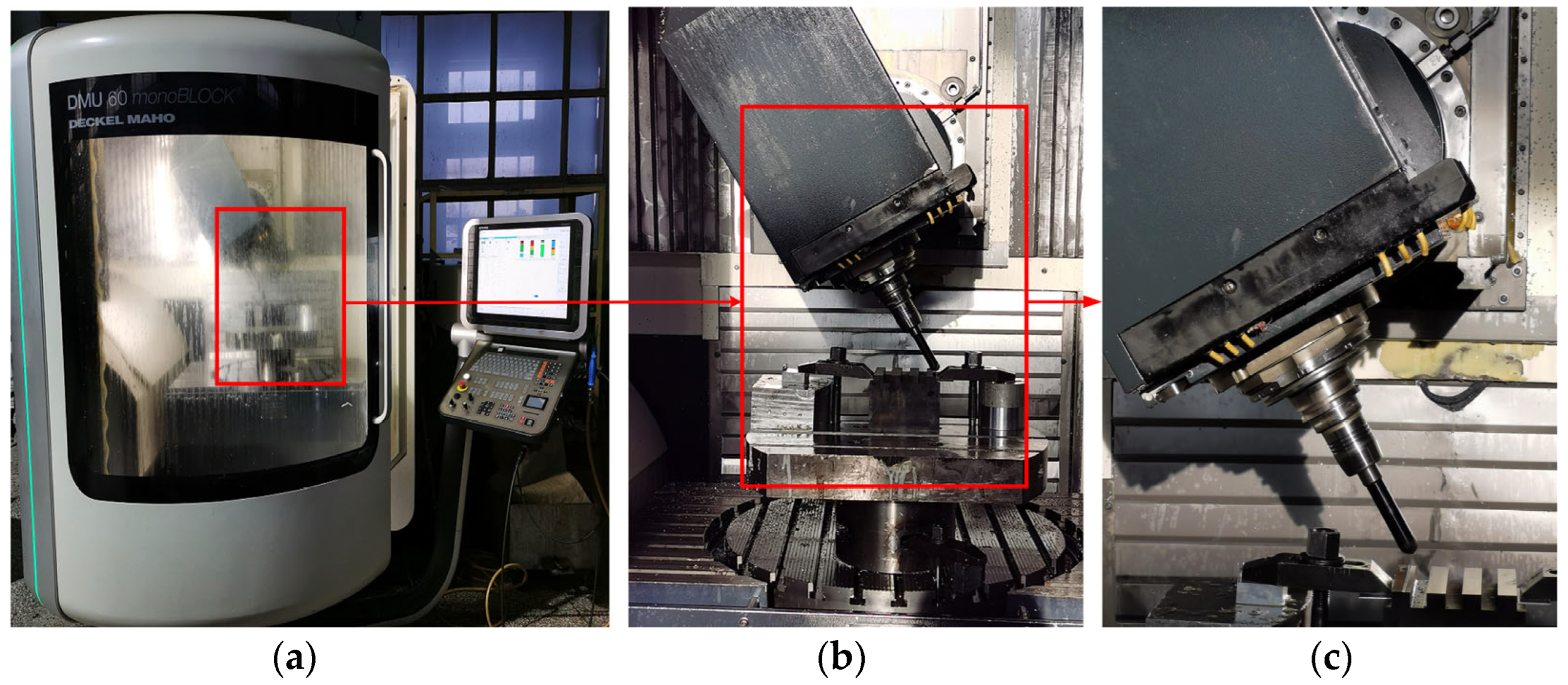

5. Empirical Test

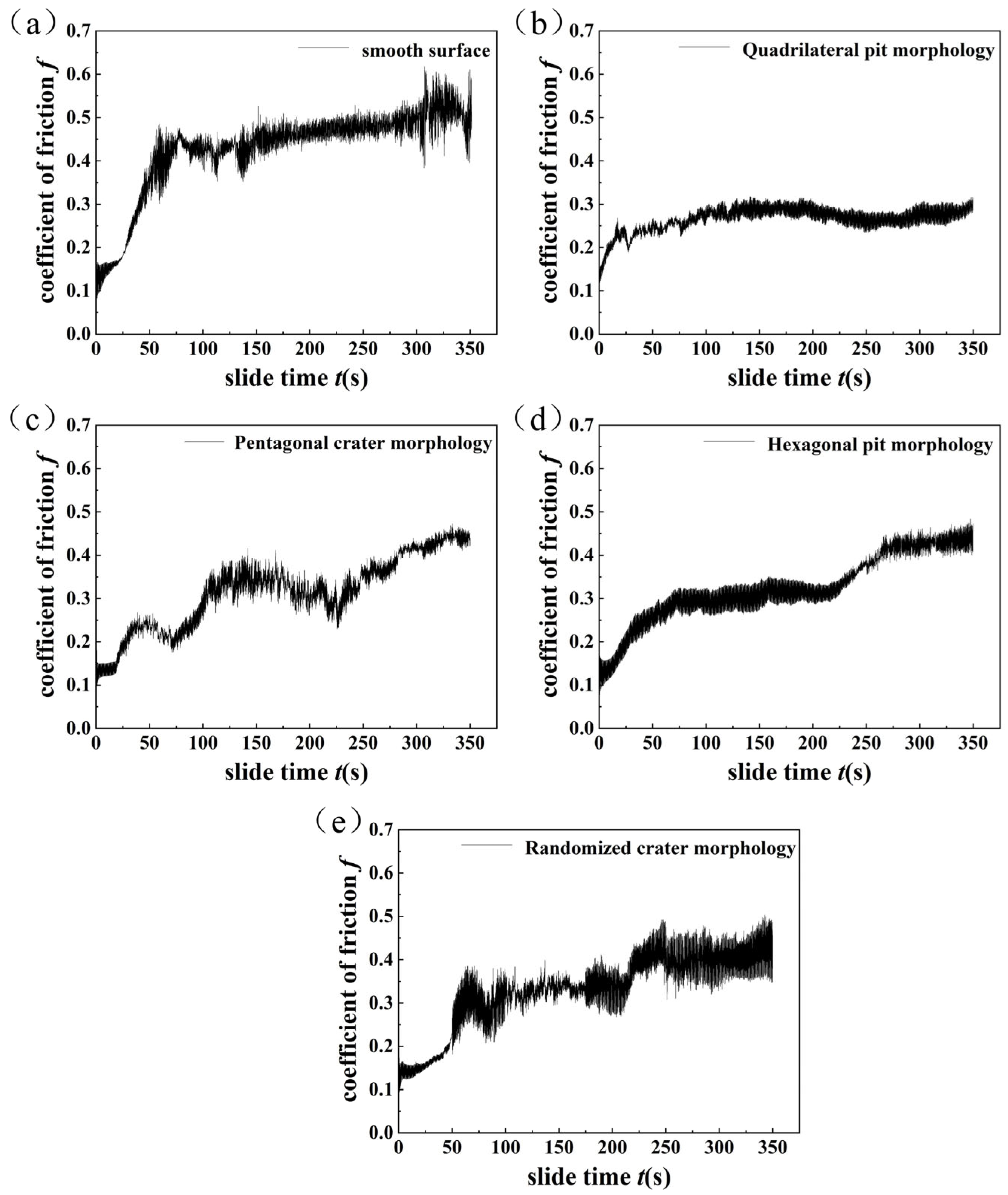

5.1. Friction Coefficient Analysis

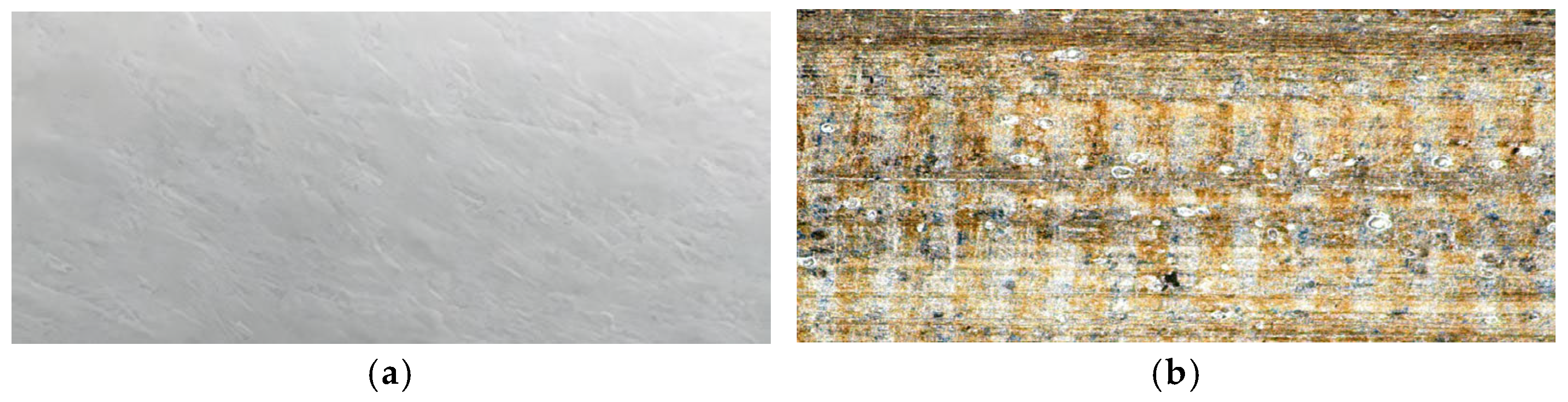

5.2. Wear Morphology Analysis

5.3. Wear Rate Analysis

6. Conclusions

- (1)

- Three biomimetic concave surfaces were constructed based on the surface morphologies of dung beetles, armadillos, and desert vipers. The results showed that the quadrilateral concave biomimetic surface had the best comprehensive performance in reducing friction and wear. This structure significantly reduces the friction coefficient and wear amount and can effectively and uniformly disperse contact stress and frictional heat generation, with excellent stress relief and heat dissipation capabilities.

- (2)

- A regression prediction model for wear volume was established, based on response surface methodology, and milling process parameters were optimized. The optimal combination of machining parameters obtained was a line spacing ae = 0.48 mm and a feed rate per tooth, fz = 0.49 mm/z, cutting depth ap = 0.53 mm.

- (3)

- The experimental verification results show that compared with a smooth surface, the friction coefficient of the quadrilateral concave biomimetic surface prepared according to the optimal parameters is reduced by 21.3%, and the wear amount is reduced by 38.6%. At the same time, the biomimetic surface exhibits excellent debris collection and storage capabilities, which can effectively delay the occurrence and development of abrasive wear, confirming the anti-friction and anti-wear advantages of the quadrilateral pit structure.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, W.; Meng, S.; Zhang, L. Analysis of wear characteristics of biomimetic surfaces in high-speed milling. J. Harbin Inst. Technol. 2019, 24, 26–32. [Google Scholar]

- Wang, Y.; Peng, W.; Tong, H.; Sun, Y.; Liu, Z.; Wu, F. A biomimetic micro-texture based on shark surface for tool wear reduction and wettability change. J. Manuf. Process. 2024, 129, 202–214. [Google Scholar] [CrossRef]

- Sheng, Z.; Zhu, H.; He, Y.; Shao, B.; Sheng, Z.; Wang, S. Tribological Effects of Surface Biomimetic Micro–Nano Textures on Metal Cutting Tools: A Review. Biomimetics 2025, 10, 283. [Google Scholar] [CrossRef]

- Zheng, X.H. Wear analysis of automotive panel hot stamping die based on Archard’s theory. Forg. Technol. 2021, 46, 150–154. [Google Scholar]

- Li, L.X.; Li, Z.X.; Xing, Z.G.; Guo, W.; Huang, Y.; Wang, H. Effect of femtosecond laser bionic texture on anti-wear properties of medical Ti-6Al-4V. Tribol. Int. 2023, 190, 109062. [Google Scholar] [CrossRef]

- Xiao, X.; Zhang, J.; Liu, Y.; Zheng, W.; Xu, J.; Luo, X.; Sun, J.; Zhang, L. Beyond smoothness: The art of surface texturing battling against friction. Int. J. Extrem. Manuf. 2025, 7, 015002. [Google Scholar] [CrossRef]

- You, C.; Zhao, G.; Chu, X.; Zhou, W.; Long, Y.; Lian, Y. Design, preparation and cutting performance of bionic cutting tools based on head microstructures of dung beetle. J. Manuf. Process. 2020, 58, 129–135. [Google Scholar] [CrossRef]

- Liu, J.; Yang, D.; Ma, W.; Cui, Y.; Li, L.; Jin, F.; Yu, L.; Li, Z. Optimization of biomimetic weave parameters using response surface methodology to improve tribological performance of HSLT-Q235. Appl. Surf. Sci. 2025, 696, 162894. [Google Scholar] [CrossRef]

- Kumar, S.S.; Singh, H.G. Tribological behavior of bioinspired surfaces. Biomimetics 2023, 8, 62. [Google Scholar] [CrossRef]

- Zhao, C.; Jia, X.; Zhao, Q.; Ma, H.; Zhang, H. Laser melting and surface texture technology: Effect on friction properties. J. Nanoelectron. Optoelectron. 2024, 19, 415–422. [Google Scholar] [CrossRef]

- Shi, H.; Ma, C.; Wang, B.; Zhang, L.; Li, Y.; Liu, Z. Influence of lubrication status on milling performance of bionic micro-textured tools. Lubricants 2024, 12, 118. [Google Scholar] [CrossRef]

- Wang, R.; Song, Z.; Wei, D.; Li, X.; Song, J.; Mo, Z.; Weng, Y.; Yang, F. Unveiling the effect of electron beam shock on the microstructure and wear resistance of Cr12MoV steel. Vacuum 2024, 226, 113347. [Google Scholar] [CrossRef]

- Etsion, I. Improving tribological performance of mechanical components by laser surface texturing. Tribol. Lett. 2004, 17, 733–737. [Google Scholar] [CrossRef]

- Yerramareddy, S.; Bahadur, S. The effect of laser surface treatments on the tribological behavior of Ti-6Al-4V. Wear 1992, 157, 245–262. [Google Scholar] [CrossRef]

- Mondal, A.K.; Kumar, S.; Blawert, C.; Dahotre, N.B. Effect of laser surface treatment on corrosion and wear resistance of ACM720 Mg alloy. Surf. Coat. Technol. 2008, 202, 3187–3198. [Google Scholar] [CrossRef]

- Zhang, K.; Deng, J.; Lei, S.; Yu, X. Effect of micro/nano-textures and burnished MoS2 addition on the tribological properties of PVD TiAlN coatings against AISI 316 stainless steel. Surf. Coat. Technol. 2016, 291, 382–395. [Google Scholar] [CrossRef]

- Liew, K.W.; Kok, C.K.; Efzan, M.N.E. Effect of EDM dimple geometry on friction reduction under boundary and mixed lubrication. Tribol. Int. 2016, 101, 1–9. [Google Scholar] [CrossRef]

- Bakirci, A.; Koca, S.; Erdogan, O.; Cakir, M.C. Wear and residual stress in high-feed milling of AISI H13 tool steel. Mater. Test. 2023, 65, 1845–1856. [Google Scholar] [CrossRef]

- Vila Pastor, J.V.; Vila Pastor, C.; Siller, H.R. A review of the factors influencing surface roughness in machining and their impact on sustainability. Sustainability 2024, 16, 1917. [Google Scholar] [CrossRef]

- Li, R.; Li, C.; Zhao, W.; Zhao, L.; Zhu, J.; Bai, T. Research on modeling of milling force of ball-end mill cutter in multi-hardness splicing area of automobile panel die steel. Integr. Ferroelectr. 2022, 226, 156–171. [Google Scholar]

- Ullah, N.; Rehan, M.; Farooq, M.U.; Li, H.; Yip, W.S.; To, S.S. A comprehensive review of micro-milling: Fundamental mechanics, challenges, and future prospective. Int. J. Adv. Manuf. Technol. 2025, 1–43. [Google Scholar] [CrossRef]

- Archard, J. Contact and rubbing of flat surfaces. J. Appl. Phys. 1953, 24, 981–988. [Google Scholar] [CrossRef]

- Hong, S.; Wu, Y.; Wang, B.; Lin, J. Improvement in tribological properties of Cr12MoV cold work die steel by HVOF sprayed WC-CoCr cermet coatings. Coatings 2019, 9, 825. [Google Scholar] [CrossRef]

- ASM International. Properties and Selection: Irons, Steels, and High-Performance Alloys; ASM Handbook; ASM International: Materials Park, OH, USA, 1990; Volume 1. [Google Scholar]

- Hashmi, K.H.; Zakria, G.; Raza, M.B.; Khalil, S. Optimization of process parameters for high speed machining of Ti-6Al-4V using response surface methodology. Int. J. Adv. Manuf. Technol. 2016, 85, 1847–1856. [Google Scholar] [CrossRef]

- Saklakoglu, I.E.; Kasman, S. Investigation of micro-milling process parameters for surface roughness and milling depth. Int. J. Adv. Manuf. Technol. 2011, 54, 567–578. [Google Scholar] [CrossRef]

- Fnides, M.; Amroune, S.; Slamani, M.; Elhadi, A.; Arslane, M.; Jawaid, M. Optimization of Manufacturing Parameters for Minimizing Vibrations and Surface Roughness in Milling Using Box–Behnken Design. J. Vib. Eng. Technol. 2025, 13, 22. [Google Scholar] [CrossRef]

| Level | Factors | ||

|---|---|---|---|

| ae (A) | fz (B) | ap (C) | |

| −1 | 0.4 | 0.4 | 0.3 |

| 0 | 0.5 | 0.5 | 0.5 |

| 1 | 0.6 | 0.6 | 0.7 |

| Level | Factors | Wear Volume | ||

|---|---|---|---|---|

| ae (A) | fz (B) | ap (C) | ||

| 1 | 0.4 | 0.5 | 0.3 | 0.00067182 |

| 2 | 0.6 | 0.6 | 0.5 | 0.00078942 |

| 3 | 0.5 | 0.5 | 0.5 | 0.00030549 |

| 4 | 0.5 | 0.4 | 0.7 | 0.00051647 |

| 5 | 0.5 | 0.4 | 0.3 | 0.00056549 |

| 6 | 0.6 | 0.5 | 0.7 | 0.00069089 |

| 7 | 0.4 | 0.5 | 0.7 | 0.00052398 |

| 8 | 0.5 | 0.5 | 0.5 | 0.00029135 |

| 9 | 0.4 | 0.4 | 0.5 | 0.00054857 |

| 10 | 0.5 | 0.6 | 0.3 | 0.00069197 |

| 11 | 0.4 | 0.6 | 0.5 | 0.00041089 |

| 12 | 0.6 | 0.4 | 0.5 | 0.00044857 |

| 13 | 0.5 | 0.6 | 0.7 | 0.00050498 |

| 14 | 0.6 | 0.5 | 0.3 | 0.00081236 |

| 15 | 0.5 | 0.5 | 0.5 | 0.00030438 |

| 16 | 0.5 | 0.5 | 0.5 | 0.00028438 |

| 17 | 0.5 | 0.5 | 0.5 | 0.00036477 |

| Source | SS | DF | MS | F-Value | p-Value | Significance |

|---|---|---|---|---|---|---|

| model | 4.784 × 10−7 | 9 | 5.316 × 10−8 | 70.59 | <0.0001 | ** |

| A | 4.292 × 10−8 | 1 | 4.292 × 10−8 | 57.00 | 0.0001 | ** |

| B | 1.265 × 10−8 | 1 | 1.265 × 10−8 | 16.80 | 0.0046 | ** |

| C | 3.192 × 10−8 | 1 | 3.192 × 10−8 | 42.39 | 0.0003 | ** |

| AB | 5.725 × 10−8 | 1 | 5.725 × 10−8 | 76.03 | <0.0001 | ** |

| AC | 1.738 × 10−10 | 1 | 1.738 × 10−10 | 0.2309 | 0.6455 | |

| BC | 4.759 × 10−9 | 1 | 4.759 × 10−9 | 6.32 | 0.0402 | * |

| A2 | 1.248 × 10−7 | 1 | 1.248 × 10−7 | 165.74 | <0.0001 | ** |

| B2 | 1.897 × 10−8 | 1 | 1.897 × 10−8 | 25.20 | 0.0015 | ** |

| C2 | 1.561 × 10−7 | 1 | 1.561 × 10−7 | 207.26 | <0.0001 | ** |

| Residual | 5.271 × 10−9 | 7 | 7.530 × 10−10 | |||

| Lack of fit | 1.215 × 10−9 | 3 | 4.050 × 10−10 | 0.3995 | 0.7616 | |

| Pure error | 4.056 × 10−9 | 4 | 1.014 × 10−9 | |||

| Total | 4.837 × 10−7 | 16 | ||||

| R2 | 0.9891 | |||||

| Adjusted R2 | 0.9751 | |||||

| Predicted R2 | 0.9467 | |||||

| Adeq Precision | 23.4964 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cui, Y.; Li, X.; Zheng, M.; Mu, H.; Liu, C.; Wang, D.; Yan, B.; Li, Q.; Wang, F.; Hu, Q. Study on Friction and Wear Performance of Bionic Function Surface in High-Speed Ball Milling. Machines 2025, 13, 597. https://doi.org/10.3390/machines13070597

Cui Y, Li X, Zheng M, Mu H, Liu C, Wang D, Yan B, Li Q, Wang F, Hu Q. Study on Friction and Wear Performance of Bionic Function Surface in High-Speed Ball Milling. Machines. 2025; 13(7):597. https://doi.org/10.3390/machines13070597

Chicago/Turabian StyleCui, Youzheng, Xinmiao Li, Minli Zheng, Haijing Mu, Chengxin Liu, Dongyang Wang, Bingyang Yan, Qingwei Li, Fengjuan Wang, and Qingming Hu. 2025. "Study on Friction and Wear Performance of Bionic Function Surface in High-Speed Ball Milling" Machines 13, no. 7: 597. https://doi.org/10.3390/machines13070597

APA StyleCui, Y., Li, X., Zheng, M., Mu, H., Liu, C., Wang, D., Yan, B., Li, Q., Wang, F., & Hu, Q. (2025). Study on Friction and Wear Performance of Bionic Function Surface in High-Speed Ball Milling. Machines, 13(7), 597. https://doi.org/10.3390/machines13070597