A Novel Rapid Design Framework for Tooth Profile of Double-Circular-Arc Common-Tangent Flexspline in Harmonic Reducers

Abstract

1. Introduction

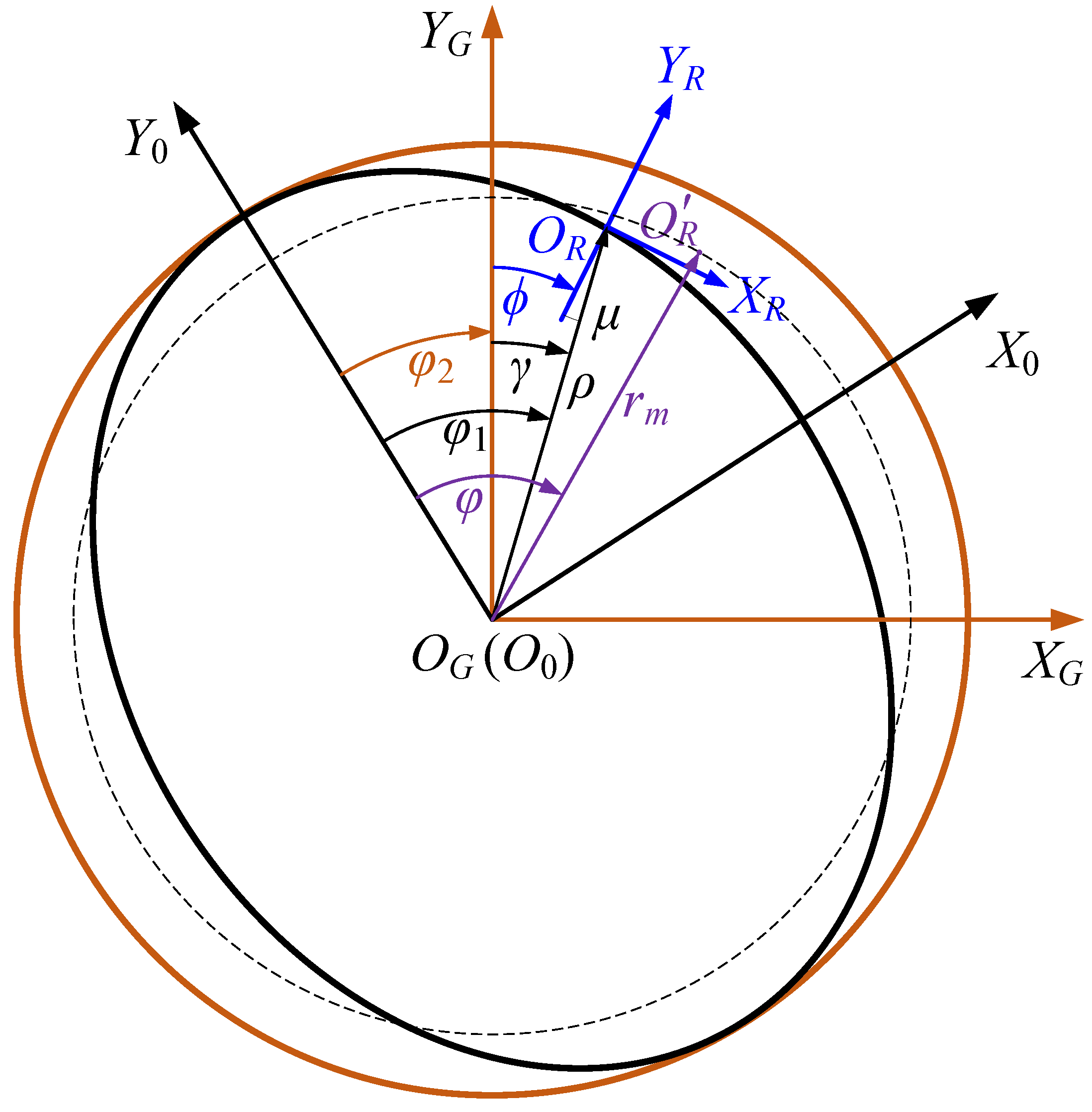

2. Mathematical Derivation of Double-Circular-Arc Common-Tangent Flexspline Tooth Profile and Its Conjugate Circular Spline Tooth Profile

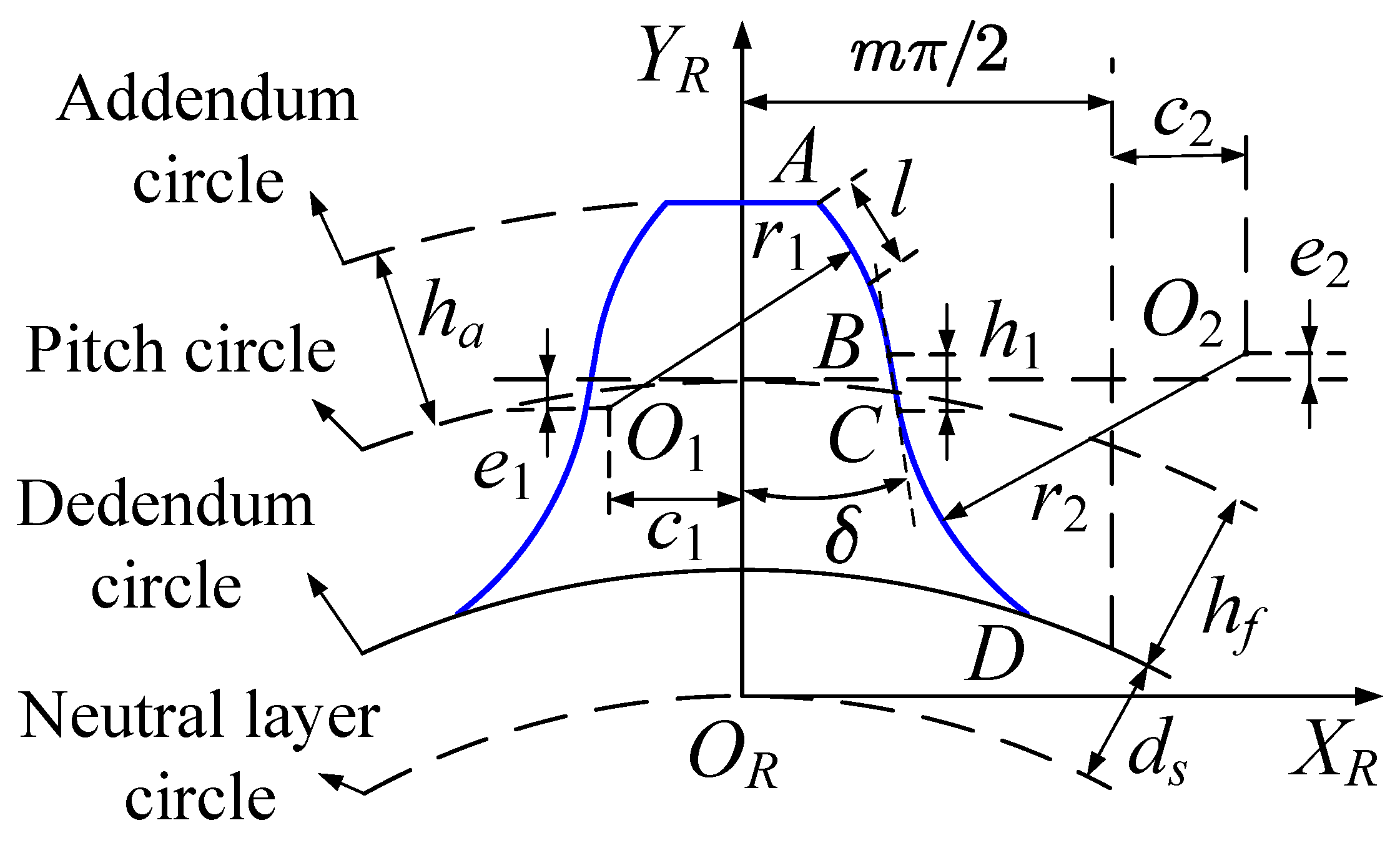

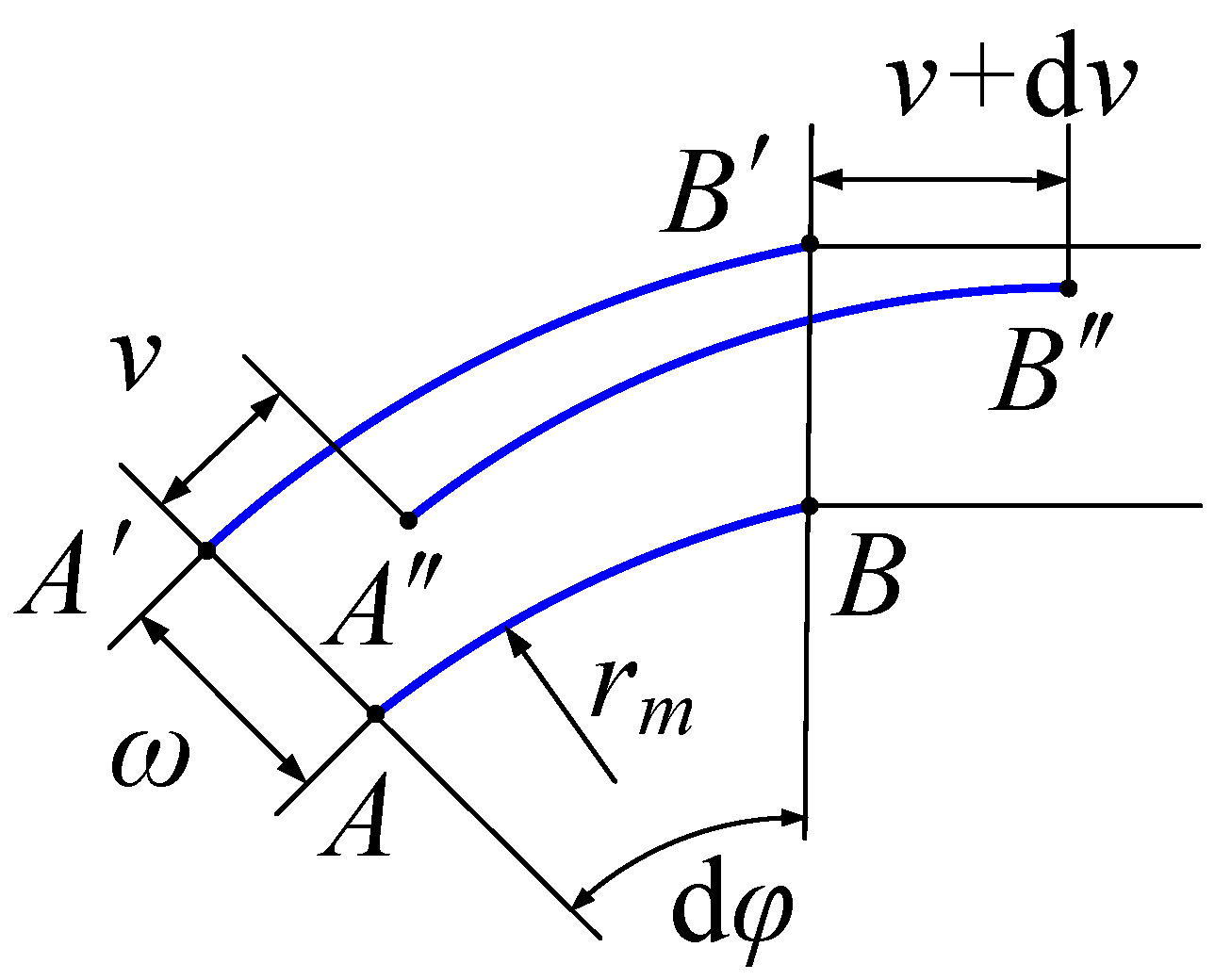

2.1. Mathematical Derivation of Double-Circular-Arc Common-Tangent Flexspline Tooth Profile

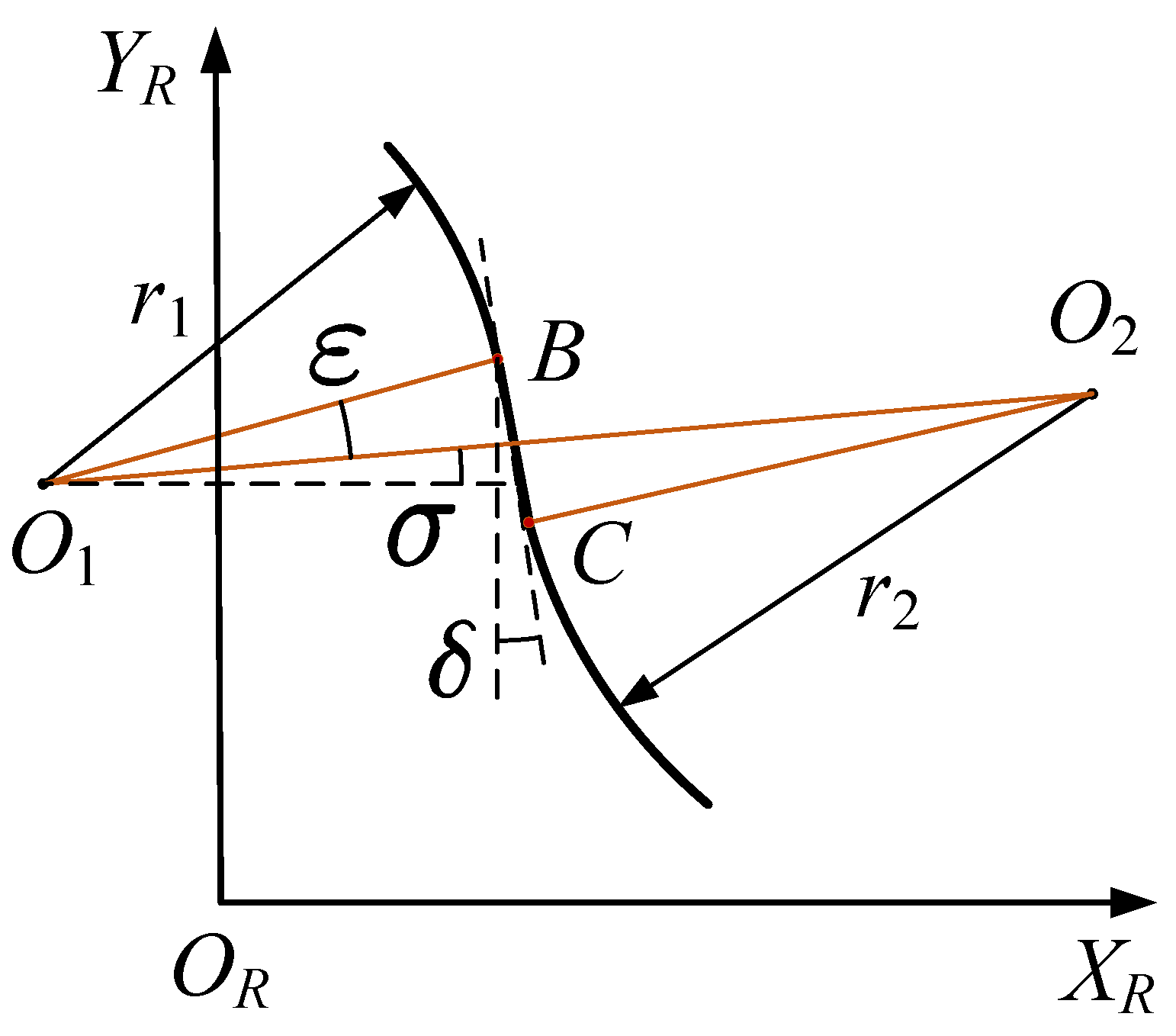

2.2. Mathematical Derivation of the Conjugate Circular Spline Tooth Profile

- (1)

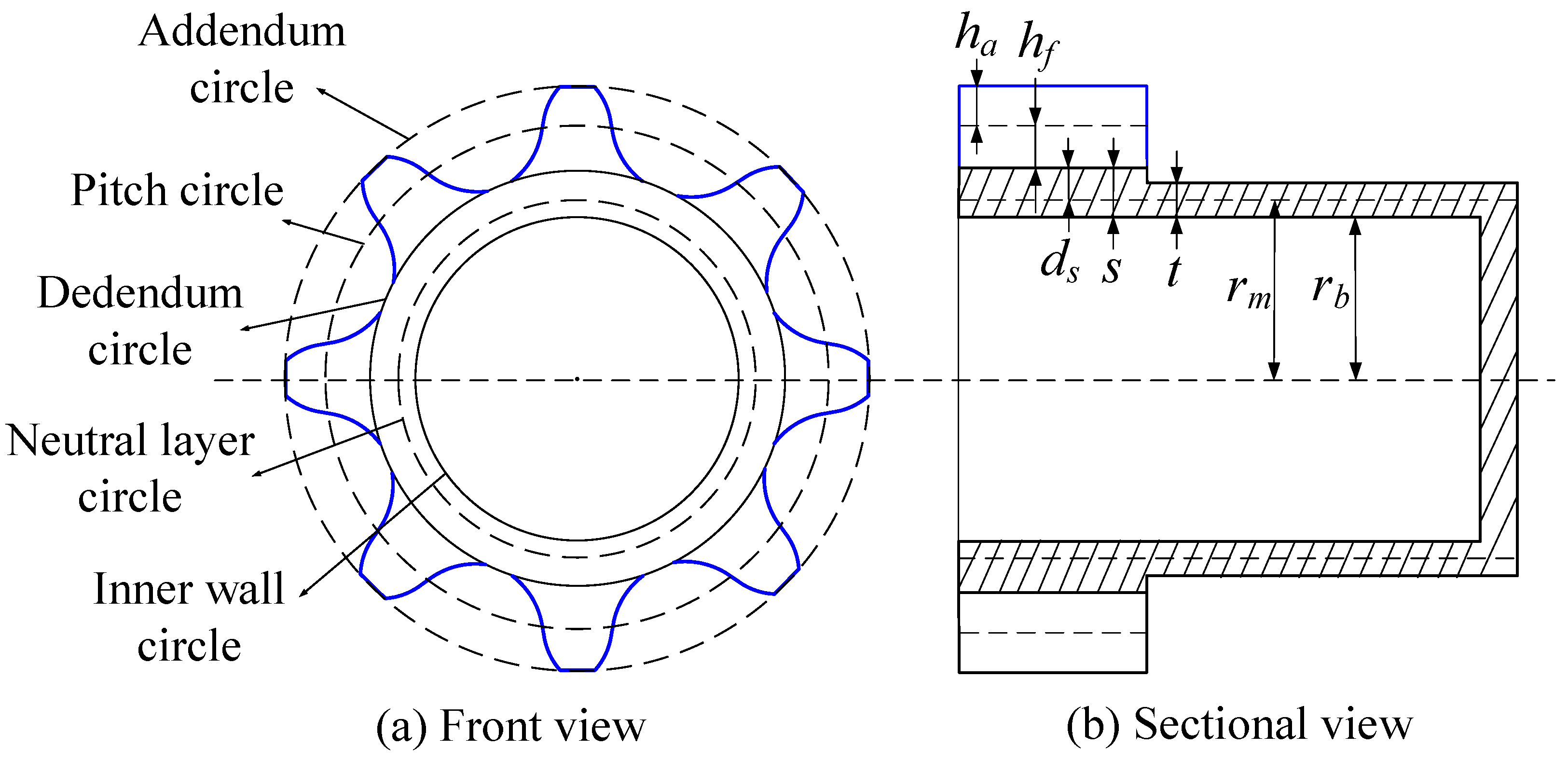

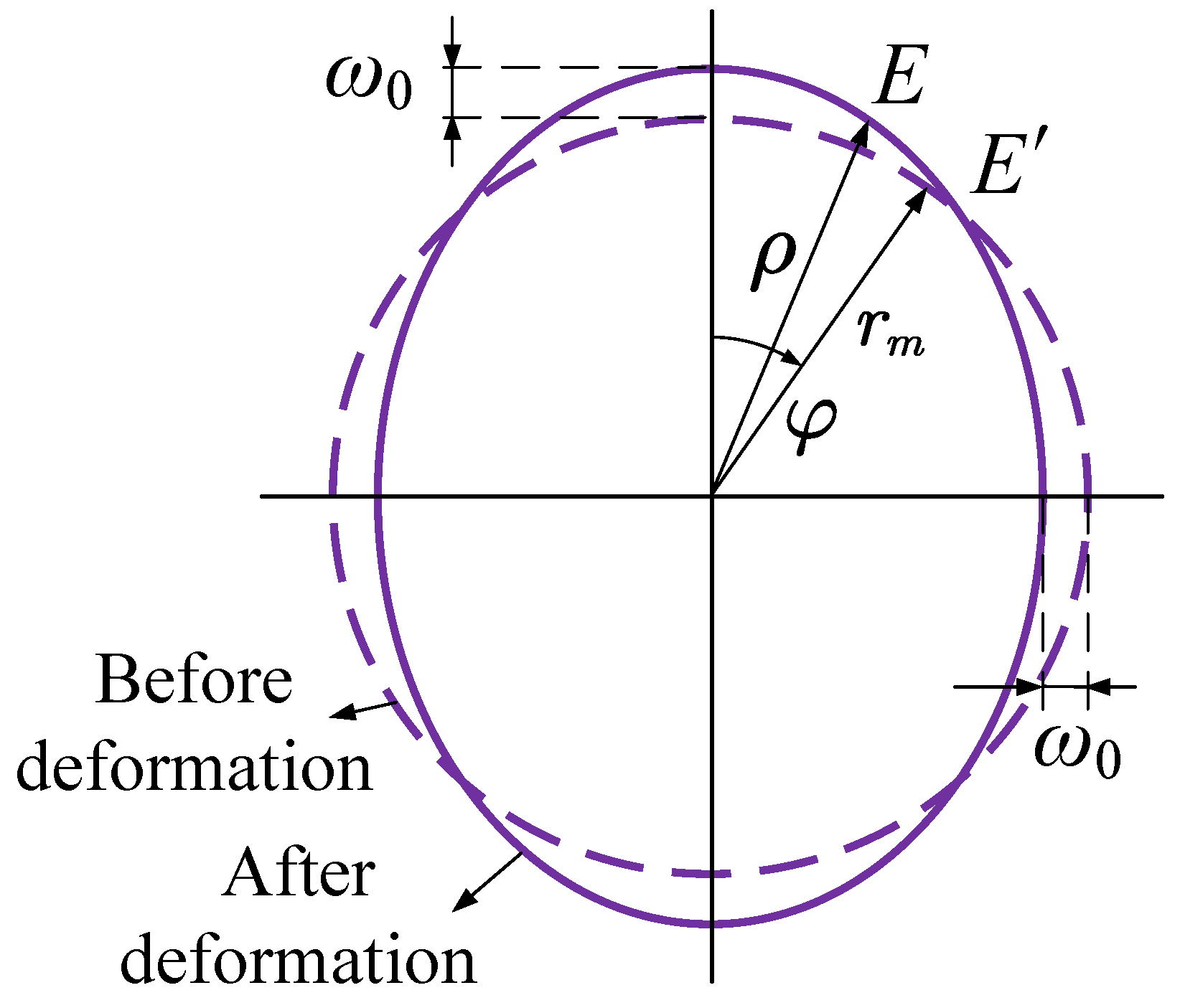

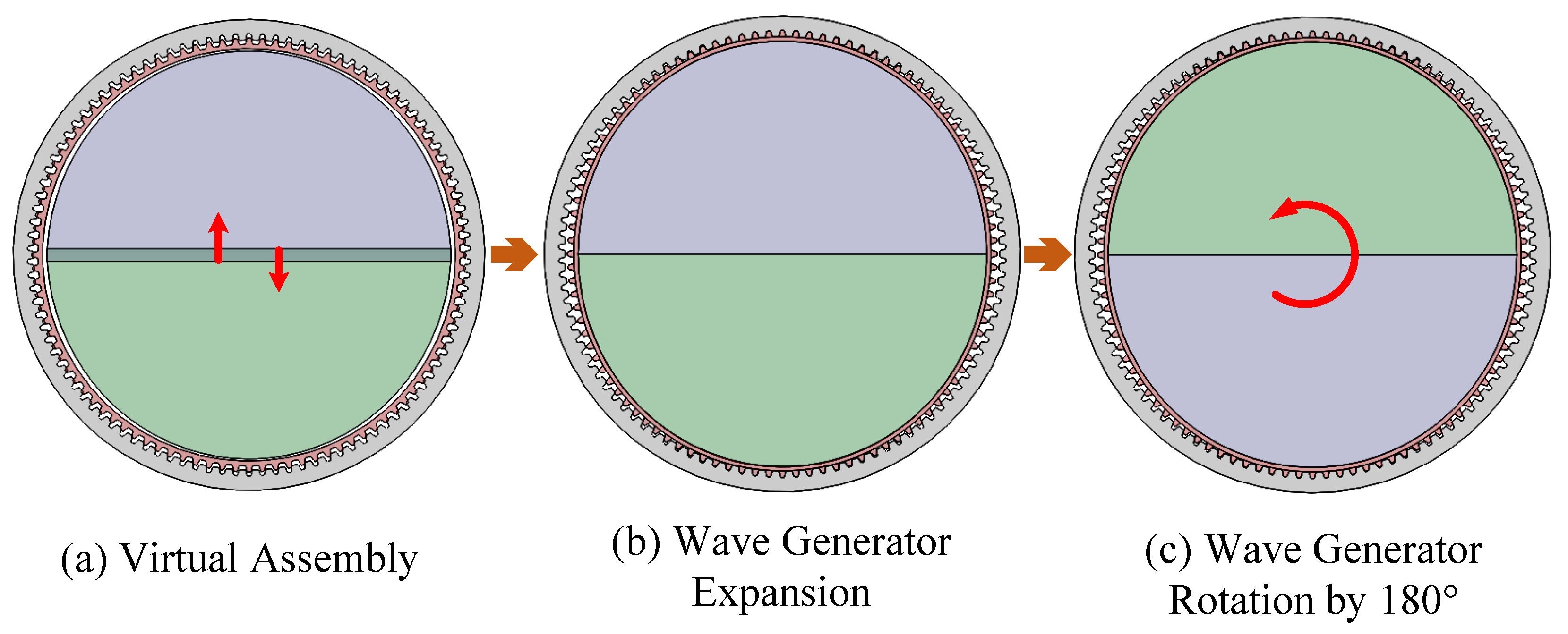

- The circumference of the neutral layer circle, as shown in Figure 1, does not change before and after the wave generator is installed.

- (2)

- After the wave generator is installed into the flexspline, deformation occurs only in the part between the dedendum circle and the inner wall circle of the flexspline. This deformation is reflected only as changes in the tooth slots between adjacent teeth, with no deformation in the tooth portions of the flexspline.

- (3)

- The wave generator is considered a rigid body, and its shape changes are not considered during the transmission process.

- (4)

- After the wave generator is installed into the flexspline, the shapes of the addendum circle, pitch circle, dedendum circle, and inner wall circle of the flexspline are all consistent with the shape of the neutral layer circle, which are equidistant offset curves of the neutral layer curve.

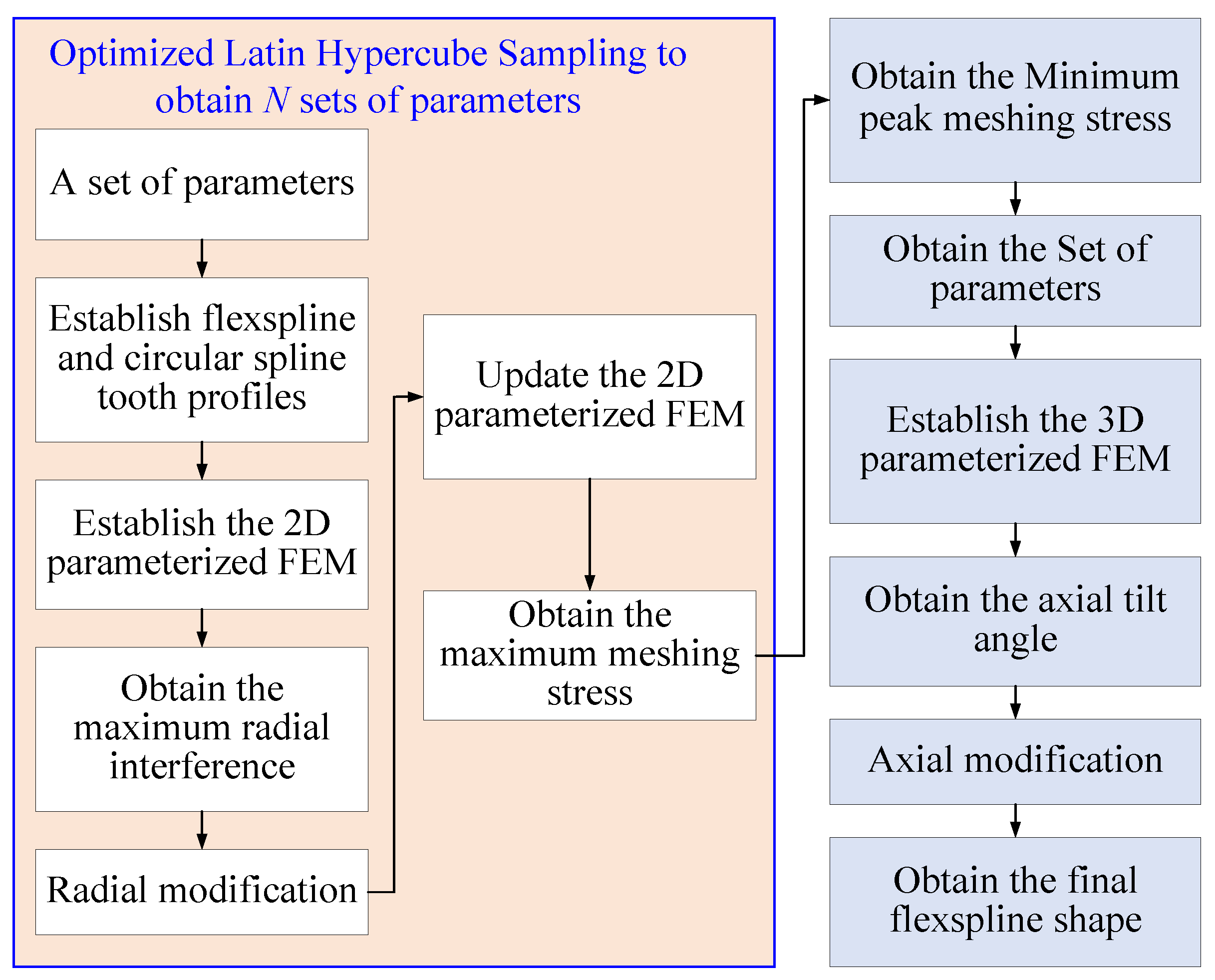

3. Profile Modification and Rapid Optimization Method for Flexspline Tooth

3.1. Finite Element Dynamic Simulation Model of the Harmonic Drive

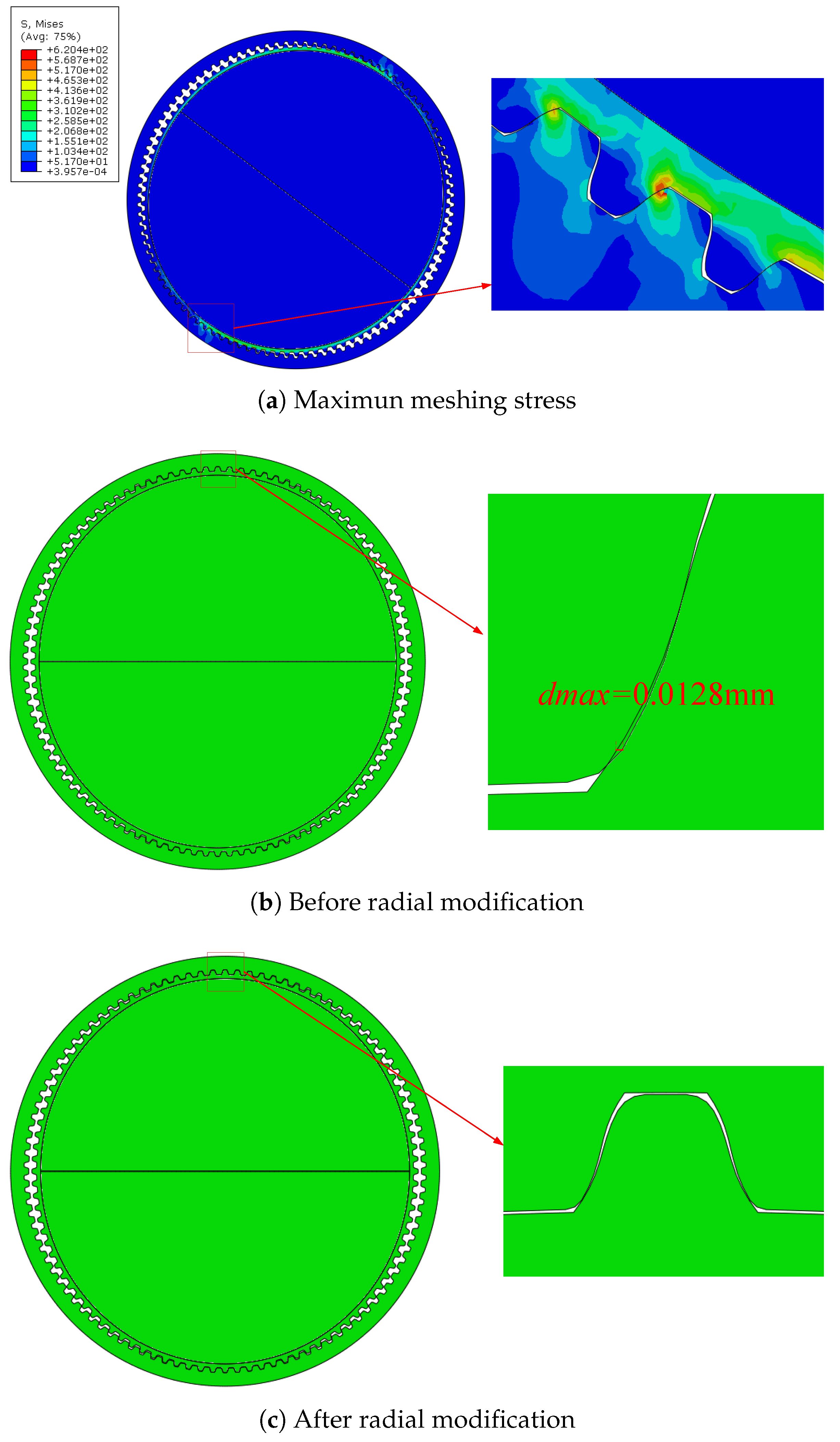

3.2. Radial Modification Method for Flexspline Tooth Profile

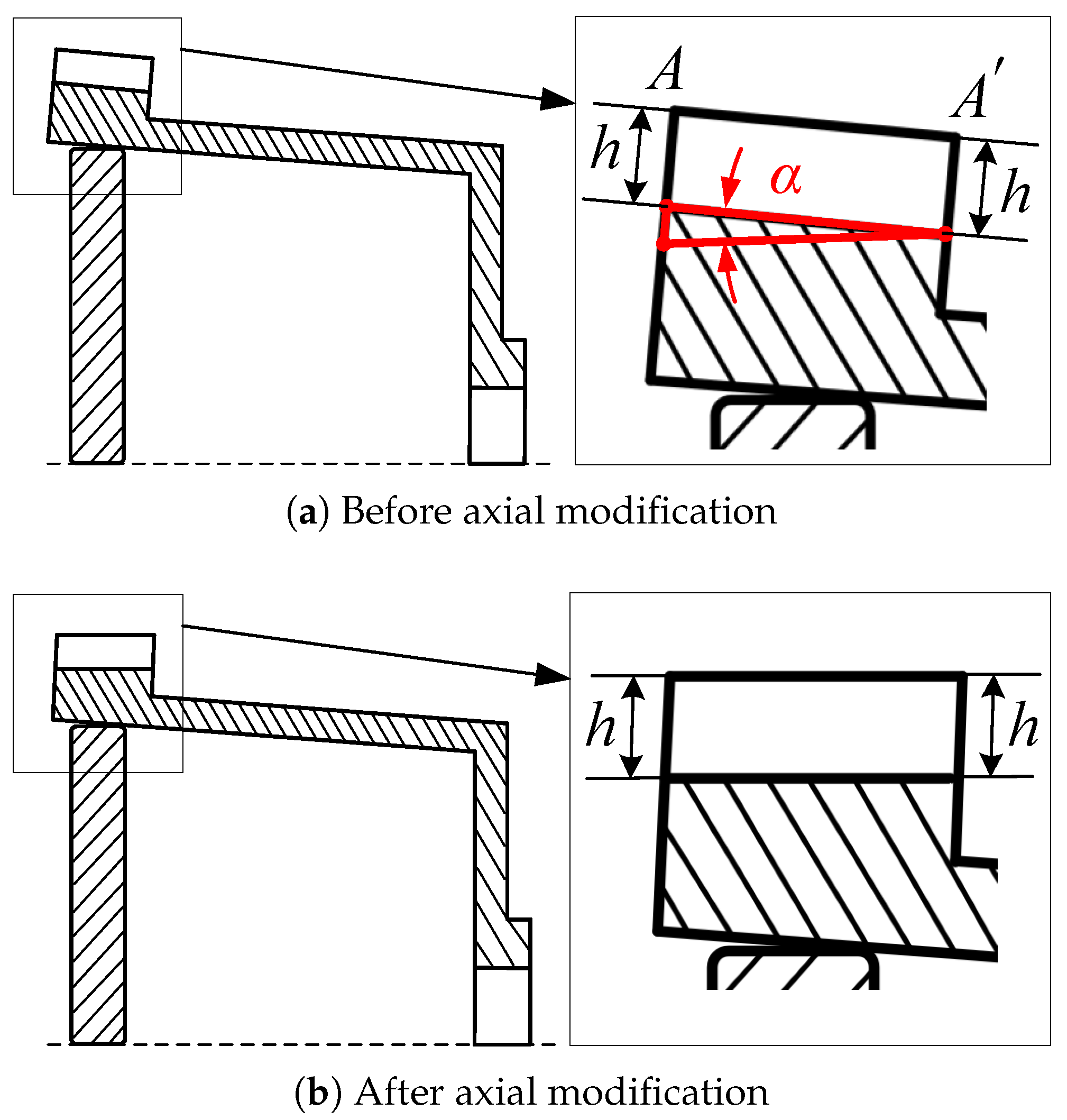

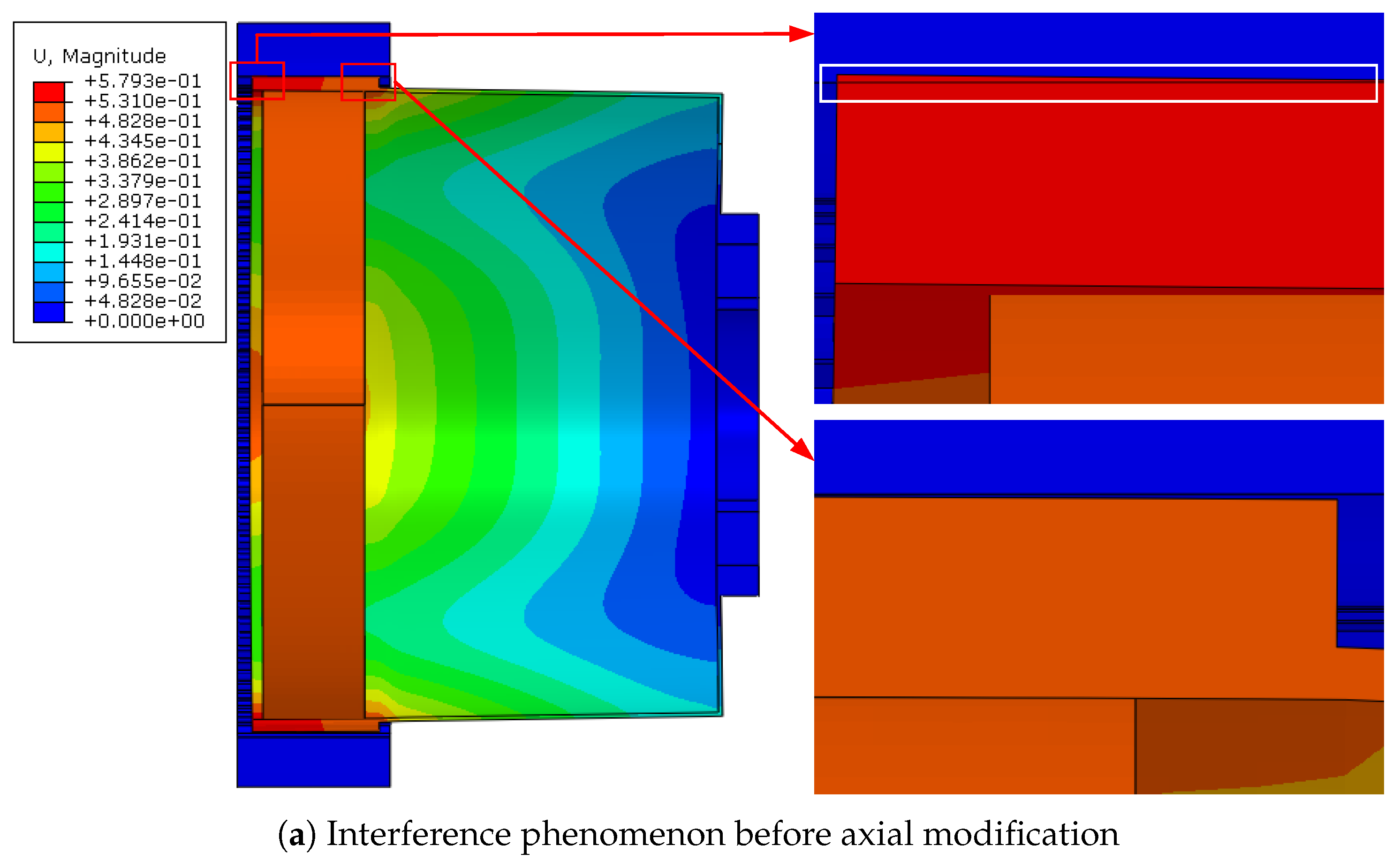

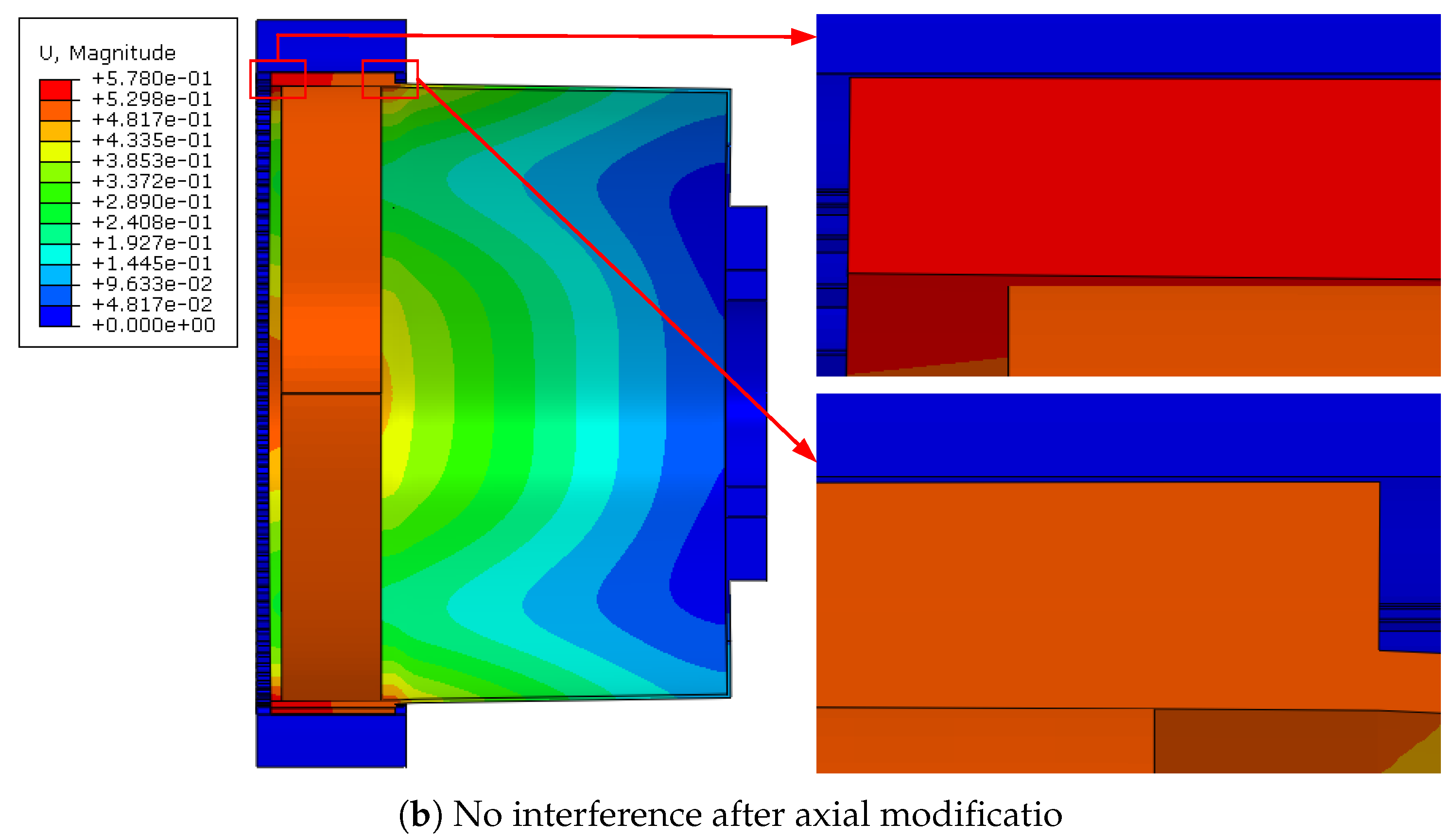

3.3. Axial Modification Method for Flexspline

3.4. Rapid Optimization Method for Flexspline Tooth

- Objective Function: min maximum meshing stress.

- Constraints: , , , , , , and in corresponding ranges.

- Design variables: , , , , , , and .

3.5. Numerical Example

4. Conclusions

- A minimum value of maximum meshing stress of 620.4 MPa.

- A maximum radial interference of 0.0128 mm.

- An axial tilt angle of .

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| 745.2 | 880.0 | 834.7 | 850.5 | 763.6 | 704.1 | 869.0 | 774.5 | 885.5 | 915.0 |

| 838.1 | 824.1 | 699.0 | 819.3 | 835.4 | 963.9 | 890.5 | 885.5 | 878.7 | 1083.6 |

| 929.3 | 651.2 | 858.3 | 808.5 | 782.9 | 845.2 | 945.2 | 744.1 | 743.2 | 749.3 |

| 813.6 | 883.0 | 693.3 | 719.9 | 642.6 | 728.3 | 757.0 | 872.5 | 732.9 | 681.0 |

| 733.6 | 790.5 | 962.7 | 757.7 | 728.0 | 832.2 | 723.7 | 761.0 | 777.1 | 896.1 |

| 864.8 | 811.2 | 912.7 | 778.9 | 1003.1 | 833.1 | 659.2 | 843.5 | 673.8 | 668.0 |

| 828.9 | 867.7 | 790.3 | 905.3 | 715.1 | 846.4 | 800.3 | 701.2 | 817.4 | 687.3 |

| 827.6 | 853.1 | 670.1 | 744.0 | 668.1 | 694.0 | 850.4 | 692.8 | 620.4 | 909.4 |

| 709.1 | 908.3 | 858.7 | 868.0 | 798.4 | 682.5 | 801.7 | 669.8 | 754.5 | 782.4 |

| 934.0 | 709.1 | 746.3 | 715.3 | 754.7 | 725.6 | 668.9 | 735.6 | 728.6 | 792.6 |

References

- Musser, C.W. Strain Wave Gearing. U.S. Patent No. 2906143, 29 September 1959. [Google Scholar]

- Ivanov, M.N. The Harmonic Drive; Defense Industry Press: Beijing, China, 1987. [Google Scholar]

- Shen, Y.; Ye, Q. Theory and Design of Harmonic Drive; China Machine Press: Beijing, China, 1985. [Google Scholar]

- Raviola, A.; Martin, A.D.; Guida, R.; Jacazio, G.; Mauro, S.; Sorli, M. Harmonic drive gear failures in industrial robots applications: An overview. In Proceedings of the PHM Society European Conference, Virtual, 28 June–2 July 2021; Volume 6, p. 11. [Google Scholar]

- Yang, D.; Qiang, D.; Chen, Z.; Wang, H.; Zhou, Z.; Zhang, X. Dynamic modeling and digital twin of a harmonic drive based collaborative robot joint. In Proceedings of the 2022 International Conference on Robotics and Au-Tomation, Philadelphia, PA, USA, 23–27 May 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 4862–4868. [Google Scholar]

- Pham, A.D.; Ahn, H.J. High precision reducers for industrial robots driving 4th industrial revolution: State of arts, analysis, design, per-formance evaluation and perspective. Int. J. Precis. Eng. Manuf.-Green Technol. 2018, 5, 519–533. [Google Scholar] [CrossRef]

- Fusaro, R.L. Preventing spacecraft failures due to tribological problems. In Proceedings of the 2001 Annual Meeting, No. NASA/TM-2001-210806, Orlando, FL, USA, 20–24 May 2001. [Google Scholar]

- Yang, W.; Duan, C.; Qiu, J.; Sun, J. Analysis on transient stress state of elastic thin-wall component of harmonic gear drive. Int. J. Precis. Eng. Manuf.-Green Technol. 2011, 317, 281–286. [Google Scholar] [CrossRef]

- Dong, H.; Ting, K.L.; Wang, D. Kinematic fundamentals of planar harmonic drives. ASME J. Mech. Des. 2011, 133, 011007. [Google Scholar] [CrossRef]

- Kondo, K.; Takada, J. Study on tooth profiles of the harmonic drive. ASME J. Mech. Des. 1990, 112, 131–137. [Google Scholar] [CrossRef]

- Chen, X.; Liu, Y.; Xing, J.; Lin, S.; Xu, W. The parametric design of double-circular-arc tooth profile and its influence on the function-al backlash of harmonic drive. Mech. Mach. Theory 2014, 73, 1–24. [Google Scholar] [CrossRef]

- Yao, Y.P.; Chen, X.X.; Xing, J.Z. Complex cycloidal tooth profile of circular spline in harmonic drive and its optimal fitting research. J. Ind. Prod. Eng. 2017, 34, 1–8. [Google Scholar] [CrossRef]

- Shi, W.; Zhen, J.; Niu, T.; Song, H. A New Type of Cycloidal Tooth Profile Design and Analysis of Harmonic Gear Drive. Mech. Eng. Technol. 2018, 7, 43–53. [Google Scholar] [CrossRef]

- Ji, C.; Zhang, Z.; Cheng, G.; Kong, M.; Li, R. Design, modeling, and control of a compact and reconfigurable variable stiffness actuator using disc spring. J. Mech. Robot. 2024, 16, 091006. [Google Scholar] [CrossRef]

- Kosse, V. Analytical investigation of the change in phase angle between the wave generator and the teeth meshing zone in high-torque mechanical harmonic drives. Mech. Mach. Theory 1997, 32, 533–538. [Google Scholar] [CrossRef]

- Zhang, L.; Yang, W.; Jiang, Q.; Wang, C.; Huang, W. Structural stress analysis of the core component of harmonic reducer. J. Mech. Transm. 2018, 42, 114–117. [Google Scholar]

- Gravagno, F.; Mucino, V.H.; Pennestri, E. Influence of wave generator profile on the pure kinematic error and centrodes of harmonic drive. Mech. Mach. Theory 2016, 104. [Google Scholar] [CrossRef]

- Sahoo, V.; Maiti, R. Load sharing by tooth pairs in involute toothed harmonic drive with conventional wave generator cam. Meccanica 2017, 53, 373–394. [Google Scholar] [CrossRef]

- Li, X.; Song, C.; Yang, Y. Optimal design of wave generator profile for harmonic gear drive using support function. Mech. Mach. Theory 2020, 152, 103941. [Google Scholar] [CrossRef]

- Rheaume, F.E.; Champliaud, H.; Liu, Z. Understanding and mod-elling the torsional stiffness of harmonic drives through finite-element method. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2009, 223, 515–524. [Google Scholar] [CrossRef]

- Song, C.; Li, X.; Yang, Y.; Sun, J. Parameter design of double-circular-arc tooth profile and its influence on meshing characteris-tics of harmonic drive. Mech. Eng. Technol. 2022, 167, 104567. [Google Scholar]

- Pacana, J.; Siwiec, D.; Pacana, A. Numerical analysis of the kine-matic accuracy of the hermetic harmonic drive in space vehicles. Appl. Sci. 2022, 13, 1694. [Google Scholar] [CrossRef]

- Song, C.; Zhu, F.; Li, X.; Du, X. Three-dimensional conjugate tooth surface design and contact analysis of harmonic drive with dou-ble-circular-arc tooth profile. Chin. J. Mech. Eng. 2022, 36, 83. [Google Scholar] [CrossRef]

- Cheng, Y.; Chen, Y. Design, analysis, and optimization of a strain wave gear with a novel tooth profile. Mech. Mach. Theory 2022, 175, 104953. [Google Scholar] [CrossRef]

- Kayabasi, O.; Erzincanli, F. Shape optimization of tooth profile of a flexspline for a harmonic drive by finite element modelling. Mater. Des. 2007, 28, 441–447. [Google Scholar] [CrossRef]

- Leon, D.; Arzola, N.; Tovar, A. Statistical analysis of the influence of tooth geometry in the performance of a harmonic drive. J. Braz. Soc. Mech. Sci. Eng. 2015, 37, 723–735. [Google Scholar] [CrossRef]

- Rajabi, M.M.; Ashtiani, B.A.; Janssen, H. Efficiency enhancement of optimized latin hypercube sampling strategies: Application to monte carlo uncertainty analysis and meta-modeling. Adv. Water Resour. 2015, 76, 127–139. [Google Scholar] [CrossRef]

| Parameters | Value Ranges (mm) |

|---|---|

| [0.650, 0.700] | |

| [0.330, 0.332] | |

| [0.150, 0.160] | |

| [0.770, 0.820] | |

| [0.329, 0.331] | |

| [0.130, 0.140] | |

| [0.250, 0.300] | |

| [0.350, 0.400] |

| Parameters | Values (mm) |

|---|---|

| 0.68517449 | |

| 0.33183981 | |

| 0.15535155 | |

| 0.78482551 | |

| 0.13439061 | |

| 0.32994565 | |

| 0.29316387 | |

| 0.35425825 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Zhang, J.; Wang, H.; Wang, X.; Ding, J. A Novel Rapid Design Framework for Tooth Profile of Double-Circular-Arc Common-Tangent Flexspline in Harmonic Reducers. Machines 2025, 13, 535. https://doi.org/10.3390/machines13070535

Liu X, Zhang J, Wang H, Wang X, Ding J. A Novel Rapid Design Framework for Tooth Profile of Double-Circular-Arc Common-Tangent Flexspline in Harmonic Reducers. Machines. 2025; 13(7):535. https://doi.org/10.3390/machines13070535

Chicago/Turabian StyleLiu, Xueao, Jianghao Zhang, Hui Wang, Xuecong Wang, and Jianzhong Ding. 2025. "A Novel Rapid Design Framework for Tooth Profile of Double-Circular-Arc Common-Tangent Flexspline in Harmonic Reducers" Machines 13, no. 7: 535. https://doi.org/10.3390/machines13070535

APA StyleLiu, X., Zhang, J., Wang, H., Wang, X., & Ding, J. (2025). A Novel Rapid Design Framework for Tooth Profile of Double-Circular-Arc Common-Tangent Flexspline in Harmonic Reducers. Machines, 13(7), 535. https://doi.org/10.3390/machines13070535