Finite Element Analysis of Post-Buckling Failure in Stiffened Panels: A Comparative Approach

Abstract

1. Introduction

2. Finite Element Modeling

2.1. Geometry of the Stiffened Panel

2.2. Material Modeling and Mesh Generation

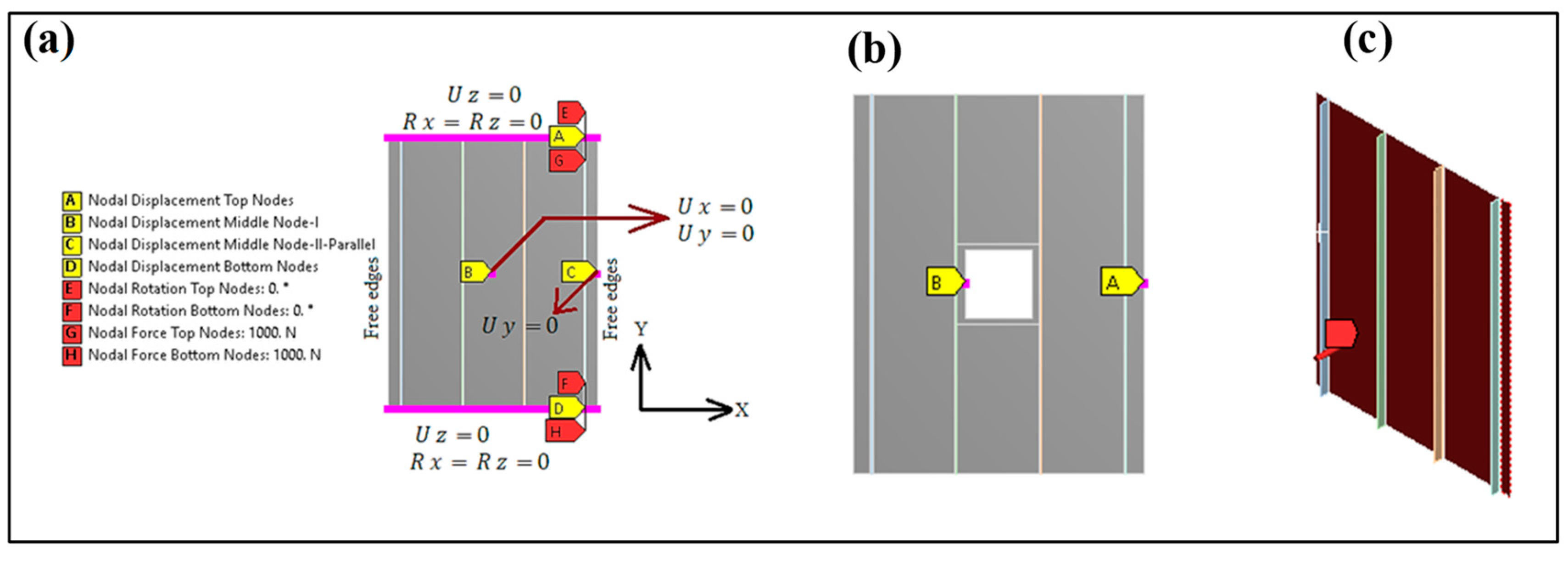

2.3. Applied Boundary and Loading Condition

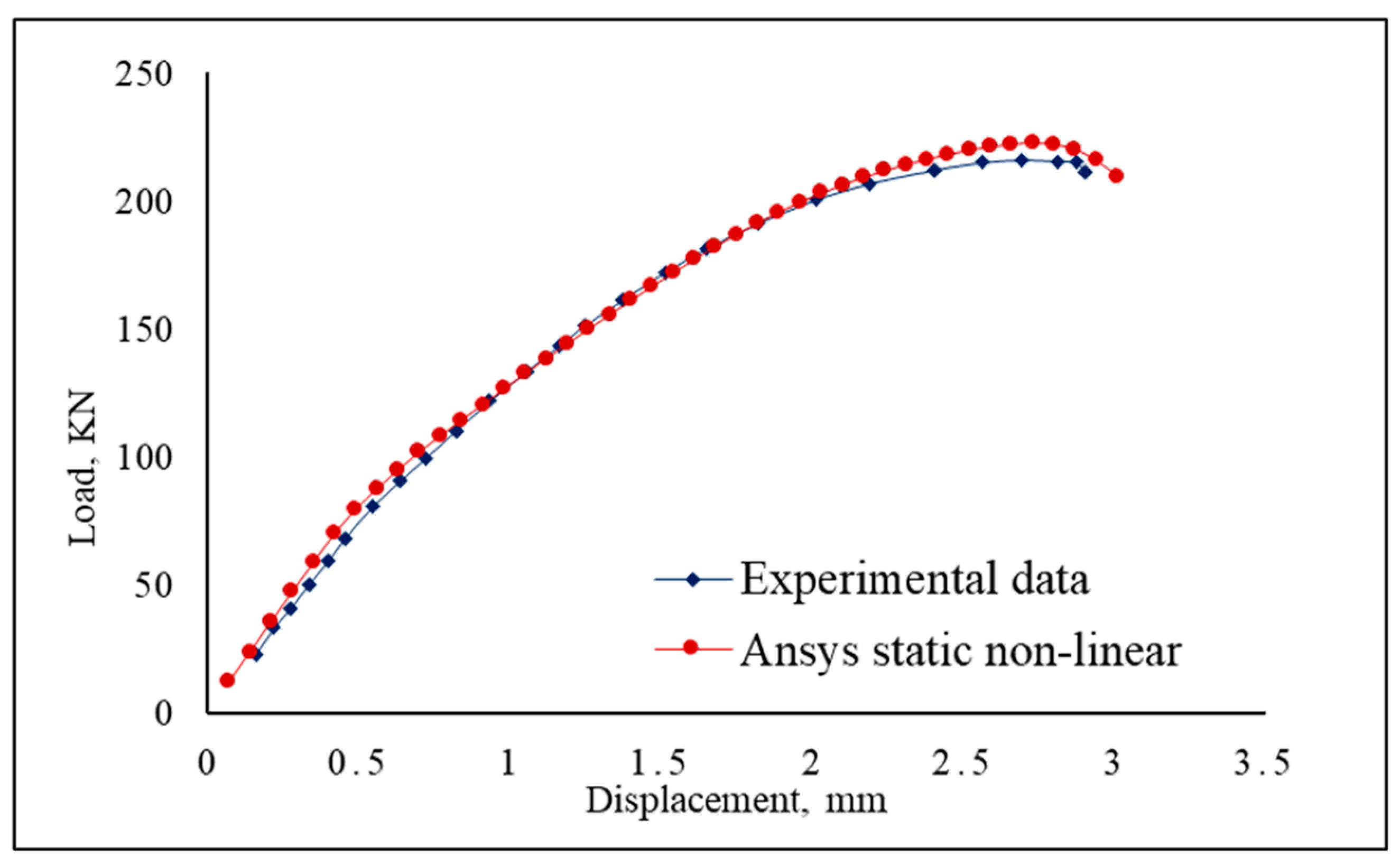

3. Numerical Validations with Experiments

4. Results and Discussions

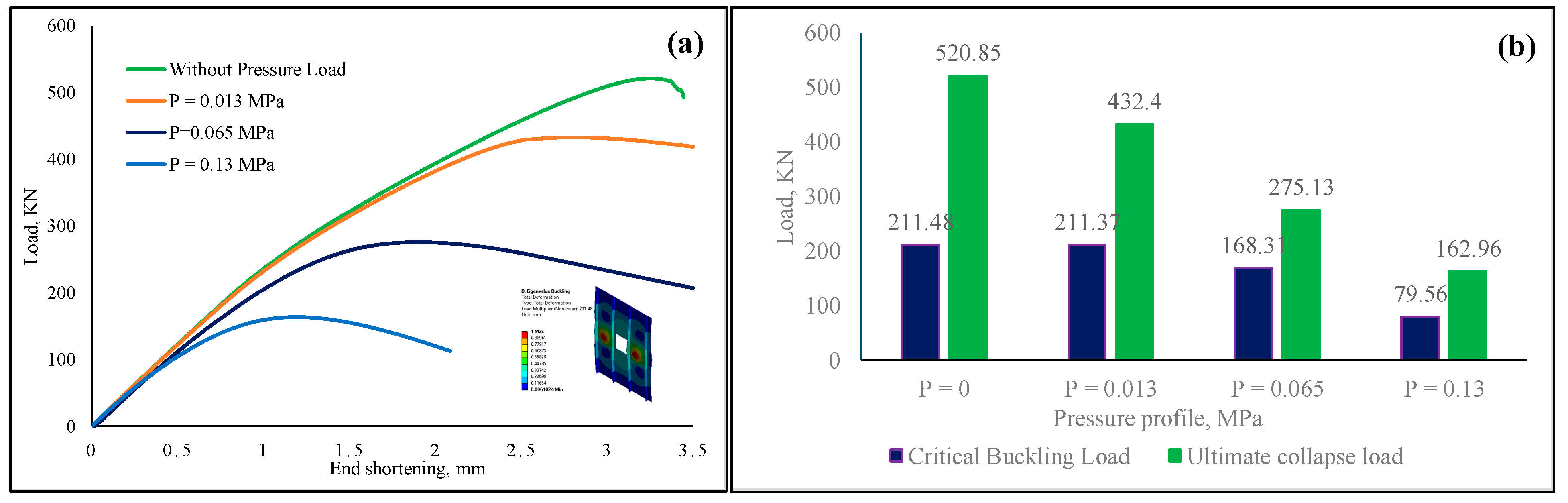

4.1. Al-Alloy 2024 Stiffened Panel

4.1.1. Stiffened Panel Without Opening

4.1.2. Stiffened Panel with Square Opening

4.1.3. Stiffened Panel with Circular Opening

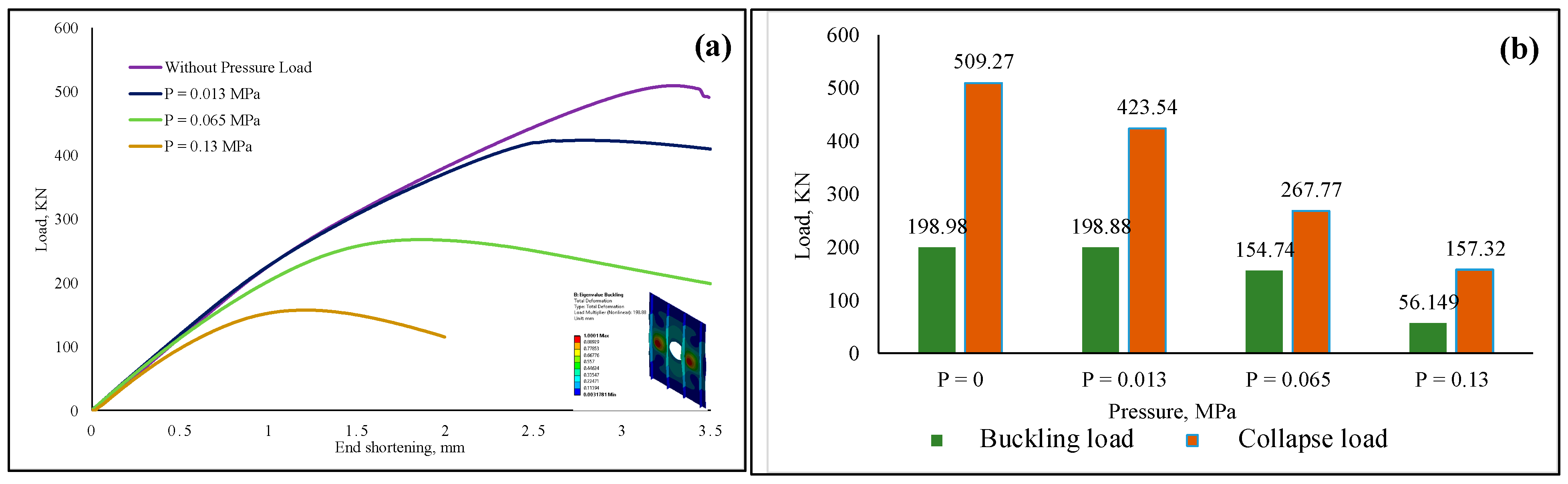

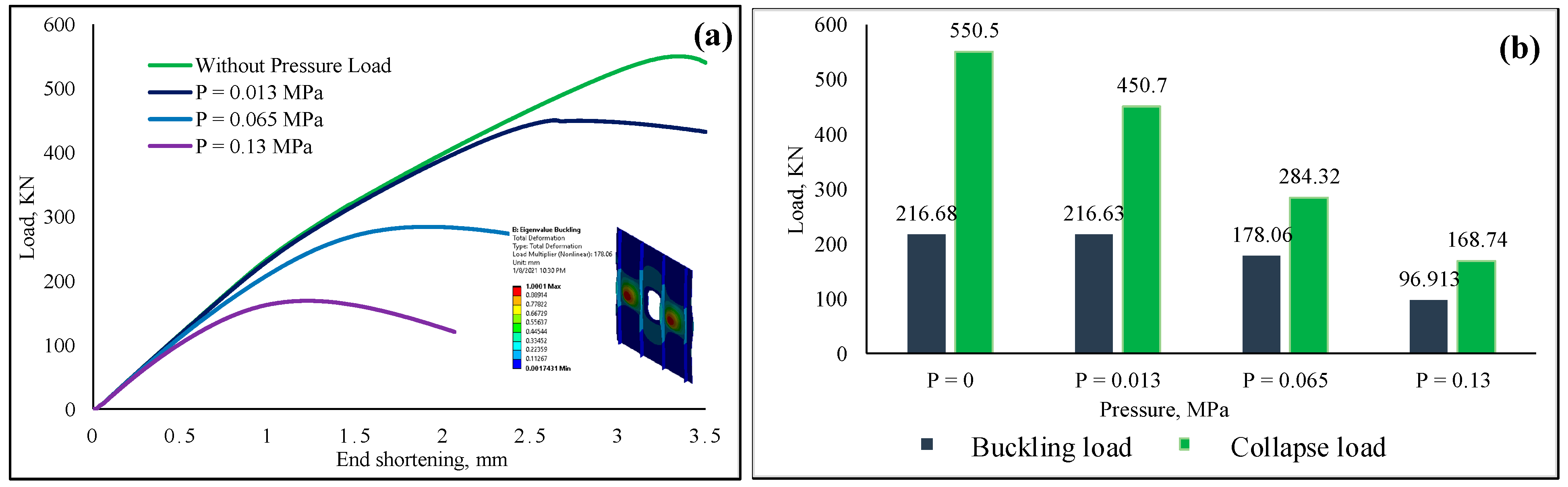

4.1.4. Stiffened Panel with Square/Hemispherical Opening

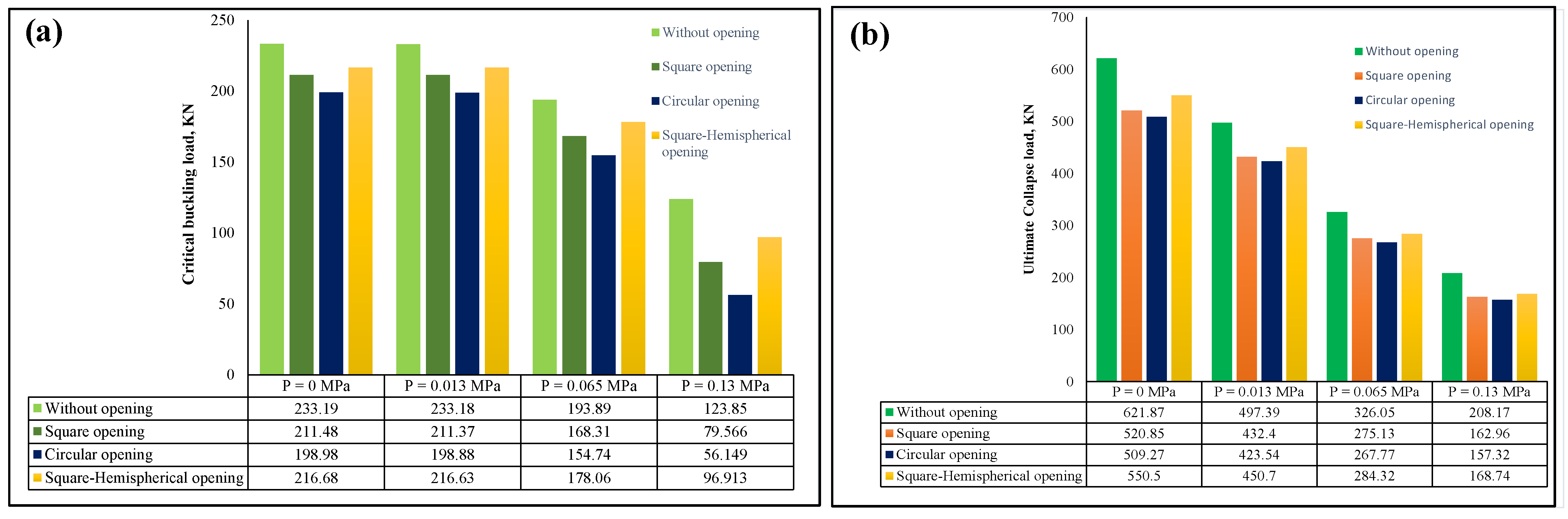

4.2. Comparison of Stiffened Panels Among Different Shapes

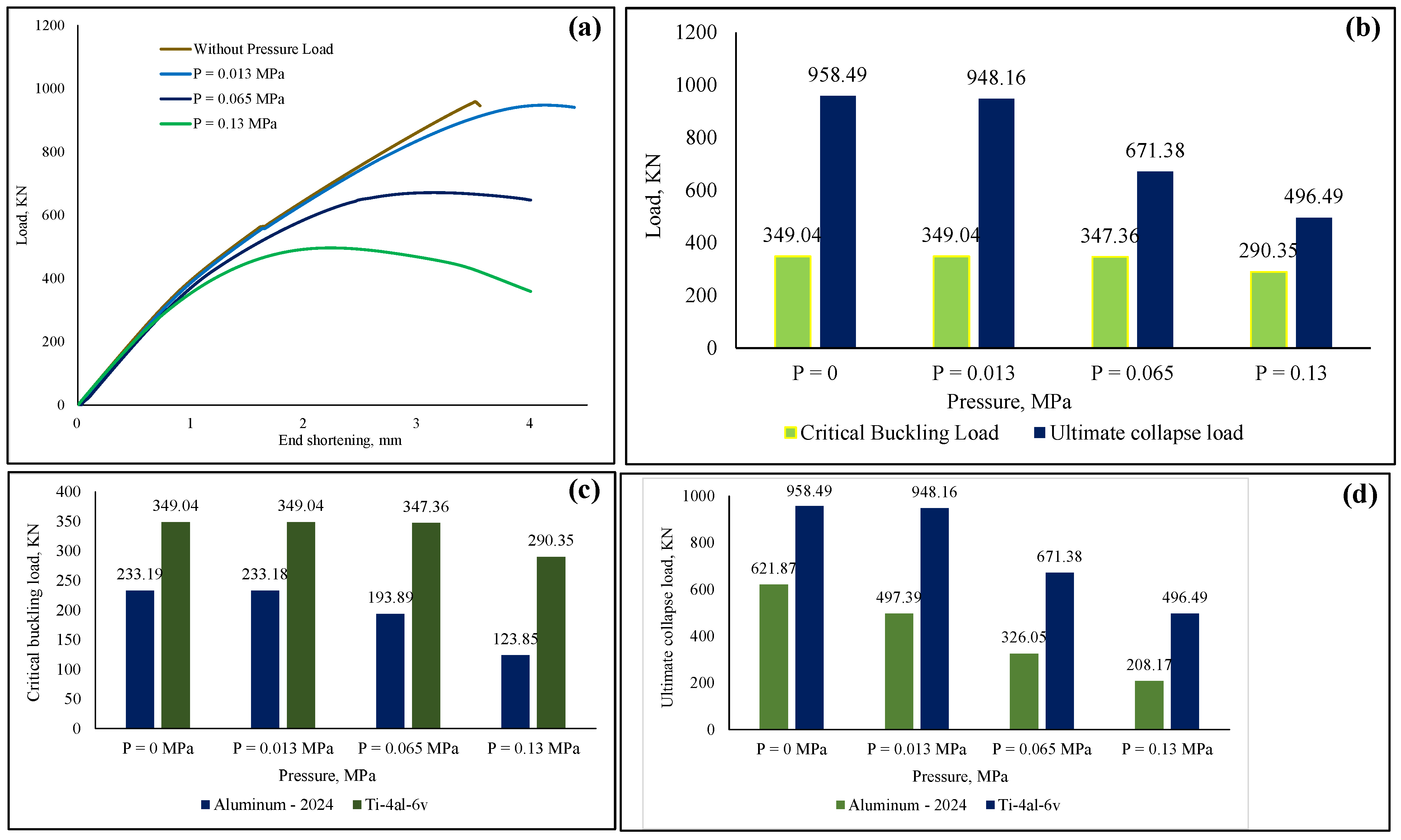

4.3. Titanium Alloy Ti-6Al-4V Stiffened Panel Comparisons

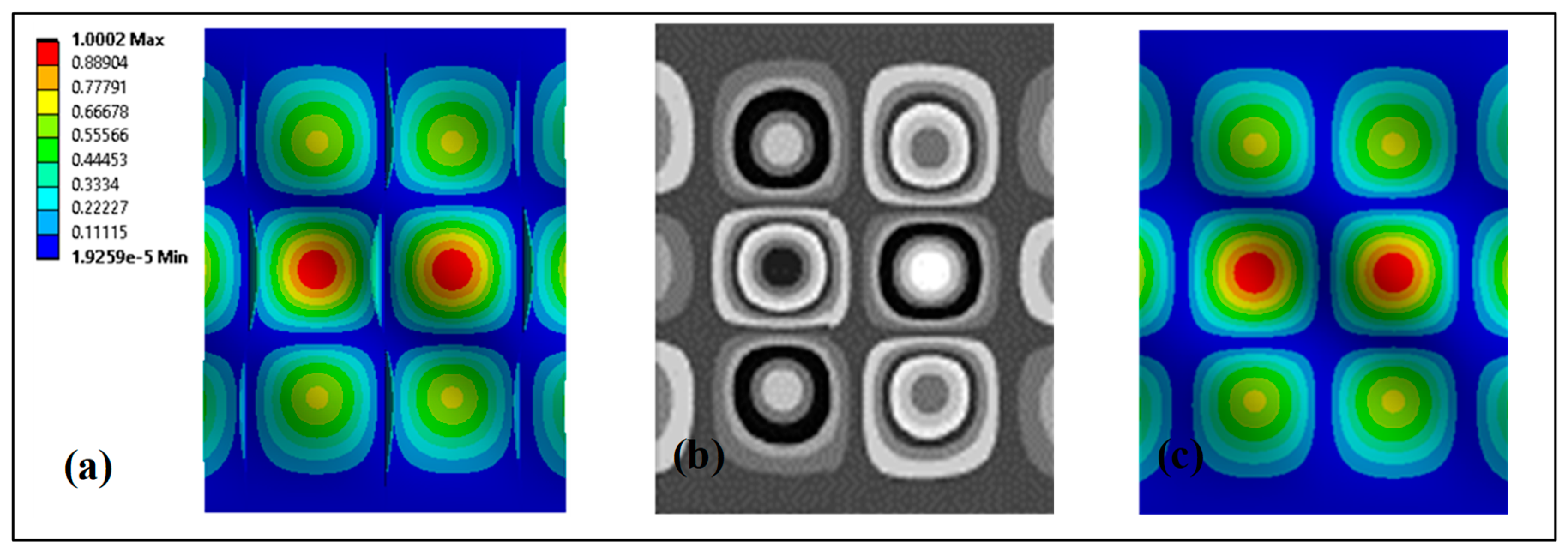

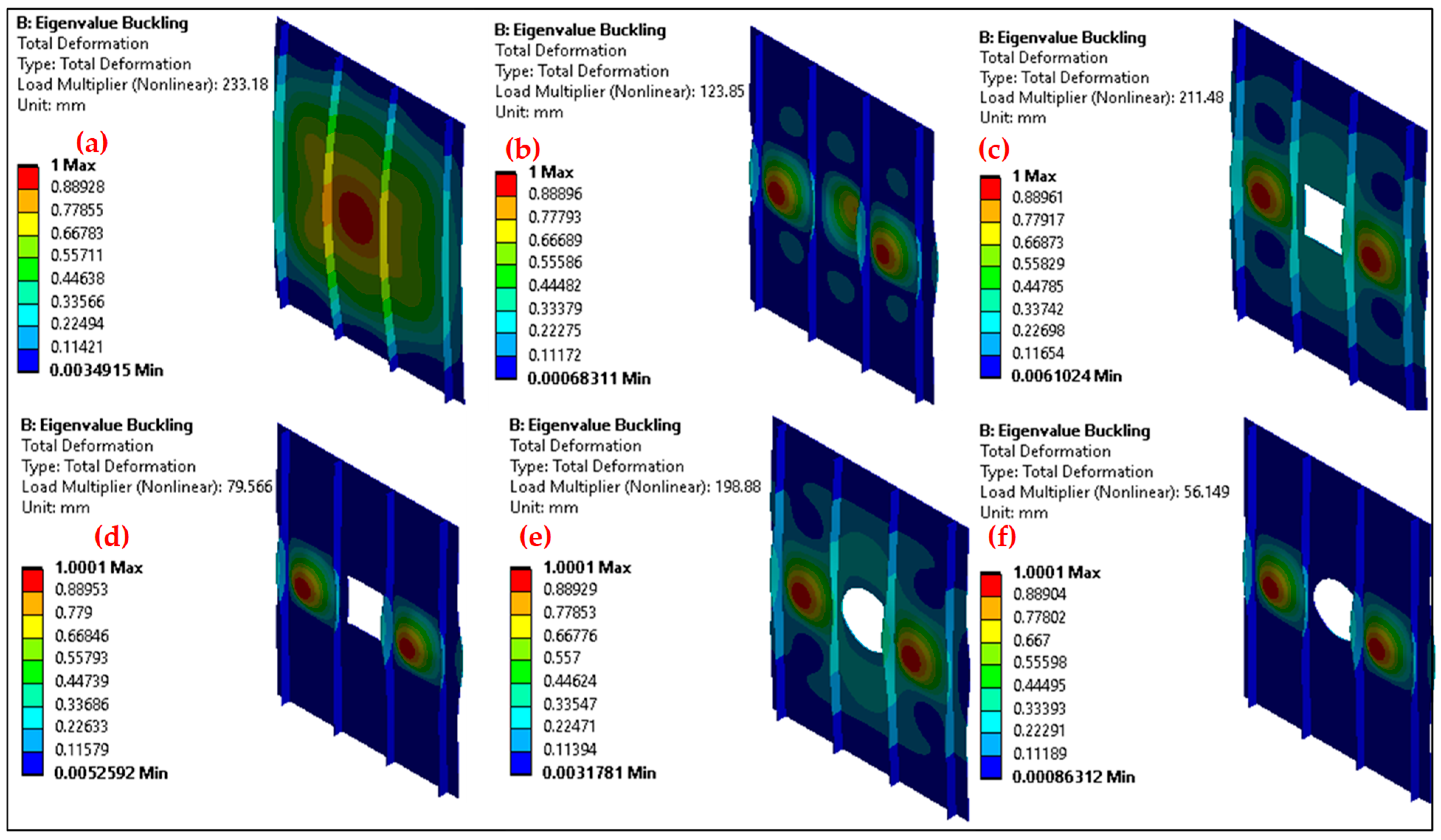

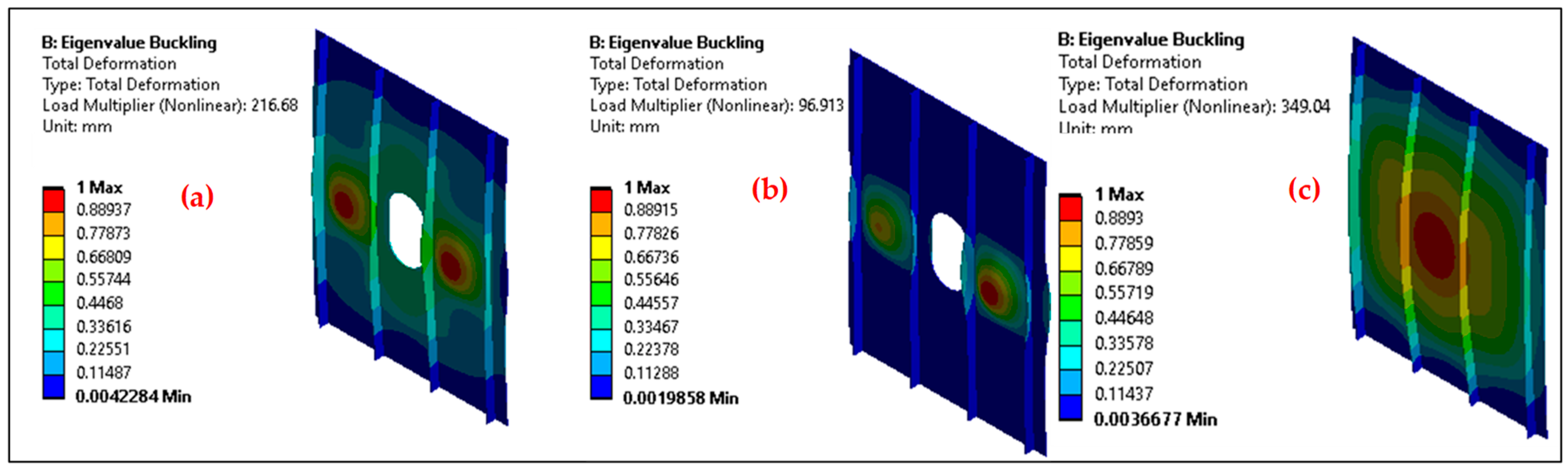

5. Eigenmode Shape Comparison

6. Future Research Scopes

- This study did not consider mesh dependency, variations in boundary conditions, or geometric imperfections; a future parametric study can investigate these factors’ effects on the behavior of stiffened panels to improve geometric precision.

- The investigation found that titanium alloy performs more efficiently than aluminum alloy. Although cost and weight reduction are primary concerns in the aerospace industry, future research could focus on comparing the weight of different cutout configurations in stiffened panels, along with conducting a life cycle cost analysis.

- Geometric imperfections, such as residual stresses and geometric deviations, are crucial considerations for any type of structure. In this study, these factors were not investigated. However, future research could be conducted on stiffened panels, considering these unintentional faults, to improve the precision of manufacturing stiffened panels.

- This research focused solely on lateral pressure ranging from 0 to 0.13 MPa. Other types of loads, such as dynamic loads, vibrations, and sudden shocks—commonly observed in the aerospace industry—were not considered in this study. Future investigations could be conducted to further understand the impact of these loads on real engineering applications from both material and structural perspectives.

- Although the finite element method is sufficiently reliable for investigating stiffener failures, future studies could involve the application of lateral pressure through solid experimentations.

7. Conclusions

- Among the investigated cases, a small amount of uniformly distributed lateral pressure load, to be precise, 0.013 MPa, did not remarkably impact the critical buckling load of the aluminum-based stiffened panels with or without opening shapes. However, the ultimate collapse load of the panel was affected by the lateral pressure load. In the case of titanium alloy, both the critical buckling and collapse load were not influenced by the prescribed pressure value.

- For the pressure load of 0.065 MPa, both the critical buckling load and ultimate collapse load were significantly affected for aluminum stiffened panels with or without opening shapes. For titanium stiffened panels, even though the critical buckling load was not affected by the pressure, the ultimate collapse load was found to be reduced by 35%.

- A significant percentage of buckling load and ultimate collapse load was found to be reduced by the application of 0.13 MPa pressure load for both aluminum and titanium panels. For the aluminum-based panels, the reduction in critical buckling load was not less than 60%, which was more severe for the ultimate collapse load, from 100% to 115%. For the case of the titanium panel, even though the critical buckling load was reduced by around 18.5%, the ultimate collapse load was almost reduced by 63%.

- The presence of opening shapes always reduced the critical buckling load and ultimate collapse load of the stiffened panel subjected to uniaxial compressive loading. The loss was more evident when the panel was subjected to both uniaxial compressive loading and lateral pressure load.

- Among the opening shapes investigated in this research, the square/hemispherical shape provided better buckling stability and ultimate collapse load to the stiffened panel. Although the square shape provided almost similar outcomes, for the pressure load of 0.13 MPa, the square/hemispherical shape exhibited better stability for the panel, around 20% higher than the square-shaped opening.

- From the investigated results, it is apparent that the lateral pressure load significantly affected the panel’s critical buckling and collapse load. The presence of the pressure load cannot be ignored and should be considered a crucial factor during the calculation of a stiffened panel subjected to uniform pressure loading conditions.

- From the mechanical properties of the titanium and aluminum alloys, it is evident that under any loading condition, titanium alloy would provide better strength than aluminum alloy with the cost of weight. Despite being lightweight, achieving the safety of a structure made from aluminum alloy is not always possible. In such conditions, titanium alloy can be utilized since it provides almost twice to thrice better buckling stability and ultimate collapse load to the panels.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ren, R.; Ma, X.; Yue, H.; Yang, F.; Lu, Y. Stiffness Enhancement Methods for Thin-Walled Aircraft Structures: A Review. Thin-Walled Struct. 2024, 201, 111995. [Google Scholar] [CrossRef]

- Zhu, J.H.; Zhang, W.H.; Xia, L. Topology Optimization in Aircraft and Aerospace Structures Design. Arch. Comput. Methods Eng. 2016, 23, 595–622. [Google Scholar] [CrossRef]

- Pietropaoli, E.; Riccio, A. Finite Element Analysis of the Stability (Buckling and Post-Buckling) of Composite Laminated Structures: Well Established Procedures and Challenges. Appl. Compos. Mater. 2012, 19, 79–96. [Google Scholar] [CrossRef]

- Cruz, M.L.S.; Carrillo, J.; De Almeida, S.F.M. Effect of Thermal Residual Stresses on Buckling and Post-Buckling Properties of Laminated Composites Perimetrally Reinforced. Lat. Am. J. Solids Struct. 2016, 13, 435–455. [Google Scholar] [CrossRef]

- Godoy, L.A. Stresses and Pressures in Thin-Walled Structures with Damage and Imperfections. Thin-Walled Struct. 1998, 32, 181–206. [Google Scholar] [CrossRef]

- Yip, W.S.; To, S.; Zhou, H. Current Status, Challenges and Opportunities of Sustainable Ultra-Precision Manufacturing. J. Intell. Manuf. 2022, 33, 2193–2205. [Google Scholar] [CrossRef]

- Ellinas, B.C.P. Buckling design of Ring-Stiffened Cylinders 3. JWPCO 1985, 110, 413–431. [Google Scholar] [CrossRef]

- Dallago, M.; Winiarski, B.; Zanini, F.; Carmignato, S.; Benedetti, M. On the Effect of Geometrical Imperfections and Defects on the Fatigue Strength of Cellular Lattice Structures Additively Manufactured via Selective Laser Melting. Int. J. Fatigue 2019, 124, 348–360. [Google Scholar] [CrossRef]

- Cervi, C.; Virgin, L.N. An Experimental Parametric Study Assessing the Effect of a Certain Initial Geometric Imperfection on Cylinder Buckling. Aerosp. Sci. Technol. 2024, 152, 109355. [Google Scholar] [CrossRef]

- Kordas, P.D.; Lampeas, G.N.; Fotopoulos, K.T. Numerical Investigation of an Experimental Setup for Thermoplastic Fuselage Panel Testing in Combined Loading. Aerospace 2024, 11, 175. [Google Scholar] [CrossRef]

- Ghadami, A.; Jawdhari, A.; PourMoosavi, G. Buckling and Post-Buckling Behavior of Top Flange Coped I-Beams with Slender Web Panels. Thin-Walled Struct. 2024, 198, 111640. [Google Scholar] [CrossRef]

- Carrera, E.; Azzara, R.; Daneshkhah, E.; Pagani, A.; Wu, B. Buckling and Post-Buckling of Anisotropic Flat Panels Subjected to Axial and Shear in-Plane Loadings Accounting for Classical and Refined Structural and Nonlinear Theories. Int. J. Non. Linear. Mech. 2021, 133, 103716. [Google Scholar] [CrossRef]

- Ueda, Y.; Rashed, S.M.H.; Paik, J.K. Buckling and Ultimate Strength Interaction in Plates and Stiffened Panels under Combined Inplane Biaxial and Shearing Forces. Mar. Struct. 1995, 8, 1–36. [Google Scholar] [CrossRef]

- Lal, M.G. Stability Analysis and Design of Structures; Springer Science & Business Media: New York, NY, USA, 2013. [Google Scholar]

- Barkanov, E.; Ozoliņš, O.; Eglitis, E.; Almeida, F.; Bowering, M.C.; Watson, G. Optimal Design of Composite Lateral Wing Upper Covers. Part I: Linear Buckling Analysis. Aerosp. Sci. Technol. 2014, 38, 1–8. [Google Scholar] [CrossRef]

- Yosiki, M.; Yamamoto, Y.; Kondo, H. Buckling of Plates Subjected to Edge Thrusts and Lateral Pressure. J. Zosen Kiokai 1965, 118, 249–258. [Google Scholar] [CrossRef]

- Brown, J.C.; Harvey, J.M. Large Deflections of Rectangular Plates Subjected To Uniform Lateral Pressure and Compressive Edge Loading. J. Mech. Eng. Sci. 1969, 11, 305–317. [Google Scholar] [CrossRef]

- Shanmugam, N.E.; Thevendran, V.; Tan, Y.H. Design Formula for Axially Compressed Perforated Plates. Thin-Walled Struct. 1999, 34, 1–20. [Google Scholar] [CrossRef]

- Ovesy, H.R.; Fazilati, J. Buckling and Free Vibration Finite Strip Analysis of Composite Plates with Cutout Based on Two Different Modeling Approaches. Compos. Struct. 2012, 94, 1250–1258. [Google Scholar] [CrossRef]

- Singh, S.B.; Kumar, D. Cutout Shape and Size Effects on Response of Quasi-Isotropic Composite Laminate under Uni-Axial Compression. Struct. Eng. Mech. 2010, 35, 335–348. [Google Scholar] [CrossRef]

- Rayhan, S.B. A Comprehensive Study on the Buckling Behaviour of Woven Composite Plates with Major Aerospace Cutouts under Uniaxial Loading. J. Mech. Eng. Sci. 2019, 13, 4756–4776. [Google Scholar] [CrossRef]

- Baba, B.O. Buckling Behavior of Laminated Composite Plates. J. Reinf. Plast. Compos. 2007, 26, 1637–1655. [Google Scholar] [CrossRef]

- Erkliǧ, A.; Yeter, E. The Effects of Cutouts on Buckling Behavior of Composite Plates. Sci. Eng. Compos. Mater. 2012, 19, 323–330. [Google Scholar] [CrossRef]

- Narayana, A.L.; Rao, K.; Kumar, R.V. Buckling Analysis of Rectangular Composite Plates with Rectangular Cutout Subjected to Linearly Varying In-Plane Loading Using Fem. Sadhana—Acad. Proc. Eng. Sci. 2014, 39, 583–596. [Google Scholar] [CrossRef]

- Baba, B.O.; Baltaci, A. Buckling Characteristics of Symmetrically and Antisymmetrically Laminated Composite Plates with Central Cutout. Appl. Compos. Mater. 2007, 14, 265–276. [Google Scholar] [CrossRef]

- Kim, J.H.; Jeon, J.H.; Park, J.S.; Seo, H.D.; Ahn, H.J.; Lee, J.M. Effect of Reinforcement on Buckling and Ultimate Strength of Perforated Plates. Int. J. Mech. Sci. 2015, 92, 194–205. [Google Scholar] [CrossRef]

- Guo, S.J. Stress Concentration and Buckling Behaviour of Shear Loaded Composite Panels with Reinforced Cutouts. Compos. Struct. 2007, 80, 1–9. [Google Scholar] [CrossRef]

- Guo, S.; Li, D.; Zhang, X.; Xiang, J. Buckling and Post-Buckling of a Composite C-Section with Cutout and Flange Reinforcement. Compos. Part B Eng. 2014, 60, 119–124. [Google Scholar] [CrossRef]

- Shojaee, T.; Mohammadi, B.; Madoliat, R. Experimental and Numerical Investigation of Stiffener Effects on Buckling Strength of Composite Laminates with Circular Cutout. J. Compos. Mater. 2020, 54, 1141–1160. [Google Scholar] [CrossRef]

- Rayhan, S.B. Elastic Buckling Response of a Composite Panel Stiffened around Cutouts. Int. J. Eng. 2019, 34, 243–252. [Google Scholar] [CrossRef]

- Quinn, D.; Murphy, A.; McEwan, W.; Lemaitre, F. Stiffened Panel Stability Behaviour and Performance Gains with Plate Prismatic Sub-Stiffening. Thin-Walled Struct. 2009, 47, 1457–1468. [Google Scholar] [CrossRef]

- Quinlan, J.R.; Gern, F.H. Conceptual Design and Structural Optimization of Nasa Environmentally Responsible Aviation (ERA) Hybrid Wing Body Aircraft. In Proceedings of the 57th AIAA/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, San Diego, CA, USA, 4–8 January 2015; pp. 1–16. [Google Scholar] [CrossRef]

- Li, D.; Chen, Z. Progressive Collapse Analysis and Ultimate Strength Estimation of Continuous Stiffened Panel under Longitudinal Extreme Cyclic Load and Lateral Pressure. Ocean Eng. 2023, 285, 115340. [Google Scholar] [CrossRef]

- Rayhan, S.B.; Rahman, M.M.; Sultana, J.; Szávai, S.; Varga, G. Finite Element and Machine Learning-Based Prediction of Buckling Strength in Additively Manufactured Lattice Stiffened Panels. Metals 2025, 15, 81. [Google Scholar] [CrossRef]

| Material | Aluminum-2024 | Ti-6Al-4V |

|---|---|---|

| Density, ρ, kgm−3 | 2780 | 4430 |

| Modulus of elasticity, E, MPa | 73,700 | 110,000 |

| Poisson’s ratio, υ | 0.33 | 0.34 |

| Initial yield stress, A, MPa | 299 | 862 |

| Hardening exponent, n | 0.406 | 0.34 |

| Tensile yield stress, MPa | 324 | 880 |

| Compressive yield stress, MPa | 324 | 880 |

| Tensile ultimate stress, MPa | 471 | 950 |

| Compressive ultimate stress, MPa | 471 | 950 |

| Type | Literature Outcomes, KN | Ansys Numerical Estimations, KN | Differences, % |

|---|---|---|---|

| Critical Buckling load | 74.5 | 70.21 | 5.9% |

| Type | Literature Outcomes, KN | Ansys Numerical Estimations, KN | Differences, % |

|---|---|---|---|

| Ultimate collapse load | 216.6 | 222.6 | 2.7% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sultana, J.; Varga, G. Finite Element Analysis of Post-Buckling Failure in Stiffened Panels: A Comparative Approach. Machines 2025, 13, 373. https://doi.org/10.3390/machines13050373

Sultana J, Varga G. Finite Element Analysis of Post-Buckling Failure in Stiffened Panels: A Comparative Approach. Machines. 2025; 13(5):373. https://doi.org/10.3390/machines13050373

Chicago/Turabian StyleSultana, Jakiya, and Gyula Varga. 2025. "Finite Element Analysis of Post-Buckling Failure in Stiffened Panels: A Comparative Approach" Machines 13, no. 5: 373. https://doi.org/10.3390/machines13050373

APA StyleSultana, J., & Varga, G. (2025). Finite Element Analysis of Post-Buckling Failure in Stiffened Panels: A Comparative Approach. Machines, 13(5), 373. https://doi.org/10.3390/machines13050373