Crone Ground Hook Suspension

Abstract

1. Introduction

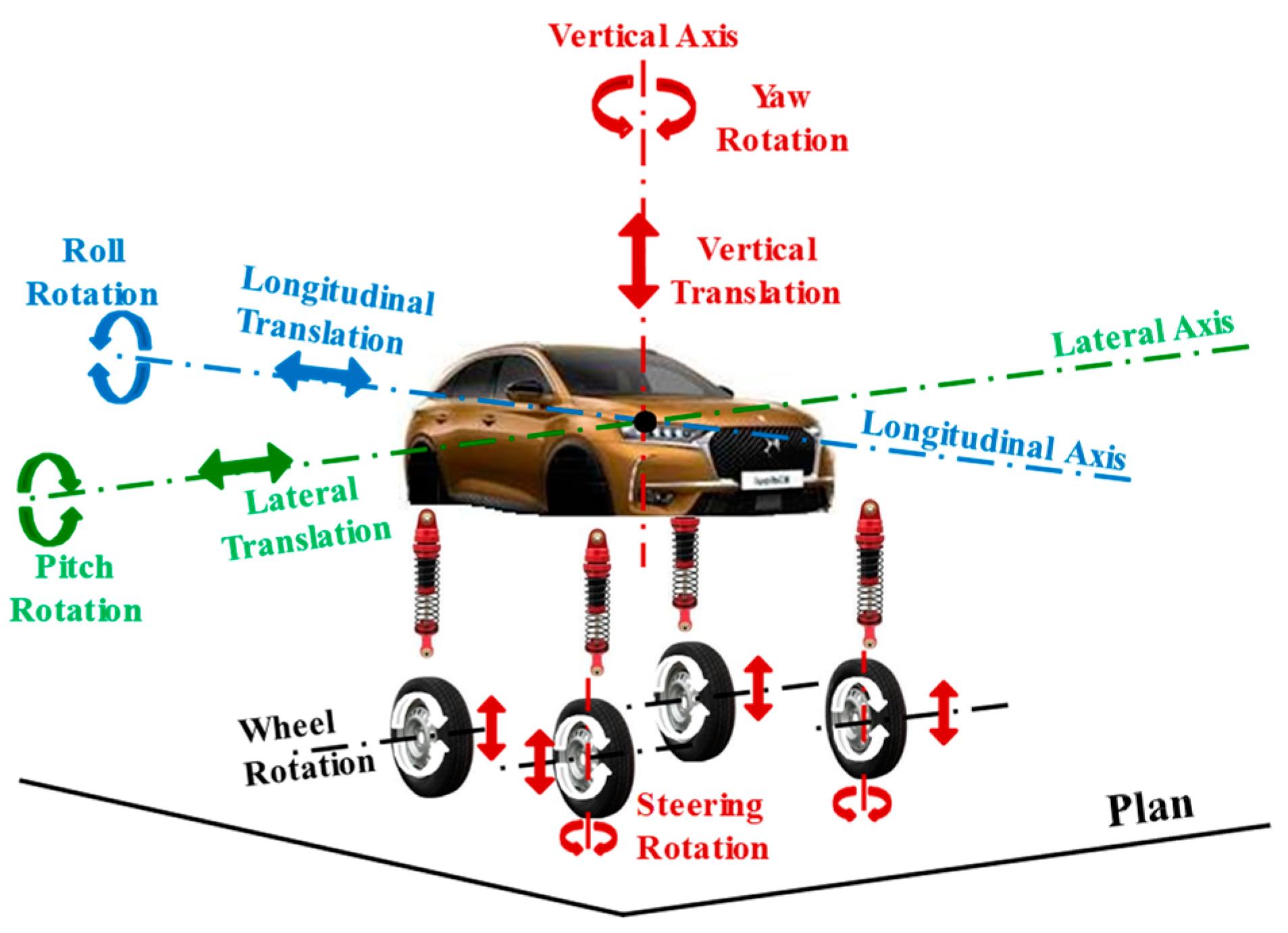

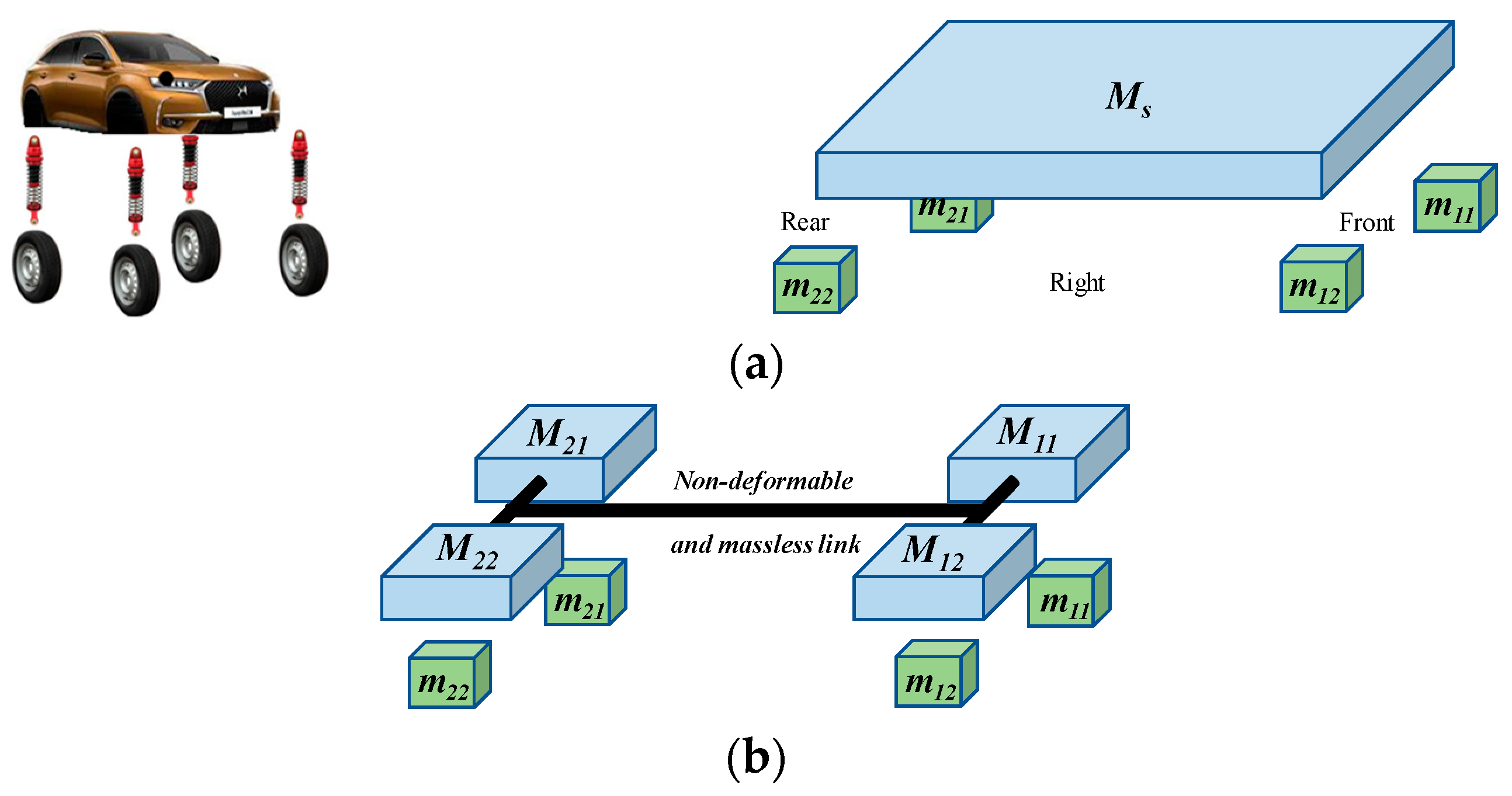

2. Modeling

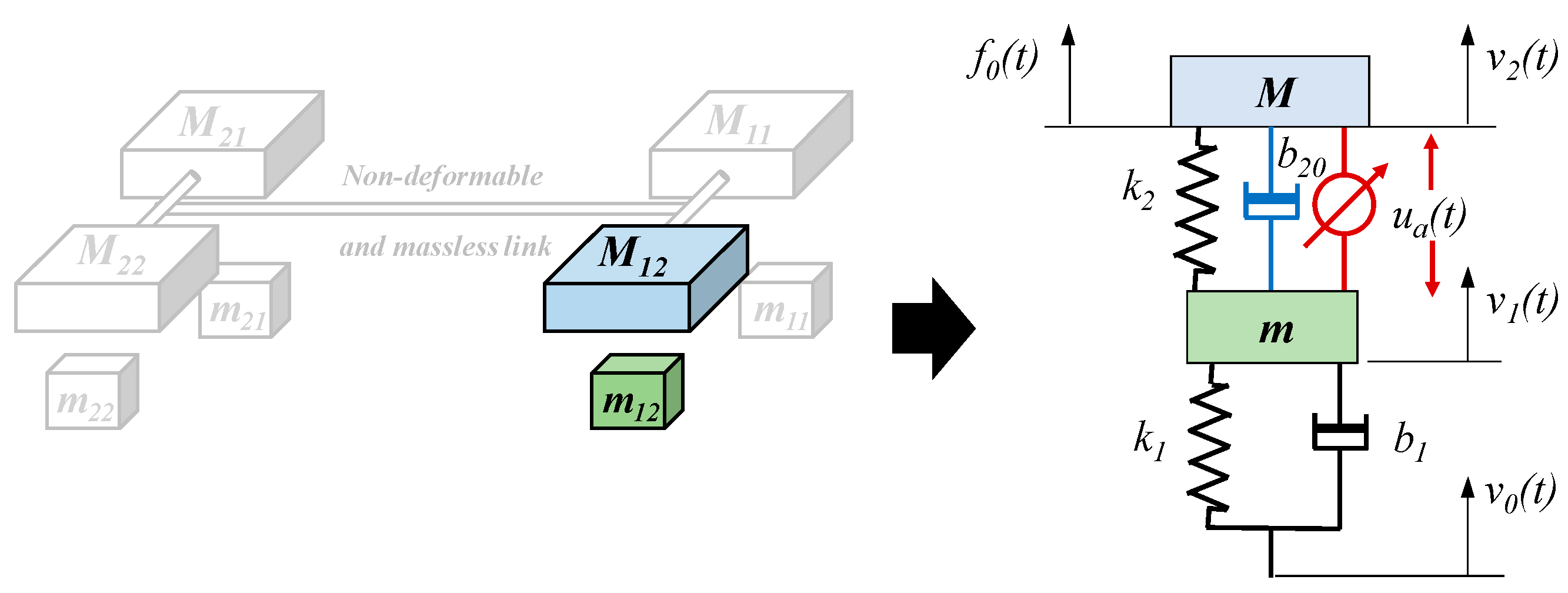

2.1. Quarter-Vehicle Model

- -

- m: unsprung mass [kg];

- -

- M: sprung mass [kg];

- -

- k1: vertical stiffness [N/m] of the tire;

- -

- k2: stiffness [N/m] of the suspension spring;

- -

- b1: equivalent viscous friction coefficient [Ns/m] of the tire;

- -

- b20: equivalent viscous friction coefficient [Ns/m] of the active suspension shock absorber;

- -

- v0(t): vertical speed [m/s] of the tire contact point on the road (road input);

- -

- v1(t): vertical speed [m/s] of the unsprung mass m1;

- -

- v2(t): vertical speed [m/s] of the sprung mass m2;

- -

- f0(t): load transfer [N] resulting from the driver’s action on the steering wheel or pedals (brake and accelerator).

2.2. Measurement Noise Model

2.3. Random Road Profiles

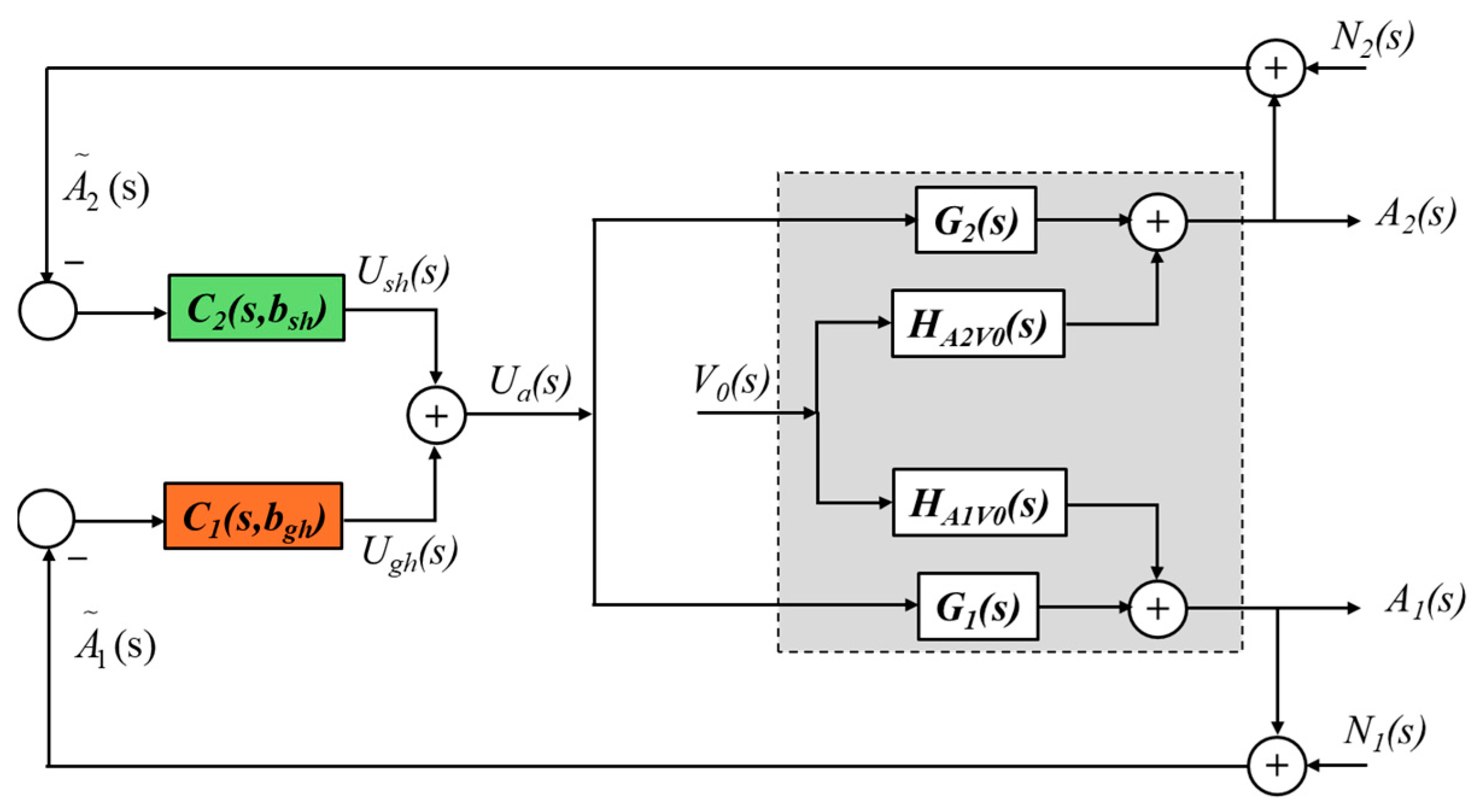

3. Suspension Control Architecture

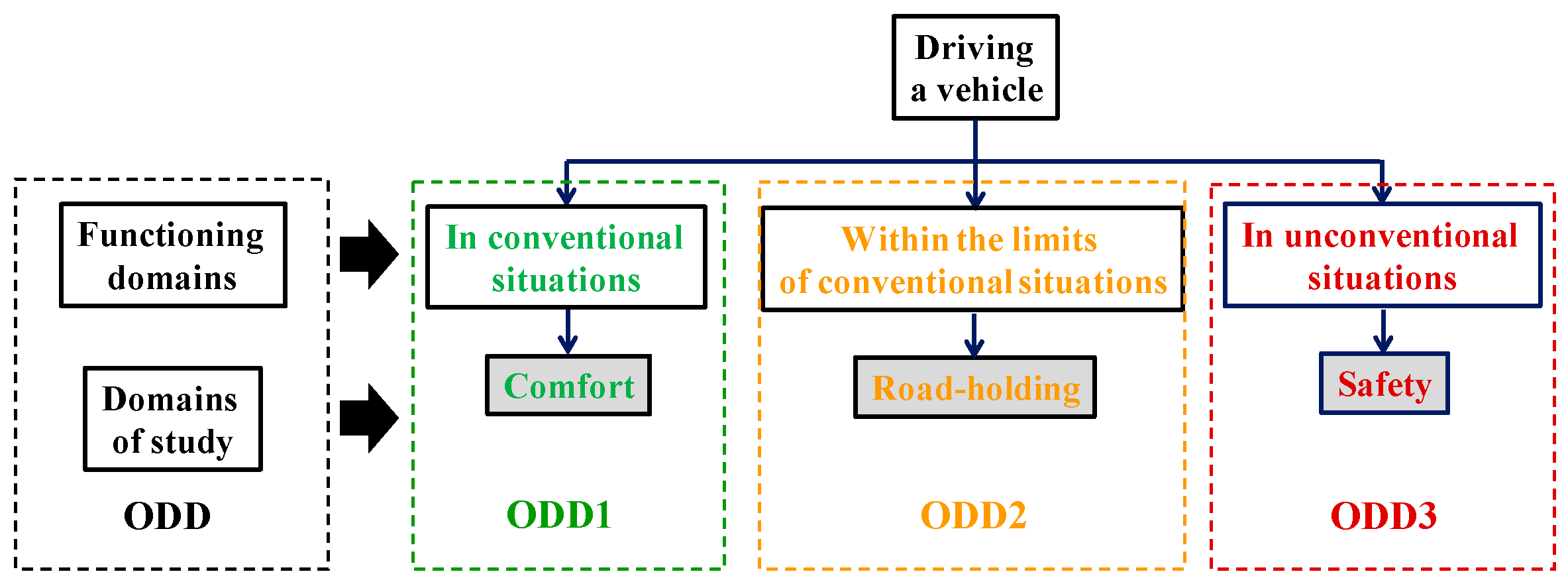

3.1. General Case Regardless of the ODD

3.2. Special Case: ODD3 and CGH

- -

- for the output A1(s):

- -

- for the control Ua(s):

- -

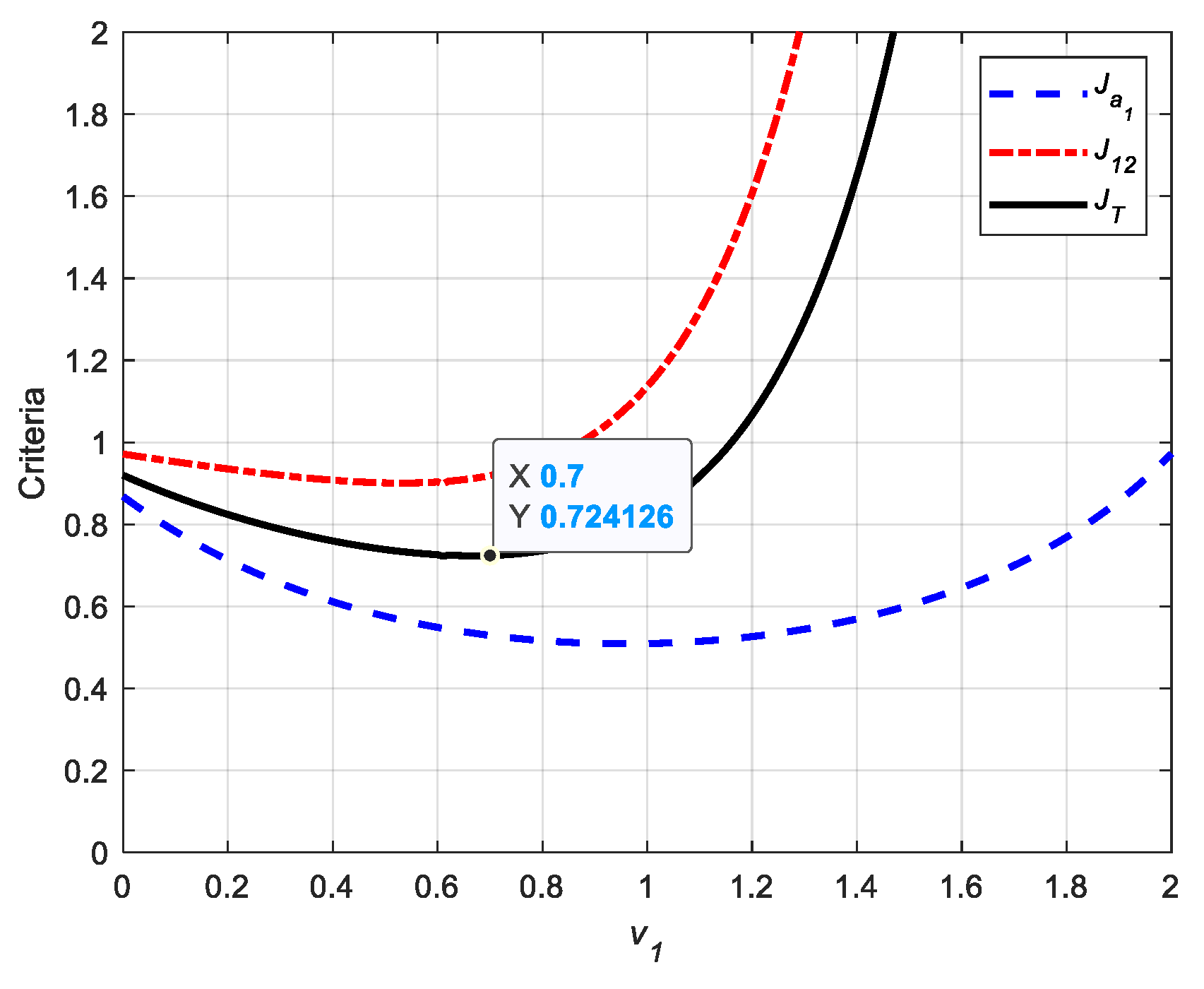

- ν1 = 0 => inertial behavior [37];

- -

- 0 < ν1 < 1 => visco-inertial behavior;

- -

- ν1 = 1 => viscous behavior;

- -

- 1 < ν1 < 2 => viscoelastic behavior;

- -

- ν1 = 2 => elastic behavior.

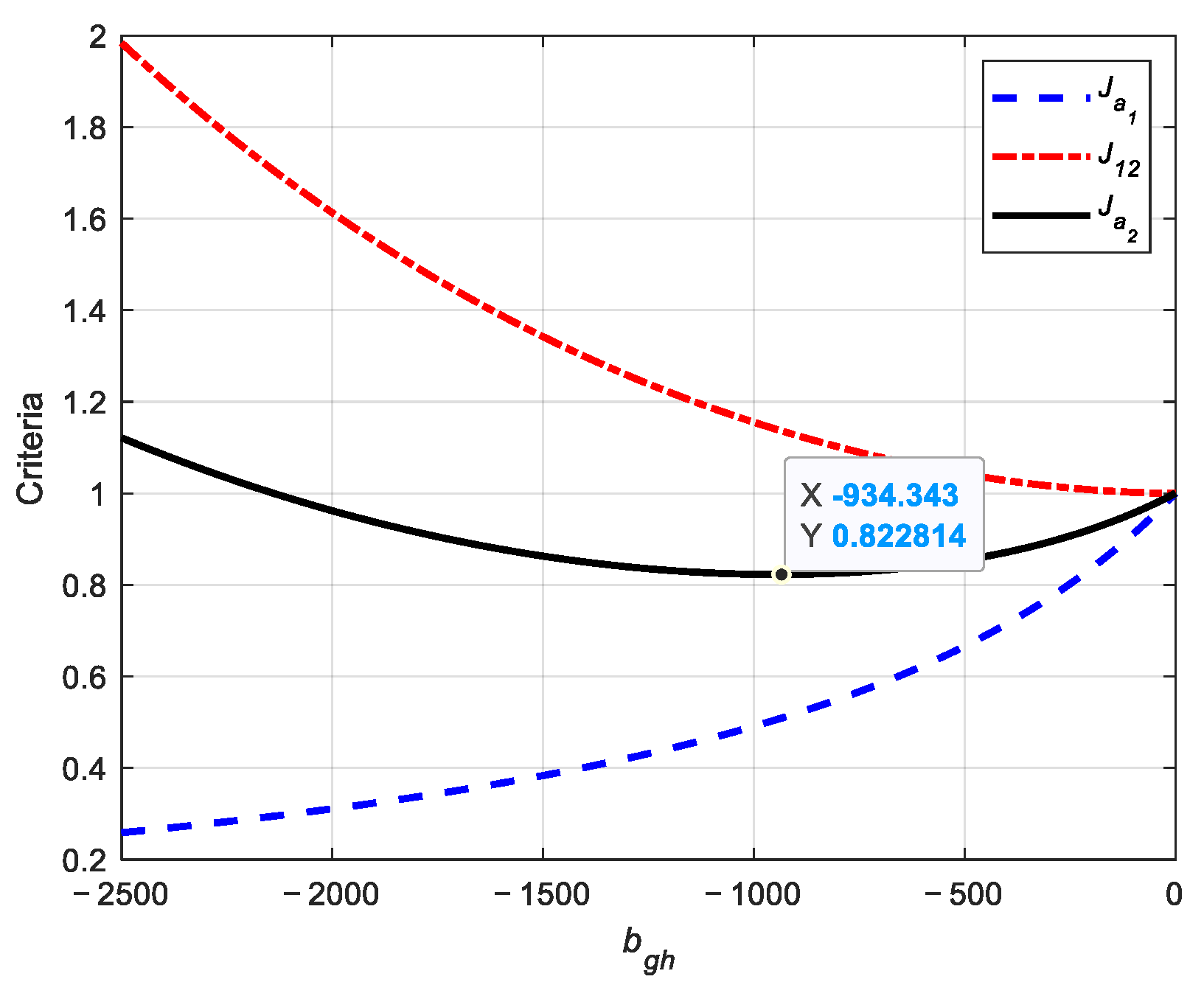

3.3. Optimal Parameters of the CGH Strategy

- -

- the acceleration a1(t) of the unsprung mass;

- -

- the suspension travel z12(t) = z1(t) − z2(t), where zi(t) represents the vertical displacement of the unsprung mass (i = 1) and the sprung mass (i =2).

4. Performance

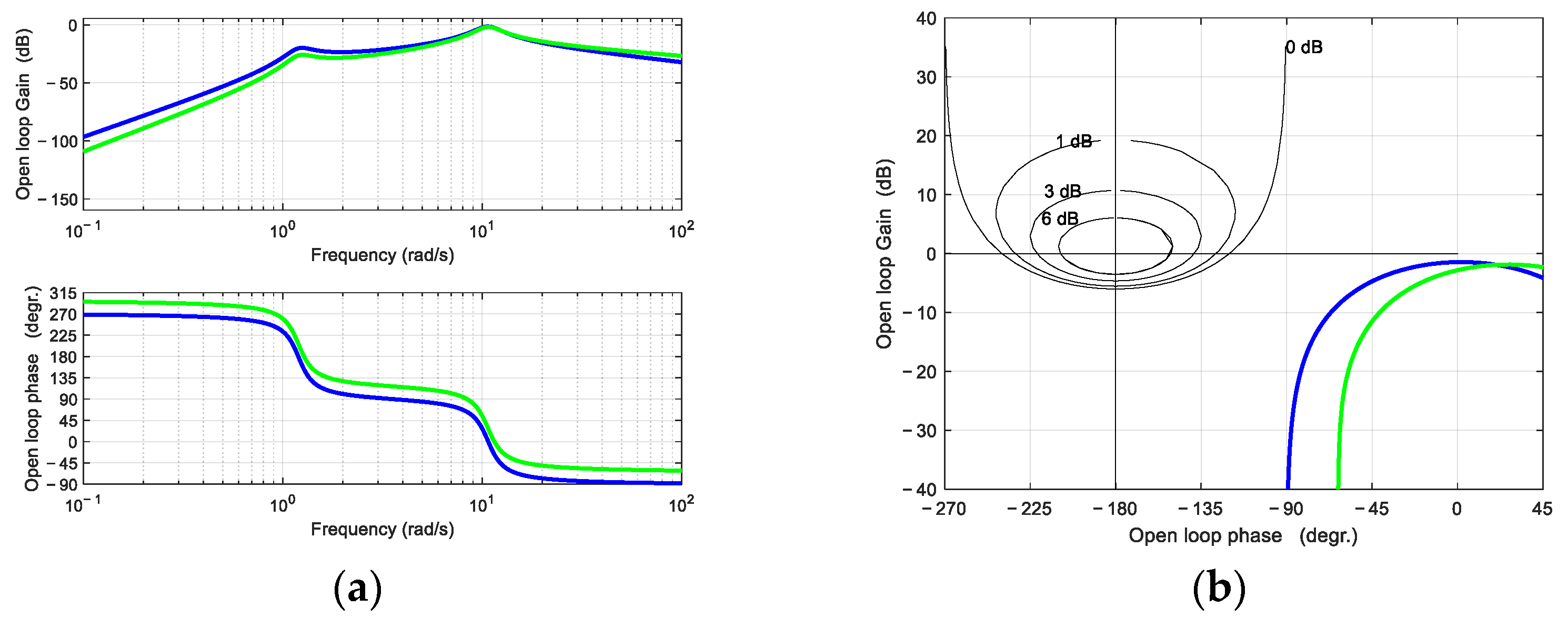

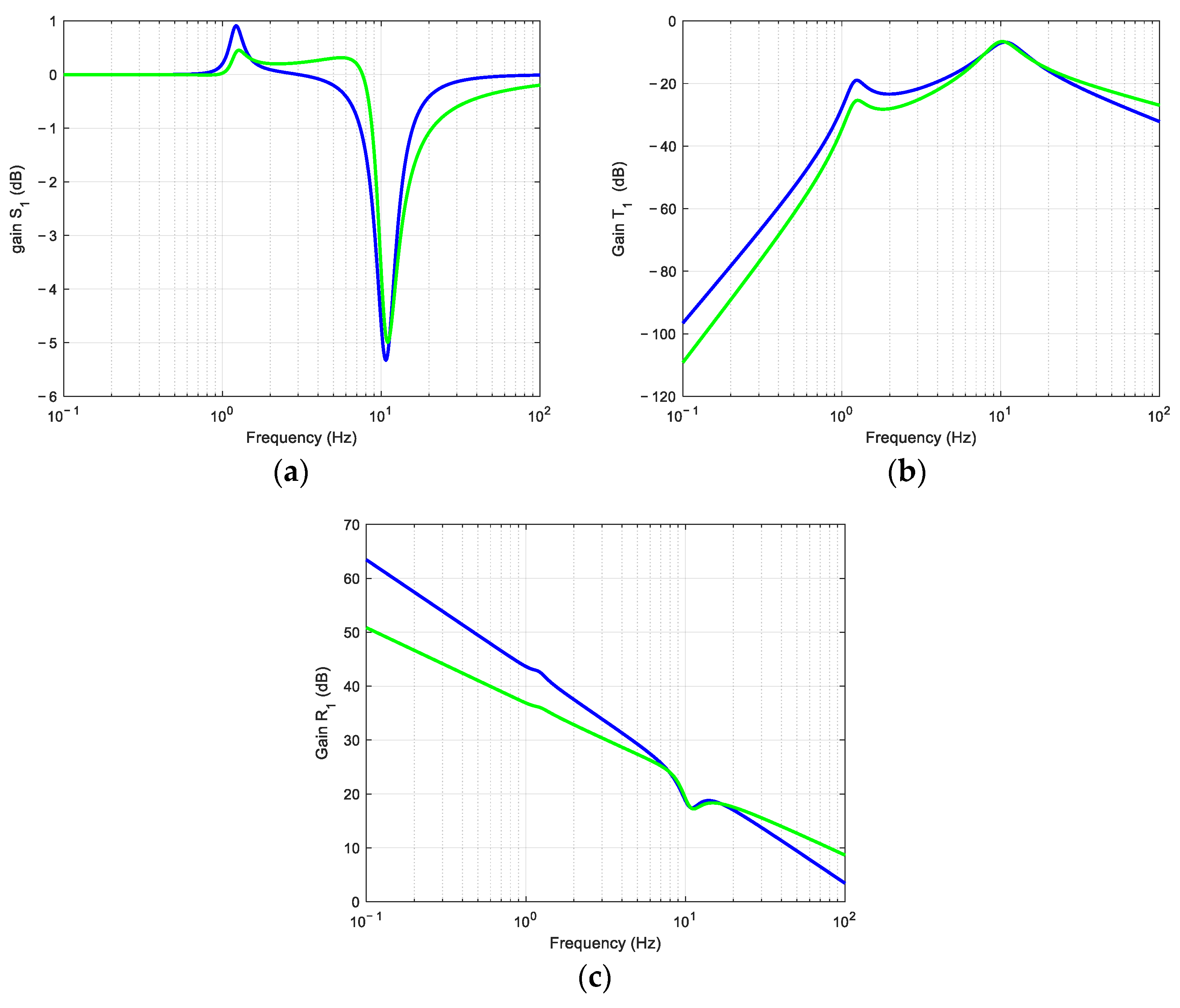

4.1. Performance from a Control Theory Perspective

- -

- in the frequency domain:

- -

- the Bode plots of the frequency response β1(jω), as well as its Black-Nichols loci;

- -

- the gain diagrams of the sensitivity functions S1, T1, and R1;

- -

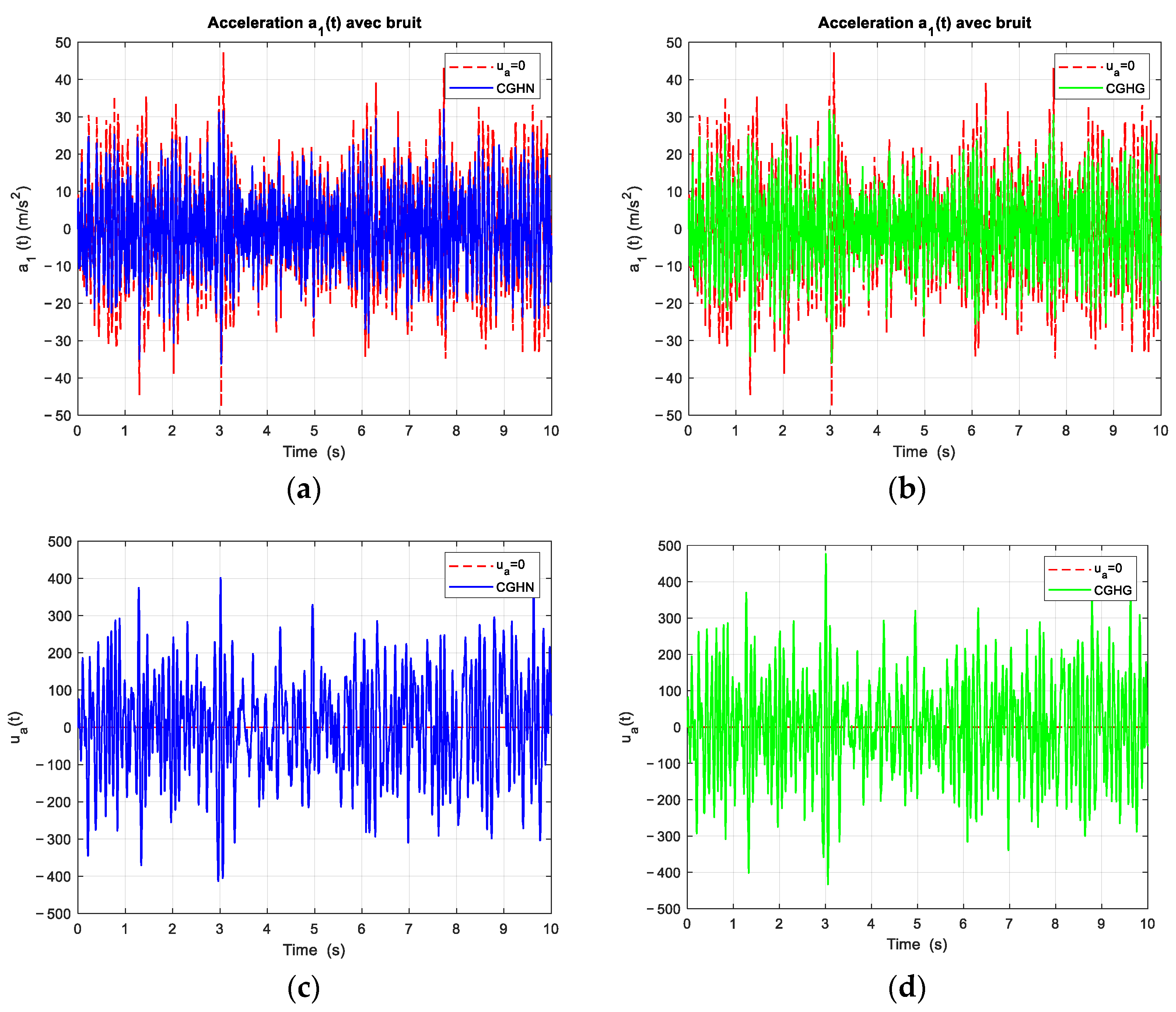

- in the time domain:

- -

- the vertical acceleration a1(t) as a regulated quantity;

- -

- the force control ua(t) (verification of the risk of saturation and of the sensitivity to measurement noise).

- -

- a local increase in the vicinity of the natural pulsation ωn2 of the sprung mass,

- -

- a local decrease in the vicinity of the natural pulsation ωn1 of the unsprung mass of the sensitivity of output A1(s) to disturbance V0(s).

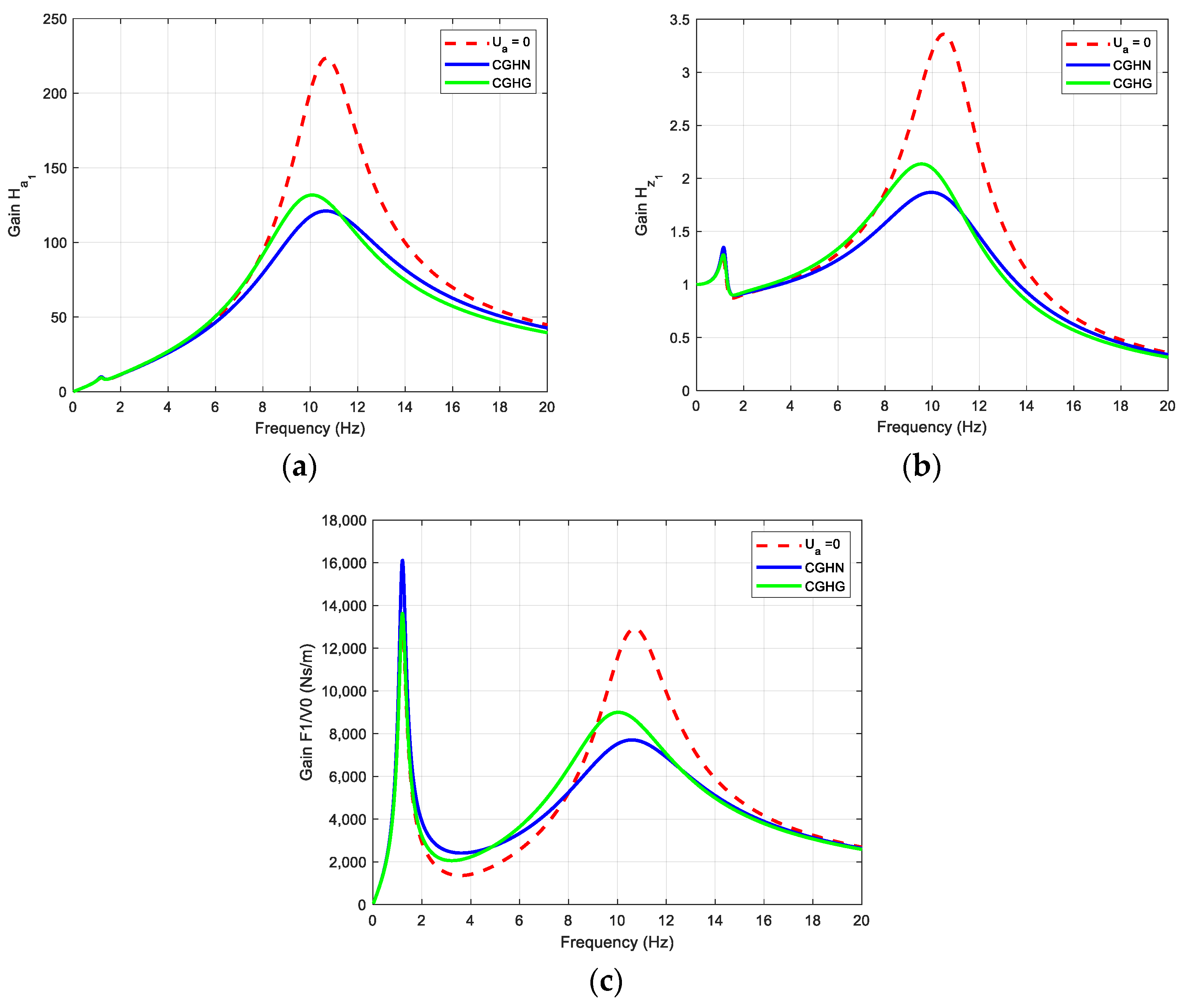

4.2. Performance from a Vibration Study Point of View

- -

- for comfort: = A2(s)/V0(s) on the interval [0; 20] Hz; = Z2(s)/Z0(s) = V2(s)/V0(s) on the interval [0; 5.5] Hz;

- -

- for operation: = Z12(s)/V0(s) on the interval [0; 20] Hz;

- -

- for wheel holding: = A1(s)/V0(s), = Z1(s)/Z0(s) = V1(s)/V0(s), and = Fz(s)/V0(s) on the interval [0; 20] Hz.

- -

- -

- -

- and where, according to the criteria, the variable x represents:

- -

- for comfort, the vertical acceleration a2 and the vertical displacement z2 of the sprung mass M (body);

- -

- for operation, suspension travel z12 (limited by stroke);

- -

- for wheel holding, the vertical acceleration a1 and the vertical displacement z1 of the unsprung mass m (wheel), as well as the dynamic component fz of the load on the tire.

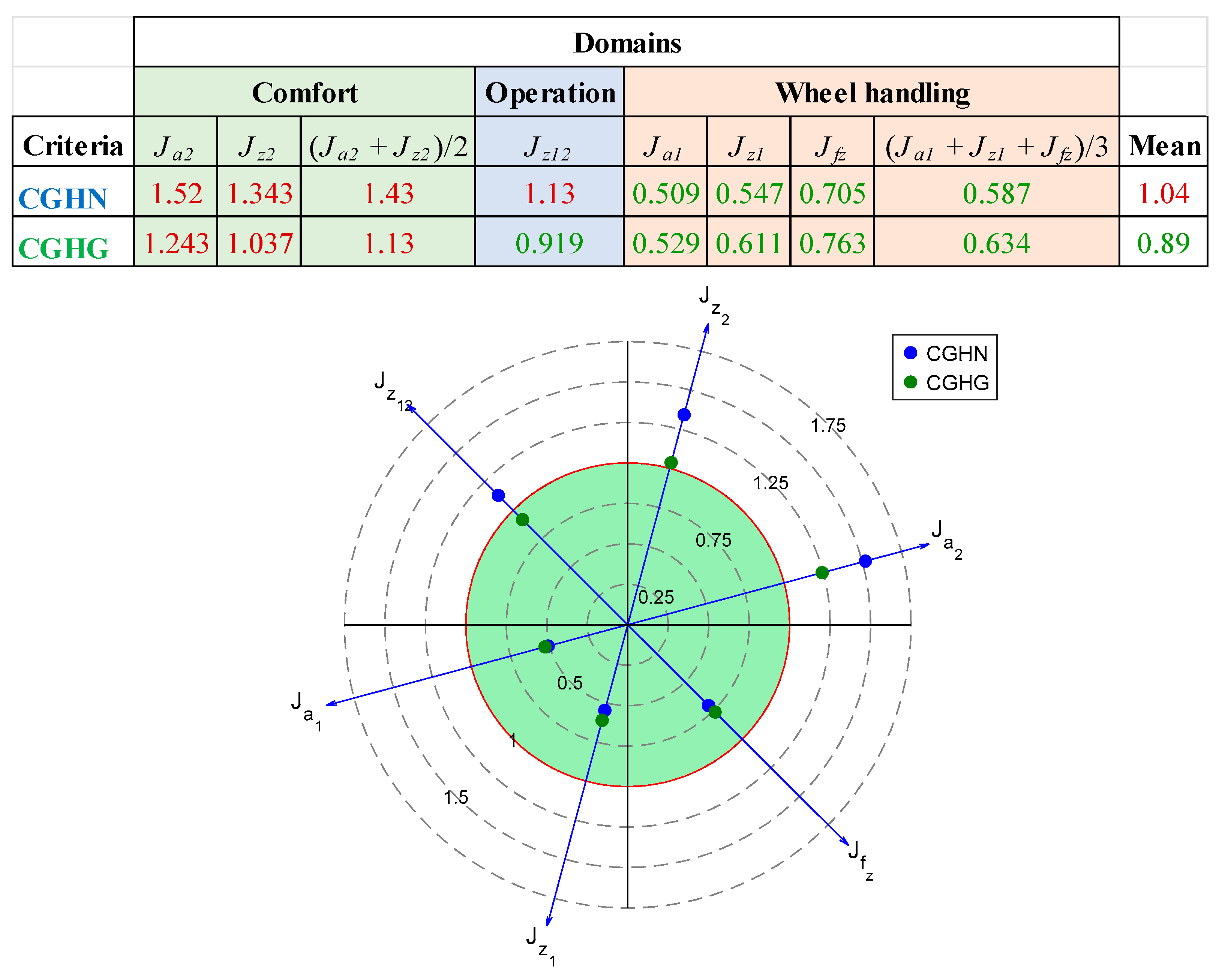

- -

- degrades vibration comfort the least (average value of the comfort criterion equal to 1.13 against 1.43 for the CGHN strategy);

- -

- undermines the acceleration-travel dilemma, since the decrease in the criterion concerning acceleration a1 is not accompanied by an increase in the criterion concerning suspension travel z12. In fact, the value of the operating criterion is equal to 0.919, which is not the case with the CGHN strategy where the value of this same criterion is equal to 1.13.

- -

- -

- -

- for comfort, the vertical acceleration a2 and the vertical displacement z2 of the sprung mass M (body);

- -

- for operation, suspension travel z12 (limited by stroke);

- -

- for wheel holding, the vertical acceleration a1 and the displacement z1 of the unsprung mass m (wheel), as well as the dynamic component fz of the load on the tire.

- -

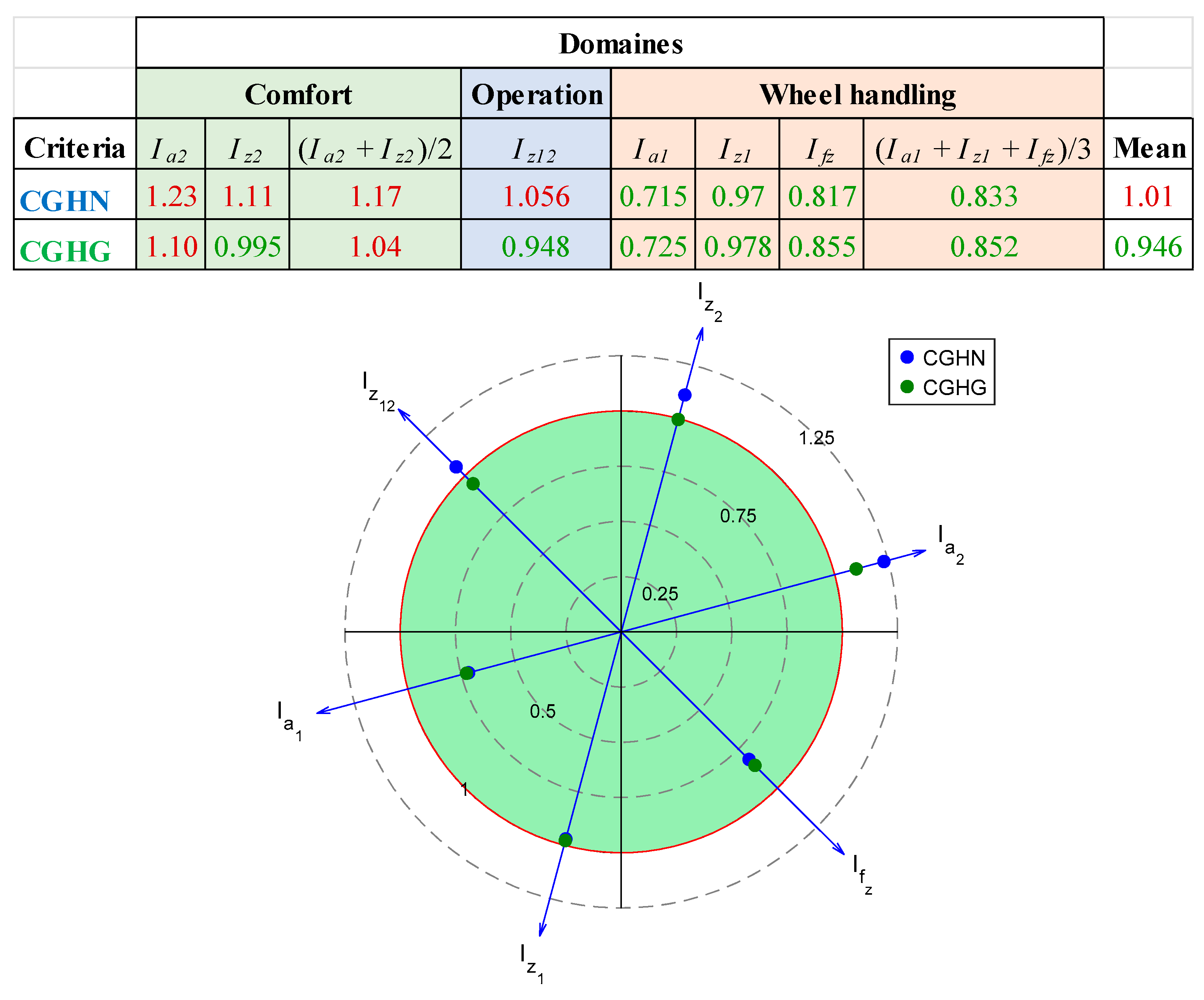

- degrades vibration comfort the least (average value of the comfort criterion equal to 1.04 against 1.17 for the CGHN strategy);

- -

- faults the acceleration-deflection dilemma with a value of the operating criterion equal to 0.948 against 1.056 with the CGHN strategy.

5. Conclusions and Perspectives

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Benine-Neto, A.; Moreau, X.; Lanusse, P. Robust control for an electro-mechanical anti-lock braking system: The CRONE approach. IFAC-PapersOnLine 2017, 50, 12575–12581. [Google Scholar] [CrossRef]

- Monot, N.; Moreau, X.; Neto, A.B.; Rizzo, A.; Aioun, F. Automated vehicle lateral guidance using multi-PID steering control and look-ahead point reference. Int. J. Veh. Auton. Syst. 2021, 16, 38. [Google Scholar] [CrossRef]

- Attia, R.; Orjuela, R.; Basset, M. Dual-mode Control Allocation for Integrated Chassis Stabilization. IFAC Proc. 2014, 47, 11219–11224. [Google Scholar] [CrossRef]

- Chokor, A. Design of Several Centralized and Decentralized Multilayer Robust Control Architectures for Global Chassis Control. Ph.D. Thesis, Université de Technologie de Compiègne, Compiègne, France, 2019. Available online: https://theses.hal.science/tel-02489343 (accessed on 9 December 2024).

- Chou, H.; D’andréa-Novel, B. Global vehicle control using differential braking torques and active suspension forces. Veh. Syst. Dyn. 2005, 43, 261–284. [Google Scholar] [CrossRef]

- Zhang, H.; Li, X.-S.; Shi, S.-M.; Liu, H.-F.; Rachel, G.; Liu, L. Phase Plane Analysis for Vehicle Handling and Stability. Int. J. Comput. Intell. Syst. 2011, 4, 1179–1186. [Google Scholar] [CrossRef]

- Sun, W.; Tian, J.; Li, S.; Yang, Z.; Ma, Z. Stability Analysis of Vehicle Negotiating a Curve in the Plane. Adv. Mech. Eng. 2013, 5, 893835. [Google Scholar] [CrossRef]

- Bobier-Tiu, C.; Beal, C.; Kegelman, J.; Hindiyeh, R.; Gerdes, J. Vehicle control synthesis using phase portraits of planar dynamics. Veh. Syst. Dyn. 2018, 57, 1318–1337. [Google Scholar] [CrossRef]

- Termous, H. Hierarchical Approach for the Global Chassis Control of an Electric Vehicle. Ph.D. Thesis, Université de Bordeaux, Bordeaux, France, 2020. Available online: https://theses.hal.science/tel-02977884 (accessed on 9 December 2024).

- Termous, H.; Moreau, X.; Francis, C.; Shraim, H. Hierarchical Approach for Driver Disturbance Rejection in an Electric Vehicle: The CRONE Approach. IEEE Trans. Veh. Technol. 2022, 71, 7008–7022. [Google Scholar] [CrossRef]

- Zin, A.; Sename, O.; Gaspar, P.; Dugard, L.; Bokor, J. Robust LPV– ∞ control for active suspensions with performance adaptation in view of global chassis control. Veh. Syst. Dyn. 2008, 46, 889–912. [Google Scholar] [CrossRef]

- Savaresi, S.M.; Poussot-Vassal, C.; Spelta, C.; Sename, O.; Dugard, L. Semi-Active Suspension Control Design for Vehicles; Elsevier: Amsterdam, The Netherlands, 2010. [Google Scholar]

- Androulakis, V. Development of an Autonomous Navigation System for the Shuttle Car in Underground Room & Pillar Coal Mines. Ph.D. Thesis, University of Kentucky, Lexington, KY, USA, 2021. [Google Scholar] [CrossRef]

- Choi, S.B.; Choi, Y.T.; Park, D.W. A sliding mode control of a full-car electrorheological suspension system via hardware in-the-loop simulation. J. Dyn. Syst. Meas. Control 2000, 122, 114–121. [Google Scholar] [CrossRef]

- Tseng, H.E.; Hrovat, D. State of the art survey: Active and semi-active suspension control. Veh. Syst. Dyn. 2015, 53, 1034–1062. [Google Scholar] [CrossRef]

- Hrovat, D. Survey of Advanced Suspension Developments and Related Optimal Control Applications. Automatica 1997, 33, 1781–1817. [Google Scholar] [CrossRef]

- Casciati, F.; Rodellar, J.; Yildirim, U. Active and semi-active control of structures—Theory and applications: A review of recent advances. J. Intell. Mater. Syst. Struct. 2012, 23, 1181–1195. [Google Scholar] [CrossRef]

- Kissai, M.; Monsuez, B.; Tapus, A.; Mouton, X.; Martinez, D. Gain-Scheduled H∞ for Vehicle High-Level Motion Control. In Proceedings of the 6th International Conference on Control, Mechatronics and Automation, in ICCMA 2018, Tokyo, Japan, 12–14 October 2018; Association for Computing Machinery: New York, NY, USA, 2018; pp. 97–104. [Google Scholar]

- Esmailzadeh, E.; Fahimi, F. Optimal Adaptive Active Suspensions for a Full Car Model. Veh. Syst. Dyn. 1997, 27, 89–107. [Google Scholar] [CrossRef]

- Fialho, I.J.; Balas, G.J. Design of Nonlinear Controllers for Active Vehicle Suspensions Using Parameter-Varying Control Synthesis. Veh. Syst. Dyn. 2000, 33, 351–370. [Google Scholar] [CrossRef]

- Cherry, A.S.; Jones, R.P. Fuzzy logic control of an automotive suspension system. IEE Proc.-Control Theory Appl. 1995, 142, 149–160. [Google Scholar] [CrossRef]

- Titli, A.; Boverie, S. Fuzzy and neuro control for semi–active and active suspension. In Advances in Automotive Control 1995; Kiencke, U., Guzzella, L., Eds.; IFAC Postprint Volume; Pergamon: Oxford, UK, 1995; pp. 49–53. [Google Scholar] [CrossRef]

- Emura, J.; Kakizaki, S.; Yamaoka, F.; Nakamura, M. Development of the Semi-Active Suspension System Based on the Sky-Hook Damper Theory. SAE Trans. 1994, 103, 1110–1119. [Google Scholar]

- Poussot-Vassal, C.; Sename, O.; Dugard, L.; Ramirez-Mendoza, R.; Flores, L. Optimal skyhook control for semi-active suspensions. IFAC Proc. 2006, 39, 608–613. [Google Scholar] [CrossRef]

- Hu, Y.; Chen, M.Z.Q. Stability analysis for active control with a sky-hook and ground-hook inerter-damper configuration. In Proceedings of the 2019 IEEE 58th Conference on Decision and Control (CDC), Nice, France, 11–13 December 2019; pp. 7752–7757. [Google Scholar]

- Atindana, V.A.; Xu, X.; Nyedeb, A.N.; Quaisie, J.K.; Nkrumah, J.K.; Assam, S.P. The Evolution of Vehicle Pneumatic Vibration Isolation: A Systematic Review. Shock. Vib. 2023, 2023, 1716615. [Google Scholar] [CrossRef]

- Karnopp, D. Analytical Results for Optimum Actively Damped Suspensions Under Random Excitation. J. Vib. Acoust. Stress Reliab. Des. 1989, 111, 278–282. [Google Scholar] [CrossRef]

- Hamrouni, E.; Moreau, X.; Benine-Neto, A.; Hernette, V. Skyhook and CRONE active suspensions: A comparative study. IFAC-Pap. 2019, 52, 243–248. [Google Scholar] [CrossRef]

- Mulla, A.; Jalwadi, S.; Unaune, D. Performance analysis of skyhook, groundhook and hybrid control strategies on semi-active suspension system. Int. J. Curr. Eng. Technol. 2014, 3, 265–269. [Google Scholar]

- Farah, F.; Moreau, X.; Daou, R.A.Z. Generalized CRONE Sky Hook Suspension. IFAC-PapersOnLine 2024, 58, 460–465. [Google Scholar] [CrossRef]

- Farah, F.; Moreau, X.; Daou, R.A.Z. Comparative Study of Two Sky Hook Strategies analyzed from a control theory perspective. In Proceedings of the 2024 28th International Conference on Methods and Models in Automation and Robotics (MMAR), Międzyzdroje, Poland, 27–30 August 2024; pp. 131–136. [Google Scholar] [CrossRef]

- Chen, K.; He, S.; Xu, E.; Tang, R.; Wang, Y. Research on ride comfort analysis and hierarchical optimization of heavy vehicles with coupled nonlinear dynamics of suspension. Measurement 2020, 165, 108142. [Google Scholar] [CrossRef]

- Guridis, R.; Moreau, X.; Benine-Neto, A.; Frej, G.B.H.; Hernette, V. Reconstruction of the road profile from sensors embedded in vehicle. 21th World Congr. Int. Fed. Autom. Control IFAC 2023, 56, 11167–11172. [Google Scholar] [CrossRef]

- Farah, F.; Moreau, X.; Daou, R.A.Z. The CRONE Sky Hook Approach to Suspension: A Strategy Focused on 100% Vibrational Comfort. In Proceedings of the 2024 International Conference on Smart Systems and Power Management (IC2SPM), Beirut, Lebanon, 28 November 2024; pp. 113–120. [Google Scholar] [CrossRef]

- ISO 8608:1995; Presented at the International Organization for Standardization-Mechanical Vibration. Road Surface Profiles: Reporting of Measured Data. Distributed Through American National Standards Institute (ANSI): Genève, Switzerland, 1995.

- Lenkutis, T.; Čerškus, A.; Šešok, N.; Dzedzickis, A.; Bučinskas, V. Road Surface Profile Synthesis: Assessment of Suitability for Simulation. Symmetry 2021, 13, 68. [Google Scholar] [CrossRef]

- Yang, Y.; Liu, C.; Lai, S.-K.; Chen, Z.; Chen, L. Frequency-dependent equivalent impedance analysis for optimizing vehicle inertial suspensions. Nonlinear Dyn. 2024. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Farah, F.; Moreau, X.; Abi Zeid Daou, R. Crone Ground Hook Suspension. Machines 2025, 13, 244. https://doi.org/10.3390/machines13030244

Farah F, Moreau X, Abi Zeid Daou R. Crone Ground Hook Suspension. Machines. 2025; 13(3):244. https://doi.org/10.3390/machines13030244

Chicago/Turabian StyleFarah, Fouad, Xavier Moreau, and Roy Abi Zeid Daou. 2025. "Crone Ground Hook Suspension" Machines 13, no. 3: 244. https://doi.org/10.3390/machines13030244

APA StyleFarah, F., Moreau, X., & Abi Zeid Daou, R. (2025). Crone Ground Hook Suspension. Machines, 13(3), 244. https://doi.org/10.3390/machines13030244