An Optoelectronic System for the Online Monitoring of the Chord Length of Steam Turbine Rotor Blades for Early Fault Detection

Abstract

1. Introduction

2. Operating Principle of the Optoelectronic System for Monitoring Rotor Blade Wear

3. Sources of Error in the System for Evaluating Blade Chord Length

3.1. Previously Investigated Error Components

| Influencing Factor | Component of the Total Error | |

|---|---|---|

| Error in determining the projection boundaries of the blade edges on the matrix photodetector [10] | where | (1) |

| Deviation in the focal length from the nominal value [7] | (2) | |

| Deviation in the distance between the principal point of the video probe lens and the blade axis [7] | (3) | |

| Deviation in the radius of the controlled cross-section from the nominal value [7] | (4) | |

| Deviation in the twist angle of the chord in the controlled cross-section from the nominal value [7] | (5) | |

| Deviation in the exposure time from the nominal value [7] | (6) | |

| Temperature change in the video probe housing [7] | (7) | |

| Deviation in the shaft rotation frequency from the nominal value δν [7] | (8) | |

| Change in the blade surface reflection coefficient δρ | where | (9) |

| Defocusing of blade edge images on photodetector planes and [24] | (10) | |

| Blade image distortion caused by lens distortion | (11) | |

| Deviation in the video probe viewing line from the normal to the blade motion plane | (12) | |

| Error in determining the rotor rotation angle by the synchro sensor | (13) |

- Variation in the reflection coefficient of blade surface δρ (9);

- Defocusing of blade edge images on the photodetector photosensitive plane and (10);

- Blade image distortion caused by the lens distortion of the video probe (11);

- Deviation in the video probe line of sight from the normal to the blade motion plane (12);

- Error in determining the rotor rotation angle using the synchro sensor δφ (13).

3.2. Error Caused by Changes in the Blade Surface Reflection Coefficient

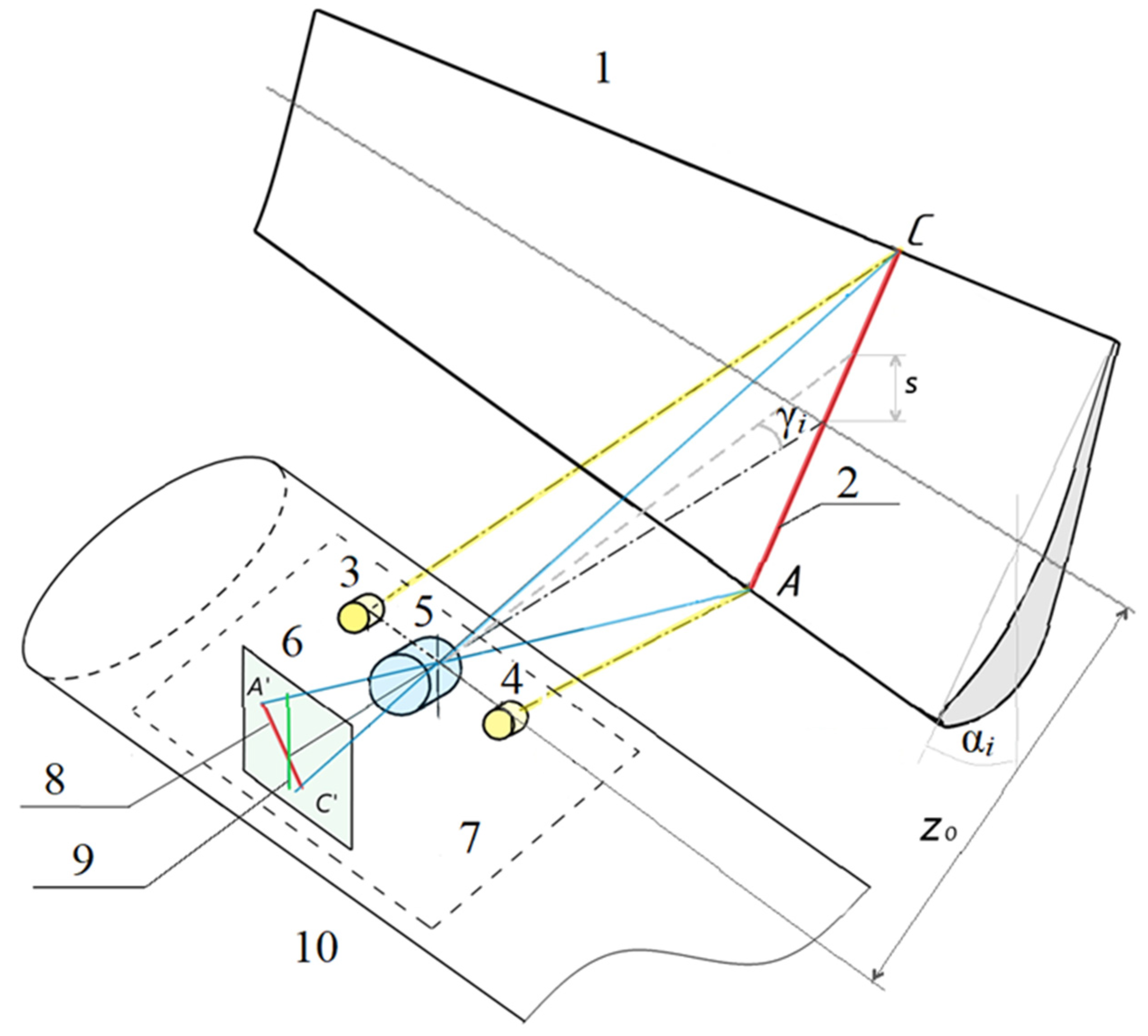

- and —diffuse reflection coefficients of the surface element of edges A and C;

- —distances from source 4 (Figure 2) to edges A;

- —distance from source 3 (Figure 2) to edge C;

- and —distances from the entrance pupil of the lens to the surface of edges A and C;

- and —angles between the direction to the edge and perpendicular to the surface of edges A and C, respectively;

- —angle of incidence of rays from source 4 on the surface of edge A;

- —angle of incidence of rays from source 3 on edge C.

3.3. Error Caused by Defocusing of Edge Images on the Photodetector Plane

3.4. Error Caused by Distortion of the Video Probe Lens

3.5. Error Caused by Deviation of the Line of Sight from the Normal to the Blade Motion Plane

- The error caused by a deviation in the distance between the principal point of the video probe lens and the blade axis from its nominal value (3).

- The error caused by a deviation in the radius of the blade section from its nominal value (4).

- Setting the viewing angle with an error of no more than .

- Defining the blade section radius with no more than a 1 mm error.

- Setting distance with an error of no more than 0.05 mm.

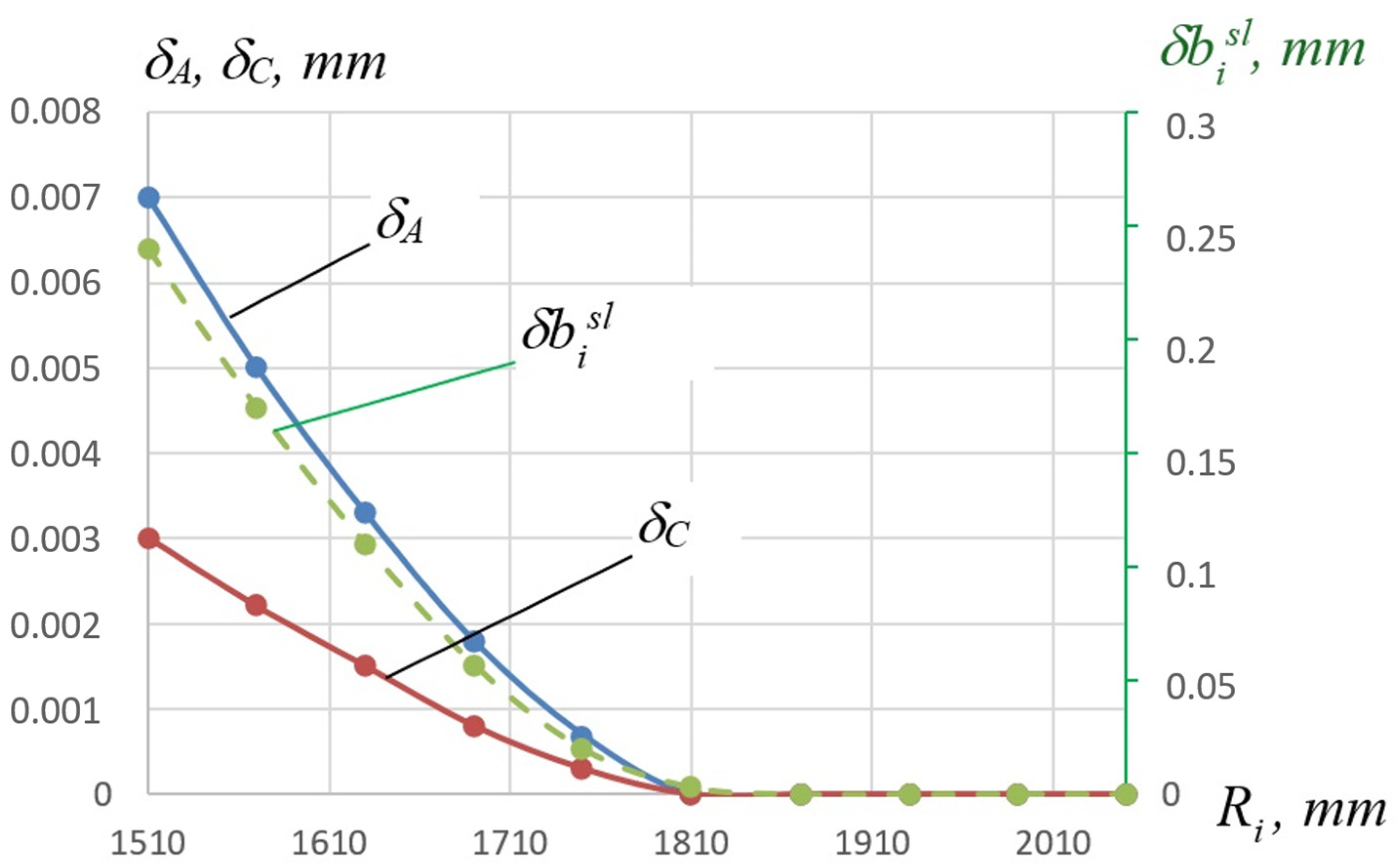

3.6. Error Caused by Rotor Angle Measurement Inaccuracy by the Synchro Sensor

- It is directly proportional to the radius of the controlled blade section.

- It is inversely proportional to the distance .

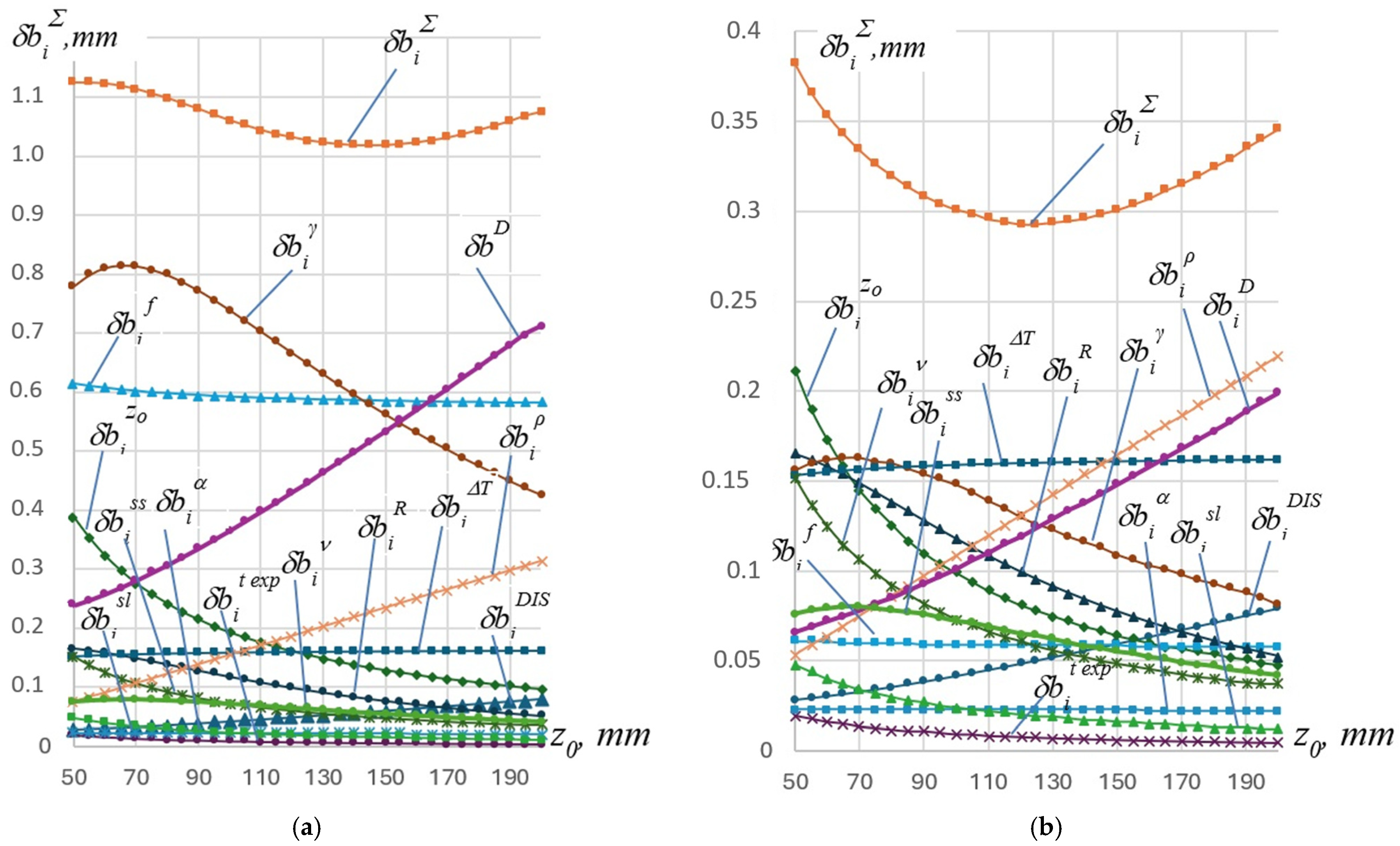

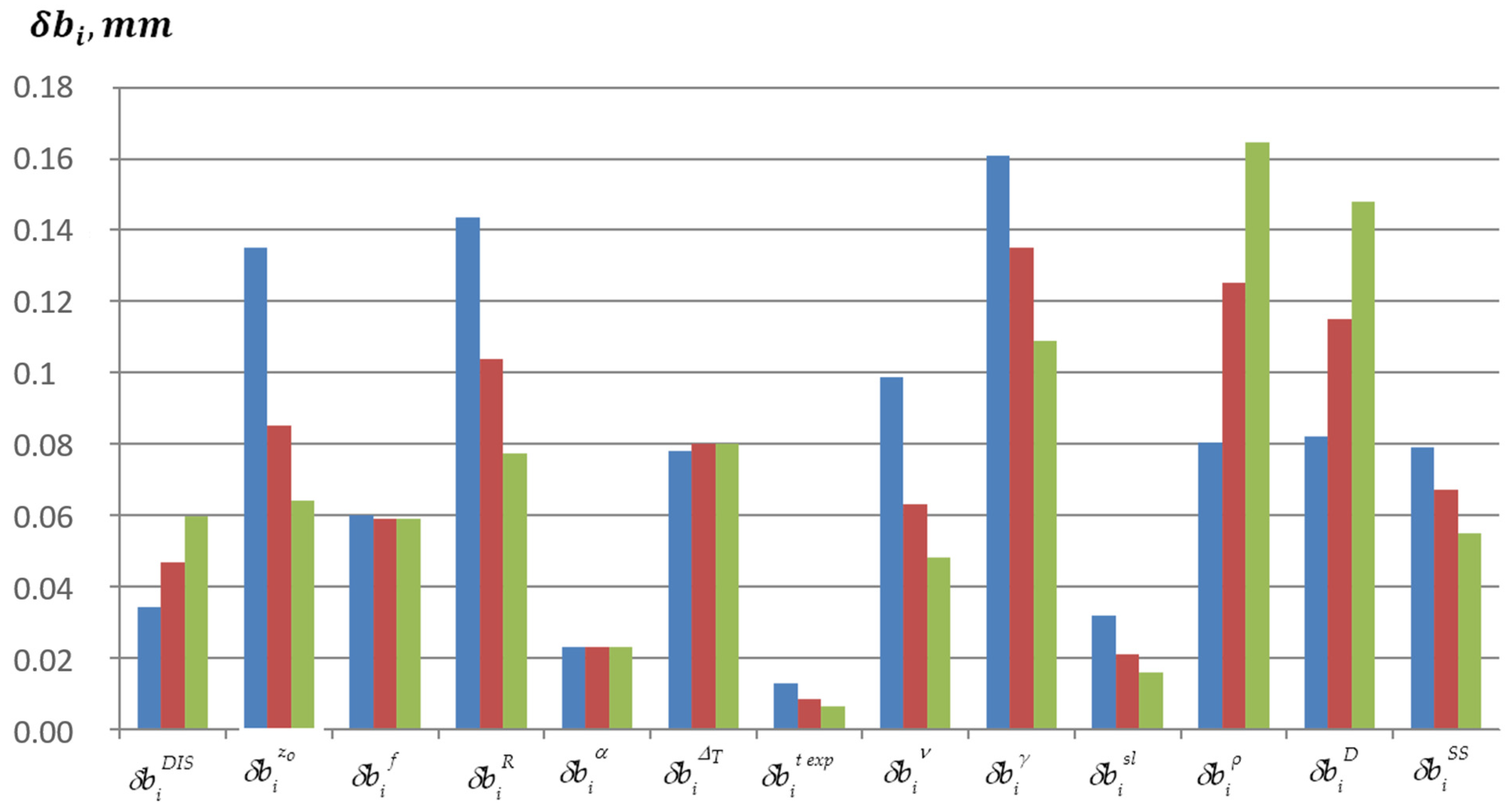

4. Analysis of the Impact of Components on the Total Error in Determining the Blade Chord Length

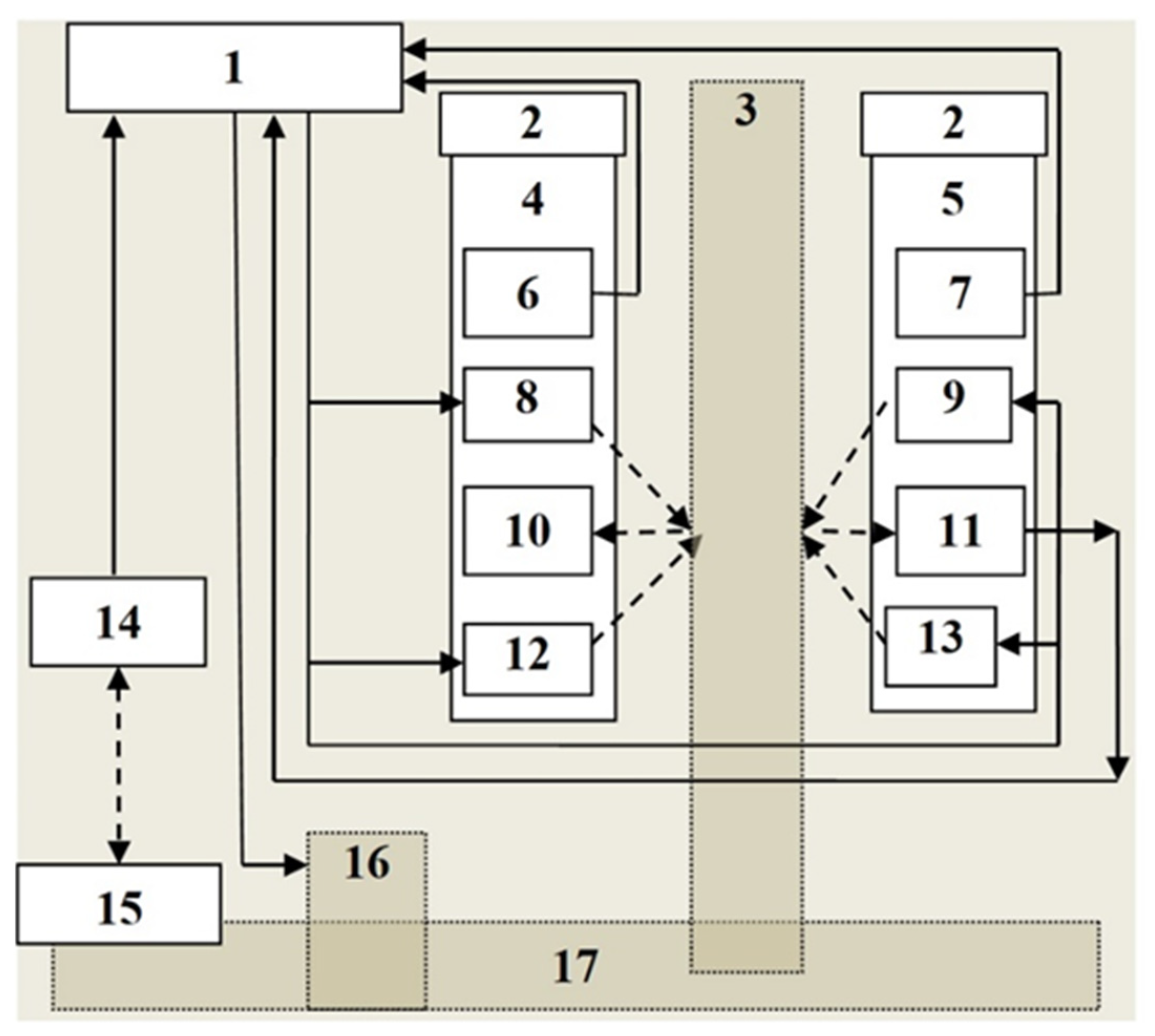

4.1. Model for Information Processing

- Changes in the measured value during measurement transformations;

- Geometric noise of the photodetector;

- Variations in the brightness of the illumination sources due to changes in ambient temperature;

- Changes in the sensitivity of the photodetector with temperature variations;

- Changes in the power of the illumination sources due to temporal degradation.

- Error due to the deviation in .

- Error due to the deviation in the controlled section radius .

- Error due to the video probe line of sight deviation from the normal to the blade motion plane .

- distance setting accuracy of no more than 0.05 mm.

- An angle orientation accuracy for the video probe of no more than .

- Implementation of software-adaptive and differential illumination of the leading and trailing edges.

- The system can be calibrated using a test object as a transparent grid.

- Compensation techniques that account for temperature-induced deformation of the system casing.

4.2. Results of Total Error Reduction Procedures and Analysis

- Focal length: .

- Nominal chord length: .

- Exposure time: .

- Controlled section radius: .

- Viewing angle: .

- Rotational speed: .

- Pixel size: .

- Frame rate: .

- Signal-to-noise ratio: .

- Focal length error: .

- Rotational speed error: .

- Distance deviation: .

- Controlled section radius deviation: .

- Error due to the video probe line of sight deviation from the normal to the blade motion plane ().

- Error caused by changes in the reflection coefficient of the blade surface ().

- Error caused by lens distortion of the video probe ().

- Error due to the deviation in the controlled section radius ().

- Error due to distance deviation ().

- Error due to temperature deformation of the video probe casing ().

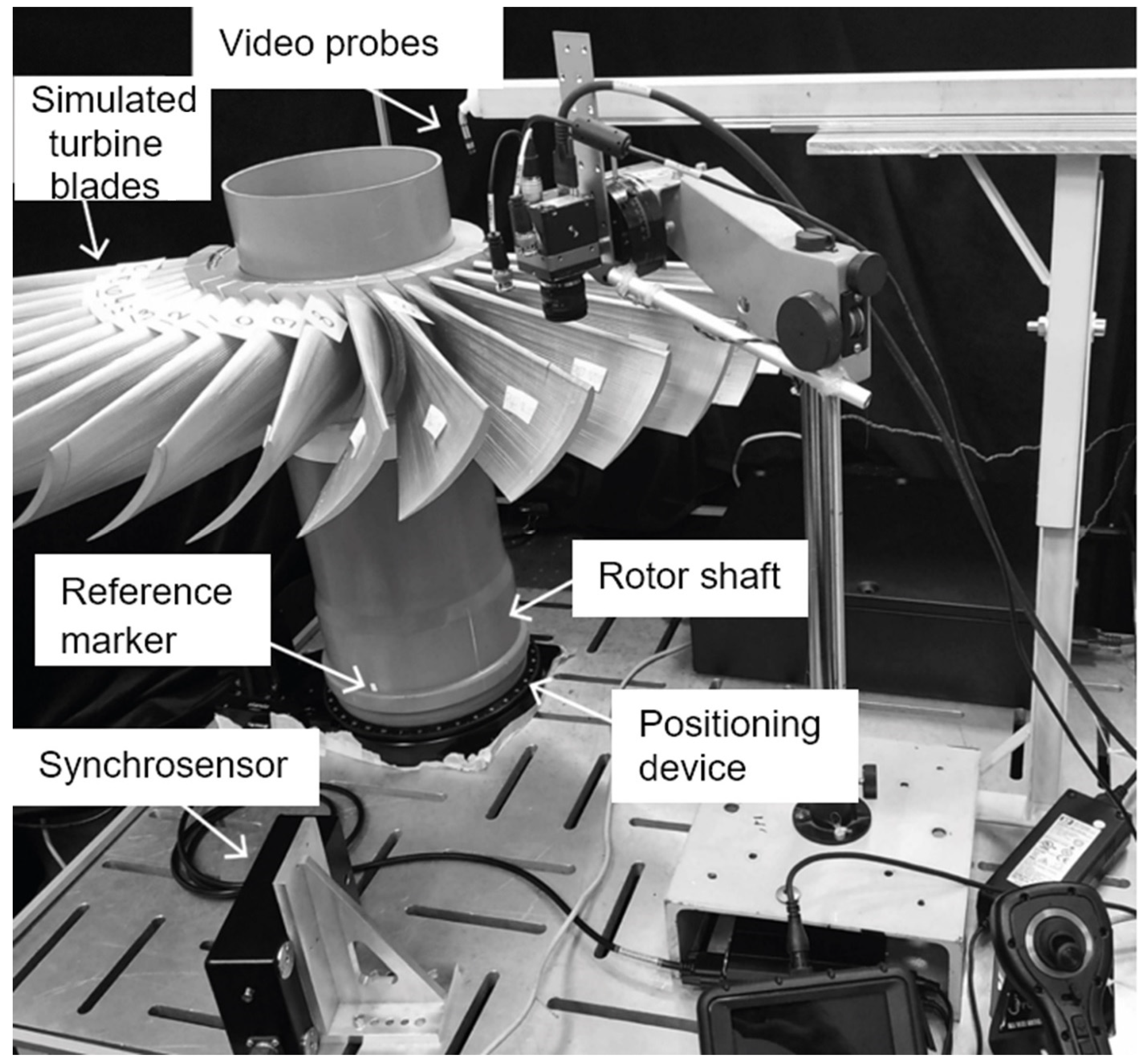

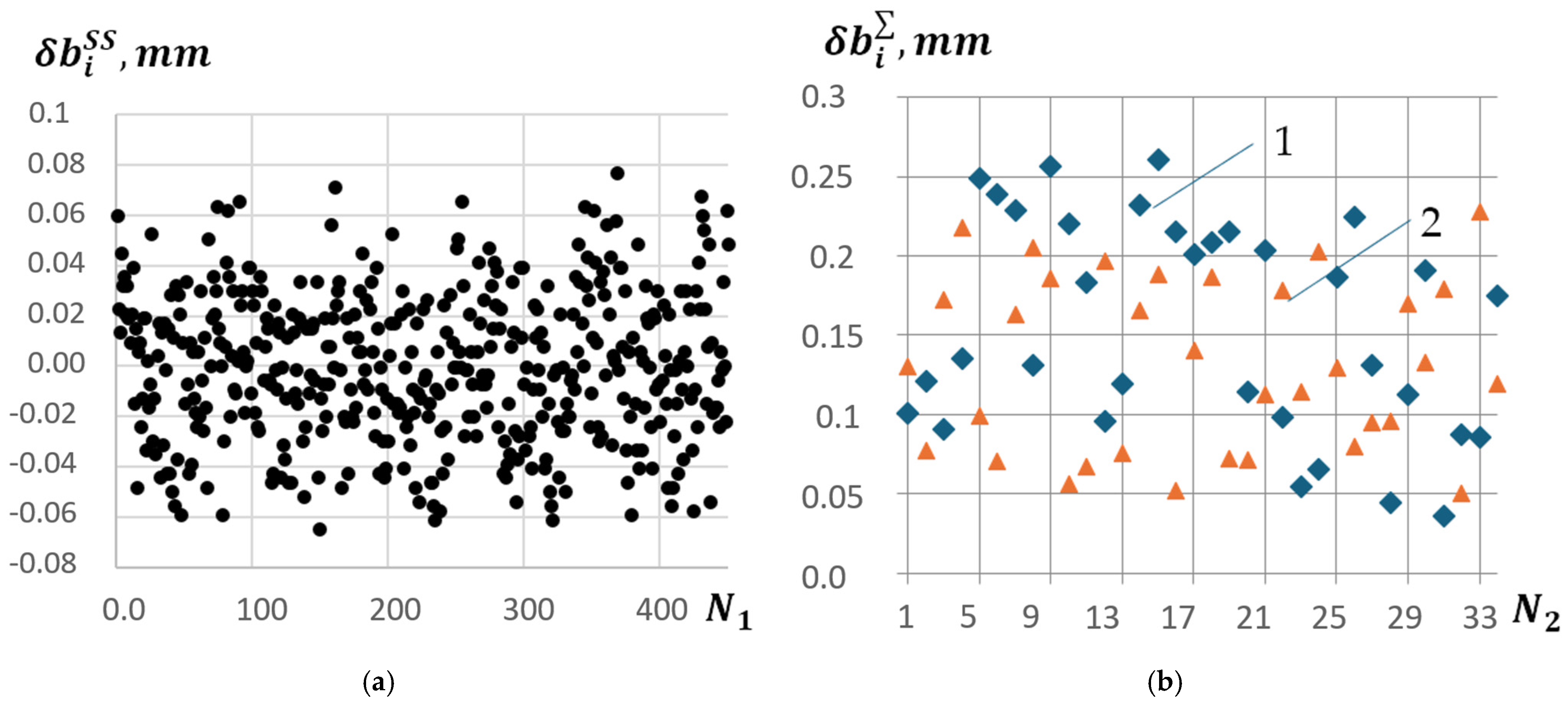

5. Experimental Studies of the System Prototype

- A total of 36 mock blades (3) with a nominal chord length of , uniformly mounted on a mock rotor shaft (17).

- The rotor shaft was coupled with the rotary part of a Standa 8MRB240-152-59 (OOO TD Alliance Forest, Saint Petersburg, Russia) stage (16).

- A flexible video probe (4) based on a SATEKO ME-0-FT2A2S-6.0-X endoscope (Sateco MTO LLC, Saint Petersburg, Russia).

- A rigid video probe (5) based on a Megeon 3325 endoscope (OOO NPP ANALYTROPROMPRIBOR, Moscow, Russia) without articulation capability.

- Computer: Acer Nitro 5 AN515-54-52N7 laptop, Intel Core i5 9300H 2400 MHz.

- Video probe positioning devices: enabled accurate placement and alignment of the video probes.

- Blade mock-up: simulated the geometry and dimensions of the turbine blades.

- Flexible video probe: SATEKO ME-0-FT2A2S-6.0-X endoscope.

- Rigid video probe: Megeon 3325 endoscope without articulation.

- Thermal sensor 1: DS18B20, used for temperature measurement.

- Thermal sensor 2: DS18B20, positioned to monitor environmental or system-specific temperature variations.

- Pulse illumination source 1: Cree XLamp XQ-E High-Density LED for blade edge imaging.

- Pulse illumination source 2: Cree XLamp XQ-E High-Density LED.

- Camera of flexible video probe: captured images transmitted by the flexible probe.

- The camera of the rigid video probe: captured images transmitted by the rigid probe.

- Pulse illumination source 3: Cree XLamp XQ-E High-Density LED.

- Pulse illumination source 4: Cree XLamp XQ-E High-Density LED.

- Synchrodetector: ODY A44A5-49N-25C2 synchronized video probe imaging and illumination timing.

- Mirror marker: assisted with calibration and alignment of the imaging system.

- Rotational stage: Standa 8MRB240-152-59 facilitated precise rotation of the mock rotor.

- Mock rotor shaft: represented the shaft structure in the turbine blade apparatus.

- In static conditions on the model with the Megion 3325 video probe, and on the model with the SATEKO ME-0-FT2A2S-6.0-X video probe, ;

- In dynamic conditions at a rotation speed of with the Megion 3325 video probe, (Figure 7b), and on the model with the SATEKO ME-0-FT2A2S-6.0-X video probe, .

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Nazolin, A. Prevention of Accidents and Catastrophes in Rotating Equipment of Critical and Strategically Important Technosphere Facilities; Russian Academy of Sciences: Moscow, Russia, 2017. (In Russian) [Google Scholar]

- Liu, X.; Han, X.; Yin, G.; Song, X.; Cui, L. Design and Processing of Gas Turbine Blades Based on Additive Manufacturing Technology. Micromachines 2023, 14, 1675. [Google Scholar] [CrossRef] [PubMed]

- Yang, L.-J.; Tasupalli, C.; Wang, W.-C.; Lee, C.-Y.; Lee, C.-Y.; Athikary, K.G.; Wu, J.-X. Initial Study of the Onsite Measurement of Flow Sensors on Turbine Blades (SOTB). Micromachines 2024, 15, 877. [Google Scholar] [CrossRef] [PubMed]

- Peng, Y.; Xu, G.; Luo, X.; He, J.; Liu, D. Particle Deposition in the Vicinity of Multiple Film Cooling Holes. Micromachines 2022, 13, 523. [Google Scholar] [CrossRef] [PubMed]

- Bolat, F.C.; Sivrioglu, S. Active Control of a Small-Scale Wind Turbine Blade Containing Magnetorheological Fluid. Micromachines 2018, 9, 80. [Google Scholar] [CrossRef] [PubMed]

- Berci, G.; Forde, K.A. History of endoscopy. Surg. Endosc. 2000, 14, 5–15. [Google Scholar] [CrossRef] [PubMed]

- Shut, G.A.; Korotaev, V.V.; Puzyrev, E.I.; Ryzhova, V.A.; Timofeev, A.N.; Akhmerov, A.K.; Rodikova, L.S. Videoendoscopy of working blades of steam turbines and control of their geometrical parameters. J. Opt. Technol. 2020, 87, 677–683. [Google Scholar] [CrossRef]

- Lee, J.M.; Hwang, Y. A novel online rotor condition monitoring system using fiber Bragg grating (FBG) sensors and a rotary optical coupler. Meas. Sci. Technol. 2008, 19, 065303. [Google Scholar] [CrossRef]

- Pesatori, A.; Norgia, M.; Svelto, C. Optical Instrument for Real Time Monitoring of Steam Turbine Grinding. In Proceedings of the IEEE Instrumentation and Measurement Technology Conference, Ottawa, ON, Canada, 16–19 May 2008; pp. 1952–1955. [Google Scholar]

- Rodikova Liliana, S.; Viktorovich, K.V.; Timofeev, A.N.; Ryzhova, V.A.; Maraev, A. Selection of parameters of optoelectronic systems for monitoring the wear for steam turbine rotor blading based on the value of the total error. J. Sci. Tech. Inf. Technol. Mech. Opt. 2024, 24, 171–181. (In Russian) [Google Scholar] [CrossRef]

- Pesatori, A.; Norgia, M.; Svelto, C.; Pignone, E. Optical barrier and 4-quadrant imaging for contact-less detection of geometrical dimension of a steam turbine. In Proceedings of the IEEE International Workshop on Imaging Systems and Techniques, Chania, Greece, 10–12 September 2008; pp. 119–122. [Google Scholar]

- Simonov, V.; Kuzin, A. Optoelectronic vibration measurement system. In Proceedings of the 20th International Congress on Instrumentation in Aerospace Simulation Facilities, ICIASF’03, Gottingen, Germany, 25–29 August 2003; pp. 105–109. [Google Scholar]

- Procházka, P.; Vaněk, F. Contactless Diagnostics of Turbine Blade Vibration and Damage. J. Phys. Conf. Ser. 2011, 305, 011001. [Google Scholar] [CrossRef]

- Anisimov, A.; Gorbachyov, A.; Krasnyashchikh, A.; Pantushin, A.; Timofeev, A. Design and test of optoelectronic system of alignment control based on CCD camera. In Proceedings of the Fifth International Symposium on Instrumentation Science and Technology, Shenyang, China, 15–18 September 2008; SPIE: Bellingham, WA, USA; Volume 7133. [Google Scholar] [CrossRef]

- Pankov, E.; Prokofiev, A.; Tymofeev, A. Autocollimational optoelectronic system for monitoring of the position of elements of turbine aggregates. In Proceedings of the Second International Conference on Lasers for Measurement and Information Transfer, St. Petersburg, Russia, 6–8 June 2001; SPIE: Bellingham, WA, USA, 2002; Volume 4680. [Google Scholar]

- Leiner, D. Digital Endoscope Design; SPIE: Bellingham, WA, USA, 2015; Volume SL10. [Google Scholar]

- Geng, J.; Xie, J. Review of 3-D Endoscopic Surface Imaging Techniques. IEEE Sens. J. 2014, 14, 945–960. [Google Scholar] [CrossRef]

- Chichigin, B.; Groo, I. Development of a Compact High-Speed Measuring Defectoscopy System and Its Testing on Mock-Up Objects. Radiotekhnika Elektron. Radioengineering Electron. 2022, 67, 668–675. (In Russian) [Google Scholar]

- Lei, Y.; Cheng, Y.; Miller, S. A Flexible Endoscopic Machining Tool. Energy Procedia 2012, 16, 1033–1040. [Google Scholar] [CrossRef][Green Version]

- Yong, Y.; Guiju, S.; Kevin, H. 3D Tracking for borescope inspections. In Proceedings of the SPIE Sensing Technology + Applications, Baltimore, MD, USA, 20–24 April 2015; SPIE: Bellingham, WA, USA, 2015. [Google Scholar] [CrossRef]

- Khaimov, V.; Kokin, E.; Puzyrev, E. Implementation of an Operational Monitoring and Diagnostic System for Erosion Wear of Blades in Powerful Steam Turbines. Energeticheskiye Stantsii Power Plants 2006, 12, 32–36. (In Russian) [Google Scholar]

- UES of Russia RAO. RD 153-34.1-17.462-00 Procedural Guidelines Assessment of Serviceability of Steam Turbine Blades in the Process of Manufacturing, Operation, and Repair; UES of Russia RAO: Moscow, Russia, 2000. [Google Scholar]

- Khaimov, V. Low-Flow Operating Modes of the Low-Pressure Cylinder of the T-250/300-240 Turbine; BHV-Petersburg: St. Petersburg, Russia, 2007; p. 240. (In Russian) [Google Scholar]

- Shut, G.; Puzyrev, E.; Vasiliev, V.A.A.; Nekrylov, I.; Akhmerov, A.; Timofeev, A. Comprehensive Endoscopy System for Monitoring Erosion Wear of Steam Turbine Blades. Izv. Vuzov. Priborostroenie High. Educ. Inst. Bull. Instrum. 2020, 63, 228–237. [Google Scholar]

- Leach, R. Abbe Error/Offset. In The International Academy for Production Engineering, CIRP Encyclopedia of Production Engineering; Laperrière, L.R.G., Ed.; Springer: Berlin/Heidelberg, Germany, 2014. [Google Scholar]

- Yakushenkov, Y. Theory and Calculation of Optoelectronic Devices: Textbook; Logos: Moscow, Russia, 2018. (In Russian) [Google Scholar]

- Salzenstein, P.; Pavlyuchenko, E. Uncertainty Evaluation on a 10.52 GHz (5 dBm) Optoelectronic Oscillator Phase Noise Performance. Micromachines 2021, 12, 474. [Google Scholar] [CrossRef] [PubMed]

- Sarvin, A. Systems for Contactless Measurement of Geometric Parameters; Leningrad State University: St. Petersburg, Russia, 1983. (In Russian) [Google Scholar]

- Bouguet, J.-Y. Camera Calibration Toolbox for Matlab. Available online: http://www.vision.caltech.edu/bouguetj/calib_doc/index.html (accessed on 7 January 2025).

- Shavrygina, M.; Konyakhin, I.; Timofeev, A.; Verezhinskaia, E. Optical-electronic system controlling the position of a railway track with the help of reference marks. In Proceedings of the Optical Modelling and Design IV, Brussels, Belgium, 5–7 April 2016; SPIE: Bellingham, WA, USA, 2016. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Korotaev, V.V.; Rodikova, L.S.; Timofeev, A.N.; Ryzhova, V.A.; Yarishev, S.N.; Djamiykov, T.S.; Marinov, M.B. An Optoelectronic System for the Online Monitoring of the Chord Length of Steam Turbine Rotor Blades for Early Fault Detection. Machines 2025, 13, 174. https://doi.org/10.3390/machines13030174

Korotaev VV, Rodikova LS, Timofeev AN, Ryzhova VA, Yarishev SN, Djamiykov TS, Marinov MB. An Optoelectronic System for the Online Monitoring of the Chord Length of Steam Turbine Rotor Blades for Early Fault Detection. Machines. 2025; 13(3):174. https://doi.org/10.3390/machines13030174

Chicago/Turabian StyleKorotaev, Valery V., Liliana S. Rodikova, Alexandr N. Timofeev, Victoria A. Ryzhova, Sergey N. Yarishev, Todor S. Djamiykov, and Marin B. Marinov. 2025. "An Optoelectronic System for the Online Monitoring of the Chord Length of Steam Turbine Rotor Blades for Early Fault Detection" Machines 13, no. 3: 174. https://doi.org/10.3390/machines13030174

APA StyleKorotaev, V. V., Rodikova, L. S., Timofeev, A. N., Ryzhova, V. A., Yarishev, S. N., Djamiykov, T. S., & Marinov, M. B. (2025). An Optoelectronic System for the Online Monitoring of the Chord Length of Steam Turbine Rotor Blades for Early Fault Detection. Machines, 13(3), 174. https://doi.org/10.3390/machines13030174