Artificial Neural Network-Based Structural Analysis of 3D-Printed Polyethylene Terephthalate Glycol Tensile Specimens

Abstract

1. Introduction

2. Material and Methods

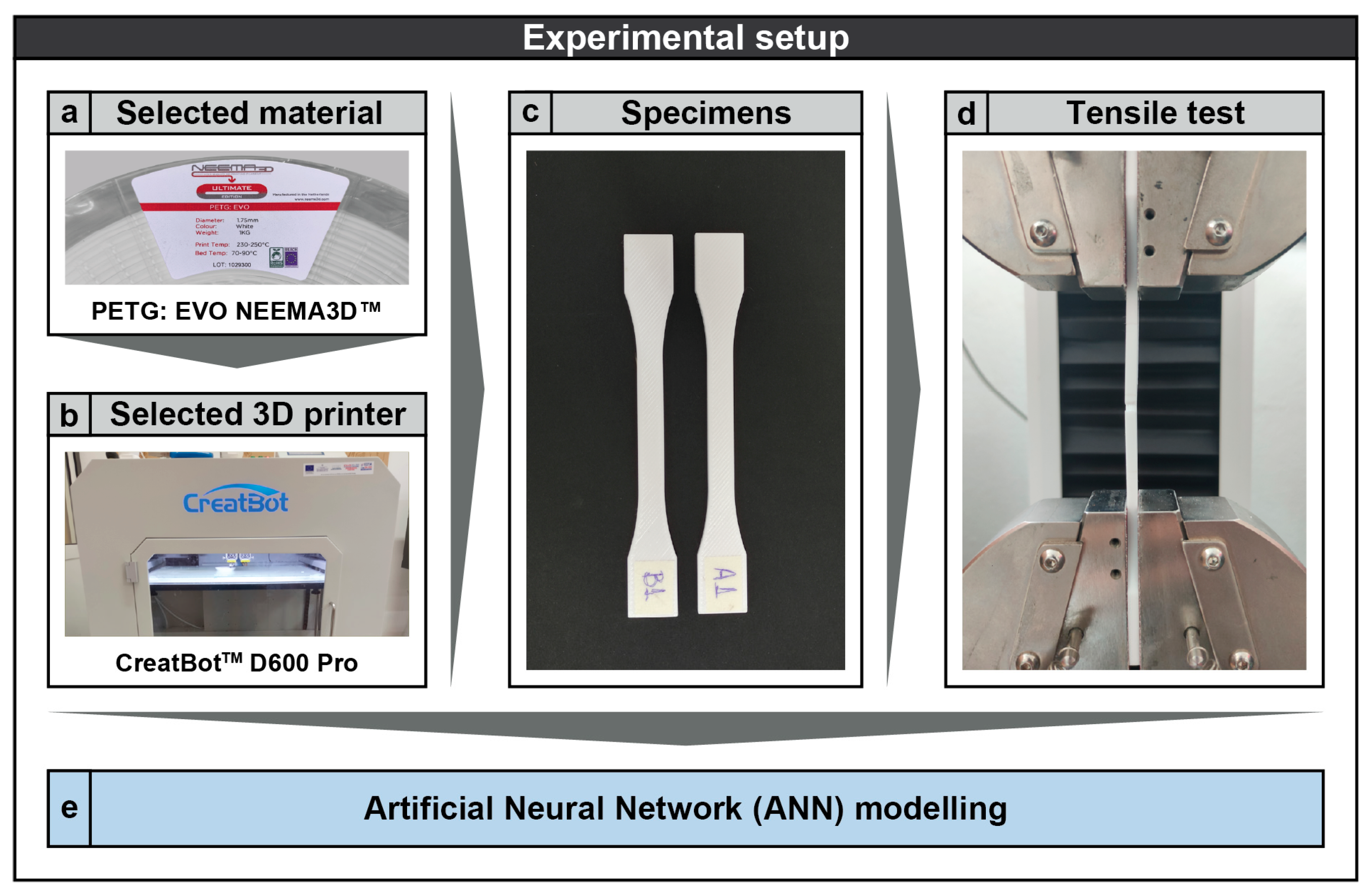

2.1. Study Workflow

- (a)

- Selected material;

- (b)

- Selected 3D printer;

- (c)

- Specimens;

- (d)

- Tensile test;

- (e)

- Artificial Neural Network (ANN) modeling.

- (a)

- The material chosen in the study was PETG: EVO (NEEMA3D™, Athens, Greece). It is a polyethylene terephthalate glycol polymer with a filament diameter of 1.75 mm. According to the manufacturer, the tensile strength is measured at 50 MPa, while its net weight is 1.27 g/cc.

- (b)

- The 3D printer used in the study was the CreatBotTM D600 Pro (Henan Creatbot Technology Limited, Zhengzhou, China). The printing area is relatively large (X = 600 mm, Y = 600 mm, and Z = 600 mm). This particular printer is of the closed type; as a result, it maintains stable conditions during printing. A significant advantage over smaller printers is that the large printing area allows for the construction of all specimens at the same time.

- (c)

- Based on three different values for each of the three printing parameters, 27 different specimens were constructed. Each specimen used a different combination of values of the variable parameters. For the increased reliability of the study, the 27 specimens with different combinations were printed twice so that the measurement results could be evaluated according to the average of each pair.

- (d)

- The printed specimens were tested in tensile stress to measure their strength. Specifically, the InstronTM 3345 universal testing machine (Instron, Norwood, MA, USA) was used in the tests. The maximum tension that the machine can exert is 5 kN, while the available space for specimens has a height of 1123 mm. According to the manufacturer, the maximum and minimum speed of the grips are 500 mm/min and 0.05 mm/min, respectively.

- (e)

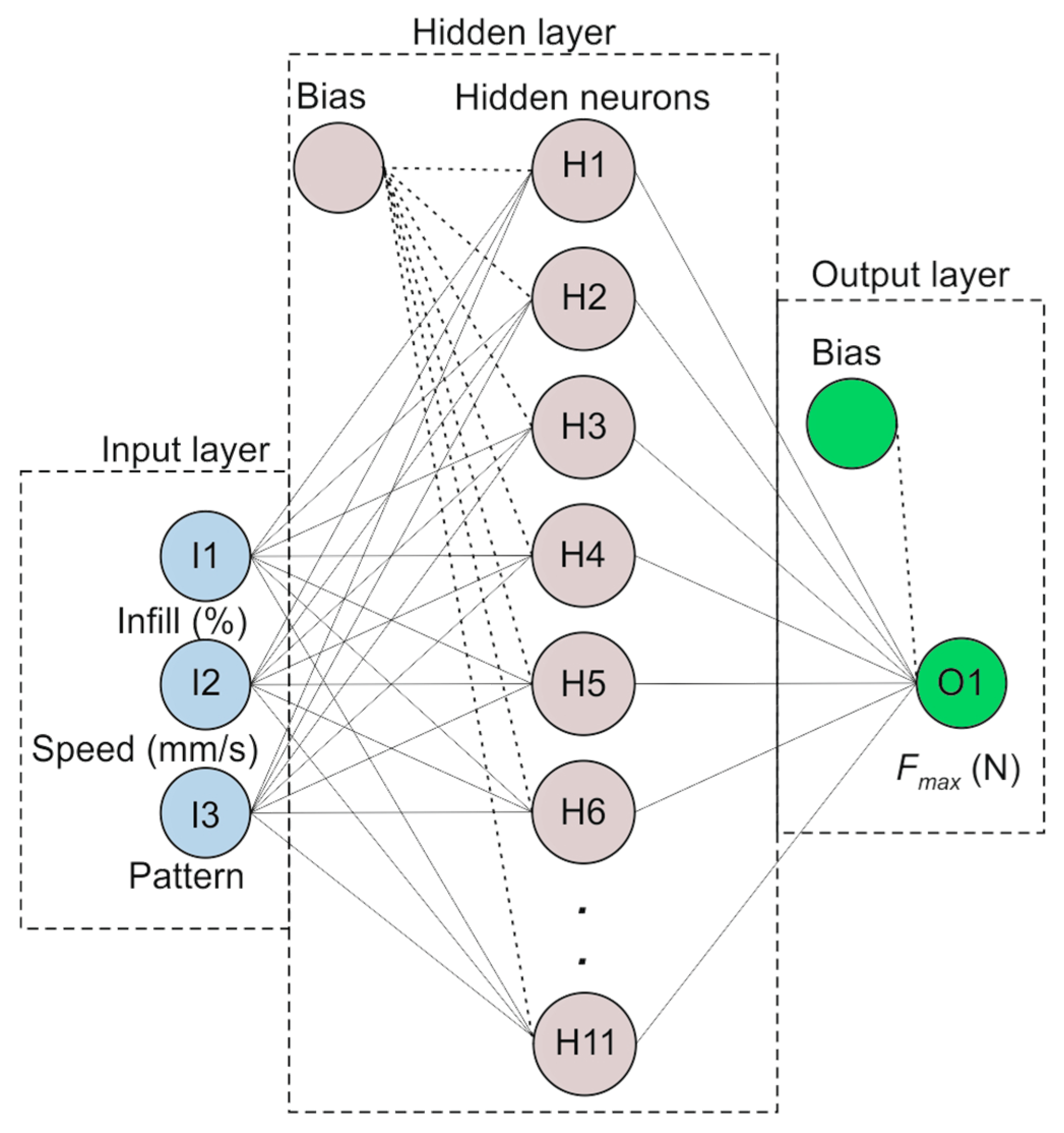

- The results of the tensile tests were evaluated using an Artificial Neural Network (ANN) model. ANNs are structures used for processing parallel distribution data. The mode of operation of this specific mathematical model is based on the mode of operation of the human brain. ANN modeling accepts data, processes them, and finally outputs the results of the analysis.

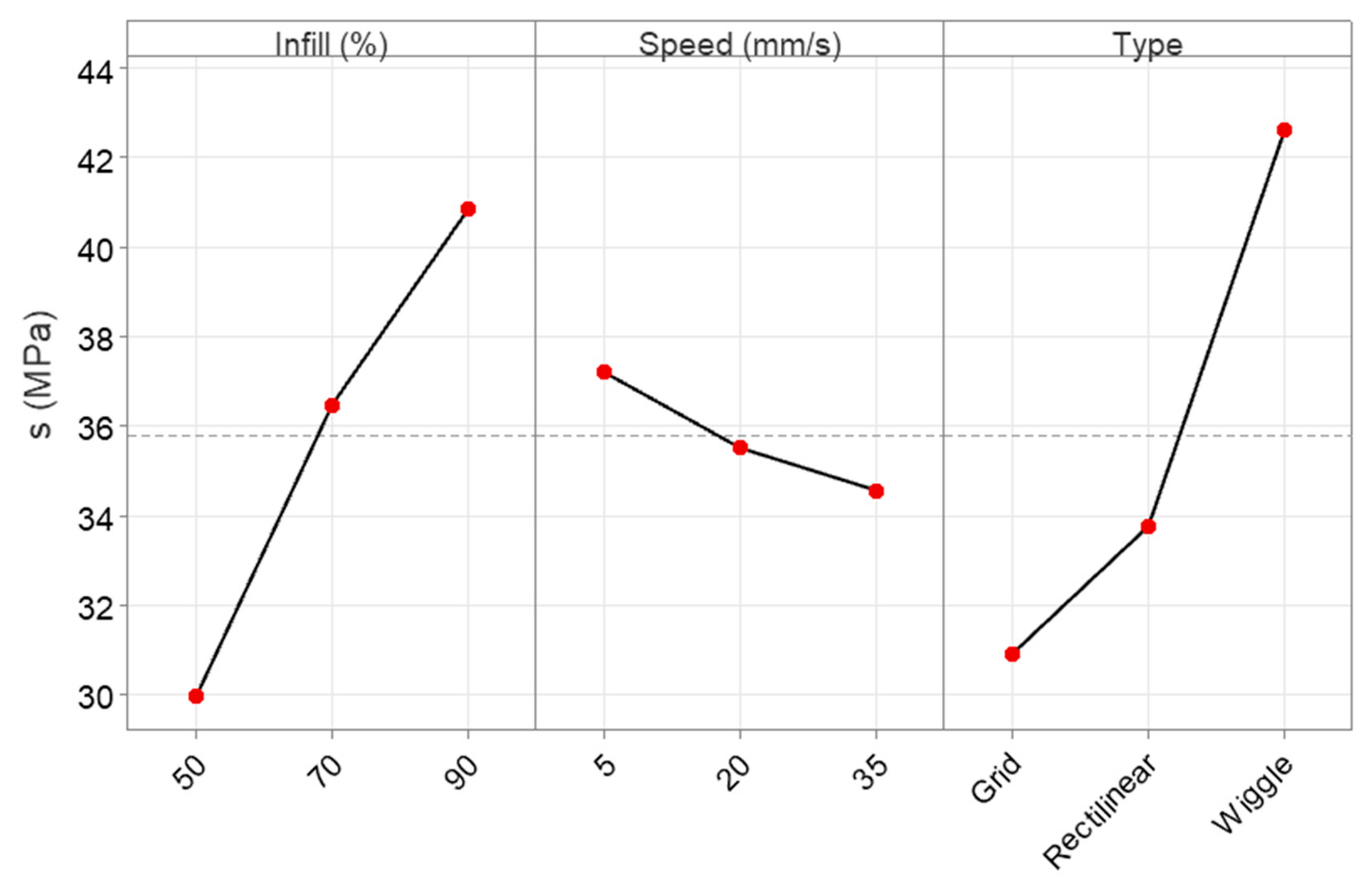

- The Infill parameter expresses the filling percentage of the printed specimens. A specimen with a full filling percentage is defined with a value of 100%. The values used in the Infill parameter were 50%, 70%, and 90%.

- The Speed parameter expresses the speed at which the nozzle will move when it extrudes the material; it is measured in millimeters per second (mm/s). The values used in the Speed parameter were 5 mm/s, 20 mm/s, and 35 mm/s.

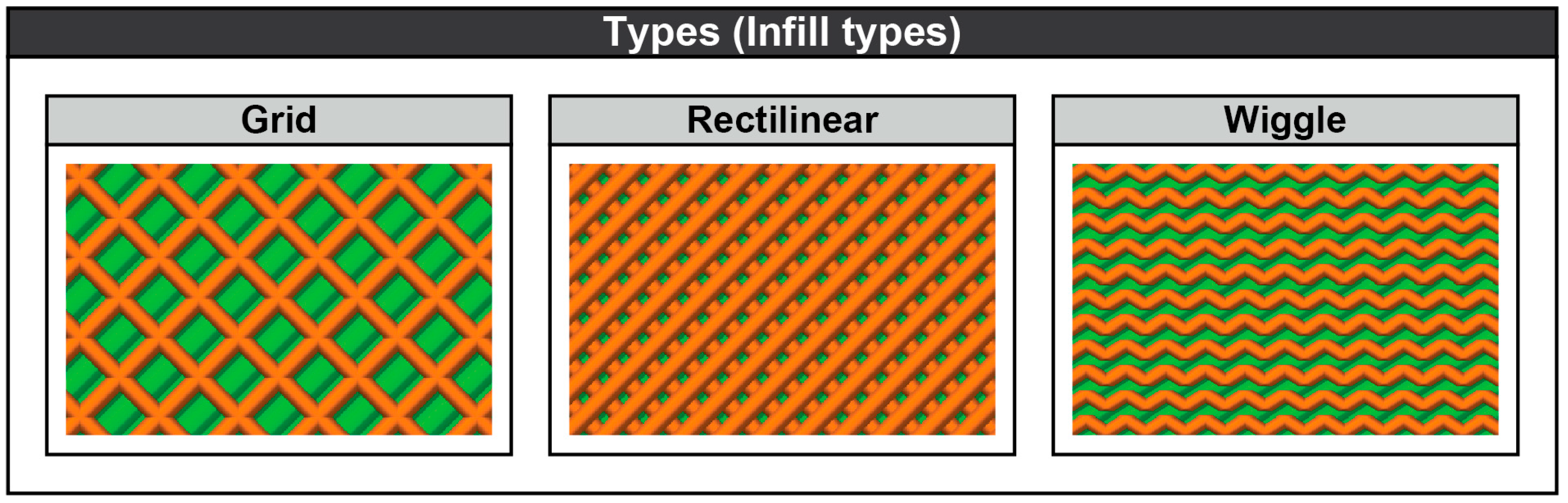

- The Type parameter expresses the type of Infill geometry. In this study, the types used were Grid, Rectilinear, and Wiggle.

2.2. ANN Modeling

3. Results and Discussion

3.1. Experimental Data

3.2. Shallow Network Development

4. Conclusions

- Both the Infill and the Type contribute the most to the response, followed by the Speed.

- Wiggle is the strongest infill pattern, yielding strength values of over 42 MPa.

- Higher Infill and lower printing speeds positively affect the response.

- The best combination was identified with 90% infill, 5 mm/s speed, and the Wiggle pattern. In this case, the strength was measured at 49.82 MPa.

- The worst combination was identified with 50% infill, 35 mm/s speed, and the Grid pattern. The strength was measured at 25.65 MPa.

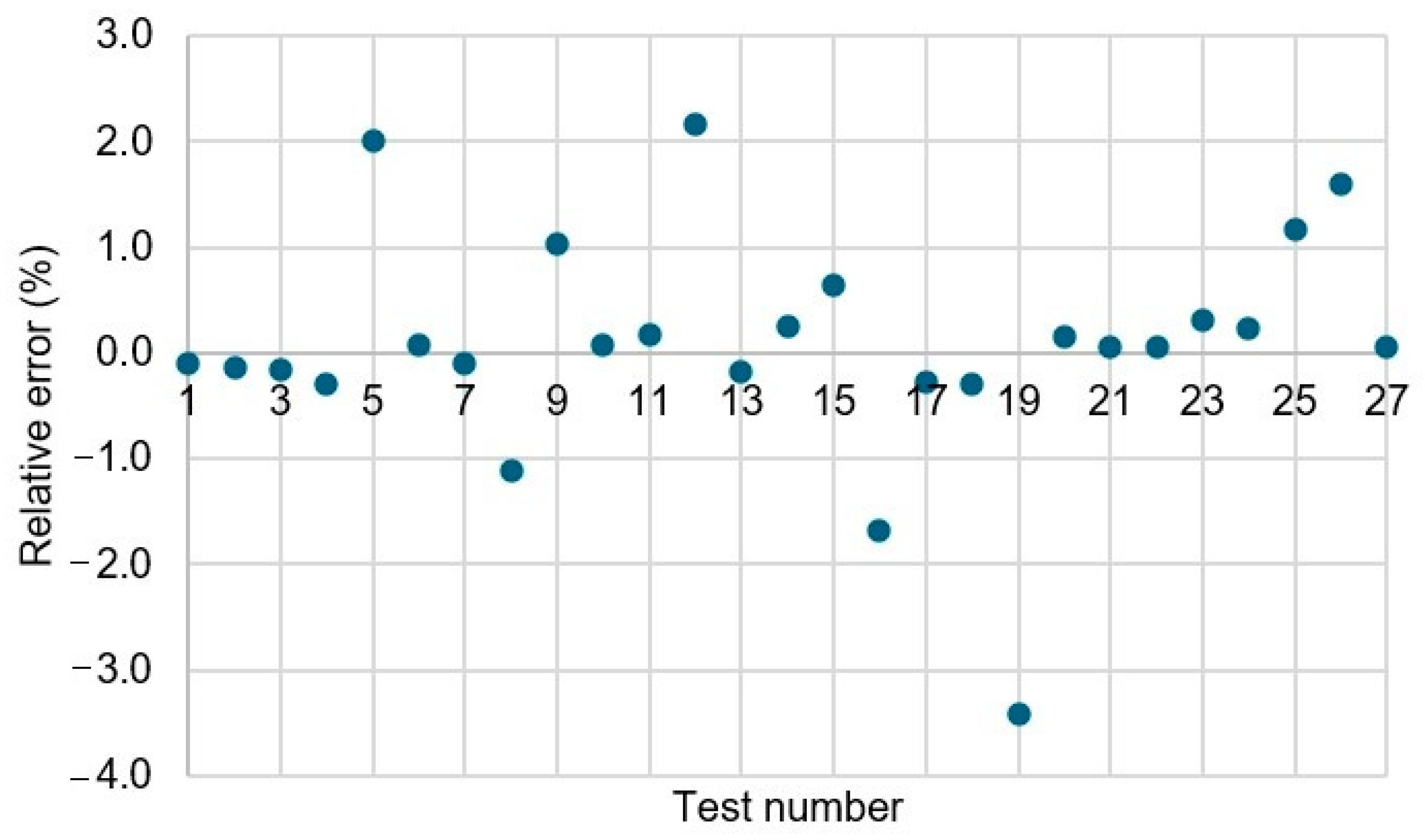

- The best ANN structure was determined to be the 3-11-1 configuration.

- The developed ANN model was proven to be accurate and robust, with the correlation coefficient for the summation of the data points being equal to 0.99859 and the relative error between the experimental and the predicted values of tensile strength being below 10%.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Firtikiadis, L.; Minaoglou, P.; Efkolidis, N.; Kyratsis, P. Slipper-sole computational design: A customer-based approach. In Proceedings of the VI International Scientific Conference in Contemporary Trends Innovations in the Textile Industry (CT&ITI 2023), Belgrade, Serbia, 14–15 September 2023. [Google Scholar]

- Manavis, A.; Minaoglou, P.; Tzetzis, D.; Efkolidis, N.; Kyratsis, P. Computational design technologies for interior designers: A case study. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1009, 012037. [Google Scholar] [CrossRef]

- Nicolau, A.; Pop, M.A.; Coșereanu, C. 3D printing application in wood furniture components assembling. Materials 2022, 15, 2907. [Google Scholar] [CrossRef] [PubMed]

- Žujović, M.; Obradović, R.; Rakonjac, I.; Milošević, J. 3D printing technologies in architectural design and construction: A systematic literature review. Buildings 2022, 12, 1319. [Google Scholar] [CrossRef]

- Yang, Y.; Dai, X.; Yang, B.; Zou, P.; Gao, F.; Duan, J.; Wang, C. Optimization of polylactic acid 3D printing parameters based on support vector regression and cuckoo search. Polym. Eng. Sci. 2023, 63, 3243–3253. [Google Scholar] [CrossRef]

- Tzotzis, A.; Manavis, A.; Efkolidis, N.; García-Hernández, C.; Kyratsis, P. Analysis of the Influence of Structural Characteristics on the Tensile Properties of Fused Filament Fabricated ABS Polymer Using Central Composite Design. Appl. Mech. 2023, 5, 20–35. [Google Scholar] [CrossRef]

- Wang, J.; Yang, B.; Lin, X.; Gao, L.; Liu, T.; Lu, Y.; Wang, R. 2020 Research of TPU materials for 3D printing aiming at non-pneumatic tires by FDM method. Polymers 2020, 12, 2492. [Google Scholar] [CrossRef]

- Atakok, G.; Kam, M.; Koc, H.B. Tensile, three-point bending and impact strength of 3D printed parts using PLA and recycled PLA filaments: A statistical investigation. J. Mater. Res. Technol. 2022, 18, 1542–1554. [Google Scholar] [CrossRef]

- Anderson, I. Mechanical properties of specimens 3D printed with virgin and recycled polylactic acid. 3D Print. Addit. Manuf. 2017, 4, 110–115. [Google Scholar] [CrossRef]

- Bergaliyeva, S.; Sales, D.L.; Delgado, F.J.; Bolegenova, S.; Molina, S.I. Manufacture and characterization of polylactic acid filaments recycled from real waste for 3D printing. Polymers 2023, 15, 2165. [Google Scholar] [CrossRef]

- Kumar, R.; Singh, R.; Farina, I. On the 3D printing of recycled ABS, PLA and HIPS thermoplastics for structural applications. PSU Res. Rev. 2018, 2, 115–137. [Google Scholar] [CrossRef]

- Panneerselvam, T.; Raghuraman, S.; Vamsi Krishnan, N. Investigating mechanical properties of 3D-printed polyethylene terephthalate glycol material under fused deposition modeling. J. Inst. Eng. (India) Ser. C 2021, 102, 375–387. [Google Scholar] [CrossRef]

- Özen, A.; Abali, B.E.; Völlmecke, C.; Gerstel, J.; Auhl, D. Exploring the role of manufacturing parameters on microstructure and mechanical properties in fused deposition modeling (FDM) using PETG. Appl. Compos. Mater. 2021, 28, 1799–1828. [Google Scholar] [CrossRef]

- Hanon, M.M.; Marczis, R.; Zsidai, L. Anisotropy evaluation of different raster directions, spatial orientations, and fill percentage of 3D printed PETG tensile test specimens. Key Eng. Mater. 2019, 821, 167–173. [Google Scholar] [CrossRef]

- Özen, A.; Auhl, D.; Völlmecke, C.; Kiendl, J.; Abali, B.E. Optimization of manufacturing parameters and tensile specimen geometry for fused deposition modeling (FDM) 3D-printed PETG. Materials 2021, 14, 2556. [Google Scholar] [CrossRef] [PubMed]

- ISO 527-2; Plastics—Determination of Tensile Properties—Part 2: Test Conditions for Moulding and Extrusion Plastics. International Organization for Standardization: Geneva, Switzerland, 2012.

- ASTMD3039/D3039M-17; Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials. ASTM International: West Conshohocken, PA, USA, 2017.

- Dolzyk, G.; Jung, S. Tensile and fatigue analysis of 3D-printed polyethylene terephthalate glycol. J. Fail. Anal. Prev. 2019, 19, 511–518. [Google Scholar] [CrossRef]

- Mercado-Colmenero, J.M.; La Rubia, M.D.; Mata-Garcia, E.; Rodriguez-Santiago, M.; Martin-Doñate, C. Experimental and numerical analysis for the mechanical characterization of petg polymers manufactured with fdm technology under pure uniaxial compression stress states for architectural applications. Polymers 2020, 12, 2202. [Google Scholar] [CrossRef] [PubMed]

- ISO 604; Plastics—Determination of Compressive Properties. International Organization for Standardization: Geneva, Switzerland, 2002.

- Malyadri, T.; Sunkara, N.; Srinivasa Rao, M.S. Investigation on Mechanical Properties of 3D Printed PETG Material. In Recent Advances in Manufacturing Processes and Systems: Select Proceedings of RAM 2021; Springer: Singapore, 2022; pp. 571–582. [Google Scholar]

- Kumaresan, R.; Samykano, M.; Kadirgama, K.; Pandey, A.K.; Rahman, M.M. Effects of printing parameters on the mechanical characteristics and mathematical modeling of FDM-printed PETG. Int. J. Adv. Manuf. Technol. 2023, 128, 3471–3489. [Google Scholar] [CrossRef]

- Aberoumand, M.; Soltanmohammadi, K.; Soleyman, E.; Rahmatabadi, D.; Ghasemi, I.; Baniassadi, M.; Abrinia, K.; Baghani, M. A comprehensive experimental investigation on 4D printing of PET-G under bending. J. Mater. Res. Technol. 2022, 18, 2552–2569. [Google Scholar] [CrossRef]

- Durgashyam, K.; Reddy, M.I.; Balakrishna, A.; Satyanarayana, K.J.M.T.P. Experimental investigation on mechanical properties of PETG material processed by fused deposition modeling method. Mater. Today Proc. 2019, 18, 2052–2059. [Google Scholar] [CrossRef]

- Wang, K.; Shen, J.; Ma, Z.; Zhang, Y.; Xu, N.; Pang, S. Preparation and Properties of Poly (ethylene glycol-co-cyclohexane-1, 4-dimethanol terephthalate)/Polyglycolic Acid (PETG/PGA) Blends. Polymers 2021, 13, 452. [Google Scholar] [CrossRef]

- Szykiedans, K.; Credo, W.; Osiński, D. Selected mechanical properties of PETG 3-D prints. Procedia Eng. 2017, 177, 455–461. [Google Scholar] [CrossRef]

- Alarifi, I.M. Mechanical properties and numerical simulation of FDM 3D printed PETG/carbon composite unit structures. J. Mater. Res. Technol. 2023, 23, 656–669. [Google Scholar] [CrossRef]

- Valvez, S.; Silva, A.P.; Reis, P.N. Compressive behaviour of 3D-printed PETG composites. Aerospace 2022, 9, 124. [Google Scholar] [CrossRef]

- Valvez, S.; Silva, A.P.; Reis, P.N. Optimization of printing parameters to maximize the mechanical properties of 3D-printed PETG-based parts. Polymers 2022, 14, 2564. [Google Scholar] [CrossRef]

- Ranganathan, S.; Palanivelu, R. Enhancing the Tribological Properties PETG and CFPETG Composites Fabricated by FDM via Various Infill Density and Annealing; SAE Technical Paper No. 2020-28-0429; SAE International: Warrendale, PA, USA, 2020; pp. 1–7. [Google Scholar]

- Amza, C.G.; Zapciu, A.; Constantin, G.; Baciu, F.; Vasile, M.I. Enhancing mechanical properties of polymer 3D printed parts. Polymers 2021, 13, 562. [Google Scholar] [CrossRef] [PubMed]

- Zapciu, A.; Amza, C.G.; Baciu, F.; Vasile, M.I. Heat treatment of 3D printed polyethylene terephthalate glycol in a supporting powder bed. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1182, 012083. [Google Scholar] [CrossRef]

- Mercado–Colmenero, J.M.; Martin–Doñate, C. A novel geometric predictive algorithm for assessing compressive elastic modulus in MEX additive processes, based on part nonlinearities and layers stiffness, validated with PETG and PLA materials. Polym. Test. 2024, 133, 108389. [Google Scholar] [CrossRef]

- Sepahi, M.T.; Abusalma, H.; Jovanovic, V.; Eisazadeh, H. Mechanical properties of 3D-printed parts made of polyethylene terephthalate glycol. J. Mater. Eng. Perform. 2021, 30, 6851–6861. [Google Scholar] [CrossRef]

- Hsueh, M.H.; Lai, C.J.; Wang, S.H.; Zeng, Y.S.; Hsieh, C.H.; Pan, C.Y.; Huang, W.C. Effect of printing parameters on the thermal and mechanical properties of 3d-printed pla and petg, using fused deposition modeling. Polymers 2021, 13, 1758. [Google Scholar] [CrossRef] [PubMed]

- Ramírez-Revilla, S.; Camacho-Valencia, D.; Gonzales-Condori, E.G.; Márquez, G. Evaluation and comparison of the degradability and compressive and tensile properties of 3D printing polymeric materials: PLA, PETG, PC, and ASA. MRS Commun. 2023, 13, 55–62. [Google Scholar] [CrossRef]

- Top, N.; Şahin, İ.; Gökçe, H. Topology optimization for furniture connection part and production with 3d printer technology. In Proceedings of the XXIXth International Conference Research for Furniture Industry, Ankara, Türkiye, 19–20 September 2019; p. 671. [Google Scholar]

- Fu, C.W.; Song, P.; Yan, X.; Yang, L.W.; Jayaraman, P.K.; Cohen-Or, D. Computational interlocking furniture assembly. ACM Trans. Graph. (TOG) 2015, 34, 1–11. [Google Scholar] [CrossRef]

- Koyama, Y.; Sueda, S.; Steinhardt, E.; Igarashi, T.; Shamir, A.; Matusik, W. AutoConnect: Computational design of 3D-printable connectors. ACM Trans. Graph. (TOG) 2015, 34, 1–11. [Google Scholar] [CrossRef]

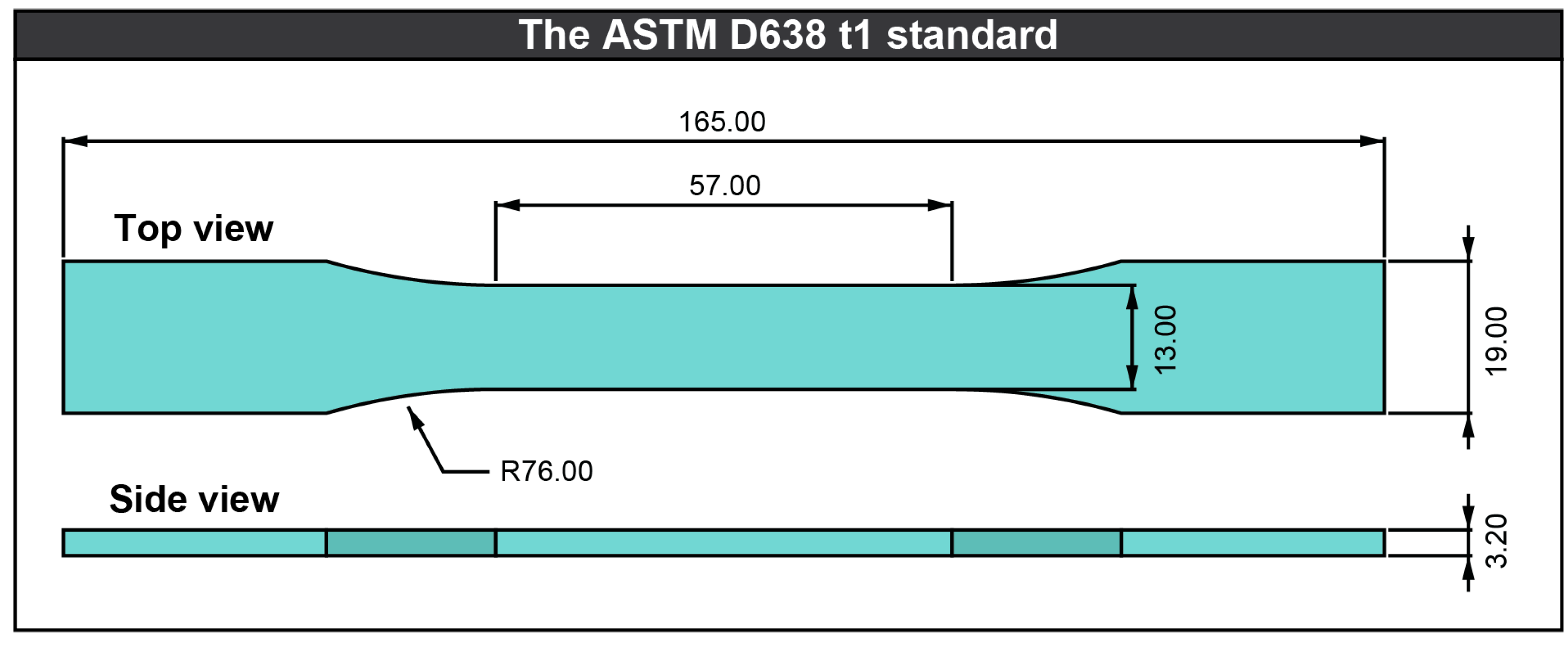

- ASTM D638-22; Standard Test Method for Tensile Properties of Plastics. American Society for Testing and Materials: West Conshohocken, PA, USA, 2022. Available online: https://www.astm.org/d0638-22.html (accessed on 14 November 2024).

- Çakar, T.; Cil, I. Artificial neural networks for design of manufacturing systems and selection of priority rules. Int. J. Comput. Integr. Manuf. 2004, 17, 195–211. [Google Scholar] [CrossRef]

- Mumali, F. Artificial neural network-based decision support systems in manufacturing processes: A systematic literature review. Comput. Ind. Eng. 2022, 165, 107964. [Google Scholar] [CrossRef]

- Nagarajan, H.P.; Mokhtarian, H.; Jafarian, H.; Dimassi, S.; Bakrani-Balani, S.; Hamedi, A.; Coatanéa, E.; Wang, G.G.; Haapala, K.R. Knowledge-based design of artificial neural network topology for additive manufacturing process modeling: A new approach and case study for fused deposition modeling. J. Mech. Des. 2019, 141, 021705. [Google Scholar] [CrossRef]

- Singh, J.; Goyal, K.K.; Kumar, R.; Gupta, V. Development of artificial intelligence-based neural network prediction model for responses of additive manufactured polylactic acid parts. Polym. Compos. 2022, 43, 5623–5639. [Google Scholar] [CrossRef]

- Lera, G.; Pinzolas, M. Neighborhood based Levenberg-Marquardt algorithm for neural network training. IEEE Trans. Neural Netw. 2002, 13, 1200–1203. [Google Scholar] [CrossRef] [PubMed]

- Tzotzis, A.; Nedelcu, D.; Mazurchevici, S.-N.; Kyratsis, P. Surface Quality Evaluation of 3D-Printed Carbon-Fiber-Reinforced PETG Polymer During Turning: Experimental Analysis, ANN Modeling and Optimization. Polymers 2024, 16, 2927. [Google Scholar] [CrossRef]

| Parameters | Value | Unit |

|---|---|---|

| Layer Height | 0.2 | mm |

| Extrusion Temperature | 240 | °C |

| Bed Temperature | 80 | °C |

| Cooling | 100 | % |

| Shell Thickness | 1.2 | mm |

| Support Structures | N/A | - |

| Parameters | Value 1 | Value 2 | Value 3 |

|---|---|---|---|

| Infill (%) | 50 | 70 | 90 |

| Speed (mm/s) | 5 | 20 | 35 |

| Type | Grid | Rectilinear | Wiggle |

| Infill (%) | Speed (mm/s) | Type | σA (MPa) | σB (MPa) | σ (MPa) | |

|---|---|---|---|---|---|---|

| 1 | 50 | 5 | Grid | 28.82 | 27.25 | 28.04 |

| 2 | 50 | 20 | Grid | 26.45 | 25.57 | 26.01 |

| 3 | 50 | 35 | Grid | 25.27 | 25.93 | 25.65 |

| 4 | 70 | 5 | Grid | 35.70 | 35.94 | 35.82 |

| 5 | 70 | 20 | Grid | 33.18 | 32.28 | 32.73 |

| 6 | 70 | 35 | Grid | 29.91 | 29.87 | 29.89 |

| 7 | 90 | 5 | Grid | 40.75 | 40.66 | 40.71 |

| 8 | 90 | 20 | Grid | 31.15 | 31.13 | 31.14 |

| 9 | 90 | 35 | Grid | 28.58 | 28.09 | 28.33 |

| 10 | 50 | 5 | Rectilinear | 26.21 | 28.42 | 27.32 |

| 11 | 50 | 20 | Rectilinear | 26.56 | 27.90 | 27.22 |

| 12 | 50 | 35 | Rectilinear | 27.05 | 27.81 | 27.42 |

| 13 | 70 | 5 | Rectilinear | 32.68 | 34.15 | 33.41 |

| 14 | 70 | 20 | Rectilinear | 31.12 | 32.25 | 31.68 |

| 15 | 70 | 35 | Rectilinear | 33.35 | 34.21 | 33.79 |

| 16 | 90 | 5 | Rectilinear | 42.63 | 42.11 | 42.37 |

| 17 | 90 | 20 | Rectilinear | 40.14 | 40.90 | 40.52 |

| 18 | 90 | 35 | Rectilinear | 39.67 | 40.83 | 40.25 |

| 19 | 50 | 5 | Wiggle | 34.08 | 34.28 | 34.18 |

| 20 | 50 | 20 | Wiggle | 38.77 | 35.33 | 37.06 |

| 21 | 50 | 35 | Wiggle | 37.96 | 35.65 | 36.80 |

| 22 | 70 | 5 | Wiggle | 44.81 | 41.76 | 43.28 |

| 23 | 70 | 20 | Wiggle | 45.78 | 42.63 | 44.19 |

| 24 | 70 | 35 | Wiggle | 44.49 | 42.78 | 43.62 |

| 25 | 90 | 5 | Wiggle | 51.56 | 48.11 | 49.82 |

| 26 | 90 | 20 | Wiggle | 50.83 | 47.51 | 49.16 |

| 27 | 90 | 35 | Wiggle | 44.65 | 46.23 | 45.43 |

| ANN Structure | R-Value |

|---|---|

| 3-6-1 | 0.95069 |

| 3-7-1 | 0.91986 |

| 3-8-1 | 0.96506 |

| 3-9-1 | 0.92851 |

| 3-10-1 | 0.73833 |

| 3-11-1 | 0.99859 |

| 3-12-1 | 0.94639 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Manavis, A.; Tzotzis, A.; Firtikiadis, L.; Kyratsis, P. Artificial Neural Network-Based Structural Analysis of 3D-Printed Polyethylene Terephthalate Glycol Tensile Specimens. Machines 2025, 13, 86. https://doi.org/10.3390/machines13020086

Manavis A, Tzotzis A, Firtikiadis L, Kyratsis P. Artificial Neural Network-Based Structural Analysis of 3D-Printed Polyethylene Terephthalate Glycol Tensile Specimens. Machines. 2025; 13(2):86. https://doi.org/10.3390/machines13020086

Chicago/Turabian StyleManavis, Athanasios, Anastasios Tzotzis, Lazaros Firtikiadis, and Panagiotis Kyratsis. 2025. "Artificial Neural Network-Based Structural Analysis of 3D-Printed Polyethylene Terephthalate Glycol Tensile Specimens" Machines 13, no. 2: 86. https://doi.org/10.3390/machines13020086

APA StyleManavis, A., Tzotzis, A., Firtikiadis, L., & Kyratsis, P. (2025). Artificial Neural Network-Based Structural Analysis of 3D-Printed Polyethylene Terephthalate Glycol Tensile Specimens. Machines, 13(2), 86. https://doi.org/10.3390/machines13020086