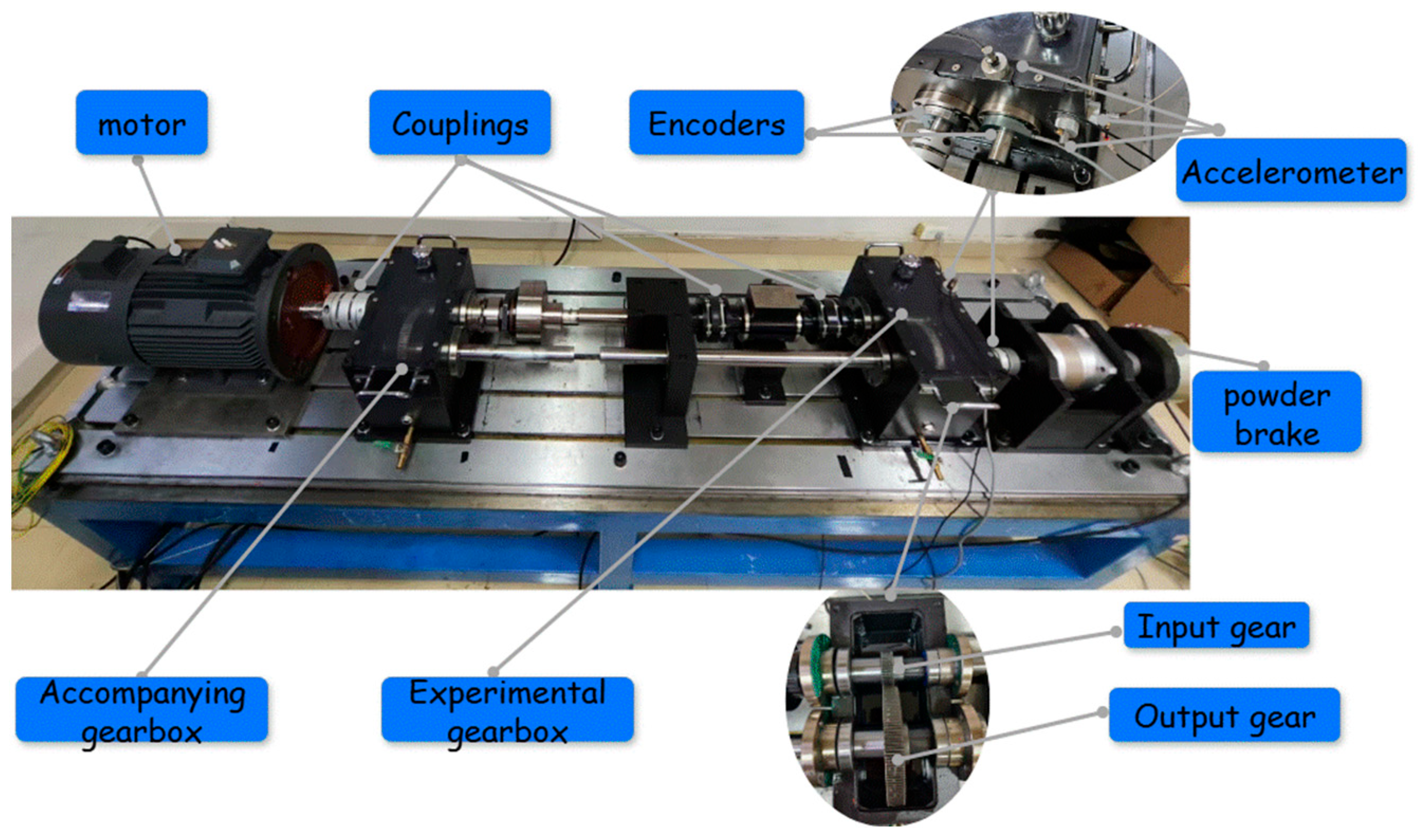

To validate the applicability of transmission error in gear fault diagnosis, an experimental gear transmission test rig was designed and implemented.

5.1. Platform Construction

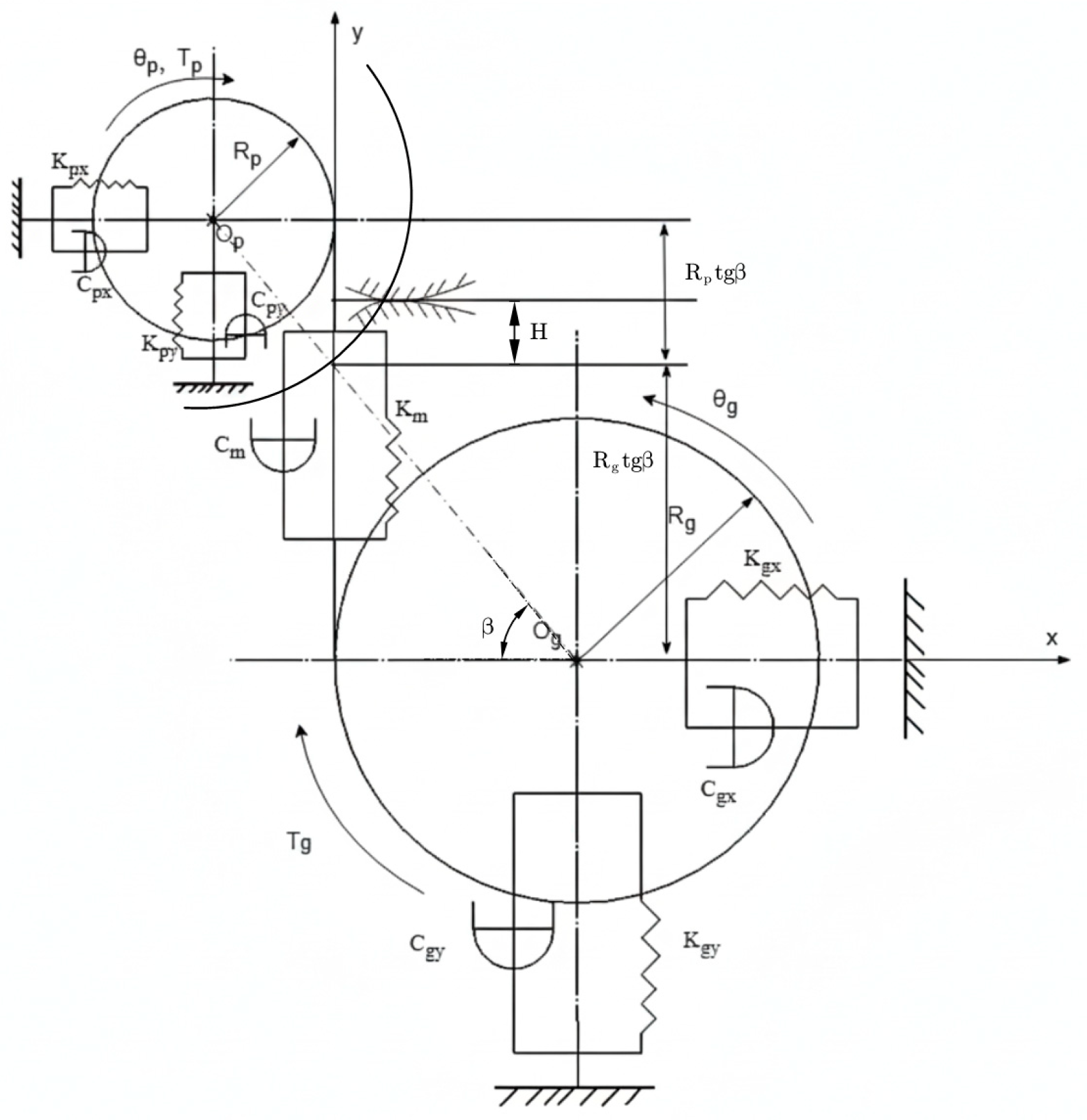

The layout of the spur gear experimental platform is shown in

Figure 22.

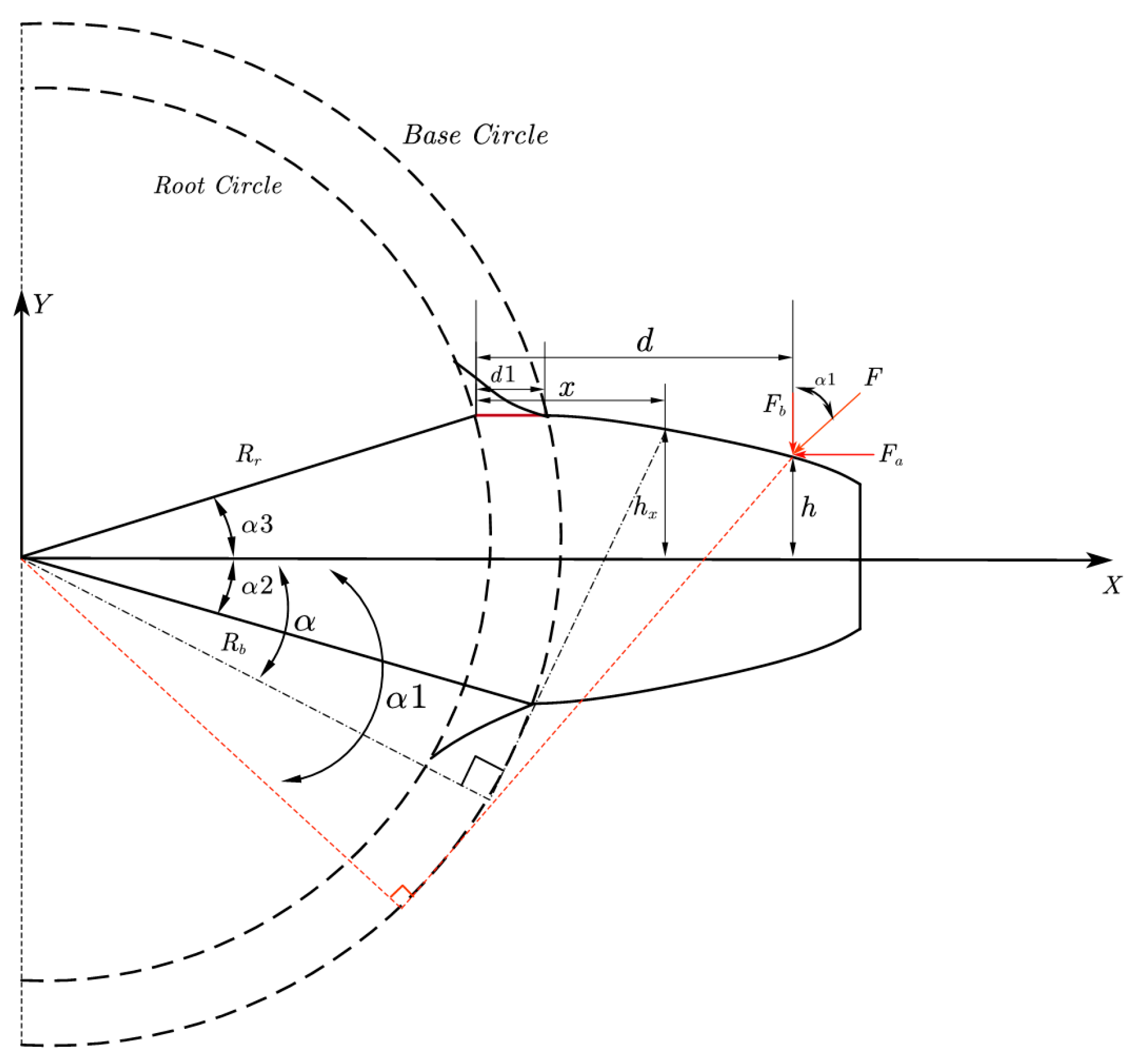

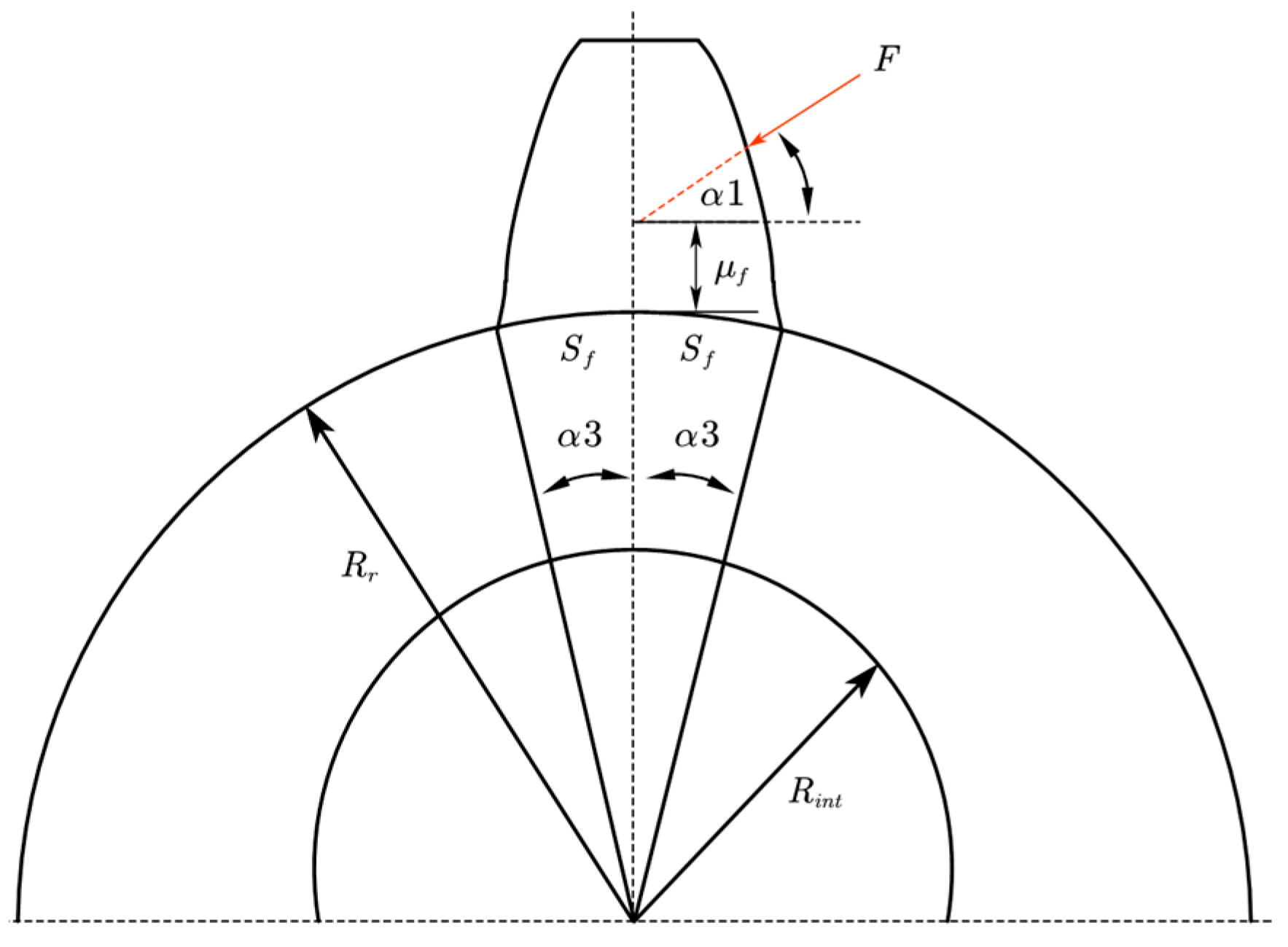

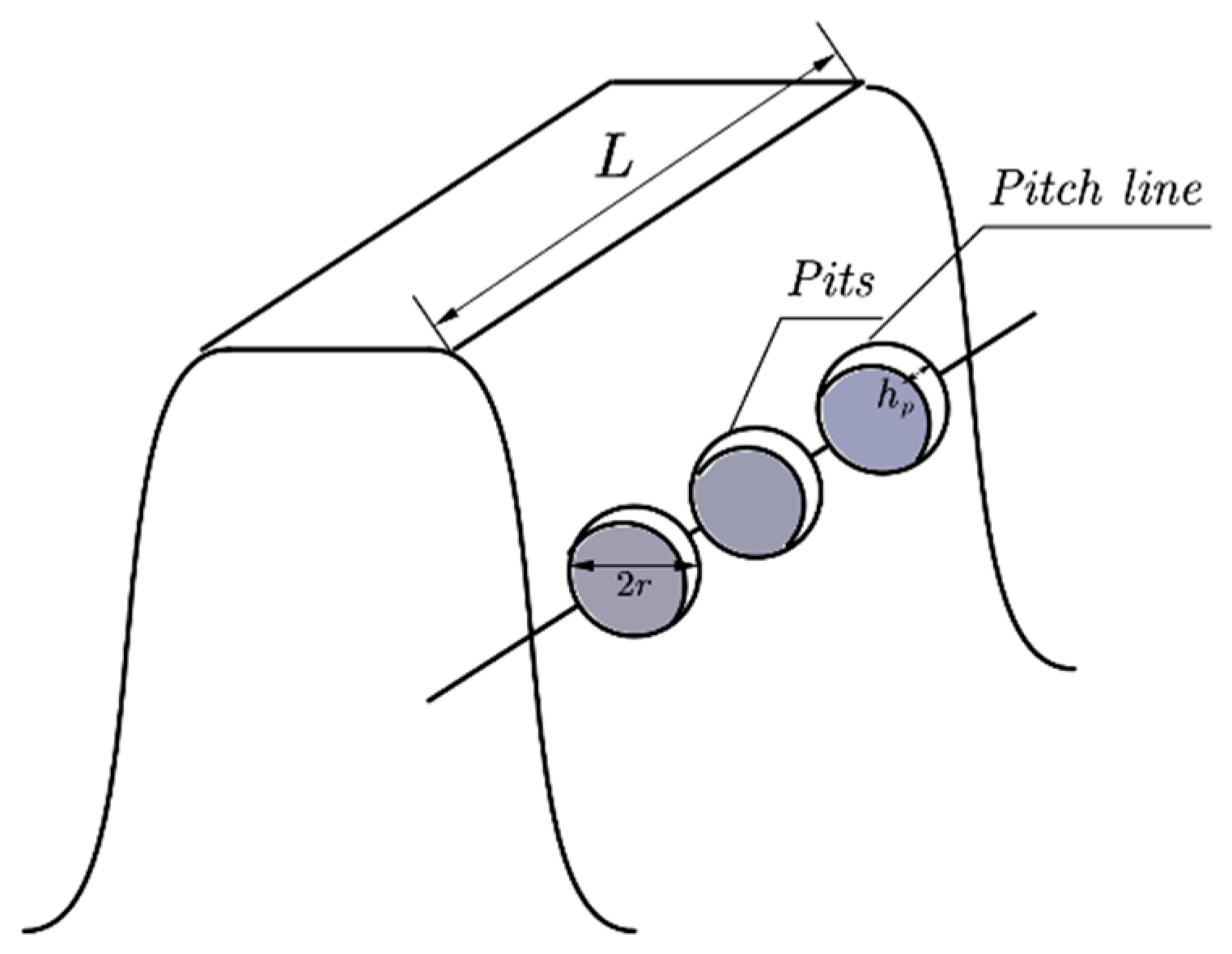

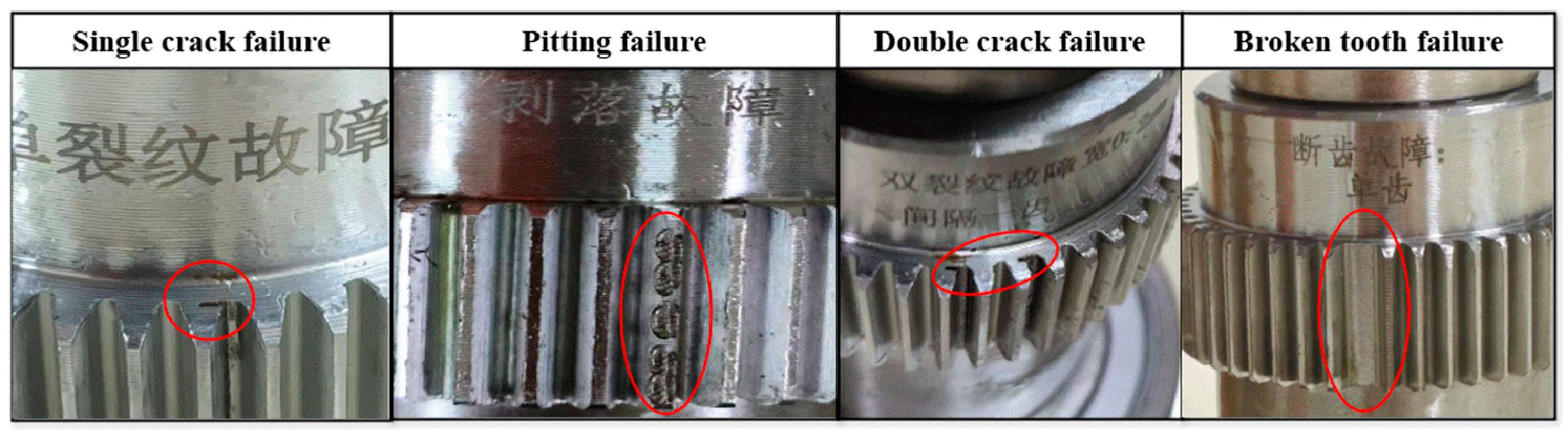

The platform mainly consists of: a 45w G-132A servo motor, two gearboxes (The accompanying gearbox is always equipped with normal gears manufactured by Huafei from Beijing, China), a magnetic powder brake, two PN72-E6S10000 incremental photoelectric encoders(Manufactured by Hengxiang from Qingdao, China), and three acceleration sensors(from Washington, DC, USA). The module of the steel spur gear is 1 mm, the number of teeth is 50 and 150, respectively, the pitch radius is 25 mm and 75 mm, respectively, the tooth width is 16 mm and 20 mm, and the pressure angle is 20°. Among them, the smaller gear is the input gear. Cracks, pitting, broken teeth, double cracks and other faults are all processed on the input gear. The crack length is 0.2 mm and the crack angle is 0°. The second crack of the double crack is separated from the previous crack by one tooth. Broken tooth: one tooth is removed from the gear. The pitting lengths are 4 mm, 2 mm, and 4 mm, the width is 2 mm, and the depth is 1 mm. The three pitting areas are concentrated close to the top of the tooth. The physical resolution of the two encoders is 10,000 ppr, which are installed on the input and output shafts of the gearbox, respectively. The sampling frequency of the encoder acquisition card is set to 10,000 Hz, and the quadruple frequency counting is realized through the AB two-phase pulse to improve the position accuracy. Considering the cost, the experiment uses a vibration acceleration signal sensor to measure the vibration acceleration signal. The acceleration sensor model is PCB-352C33, the sensitivity is 10.25 mV/m/s2, and the sampling frequency is 10,240 HZ.

The faulty gears used four fault types, namely cracks, pitting, double cracks and broken teeth, as shown in

Figure 23.

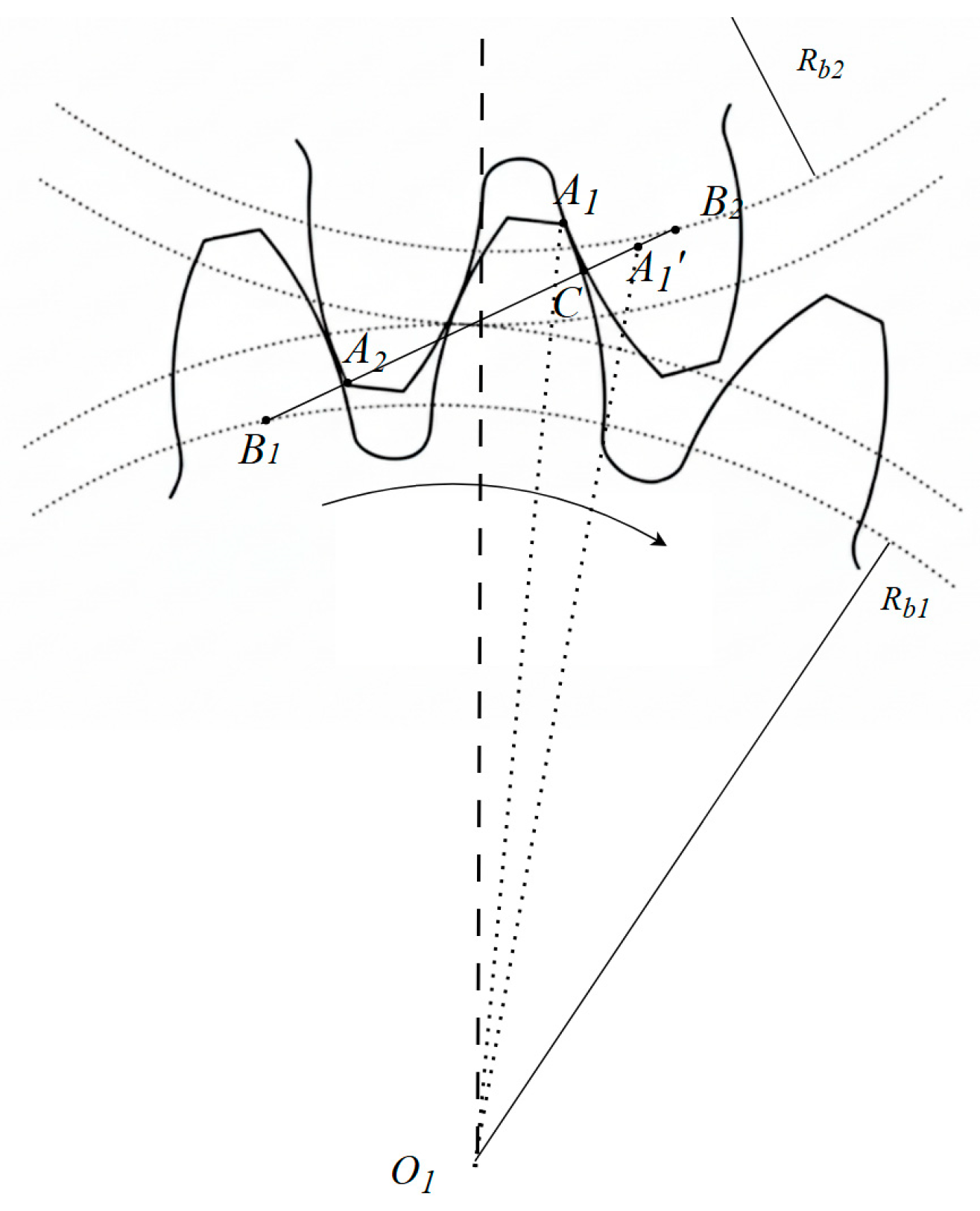

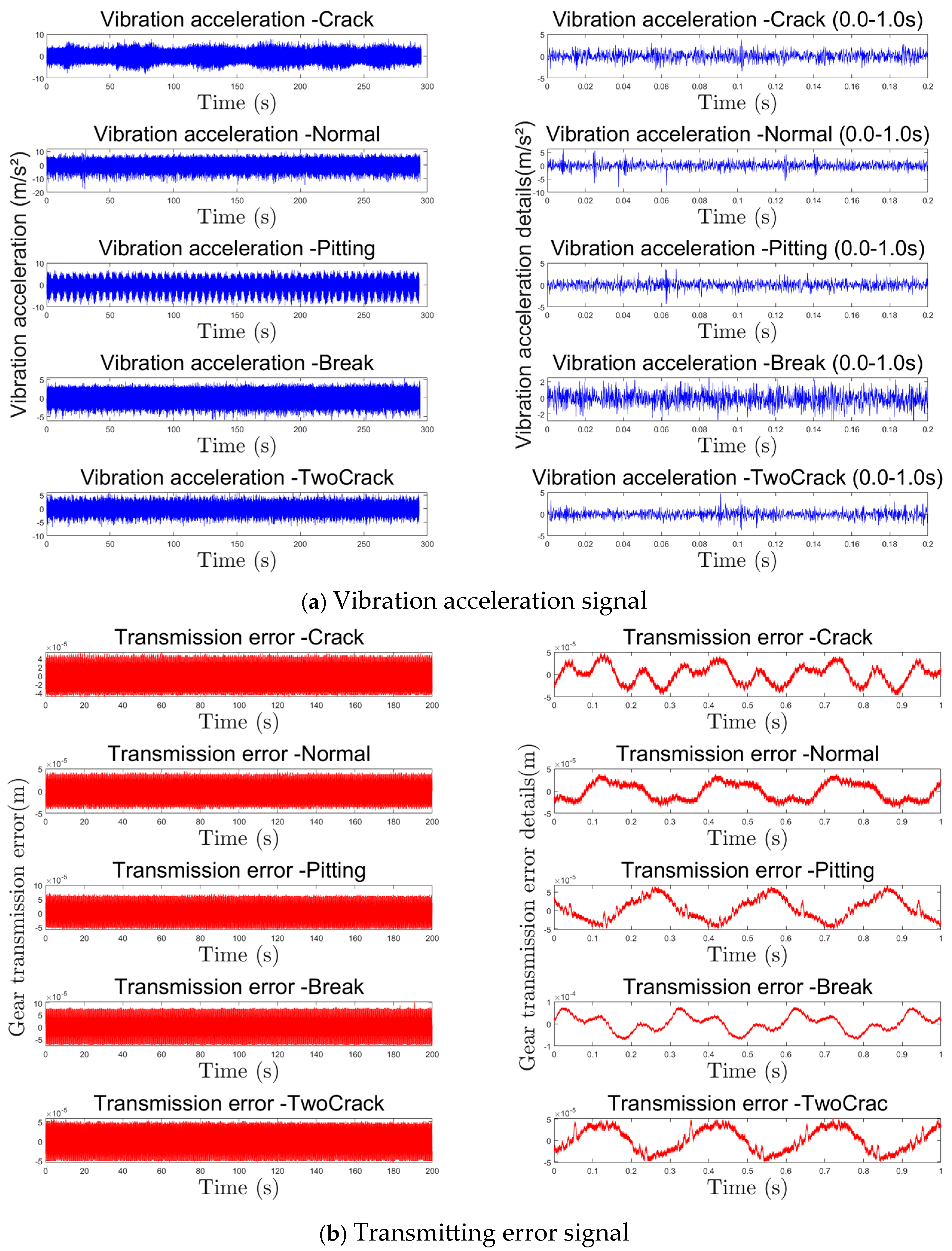

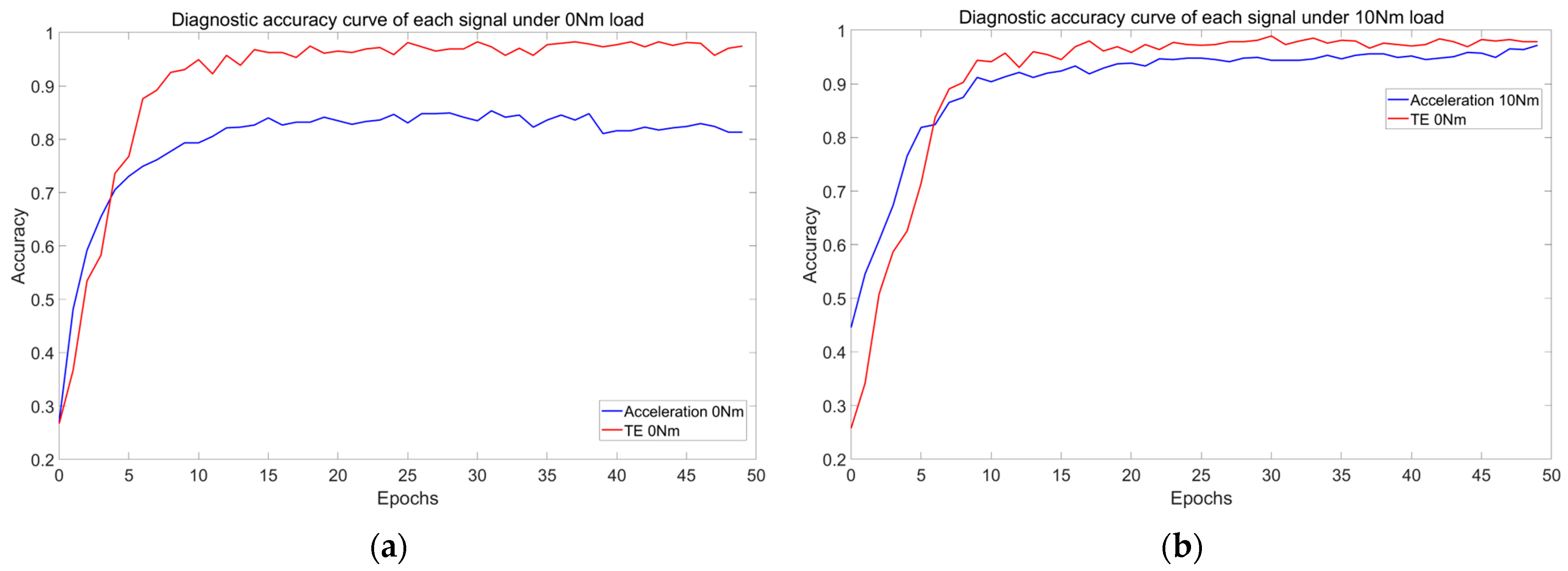

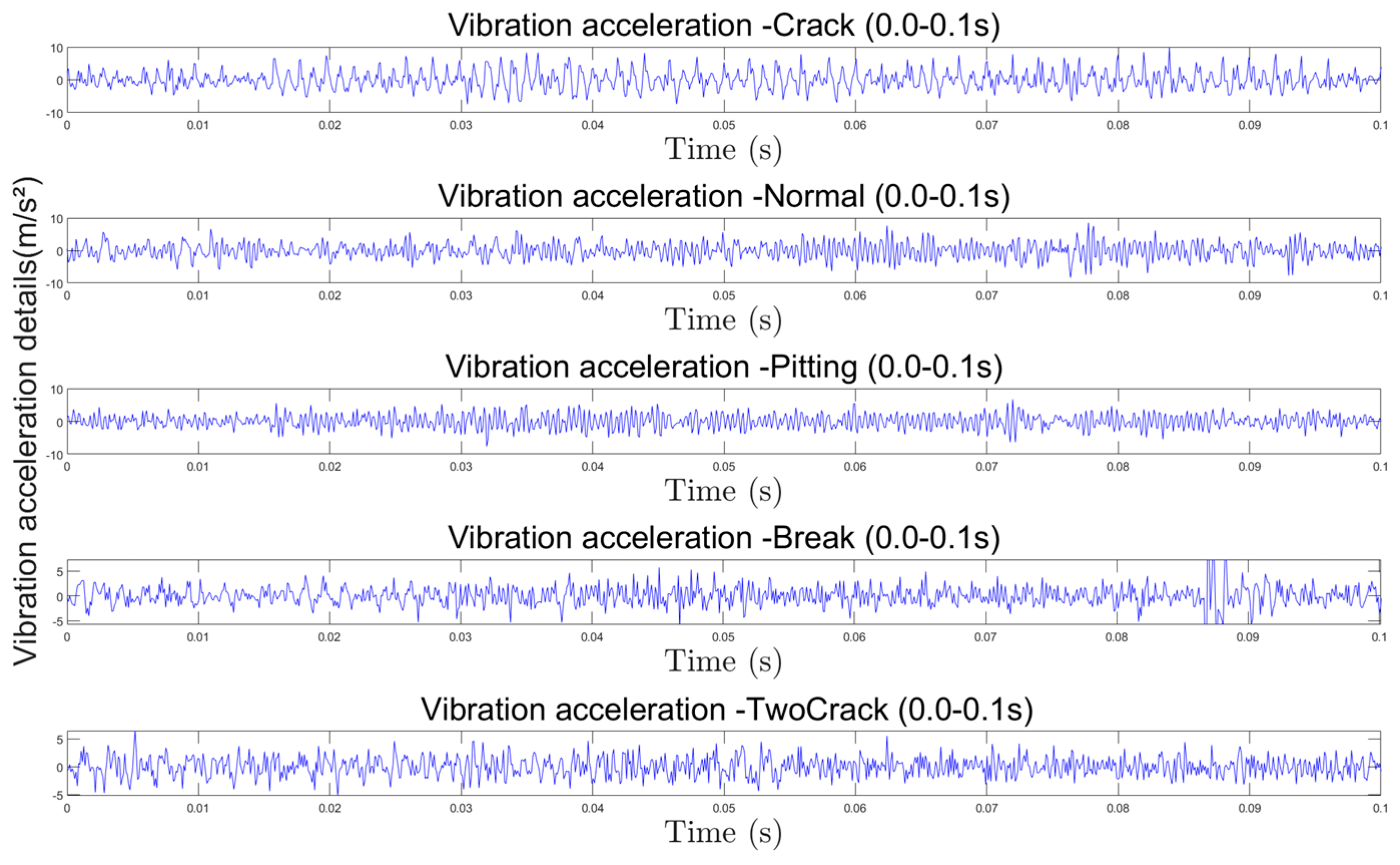

Under rated conditions (600 RPM, 0 Nm output shaft load), we conducted synchronous measurements of transmission error signals and vibration acceleration signals. To mitigate assembly-induced variability, the gear pair was repeatedly disassembled and reinstalled, with identical measurement procedures performed for each trial. This process yielded consistent TE and vibration datasets for both healthy and faulted gears under identical operating conditions, as visualized in

Figure 24.

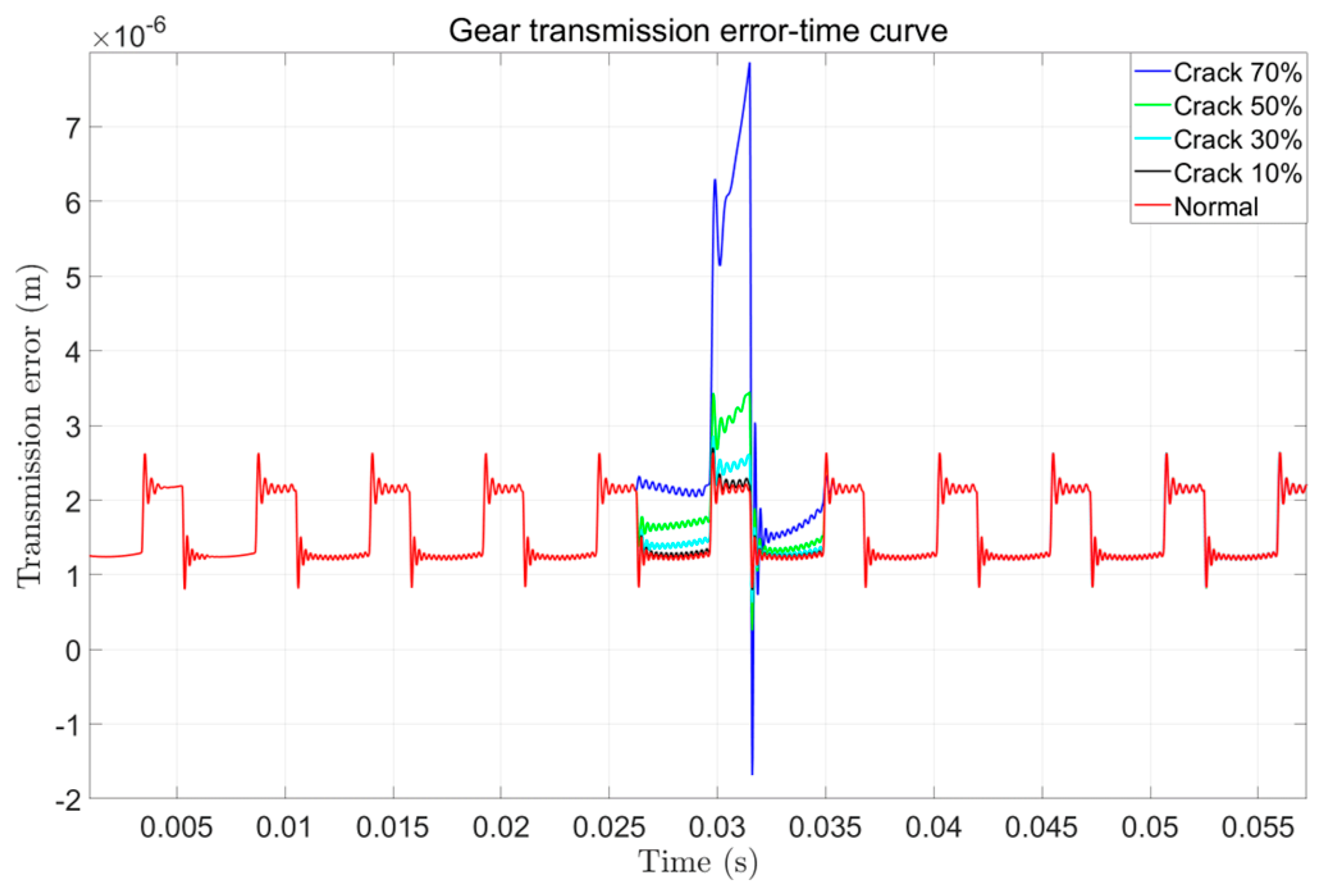

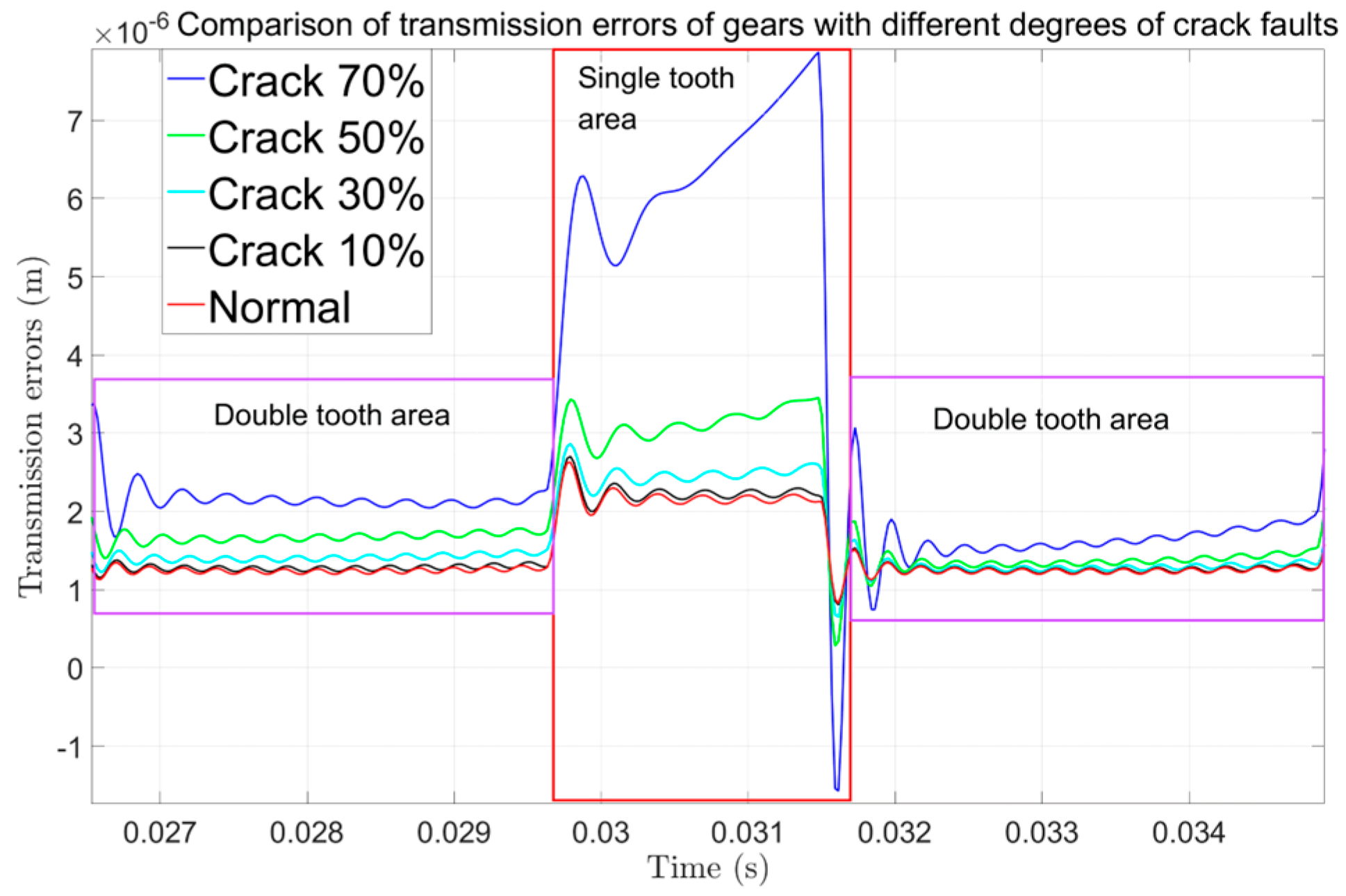

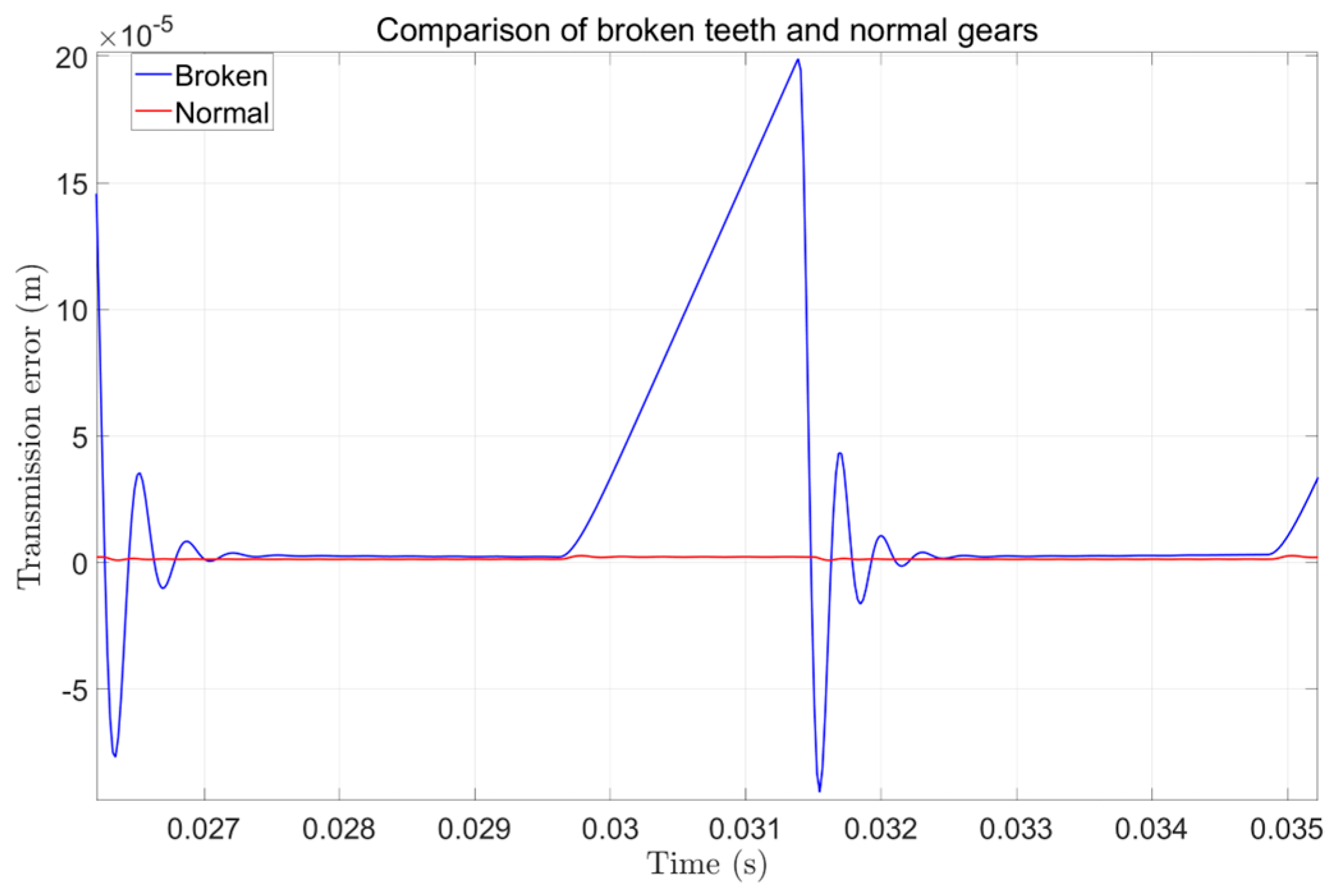

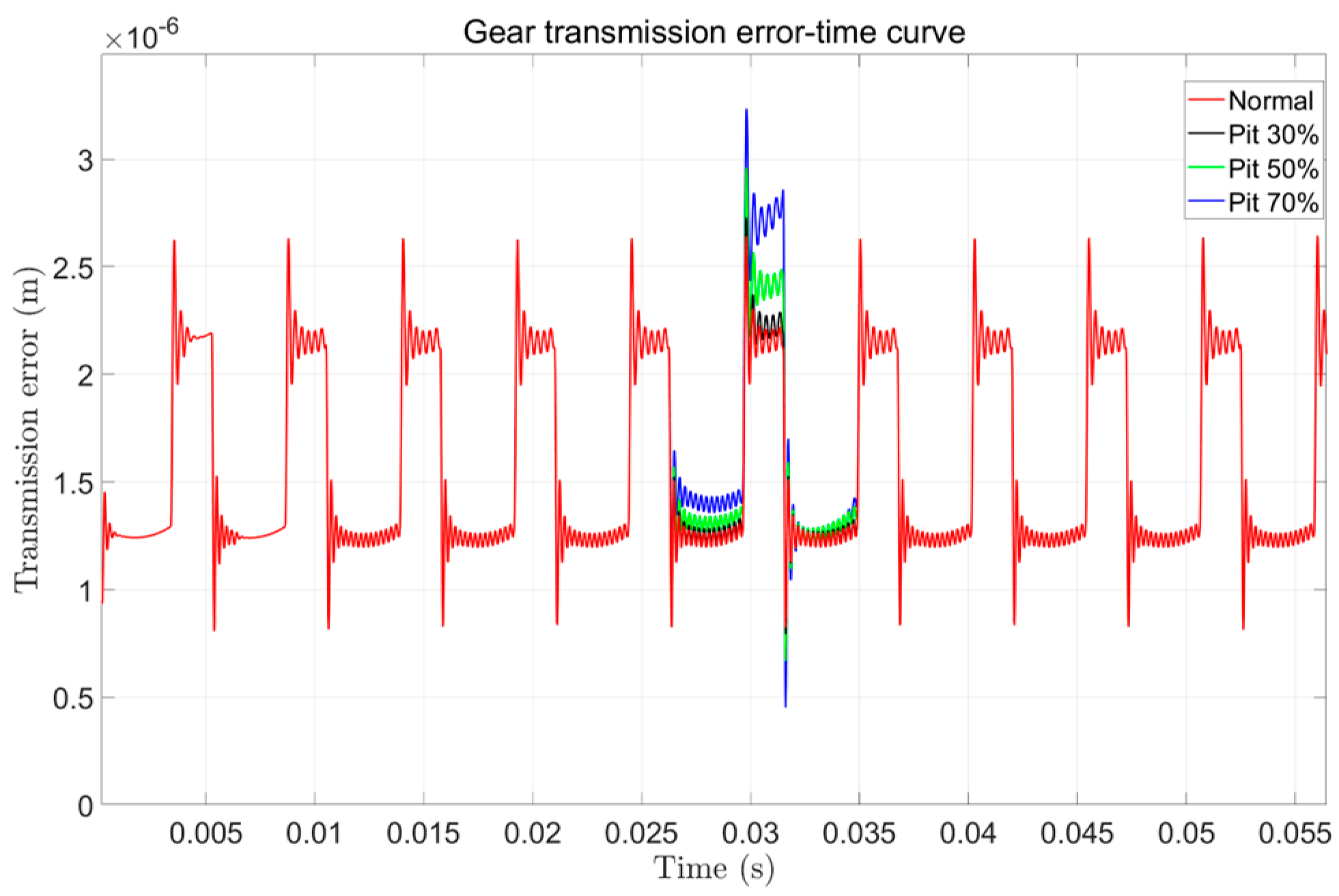

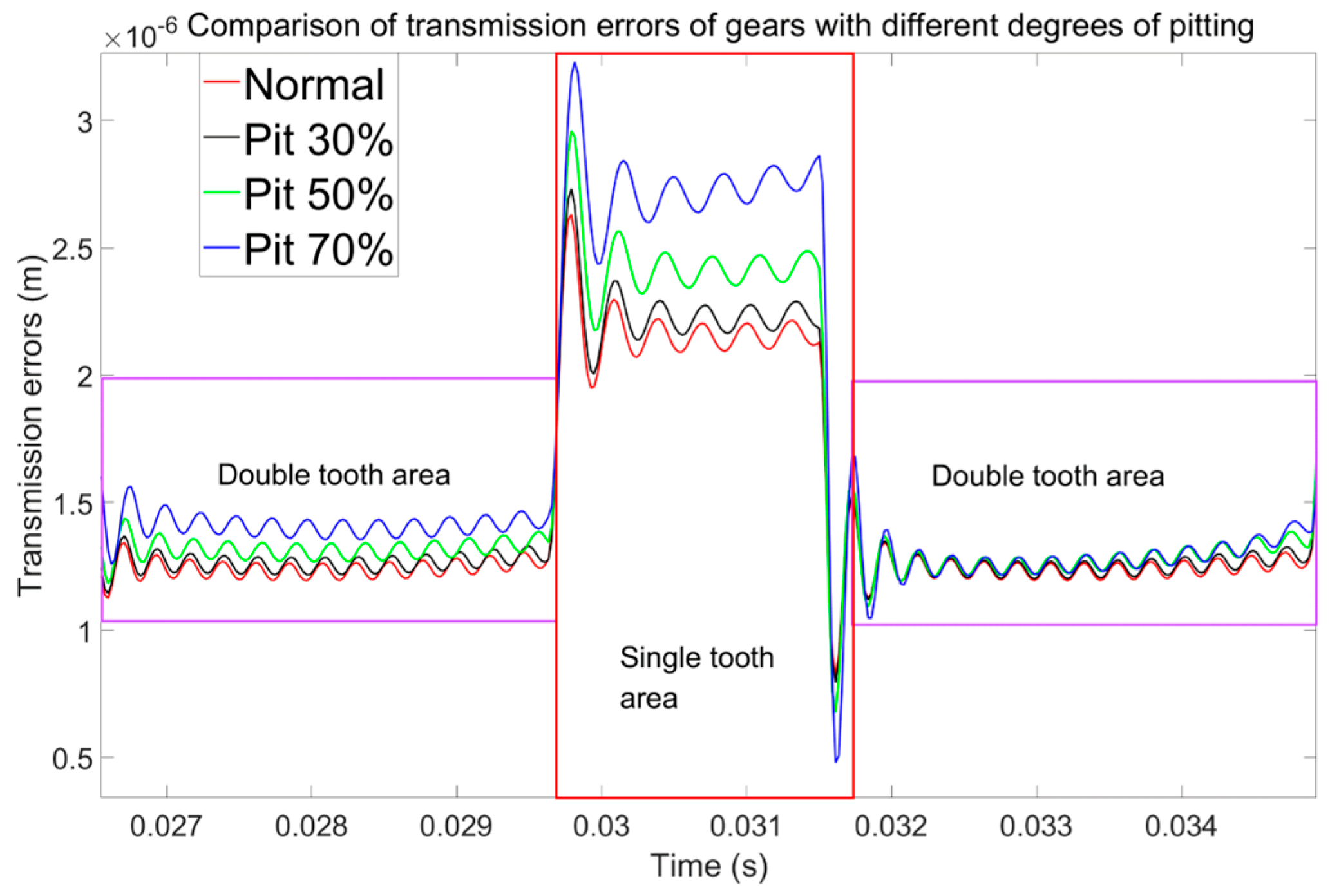

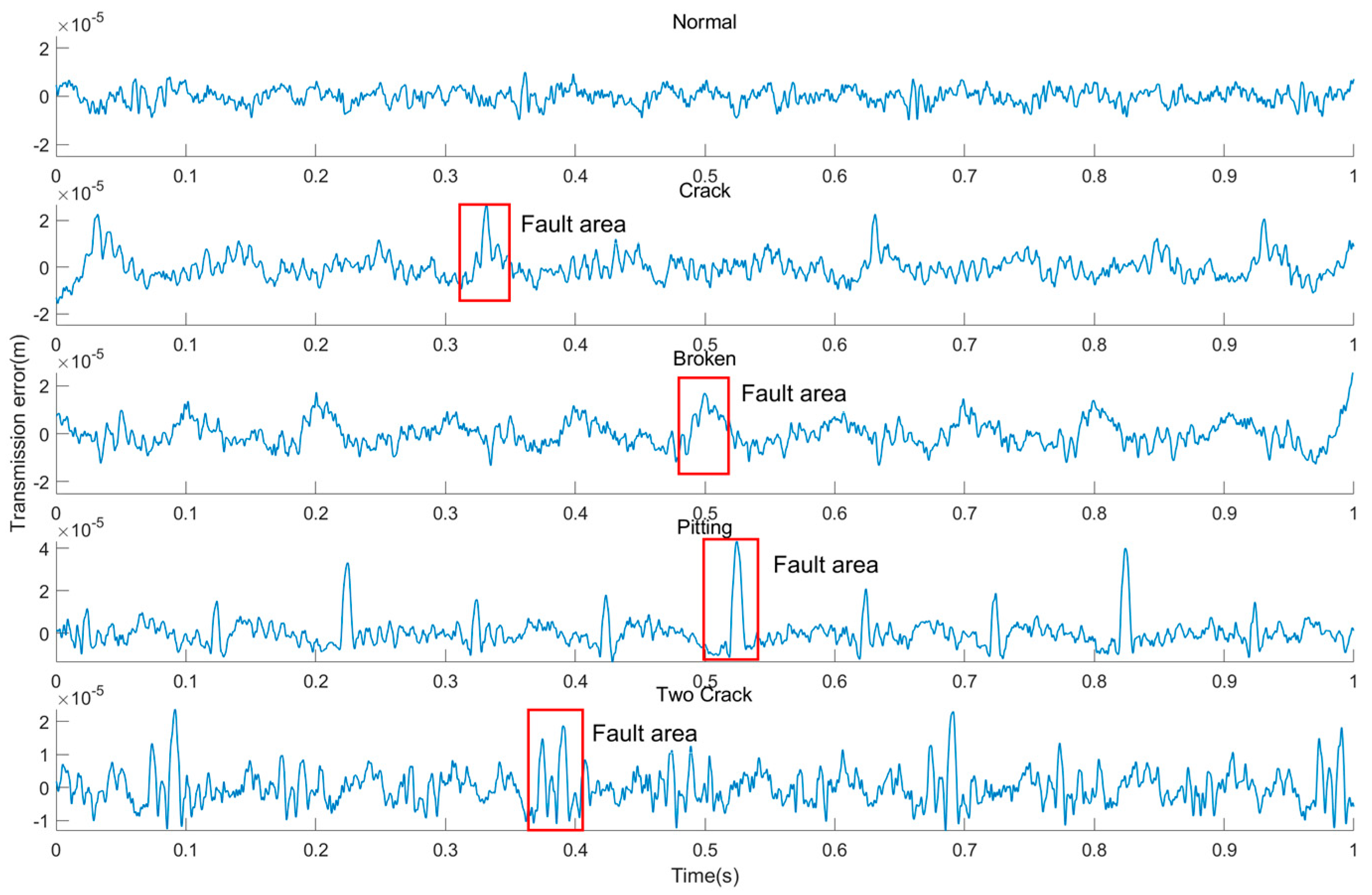

Figure 24a reveals distinct vibration acceleration characteristics across fault types. Especially in the case of broken teeth, the acceleration signal presents a significant periodic impact behavior, and its period is consistent with the rotation period of the faulty gear. Similarly, it can be seen from the transmission error signal of

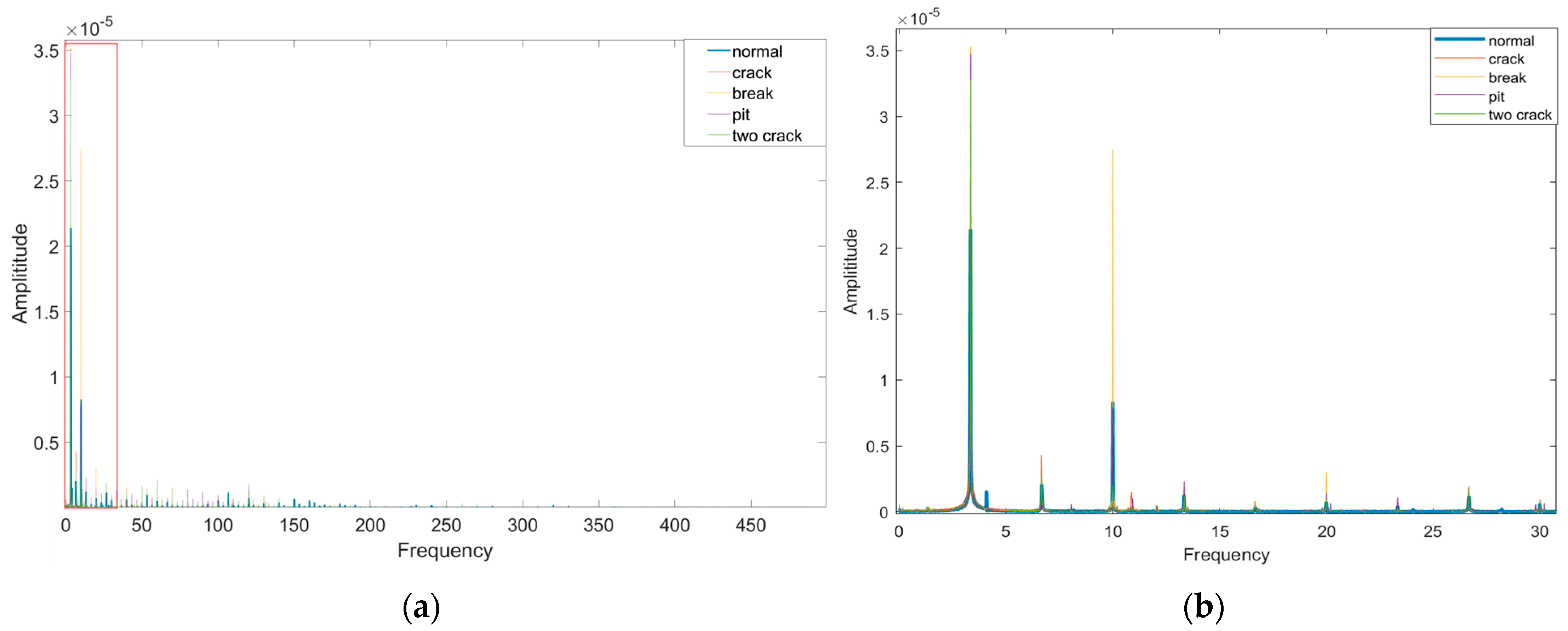

Figure 24b that the transmission error of the system also presents different signal characteristics. However, for the transmission error, no matter what kind of fault signal it is, it shows a periodicity of about 0.3 s, which is consistent with the rotation period of the large gear of the system. The 0.3 s periodicity shown by the system transmission error is not matched with the gear meshing period. In order to explore the cause of its formation, we perform a Fourier transform on the transmission error signal and obtain the frequency-amplitude characteristics shown in

Figure 25. The spectral analysis reveals dominant energy concentrations at approximately 3.33 Hz and 10 Hz, corresponding directly to the rotational frequencies of the large gear and small gear, respectively. This frequency alignment indicates a potential dynamic imbalance in the gear system. Spectral analysis further identifies a significant amplitude peak at 6.66 Hz—precisely twice the fundamental rotational frequency of the large gear (3.33 Hz). This second harmonic component indicates probable angular misalignment in the large gear assembly. In order to reduce the impact of gear dynamic imbalance and misalignment on the transmission error signal, we bandpass filter the transmission error signal to filter out frequencies below 10 Hz and above 1000 Hz. The filtered transmission error signal is shown in

Figure 26. It now clearly exhibit that the transmission error signals of different faults after filtering clearly show the fault characteristics unique to other faults. For example, if there is a crack in the gear, it can be seen that the transmission error signal has prominent periodic peaks; when there is a double crack in the gear, periodic double peaks appear, which is consistent with the results obtained by the theoretical model.

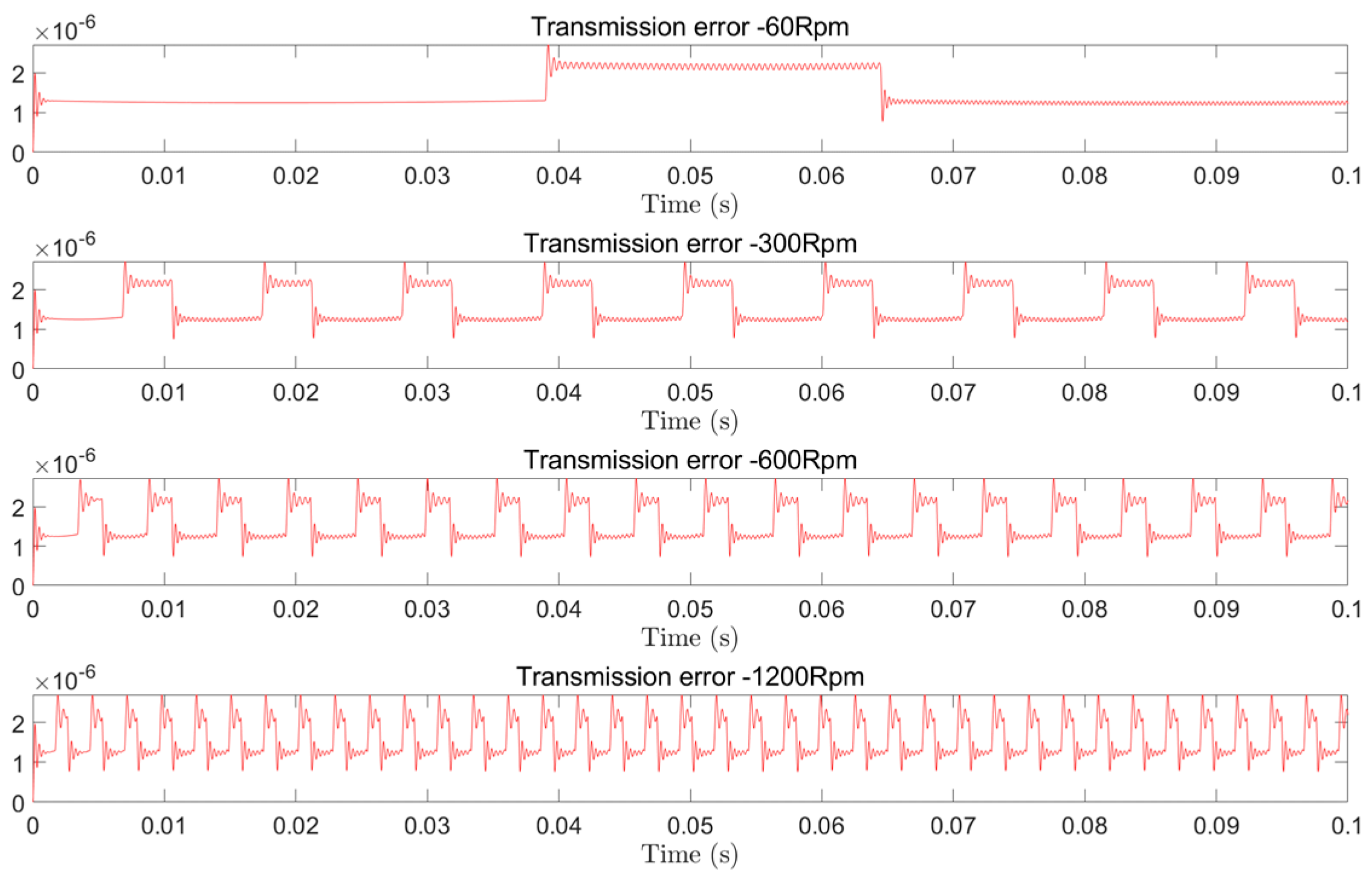

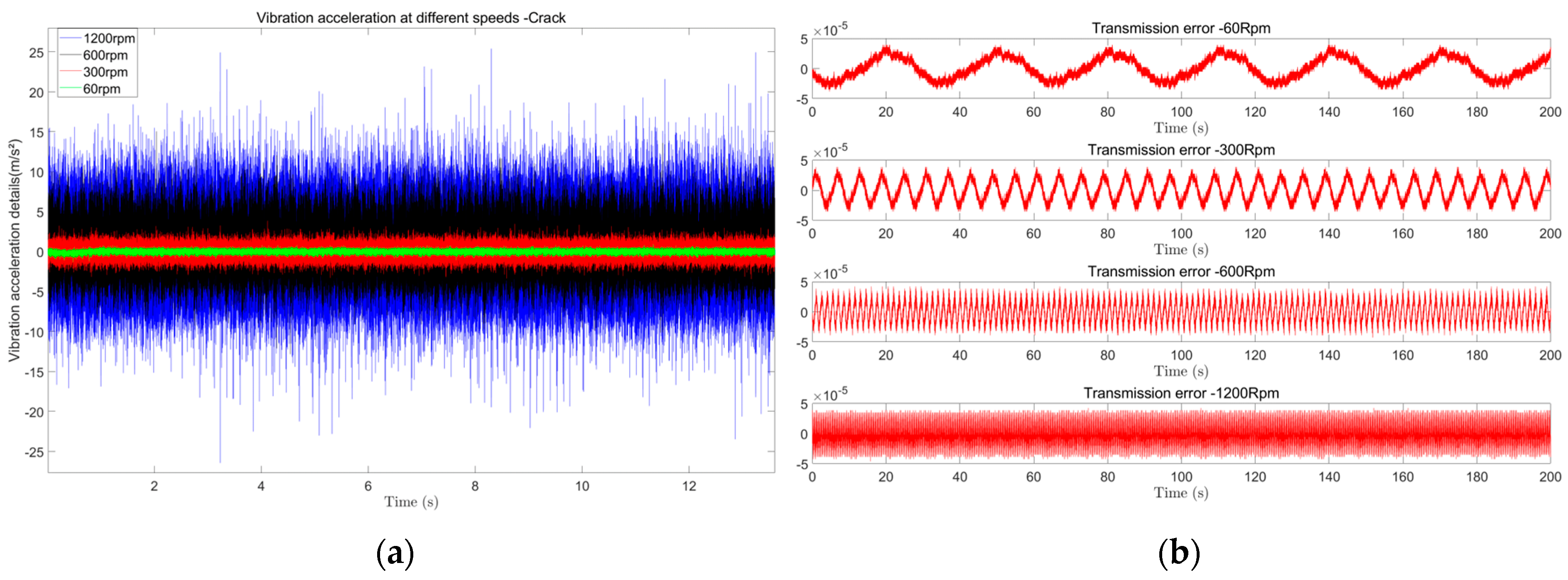

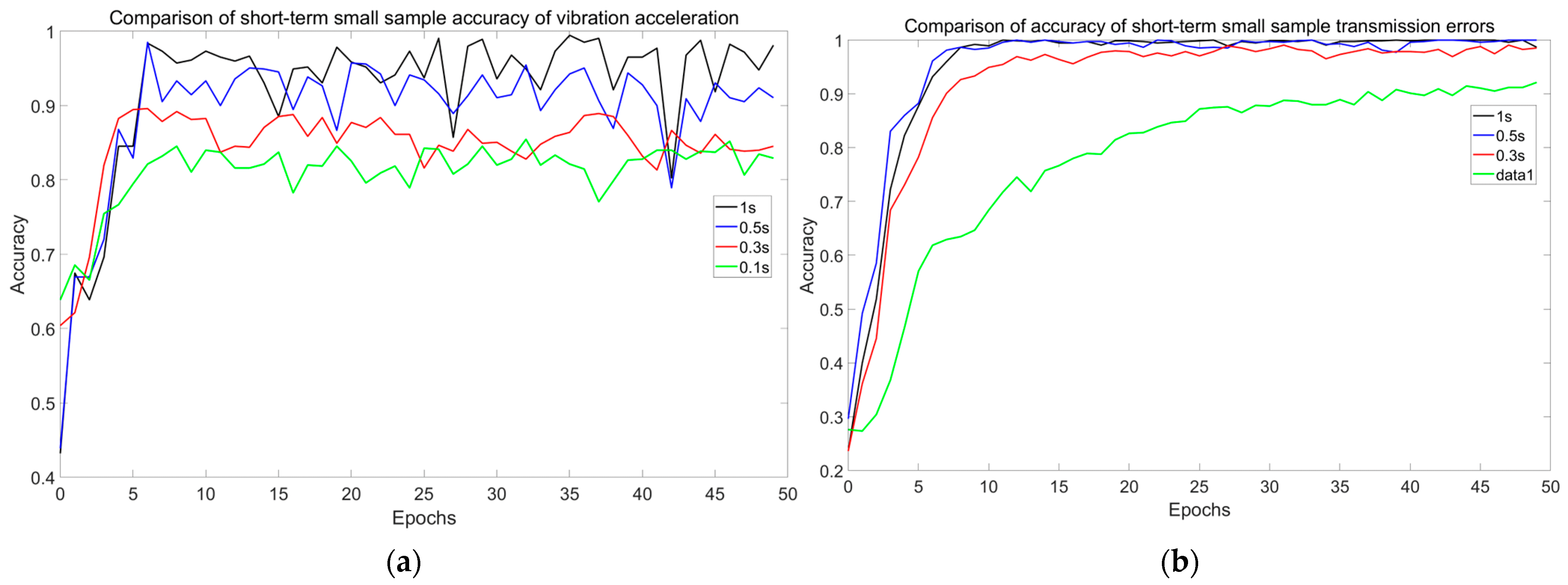

Subsequently, to assess rotational speed effects, we performed comparative testing on a cracked gear at four discrete speeds (60, 300, 600, and 1200 RPM), simultaneously recording vibration acceleration and transmission error signals. The acquired datasets are presented in

Figure 27, highlighting speed-dependent dynamic behaviors.

As evident from

Figure 27a, the vibration acceleration amplitude increases significantly with rotational speed. This amplification stems from heightened inertial forces at higher speeds (e.g., 1200 RPM), which enhance crack-induced impulse visibility, but it will also introduce broadband noise that may obscure faults. Conversely, low-speed operation (60 RPM) yields weaker vibration signals that risk being masked by sensor noise.

Figure 27b demonstrates the transmission error signals’ superior robustness:

Speed invariance: Amplitude variation <5% across tested speeds (60–1200 RPM)

Diagnostic consistency: Fault features (e.g., crack-induced stiffness drops) remain identifiable regardless of speed.

Early fault sensitivity: Detects incipient cracks even at 60 RPM

These findings align with the dynamic model predictions in

Figure 11, validating the theoretical framework.

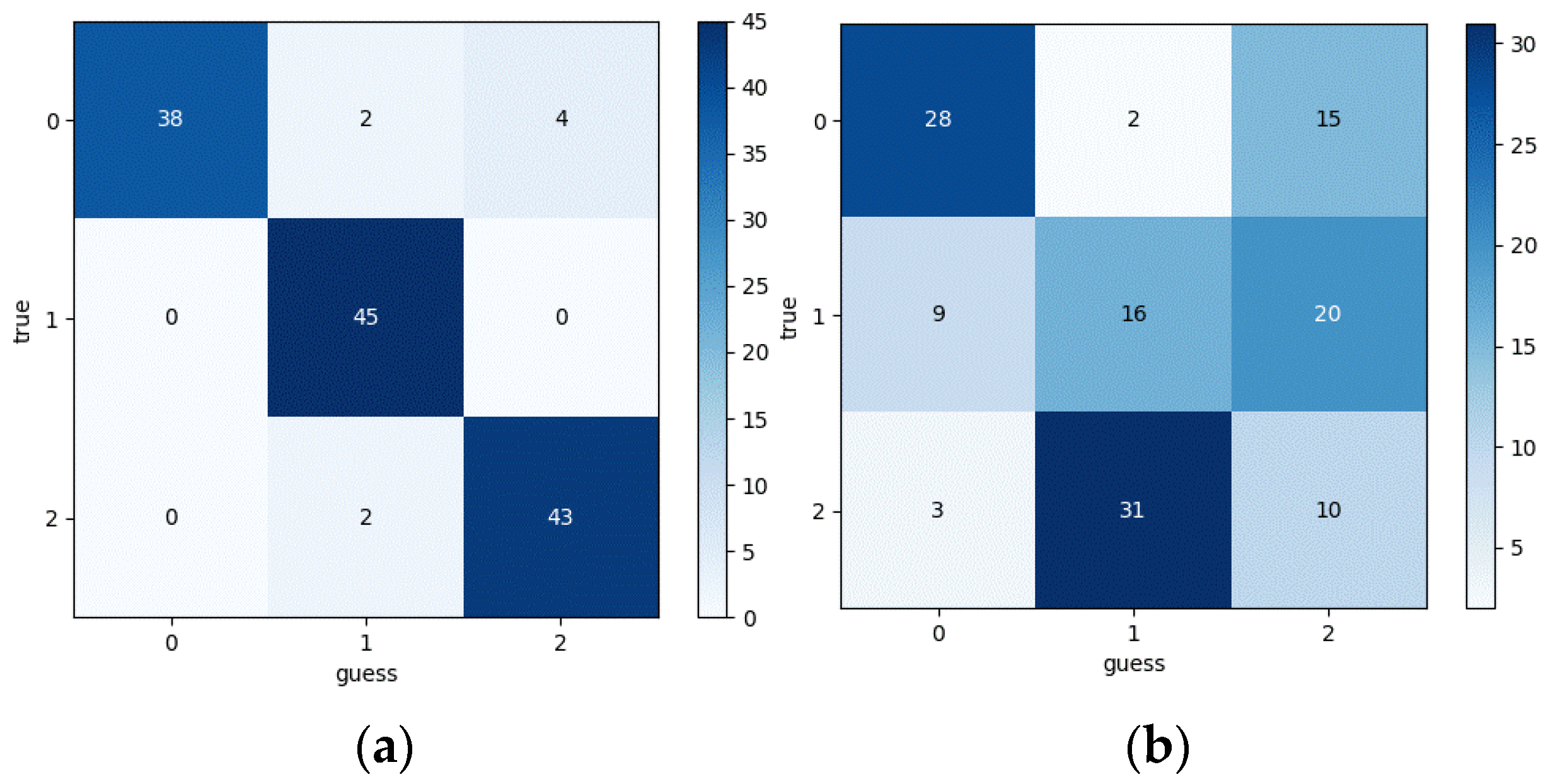

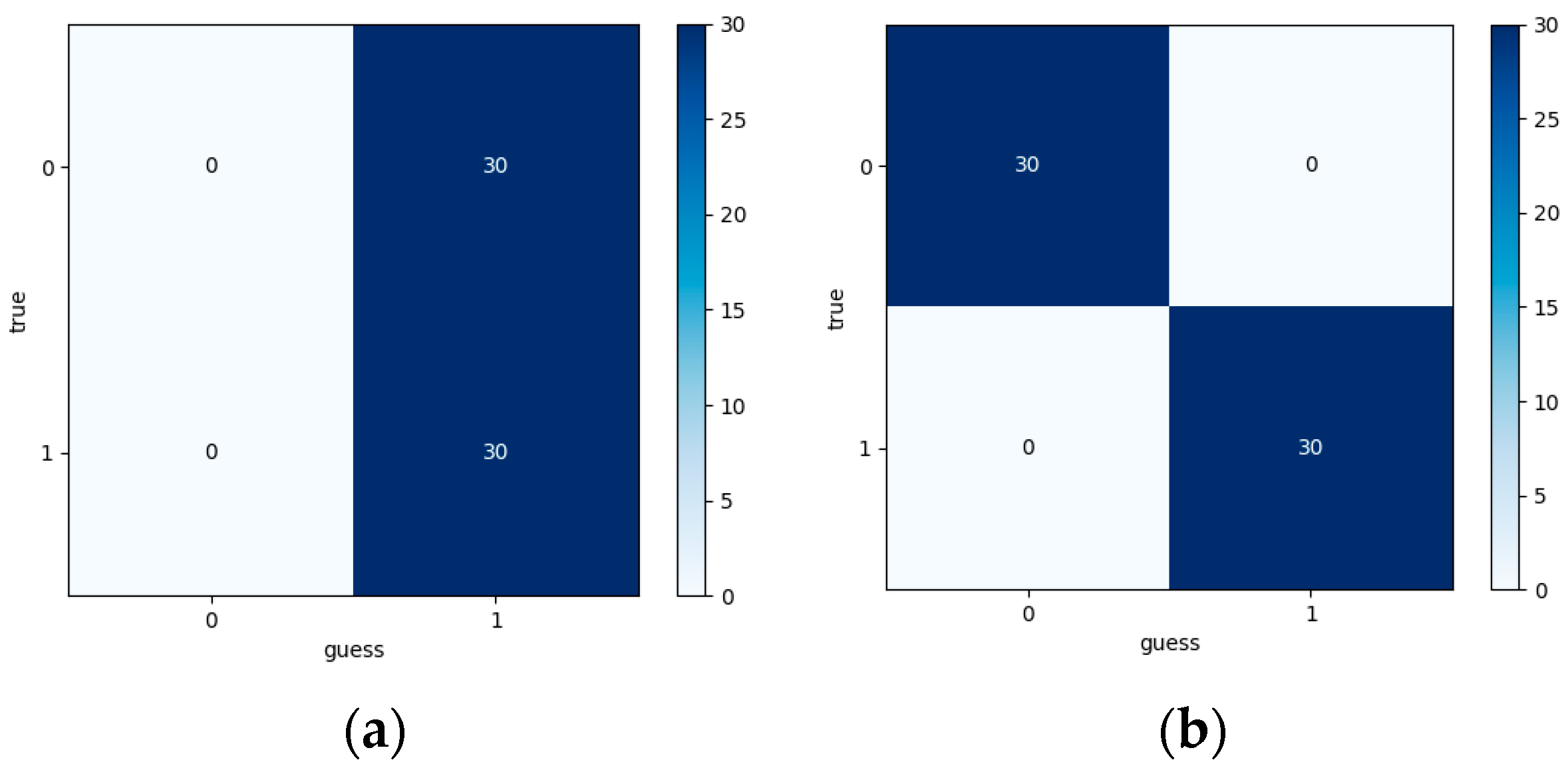

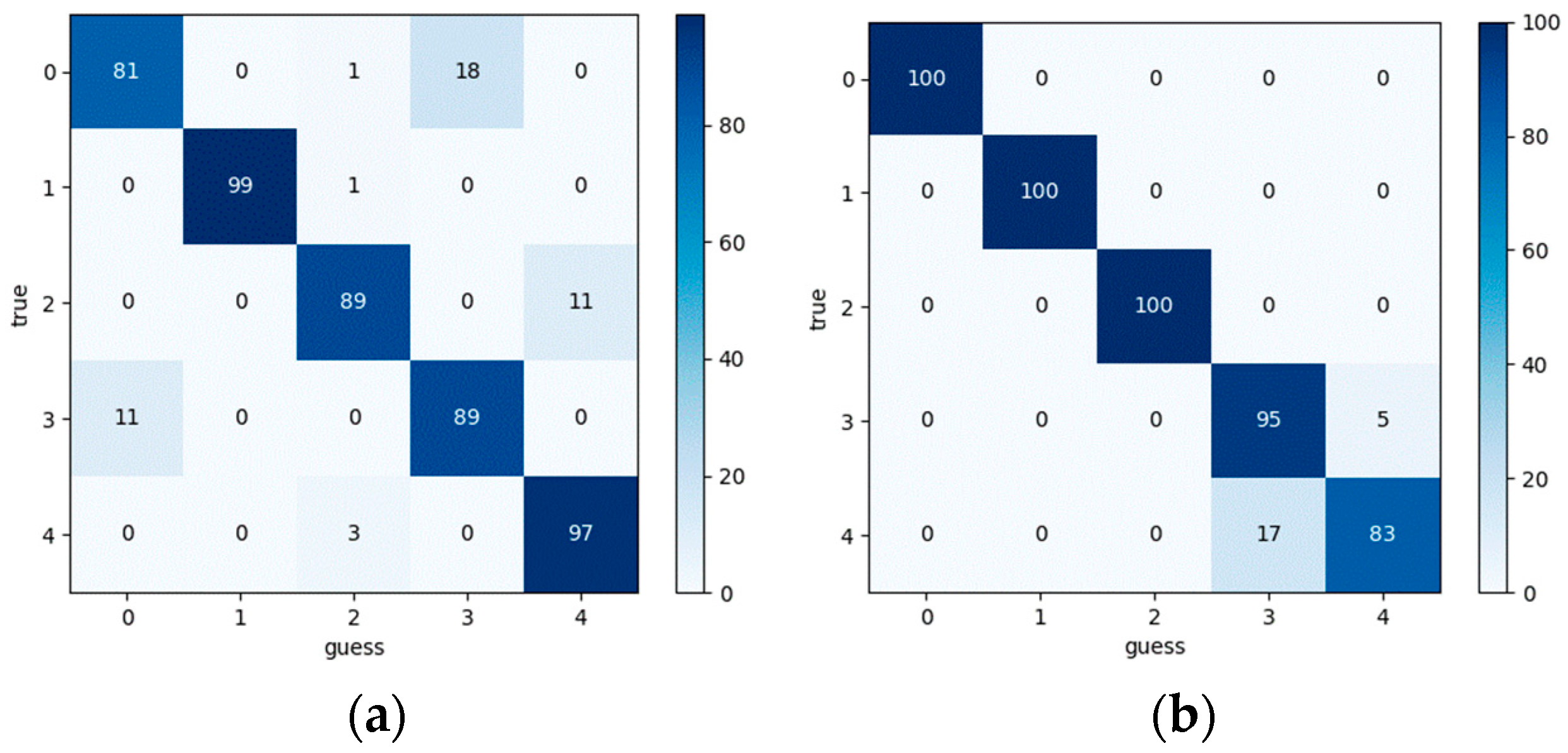

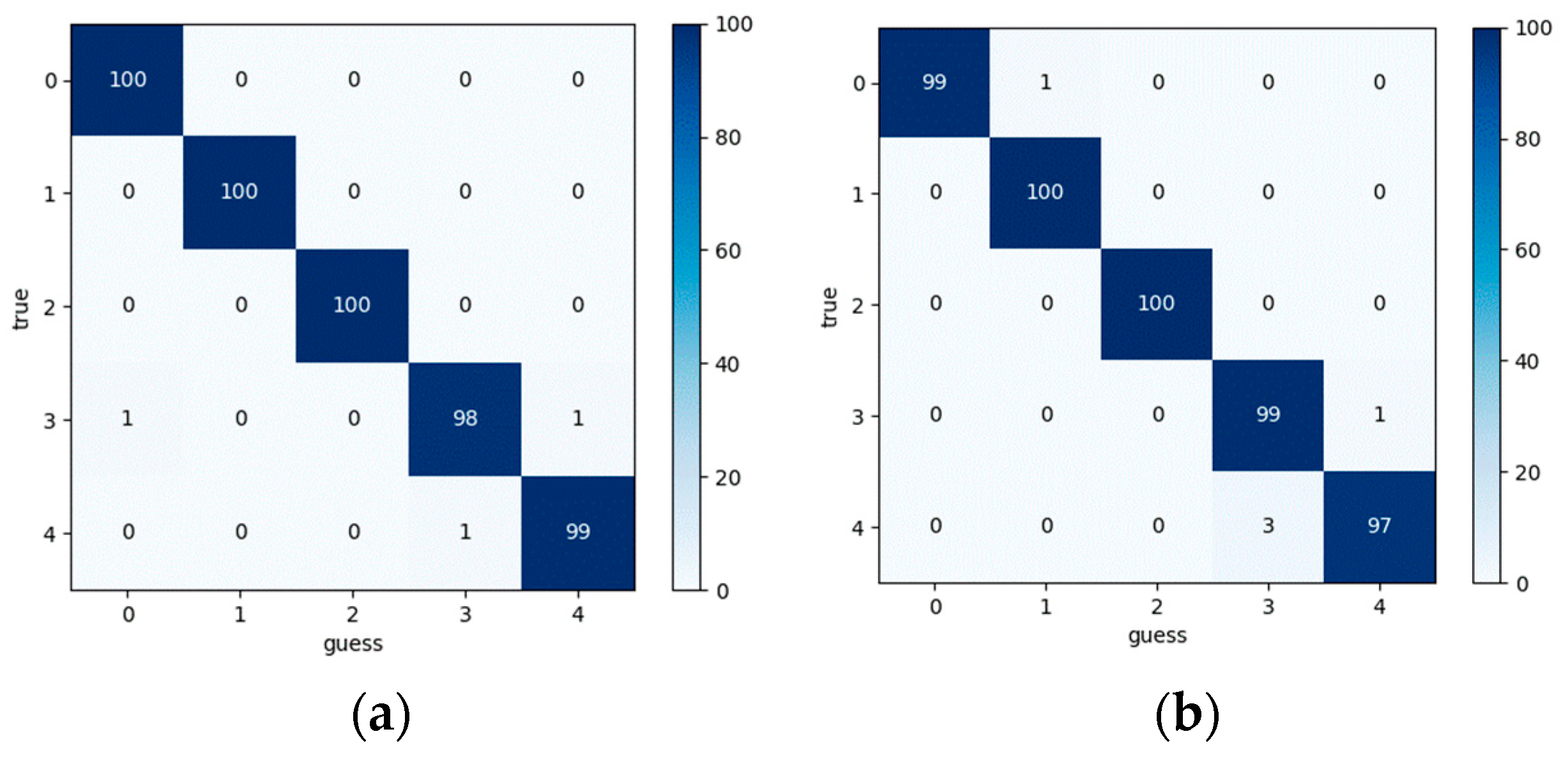

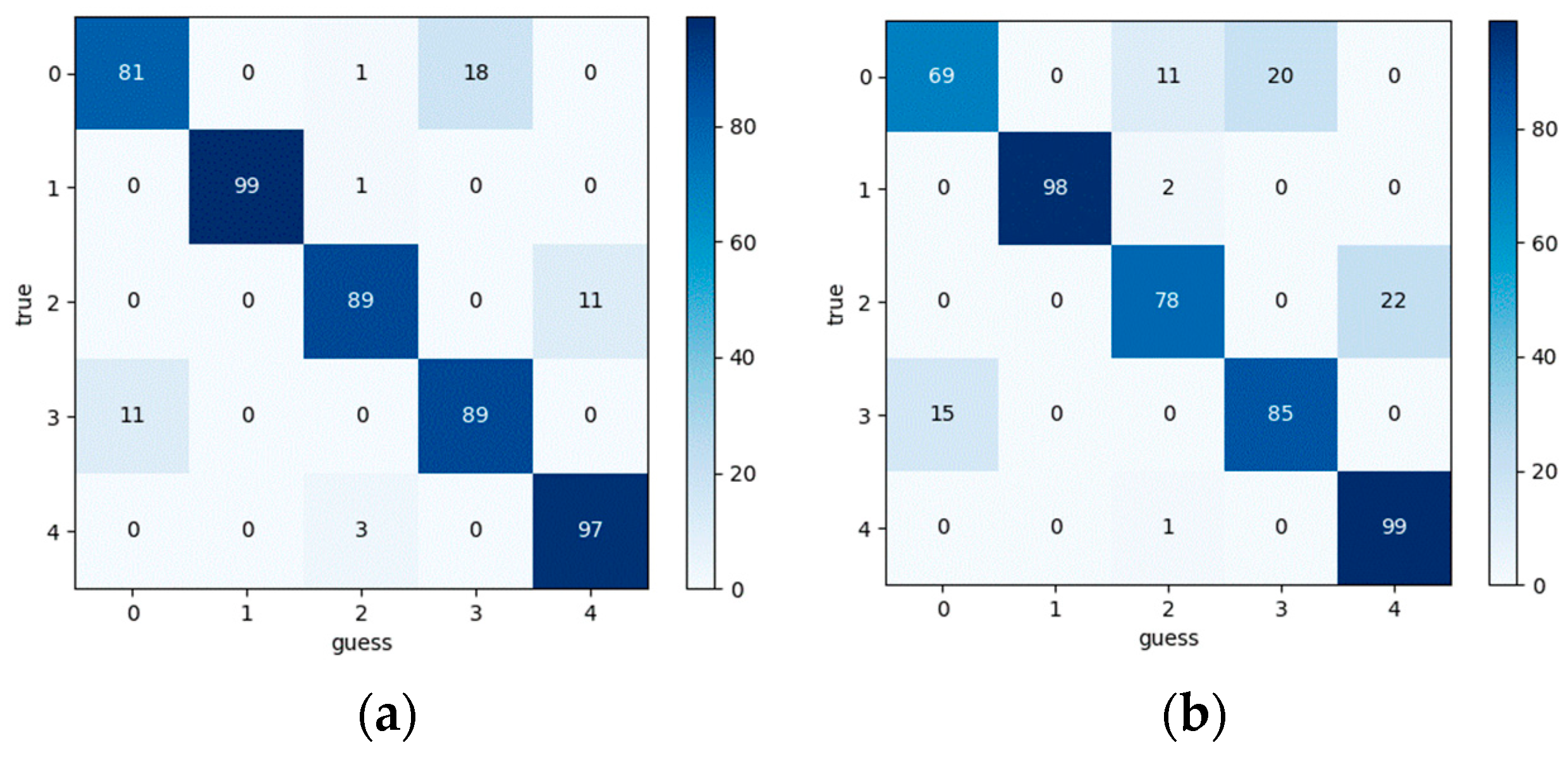

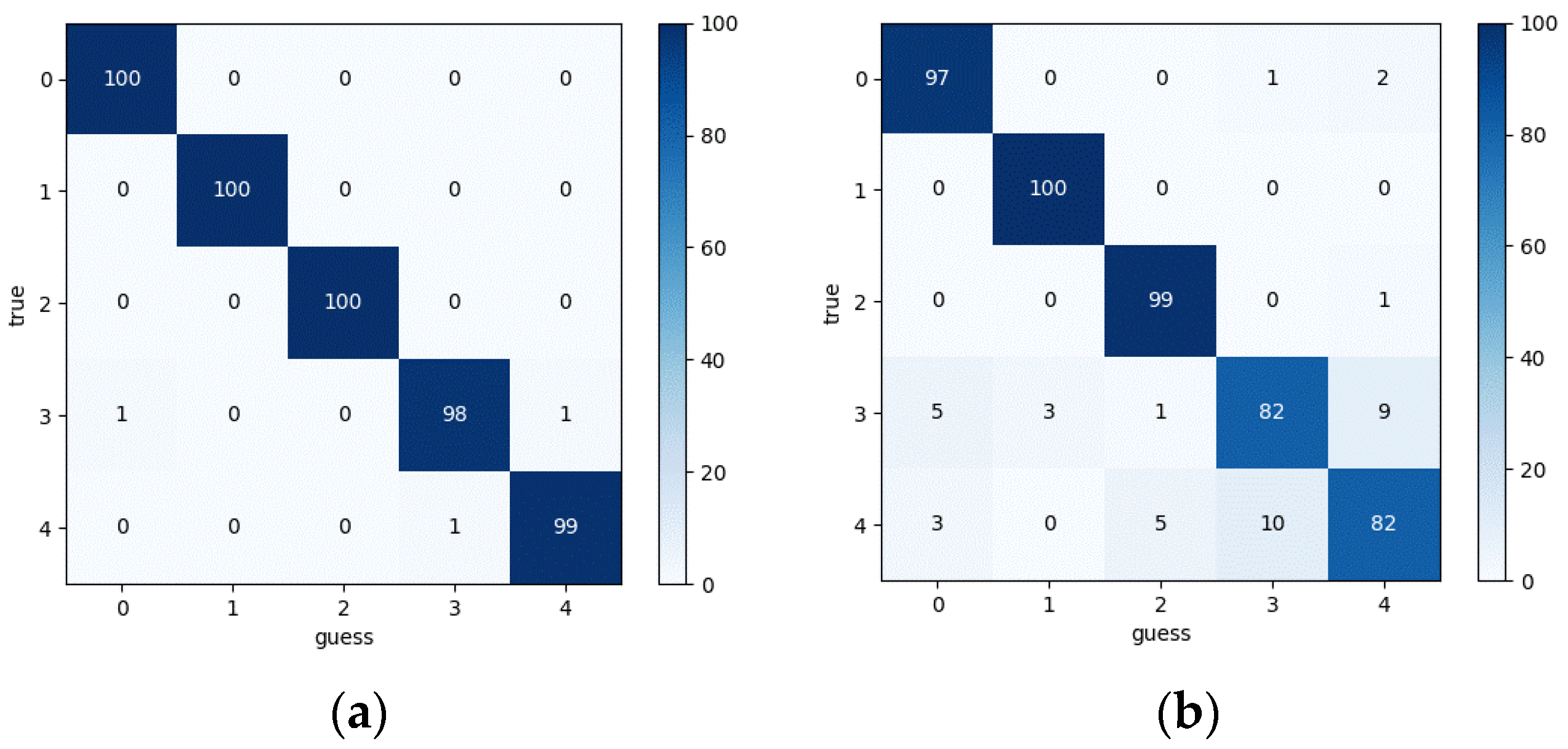

Using an existing 1DCNN model, the model was trained on normal (label 0) and crack (label 1) fault data under a 600 RPM and 10 Nm load. The vibration acceleration signal and the transmission error signal both achieved 100% accuracy.

This trained model was then used to identify normal and crack fault data under a 10 Nm load at 60 RPM. To ensure the data length used for identification remained the same as at 600 RPM the sampling frequency for the 60 RPM propagation error data was changed to 1000 Hz, and the sampling frequency for the vibration acceleration signal was changed to 1024 Hz.

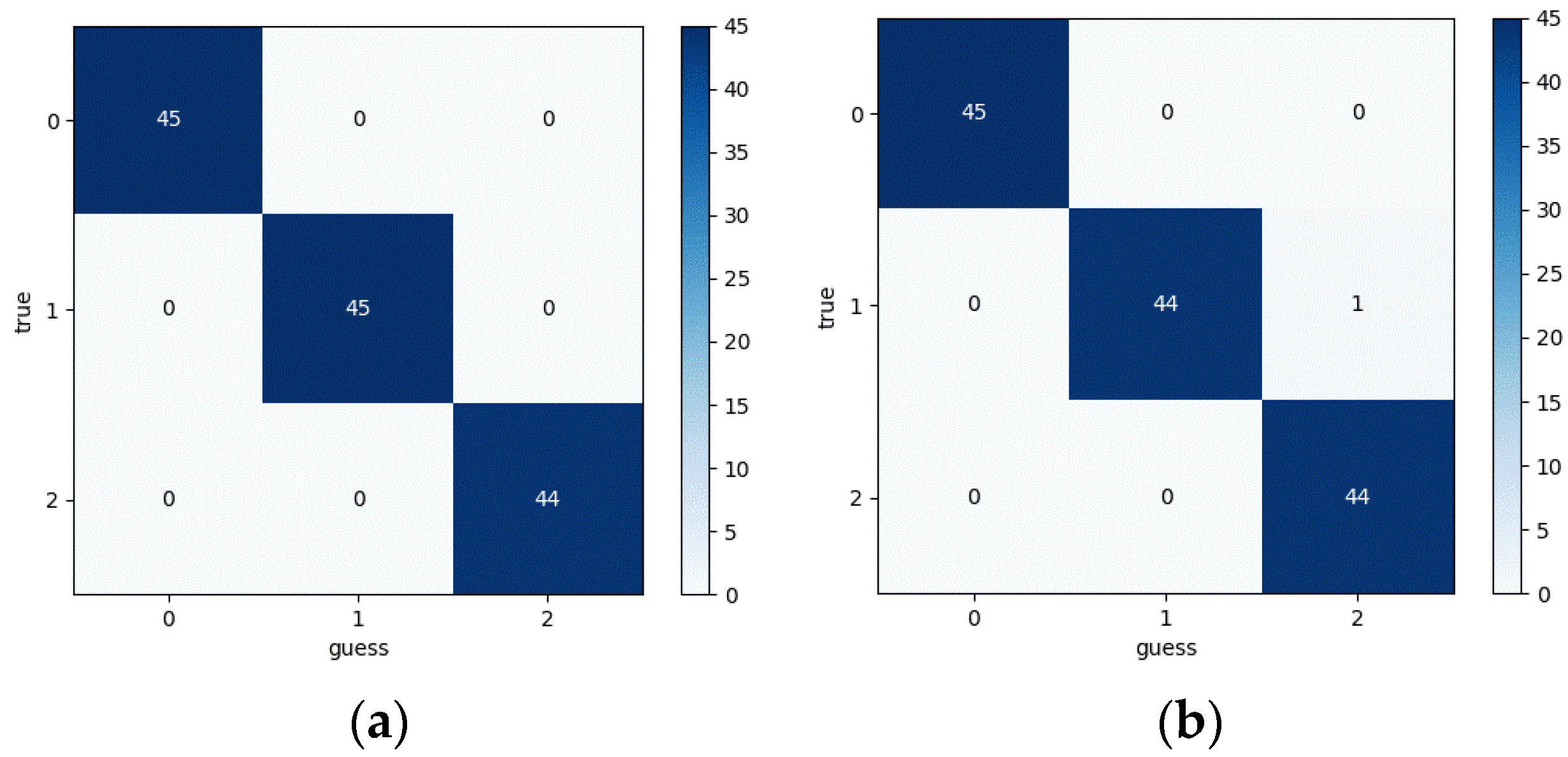

The model trained using the 600 RPM normal and crack fault data was then used to identify normal and crack fault data at 60 RPM. At different speeds, the propagation error signal still achieved 100% accuracy, while the vibration acceleration signal showed 50% accuracy. As shown in

Figure 28.