Structural Design and Analysis of an Automated Cutting Device for a Grass Carp Product Based on SolidWorks

Abstract

1. Introduction

2. Selection of Design Scheme

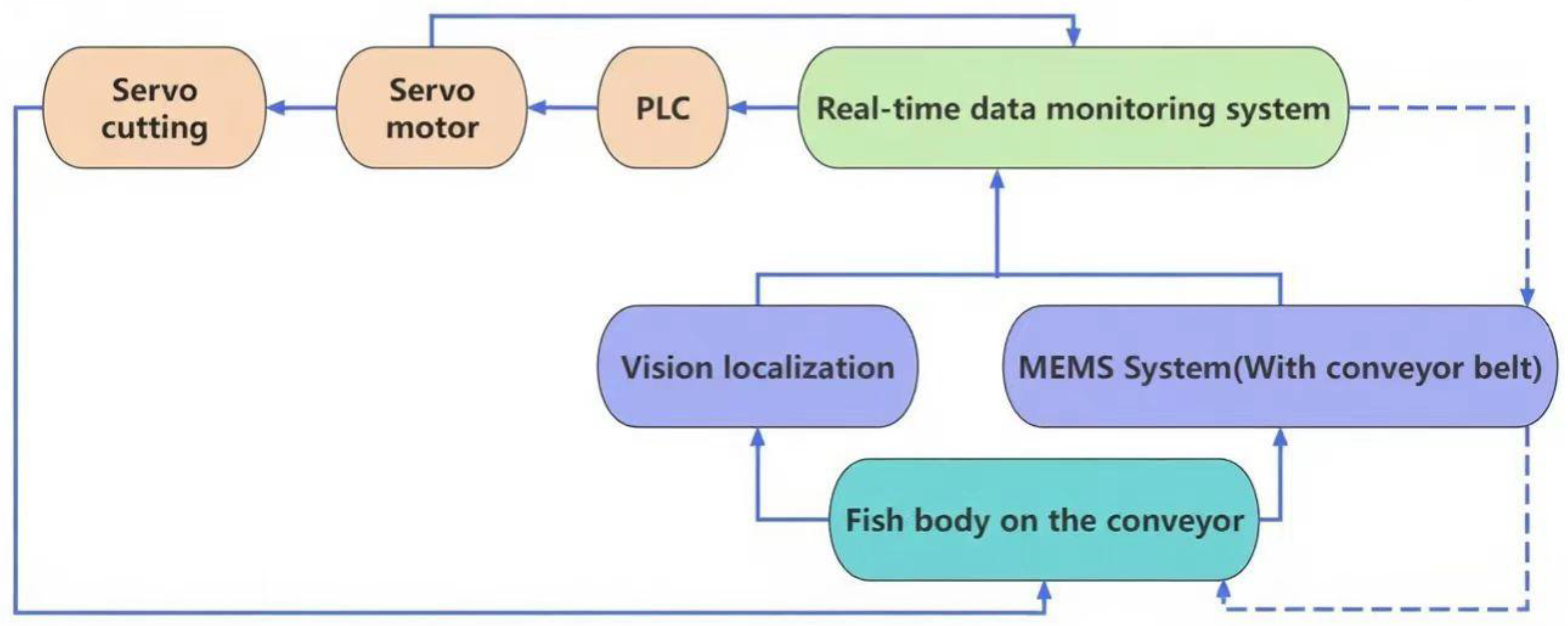

2.1. Design Ideas and Methods

2.2. Selection of Design Plan

2.2.1. Selection of Cutting Schemes

- (1)

- Line saw cutting or circular saw cutting

- (2)

- Knife cutters-type blade cutting

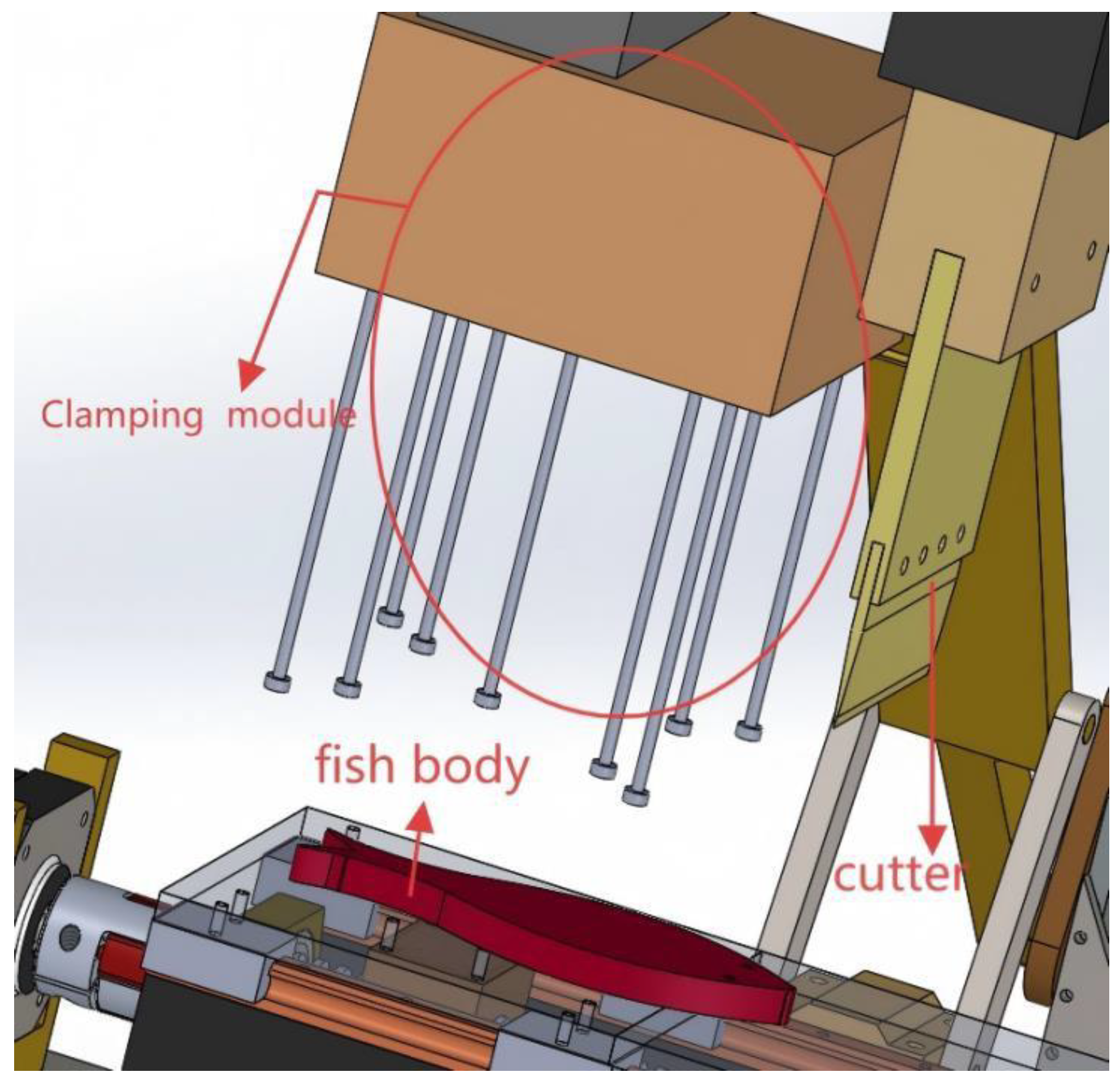

2.2.2. Design of Clamping Module

2.2.3. Transmission Scheme Selection

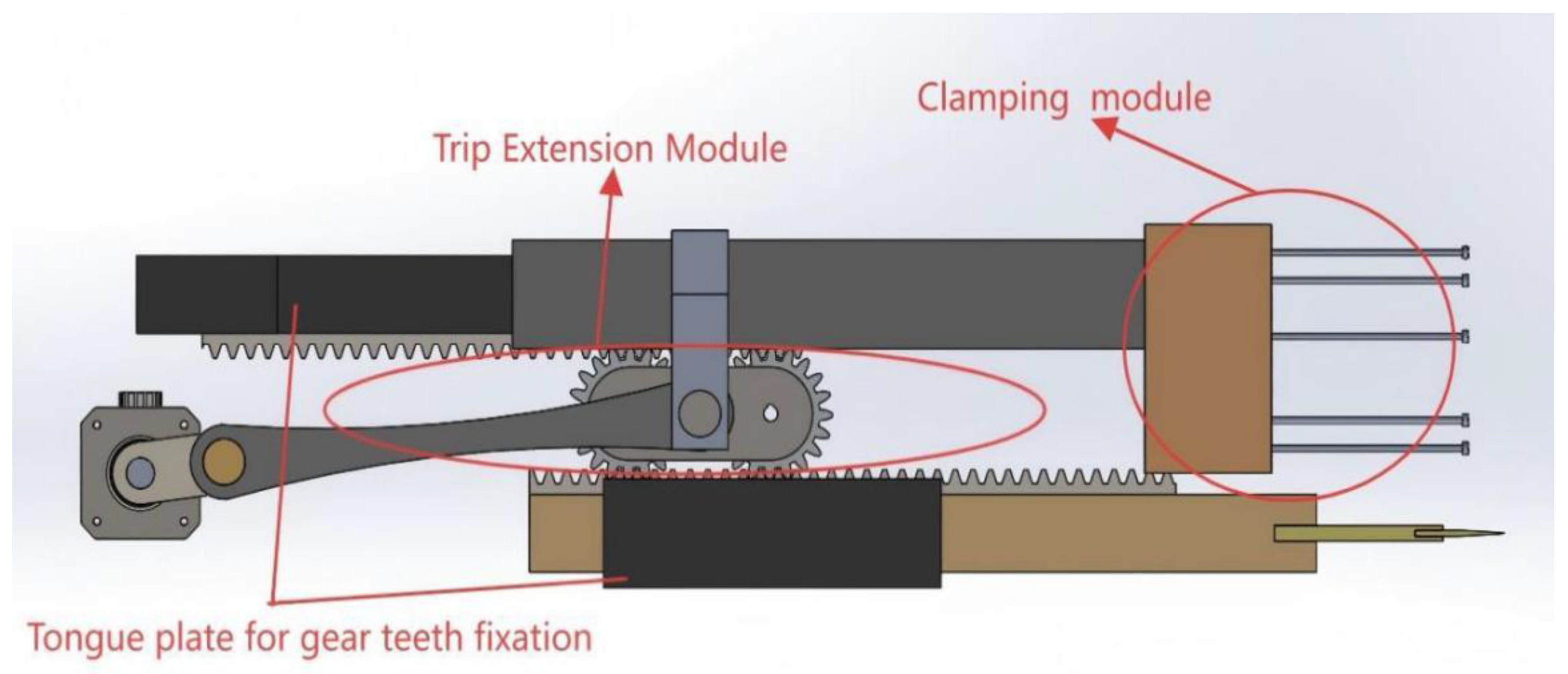

2.2.4. Push Scheme Selection

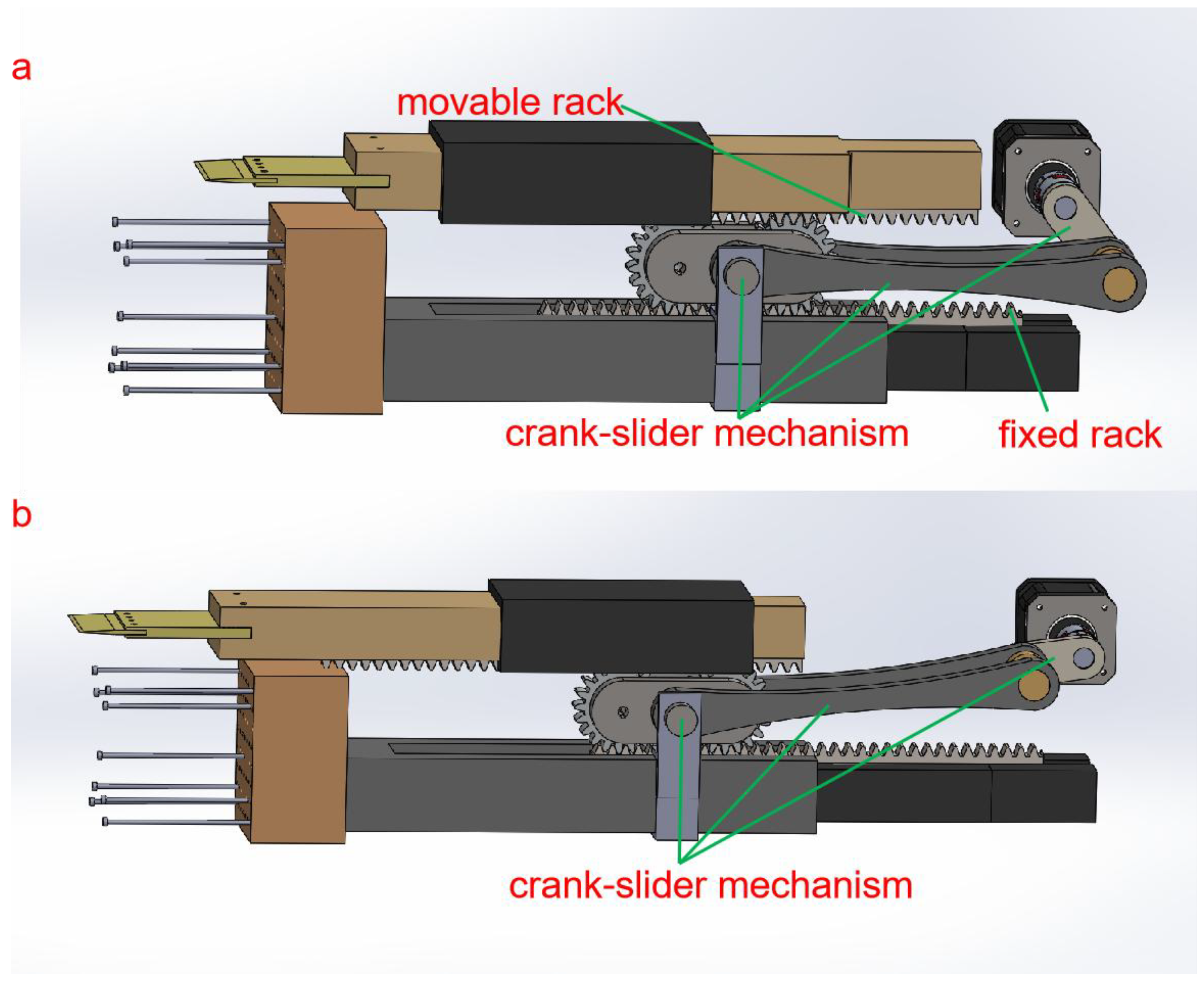

3. Design of Some Major Parts

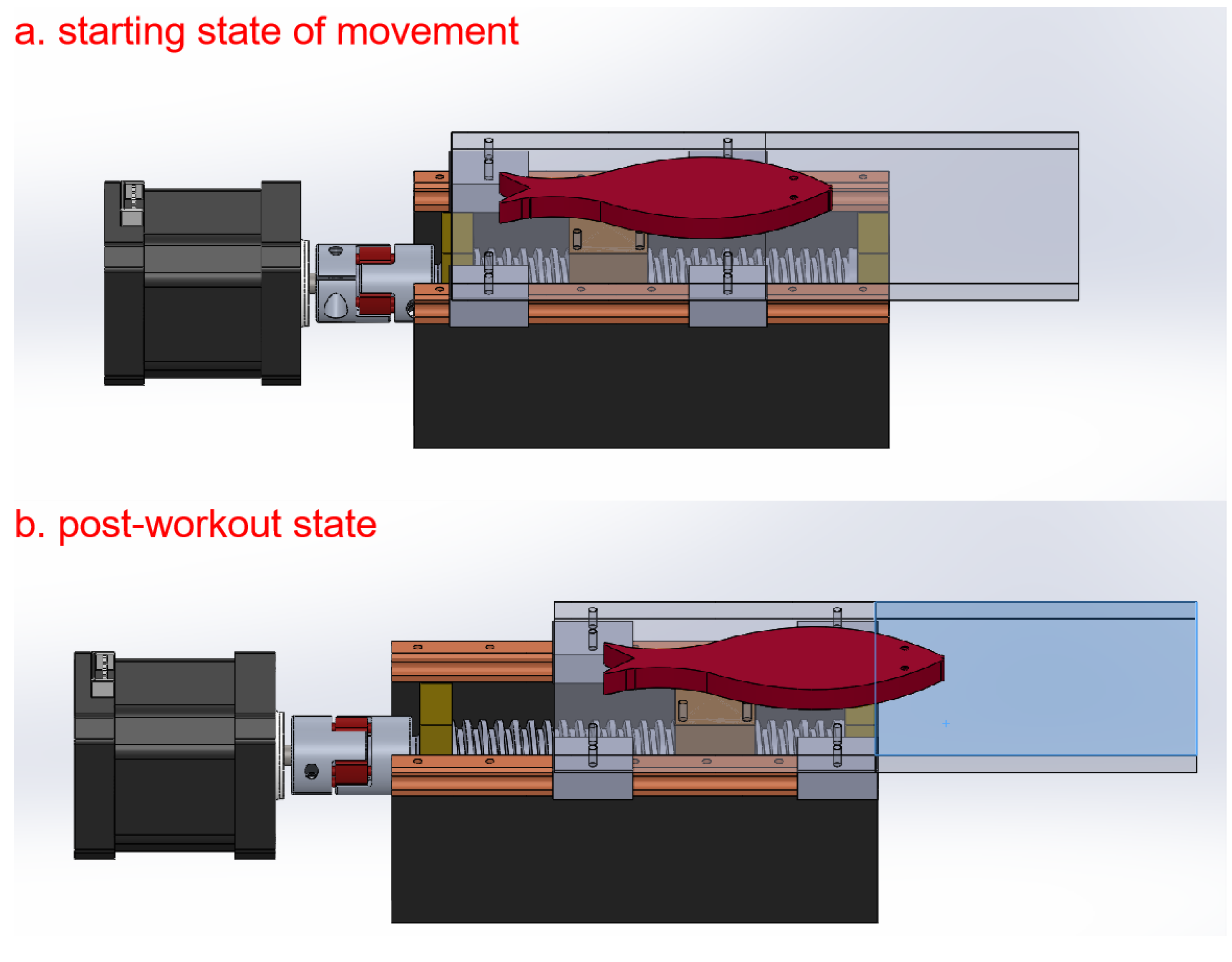

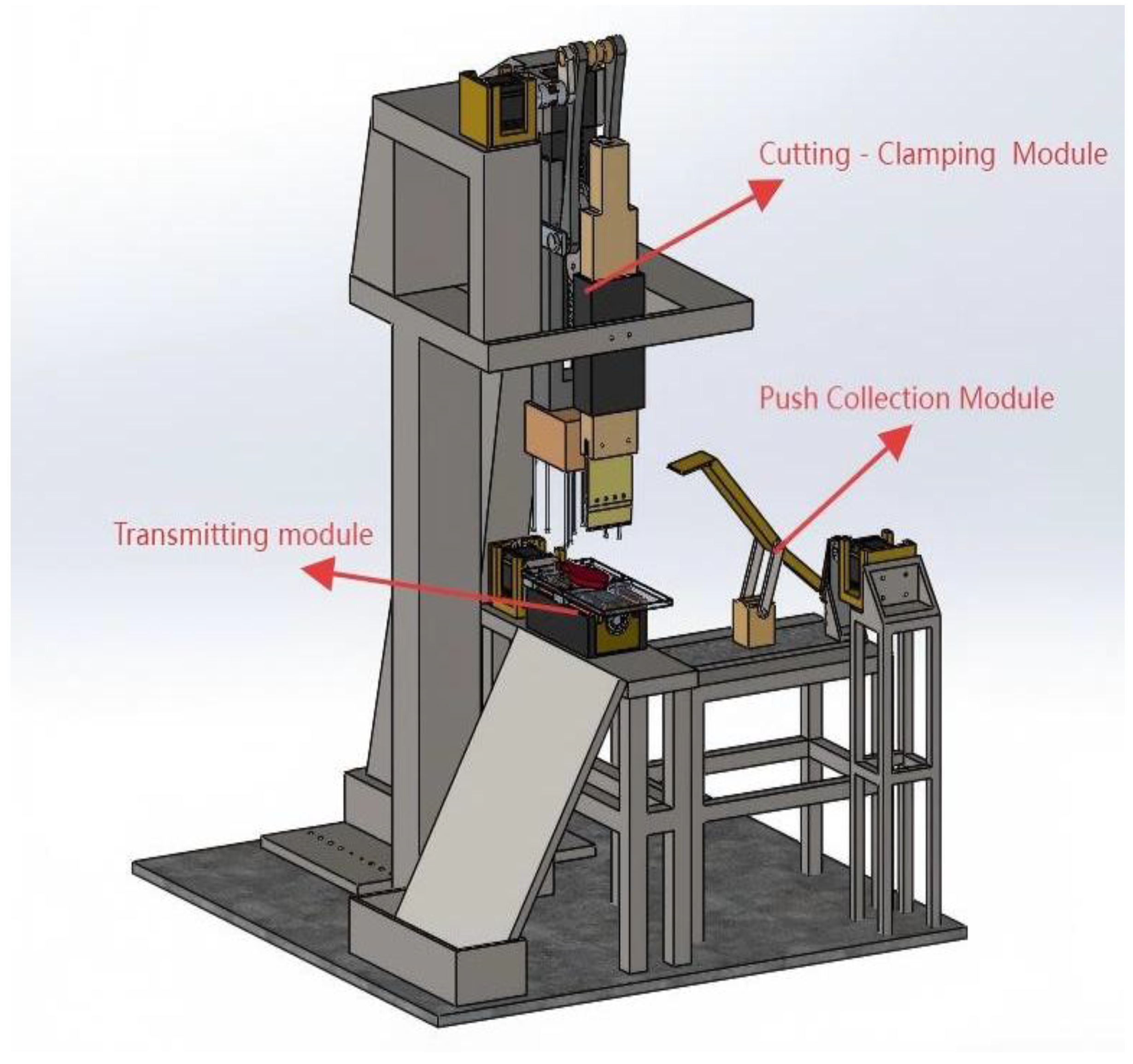

3.1. Equipment Processing Procedure of the Device

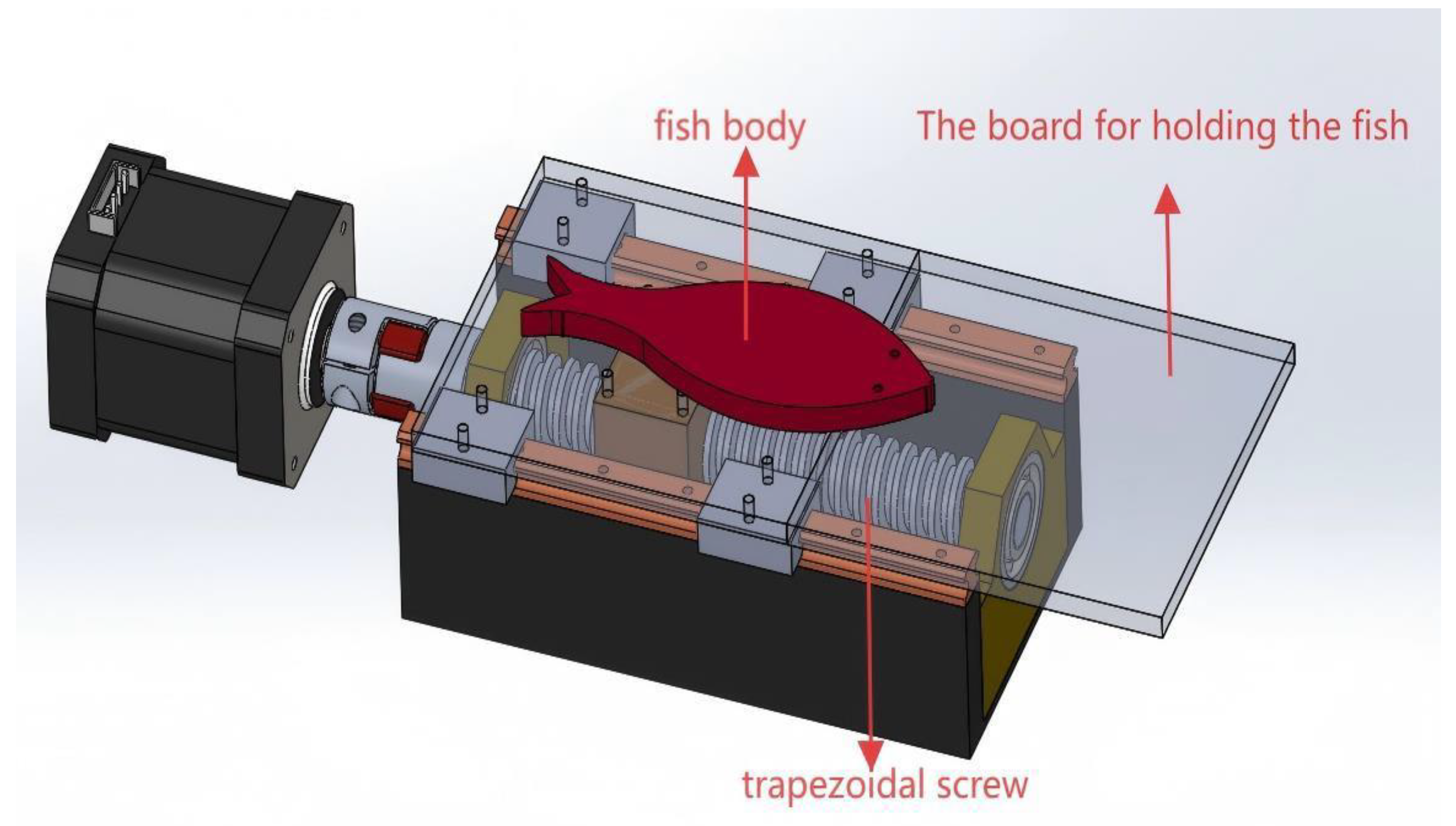

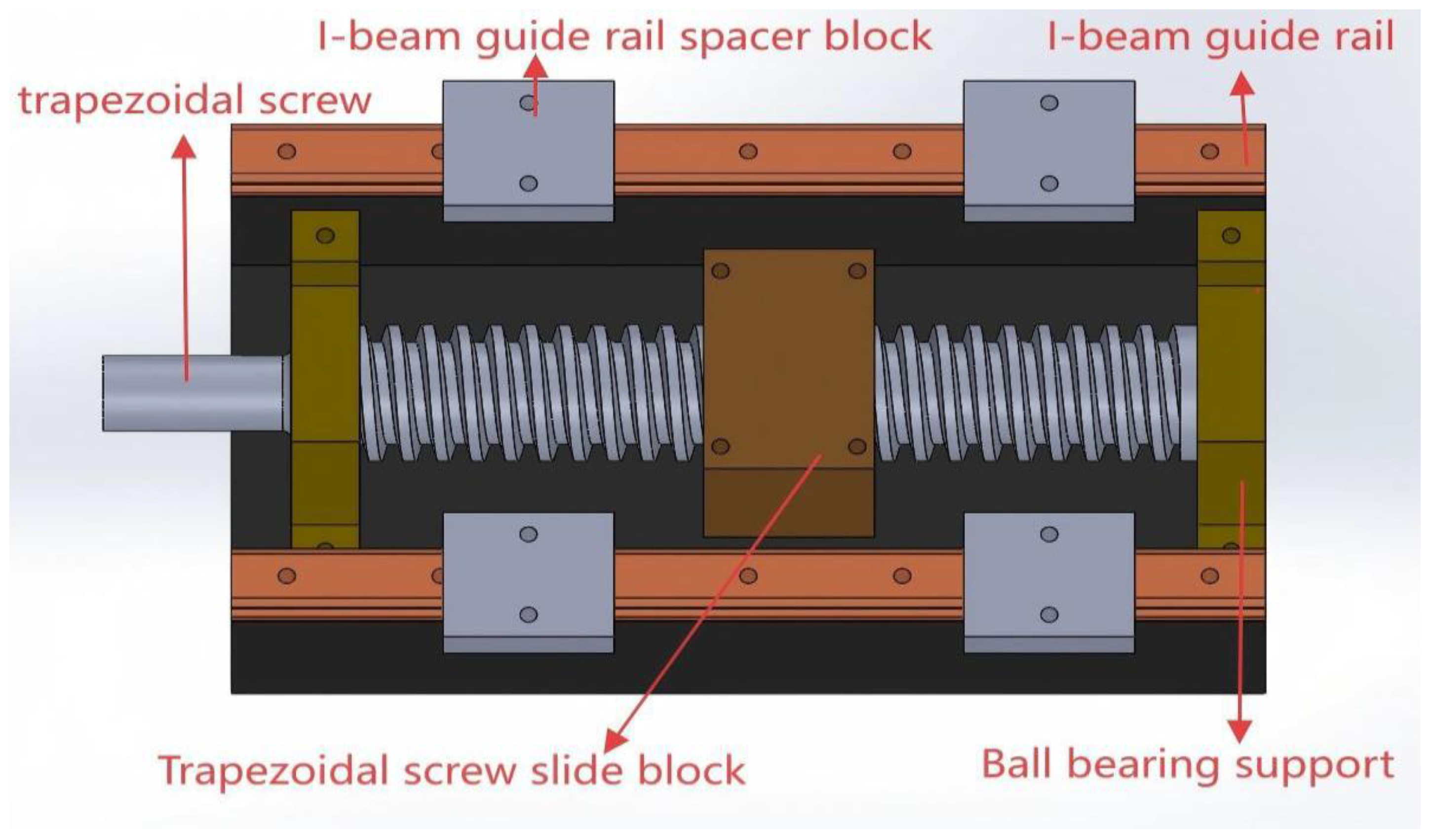

3.2. Selection of Lead Screw

3.3. Design of Cutting Tools and Their Movement Processes

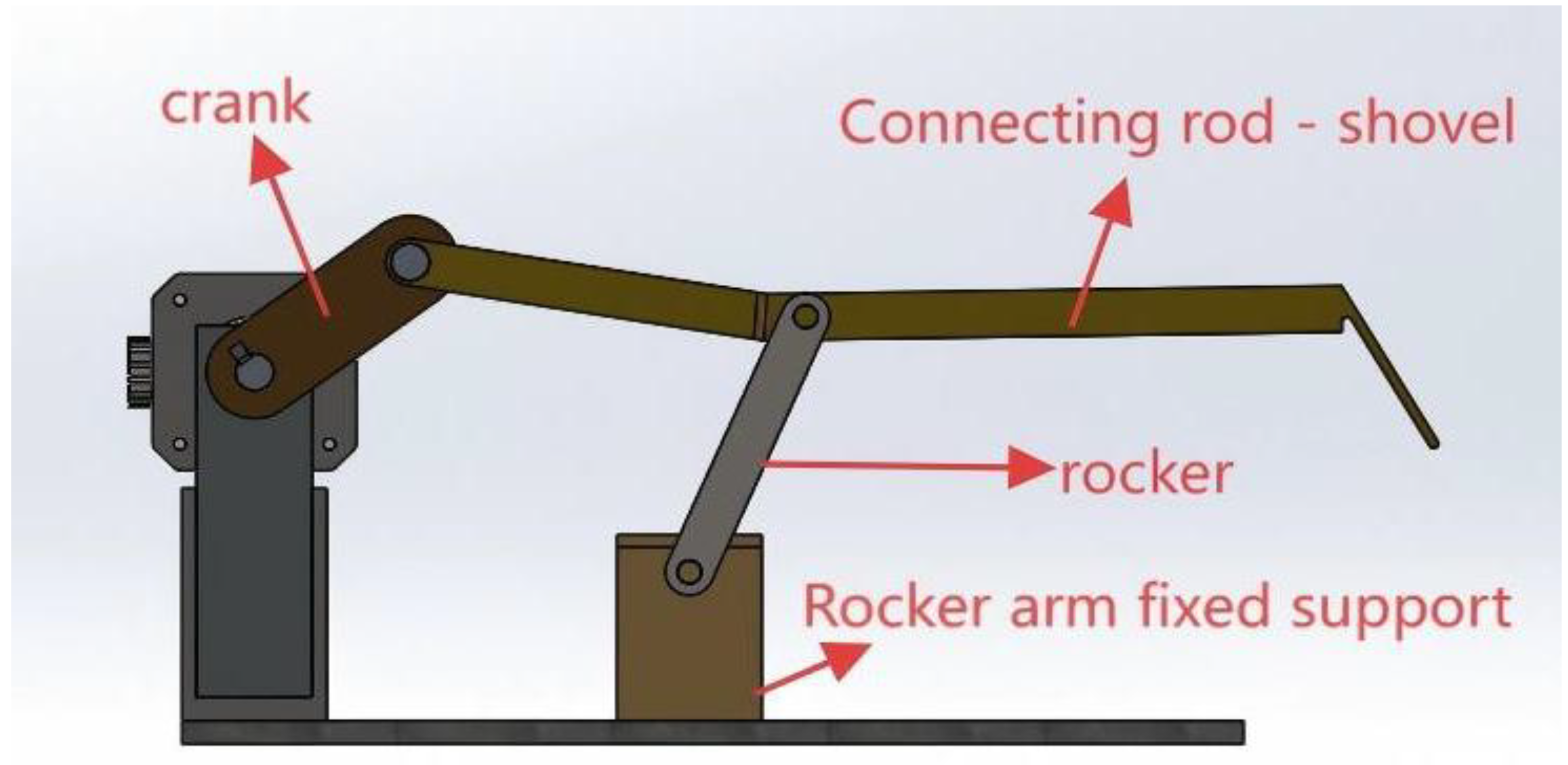

3.4. The Design of the Push Module

3.5. Calculation for Motor Selection

- Calculate the cutting force:where τ is the shear strength of the fish meat (0.44 MPa), l is the cut width (15 mm), and t is the cut thickness (10 mm).F = τ × l × tF = 0.44 × 106 × 15 × 10−3 × 10 × 10−3 = 66 N

- Calculate the power of the motorwhere v is the cutting speed (0.1 m/s).P = F × vP = 66 × 0.1 = 6.6 W

- Determine the speed of the motor.where s is the tool’s travel (20 cm).N = 60 v/sn = 60 × 10/20 = 30 rpm

- Calculate the torque of the motor, where n is the motor speed (30 rpm).

4. Fabrication and Testing of Automated Cutting Prototype

4.1. Fabrication of Automated Cutting Prototype

4.2. Testing of Automated Cutting Prototype

5. Conclusions

- (1)

- The optimized cutting scheme was designed using the SolidWorks software after comparing two cutting schemes, and the automatic clamping module, conveying module, and pushing module schemes were also designed.

- (2)

- The key components inside the device were designed and analyzed structurally, and a three-dimensional model of the automatic grass carp cutting device was constructed. A prototype was manufactured.

- (3)

- The prototype was used to conduct cutting tests on the grass carp. The results showed that the cutting rate was 200 kg/h, and the surface damage rate was less than 5%, achieving the expected cutting effect.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bjørlykhaug, E.; Egeland, O. Vision system for quality assessment of robotic cleaning of fish processing plants using CNN. IEEE Access 2019, 7, 71675–71685. [Google Scholar] [CrossRef]

- Hlavač, L.M. Application of water jet description on the descaling process. Int. J. Adv. Manuf. Technol. 2015, 80, 721–735. [Google Scholar] [CrossRef]

- Sampels, S. The effects of processing technologies and preparation on the final quality of fish products. Trends Food Sci. Technol. 2015, 44, 131–146. [Google Scholar] [CrossRef]

- Xu, W.; He, Y.; Li, J.; Zhou, J.; Xu, E.; Wang, W.; Liu, D. Robotization and intelligent digital systems in the meat cutting industry: From the perspectives of robotic cutting, perception, and digital development. Trends Food Sci. Technol. 2023, 135, 234–251. [Google Scholar] [CrossRef]

- Yi, L.; Wang, W.; Diao, Y.; Yi, S.; Shang, Y.; Ren, D.; Ge, K.; Gu, Y. Recent advances of artificial intelligence in quantitative analysis of food quality and safety indicators: A review. Trends Anal. Chem. 2024, 180, 117944. [Google Scholar] [CrossRef]

- Xu, W.; Wang, J.; Deng, Y.; Li, J.; Yan, T.; Zhao, S.; Yang, X.; Xu, E.; Wang, W.; Liu, D. Advanced cutting techniques for solid food: Mechanisms, applications, modeling approaches, and future perspectives. Compr. Rev. Food Sci. Food Saf. 2022, 21, 1568–1597. [Google Scholar] [CrossRef] [PubMed]

- ISO 4833-1:2013; Microbiology of the Food Chain—Horizontal Method for the Enumeration of Microorganisms—Part 1: Colony Count at 30 °C by the Pour Plate Technique. International Organization for Standardization (ISO): Geneva, Switzerland, 2013.

- Yuan, S.; Xu, J.; Yuan, H.; Ku, J.; Liu, Z. Design and Testing of a Fully Automatic Aquatic Plant Combining Machine for Crab Farming. Machines 2024, 12, 639. [Google Scholar] [CrossRef]

- Wu, H.; Luo, N.; Wang, C. Study on control strategy of the rotary synchronous fixed-length cutting system. J. Vibroeng. 2013, 15, 713–725. [Google Scholar]

- Komlatsky, V.I.; Podoinitsyna, T.A.; Verkhoturov, V.V.; Kozub, Y.A. Automation technologies for fish processing and production of fish products. J. Phys. Conf. Ser. 2019, 1399, 044050. [Google Scholar] [CrossRef]

- Mainali, S.; Li, C. A robotic fish processing line enhanced by machine learning. Aquac. Eng. 2025, 108, 102481. [Google Scholar] [CrossRef]

- Fu, J.; He, Y.; Cheng, F. Intelligent cutting in fish processing: Efficient, high-quality, and safe production of fish products. Food Bioprocess Technol. 2024, 17, 828–849. [Google Scholar] [CrossRef]

- Duan, M.; Zhu, Z.; Pi, H.; Chen, J.; Cai, J.; Wu, Y. Mechanistic Insights and Analytical Advances in Food Antioxidants: A Comprehensive Review of Molecular Pathways, Detection Technologies, and Nutritional Applications. Antioxidants 2025, 14, 438. [Google Scholar] [CrossRef] [PubMed]

- Huang, L.Y.; Chen, Z.S. Effect of technological parameters on hydrodynamic performance of ultra-high-pressure water-jet nozzle. Appl. Ocean Res. 2022, 129, 103410. [Google Scholar] [CrossRef]

- Perianu, I.A.; Murariu, A.C.; Botila, L.N.; Marin-Corciu, M.; Duma, I.; Baeră, C. Advancements in Abrasive Waterjet Cutting Technologies: A Comprehensive Overview and Future Prospects in the Manufacturing Industry. Key Eng. Mater. 2024, 996, 77–86. [Google Scholar] [CrossRef]

- Ma, K.; Zhang, J.; Feng, P.; Yu, D.; Wu, Z. Modeling and fitting of an ultrasonic straight-blade cutting system. Int. J. Adv. Manuf. Technol. 2021, 112, 833–843. [Google Scholar] [CrossRef]

- Vasilyev, A.M. Deep processing-the main direction in enhancing the efficiency of fish utilization. Ekon. I Sotsialnye Peremeny 2013, 29, 79. [Google Scholar]

- Chen, J.S.; Chen, J.B.; Shi, Q.Y.; Wang, Y.T.; Xia, X.Z.; Li, R.D. Microstructure and high-temperature performance of heat-resistant Al− Fe− Mn alloy prepared by laser powder bed fusion. Trans. Nonferrous Met. Soc. China 2025, 35, 2183–2200. [Google Scholar] [CrossRef]

- Liao, I.C.; Hsu, Y.K.; Lee, W.C. Technical innovations in eel culture systems. Rev. Fish. Sci. 2002, 10, 433–450. [Google Scholar] [CrossRef]

- Kapłonek, W.; Nadolny, K.; Zieliński, B.; Plichta, J.; Pimenov, D.Y.; Sharma, S. The role of observation–Measurement methods in the surface characterization of X39Cr13 stainless-steel cutting blades used in the fish processing industry. Materials 2020, 13, 5796. [Google Scholar] [CrossRef]

- Liu, Z.; Liao, Z.; Wang, D.; Wang, C.; Song, C.; Li, H.; Liu, Y. Recent advances in soft biological tissue manipulating technologies. Chin. J. Mech. Eng. 2022, 35, 89. [Google Scholar] [CrossRef]

- Skjoldebrand, C. Food-processing equipment. In Handbook of Food Factory Design; Springer: New York, NY, USA, 2013; pp. 51–77. [Google Scholar]

- De Silva, C.W.; Wickramarachchi, N. An innovative machine for automated cutting of fish. IEEE/ASME Trans. Mechatron. 2002, 2, 86–98. [Google Scholar] [CrossRef]

- Li, Q.; Ma, H.; Min, W.; Wang, Y.; Zhao, R.; Zhou, Y.; Tan, Y.; Luo, Y.; Hong, H. Recent advances in fish cutting: From cutting schemes to automatic technologies and internet of things innovations. Compr. Rev. Food Sci. Food Saf. 2024, 23, e70039. [Google Scholar] [CrossRef]

- Bibwe, B.R.; Hiregoudar, S.; Nidoni, U.R.; Anantachar, M.; Shrestha, B. Development of a meat-bone separator for small-scale fish processing. J. Food Sci. Technol. 2013, 50, 763–769. [Google Scholar] [CrossRef] [PubMed]

- Cheng, J.H.; Sun, D.W.; Han, Z.; Zeng, X.A. Texture and structure measurements and analyses for evaluation of fish and fillet freshness quality: A review. Compr. Rev. Food Sci. Food Saf. 2014, 13, 52–61. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.H.; Kang, S.I.; Mansoor, S.; Lee, I.; Kim, D.Y.; Kim, Y.Y.; Park, Y.; Sohn, J.H.; Bashir, K.M.I.; Choi, J.S. Development and process optimization of a steamed fish paste cake prototype for room temperature distribution. Processes 2024, 12, 795. [Google Scholar] [CrossRef]

- Aly, B.A.; Low, T.; Long, D.; Brett, P.; Baillie, C. Tactile sensing for tissue discrimination in robotic meat cutting: A feasibility study. J. Food Eng. 2024, 363, 111754. [Google Scholar] [CrossRef]

- Mu, X.; Xue, Y.; Jia, Y.B. Robotic cutting: Mechanics and control of knife motion. In Proceedings of the 2019 International Conference on Robotics and Automation (ICRA), Montreal, QC, Canada, 20–24 May 2019; pp. 3066–3072. [Google Scholar]

- Shaw, K.P.; Chung, J.H.; Chung, F.C.; Tseng, B.Y.; Pan, C.H.; Yang, K.T.; Yang, C.P. A method for studying knife tool marks on bone. J. Forensic Sci. 2011, 56, 967–971. [Google Scholar] [CrossRef]

- Biallas, G.H. High Force Spring Clamp System; Hyperboloid LLC: Yorktown, VA, USA, 2021. [Google Scholar]

- ISO 22000:2018; Food Safety Management Systems—Requirements for Any Organization in the Food Chain. International Organization for Standardization (ISO): Geneva, Switzerland, 2018.

- Chen, J.; Liu, Y.; Yang, J.; He, L.; Tang, H.; Li, X. A review of development and applications of SiC power devices in packaging and interconnect technology. Solder. Surf. Mt. Technol. 2025, 37, 76–83. [Google Scholar] [CrossRef]

- El-Elamy, M.I. Improving the Dynamic Performance of the Crank-Rocker Mechanism Using Composite Links. ERJ. Eng. Res. J. 2023, 46, 471–484. [Google Scholar] [CrossRef]

- Reytskiy, M.; Kovalenko, M.; Tymoshchuk, O. Selection and Calculation of Servo Motors for CNC. Наукoвий журнал «Енергетика: екoнoміка, технoлoгії, екoлoгія» 2021, 2. [Google Scholar]

- Busch-Vishniac, I.J. Electromechanical Sensors and Actuators; Springer Science & Business Media: Berlin/Heidelberg, Germany, 1998. [Google Scholar]

- Chen, J.; Chen, J.; Wang, H.; He, L.; Huang, B.; Dadbakhsh, S.; Bartolo, P. Fabrication and development of mechanical metamaterials via additive manufacturing for biomedical applications: A review. Int. J. Extrem. Manuf. 2025, 7, 012001. [Google Scholar] [CrossRef]

- Shi, Q.; Chen, J.; Chen, J.; Liu, Y.; Wang, H. Application of additively manufactured bone scaffold: A systematic review. Biofabrication 2024, 16, 022007. [Google Scholar] [CrossRef]

- Hu, M.; Zhi, S.; Chen, J.; Li, R.; Liu, B.; He, L.; Yang, H.; Wang, H. Restraint of intermetallic compound and improvement of mechanical performance of Ti/Al dissimilar alloy by rotary friction welding based on laser powder bed fusion. J. Manuf. Process. 2024, 131, 440–454. [Google Scholar] [CrossRef]

- Wang, Y.; Guo, W.; Li, H.; Xie, Y.; Shi, J.; Liang, Z.; Han, P.; Li, S.; Zhang, H. Nano-scale microstructural evolution and mechanical property enhancement mechanism during crack inhibition in nickel-based superalloys fabricated by laser powder bed fusion. Addit. Manuf. 2025, 100, 104685. [Google Scholar] [CrossRef]

- Liao, Z.; La Monaca, A.; Murray, J.; Speidel, A.; Ushmaev, D.; Clare, A.; Axinte, D.; M’Saoubi, R. Surface integrity in metal machining-Part I: Fundamentals of surface characteristics and formation mechanisms. Int. J. Mach. Tools Manuf. 2021, 162, 103687. [Google Scholar] [CrossRef]

- Commission Regulation (EU) 2025/1090; Amending REACH Annex XVII regarding DMAC and NEP. Publications Office of the European Union: Luxembourg, Luxembourg, 2025.

| Group | Number (Piece) | Speed (Fish/h) | Fish Body Surface Area (cm2) | Damage Area (cm2) | The Damage Rate (%) |

|---|---|---|---|---|---|

| 1 | 100 | 200 | 20 | 0.76 | 3.8 |

| 2 | 100 | 250 | 25 | 1.075 | 4.3 |

| 3 | 100 | 300 | 30 | 1.35 | 4.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, X.; Chen, J.; Wu, Y. Structural Design and Analysis of an Automated Cutting Device for a Grass Carp Product Based on SolidWorks. Machines 2025, 13, 1081. https://doi.org/10.3390/machines13121081

Chen X, Chen J, Wu Y. Structural Design and Analysis of an Automated Cutting Device for a Grass Carp Product Based on SolidWorks. Machines. 2025; 13(12):1081. https://doi.org/10.3390/machines13121081

Chicago/Turabian StyleChen, Xiaoqiu, Jibing Chen, and Yiping Wu. 2025. "Structural Design and Analysis of an Automated Cutting Device for a Grass Carp Product Based on SolidWorks" Machines 13, no. 12: 1081. https://doi.org/10.3390/machines13121081

APA StyleChen, X., Chen, J., & Wu, Y. (2025). Structural Design and Analysis of an Automated Cutting Device for a Grass Carp Product Based on SolidWorks. Machines, 13(12), 1081. https://doi.org/10.3390/machines13121081