Abstract

The increasing complexity of mechanical manufacturing demands intelligent, integrated solutions to maintain high levels of precision, efficiency, and traceability. While ERP systems provide centralized management for core business functions, they often fall short in addressing operational-level workflows on the shopfloor. This paper presents the development and implementation of GIP (Gestão Integrada de Produção—Integrated Production Management), a custom software solution designed to bridge this gap for a small-to-medium enterprise (SME) specializing in precision mechanical components. GIP automates manual tasks such as technical drawing validation, file management, and part tracking, significantly reducing approval times and human error while enhancing traceability through unique DataMatrix part marking and centralized data logging. Developed with a modular, user-centered design using C# and SQL Server, the system integrates seamlessly with existing ERP infrastructure, following Industry 4.0 principles. Its deployment resulted in quantifiable improvements in productivity, data security, interdepartmental communication, and project delivery times. The success of GIP underscores the benefits of complementing ERP platforms with task-specific tools tailored to real user workflows. This approach aligns with smart manufacturing trends such as digital threads and digital twins, laying the groundwork for future enhancements in predictive maintenance and real-time analytics. GIP demonstrates how agile, scalable digital tools can drive competitiveness in modern industrial environments.

1. Introduction

The evolution of the manufacturing sector, particularly within mechanical engineering, has increasingly demanded intelligent, integrated systems capable of meeting rising expectations for precision, efficiency, traceability, quality assurance and inventory management while also facilitating effective planning and, consequently, deadline management [1,2]. As industrial competitiveness intensifies, enterprises are prioritizing digital transformation to achieve process efficiency and reduce potential operational errors [3,4,5]. Among the most impactful technological advancements within digital transformation are software solutions designed to manage and integrate project design with production workflows. These tools enable enterprises to streamline operations, minimize manual interventions, and enhance overall traceability [6].

Mechanical manufacturing processes are inherently complex, involving multiple interconnected stages such as design, machining, quality control, surface or heat treatment, and assembly [7]. Traditionally, these stages have relied on manual document validation, interdepartmental communication, and manual task execution, which often result in fragmented workflows, inefficiencies, and increased error rates [8]. These challenges are particularly pronounced in small and medium-sized enterprises (SMEs), which frequently lack the necessary resources for full-scale digital integration across departments [9,10]. Enterprise Resource Planning (ERP) systems are widely adopted across industrial sectors to manage core business functions such as finances, logistics, procurement, and resource allocation, providing centralized data management and facilitating overall operational efficiency [11].

Despite their potential in central management, ERP systems often struggle to handle operational-level tasks such as project validation, individual components tracking, and synchronization of real-time activities on the shopfloor [12,13,14]. To address these limitations, many enterprises have also implemented customized digital tools that complement ERP systems by addressing task-specific needs, particularly in high-precision and multi-phase operations where detailed tracking, operational flexibility, and real-time responsiveness are critical [15,16,17]. In this context, this paper presents the development of GIP (Gestão Integrada de Produção—Integrated Production Management), a dedicated software solution aimed at enhancing production management within an SME operating in industrial automation and mechanical component manufacturing. The enterprise’s workflow encompasses a wide range of interconnected activities including mechanical design, computer numerical control (CNC) machining, automation, on-site installation, and technical support. Given the complexity and breadth of this workflow, high coordination between design and production phases is essential, yet often difficult to achieve with conventional management tools. To address these challenges, GIP was developed to automate repetitive administrative and production-related tasks, eliminate potential communication bottlenecks, and implement robust traceability mechanisms throughout the production cycle, following the fundamental principles of Industry 4.0 [18,19,20].

2. Background

ERPs are integrated software platforms that unify various business functions, such as finance, human resources, sales, and logistics, into a single cohesive system [13]. By facilitating seamless data flow across departments, ERPs promote centralized information management and enhance interdepartmental communication [13]. Their primary objective is to optimize management processes and decision making, thereby improving operational efficiency and minimizing errors. Through real-time data access, ERP systems enable organizations to monitor and control their processes more accurately, supporting informed decision making and timely interventions [21].

Complementing these systems, Manufacturing Execution Systems (MESs) are specialized software solutions designed to monitor, control, and optimize production processes in real time within manufacturing environments [22]. Serving as a vital link between ERP systems and the shopfloor, MES solutions ensure that manufacturing activities are executed as planned while providing real-time visibility into production performance [22,23]. While ERP systems focus on high-level business planning and resource management, MESs operate closer to the production, offering detailed insights into production processes, work order management, and quality control [24].

A wide range of MES and ERP solutions is available on the market, varying in scope, cost, and flexibility. Commercial systems such as Opcenter, FactoryTalk, and AVEVA MES provide extensive functionality and robust scalability, making them well suited for large manufacturing operations [25,26,27]. In contrast, open-source or lower-cost alternatives like ERPNext and Odoo offer more flexible and customizable solutions at significantly reduced implementation costs, making them particularly attractive for SMEs [28,29]. These varied solutions illustrate the broad spectrum of MES offerings currently available, from comprehensive commercial suites to adaptable open-source platforms, each with its own balance of cost, functionality, and flexibility.

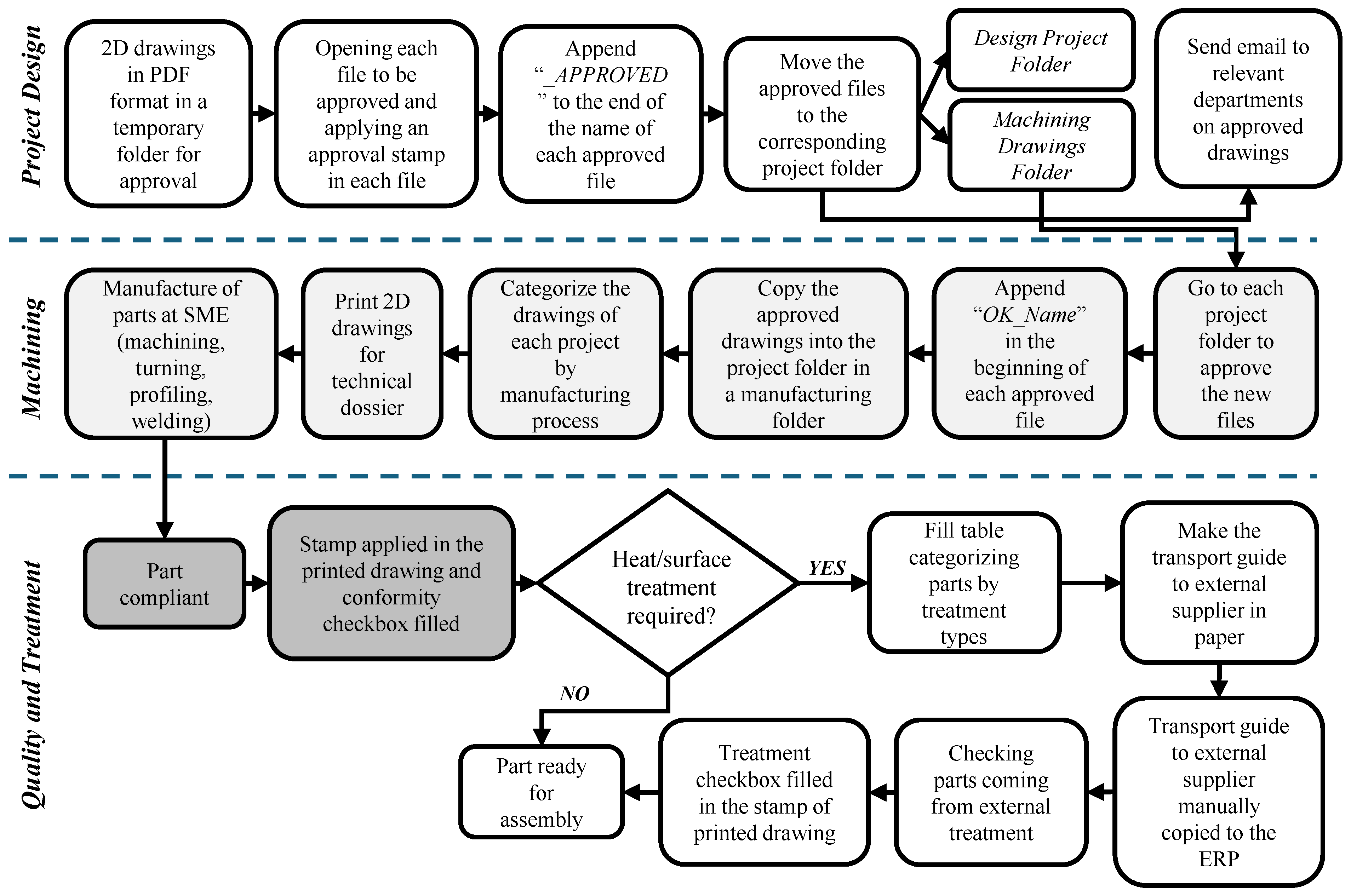

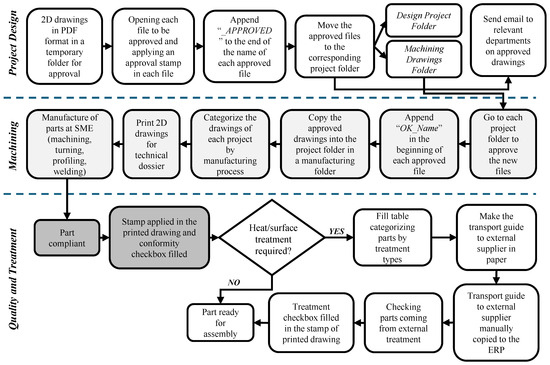

ERP systems are generally designed to be highly customizable, allowing them to adapt to the specific workflows and operational requirements of different organizations, a crucial role in integrating business functions and improving efficiency. Still, despite their recognized potential in industrial settings, some ERP systems are often unable to address specific demands of project-based manufacturing and production workflows, given that they are generally designed for administrative and financial management, rather than engineering and production. In these cases, tailored digital tools are required to maintain the growing demands for efficiency, traceability, and precision [11,12,13,30]. This was precisely the case of the SME reported in this study, which specializes in the design and manufacturing of industrial mechanical components and systems. Although being equipped with a robust ERP platform (PHC) for overall business management, this SME’s system lacked the necessary automation capabilities to efficiently handle technical project approvals, manage design iterations, and track production workflows on the shopfloor. Indeed, tasks such as manual validation of technical drawings, renaming files, organizing them into designated folders, and notifying relevant departments via email created production bottlenecks, which reduced productivity and introduced risks of error or data inconsistency. A workflow of the process prior to the GIP implementation is detailed in Figure 1.

Figure 1.

Workflow diagram of all manual tasks before the implementation of GIP software.

These limitations became increasingly evident as the enterprise scaled up its operations. Indeed, coordination among key departments, including mechanical design, machining, quality assurance, and logistics, was frequently hindered by fragmented communication channels and lack of real-time data integration. Furthermore, traceability throughout the production cycle was inconsistently maintained, posing risks to quality compliance and customer accountability, particularly in stages involving thermal or surface treatments and communications with external suppliers. Although ERP platforms typically offer configuration and integration options, these often involve significant financial and human resource investments.

To address all these challenges, several studies have recommended the implementation of customized digital tools, which have shown consistently positive outcomes in improving process efficiency and integration [15,17]. In fact, research has shown that even the digitalization of minor aspects of production processes within SMEs can act as a catalyst for achieving higher levels of digital maturity under the framework of Industry 4.0 [31,32].

In this context, and as an initial step toward digital transformation, a comprehensive analysis of the core concepts underlying ERP and MESs was conducted to identify the essential capabilities that the software should provide. These include task automation, enhanced interdepartmental communication, centralized information management, and improved traceability of components, all contributing to more effective project management and clearer definition of deadlines. Furthermore, the system was designed to integrate the entire production process into a cohesive and streamlined workflow.

Beyond adopting ERP and MES principles, a critical stage in the development process was the in-depth analysis of the SME’s internal operations. This involved systematically mapping each stage of the production process and detailing daily tasks, thereby establishing a robust foundation for a solution that is closely aligned with the company’s workflows and practical requirements. Moreover, the application was designed not only to ensure reliable component traceability but also strengthen quality assurance through digital validations and stamping, support project management, centralized database logging, and laser-based DataMatrix part marking, all in line with the Industry 4.0 principles [18,19]. By addressing these critical gaps, GIP emerged as an essential tool for synchronizing project and production workflows, minimizing human errors, and boosting productivity in practical industrial contexts.

Unlike previously developed frameworks that emphasize the integration of data from multiple specialized manufacturing systems, such as MES, SCADA, PLM, and QMS, using advanced machine learning techniques [33], GIP adopts a more centralized and cohesive approach aligned with ERP principles. Instead of focusing solely on shopfloor monitoring, GIP was designed as a lightweight, in-house ERP-like system aimed at automating key tasks, consolidating information across departments, and enhancing internal communication. By centralizing data related to component tracking and production processes, the system facilitates the creation of real-time dashboards and enables cross-referencing of operational information, capabilities typically found in commercial ERP systems such as PHC. Although GIP does not yet match the technological sophistication or scalability of fully integrated Industry 4.0 platforms, it offers a practical and cost-effective pathway toward digital transformation in an SME context, with strong potential for future interoperability and expanded data integration.

3. Materials and Methods

The development of GIP followed a structured and iterative approach to guarantee technical robustness, user-friendliness, and seamless integration with existing operations. During the initial phase of the software development process, the IT department provided substantial support, offering guidance on the selection of appropriate technologies to ensure that the application would be flexible, easily adaptable, and broadly accessible to all users. The software application was developed using C# in Microsoft Visual Studio (version 7.3), leveraging Windows Presentation Foundation (WPF) (NET Framework 4.7.2) to build a responsive and visually intuitive desktop interface. WPF’s support for data binding and custom UI elements proved to be particularly effective for dynamically managing technical drawings, approval workflows, and user interactions in real-time production environments.

Alongside the application’s development, a database was created using SQL Server Management Studio 18 (version 20.2.30.0), to not only centralize and store all the information managed by the application but also integrate and connect all the stages of the mechanical manufacturing process. The IT department also assisted in this, playing a key role in defining the most suitable project structures for both the desktop application and the website. The Agile methodology was adopted throughout the development process, emphasizing incremental deliveries, constant stakeholder feedback, and adaptability to evolving operational requirements. This flexible approach enabled rapid prototyping and continuous improvement based on user input.

The IT team also supported the deployment of the application, which was hosted on the SME’s internal server, enabling users to access and install it as needed. Significant assistance was also provided in the development and publication of the website, a more complex and time-consuming task. After evaluating multiple hosting options, the team decided to publish the website via Internet Information Services (IIS), limiting access to users connected to the SME’s internal network. While this enhanced security and manageability, it currently represents one of the system’s main limitations, as the ideal scenario would allow remote access regardless of location or network connection. For the time being, however, restricting access to the internal network was deemed the most secure and practical solution.

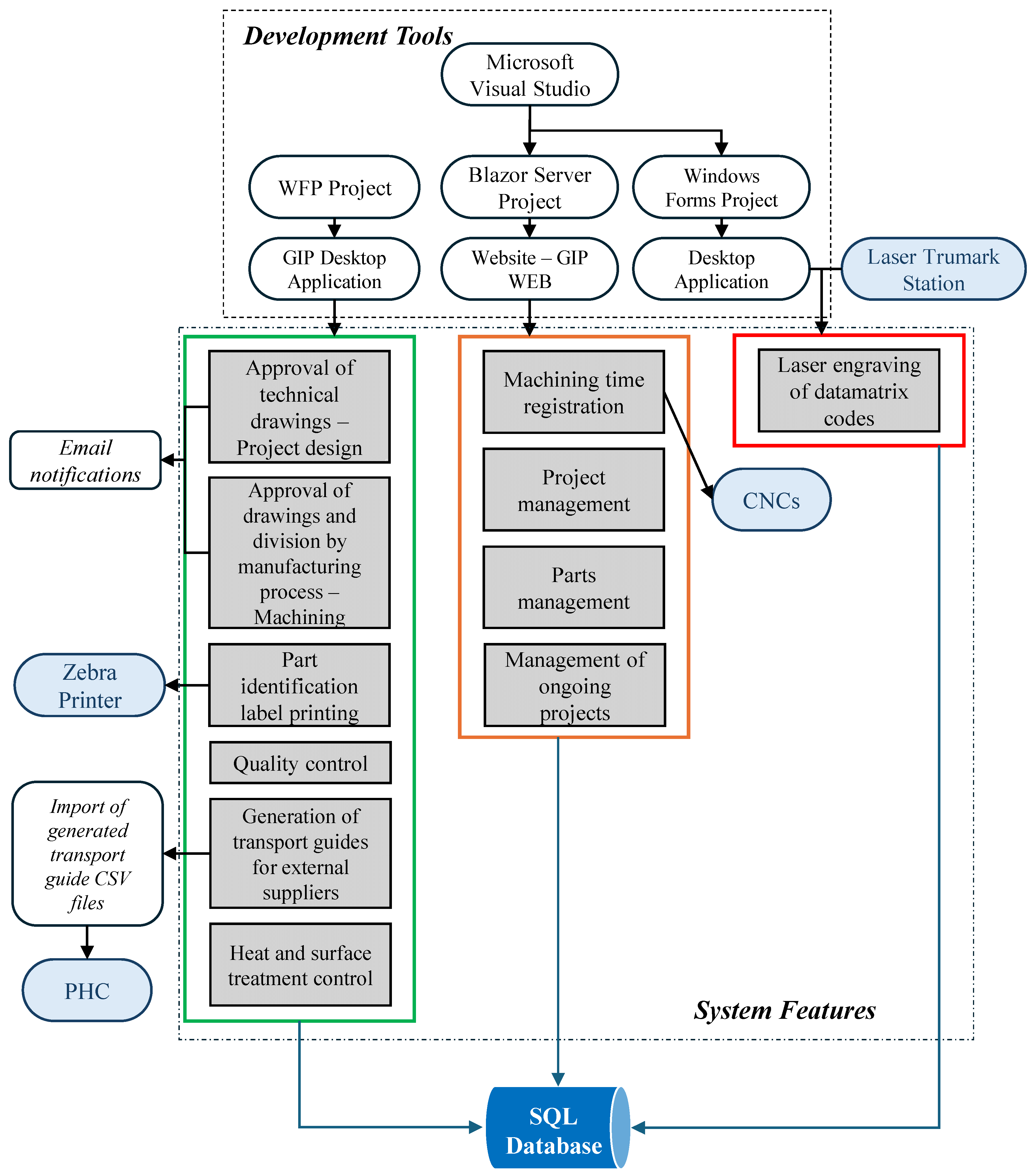

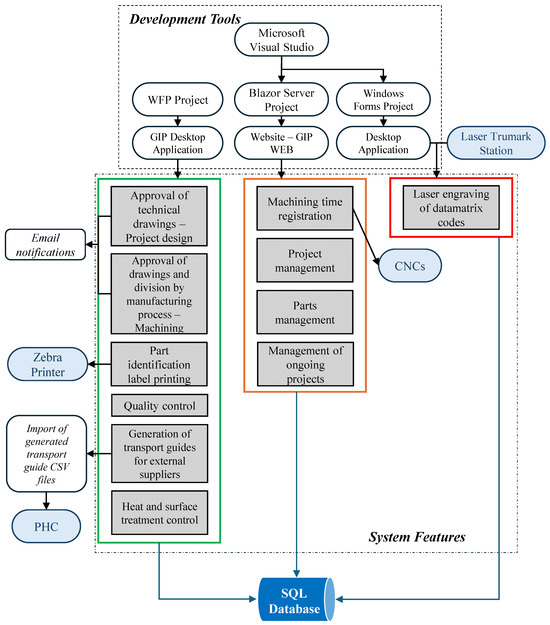

The development process was structured into five key phases: (1) requirement analysis; (2) system design; (3) software development; (4) testing and validation; and (5) implementation and integration. During the requirements analysis phase, comprehensive interviews were conducted with engineers and technicians from all relevant departments to identify critical inefficiencies in existing workflows, particularly recurring issues related to drawing approvals, data redundancy, and communication bottlenecks. Following this, a modular architecture based on the Model–View–Viewmodel pattern was designed and defined to ensure clear separation between the user interface, business logic, and data layers. This architectural approach enhanced scalability, maintainability, and testing efficiency. Although the study was grounded in an applied development process, the proposed methodological framework was intentionally designed to systematize and formalize this process into well-defined, replicable stages, thereby extending beyond a mere descriptive case study. Figure 2 shows the modular architecture of the GIP, clarifying the logical relationships between components and emphasizing the structured methodology that guided its development.

Figure 2.

Diagram of the modular GIP architecture.

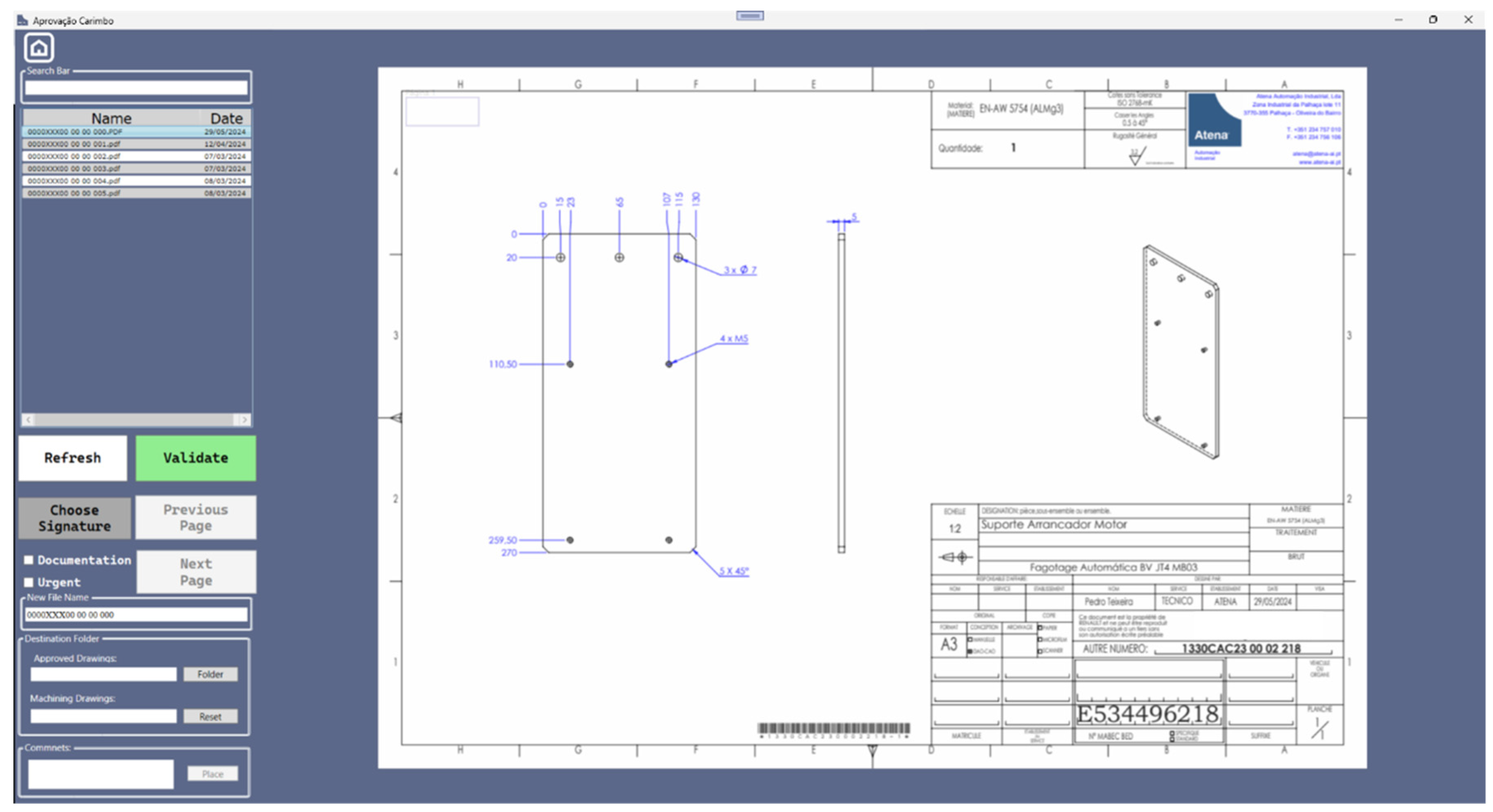

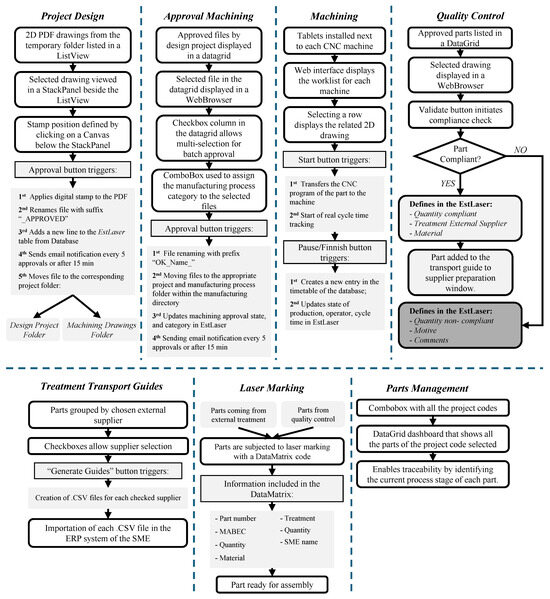

In the development phase, core functionalities were implemented, including automated digital stamping of technical drawings, user role management, file tracking and intelligent classification, generation of DataMatrix code for laser-based part marking, and automated notifications to streamline project stage transitions. These features collectively address the operational gaps identified during the analysis phase. Figure 3 illustrates the detailed software workflow and its integration across departments.

Figure 3.

Workflow diagram with GIP software.

Once development was complete, the system underwent rigorous unit testing for each functional module and user acceptance testing with actual operators, ensuring the software’s reliability, usability and performance under real industrial conditions. Finally, during the implementation and integration phase, the software was gradually deployed across all relevant departments. A dedicated training program was provided to staff, ensuring a smooth transition, minimizing resistance to change, and promoting an effective adoption of the new digital workflow.

4. Key Features of the GIP Software

The GIP software integrated multiple features designed to streamline file management, improve interdepartmental communication, and enable precise tracking of manufactured components. The following sections provide a detailed description of the key functionalities incorporated into the software, each carefully designed to address the specific operational needs of the SME.

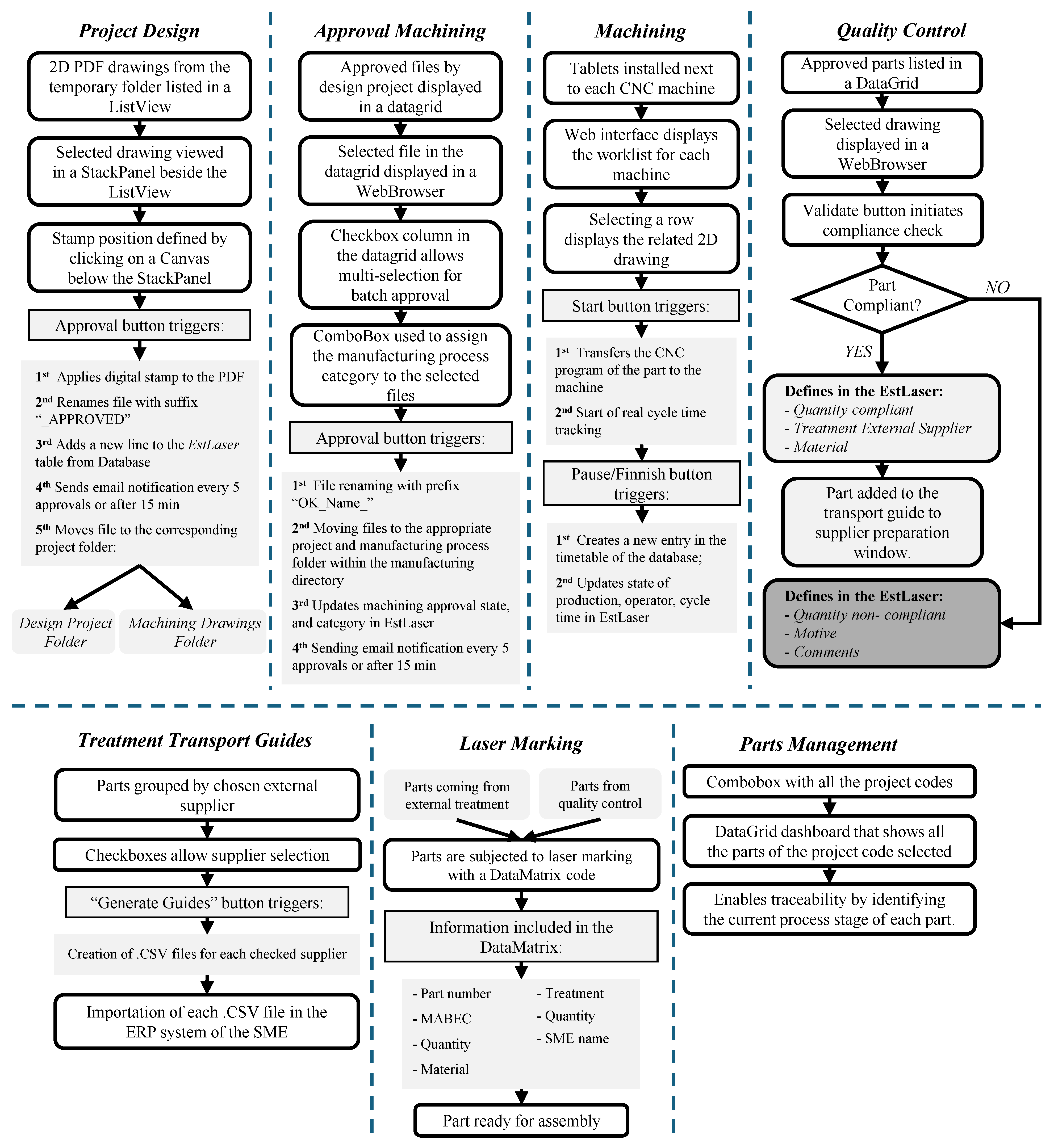

4.1. Automated Project Validation

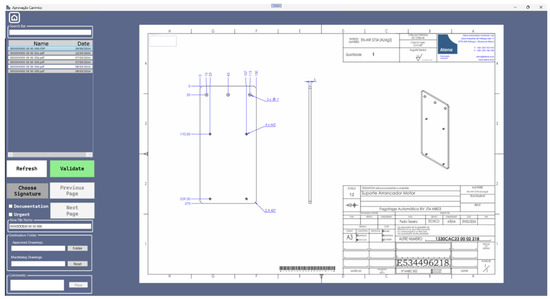

One of the most time-consuming and error-prone tasks in the original workflow was the manual validation of technical drawings. Using GIP, this validation occurs at two distinct stages of the process. The first stage takes place during the project design approval process, with the respective approval window illustrated in Figure 4. At this point, GIP automates the entire process by applying digital approval stamps upon successful validation. Once approved, the system automatically renames each file according to predefined naming conventions and organizes them into the appropriate directories.

Figure 4.

Technical drawings approval window by design department.

The second stage involves the classification of the technical drawings based on their fabrication process (e.g., laser cutting, turning, milling). GIP automatically assigns files to the correct fabrication process folders based on this classification. This procedure allows the simultaneous validation of multiple drawings within the same fabrication process. At both stages of approval, GIP automatically generates and sends emails to the relevant departments, containing all pertinent information of the approved drawings. This automation significantly reduces the risk of human error and ensures that only validated and correctly formatted documents proceed to the manufacturing floor.

4.2. CNC Machining Workflow

GIP also features a dedicated interface that simplifies access to the 3D files used to create CNC programs for components in Mastercam. When a 3D file is retrieved, the system automatically generates a structured folder for the component, which includes the 3D model, the corresponding 2D drawing, and a subfolder reserved for the CNC program. Beyond file management, this interface allows users to define several production parameters, including the machine to use, the theoretical cycle time, the component’s position in the work queue, and the type of operation (e.g., milling, turning and milling, or welding and milling). Furthermore, it is possible to add relevant supporting documentation to the folder, such as text files containing important notes (e.g., tool lists) or images (e.g., illustrating the part’s zero point), ensuring all relevant information is centralized and easily accessible.

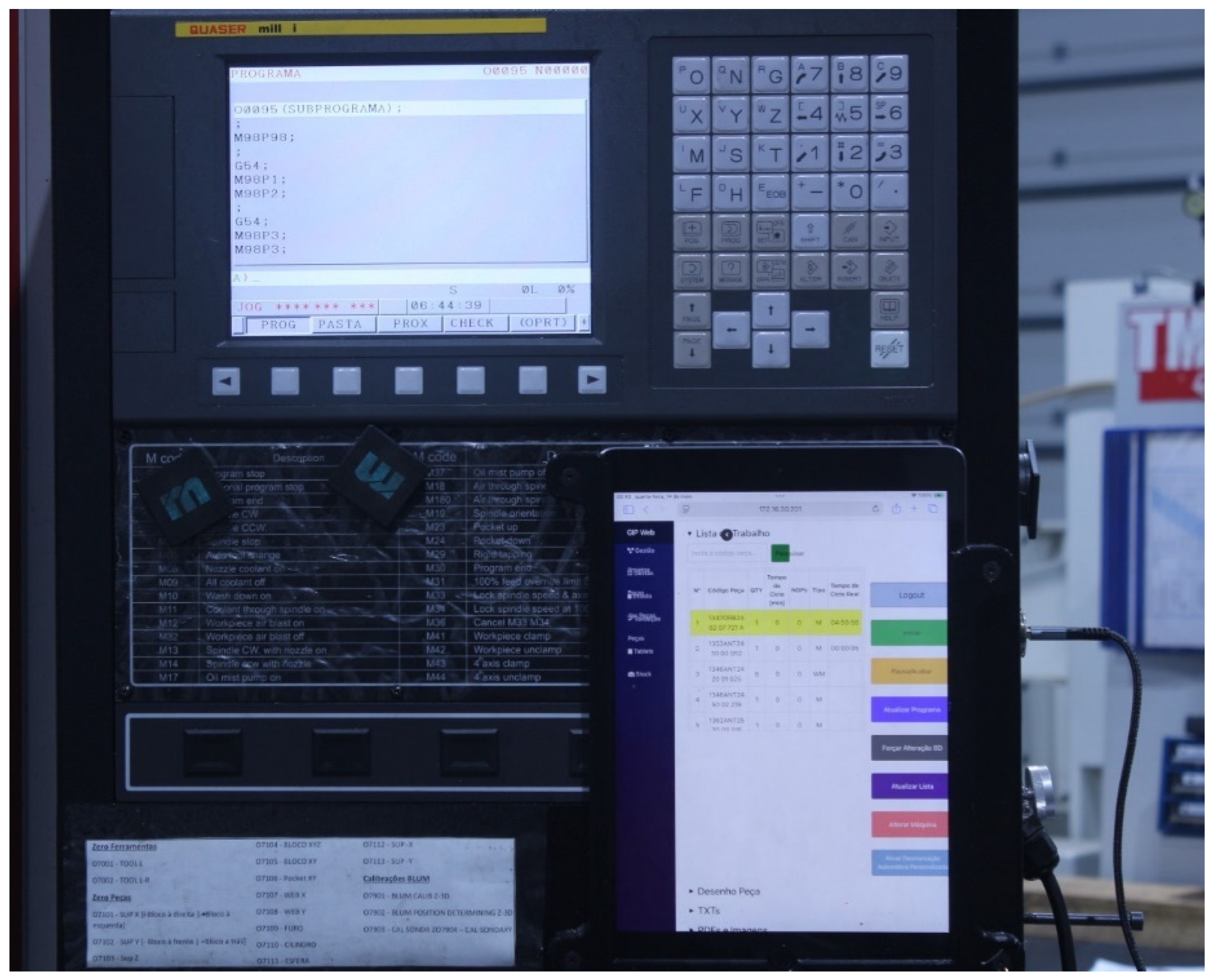

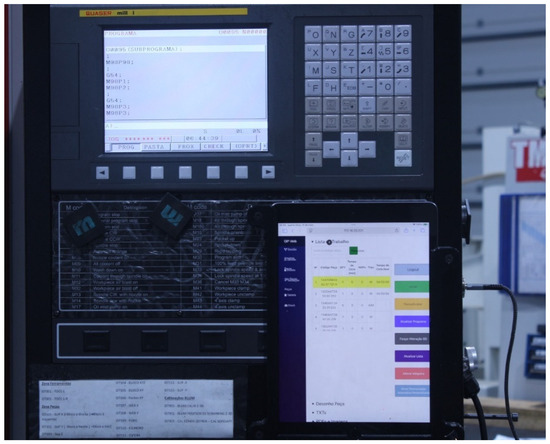

To further enhance shopfloor efficiency, a web-based version of GIP was initially developed to record actual machining times for parts processed in the SME, being later customized for the tablets installed adjacent to each CNC machine, as illustrated in Figure 5. This interface displays the machine’s work list in a clear and tabular format. When a row is selected in this list, the system presents the associated drawings and any attached text files or images, if available. When the user starts the timer for the part, the corresponding CNC program is automatically transferred to the respective machine. Once the machining process is completed, the program is also automatically removed from the machine. If, on the other hand, the part needs to be reassigned to another machine, this can be done directly through the same interface.

Figure 5.

Tablet installed next to the CNC machine.

4.3. Integrated Production Workflow

GIP establishes a centralized digital environment that enables seamless interaction between design and production departments. All validated files are stored in shared directories accessible to CNC operators, quality inspectors, and logistics staff, minimizing delays caused by misplaced documents or redundant email exchanges and providing real-time access to updated technical data. Additionally, the interface allows users to filter files by status, department, or type of operation, enhancing transparency and workflow continuity across teams.

4.4. Laser Marking System

A key innovation in the GIP software is its integration with the enterprise’s laser engraving system. Once a part is approved by quality control and is cleared for assembly, GIP automatically generates a unique DataMatrix code containing all essential metadata, such as the part’s serial number, material type, quantity and any specified surface or heat treatments applied. This code is then engraved directly onto the part using a fiber laser engraver, ensuring that each component can be uniquely identified throughout its lifecycle. This functionality not only improves traceability but also supports compliance with quality standards such as ISO 9001 [34] and IATF 16949 [35], which require robust and verifiable documentation of product histories.

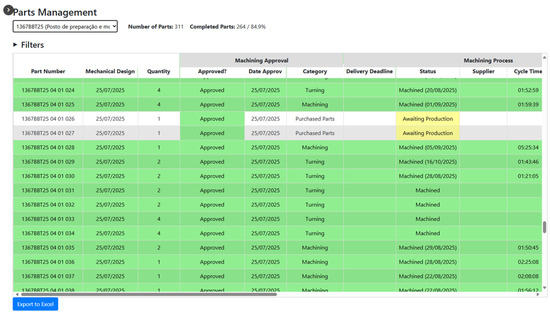

4.5. Traceability Dashboard

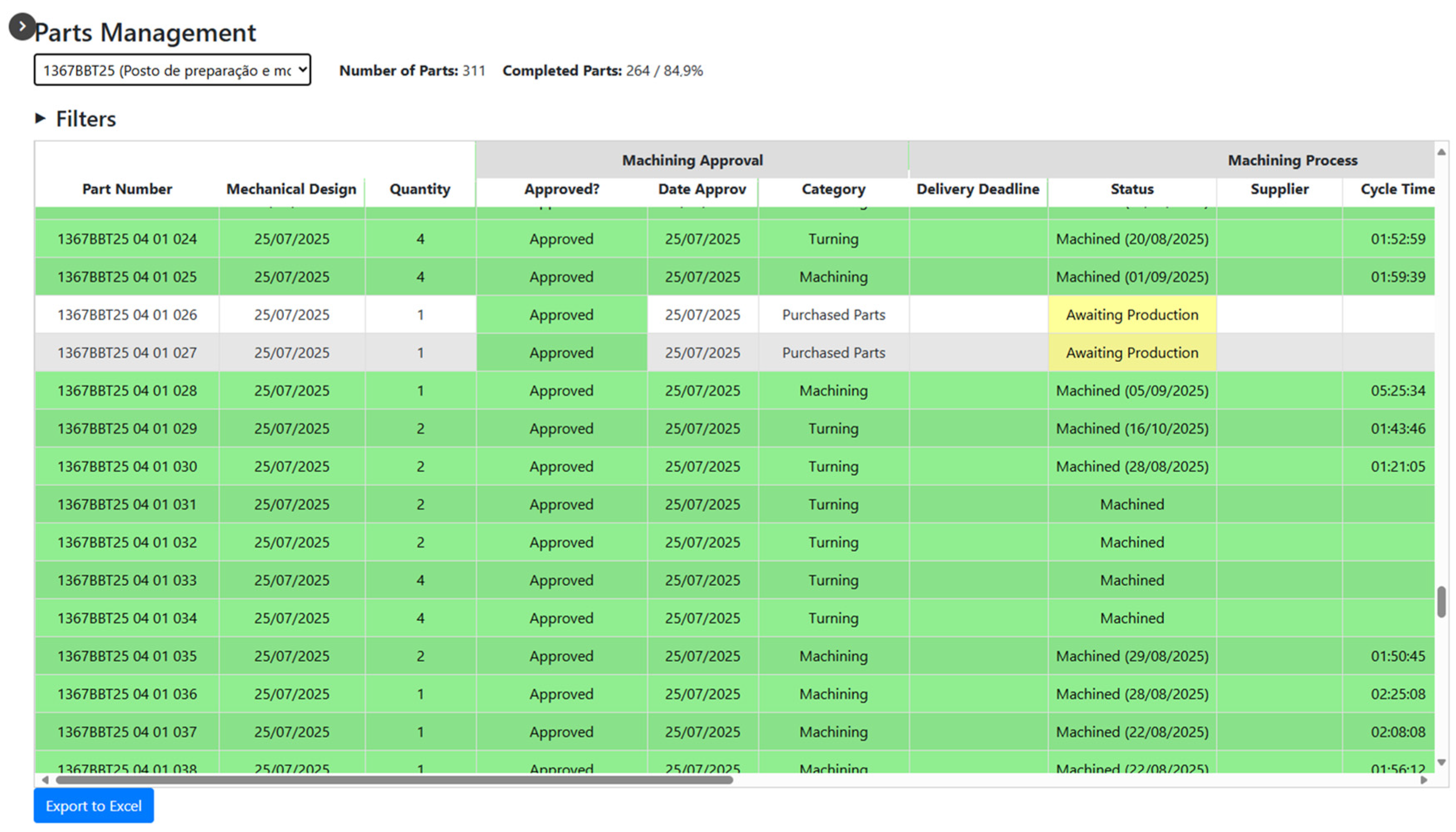

To further enhance visibility across the production pipeline, GIP features a comprehensive traceability dashboard, depicted in Figure 6. This visual interface enables users to monitor the real-time status of each part from initial project design validation to readiness for assembly. At each automated stage of the process, the database shows the current status of the part, whether it is currently in progress or has successfully completed that stage. This platform provides continuous and real-time tracking of the part’s progression through the process. When a part is approved during the project design phase, a new record with the part number is created in the database. As the part moves through subsequent stages (machining approval, machining, quality control, and treatments carried out by external suppliers), the system logs status updates accordingly. Once all stages are completed, the part is considered finished and ready for assembly in the project, with the corresponding entries in the grid turning green to signify completion.

Figure 6.

GIP traceability dashboard of each component of each project.

4.6. Stock Management Workflow

A recent development within the project was the introduction of labels that accompany each part throughout the production cycle, effectively replacing the previously used printed paper drawings. To support this transition, a stock management feature was added to the web version of GIP. This new module displays a list of parts that require verification of raw material availability before manufacturing can proceed. Once material availability is confirmed, labels are printed using a ZD421T Zebra printer (Zebra Technologies, Lincolnshire, IL, USA) and attached directly to the raw material of each part. Each label contains detailed information including the part’s code, quantity, type of material, if required heat or surface treatment, bounding box dimensions, the SME logo, a QR code and a snapshot image of the part. An example of these printed labels is shown in Figure 7. The label printing process was implemented using Python (version 3.13), due to its straightforward integration with the printer. The script is triggered directly from the Blazor Server application.

Figure 7.

Printed labels that will be attached to the raw materials.

4.7. Integration with the ERP

The automation of the component manufacturing process, combined with the centralization of information in a single database, enabled several valuable integrations with the SME’s existing ERP system. One of these involved importing transport guides (in “.csv” format files) from external suppliers responsible for surface and/or heat treatments, which is possible by the automatization of the part’s quality control process. Another relevant integration was related to the recording of manufacturing times for parts produced at SME’s facilities. Indeed, GIP provided more precise time tracking than ERP, by accounting for the number of parts produced simultaneously and the number of machines operated by a single employee. This increased accuracy led to the decision to allow PHC to read machining time data directly from the GIP database, ensuring more reliable calculation of machining costs.

4.8. User Role Management

Maintaining data security and operational discipline is critical in any integrated system. GIP tackles this need through a structured user role management feature that assigns access levels according to each user’s role. Project managers and engineers are granted full permissions to validate, modify, and approve drawings, while production operators have restricted access limited to viewing approved files and updating part status during manufacturing. This hierarchical access model prevents unauthorized modifications and ensures that each user interacts with the system strictly within their defined responsibilities.

4.9. Notification System

One of the key challenges identified in the previous workflow was the frequent communication delays between departments. GIP addresses this issue with an integrated notification mechanism that keeps stakeholders automatically informed. Users receive automatic alerts when new drawings require approval, parts are ready for inspection, or deviations occur within the workflow. Additionally, alerts are triggered whenever non-conformities are identified during quality control. These notifications are displayed directly within the interface and can be optionally sent via email, ensuring timely responses and minimizing downtime across operations.

4.10. Implementation Context

The software was implemented at a Portuguese SME specializing in precision mechanical components. Integration with existing ERP systems was achieved via API connections, enabling bi-directional data exchange. The centralization of production process data in a unified database was a key factor in the project’s success, significantly improving part traceability and process visibility. Comprehensive user training sessions were organized, supported by clear digital documentation. Over six months, the software was iteratively refined based on user feedback, ensuring complete alignment with actual industrial workflows. High adoption rates were achieved thanks to the system’s intuitive interface and tangible benefits of real-time information flow.

5. Challenges and Opportunities in GIP Implementation

When a process has been established for a long time, some degree of resistance to change is inevitable. While some individuals adapt quickly, others may initially respond with skepticism or hesitation. In this particular case, several users initially lacked confidence in the new system and were therefore reluctant to adopt it. Conversely, those who had long advocated for the automation of specific tasks demonstrated strong interest and motivation to learn how to use the newly developed software. To encourage adoption, small yet effective mechanisms were strategically implemented. For instance, at CNC workstations, a condition was introduced whereby the CNC program file would only be transmitted to the machine once the operator initiated the time-tracking process for the corresponding component on the web platform. This measure helped to ensure consistent engagement with the system and reinforced its integration into daily operations. Over time, the software has become an indispensable tool within the company and is now used on a daily basis. Beyond automating component production, user-friendly dashboards were developed to provide a clear and comprehensive overview of part-related data, significantly improving visibility and decision making.

As with any software system, GIP has certain limitations, which could be optimized. Its most notable limitation is its dependency on the internal server, which, while enhancing cybersecurity, makes both the application and the web platform inaccessible whenever the server is offline, preventing remote access. The web platform also proved to be the most technically constrained component, partly due to the steep learning curve involved in its development.

Despite these challenges, both the desktop application and the website proved to be adaptable to increasing workloads and continued to evolve without compromising existing functionality. The web platform, however, exhibited occasional instability when processing a large number of database requests, leading to temporary and occasional errors. These issues are currently being addressed, and gradual improvements have already been implemented. Additionally, when multiple users access the web application simultaneously, a noticeable decrease in performance may occur. To mitigate this, potential solutions are being explored, one of which includes the implementation of a dedicated server exclusively for the GIP platform, aimed at improving overall performance and scalability.

Compared to existing MES solutions, both commercial and open-sourced, GIP distinguishes itself through cost-efficiency and adaptability. Unlike commercial platforms such as Opcenter or FactoryTalk [26,27], which often involve substantial licensing fees and complex implementation processes, GIP was developed entirely using internal company resources and incurred no additional financial investment. While it may not yet match the full functionality of commercial platforms, it effectively fulfills the enterprise’s specific operational needs, such as component tracking, CNC integration, and real-time visualization, while offering significant potential for further development across various SME processes.

Relative to open-source alternatives like ERPNext or Odoo [28,29], GIP offers comparable flexibility with the added advantage of being fully tailored to the enterprise’s production environment. While these platforms provide a wide range of pre-built modules and allow for broad adaptability across industries, they still require significant customization to handle company-specific exceptions or uncommon production scenarios. GIP, by contrast, was designed from the ground up to match the unique and sometimes irregular workflows of the SME, avoiding the constraints of generalized solutions and enabling faster alignment with real-world needs. Its implementation required no new purchases, since existing infrastructure, including servers and repurposed tablets at CNC workstations, was used throughout the project.

Development was largely driven by autonomous learning, supported by the company’s IT department. Online resources such as YouTube tutorials, Stack Overflow, and AI tools played a key role in overcoming challenges and accelerating development. Although this approach minimized the need for formal training, the company is now considering engaging external consultants to further optimize the system and enhance user adoption.

6. Results and Impact

The implementation of the GIP software system at the SME led to significant improvements in overall efficiency, traceability, and accuracy of project and production management. Prior to deployment, several key operations, such as drawing validation, documentation updates, and part tracking, were carried out manually, resulting in substantial workflow bottlenecks, data inconsistencies, and elevated risks of human error. By automating these critical tasks, the software produced quantifiable improvements across multiple operation dimensions, including time efficiency, error reduction, traceability, data security, productivity and project management support.

One of the most noticeable improvements was the drastic reduction in the time required for drawing validation and approval. Previously, project teams manually inspected, renamed, stamped, and relocated each file, a process that typically took 2 to 3 min per drawing. With the implementation of GIP, these tasks were executed through automated routines and single-click actions, significantly reducing processing time and enabling the approval of approximately 4–5 drawings per minute. This corresponded to an estimated 91% increase in efficiency in the drawing validation and approval process. Furthermore, GIP has also contributed to a noticeable reduction in errors commonly associated with manual handling. Similarly, during the machining approval phase, locating and approving drawings required time-consuming navigation through individual project folders and manual drawing revision, renaming, and moving to the appropriate folders. GIP now allows bulk approval of multiple drawings associated with the same manufacturing process simultaneously, reducing approval times drastically. Indeed, database records showed that up to 49 drawings are approved in a single minute. This acceleration has expedited project handovers to the production floor and significantly shortened product development cycles.

Besides time savings, error reduction has also been a major benefit of this software. Indeed, manual handling of technical documentation often resulted in version mismatches, improper naming conventions, or incomplete data annotations. The introduction of automated validation checks during the approval stage, such as alerts for missing stamps, duplicate approvals, or attempts to register already existing drawings, has effectively reduced the occurrence of errors at the point of approval, thereby improving the overall quality and reliability of the process and ensuring that drawings meet conformity rules before proceeding. Furthermore, by centralizing all information within a unified database and integrating a proactive notification system, any errors that do arise are quickly identified and precisely located, allowing faster resolution and minimizing disruption to the overall workflow.

In terms of traceability, each manufactured part is assigned a unique part number, facilitating tracking from project design through to any external treatments performed by external suppliers. Throughout the production process, clear labelling ensures accurate component identification. Additionally, each part is laser-marked with a unique DataMatrix generated by the GIP system. This code stores essential metadata, including the serial number, quantity, material type, required surface or heat treatment, and design revision, enabling comprehensive tracking even after delivery to the customer. These traceability enhancements not only reinforced quality control and support compliance audits but also played a critical role in fault analysis and warranty claim resolution.

Regarding data security, the role-based access control implemented in GIP guarantees that sensitive technical documentation is accessible only to authorized personnel. By regulating user permissions across departments, the system significantly reduces the risk of accidental file alterations or data breaches, thereby safeguarding the integrity and confidentiality of project information.

By automating repetitive administrative functions, GIP enabled staff to redirect their time and focus on value-added tasks such as design optimization, process improvement, or quality inspections. This shift in workload allocation not only boosted overall productivity but also fostered a more motivated and engaged workforce.

A key improvement introduced by GIP was the accurate tracking of machining times for parts produced at SME. Prior to GIP, time tracking was carried out through the PHC system, which had significant limitations: it only allowed one part to be associated with each machine and each operator at a time. However, in practice, both machines and operators often worked on multiple parts simultaneously, which led to inaccuracies: some parts ended up with no recorded machining time (and therefore no associated machining cost), while others accumulated inflated costs because machines and operators remained “picked” on a single part despite having moved on to others. GIP resolved this issue by allowing both operators and machines to be assigned to multiple parts concurrently, providing a far more accurate representation of machining times. Furthermore, as part of the workflow, part counting was initiated before the CNC program could be transferred to the machine, which further improves time traceability. These enhancements enable more realistic production cost calculations, as machining and operator times can be proportionally distributed across overlapping jobs.

Table 1 presents a comparison between machining times recorded in GIP and those logged in PHC, distinguishing between machine time and operator time for each part. For Part 1, operator time in PHC is considerably lower than in GIP, despite both systems reporting similar machine times. This discrepancy suggests that PHC’s operator logs do not accurately reflect the time spent, likely due to manual input errors or omissions. For Parts 2 and 4, large differences between machine and operator times in PHC further confirm the system’s limitations, as machines and operators were often recorded as working on a single part for an entire shift, regardless of actual activity. Additionally, for Part 3, PHC recorded no operator time at all, underscoring the unreliability of its manual tracking approach. Overall, the data obtained through GIP provide a much more accurate and realistic representation of production activity than those recorded in PHC. This demonstrates GIP’s effectiveness as a reliable, automated solution for capturing real-time machine and operator data, thereby improving traceability and the accuracy of production cost estimation.

Table 1.

Comparison between machining and operator times with GIP and only with PHC.

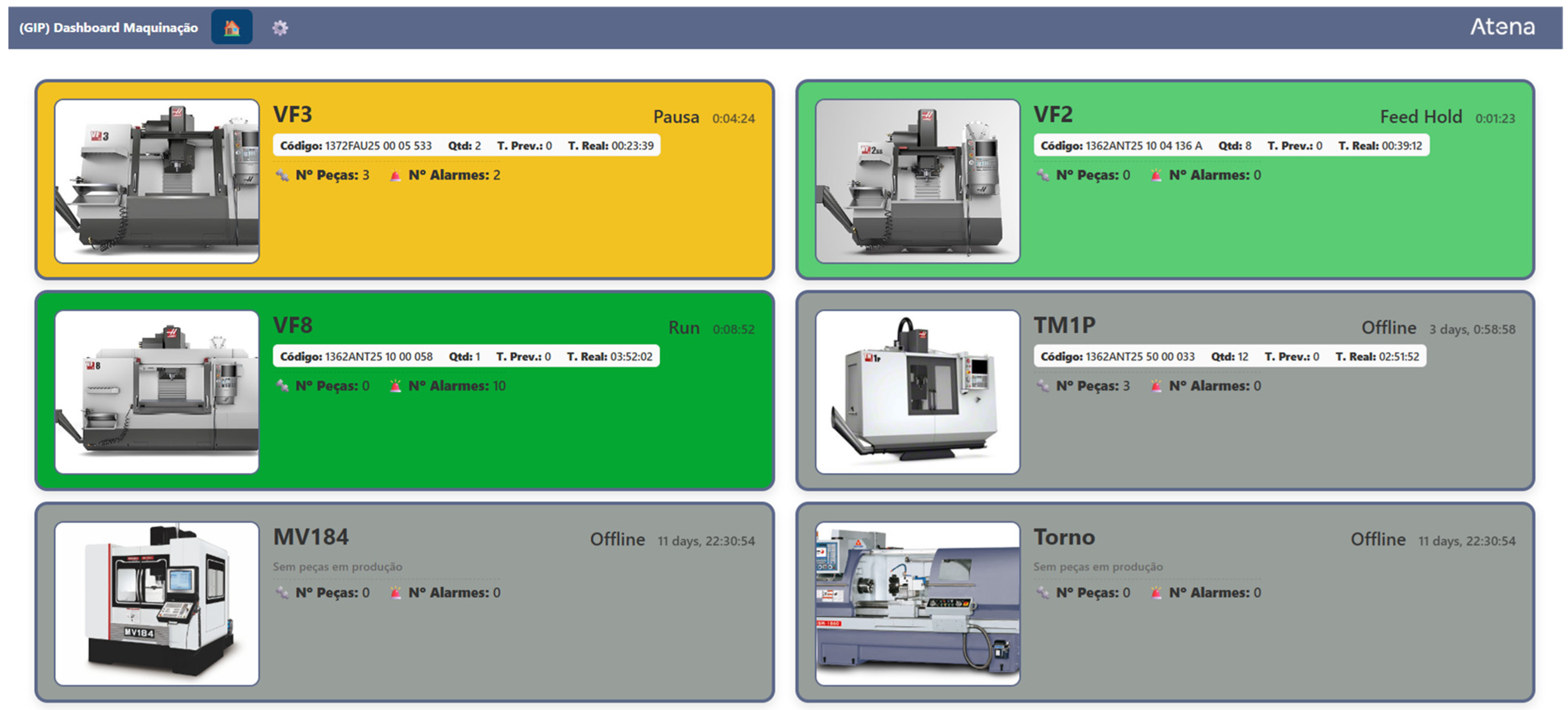

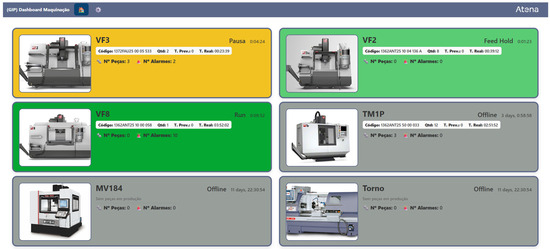

GIP also enabled the development of a monitoring dashboard for the SME’s CNC machines through the reading of each machine’s status lights. This allowed the construction of timelines indicating the duration each machine spent in various states, such as run, pause, and feed hold. Consequently, it is possible to determine the percentage and amount of time each machine was operational on a given day, providing insight into its performance. Figure 8 shows the dashboard under development.

Figure 8.

CNC monitoring dashboard.

Another important benefit of GIP was the improved control and registration of non-conformities during production. Prior to its adoption, the identification and documentation of non-conformities were limited and inconsistent, reducing traceability and hindering corrective action. With GIP, the registration of non-conformities became more systematic and frequent, enabling better monitoring, follow-up and documentation. The system also supported the definition of corrective actions and the estimation of rework times for each non-conforming part. As a result, control and traceability of non-conformities increased by 70%, leading to improved process quality, reduced recurrence of issues, and more accurate evaluation of rework-related production costs.

Additionally, GIP significantly reduced the time required to generate transport guides for parts requiring external treatments. Previously, the process was entirely manual: quality control staff prepared handwritten lists of parts grouped by supplier, which then had to be re-entered into the PHC system to generate the transport guides. Depending on shipment size, this task took between 20 and 40 min. With GIP, parts were automatically grouped by supplier in the system interface, and the user simply selected the relevant checkboxes to generate the required guides. Upon confirmation, a CSV file was automatically created for each guide and directly imported into PHC. This workflow reduced processing time from an average of 30 min to a maximum of 5 min, representing an estimated 83% improvement in efficiency, while also ensuring greater standardization and minimizing the potential for manual entry errors.

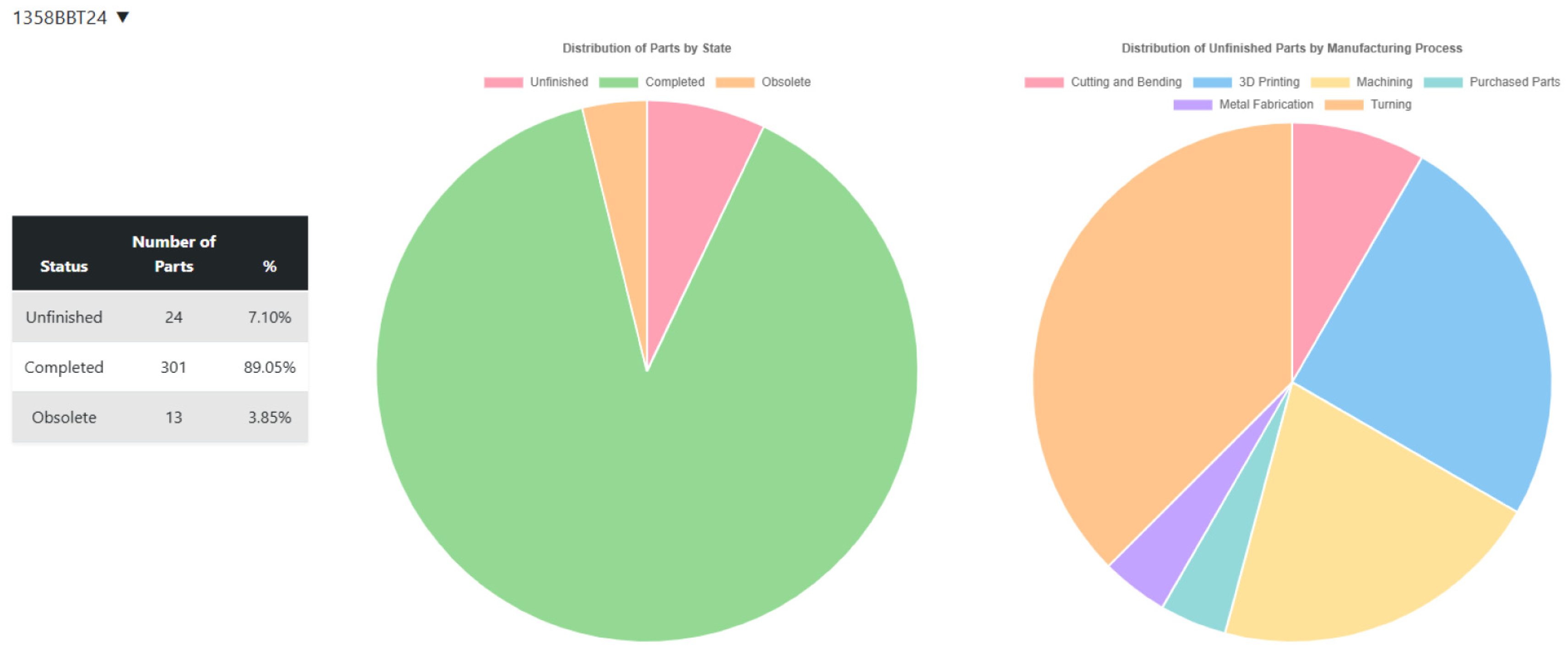

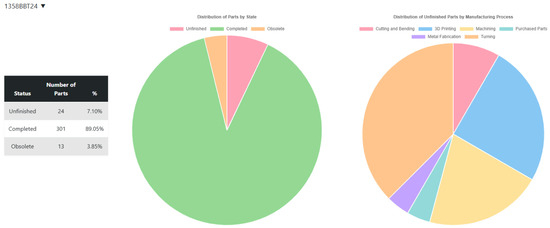

The centralization of information within a single database allowed for the development of a comprehensive dashboard that displayed key data for each part, organized by project. Users can easily select a specific project to view all associated components, facilitating real-time tracking throughout the production cycle. This improved visibility made it easier to identify the current stage of each part within the workflow, enhancing the ability to forecast production completion times and predict when specific parts will be ready. As a result, project managers can provide more accurate delivery schedules and better meet the customer deadlines. Figure 9 shows another dashboard that provides an overall view of the project. It displayed the percentage and number of parts that have been completed and those still pending. For the unfinished parts, it also indicated the manufacturing processes to which the remaining parts belong.

Figure 9.

Example of a project overview dashboard.

7. Discussion

Industry 4.0 technologies are widely recognized for their pivotal role in modernizing SMEs by digitalization production management processes, reducing inefficiencies, and boosting competitiveness in demanding markets [9,10,20]. In this context, the implementation of the GIP software application at the reported SME demonstrated the transformative impact of digitalization for precision mechanical component manufacturing.

One key outcome was the improvement in workflow automation and traceability. Manual operations, such as technical drawing validation and approval, that were once labor-intensive and time-consuming, were streamlined through automation. This significantly reduced approval cycles, improved interdepartmental information flow, and lowered the risk of human error. Similar benefits have been reported in other digital transformation studies in manufacturing [12,36,37]. A critical enabler of these improvements was GIP’s modular architecture and centralized database, which created a digital ecosystem for managing documents, parts, and processes.

In addition to its modularity, the scalability of the GIP system to other SMEs within the same industrial sector proves to be both feasible and promising. Enterprises involved in the production of components, parts, structures, or machinery, which require the approval of technical drawings, organization of manufacturing processes, fabrication, and conformity verification, can find an effective solution in GIP. Although each SME has its own specific working methods, the robust foundation of the system allows for tailored adaptations without compromising the integrity of the application. Modules such as parts and project management are reusable and adaptable to different industrial contexts, facilitated by the centralization of information within a single database, ensuring consistency and coherence across departments. By registering data at the part level, including serial numbers, batch codes, material specifications, and revision histories, the system enabled robust traceability aligned with international quality standards such as ISO 9001 and IATF 16949 [38,39,40].

These functionalities support broader Industry 4.0 concepts such as digital thread and digital twin, which are increasingly regarded as foundational elements of smart manufacturing [41,42,43,44,45]. By linking real-time manufacturing data with design information, GIP also lays a strong foundation for future applications in lifecycle management and predictive analytics [41,42]. It should be noted that this project’s success was not solely technical; it also emphasized the need to align digital tools with actual user workflows. GIP interface was designed to reflect how engineers and technicians already interact with production data, facilitating user adoption and minimizing the learning curve. This user-centered approach, coupled with an agile development methodology, ensured that feedback from operators and engineers was quickly incorporated into subsequent iterations, improving usability and system performance [46]. Additional features such as project dashboards, performance indicators, and automated alerts supported continuous monitoring and decision making. Features such as visual progress tracking, delay notifications, and part-level cost analytics enabled teams to detect bottlenecks, follow up on milestones, and respond proactively to deviations. A continuous feedback loop from users ensures that the system evolves in alignment with operational needs.

The digitalization process faced challenges common to many transformation initiatives, including initial resistance to change and unforeseen technical issues during deployment. These challenges were effectively addressed through structured onboarding programs, responsive technical support, and continuous improvement cycles, which align with best practices reported in other successful MES implementations [47,48].

Overall, the GIP system illustrated how tailored digital solutions can complement existing ERP systems to significantly enhance agility, efficiency, and traceability in the manufacturing operations. Its success reaffirmed the importance of modular design, cross-functional collaboration, and iterative development as essential factors in implementing effective digital tools within modern industrial environments. Notably, GIP helped standardize workflows, even in less frequent or ambiguous scenarios, improving operational clarity and consistency. The project also demonstrated that internal solutions, designed to fit the specific needs of an enterprise, can be a viable alternative to commercial ERP systems, especially for SMEs with limited resources. Furthermore, the experience revealed the gap between theoretical system design and industrial reality, highlighting the importance of flexibility and alignment with real user needs.

Looking ahead, the GIP system could evolve through the integration of advanced technologies aligned with Industry 4.0 principles, such as predictive analytics, Internet of Things (IoT), and machine learning [49]. By connecting equipment and sensors through IoT, real-time data on machine performance and process conditions could be continuously collected and analyzed [50]. Machine learning algorithms could then identify anomalies and forecast potential equipment failures, enabling predictive maintenance strategies [51]. Predictive analytics would further enhance decision making by optimizing resource allocation, minimizing downtime, and improving overall equipment effectiveness [52]. While such developments lie beyond the scope of the current study, they represent promising directions for the continued digital transformation of the SME’s manufacturing processes.

8. Conclusions

The implementation of this software application has demonstrated notable benefits in project and production management for mechanical components. By automating critical workflows, the system has markedly improved efficiency, accuracy, and traceability throughout the manufacturing process. It exemplified how digital tools can be specifically tailored to address unique industrial challenges, effectively supporting the broader goals of digital transformation within manufacturing environments. The success of this initiative highlighted the potential of in-house software solutions that complement existing ERP systems, driving operational excellence and enhancing overall agility. The GIP proved effective in standardizing workflows and clarifying infrequent or ambiguous processes, enhancing operational consistency. It also demonstrated that tailor-made internal solutions could serve as practical alternatives to commercial ERP systems for resource-constrained SMEs while underscoring the importance of flexibility and alignment between system design and real industrial needs. Future developments are planned to further expand the software’s functionalities. These include: (1) predictive maintenance, through the integration with machine data to anticipate failures; (2) real-time analytics, through the implementation of dashboards displaying production key performance indicators; (3) full ERP integration, which allows seamless interaction with financial and inventory systems; (4) mobile access, using Android/iOS compatibility for real-time updates. Expanding the software’s architecture to accommodate multi-site operations is also planned, making the system scalable for larger manufacturing networks.

Author Contributions

B.A.: Conceptualization, Investigation, Methodology, Software, Writing—original draft; A.B.: Conceptualization, Software, Supervision, Writing—review & editing; A.S.: Formal analysis, Visualization, Writing—review & editing; A.C.: Conceptualization, Funding acquisition, Project administration, Supervision, Writing—review & editing. All authors have read and agreed to the published version of the manuscript.

Funding

The present study was developed in the scope of the project “Agenda ILLIANCE” [C644919832-00000035 | Project nº 46], financed by PRR—Plano de Recuperação e Resiliência under the Next Generation EU from the European Union. This work is funded by national funds through FCT—Fundação para a Ciência e a Tecnologia, I.P., the project/contract UID 00481—Centre for Mechanical Technology and Automation.

Data Availability Statement

Data generated during the current study is unavailable due to corporate confidentiality.

Conflicts of Interest

The authors have no competing interests to declare that are relevant to the content of this article.

References

- ElMaraghy, H.; Monostori, L.; Schuh, G.; ElMaraghy, W. Evolution and Future of Manufacturing Systems. CIRP Ann. 2021, 70, 635–658. [Google Scholar] [CrossRef]

- Sahoo, S.; Lo, C.-Y. Smart Manufacturing Powered by Recent Technological Advancements: A Review. J. Manuf. Syst. 2022, 64, 236–250. [Google Scholar] [CrossRef]

- Duraivelu, K. Digital Transformation in Manufacturing Industry—A Comprehensive Insight. Mater. Today Proc. 2022, 68, 1825–1829. [Google Scholar] [CrossRef]

- da Silva, E.R.; Shinohara, A.C.; Nielsen, C.P.; de Lima, E.P.; Angelis, J. Operating Digital Manufacturing in Industry 4.0: The Role of Advanced Manufacturing Technologies. Procedia CIRP 2020, 93, 174–179. [Google Scholar] [CrossRef]

- Schioenning Larsen, M.S.; Lassen, A.H. Design Parameters for Smart Manufacturing Innovation Processes. Procedia CIRP 2020, 93, 365–370. [Google Scholar] [CrossRef]

- Shafiee, S. Integration of Product and Manufacturing Design: A Systematic Literature Review. Procedia CIRP 2024, 121, 19–24. [Google Scholar] [CrossRef]

- Patel, A.J.; Kilic, G.A. A Review on Advanced Manufacturing Techniques and Their Applications. In Computational Optimization Techniques and Applications; Sarfraz, M., Karim, S.A.A., Eds.; IntechOpen: Rijeka, Croatia, 2021. [Google Scholar]

- Torres, Y.; Nadeau, S.; Landau, K. Classification and Quantification of Human Error in Manufacturing: A Case Study in Complex Manual Assembly. Appl. Sci. 2021, 11, 749. [Google Scholar] [CrossRef]

- Sagala, G.H.; Őri, D. Toward SMEs Digital Transformation Success: A Systematic Literature Review. Inf. Syst. e-Bus. Manag. 2024, 22, 667–719. [Google Scholar] [CrossRef]

- Moeuf, A.; Pellerin, R.; Lamouri, S.; Tamayo-Giraldo, S.; Barbaray, R. The Industrial Management of SMEs in the Era of Industry 4.0. Int. J. Prod. Res. 2018, 56, 1118–1136. [Google Scholar] [CrossRef]

- AlBar, A.M.; Hddas, M.A.; Hoque, M.R. Enterprise Resource Planning (ERP) Systems: Emergence, Importance and Challenges. Int. Technol. Manag. Rev. 2014, 4, 170. [Google Scholar] [CrossRef]

- Monostori, L.; Kádár, B.; Bauernhansl, T.; Kondoh, S.; Kumara, S.; Reinhart, G.; Sauer, O.; Schuh, G.; Sihn, W.; Ueda, K. Cyber-Physical Systems in Manufacturing. CIRP Ann. 2016, 65, 621–641. [Google Scholar] [CrossRef]

- Martins, E.J.; Belfo, F.P. Major Concerns about Enterprise Resource Planning (ERP) Systems: A Systematic Review of a Decade of Research (2011–2021). Procedia Comput. Sci. 2023, 219, 378–387. [Google Scholar] [CrossRef]

- Shojaeinasab, A.; Charter, T.; Jalayer, M.; Khadivi, M.; Ogunfowora, O.; Raiyani, N.; Yaghoubi, M.; Najjaran, H. Intelligent Manufacturing Execution Systems: A Systematic Review. J. Manuf. Syst. 2022, 62, 503–522. [Google Scholar] [CrossRef]

- Zambrano, V.; Rodríguez-Barrachina, R.; Calvo, S.; Izquierdo, S. TWINKLE: A Digital-Twin-Building Kernel for Real-Time Computer-Aided Engineering. SoftwareX 2020, 11, 100419. [Google Scholar] [CrossRef]

- Panayiotou, K.; Tsardoulias, E.; Symeonidis, A.L. Commlib: An Easy-to-Use Communication Library for Cyber–Physical Systems. SoftwareX 2022, 19, 101180. [Google Scholar] [CrossRef]

- Yilmaz, G.; Treviño Almaguer, F.R.; Hawkridge, G.; McFarlane, D. AISLE: A Matchmaking Tool for Pairing SMEs with Digital Solutions. SoftwareX 2024, 28, 101941. [Google Scholar] [CrossRef]

- Singh, M.; Goyat, R.; Panwar, R. Fundamental Pillars for Industry 4.0 Development: Implementation Framework and Challenges in Manufacturing Environment. TQM J. 2024, 36, 288–309. [Google Scholar] [CrossRef]

- Moiceanu, G.; Paraschiv, G. Digital Twin and Smart Manufacturing in Industries: A Bibliometric Analysis with a Focus on Industry 4.0. Sensors 2022, 22, 1388. [Google Scholar] [CrossRef]

- Dillinger, F.; Bernhard, O.; Kagerer, M.; Reinhart, G. Industry 4.0 Implementation Sequence for Manufacturing Companies. Prod. Eng. 2022, 16, 705–718. [Google Scholar] [CrossRef]

- Nour, M.A. The Impact of ERP Systems on Organizational Performance. Int. J. Enterp. Inf. Syst. 2023, 19, 1–29. [Google Scholar] [CrossRef]

- Mantravadi, S.; Møller, C. An Overview of Next-Generation Manufacturing Execution Systems: How Important Is MES for Industry 4.0? Procedia Manuf. 2019, 30, 588–595. [Google Scholar] [CrossRef]

- Tabim, V.M.; Ayala, N.F.; Marodin, G.A.; Benitez, G.B.; Frank, A.G. Implementing Manufacturing Execution Systems (MES) for Industry 4.0: Overcoming Buyer-Provider Information Asymmetries through Knowledge Sharing Dynamics. Comput. Ind. Eng. 2024, 196, 110483. [Google Scholar] [CrossRef]

- Fatima, B.; Sarah, A.; Driss, A. The Manufacturing Executing System Instead of ERP as Shop Floor Management. In Proceedings of the 2020 IEEE 13th International Colloquium of Logistics and Supply Chain Management (LOGISTIQUA), Fez, Morocco, 2–4 December 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 1–7. [Google Scholar]

- AVEVATM Manufacturing Execution System—Smart Manufacturing Operations Management. Available online: https://www.aveva.com/en/products/manufacturing-execution-system/ (accessed on 9 October 2025).

- FactoryTalk—The Foundation for Your Industrial Digital Transformation. Available online: https://www.rockwellautomation.com/en-gb/products/software/factorytalk.html (accessed on 9 October 2025).

- Opcenter—Manufacturing Operations Management. Available online: https://plm.sw.siemens.com/en-US/opcenter/ (accessed on 9 October 2025).

- ERPNext—The Only ERP You’ll Ever Need. Available online: https://frappe.io/erpnext (accessed on 9 October 2025).

- Odoo—Software de Gestão Cloud Com Inteligência Artificial. Available online: https://odoo.tko.pt/ (accessed on 9 October 2025).

- Li, X.; Ji, X.; He, J. Modular Design and Custom Development in ERP Systems. Appl. Comput. Eng. 2024, 93, 155–160. [Google Scholar] [CrossRef]

- Amaral, A.; Peças, P. SMEs and Industry 4.0: Two Case Studies of Digitalization for a Smoother Integration. Comput. Ind. 2021, 125, 103333. [Google Scholar] [CrossRef]

- Romero, I.; Mammadov, H. Digital Transformation of Small and Medium-Sized Enterprises as an Innovation Process: A Holistic Study of Its Determinants. J. Knowl. Econ. 2025, 16, 8496–8523. [Google Scholar] [CrossRef]

- Oliveira, A.; Filipe, V.; Amorim, E.V. Data Integration in Shop Floor for Industry 4.0. In Distributed Computing and Artificial Intelligence, Volume 2: Special Sessions 18th International Conference; Springer: Cham, Switzerland, 2022; pp. 190–193. [Google Scholar]

- ISO 9001:2015; Quality Management Systems—Requirements. International Organization for Standardization: Geneva, Switzerland, 2015.

- IATF 16949:2016; Quality Management System Requirements for Automotive Production and Relevant Service Parts Organizations. International Automotive Task Force: Turin, Italy, 2016.

- Kolberg, D.; Zühlke, D. Lean Automation Enabled by Industry 4.0 Technologies. IFAC-PapersOnLine 2015, 48, 1870–1875. [Google Scholar] [CrossRef]

- Kolberg, D.; Knobloch, J.; Zühlke, D. Towards a Lean Automation Interface for Workstations. Int. J. Prod. Res. 2017, 55, 2845–2856. [Google Scholar] [CrossRef]

- Bozola, P.M.; Nunhes, T.V.; Barbosa, L.C.F.M.; Machado, M.C.; Oliveira, O.J. Overcoming the Challenges of Moving from ISO/TS 16949 to IATF 16949: Recommendations for Implementing a Quality Management System in Automotive Companies. Benchmarking Int. J. 2023, 30, 3699–3724. [Google Scholar] [CrossRef]

- Laskurain, I.; Arana, G.; Heras-Saizarbitoria, I. Adopting ISO/TS 16949 and IATF 16949 Standards: An Exploratory and Preliminary Study. In ISO 9001, ISO 14001, and New Management Standards; Springer: Cham, Switzerland, 2018; pp. 131–143. [Google Scholar]

- Gartner, P.; Benfer, M.; Kuhnle, A.; Lanza, G. Potentials of Traceability Systems—A Cross-Industry Perspective. Procedia CIRP 2021, 104, 987–992. [Google Scholar] [CrossRef]

- Leng, J.; Zhang, H.; Yan, D.; Liu, Q.; Chen, X.; Zhang, D. Digital Twin-Driven Manufacturing Cyber-Physical System for Parallel Controlling of Smart Workshop. J. Ambient Intell. Humaniz. Comput. 2019, 10, 1155–1166. [Google Scholar] [CrossRef]

- Tao, F.; Zhang, H.; Liu, A.; Nee, A.Y.C. Digital Twin in Industry: State-of-the-Art. IEEE Trans. Ind. Inform. 2019, 15, 2405–2415. [Google Scholar] [CrossRef]

- Soori, M.; Arezoo, B.; Dastres, R. Digital Twin for Smart Manufacturing, A Review. Sustain. Manuf. Serv. Econ. 2023, 2, 100017. [Google Scholar] [CrossRef]

- Abdel-Aty, T.A.; Negri, E. Conceptualizing the Digital Thread for Smart Manufacturing: A Systematic Literature Review. J. Intell. Manuf. 2024, 35, 3629–3653. [Google Scholar] [CrossRef]

- Khan, T.; Khan, U.; Khan, A.; Mollan, C.; Morkvenaite-Vilkonciene, I.; Pandey, V. Data-Driven Digital Twin Framework for Predictive Maintenance of Smart Manufacturing Systems. Machines 2025, 13, 481. [Google Scholar] [CrossRef]

- Kovalev, I.A.; Kvashnin, D.Y.; Chervonnova, N.Y.; Nikich, A.N. Application of Agile Methodology at Industrial Manufacturing as Part of the Industry 4.0. IOP Conf. Ser. Mater. Sci. Eng. 2020, 971, 052034. [Google Scholar] [CrossRef]

- Bianchini, A.; Savini, I.; Andreoni, A.; Morolli, M.; Solfrini, V. Manufacturing Execution System Application within Manufacturing Small–Medium Enterprises towards Key Performance Indicators Development and Their Implementation in the Production Line. Sustainability 2024, 16, 2974. [Google Scholar] [CrossRef]

- Menezes, S.; Creado, S.; Zhong, R.Y. Smart Manufacturing Execution Systems for Small and Medium-Sized Enterprises. Procedia CIRP 2018, 72, 1009–1014. [Google Scholar] [CrossRef]

- Rejeb, A.; Rejeb, K.; Süle, E.; Hassoun, A.; Keogh, J.G. Knowledge Flows in Industry 4.0 Research: A Longitudinal and Dynamic Analysis. J. Data Inf. Manag. 2025, 7, 123–145. [Google Scholar] [CrossRef]

- Syafrudin, M.; Alfian, G.; Fitriyani, N.L.; Rhee, J. Performance Analysis of IoT-Based Sensor, Big Data Processing, and Machine Learning Model for Real-Time Monitoring System in Automotive Manufacturing. Sensors 2018, 18, 2946. [Google Scholar] [CrossRef]

- Aminzadeh, A.; Sattarpanah Karganroudi, S.; Majidi, S.; Dabompre, C.; Azaiez, K.; Mitride, C.; Sénéchal, E. A Machine Learning Implementation to Predictive Maintenance and Monitoring of Industrial Compressors. Sensors 2025, 25, 1006. [Google Scholar] [CrossRef]

- Singh, S.; Batheri, R.; Dias, J. Predictive Analytics: How to Improve Availability of Manufacturing Equipment in Automotive Firms. IEEE Eng. Manag. Rev. 2023, 51, 157–168. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).